AC-Induced Corrosion of Cathodically Protected Pipelines: Experimental Study and Probabilistic Modeling

Abstract

1. Introduction

- CP potential: cathodic protection potential applied on the working electrode (WE) (i.e., pipeline metal).

- CP current density: cathodic protection direct current density flowing through the WE.

- DC potential: real-time actual potential applied to the WE based on the reference electrode (RE) as the feedback of the applied CP current density.

- DC current density: real-time current density flowing through the WE as the feedback of the applied CP potential.

- AC current density: AC current density flowing through the WE

- AC voltage: alternating voltage applied on the WE.

2. Materials and Methods

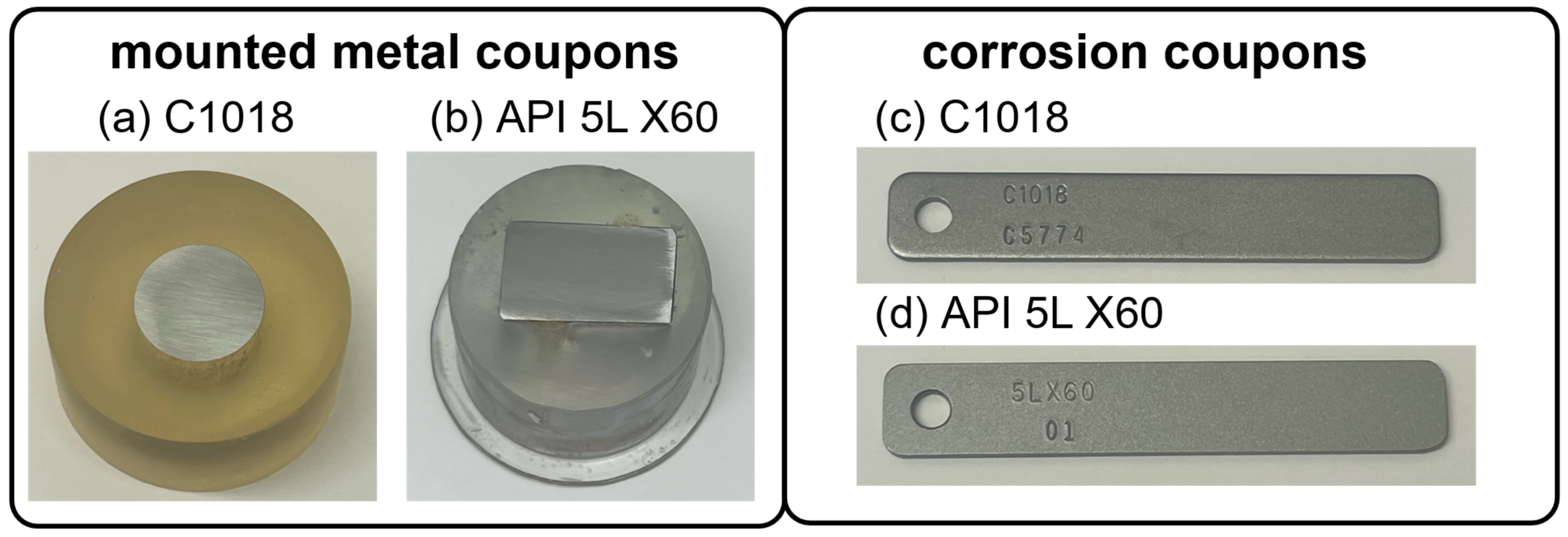

2.1. Metals

2.2. Chemical Composition of the Solution

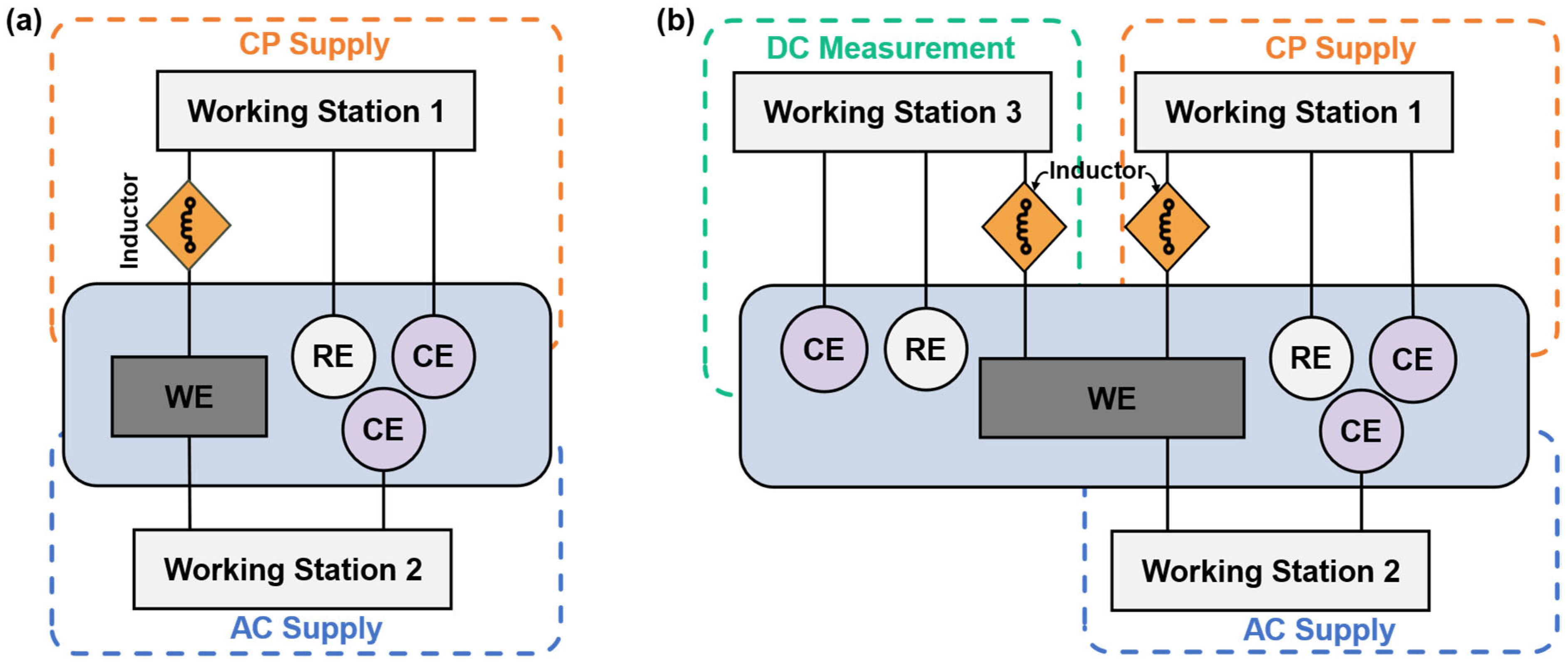

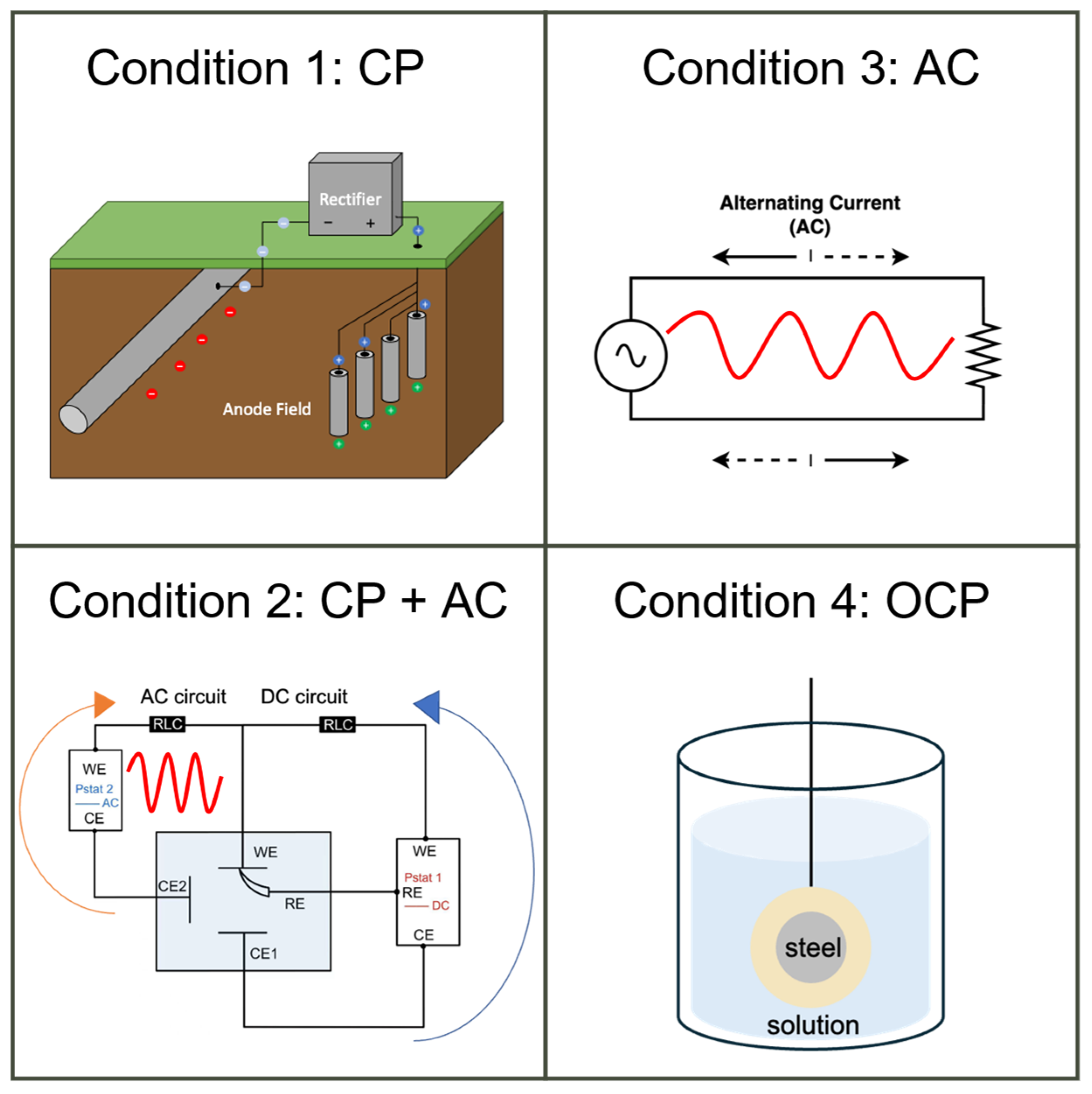

2.3. Experimental Setup

2.4. Corrosion Rate Tests

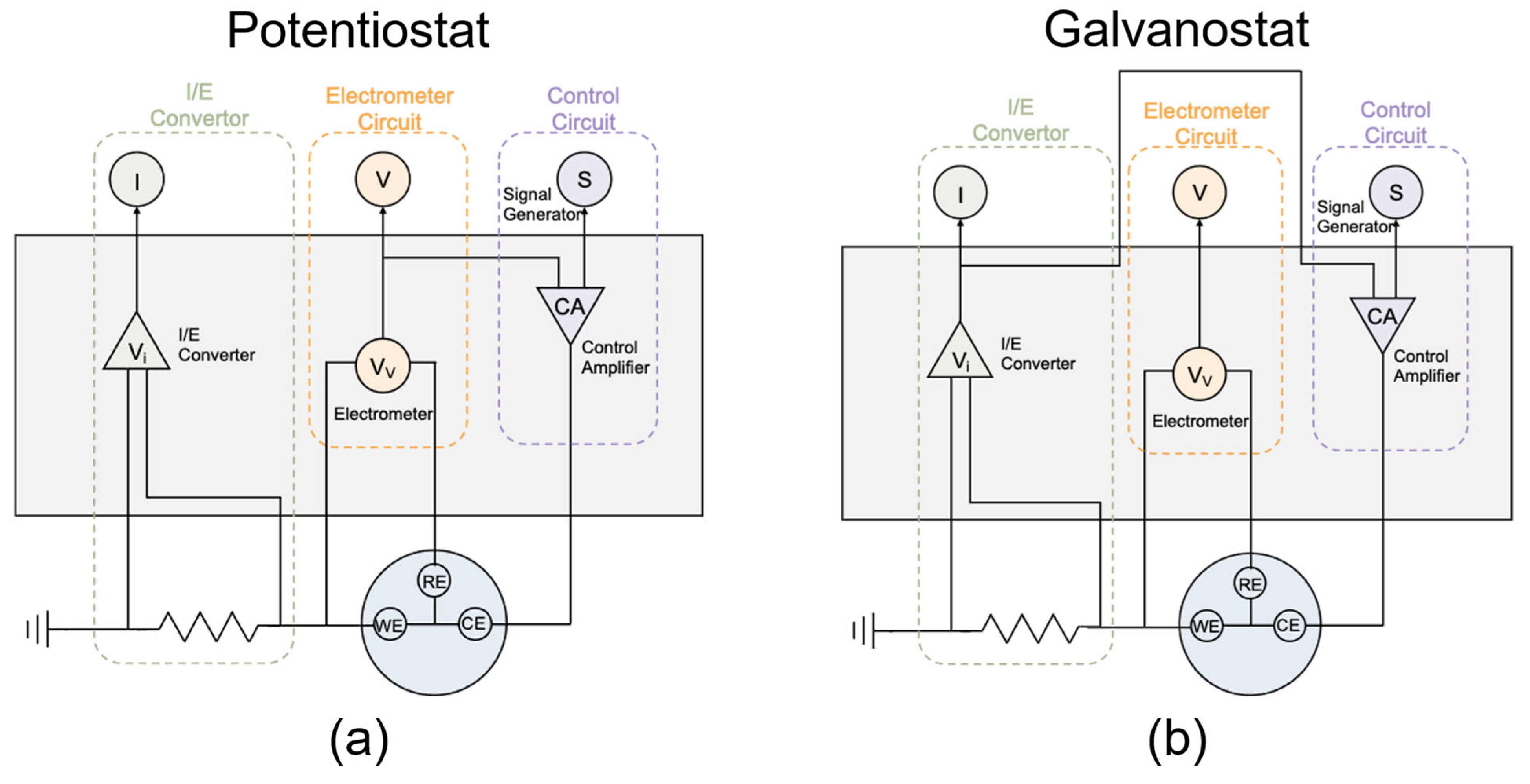

2.4.1. Tafel Measurement

2.4.2. Weight Loss Measurement

3. Results

3.1. Real-Time Feedback of DC Current Density When Applying CP Potential

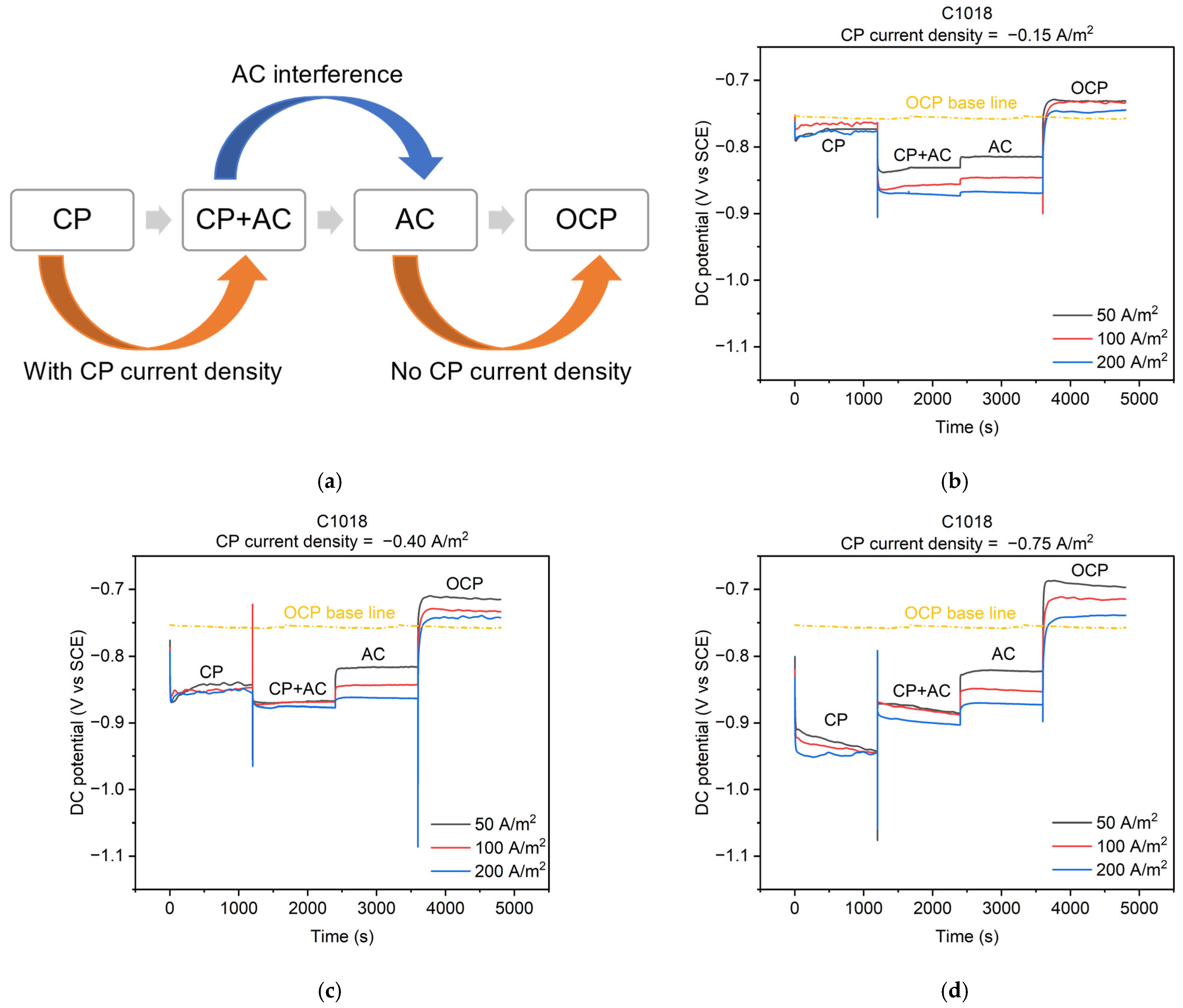

3.2. Real-Time Feedback of DC Potential When Applying CP Current Density

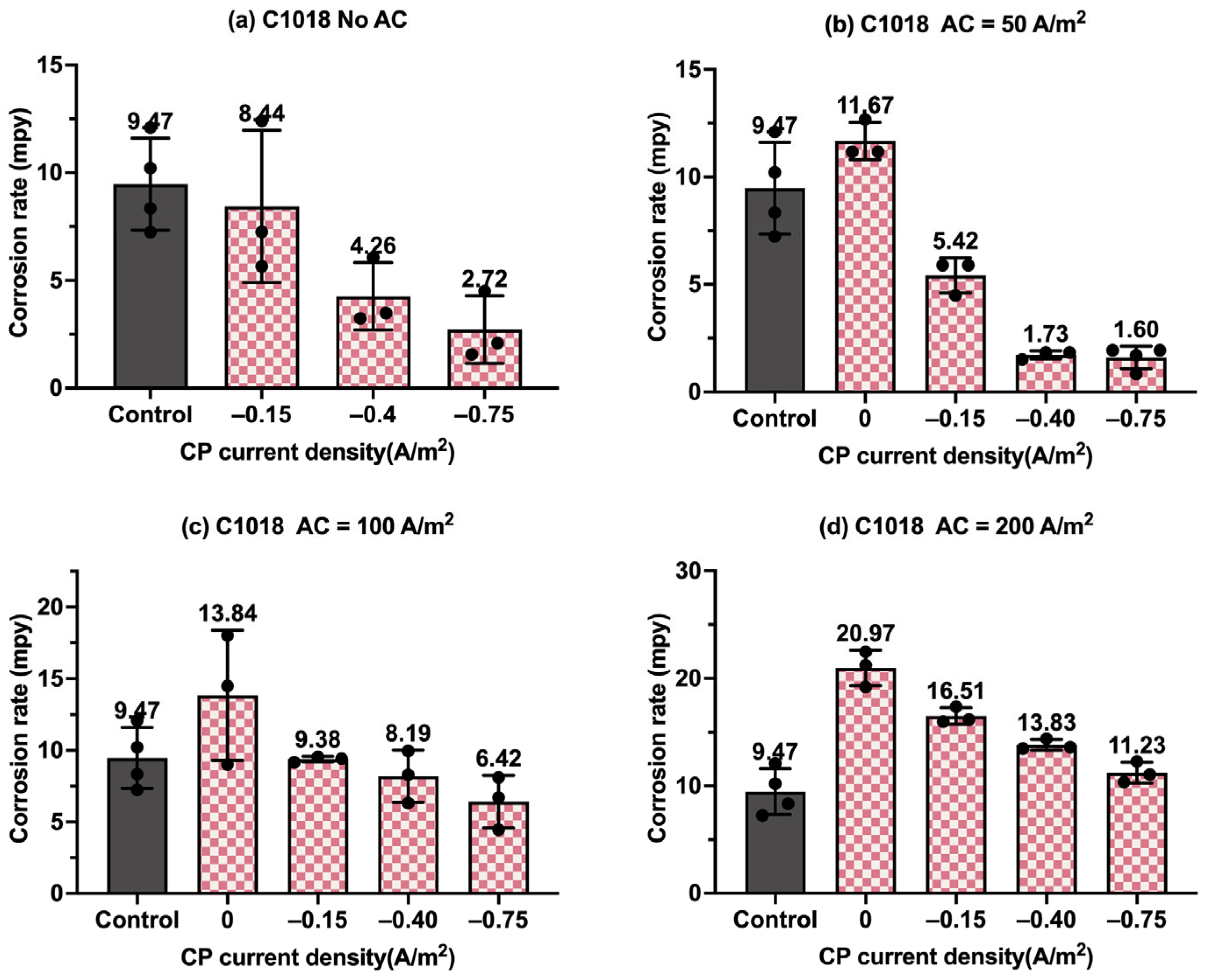

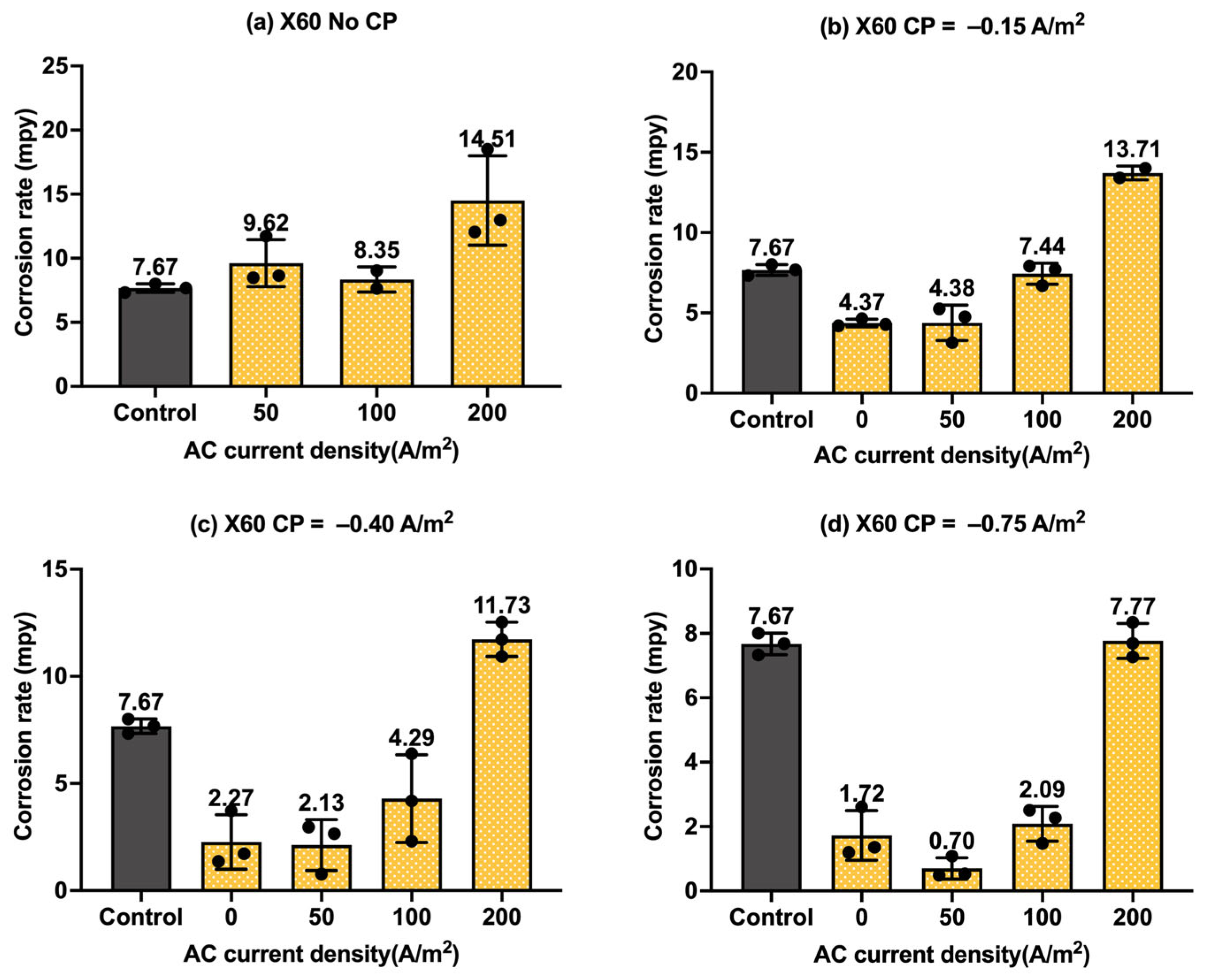

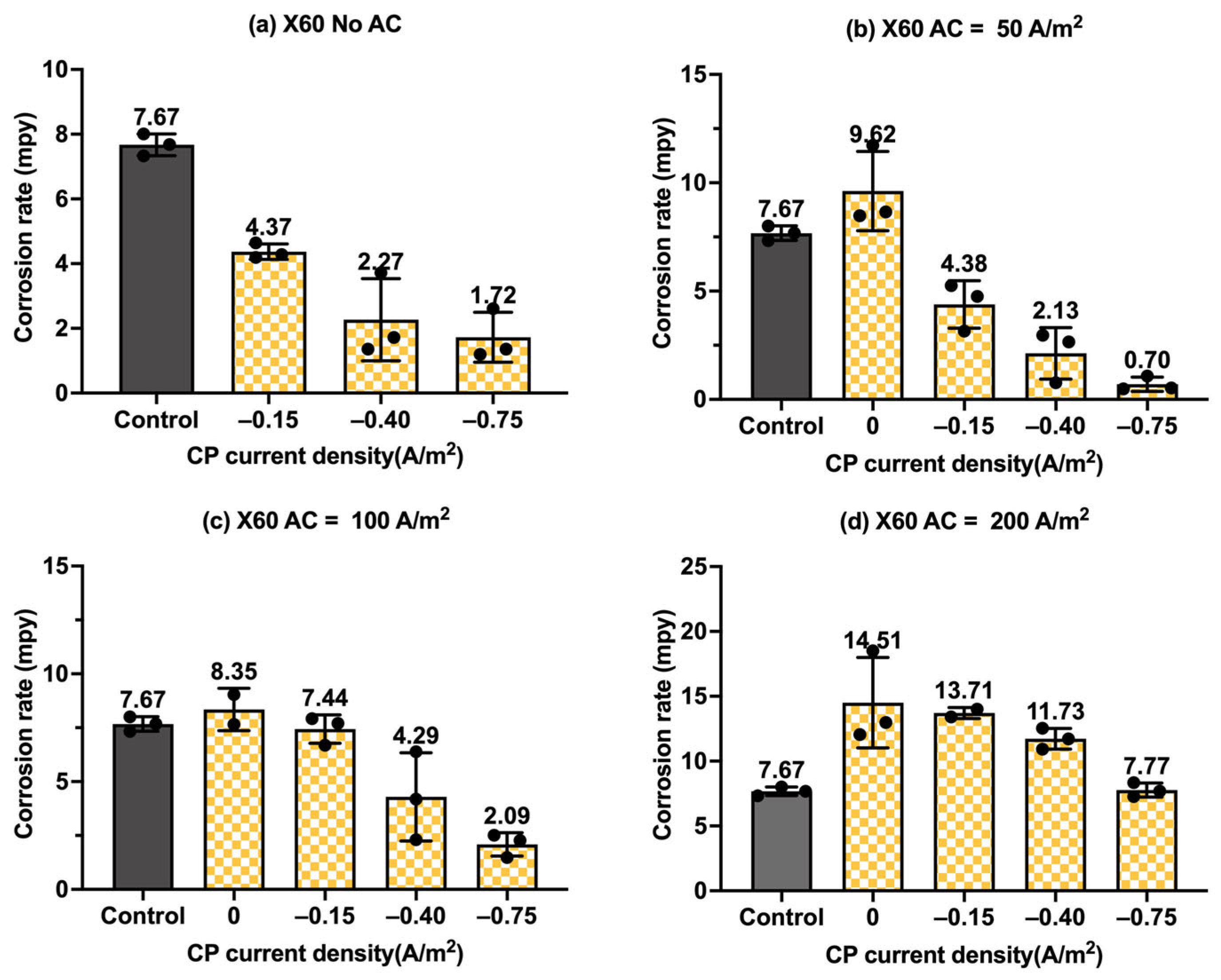

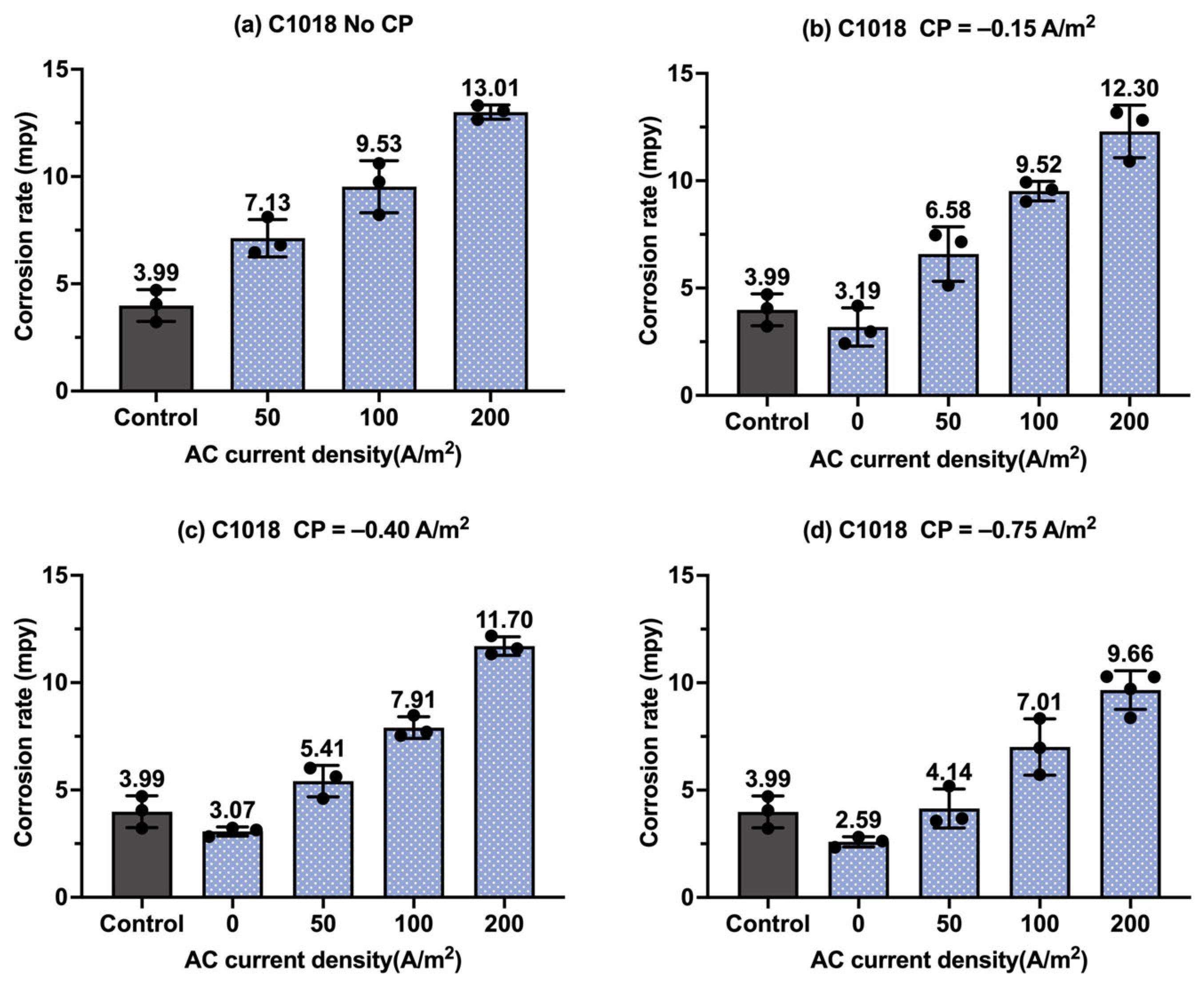

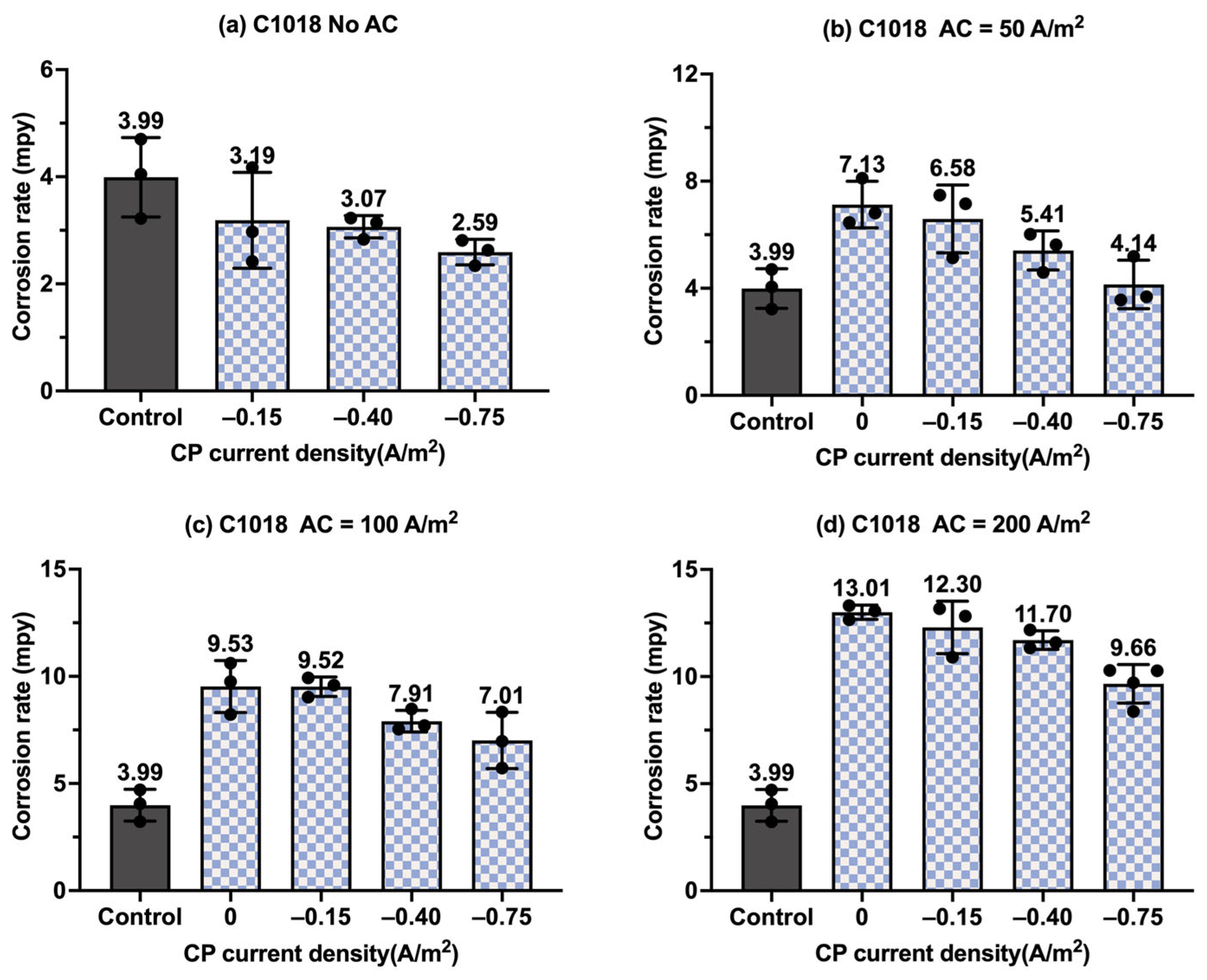

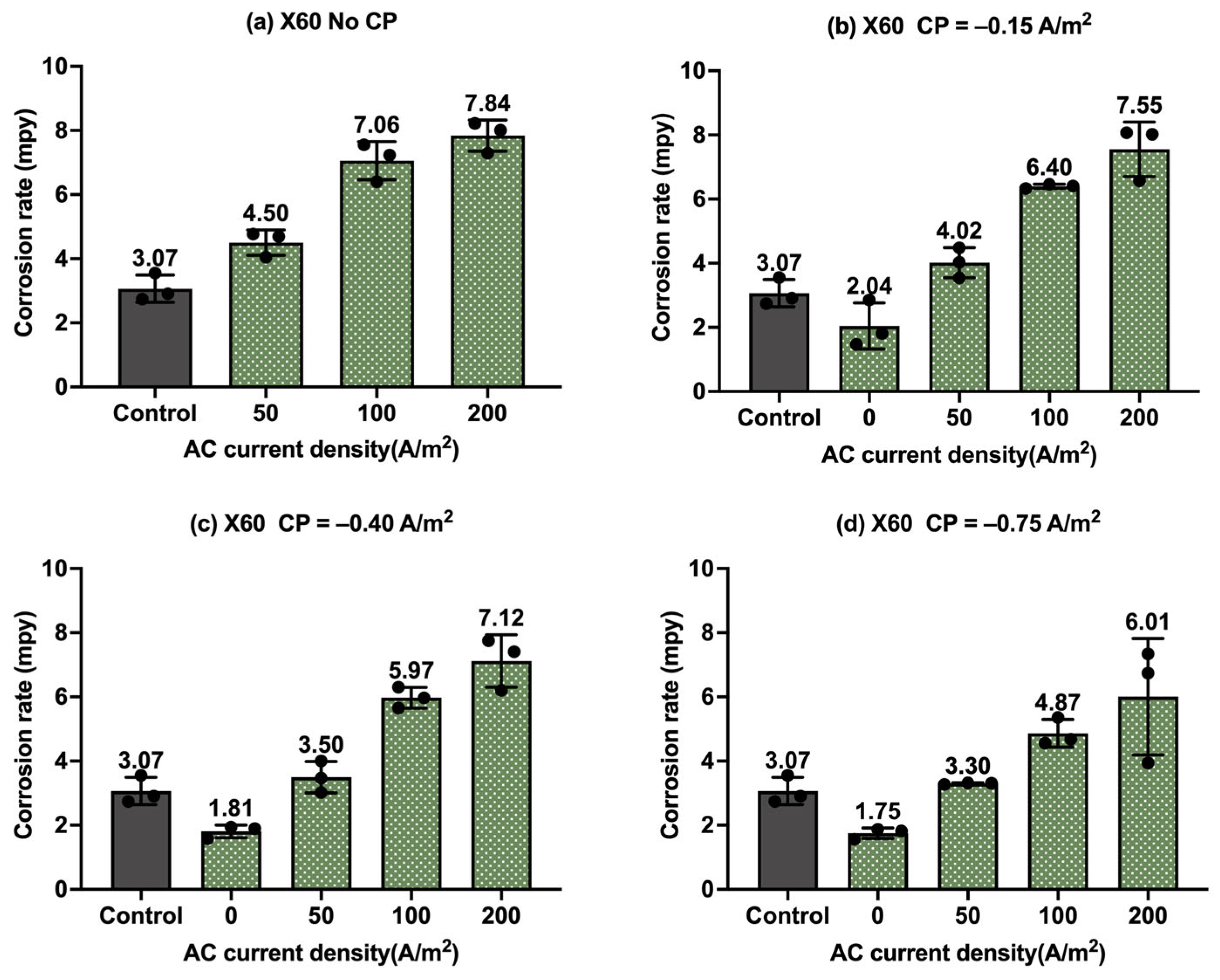

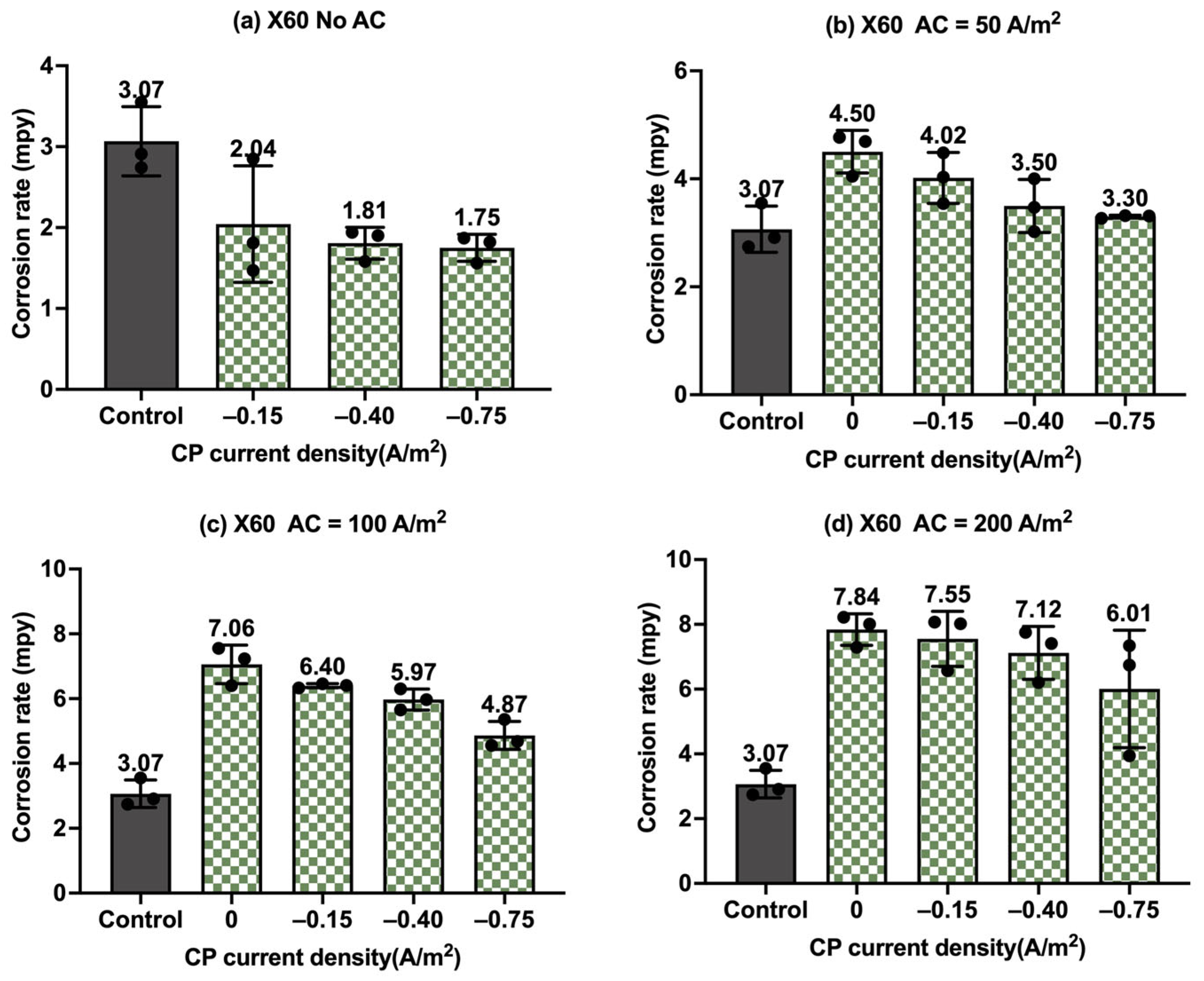

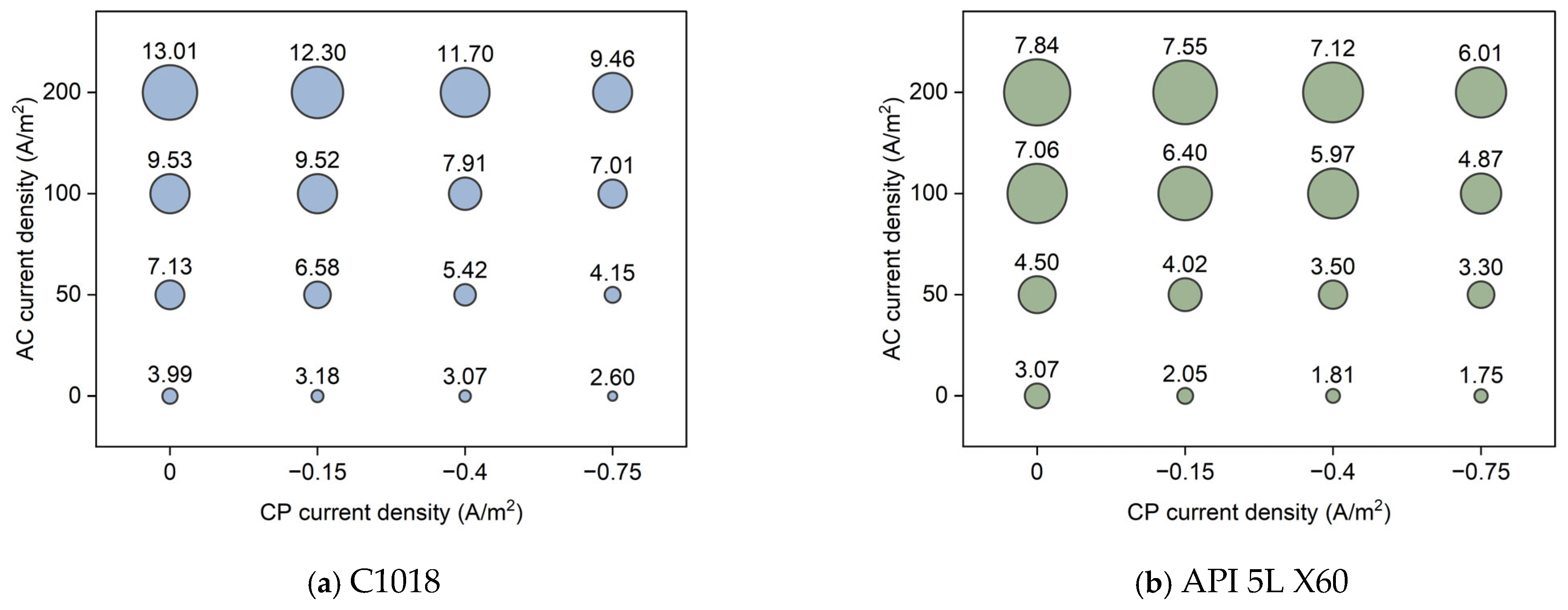

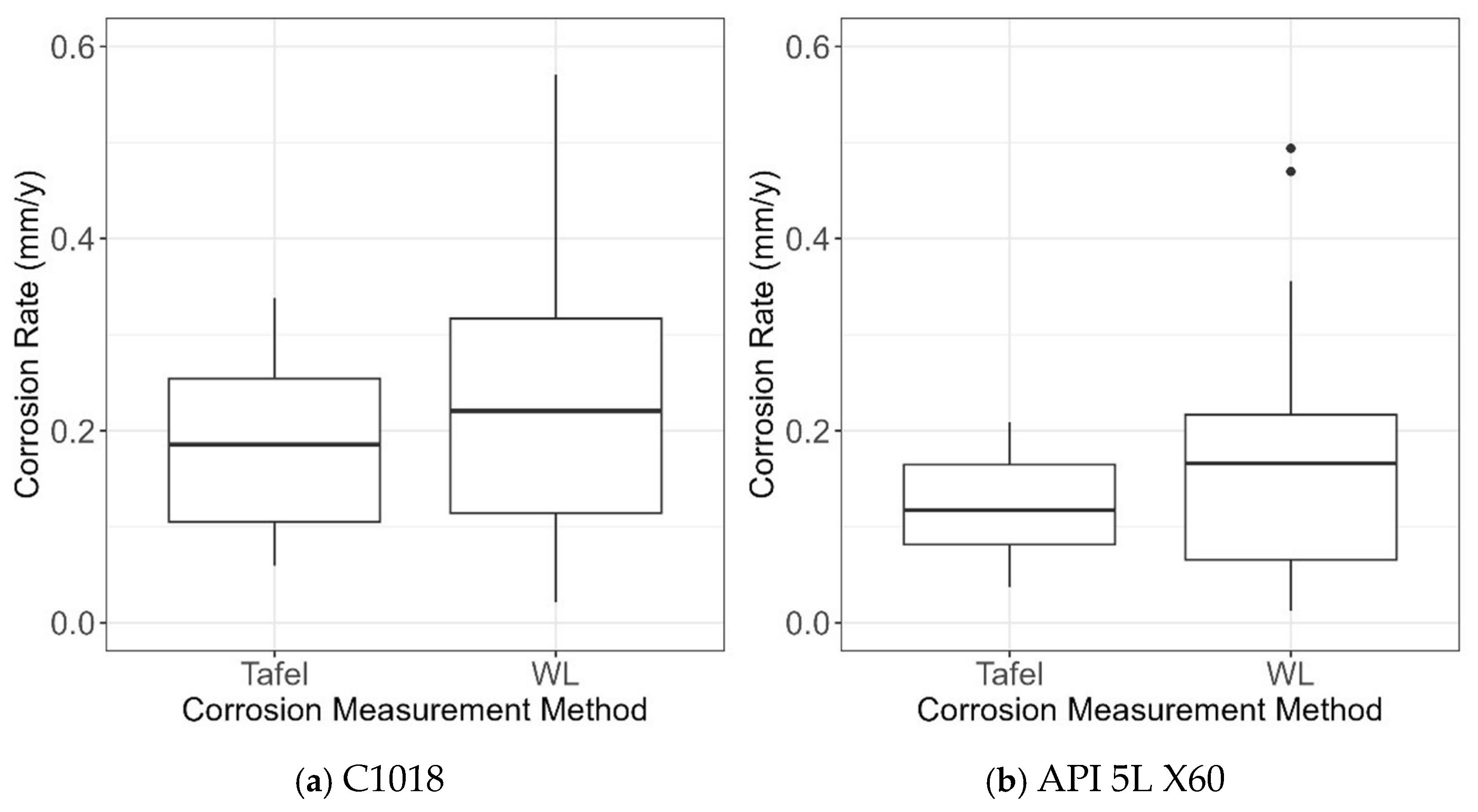

3.3. Corrosion Rate by Weight Loss Measurement

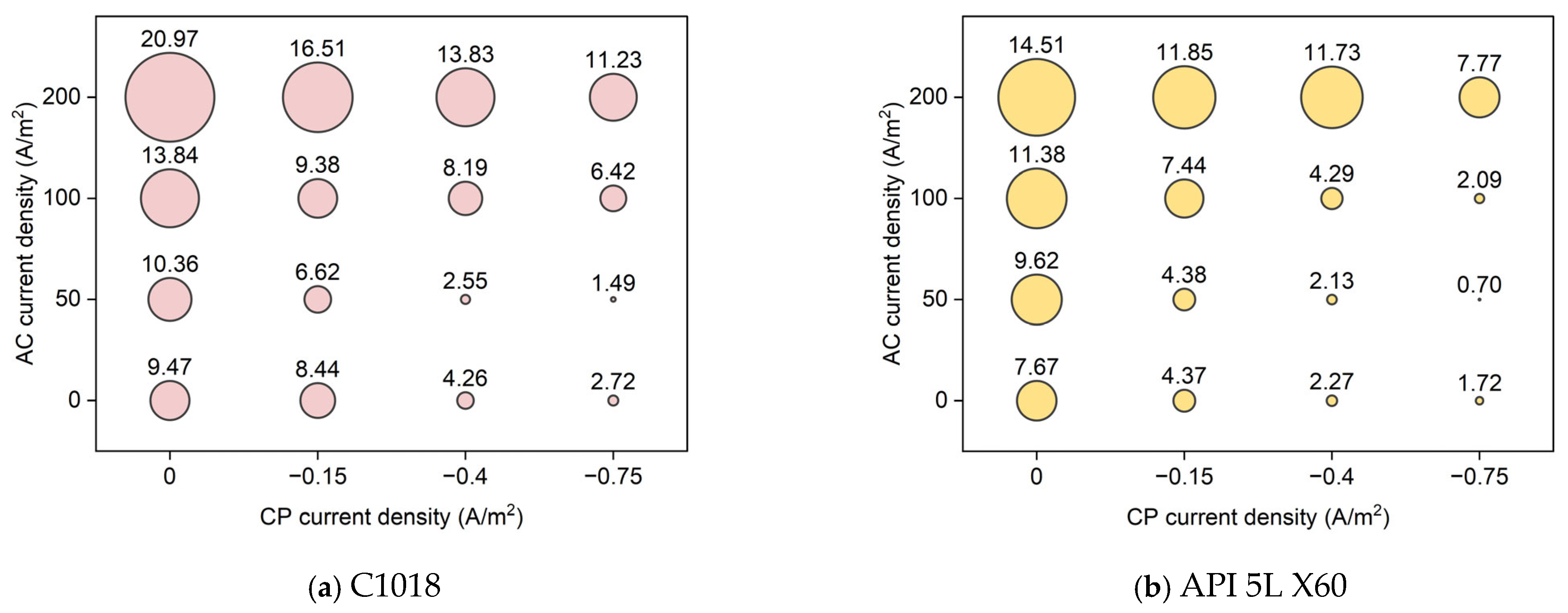

3.4. Corrosion Rate by Tafel Measurement

4. Probabilistic Prediction Model of AC-Induced Corrosion

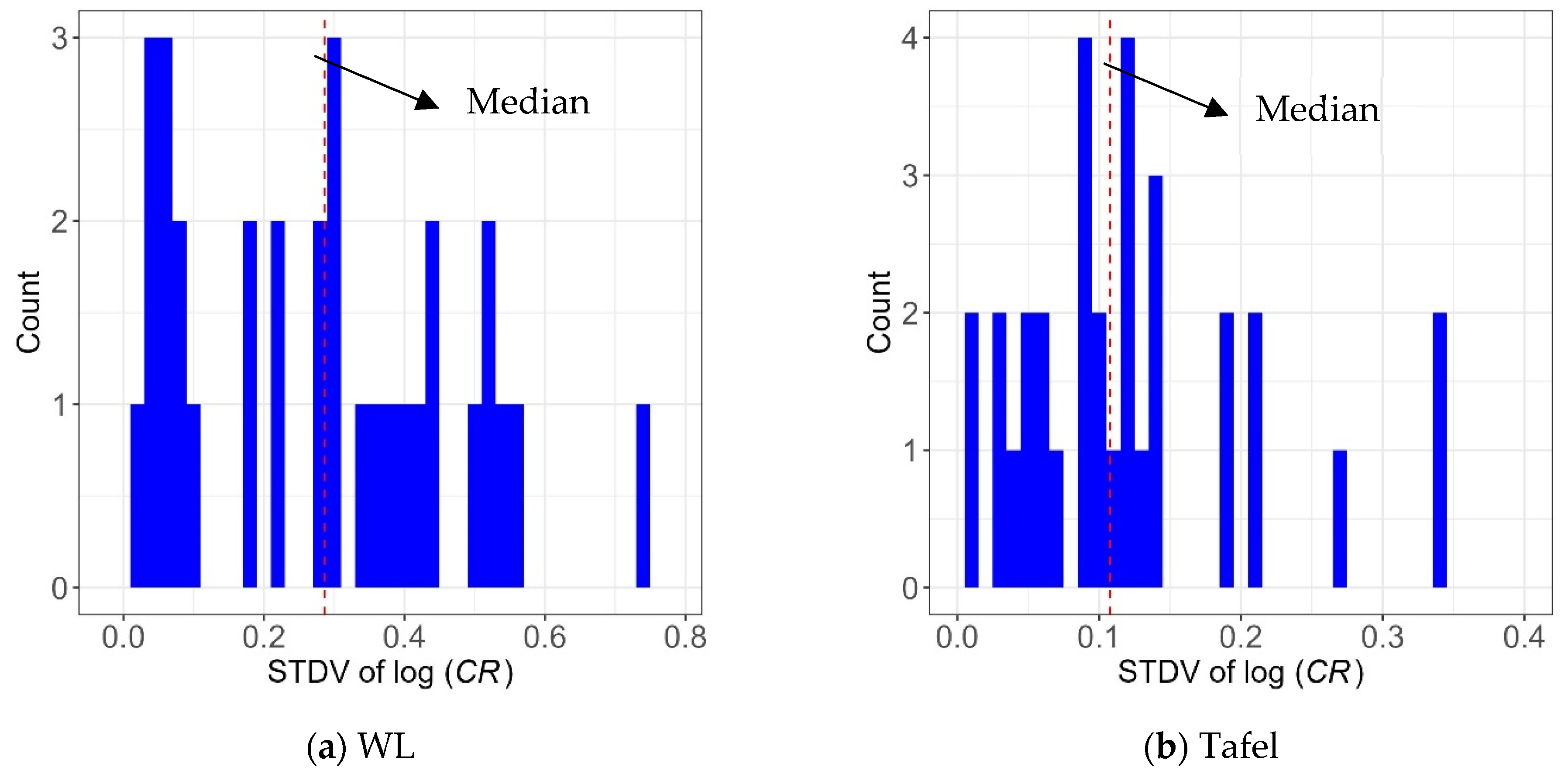

4.1. Data Review

4.2. Model Development

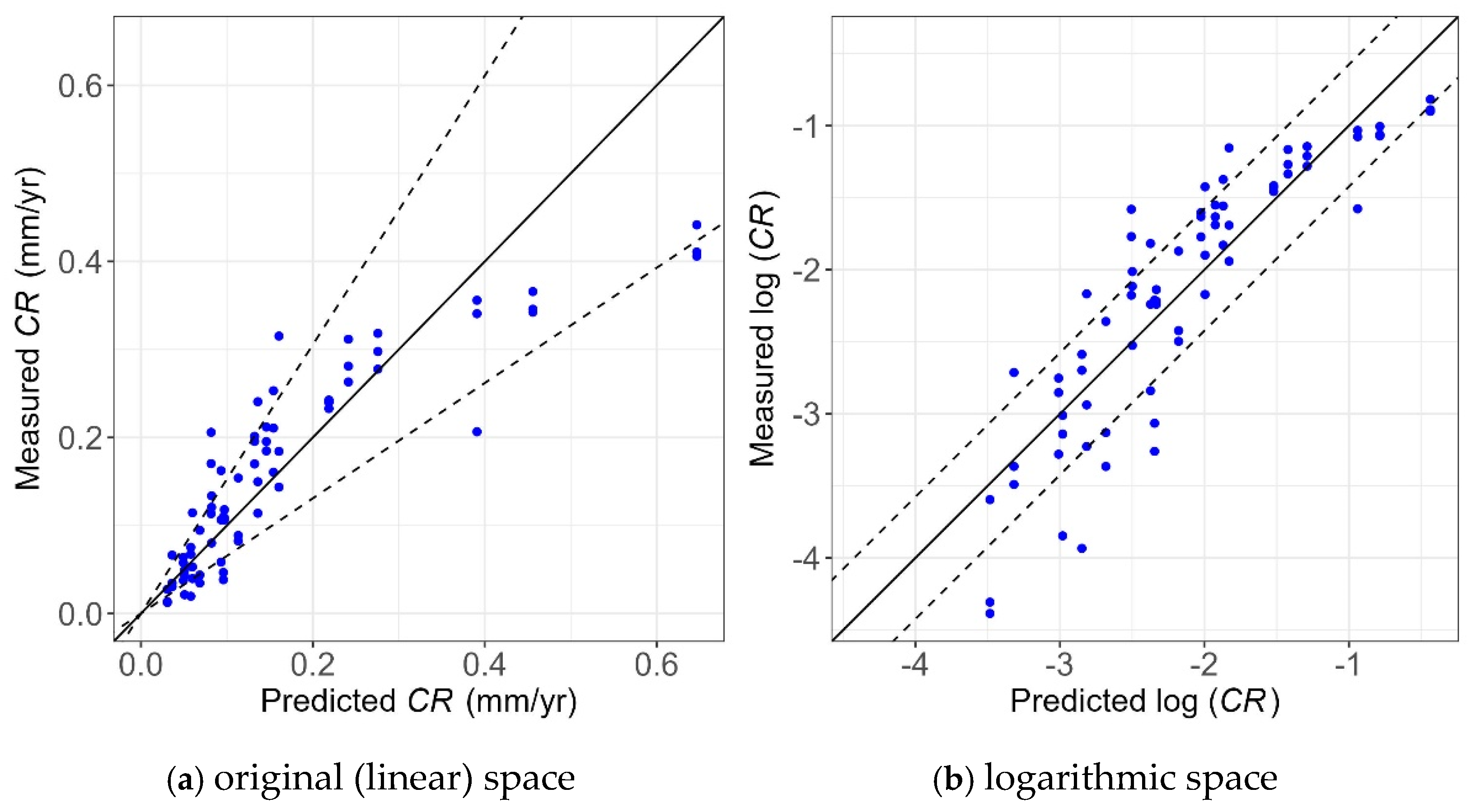

4.3. Model Performance

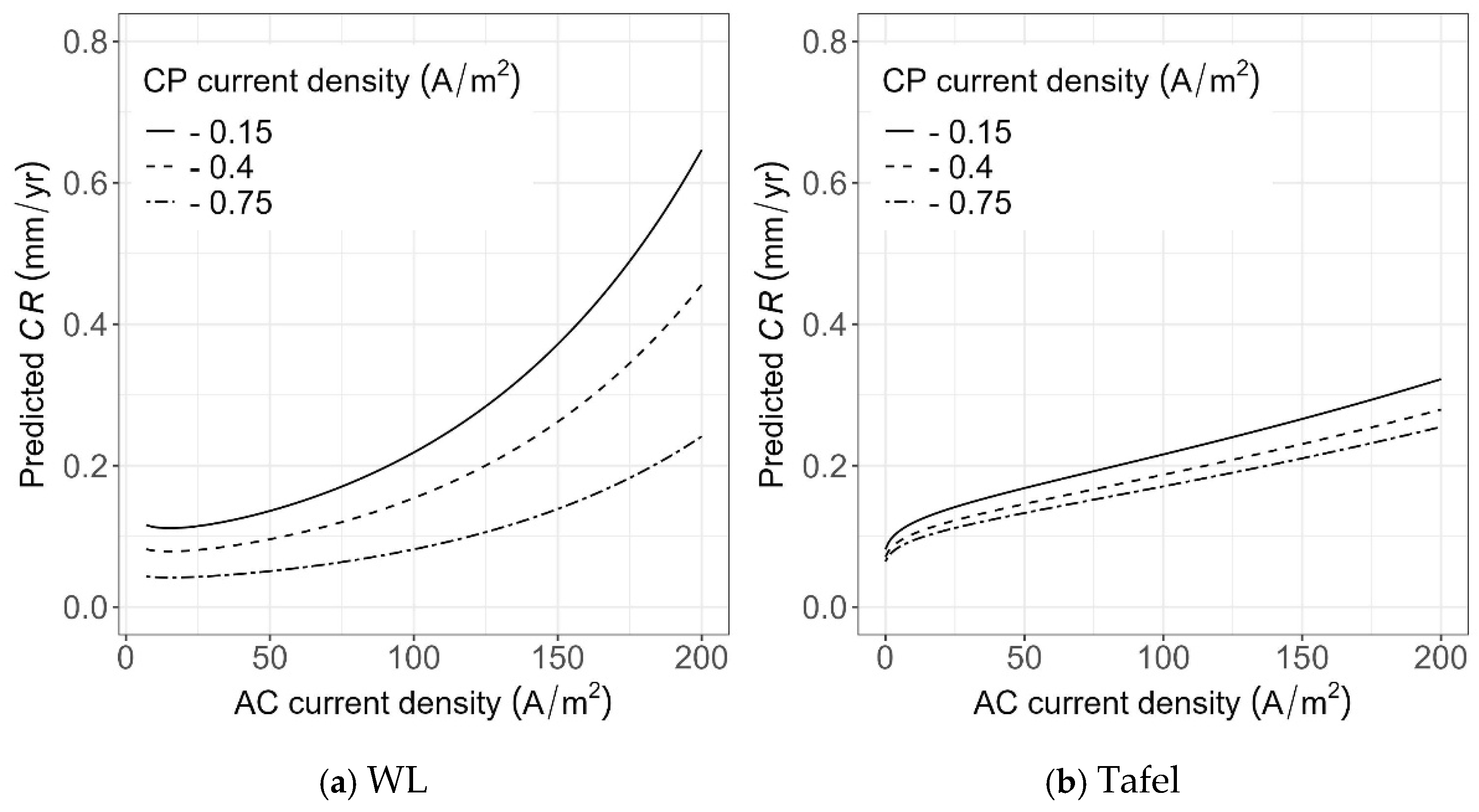

4.4. Sensitivity Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, Y.F. AC Corrosion of Piplelines; Ampp: Houston, TX, USA, 2021; ISBN 978-1-57590-400-9. [Google Scholar]

- Xu, L.Y.; Su, X.; Caheng, Y.F. Effect of Alternating Current on Cathodic Protection on Pipelines. Corros. Sci. 2013, 66, 263–268. [Google Scholar] [CrossRef]

- Kuang, D.; Cheng, Y.F. AC Corrosion at Coating Defect on Pipelines. Corrosion 2015, 71, 267–276. [Google Scholar] [CrossRef] [PubMed]

- Palumbo, G.; Górny, M.; Banaś, J. Corrosion Inhibition of Pipeline Carbon Steel (N80) in CO2-Saturated Chloride (0.5 M of KCl) Solution Using Gum Arabic as a Possible Environmentally Friendly Corrosion Inhibitor for Shale Gas Industry. J. Mater. Eng. Perform. 2019, 28, 6458–6470. [Google Scholar] [CrossRef]

- Davoodi, F.; Akbari-Kharaji, E.; Danaee, I.; Zaarei, D.; Shishesaz, M. Corrosion Behavior of Epoxy/Polysulfide Coatings Incorporated with Nano-CeO2 Particles on Low Carbon Steel Substrate. Corrosion 2022, 78, 785–798. [Google Scholar] [CrossRef]

- Yunovich, M.; Thompson, N.G. AC Corrosion: Corrosion Rate and Mitigation Requirements; OnePetro: Richardson, TX, USA, 2004. [Google Scholar]

- Gummow, R.A.; Wakelin, R.G.; Segall, S.M. AC Corrosion: A New Threat to Pipeline Integrity? In Proceedings of the 1996 1st International Pipeline Conference, Calgary, AB, Canada, 9–13 June 1996; Volume 1: Regulations, Codes, and Standards; Current Issues; Materials; Corrosion and Integrity; American Society of Mechanical Engineers. pp. 443–453. [Google Scholar]

- Wang, H.; Du, C.; Liu, Z.; Wang, L.; Ding, D. Effect of Alternating Current on the Cathodic Protection and Interface Structure of X80 Steel. Materials 2017, 10, 851. [Google Scholar] [CrossRef]

- Xu, L.Y.; Su, X.; Yin, Z.X.; Tang, Y.H.; Cheng, Y.F. Development of a Real-Time AC/DC Data Acquisition Technique for Studies of AC Corrosion of Pipelines. Corros. Sci. 2012, 61, 215–223. [Google Scholar] [CrossRef]

- Tang, D.Z.; Du, Y.X.; Lu, M.X.; Jiang, Z.T.; Dong, L.; Wang, J.J. Effect of AC Current on Corrosion Behavior of Cathodically Protected Q235 Steel: AC Corrosion of Cathodically Protected Q235 Steel. Mater. Corros. 2013, 66, 278–285. [Google Scholar] [CrossRef]

- Kuang, D.; Cheng, Y.F. Effects of Alternating Current Interference on Cathodic Protection Potential and Its Effectiveness for Corrosion Protection of Pipelines. Corros. Eng. Sci. Technol. 2016, 52, 22–28. [Google Scholar] [CrossRef]

- Ormellese, M.; Goidanich, S.; Lazzari, L. Effect of AC Interference on Cathodic Protection Monitoring. Corros. Eng. Sci. Technol. 2011, 46, 618–623. [Google Scholar] [CrossRef]

- SP0169-2013; Control of External Corrosion on Underground or Submerged Metallic Piping Systems. NACE: Houston, TX, USA, 2013.

- Edward, M. Introduction to Corrosion Science; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 978-0-470-27725-6. [Google Scholar]

- Du, Y.; Tang, D.; Lu, M.; Chen, S. Researches on the Effects of AC Interference on CP Parameters and AC Corrosion Risk Assessment for Cathodic Protected Carbon Steel. In Proceedings of the CORROSION 2017, New Orleans, LA, USA, 26–30 March 2017; OnePetro: Richardson, TX, USA, 2017. [Google Scholar]

- Ormellese, M.; Lazzari, L.; Brenna, A.; Trombetta, A. Proposal of CP Criterion in the Presence of AC-Interference. In Proceedings of the NACE CORROSION, San Antonio, TX, USA, 14–18 March 2010; p. 18. [Google Scholar]

- Brenna, A.; Lazzari, L.; Pedeferri, M.; Ormellese, M. Cathodic Protection Condition in the Presence of AC Interference. Corrosione 2014, 6, 29–34. [Google Scholar]

- Tang, D.; Du, Y.; Li, X.; Liang, Y.; Lu, M. Effect of Alternating Current on the Performance of Magnesium Sacrificial Anode. Mater. Des. 2016, 93, 133–145. [Google Scholar] [CrossRef]

- Ormellese, M.; Lazzari, L.; Brenna, A. AC Corrosion of Cathodically Protected Buried Pipelines: Critical Interference Values and Protection Criteria. In Proceedings of the NACE—International Corrosion Conference Series, Dallas, TX, USA, 15–19 March 2015; Volume 2015. [Google Scholar]

- He, X.; Jiang, G.; Qiu, Y.; Zhang, G.; Jin, X.; Xiang, Z.; Zhang, Z.; Tang, H. Study of Criterion for Assuring the Effectiveness of Cathodic Protection of Buried Steel Pipelines Being Interfered with Alternative Current. Mater. Corros. 2011, 63, 534–543. [Google Scholar] [CrossRef]

- Olesen, A.J.; Dideriksen, K.; Nielsen, L.V.; Møller, P. Corrosion Rate Measurement and Oxide Investigation of AC Corrosion at Varying AC/DC Current Densities. Corrosion 2019, 75, 1026–1033. [Google Scholar] [CrossRef]

- Guo, Y.-B.; Liu, C.; Wang, D.-G.; Liu, S.-H. Effects of Alternating Current Interference on Corrosion of X60 Pipeline Steel. Pet. Sci. 2015, 12, 316–324. [Google Scholar] [CrossRef]

- Moran, A.; Lillard, R.S. AC Corrosion Evaluation of Cathodically Protected Pipeline Steel. Corrosion 2019, 75, 144–146. [Google Scholar] [CrossRef]

- Goidanich, S.; Lazzari, L.; Ormellese, M. AC Corrosion. Part 2: Parameters Influencing Corrosion Rate. Corros. Sci. 2010, 52, 916–922. [Google Scholar] [CrossRef]

- Fu, A.Q.; Cheng, Y.F. Effect of Alternating Current on Corrosion and Effectiveness of Cathodic Protection of Pipelines. Can. Metall. Q. 2012, 51, 81–90. [Google Scholar] [CrossRef]

- Xiao, Y.; Du, Y.; Tang, D.; Ou, L.; Sun, H.; Lu, Y. Study on the Influence of Environmental Factors on AC Corrosion Behavior and Its Mechanism. Mater. Corros. 2018, 69, 601–613. [Google Scholar] [CrossRef]

- Guo, Y.; Meng, T.; Wang, D.; Tan, H.; He, R. Experimental Research on the Corrosion of X Series Pipeline Steels under Alternating Current Interference. Eng. Fail. Anal. 2017, 78, 87–98. [Google Scholar] [CrossRef]

- Qin, Q.; Wei, B.; Bai, Y.; Fu, Q.; Xu, J.; Sun, C.; Wang, C.; Wang, Z. Effect of Alternating Current Frequency on Corrosion Behavior of X80 Pipeline Steel in Coastal Saline Soil. Eng. Fail. Anal. 2021, 120, 105065. [Google Scholar] [CrossRef]

- Thakur, A.K.; Arya, A.K.; Sharma, P. Analysis of Cathodically Protected Steel Pipeline Corrosion under the Influence of Alternating Current. Mater. Today Proc. 2022, 50, 789–796. [Google Scholar] [CrossRef]

- Zhu, M. Corrosion Behavior of X65 and X80 Pipeline Steels under AC Interference Condition in High pH Solution. Int. J. Electrochem. Sci. 2018, 13, 10669–10678. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, L.; Li, J.; Zhu, Z.; Bai, S.; Cui, Z. Combined Effect of Alternating Current Interference and Cathodic Protection on Pitting Corrosion and Stress Corrosion Cracking Behavior of X70 Pipeline Steel in Near-Neutral pH Environment. Materials 2018, 11, 465. [Google Scholar] [CrossRef] [PubMed]

- Wang, X. Study on Corrosion and Delamination Behavior of X70 Steel under the Coupling Action of AC-DC Interference and Stress. Int. J. Electrochem. Sci. 2019, 1968–1985. [Google Scholar] [CrossRef]

- Yang, J.; Le, Z.; Zhao, B.; Ma, J.; Yuan, Y. Influence of Alternating Current on Corrosion Behavior of X100 Steel in Golmud Soil Simulated Solution with Different pH. Int. J. Electrochem. Sci. 2020, 15, 10423–10431. [Google Scholar] [CrossRef]

- Xu, L.; Shi, S.; Huang, Y.; Yan, F.; Yang, X.; Bao, Y. Corrosion Monitoring and Assessment of Steel under Impact Loads Using Discrete and Distributed Fiber Optic Sensors. Opt. Laser Technol. 2024, 174, 110553. [Google Scholar] [CrossRef]

- Xu, L.; Shi, S.; Yan, F.; Huang, Y.; Bao, Y. Experimental Study on Combined Effect of Mechanical Loads and Corrosion Using Tube-Packaged Long-Gauge Fiber Bragg Grating Sensors. Struct. Health Monit. 2023, 22, 3985–4004. [Google Scholar] [CrossRef]

- Ahmad, Z. Principles of Corrosion Engineering and Corrosion Control; Elsevier: Amsterdam, The Netherlands, 2006; ISBN 978-0-08-048033-6. [Google Scholar]

- Farahani, E.M.; Su, Y.; Chen, X.; Wang, H.; Laughorn, T.R.; Onesto, F.; Zhou, Q.; Huang, Q. AC Corrosion of Steel Pipeline under Cathodic Protection: A State-of-the-art Review. Mater. Corros. 2023, 75, 290–314. [Google Scholar] [CrossRef]

- James, G. An Introduction to Statistical Learning: With Applications in R, 1st ed.; Springer: New York, NY, USA, 2013; ISBN 978-1-4614-7137-0. [Google Scholar]

| Specimens | C (wt.%) | Mn (wt.%) | Si (wt.%) | P (wt.%) | S (wt.%) | Fe (wt.%) | Yield Strength (psi) |

|---|---|---|---|---|---|---|---|

| C1018 | 0.16 | 0.64 | 0.20 | 0.04 | 0.5 | Bal. | 54,000 |

| API 5L X60 | 0.12 | 1.23 | 0.23 | 0.008 | 0.001 | Bal. | 60,000 |

| Type of Variable | Considered Variables |

|---|---|

| Continuous | AC current density (A/m2), AC |

| DC current density (A/m2), DC | |

| log((AC + 1)/|DC|) | |

| Categorical | Metal type, m (=1 for C1018, =0 for X60) |

| Interactional | m × DC, |

| m × AC | |

| m × log((AC + 1)/|DC|) |

| Model Parameter | Variable | Estimate | Standard Error | p-Value |

|---|---|---|---|---|

| θ0 | Intercept | −1.63 × 100 | 2.09 × 10−1 | 5.13 × 10−11 |

| θ1 | DC | 2.17 × 100 | 2.41 × 10−1 | 3.38 × 10−13 |

| θ2 | AC | 1.22 × 10−2 | 1.25 × 10−3 | 1.90 × 10−14 |

| θ3 | log((AC + 1)/|DC|) | −1.97 × 10−1 | 4.50 × 10−2 | 4.09 × 10−5 |

| θ4 | m | 5.03 × 10−1 | 1.03 × 10−1 | 6.91 × 10−6 |

| Model Parameter | Variable | Estimate | Standard Error | p-Value |

|---|---|---|---|---|

| θ0 | Intercept | −3.21 × 100 | 5.05 × 10−2 | < 2 × 10−16 |

| θ1 | AC | 3.00 × 10−3 | 4.27 × 10−4 | 1.20 × 10−9 |

| θ2 | log((AC + 1)/|DC|) | 1.46 × 10−1 | 1.46 × 10−2 | 5.38 × 10−15 |

| θ3 | m | 4.24 × 10−1 | 3.84 × 10−2 | < 2 × 10−16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Majdabadi Farahani, E.; Huang, Q.; Zhou, Q. AC-Induced Corrosion of Cathodically Protected Pipelines: Experimental Study and Probabilistic Modeling. Corros. Mater. Degrad. 2025, 6, 26. https://doi.org/10.3390/cmd6020026

Su Y, Majdabadi Farahani E, Huang Q, Zhou Q. AC-Induced Corrosion of Cathodically Protected Pipelines: Experimental Study and Probabilistic Modeling. Corrosion and Materials Degradation. 2025; 6(2):26. https://doi.org/10.3390/cmd6020026

Chicago/Turabian StyleSu, Yuhan, Emadoddin Majdabadi Farahani, Qindan Huang, and Qixin Zhou. 2025. "AC-Induced Corrosion of Cathodically Protected Pipelines: Experimental Study and Probabilistic Modeling" Corrosion and Materials Degradation 6, no. 2: 26. https://doi.org/10.3390/cmd6020026

APA StyleSu, Y., Majdabadi Farahani, E., Huang, Q., & Zhou, Q. (2025). AC-Induced Corrosion of Cathodically Protected Pipelines: Experimental Study and Probabilistic Modeling. Corrosion and Materials Degradation, 6(2), 26. https://doi.org/10.3390/cmd6020026