Abstract

Corrosion of steel reinforcement is one of the primary causes of deterioration in reinforced concrete structures, significantly impacting their durability and structural performance. This review comprehensively examines various techniques used to evaluate rebar corrosion, categorizing them into electrochemical, physical, and advanced non-destructive methods. Each method is discussed with respect to its operational principles, advantages, limitations, and field applicability. This comparative overview aims to support the selection of suitable evaluation strategies tailored to diverse structural conditions.

1. Introduction

Steel reinforcement, commonly referred to as rebar, plays a vital role in cement-based structures by providing tensile strength and enhancing the overall structural integrity of concrete [1,2,3]. Concrete alone is strong in compression but weak in tension; embedding steel reinforcement compensates for this weakness, allowing for the construction of durable bridges, buildings, and other infrastructure.

However, the corrosion of embedded steel reinforcement poses a major threat to the durability and safety of concrete structures, especially in aggressive environments such as marine atmospheres or regions exposed to deicing salts [4,5]. Corrosion of reinforcing steel is an electrochemical process that progresses through two primary stages: the initiation period and the propagation period.

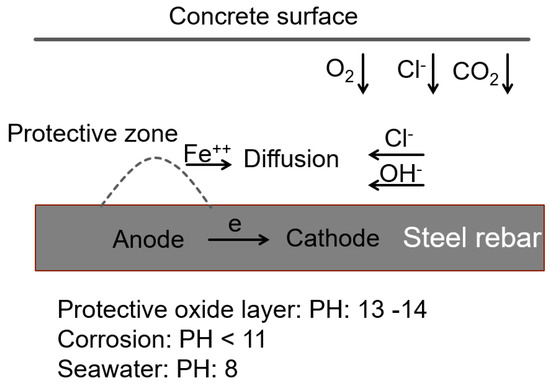

During the initiation period, a passive layer—primarily composed of iron oxides—naturally forms on the steel surface in the highly alkaline pore solution of concrete (pH > 12.5). This passive film provides temporary protection against corrosion. However, its stability is compromised when chloride ions from external sources (e.g., seawater or de-icing salts) or carbonation reduce the local alkalinity. Once the chloride concentration at the rebar surface exceeds a critical threshold or the pH drops sufficiently, the passive layer breaks down, marking the onset of active corrosion [6,7].

The breakdown of the passive layer involves complex physicochemical mechanisms. Chloride ions penetrate the concrete matrix and accumulate at the steel–concrete interface, leading to localized depassivation. This results in the formation of anodic sites where iron dissolves into Fe2+ ions, and cathodic sites where oxygen reduction occurs. The differential aeration around these sites accelerates corrosion through the formation of microcells [8]. Furthermore, factors such as moisture content, oxygen availability, and temperature fluctuations can influence the corrosion kinetics significantly.

Once active corrosion begins, the propagation period is characterized by the formation of expansive corrosion products (e.g., Fe2O3, Fe3O4), which exert internal pressure on the surrounding concrete, causing cracking, delamination, and eventually spalling. These deterioration processes can severely impair the structural capacity and service life of reinforced concrete components [9]. Figure 1 shows the corrosion mechanism of steel rebar [10].

Figure 1.

Corrosion mechanism of steel rebar [10].

Given the complexity and critical importance of these degradation mechanisms, the early detection and quantification of rebar corrosion are essential. Non-destructive testing (NDT) techniques offer valuable tools for assessing corrosion without damaging the structural integrity of concrete. This paper provides a comprehensive review of current NDT methods for evaluating corrosion in reinforced concrete, with a focus on their principles, capabilities, limitations, and potential for field deployment.

2. Steel Rebar Corrosion Evaluation and Methods

Numerous techniques have been developed to detect the corrosion of steel rebar in concrete. Commonly used methods include electrochemical techniques, ultrasonic methods, X-ray tomography, infrared thermography method, ground penetration radar method, magnetic flux leakage method, and eddy current testing. This paper focuses on summarizing these non-destructive evaluation approaches, while methods involving embedded sensors within the concrete will not be covered.

2.1. Electrochemical Techniques

Electrochemical techniques are widely used for assessing the corrosion behavior of steel rebar in concrete due to their sensitivity, quantitative capabilities, and suitability for both laboratory and field applications. These methods are based on the electrochemical nature of corrosion and provide valuable information about the corrosion potential, rate, and mechanisms. The most common electrochemical techniques include half-cell potential measurement, concrete resistivity measurement, linear polarization resistance (LPR), and electrochemical impedance spectroscopy (EIS).

2.1.1. Half-Cell Potential Measurement

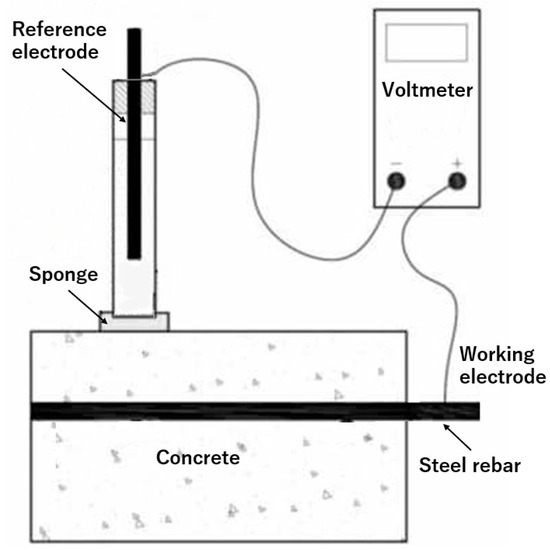

Half-cell potential (HCP) measurement is also called open-circuit potential (OCP) measurement, which is a widely used non-destructive technique to assess the corrosion activity of steel reinforcement in concrete structures [11,12]. Figure 2 shows a schematic diagram of the technique. It measures the electrical potential difference between the embedded steel and a standard reference electrode placed on the concrete surface. The technique is based on electrochemical principles. When steel corrodes in concrete, electrochemical cells are formed, creating anodic (corroding) and cathodic (non-corroding) regions.

Figure 2.

Schematic diagram of half-cell potential measurement.

A saturated calomel electrode (SCE), copper/copper sulfate electrode (CSE), or silver/silver chloride electrode is usually used as the standard reference electrode. As per ASTM C 876 [13] standards, the probability of reinforcement corrosion is as shown in Table 1.

Table 1.

Corrosion conditions related to HCP measurements.

To ensure accurate and reliable measurements, certain technical specifications must be met. The voltmeter used should have an input impedance of at least 10 MΩ to minimize current draw and avoid polarization of the reference electrode. Lower impedance devices can cause current flow, leading to distorted readings and misinterpretation of the corrosion state.

Moisture content in the concrete plays a critical role in potential measurement. Adequate pore water conductivity is necessary to establish a stable electrical path between the rebar and reference electrode. In dry concrete, measurements may be erratic or yield artificially high potentials due to insufficient ionic conduction. To address this, pre-wetting of the concrete surface or the use of wet sponges is commonly practiced in field applications.

Additionally, the stabilization time of the potential signal is essential. After connecting the measurement circuit, the potential may fluctuate initially due to capacitive effects and electrode settling. It is recommended to allow the signal to stabilize—typically for 30–60 s—before recording the reading. Automated systems may incorporate real-time stabilization detection to improve reliability.

While HCP provides a qualitative indication of corrosion probability, it does not quantify the corrosion rate. Therefore, it is often used in combination with other electrochemical techniques such as linear polarization resistance (LPR) or electrochemical impedance spectroscopy (EIS) for more comprehensive corrosion assessment.

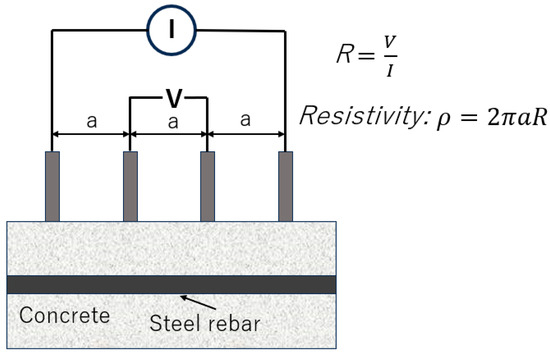

2.1.2. Concrete Resistivity Measurement

In addition to corrosion potential (Ecorr) measurements, concrete resistivity is a key electrochemical parameter that provides valuable complementary information regarding the likelihood and rate of corrosion [14]. While Ecorr reflects the thermodynamic tendency for corrosion, resistivity relates to the ionic conductivity of the concrete, which governs the availability of electrolyte paths for electrochemical reactions.

Concrete resistivity is typically measured using the Wenner four-point method, which involves placing four equally spaced electrodes on the concrete surface and applying a known current across the outer probes while measuring the potential drop across the inner probes [15]. Figure 3 shows the setup of the measurement. The measurement is influenced by surface moisture, temperature, aggregate content, and the presence of cracks. Field protocols often recommend performing resistivity measurements in tandem with half-cell potential mapping, especially during condition surveys of bridge decks, parking structures, and marine platforms.

Figure 3.

Circuit for electrical resistance measurements.

Low resistivity (<10 kΩ·cm) typically indicates high ionic mobility, which facilitates the corrosion process, especially under conditions where oxygen and moisture are present. Conversely, high resistivity (>100 kΩ·cm) suggests limited ion transport and may inhibit corrosion, even if Ecorr values indicate a depassivated state. As such, the combined interpretation of Ecorr and resistivity provides a more robust and reliable assessment of corrosion risk [16].

The importance of this complementary approach has been emphasized in several international guidelines and research publications. In particular, Elsener et al. [17] highlight that half-cell potential mapping alone may be misleading when concrete resistivity is either extremely high (dry concrete) or extremely low (due to carbonated zones or high humidity). In such cases, resistivity measurements help contextualize Ecorr results and avoid false positives or negatives in structural assessments.

2.1.3. Linear Polarization Resistance

The linear polarization resistance (LPR) method is used to measure the corrosion rate of metal in an electrolyte [18,19,20]. Figure 4 shows the schematic diagram of the LPR method.

Figure 4.

Setup of linear polarization resistance measurement.

If we apply small potential perturbation (typically ±10–20 mV) to the metal’s open-circuit potential (Ecorr), the electrochemical reaction at the metal surface will respond by developing a small current. Within this small polarization range, the current (ΔI) is directly proportional to the applied potential (ΔE). This linear relation obeys Ohm’s law:

Here Rp is the polarization resistance. Then, the corrosion current icorr can be calculated by the Stern–Geary equation:

The constant B (Stern–Geary constant) typically falls within 13–52 mV for steel in concrete, depending on conditions. Once icorr is known, we can compute the corrosion rate (v) in millimeters per year by applying Faradays’ law:

k is a conversion constant that depends on the atomic weight of iron, the valence of the metal dissolution reaction (typically 2 for iron), the density of steel, and Faradays’ constant.

The LPR method is a powerful tool to quickly and non-destructively assess the corrosion rate of steel rebars in concrete structures. In order to overcome the problem of confining the current to a predetermined area, the use of a second auxiliary guard ring electrode surrounding the inner auxiliary electrode has been developed [21]. Table 2 shows the relationship between the condition of steel rebar and the corrosion current [22].

Table 2.

The relationship between the condition of steel rebar and the corrosion current.

Figure 4 presents a typical laboratory setup for electrochemical testing where the environmental parameters are controlled. However, on-site applications of electrochemical methods require additional considerations due to variable conditions and unknown electrode geometries. In field settings, the exact surface area of the rebar is generally unknown, and corrosion products or concrete cover may introduce contact resistance. To address these issues, protocols such as those proposed by Polder [16] recommend using a reference electrode in combination with a guard ring or signal confinement method to estimate polarization area and reduce edge effects [16]. Portable systems have been developed to apply short current pulses to induce polarization and analyze the electrochemical response, which is then correlated to the corrosion rate through calibration models.

Moreover, recent advances in electrochemical testing have led to the development of novel techniques that enhance sensitivity and adaptability for both laboratory and field use. For instance, a new method utilizing a modified three-electrode configuration embedded into concrete has been shown to improve accuracy and reduce noise in LPR readings, even under highly resistive conditions [23]. Another innovative approach employs embedded microsensors for continuous electrochemical monitoring in concrete structures, which enables real-time corrosion diagnostics without surface access [24].

These new developments are particularly important for in situ monitoring of infrastructures like bridges, tunnels, and marine platforms, where continuous or periodic corrosion assessment is needed without damaging the structure. Such techniques contribute significantly to the implementation of predictive maintenance strategies and lifecycle-based asset management.

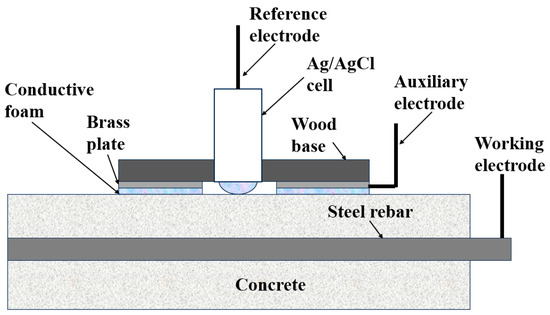

2.1.4. Electrochemical Impedance Spectroscopy

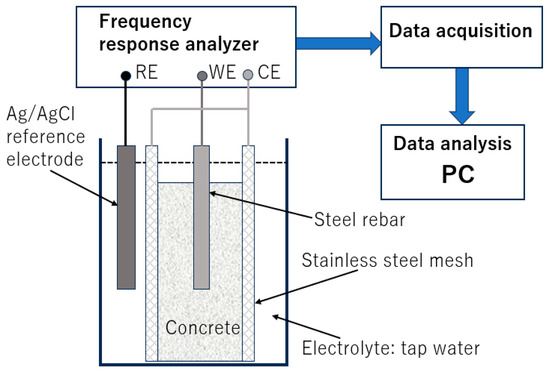

Electrochemical impedance spectroscopy (EIS) is a powerful, non-destructive electrochemical technique used to investigate the corrosion mechanisms and kinetics of metal in an electrolyte [25,26]. In standard laboratory practice, EIS is performed using a three-electrode configuration. Figure 5 shows the setup [27]. The reinforcing steel acts as the working electrode (WE). A reference electrode (RE)—typically a saturated calomel electrode (SCE) or Ag/AgCl—is placed near the rebar. A counter electrode (CE) is also used, which is often made of stainless steel or graphite.

Figure 5.

Setup for EIS measurements.

Instead of applying small DC polarization (like in LPR), EIS involves applying a small alternating voltage (AC) of low amplitude (typically 5–10 mV) to the rebar’s surface and measuring the resulting AC current. The frequency is varied over a wide range (e.g., 0.01 Hz to 100 kHz) to probe different electrochemical processes. The system’s impedance (Z) is measured as a complex quantity (real Z′ and imaginary Z″ components). The response depends on the electrochemical processes at the rebar–concrete interface (e.g., charge transfer, diffusion, oxide layer behavior).

Electrochemical impedance spectroscopy (EIS) has been applied to investigate the corrosion of steel rebars within concrete structures. Dawson et al. [28] performed impedance measurements on mild steel rebars embedded in concrete using two-electrode or three-electrode configurations and subsequently interpreted these spectra with the Randles equivalent circuit. Multiple equivalent circuits have been put forward to describe the dissolution process of steel rebars in concrete or mortar, based on impedance spectra collected with two- or three-electrode setups [29,30,31].

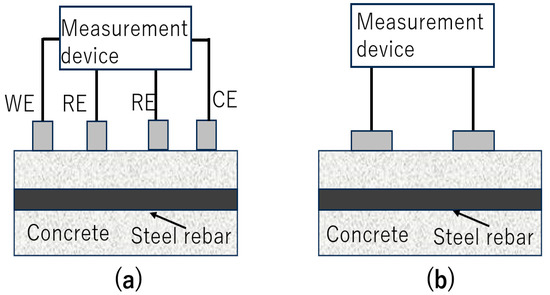

To avoid having to connect directly to the steel rebar, some researchers have investigated an indirect approach employing a four-electrode or two-electrode configuration [32,33], as shown in Figure 6.

Figure 6.

Schematic of (a) four-electrode setup and (b) two-electrode setup of electrochemical impedance spectroscopy. Based on ref. [33].

It should be noted that EIS is predominantly a laboratory technique due to several limitations in field environments: long measurement times at low frequencies; the need for stable environmental and moisture conditions; difficulty in establishing proper contact with embedded reinforcement; and the complexity of interpreting multi-component impedance spectra.

2.2. Ultrasonic Method

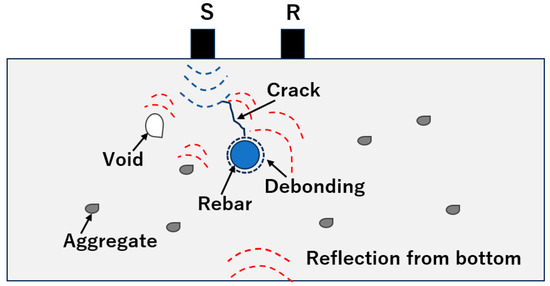

Ultrasonic testing is a powerful non-destructive method for evaluating the condition of steel rebars in reinforced concrete structures. Figure 7 shows the approach of ultrasonic testing. It operates by sending high-frequency stress waves into the material and analyzing their propagation, reflection, and attenuation to assess internal conditions.

Figure 7.

Approach of ultrasonic testing.

As ultrasound propagates through the concrete and reaches the steel, it reflects toward the transducer, allowing for measurement of the travel time and reflection amplitude. A reduction in the cross-sectional area due to corrosion, the presence of voids, or poor bond conditions can affect these signals, making it possible to identify and quantify damage without physically removing material. Ultrasonic testing is frequently used on-site because it is lightweight, portable, and can provide localized information about a small area of a structure.

The pulse velocity (UPV) method has been broadly applied to assess the condition of concrete structures. This approach, which involves measuring the speed of acoustic waves traveling through the material, is sensitive to the bond between steel and concrete and to the presence of cracks [34]. Table 3 shows the relationship between ultrasonic pulse velocity and the quality of concrete [15,35].

Table 3.

Longitudinal pulse velocity vs. quality of concrete.

The impact echo (IE) method, which relies on striking the surface mechanically and then recording the signals captured by nearby sensors, has been used less frequently to identify damage stemming from the corrosion of embedded steel [36]. Some researchers have pointed out that the reliability of IE decreases as the thickness of the concrete increases [37].

Nonlinear ultrasonic (NLU) techniques have demonstrated potential for evaluating material deterioration [38,39]. Specifically, these methods are well-suited for detecting early-stage cracking [40]. NLU is based on the principle that the interaction of ultrasound with a flawed material produces higher-frequency components in the acoustic signals [41].

Nevertheless, factors such as surface roughness, material heterogeneity, and moisture content can influence the signals and sometimes make their interpretation challenging. Nevertheless, when applied by skilled inspectors, ultrasonic testing is a valuable tool for condition assessment and maintenance planning of reinforced concrete structures.

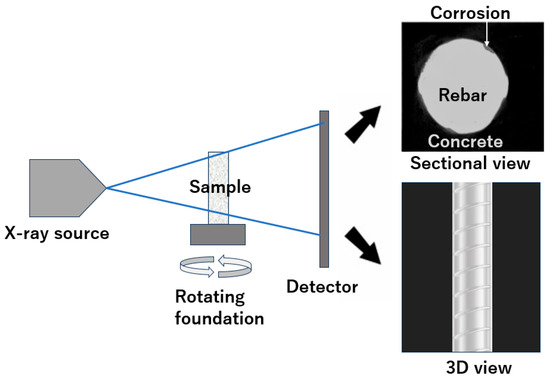

2.3. X-Ray Tomography Method

X-ray tomography, particularly X-ray computed tomography(X-CT), has become a powerful non-destructive tool for evaluating the internal condition of steel rebars in reinforced concrete structures [42,43,44,45]. It utilizes X-rays to generate a series of radiographic images from different angles. These two-dimensional projections are then computationally reconstructed into a high-resolution, three-dimensional view of the material’s internal structure. X-ray tomography enables a direct visualization of the rebar’s geometry, surface morphology, and any internal defects or abnormalities that may be present due to corrosion.

This method operates on the principle of X-rays being differentially absorbed by materials of different densities and atomic numbers. Steel has a higher density than the surrounding concrete, which results in greater absorption of X-rays. Furthermore, areas where corrosion has removed metal or filled voids with rust products appear as regions of lower density. The result is a detailed 3D map of the rebar’s condition, allowing engineers to quantify the depth of pitting, reduction in cross-sectional area, and the distribution of corrosion products.

Figure 8 shows the schematic diagram of the X-ray tomography method to evaluate the corrosion of steel rebar. The X-ray source emits a beam of X-rays that penetrates the concrete sample containing the steel rebar. The intensity of X-rays is attenuated differently by various materials (concrete, steel, corrosion products), enabling contrast in the captured images. The concrete sample with embedded steel rebar is mounted on a rotating foundation. The X-ray detector is positioned on the opposite side of the X-ray source; the detector collects the transmitted X-rays after they pass through the sample. A reconstructed 2D cross-sectional image of the sample shows the internal structure. By combining multiple cross-sectional slices, a 3D volume image is reconstructed. This 3D view enables the comprehensive visualization of corrosion morphology, such as pit depth, distribution, and volume loss.

Figure 8.

Schematic diagram of X-ray tomography method.

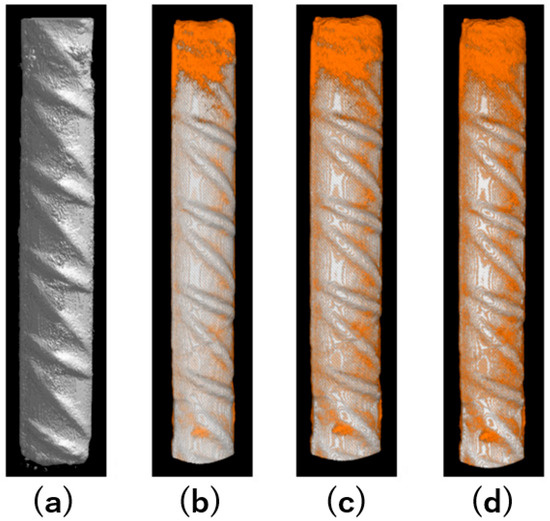

Figure 9 shows the progression of corrosion of steel rebar observed by 3D X-ray micro-computed tomography [46]. After 14 days of chloride-accelerated corrosion testing, clear signs of corrosion appeared on the rebar, primarily in the portions exposed outside the concrete cube. By day 42, corrosion on the exposed rebar had significantly intensified, while changes within the concrete remained relatively minor. Similar patterns were observed after 70 days, with external corrosion continuing to advance and internal corrosion showing only slight progression.

Figure 9.

The 3D X-ray micro-CT visualization of steel rebar, based on ref. [46]: (a) before corrosion acceleration experiment, (b) 14th day of the experiment, noticeable first corrosion changes within the rebar, (c) 42nd day of the experiment, and (d) 70th day of the experiment.

One key advantage of X-ray tomography is its ability to produce high-resolution, non-destructive, and volumetric data. Traditionally, assessing internal corrosion required cutting or coring, which is invasive and destroys the specimen. X-CT avoids this by allowing a complete view of the interior without physical intervention. Furthermore, it can resolve fine details, often at a micron scale, which makes it suitable for identifying small defects and initiation sites of corrosion that might not be detectable by surface methods.

Despite its capabilities, X-ray tomography has some limitations. The method typically requires specialized equipment, a radiation-safe environment, and extensive computing resources for data reconstruction and analysis. Furthermore, the size of the specimen that can be scanned at high resolution is limited by the dimensions of the X-ray imaging apparatus. Dense materials, large dimensions, or thick protective covers can diminish resolution and contrast. Nonetheless, for small cores or segments of reinforced concrete, X-CT provides unparalleled insight into internal conditions and damage mechanisms.

2.4. Infrared Thermography Method

Infrared thermography (IRT) is a non-destructive testing (NDT) technique that enables surface and subsurface defect detection based on thermal imaging. In the field of civil engineering, IRT has emerged as a promising tool for evaluating the corrosion of steel reinforcement (rebar) in concrete structures [47,48,49,50]. All materials emit infrared radiation in proportion to their temperature; by employing a thermal camera, this radiation can be captured and processed into a thermal image. The principle of infrared thermography for corrosion evaluation lies in the thermal anomalies that arise from differences in material properties, defects, or damage beneath the surface.

When corrosion occurs in a steel rebar, the products of corrosion (such as rust) typically have different thermal properties, including thermal conductivity and emissivity, than the base metal. Furthermore, the formation of corrosion products can affect the bond between steel and the surrounding concrete, creating small voids or detachments. These abnormalities manifest as localized temperature variations on the surface of the structure.

Two main approaches are used in IRT for corrosion detection: passive thermography and active thermography. Passive thermography relies on naturally occurring thermal gradients (e.g., solar heating) to reveal anomalies [51,52]. Active thermography involves external stimulation (e.g., heat lamps, flash lamps, eddy current) to induce thermal waves, allowing for better subsurface defect detection [53,54,55,56].

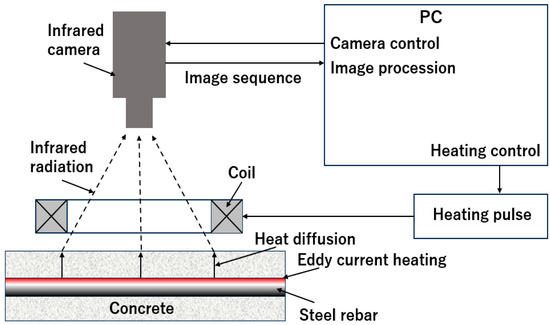

Figure 10 shows the schematic setup of the eddy current heating infrared thermography method to evaluate the corrosion of steel rebar [56]. A coil is positioned above the concrete surface. When an alternating current is applied to the coils, eddy currents are induced within the steel rebar. The eddy current generates localized heating in the rebar due to its electrical resistance (Joule heating). The heat generated in the steel rebar diffuses outward through the surrounding concrete. Any variations in the diffusion pattern—caused by corrosion or defects—affect the temperature distribution on the concrete surface. An infrared (IR) camera is used to monitor the surface temperature changes by capturing the emitted infrared radiation. The camera records a sequence of thermal images showing how the heat propagates over time. A PC controls the system, including both the heating pulse (timing and intensity) and the infrared camera. The captured image sequence is processed on the PC to analyze thermal contrasts and detect anomalies associated with corrosion.

Figure 10.

Setup of eddy current heating infrared thermography method to evaluate corrosion of steel rebar.

Infrared thermography is a quick, non-invasive, and non-contact technique. Large areas of a structure can be scanned rapidly, making it well-suited for the preliminary screening of extensive reinforced concrete components, such as bridges, decks, and parking garages. The captured thermal images can be processed to highlight regions of potential deterioration, guiding further investigations with more invasive or localized methods if necessary.

However, the IRT method has some limitations. The accuracy of infrared thermography depends on environmental conditions, such as solar radiation, wind, and surface wetness, which can affect temperature signals. The depth of defects detectable by infrared is typically limited to shallow abnormalities—typically 2~3 cm below the surface—and the method may be less effective for detecting deep or uniformly distributed corrosion. Furthermore, proper data interpretation requires specialized knowledge and experience to account for these influencing factors.

2.5. Ground Penetrating Radar Method

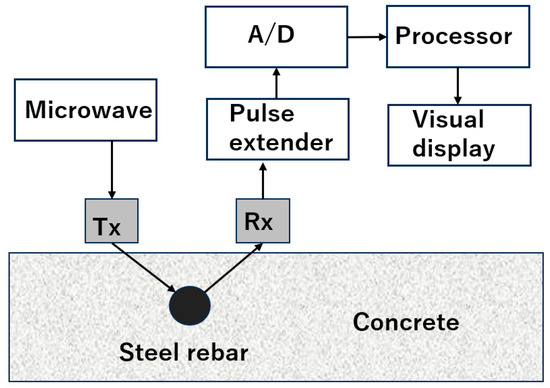

Ground penetrating radar (GPR) is a non-destructive testing method that utilizes electromagnetic waves to image the interior of materials [57,58,59]. Figure 11 shows a schematic diagram of the GPR system. The microwave source generates high-frequency electromagnetic pulses (usually in the range 10 MHz to 2.6 GHz), and the transmitter (Tx) antenna directs the microwave signal into the concrete structure. As the signal penetrates the concrete, it interacts with embedded objects, such as steel rebar. The presence of steel rebar causes part of the microwave signal to reflect due to its different dielectric properties. The level and characteristics of this reflection can be affected by corrosion, which alters the electrical and magnetic properties of the rebar [60,61,62]. The receiver (Rx) antenna captures the reflected microwave signals after interacting with the steel rebar. The time delay and amplitude of the received signal provide information about the depth and condition of the rebar. The pulse extender enhances and shapes the received signal for better analysis and resolution. It helps distinguish between reflections from different layers or objects. The A/D converter (analog-to-digital converter) converts the analog microwave signals into digital data for computational processing. The processor analyzes the digitized signals to extract meaningful information about the location and condition of the steel rebar. It may apply signal processing techniques like filtering, deconvolution, or time-domain analysis. The visual display presents the processed data as images or graphs. It typically shows rebar position, potential corrosion zones, or signal amplitude vs. depth.

Figure 11.

Schematic diagram of ground penetrating radar for evaluation of steel rebar.

The principle of GPR for evaluating corrosion lies in the contrast in electromagnetic properties—particularly the permittivity and conductive properties [63]. As rebar corrodes, rust products form and microcracks develop in the surrounding concrete, affecting its ability to reflect radar signals. Furthermore, thinning of the steel due to corrosion weakens the reflection from the rebar. The degree of reflection attenuation and the spreading of the radar pulse can be indicators of the condition of the rebar.

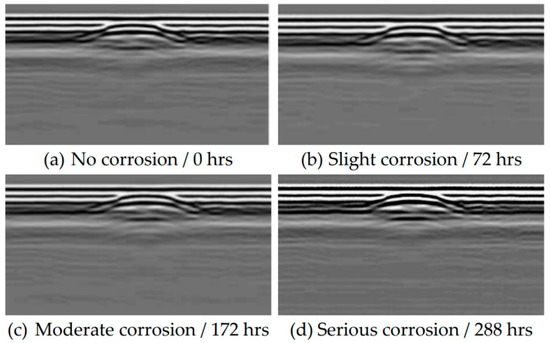

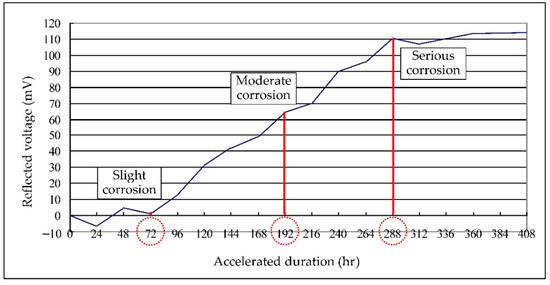

Figure 12 shows the GPR scanning profile of steel rebar with different corrosion levels [64]. Since the ground penetrating radar (GPR) profile presents a simulated signal image, visual differences between corrosion states are not readily apparent. Therefore, corrosion assessment in this study relies on coded signal analysis. The reflected electromagnetic wave voltage from steel bars embedded in concrete was examined at various stages of accelerated corrosion (ranging from 0 to 408 h). GPR results indicated that during the selected corrosion durations of 72, 192, and 288 h, the reflected voltage varied according to the extent of corrosion, as illustrated in Figure 13. These findings demonstrate that the degree of corrosion increases with longer exposure to the accelerated corrosion process.

Figure 12.

GPR scanning profile of steel rebar corrosion (thickness of 4 cm), based on ref. [64].

Figure 13.

Reflected voltages of steel rebars with 4 cm protective layer, based on ref. [64].

GPR is a high-resolution, non-invasive, and rapid method for scanning large areas of reinforced concrete structures. It is frequently used to produce two-dimensional and, by collecting data on a grid, even three-dimensional images of the internal configuration of rebars. GPR can provide valuable information on the depth, spacing, and condition of the reinforcements without disturbing or damaging the structure [65,66].

However, GPR has some limitations. The depth of penetration is influenced by concrete properties, moisture content, and frequency of the antenna [67]. Higher-frequency antennas provide greater resolution but less penetration depth. Additionally, GPR signals can become weak or distorted in materials with high clay content or heavy chloride contamination [68]. The interpretation of GPR data also requires expertise and experience, as signals can be influenced by numerous factors unrelated to corrosion.

2.6. Magnetic Flux Leakage Method

The magnetic flux leakage (MFL) method is a well-established, non-destructive testing (NDT) technique used for the inspection of ferromagnetic materials [69,70,71]. It has been increasingly adopted for the evaluation of corrosion in steel reinforcement bars (rebars) embedded in concrete structures [72,73,74]. The principle of MFL relies on the distortion of magnetic fields in regions where metal loss or structural discontinuities, such as corrosion pits, are present.

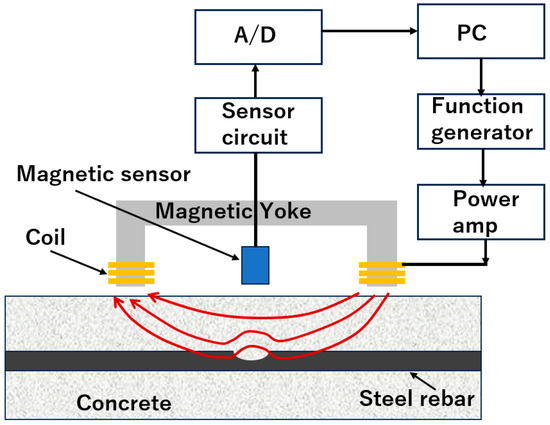

Figure 14 shows the setup of the MFL method for the corrosion evaluation of steel rebar. The excitation coils, on either side of a magnetic yoke, generate a controlled magnetic field that passes through the concrete and steel rebar. The coils are driven by a function generator and power amplifier connected to a PC, which allows for precise control of the excitation current and waveform (typically sinusoidal or pulsed). The magnetic yoke provides a path for the magnetic field to flow through and concentrate over the steel rebar. It ensures that magnetic flux enters the steel bar and returns to the coil circuit, creating a closed magnetic loop. When the rebar is magnetized, intact regions guide the flux smoothly, while corroded regions cause magnetic flux leakage due to air gaps or material discontinuities from rust loss. The leakage field appears on the concrete surface and can be detected above the rebar. The magnetic sensor is positioned in the center of the magnetic yoke and (e.g., Hall-effect sensor, giant magnetoresistance sensor) detects changes in magnetic flux density. Anomalies in the measured signal indicate the presence and severity of corrosion.

Figure 14.

Setup of magnetic flux leakage device for evaluation of steel rebar.

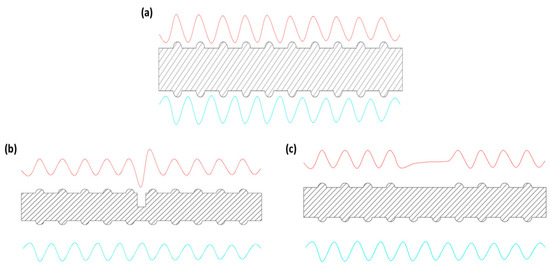

Figure 15 shows the typical MFL signals for the steel rebars with no defect, saw cutting defect, and grinding defect [73]. The MFL signals display a sinusoidal waveform as the sensor passes over the ribs of the reinforcing steel, as shown in Figure 15a. When a defect is present in the specimen, the waveform changes in both amplitude and bandwidth, reflecting variations in defect width and depth, as shown in Figure 15b. In the case of grinding-induced defects (rib loss), the signal loses its oscillatory pattern and becomes straighter, connecting directly to the next rib peak, as shown in Figure 15c.

Figure 15.

Typical waveforms of MFL signal over reinforcing steel: (a) new rebar, (b) rebar with cutting defects, and (c) rebar with grinding defects. Based on ref. [73].

The MFL method is a powerful tool for detecting and quantifying rebar corrosion, offering advantages in speed and accuracy. Recent advancements in sensor technology [75,76,77] and AI-driven signal processing have enhanced its reliability [78,79,80]. However, challenges like concrete cover interference necessitate further research. Future developments in multi-sensor fusion and automated inspection systems will broaden MFL’s applicability in structural health monitoring.

2.7. Eddy Current Testing Method

Eddy current testing (ECT) is a non-destructive testing technique widely used for inspecting conductive materials. Its ability to detect surface and near-surface flaws makes it a powerful tool in various industries, including aerospace, automotive, and civil infrastructure [81,82,83,84,85]. The principle of this technique relies on alternating current passing through a coil, which generates an alternating magnetic field. When this coil is brought close to a conductive material, eddy currents are induced in the material’s surface. The flow of these eddy currents depends directly on the material’s properties, such as its electrical conductivity, permeability, dimensions, and its condition, including the presence of defects or corrosion.

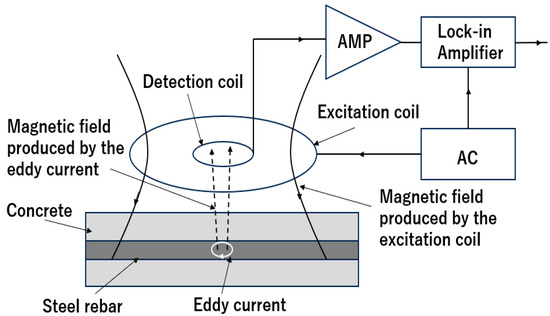

Figure 16 shows the principle of the ECT method to evaluate the corrosion of steel rebar. The excitation coil generates a primary oscillating magnetic field when powered by the AC source. The magnetic field penetrates the concrete and induces eddy currents in the conductive steel rebar located beneath the surface. Corrosion in the rebar affects the magnitude and distribution of these eddy currents. The detection coil detects the secondary magnetic field produced by the eddy currents in the steel rebar. The strength and phase of this induced field are influenced by changes in the rebar’s condition (e.g., due to corrosion or section loss). The lock-in amplifier is used to filter out noise and extract the desired signal that is synchronized with the reference signal from the AC source.

Figure 16.

Principle of eddy current testing method for corrosion detection of steel rebar.

ECT is used to detect pitting corrosion, loss of cross-sectional area, and surface cracks in steel rebars [86,87,88,89,90,91,92]. It is particularly effective in early-stage corrosion detection, where minimal visual signs are present. The technique can be applied in laboratory settings and on-site inspections, using portable equipment [93,94].

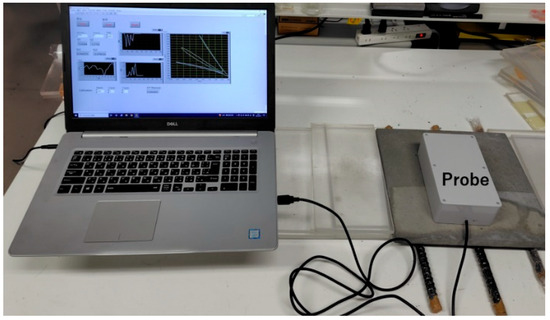

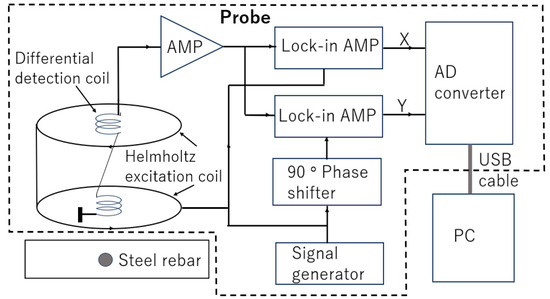

Figure 17 shows a portable compact ECT system for the corrosion evaluation of steel rebar. Figure 18 shows the block diagram of the system [94]. The frequency of 80 kHz is used. All the core components, including the excitation coil, detection coil, signal amplifier, lock-in amplifier, signal generator, and analog-to-digital (AD) converter, were integrated into a compact plastic probe box with a size of 17 cm in length, 8.5 cm in width, and 6 cm in height. The probe was connected to a computer via a single USB cable, which served a dual function by supplying both electrical power and enabling data communication. The total power consumption of the system was under 1 watt, making it highly energy-efficient. A Helmholtz excitation coil with a diameter of 5 cm and a differential detection coil with a diameter of 1 cm were used. The corrosion of steel rebar with a covering depth of 75 mm can be detected using this technique [94].

Figure 17.

Photo of corrosion detection system with eddy current testing method.

Figure 18.

Block diagram of ECT system for corrosion detection of steel rebar.

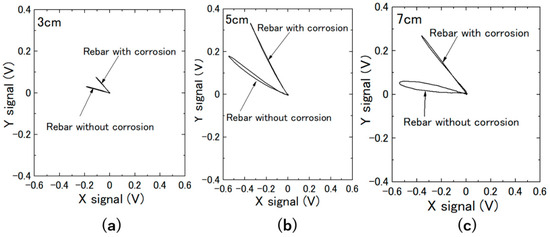

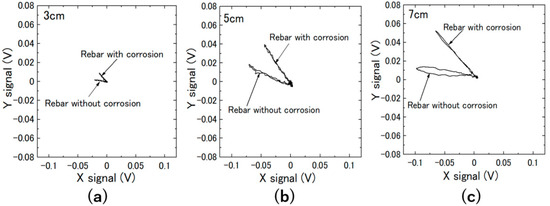

Figure 19 and Figure 20 present the signals obtained using the same detection coil and excitation coils with diameters of 3 cm, 5 cm, and 8 cm, corresponding to steel rebar depths of 25 mm and 45 mm, respectively [94]. The phase differences between corroded and uncorroded rebars are clearly observed. Increased detection depth can be obtained using a bigger excitation coil.

Figure 19.

ECT signals of steel rebars with depth of 25 mm. (a) Excitation coil diameter: 3 cm. (b) Excitation coil diameter: 5 cm. (c) Excitation coil diameter: 7 cm. Based on ref. [94].

Figure 20.

ECT signals of steel rebars with depth of 45 mm. (a) Excitation coil diameter: 3 cm. (b) Excitation coil diameter: 5 cm. (c) Excitation coil diameter: 7 cm. Based on ref. [94].

With the advancement of sensor technologies and data processing algorithms, eddy current testing is expected to become more accurate and accessible. Developments in high-frequency probes, machine learning for signal analysis, and integration with other NDT techniques may improve the reliability of corrosion assessment in complex structural elements. ECT remains a valuable technique for ensuring the long-term performance of reinforced concrete infrastructure.

3. Summary, Discussion, and Recommendations

The evaluation of corrosion in steel rebars is a crucial aspect of structural health monitoring and maintenance. A range of methods—electrochemical, ultrasonic, radiographic, thermal, and electromagnetic—are available to assess the condition of rebars in a non-destructive or minimally invasive manner. Each method operates on different physical principles and has unique capabilities, limitations, and applications. Table 4 summarizes the principles, advantages, limitations, typical applications, corrosion stage to be detected, and relative cost of each technique.

Table 4.

Comparison of different steel rebar corrosion evaluation methods.

Electrochemical techniques, such as half-cell potential, polarization resistance, and electrochemical impedance spectroscopy, directly measure electrochemical parameters at the metal’s surface. They are well-suited for identifying active corrosion and estimating its rate of progression. Nevertheless, these techniques typically require physical contact and careful surface preparation, which can be challenging in some cases.

Ultrasonic methods rely on the propagation of high-frequency stress waves through materials. Disruptions in wave signals can reveal defects and thinning in rebars. Ultrasonic testing is useful for deep penetration and imaging internal defects, although it may be affected by surface conditions and material heterogeneity.

X-ray tomography provides a non-destructive, high-resolution, 3D view of internal structures. It can visualize corrosion damage directly and accurately; however, it requires specialized equipment and radiation safety measures and is typically unsuitable for large structures in situ.

Infrared thermography detects abnormalities by measuring temperature distributions on a structure’s surface. It can quickly scan large areas to find regions of potential damage. Nevertheless, it mainly reveals near-surface abnormalities and is influenced by surface conditions and environmental factors.

GPR emits electromagnetic signals into a structure and detects reflection signals from rebars and defects. GPR is effective for mapping rebars’ depth and spacing and identifying areas of deterioration, although it has limited resolution at greater depth, and signals may be affected by material properties and moisture.

MFL is a powerful method for detecting localized metal thinning and pitting by measuring disturbances in a magnetic field. However, the method mainly responds to metal loss defects and is not sensitive to the initial corrosion of steel rebar. The device is normally heavy and needs a big working space.

Eddy current testing utilizes electromagnetic induction to generate eddy currents in the metal. It is highly sensitive, contactless, and well-suited for the detection of early-stage corrosion of steel rebar; a small, compact ECT device can be realized, although its depth of penetration is limited, and signals can be influenced by nearby conductive materials.

Despite the extensive theoretical basis and demonstrated accuracy of each method, practical implementation challenges often arise during field applications. For instance, electrochemical techniques like half-cell potential or EIS require direct electrical connection to the rebar, which may not be feasible without partial concrete removal [13,22]. X-ray tomography, although offering unmatched internal resolution, is generally confined to laboratory settings due to the need for bulky radiation-safe equipment and computational resources [36,39]. Similarly, EIS and LPR may face signal interpretation difficulties under varying concrete compositions, moisture levels, or electromagnetic interference [19,20,27]. Infrared thermography, while fast and non-contact, depends heavily on ambient thermal conditions and is limited to shallow defects [41,44]. Field engineers must also contend with factors such as equipment portability, accessibility of measurement locations, environmental variability, and the need for skilled personnel, which may restrict the real-world deployment of otherwise promising methods.

In addition to operational challenges, cost–performance trade-offs are also important for selecting appropriate techniques in practice. High-resolution methods such as X-ray CT and 3D ultrasonic imaging involve expensive and sophisticated equipment, which may be justified only for critical structures or advanced diagnostic stages. In contrast, more affordable techniques such as half-cell potential, infrared thermography, or the ECT method, while limited in depth and resolution, provide valuable preliminary insights and are often more suitable for large-scale or routine inspections. Understanding the balance between equipment cost and the actionable information provided is essential when developing an efficient and realistic inspection strategy.

Given these practical constraints, it is increasingly evident that no single method offers a universal solution. Therefore, a combined or hybrid approach is often more effective, such as the following examples:

- -

- Pairing electrochemical techniques (for quantifying corrosion rates) with thermographic imaging (for rapid scanning of large surface areas) allows for both quantitative assessment and spatial screening [44,47].

- -

- Ground penetrating radar (GPR), which is effective in mapping rebar location and cover depth, can be complemented by magnetic flux leakage (MFL) or eddy current testing (ECT) for detecting localized corrosion or loss of cross-sectional area [53,63,88].

- -

- Ultrasonic pulse velocity measurements, although affected by heterogeneous materials, can offer internal profiling when combined with X-ray or thermography data, improving defect localization [28,30,36].

As a hypothetical case example, in bridge deck inspections, passive infrared thermography can be used for preliminary screening during daytime heating [45]. Suspected corrosion zones can then be examined using GPR to determine depth and rebar layout [52], followed by LPR measurements to quantify corrosion rates [15]. This multimodal framework improves diagnostic reliability and prioritization for maintenance.

In practice, selecting appropriate techniques requires balancing cost, accessibility, required expertise, and structural characteristics. Future trends in this field are likely to emphasize integrated sensor systems, automated scanning platforms, and AI-based data fusion algorithms, which can synthesize signals from multiple NDT methods into a comprehensive corrosion map [72,73]. The miniaturization of equipment and increased portability will further enhance on-site applicability, while cloud-based diagnostic systems may allow for remote expert evaluation [88].

In conclusion, while each technique offers distinct advantages, a multidisciplinary and integrative strategy is recommended for robust, efficient, and practical corrosion evaluation in reinforced concrete structures. This approach ensures both early detection and reliable condition assessment, contributing to extended service life and enhanced structural safety.

Funding

This work was not supported by any funding agency.

Data Availability Statement

Data are available upon request.

Conflicts of Interest

The author declares no conflict of interest.

References

- Amir, O. A topology optimization procedure for reinforced concrete structures. Comput. Struct. 2013, 114, 46–58. [Google Scholar] [CrossRef]

- Melchers, R.E. Long-Term Durability of Marine Reinforced Concrete Structures. J. Mar. Sci. Eng. 2020, 8, 290. [Google Scholar] [CrossRef]

- Nishiyama, M. Mechanical properties of concrete and reinforcement—State-of-the-art report on HSC and HSS in Japan. J. Adv. Concr. Technol. 2009, 7, 157–182. [Google Scholar] [CrossRef]

- Cabrera, J.G. Deterioration of concrete due to reinforcement steel corrosion. Cem. Concr. Compos. 1996, 18, 47–59. [Google Scholar] [CrossRef]

- Abosrra, L.; Ashour, A.F.; Youseffi, M. Corrosion of steel reinforcement in concrete of different compressive strengths. Constr. Build. Mater. 2011, 25, 3915–3925. [Google Scholar] [CrossRef]

- Pradhan, B. Corrosion behavior of steel reinforcement in concrete exposed to composite chloride-sulfate environment. Constr. Build. Mater. 2014, 72, 398–410. [Google Scholar] [CrossRef]

- Green, W.K. Steel reinforcement corrosion in concrete—An overview of some fundamentals. Corros. Eng. Sci. Technol. 2020, 55, 289–302. [Google Scholar] [CrossRef]

- Montemor, M.F. Functional and smart coatings for corrosion protection: A review of recent advances. Surf. Coat. Technol. 2014, 258, 17–37. [Google Scholar] [CrossRef]

- Ahmad, S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction—A review. Cem. Concr. Compos. 2003, 25, 459–471. [Google Scholar] [CrossRef]

- He, D. Evaluation of Steel Rebar in Concrete Using Electromagnetic Method. In Failure Analysis; Huang, Z.-M., Hemeda, S., Eds.; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Ohtsu, M.; Tomoda, Y. Compensated half-cell potential technique for NDE of rebar corrosion. In Proceedings of the 26th Seiken Symposium on Non-Destructive Testing in Civil Engineering 2000, Tokyo, Japan, 25–27 April 2000; pp. 615–624. [Google Scholar][Green Version]

- Pour-Ghaz, M.; Isgor, O.B.; Ghods, P. Quantitative interpretation of half-cell potential measurements in concrete structures. J. Mater. Civ. Eng. 2009, 21, 467–475. [Google Scholar] [CrossRef]

- ASTM C876-91; Standard Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete. Annual Book of ASTM Standards: Philadelphia, PA, USA, 1999.[Green Version]

- Feliu, S.; González, J.A.; Feliu, S.; Andrade, C. Relationship between conductivity of concrete and corrosion of reinforcing bars. Br. Corros. J. 1989, 24, 195–198. [Google Scholar] [CrossRef]

- Song, H.W.; Saraswathy, V. Corrosion monitoring of reinforced concrete structures—A review. Int. J. Electrochem. Sci. 2007, 2, 1–28. [Google Scholar] [CrossRef]

- Polder, R.B. Test methods for onsite measurement of resistivity of concrete—A RILEM TC-154 technical recommendation. Constr. Build. Mater. 2001, 15, 125–131. [Google Scholar] [CrossRef]

- Elsener, B.; Andrade, C.; Gulikers, J.; Polder, R.; Raupach, M.; Reichling, K.; Vennesland, Ø. Half-cell potential measurements—Potential mapping on reinforced concrete structures. Mater. Struct. 2003, 36, 461–471. [Google Scholar] [CrossRef]

- So, H.S.; Millard, S.G. On-site measurements on corrosion rate of steel in reinforced concrete. ACI Mater. J. 2007, 104, 638–642. [Google Scholar] [CrossRef]

- Sadowski, L. New non-destructive method for linear polarisation resistance corrosion rate measurement. Arch. Civ. Mech. Eng. 2010, 10, 109–116. [Google Scholar] [CrossRef]

- Videm, K.; Myrdal, R. Electrochemical behavior of steel in concrete and evaluation of the corrosion rate. Corrosion 1997, 53, 734–742. [Google Scholar] [CrossRef]

- Milliard, S.G.; Law, D.W.; Bunsey, J.H.; Cairus, J. Environmental influences on linear polarization corrosion rate measurement in reinforced concrete. NDT E Int. 2001, 34, 409–417. [Google Scholar] [CrossRef]

- Andrade, C.; Alonso, M.C.; Gonzalez, J.A. An initial effort to use corrosion rate measurements for estimating rebar durability. In Corrosion Rates of Steel in Concrete; ASTM STP 1065; Berke, N.S., Chaker, V., David Whiting, D., Eds.; ASTM: West Conshohocken, PA, USA, 1990; pp. 29–37. [Google Scholar][Green Version]

- Ramón, J.E.; Martínez, I.; Gandía-Romero, J.M.; Soto, J. Improved Tafel-Based Potentiostatic Approach for Corrosion Rate Monitoring of Reinforcing Steel. J. Nondestruct. Eval. 2022, 41, 70. [Google Scholar] [CrossRef]

- Ramón, J.E.; Gandía-Romero, J.M.; Bataller, R.; Alcañiz, M.; Valcuende, M.; Soto, J. Potential step voltammetry: An approach to corrosion rate measurement of reinforcements in concrete. Cem. Concr. Compos. 2020, 110, 203590. [Google Scholar] [CrossRef]

- Dhouibi, L.; Triki, E.; Raharinaivo, A. The application of electrochemical impedance spectroscopy to determine the long-term effectiveness of corrosion inhibitors for steel in concrete. Cem. Concr. Compos. 2002, 24, 35–43. [Google Scholar] [CrossRef]

- Zhao, X.Q.; Xiong, J. Effectively analysis of concrete bridge deck corrosion using electrochemical impedance spectroscopy. Int. J. Electrochem. Sci. 2016, 11, 5702–5709. [Google Scholar] [CrossRef]

- Herrera Hernández, H.; González Díaz, F.; Fajardo San Miguel, G.D.J.; Velázquez Altamirano, J.C.; González Morán, C.O.; Morales Hernández, J. Electrochemical Impedance Spectroscopy as a Practical Tool for Monitoring the Carbonation Process on Reinforced Concrete Structures. Arab. J. Sci. Eng. 2019, 44, 10087–10103. [Google Scholar] [CrossRef]

- Dawson, J.L.; Callow, L.M.; Hladky, K.; Richardson, J.A. Use of electrochemical impedance measurements applied to the corrosion of reinforcing steel in concrete. In Proceedings of the Corrosion ‘78, Bethlehem, PA, USA, 13–15 November 1978; p. 125. [Google Scholar][Green Version]

- Feliu, V.; Gonzalez, J.A.; Andrade, C.; Feliu, S. Equivalent circuit for modelling the steel-concrete interface. I. Experimental evidence and theoretical predictions. Corros. Sci. 1998, 40, 975–993. [Google Scholar] [CrossRef]

- Choi, Y.S.; Kim, J.G.; Lee, K.M. Corrosion behavior of steel bar embedded in fly ash concrete. Corros. Sci. 2006, 48, 1733–1745. [Google Scholar] [CrossRef]

- Hoshi, Y.; Hasegawa, C.; Okamoto, T.; Soukura, M.; Tokieda, H.; Shitanda, I.; Itagaki, M.; Kato, Y. Electrochemical impedance analysis of corrosion of reinforcing bars in concrete. Electrochemistry 2019, 87, 78–83. [Google Scholar] [CrossRef]

- Andrade, C.; Martinez, I.; Castellote, M. Feasibility of determining corrosion rates by means of stray current-induced polarization. J. Appl. Electrochem. 2008, 38, 1467–1476. [Google Scholar] [CrossRef]

- Hoshi, Y.; Koike, T.; Tokieda, H.; Shitanda, I.; Itagaki, M.; Kato, Y. Non-contact measurement to detect steel rebar corrosion in reinforced concrete by electrochemical impedance spectroscopy. J. Electrochem. Soc. 2019, 166, C3316–C3319. [Google Scholar] [CrossRef]

- Sharma, S.; Mukherjee, A. Longitudinal guided waves for monitoring chloride corrosion in reinforcing bars in concrete. Struct. Health Monit. 2010, 9, 555–567. [Google Scholar] [CrossRef]

- C-597-83; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 1989.[Green Version]

- Liang, M.T.; Su, P.J. Detection of the corrosion damage of rebar in concrete using impact-echo method. Cem. Concr. Res. 2001, 31, 1427–1436. [Google Scholar] [CrossRef]

- Zaki, A.; Chai, H.K.; Aggelis, D.G.; Alver, N. Non-destructive evaluation for corrosion monitoring in concrete: A review and capability of acoustic emission technique. Sensors 2015, 15, 19069–19101. [Google Scholar] [CrossRef]

- Jhang, K.Y. Nonlinear ultrasonic techniques for non-destructive assessment of microdamage in materials: A review. Int. J. Precis. Eng. Manuf. 2009, 10, 123–135. [Google Scholar] [CrossRef]

- Climent, M.Á.; Miró, M.; Carbajo, J.; Poveda, P.; de Vera, G.; Ramis, J. Use of non-linear ultrasonic techniques to detect cracks due to steel corrosion in reinforced concrete structures. Materials 2019, 12, 813. [Google Scholar] [CrossRef]

- Shah, A.A.; Ribakov, Y.; Hirose, S. Nondestructive evaluation of damaged concrete using nonlinear ultrasonics. Mater. Des. 2009, 30, 775–782. [Google Scholar] [CrossRef]

- Xiang, H.; Newtson, C.M.; Woodward, C. Optimization of nonlinear ultrasound results to determine dynamic properties of concrete. J. Mater. Civ. Eng. 2008, 20, 700–706. [Google Scholar] [CrossRef]

- Robuschi, S.; Tengattini, A.; Dijkstra, J.; Fernandez, I.; Lundgren, K. A closer look at corrosion of steel reinforcement bars in concrete using 3D neutron and X-ray computed tomography. Cem. Concr. Res. 2021, 144, 106439. [Google Scholar] [CrossRef]

- Dong, B.; Shi, G.; Dong, P.; Ding, W.; Teng, X.; Qin, S.; Liu, Y.; Xing, F.; Hong, S. Visualized tracing of rebar corrosion evolution in concrete with x-ray microcomputed tomography method. Cem. Concr. Compos. 2018, 92, 102–109. [Google Scholar] [CrossRef]

- Michel, A.; Pease, B.J.; Geiker, M.R.; Stang, H.; Olesen, J.F. Monitoring reinforcement corrosion and corrosion-induced cracking using non-destructive x-ray attenuation measurements. Cem. Concr. Res. 2011, 41, 1085–1094. [Google Scholar] [CrossRef]

- Xi, X.; Yang, S.T. Investigating the spatial development of corrosion of corner-located steel bar in concrete by X-ray computed tomography. Constr. Build. Mater. 2019, 221, 177–189. [Google Scholar] [CrossRef]

- Skarżyński, Ł.; Kibort, K.; Małachowska, A. 3D X-ray Micro-CT Analysis of Rebar Corrosion in Reinforced Concrete Subjected to a Chloride-Induced Environment. Molecules 2022, 27, 192. [Google Scholar] [CrossRef] [PubMed]

- Maldague, X.P.V. Theory and Practice of Infrared Technology for Nondestructive Testing; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Avdelidis, N.P.; Moropoulou, A. Applications of infrared thermography for the investigation of historic structures. J. Cult. Herit. 2004, 5, 119–127. [Google Scholar] [CrossRef]

- Tran, Q.H.; Huh, J.; Mac, V.H.; Kang, C.; Han, D. Effects of rebars on the detectability of subsurface defects in concrete bridges using square pulse thermography. NDT E Int. 2018, 100, 92–100. [Google Scholar] [CrossRef]

- Yuan, F.; Liu, Q.; Liu, G.; Wang, J. Application of UAV-based infrared thermography in detecting subsurface delamination of bridge decks. Autom. Constr. 2020, 112, 103102. [Google Scholar]

- Ichi, E.O. Validating NDE Dataset and Benchmarking Infrared Thermography for Delamination Detection in Bridge Decks. Master’s Thesis, University of North Dakota, Grand Forks, ND, USA, 2021. Available online: https://commons.und.edu/theses/4170 (accessed on 26 June 2025).

- Leon-Salas, W.D.; Halmen, C. A RFID sensor for corrosion monitoring in concrete. IEEE Sens. J. 2015, 16, 32–42. [Google Scholar] [CrossRef]

- Baek, S.; Bortolin, A.; Ferrarini, G.; Molinas, B.; Giantin, D.; Zonta, P.; Bison, P. Nondestructive corrosion detection in RC through integrated heat induction and IR thermography. J. Nondestruct. Eval. 2012, 31, 181–190. [Google Scholar] [CrossRef]

- Na, S.; Paik, I. Application of thermal image data to detect rebar corrosion in concrete structures. Appl. Sci. 2019, 9, 4700. [Google Scholar] [CrossRef]

- Keo, S.A.; Brachelet, F.; Breaban, F.; Defer, D. Steel detection in reinforced concrete wall by microwave infrared thermography. NDT E Int. 2014, 62, 172–177. [Google Scholar] [CrossRef]

- He, Y.; Tian, G.; Pan, M.; Chen, D. Eddy current pulsed phase thermography and feature extraction. Appl. Phys. Lett. 2013, 103, 084104. [Google Scholar] [CrossRef]

- Neal, A. Ground-penetrating radar and its use in sedimentology: Principles, problems and progress. Earth-Sci. Rev. 2004, 66, 261–330. [Google Scholar] [CrossRef]

- Maierhofer, C. Nondestructive evaluation of concrete infrastructure with ground penetrating radar. J. Mater. Civil. Eng. 2003, 15, 287–297. [Google Scholar] [CrossRef]

- Barnes, C.L.; Trottier, J.F.; Forgeron, D. Improved concrete bridge deck evaluation using GPR by accounting for signal depth–amplitude effects. NDT E Int. 2008, 41, 427–433. [Google Scholar] [CrossRef]

- Sbartaï, Z.M.; Laurens, S.; Rhazi, J.; Balayssac, J.P.; Arliguie, G. Using radar direct wave for concrete condition assessment: Correlation with electrical resistivity. J. Appl. Geophys. 2007, 62, 361–374. [Google Scholar] [CrossRef]

- Lai, W.L.; Derobert, X.; Annan, P. A review of ground penetrating radar application in civil engineering: A 30-year journey from locating and testing to imaging and diagnosis. NDT E Int. 2018, 96, 58–78. [Google Scholar] [CrossRef]

- Bungey, J.H. Sub-surface radar testing of concrete: A review. Constr. Build. Mater. 2004, 18, 1–8. [Google Scholar] [CrossRef]

- Annan, A.P. Electromagnetic principles of ground penetrating radar. In Ground Penetrating Radar: Theory and Applications, 1st ed.; Jol, H.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 4–40. [Google Scholar]

- Chang, C.-W.; Tsai, C.-A.; Shiau, Y.-C. Inspection of Steel Bars Corrosion in Reinforced Concrete Structures by Nondestructive Ground Penetrating Radar. Appl. Sci. 2022, 12, 5567. [Google Scholar] [CrossRef]

- Varnavina, A.V.; Khamzin, A.K.; Sneed, L.H.; Torgashov, E.V.; Anderson, N.L.; Maerz, N.H.; Boyko, K.J. Concrete bridge deck assessment: Relationship between GPR data and concrete removal depth measurements collected after hydrodemolition. Constr. Build. Mater. 2015, 99, 26–38. [Google Scholar] [CrossRef]

- Zaki, A.; Johari, M.; Azmi, M.; Hussin, W.; Aminuddin, W.M.; Jusman, Y. Experimental assessment of rebar corrosion in concrete slab using ground penetrating radar (GPR). Int. J. Corros. 2018, 2018, 5389829. [Google Scholar] [CrossRef]

- Hugenschmidt, J.; Loser, R. Detection of chlorides and moisture in concrete structures with ground penetrating radar. Mater. Struct. 2008, 41, 785–792. [Google Scholar] [CrossRef]

- Tarussov, A.; Vandry, M.; Haza, A.D.L. Condition assessment of concrete structures using a new analysis method: Ground-penetrating radar computer-assisted visual interpretation. Constr. Build. Mater. 2013, 38, 1246–1254. [Google Scholar] [CrossRef]

- Feng, B.; Wu, J.; Tu, H.; Tang, J.; Kang, Y. A review of magnetic flux leakage nondestructive testing. Materials 2022, 15, 7362. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, Y. Magnetic mechanisms of magnetic flux leakage nondestructive testing. Appl. Phys. Lett. 2013, 103, 184104. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and application of magnetic flux leakage pipeline detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, W.; Jing, Y. Quantitative linear correlation between self-magnetic flux leakage field variation and corrosion unevenness of corroded rebars. Measurement 2023, 218, 113173. [Google Scholar] [CrossRef]

- Yousaf, J.; Harseno, R.W.; Kee, S.-H.; Yee, J.-J. Evaluation of the size of a defect in reinforcing steel using magnetic flux leakage (MFL) measurements. Sensors 2023, 23, 5374. [Google Scholar] [CrossRef]

- Yang, M.; Zhou, J.; Zhao, Q.; Xia, Q.; Zhang, H.; Wang, L. Quantitative detection of corroded reinforced concrete of different sizes based on SMFL. KSCE J. Civ. Eng. 2022, 26, 143–154. [Google Scholar] [CrossRef]

- Jin, Z.; Mohd Noor Sam, M.A.I.; Oogane, M.; Ando, Y. Serial MTJ-based TMR sensors in bridge configuration for detection of fractured steel bar in magnetic flux leakage testing. Sensors 2021, 21, 668. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, S.; Wang, J.; Jing, L.; Mao, F. A novel magnetic flux leakage method incorporating TMR sensors for detecting zinc dross defects on the surface of hot-dip galvanized sheets. Magnetochemistry 2024, 10, 101. [Google Scholar] [CrossRef]

- Nicolicea, A.; Oliveros-Mata, E.S.; Zabila, Y.; Makarov, D.; Melzer, M.; Pelkner, M. Flexible anisotropic magnetoresistive sensors for novel magnetic flux leakage testing capabilities. NDT E Int. 2024, 146, 103160. [Google Scholar] [CrossRef]

- Huang, S.; Peng, L.; Sun, H.; Li, S. Deep learning for magnetic flux leakage detection and evaluation of oil & gas pipelines: A review. Energies 2023, 16, 1372. [Google Scholar] [CrossRef]

- Kim, J.-W.; Park, S. Magnetic Flux Leakage Sensing and Artificial Neural Network Pattern Recognition-Based Automated Damage Detection and Quantification for Wire Rope Non-Destructive Evaluation. Sensors 2018, 18, 109. [Google Scholar] [CrossRef]

- Li, S.; Bai, L.; Ren, C.; Zhang, X.; Ai, J.; Zhang, J. A multidirectional magnetic flux leakage detection based crack 3-D profile reconstruction method. Mech. Syst. Signal Process. 2025, 228, 112408. [Google Scholar] [CrossRef]

- Machado, M.A. Eddy Currents Probe Design for NDT Applications: A Review. Sensors 2024, 24, 5819. [Google Scholar] [CrossRef] [PubMed]

- García-Martín, J.; Gómez-Gil, J.; Vázquez-Sánchez, E. Non-destructive techniques based on eddy current testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef] [PubMed]

- Alvarenga, T.A.; Carvalho, A.L.; Honorio, L.M.; Cerqueira, A.S.; Filho, L.M.A.; Nobrega, R.A. Detection and Classification System for Rail Surface Defects Based on Eddy Current. Sensors 2021, 21, 7937. [Google Scholar] [CrossRef]

- He, D.; Kusano, M.; Watanabe, M. Detecting the defects of warm-sprayed Ti-6Al-4V coating using Eddy current testing method. NDT E Int. 2022, 125, 102565. [Google Scholar] [CrossRef]

- He, D.F.; Zhang, Y.Z.; Shiwa, M.; Moriya, S. Development of eddy current testing system for inspection of combustion chambers of liquid rocket engines. Rev. Sci. Instrum. 2013, 84, 014701. [Google Scholar] [CrossRef]

- Gaydecki, P.A.; Burdekin, F.M. An inductive scanning system for two dimensional imaging of reinforcing components in concrete structures. Meas. Sci. Technol. 1994, 5, 1272–1280. [Google Scholar] [CrossRef]

- Yu, Z.Z.; Gaydecki, P.A.; Silva, I.; Fernandes, B.T.; Burdekin, F.M. Magnetic field imaging of steel reinforcing bars in concrete using portable scanning systems. Rev. Prog. Quant. Nondestruct. Eval. 1999, 18, 2145–2152. [Google Scholar]

- Gaydecki, P.; Silva, I.; Fernandes, B.T.; Yu, Z. Z A portable inductive scanning system for imaging steel-reinforcing bars embedded within concrete. Sens. Actuators A 2000, 84, 25–32. [Google Scholar] [CrossRef]

- Miller, G.; Gaydecki, P.; Quek, S.; Fernandes, B.; Zaid, M. A combined Q and heterodyne sensor incorporating real-time DSP for reinforcement imaging, corrosion detection and material characterization. Sens. Actuators A Phys. 2005, 121, 339–346. [Google Scholar] [CrossRef]

- Ricken, W.; Mehlhorn, G.; Becker, W. Determining of the concrete cover thickness and the bar diameter in reinforced concrete with a method of eddy current testing. Proc. Int. Symp. Non-Destr. Test. Civ. Eng. 1995, 1, 197–204. [Google Scholar]

- Miller, G.; Gaydecki, P.; Quek, S.; Fernandes, B.T.; Zaid, M.A.M. Detection and imaging of surface corrosion on steel reinforcing bars using a phase-sensitive inductive sensor intended for use with concrete. NDT E Int. 2003, 36, 19–26. [Google Scholar] [CrossRef]

- He, D. Surface corrosion evaluation of steel cable for suspension bridge using electromagnetic method. Surf. Sci. Tech. 2023, 1, 16. [Google Scholar] [CrossRef]

- He, D. Corrosion evaluation of steel rebar using electromagnetic induction method. Stud. Appl. Electromagn. Mech. 2020, 45, 141–146. [Google Scholar]

- He, D. Detecting the Corrosion of a Steel Rebar Using the Eddy Current Testing Method. Standards 2024, 4, 286–299. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).