Chemical Equilibrium Fracture Mechanics—Hydrogen Embrittlement Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Areas of Hydrogen in Solid Solution

2.2. Areas of Hydride Precipitation

3. Results and Discussion

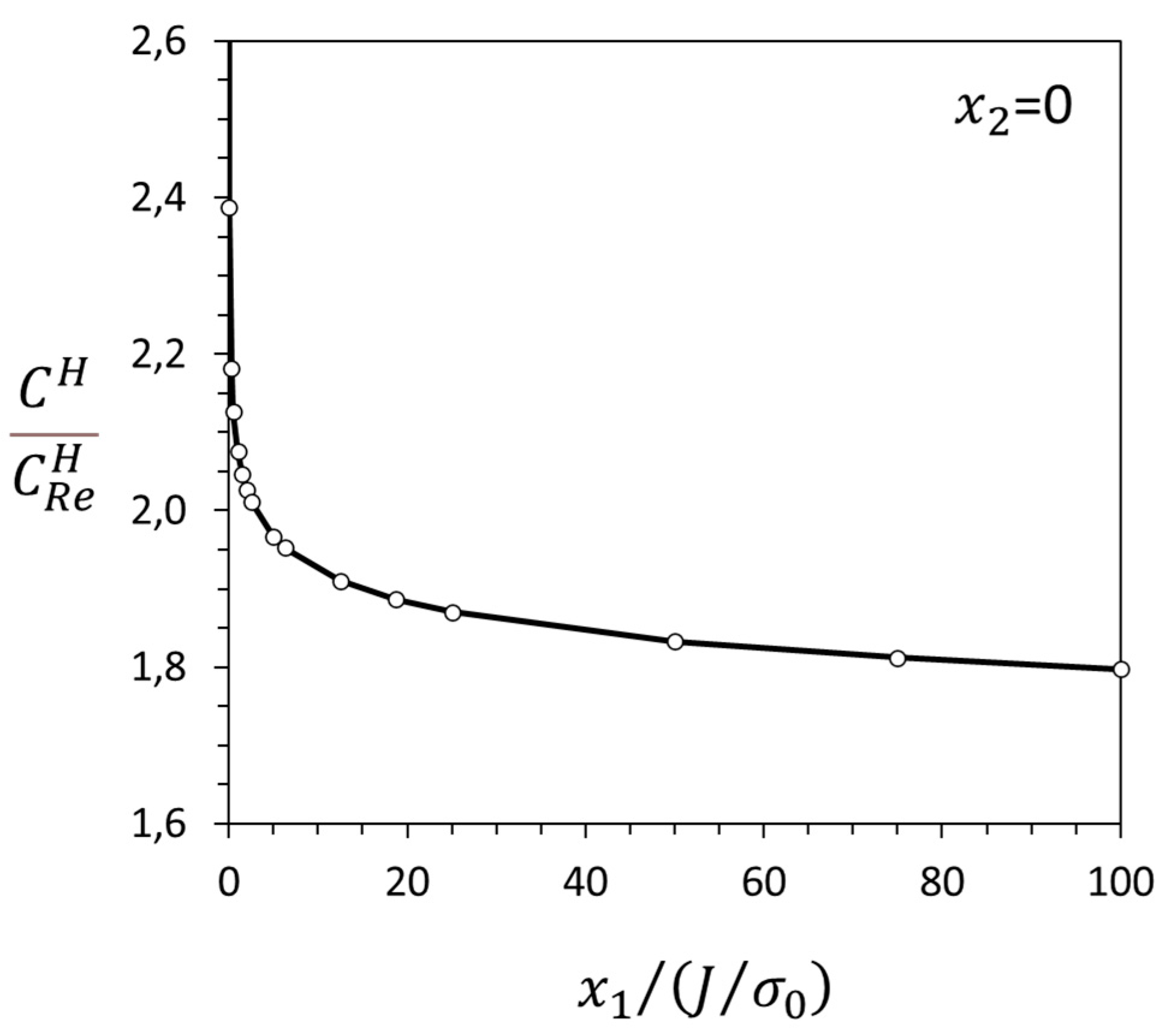

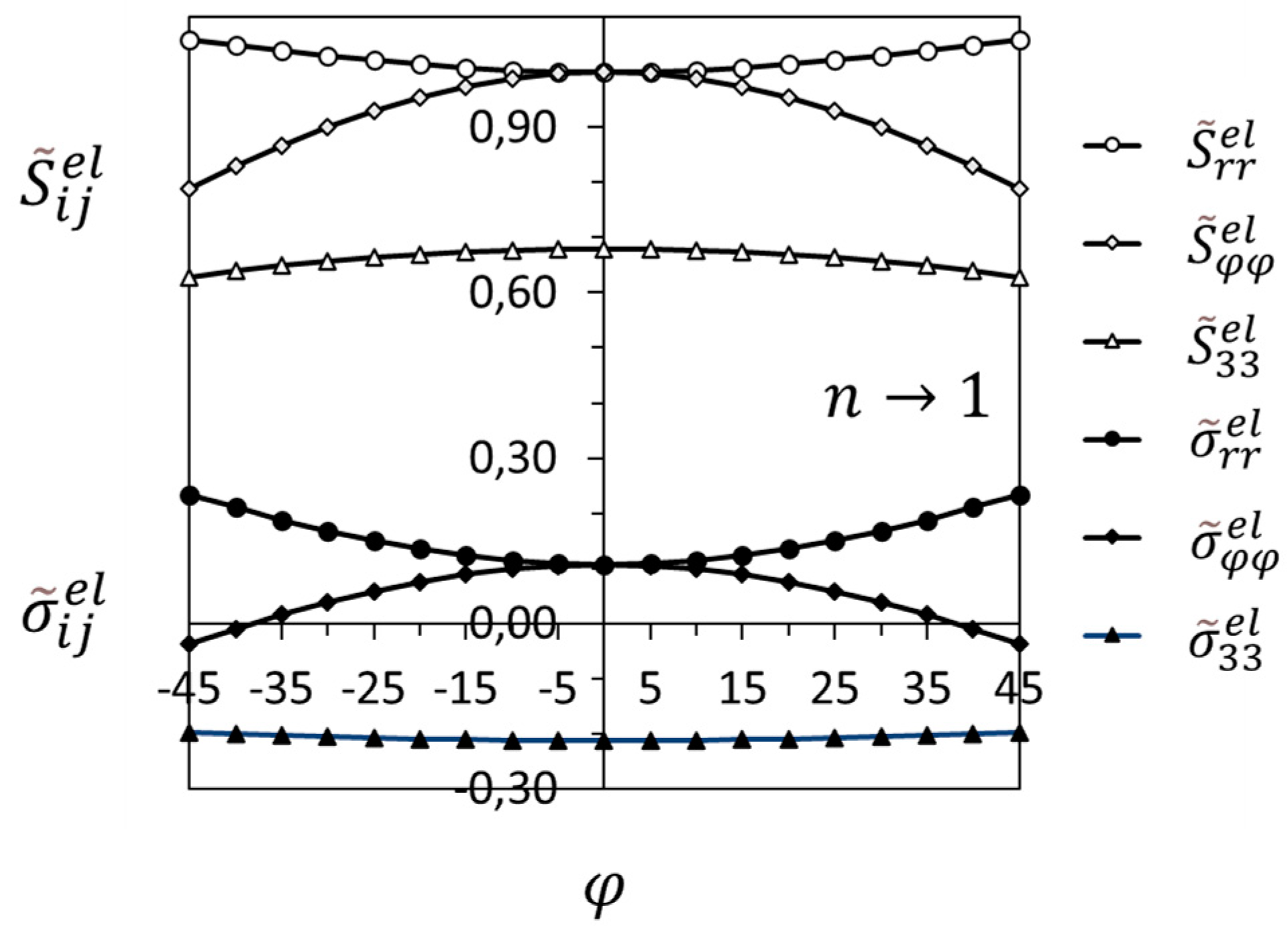

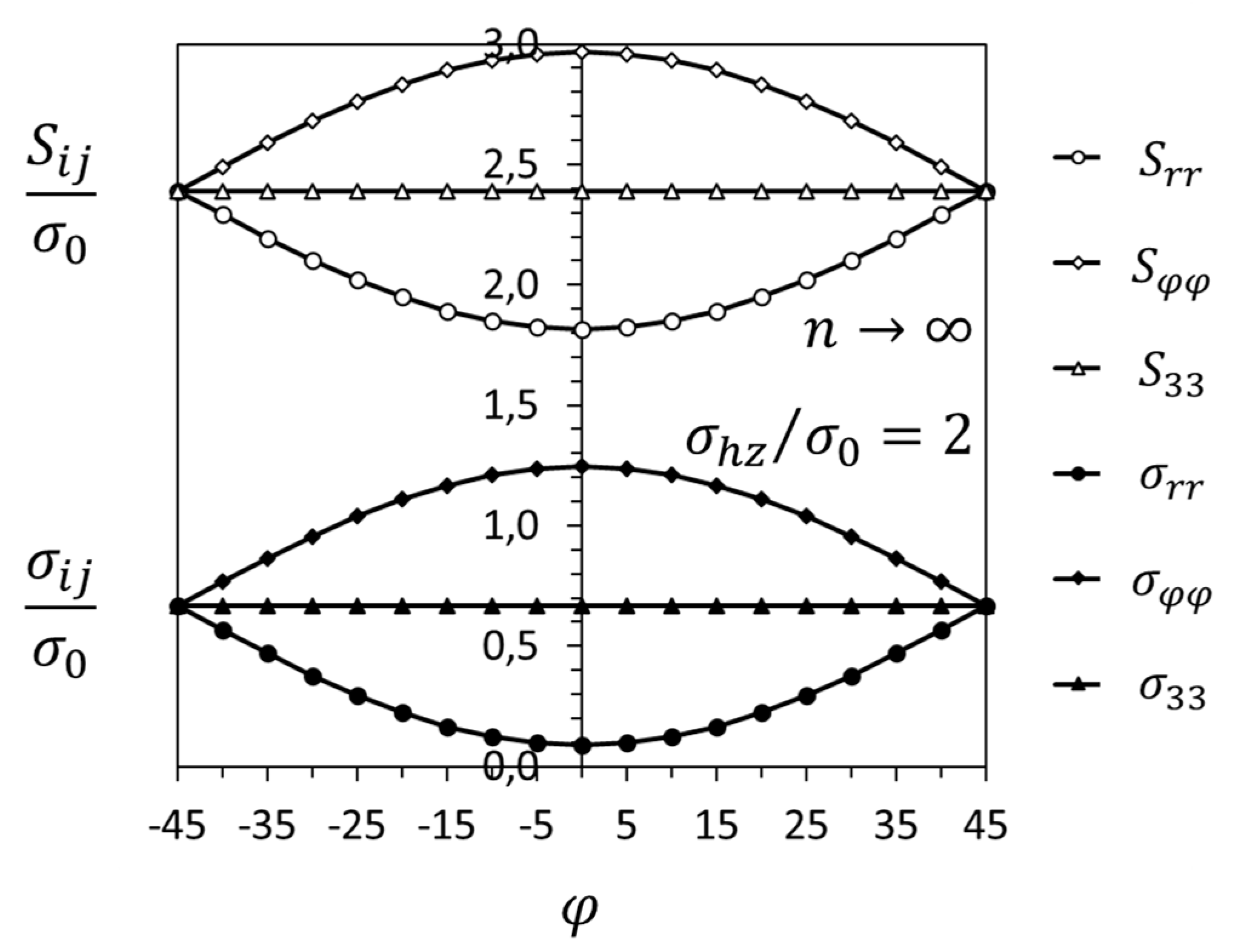

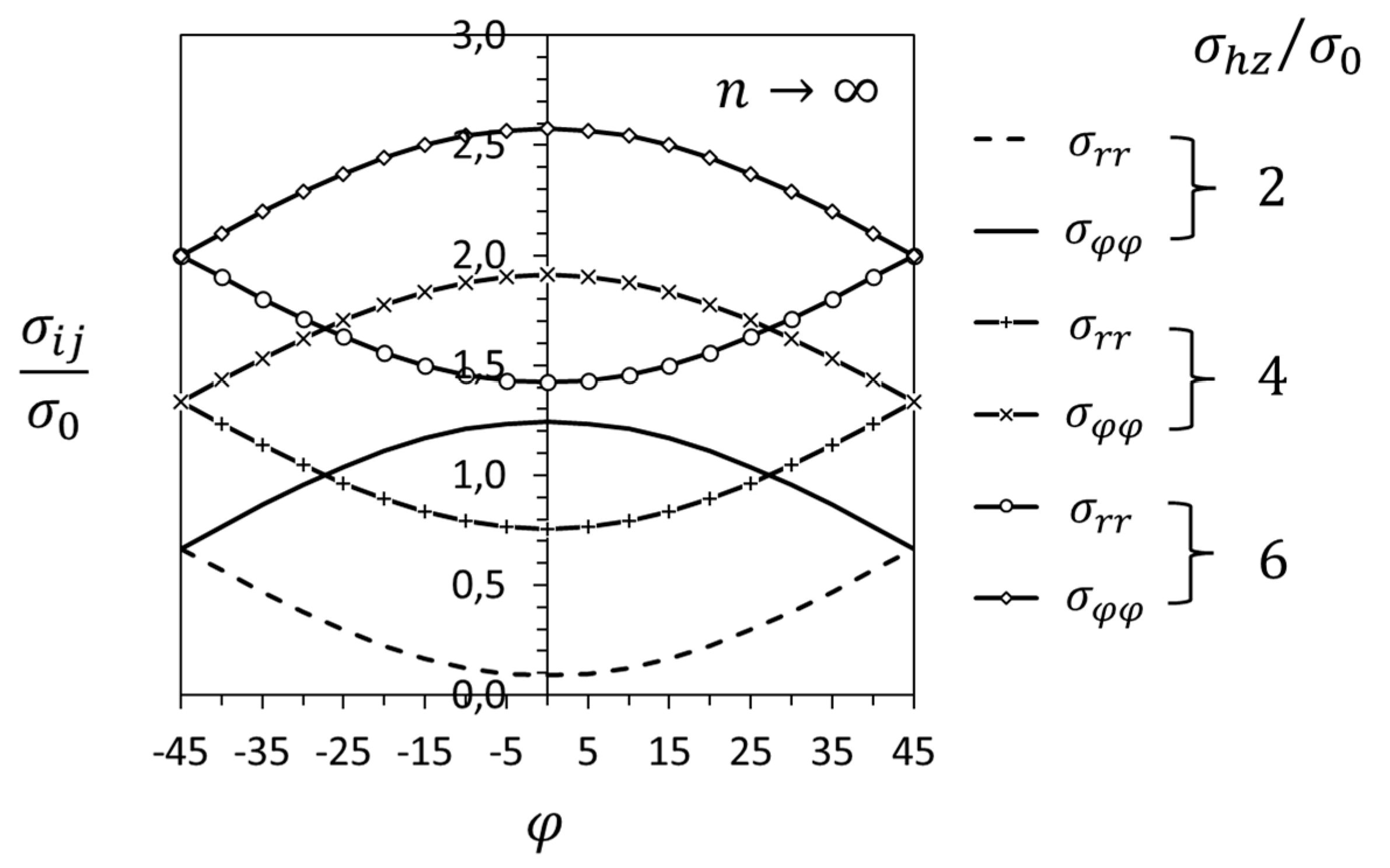

3.1. Crack-Tip Fields for Hydrogen in Solid Solution

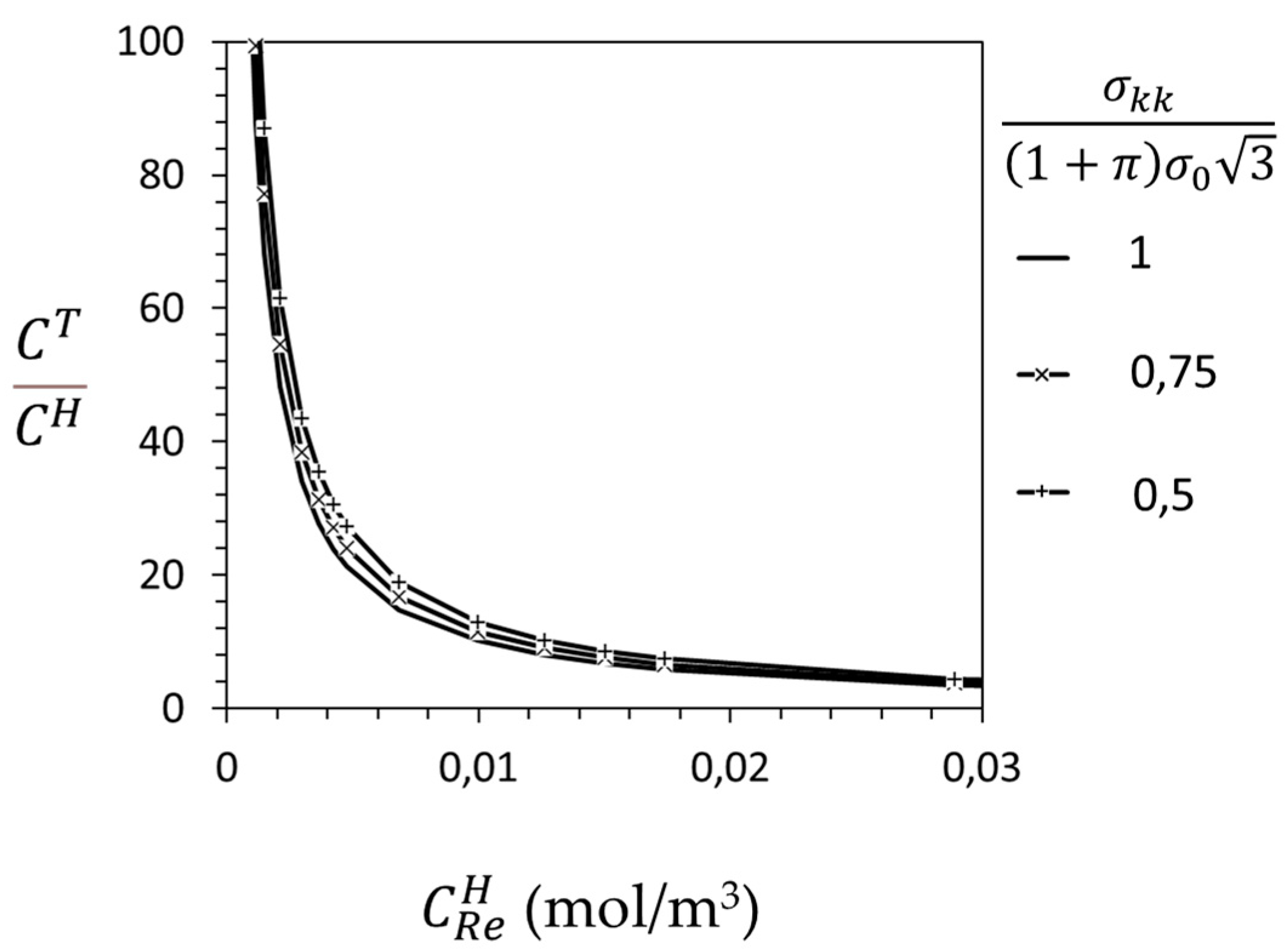

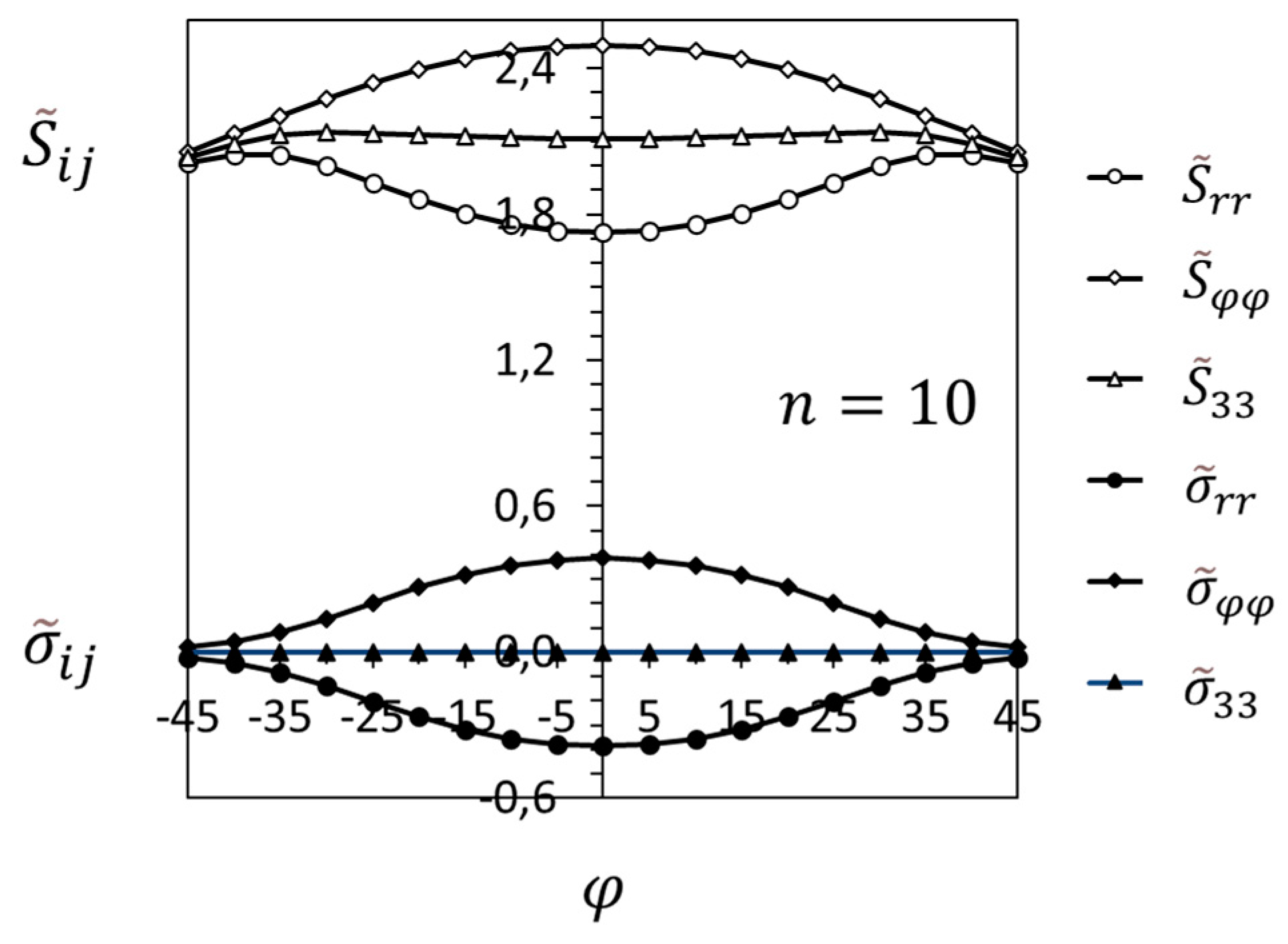

3.2. Crack-Tip Fields in the Hydride Precipitation Zone

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brewer, T. Climate Change: An Interdisciplinary Introduction; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

- Nuttal, W.J.; Powel, J.B.; Anaya-Stucchi, K.L.; Bakenne, A.T.; Wilson, A. Insights into the New Hydrogen Economy; Springer Nature: Cham, Switzerland, 2025. [Google Scholar]

- Barrera, O.; Bombac, D.; Chen, Y.; Daff, T.D.; Galindo-Nava, E.; Gong, P.; Haley, D.; Horton, R.; Katzarov, I.; Kermode, J.R.; et al. Understanding and mitigating hydrogen embrittlement of steels: A review of experimental, modelling and design progress from atomistic to continuum. J. Mater. Sci. 2018, 53, 6251–6290. [Google Scholar] [CrossRef] [PubMed]

- Coleman, C.E. Cracking of hydride-forming metals and alloys. Compr. Struct. Integr. 2003, 6, 103–161. [Google Scholar]

- Takano, S.; Suzuki, T. An electron-optical study of β-hydride and hydrogen embrittlement of vanadium. Acta Metall. 1974, 22, 265–274. [Google Scholar] [CrossRef]

- Birnbaum, H.K.; Grossbeck, M.L.; Amano, M. Hydride precipitation in Nb and some properties of NbH. J. Less-Common Met. 1976, 49, 357–370. [Google Scholar] [CrossRef]

- Northwood, D.O.; Kosasih, U. Hydrides and delayed hydrogen cracking in zirconium and its alloys. Int. Met. Rev. 1983, 28, 92–121. [Google Scholar] [CrossRef]

- Shih, D.S.; Robertson, I.M.; Birnbaum, H.K. Hydrogen embrittlement of α titanium: In situ TEM studies. Acta Metall. 1988, 36, 111–124. [Google Scholar] [CrossRef]

- Lufrano, J.; Sofronis, P.; Birnbaum, H.K. Modeling of hydrogen transport and elastically accommodated hydride formation near a crack tip. J. Mech. Phys. Solids 1996, 44, 179–205. [Google Scholar] [CrossRef]

- Lufrano, J.; Sofronis, P.; Birnbaum, H.K. Elastoplastically accommodated hydride formation and embrittlement. J. Mech. Phys. Solids 1998, 46, 1497–1520. [Google Scholar] [CrossRef]

- Varias, A.G.; Massih, A.R. Simulation of hydrogen embrittlement in zirconium alloys under stress and temperature gradients. J. Nucl. Mater. 2000, 279, 273–285. [Google Scholar] [CrossRef]

- Varias, A.G.; Massih, A.R. Hydride-induced embrittlement and fracture in metals—Effect of stress and temperature distribution. J. Mech. Phys. Solids 2002, 50, 1469–1510. [Google Scholar] [CrossRef]

- Varias, A.G.; Feng, J.L. Simulation of hydride-induced steady-state crack growth in metals—Part I: Growth near hydrogen chemical equilibrium. Comput. Mech. 2004, 34, 339–356. [Google Scholar] [CrossRef]

- Varias, A.G.; Feng, J.L. Simulation of hydride-induced steady-state crack growth in metals—Part II: General near-tip field. Comput. Mech. 2004, 34, 357–376. [Google Scholar] [CrossRef][Green Version]

- Winzer, N.; Atrens, A.; Dietzel, W.; Song, G.; Kainer, K.U. Evaluation of the delayed hydride cracking mechanism for transgranular stress corrosion cracking of magnesium alloys. Mater. Sci. Eng. A 2007, 466, 18–31. [Google Scholar] [CrossRef]

- Courty, O.; Motta, A.T.; Hales, J.D. Modeling and simulation of hydrogen behavior in Zircaloy-4 fuel cladding. J. Nucl. Mater. 2014, 452, 311–320. [Google Scholar] [CrossRef]

- Jernkvist, L.O.; Massih, A.R. Multi-field modelling of hydride forming metals Part I: Model formulation and validation. Comput. Mater. Sci. 2014, 85, 363–382. [Google Scholar] [CrossRef]

- Jernkvist, L.O. Multi-field modelling of hydride forming metals Part II: Application to fracture. Comput. Mater. Sci. 2014, 85, 383–401. [Google Scholar] [CrossRef]

- Abdolvand, H. Progressive modelling and experimentation of hydrogen diffusion and precipitation in anisotropic polycrystals. Int. J. Plast. 2019, 116, 39–61. [Google Scholar] [CrossRef]

- Xia, Z.; Zang, J.; Tong, Q.; Ding, S. Multi-physics modeling of delayed hydride cracking in zirconium alloys. J. Mech. Phys. Solids 2019, 132, 103677. [Google Scholar] [CrossRef]

- Ding, G.; Xia, Z.; Zhang, J.; Ding, S.; Pang, H.; Song, X.; Chen, L. Effects of irradiation on the multi-field coupling delayed hydride cracking behavior of zirconium alloys. J. Nucl. Mater. 2022, 563, 153605. [Google Scholar] [CrossRef]

- Varias, A.G. Elastic crack-tip field in hydride forming metals under hydrogen chemical equilibrium. Int. J. Fract. 2024, 245, 183–194. [Google Scholar] [CrossRef]

- Varias, A.G. Elastic-plastic crack-tip field in hydride forming metals under hydrogen chemical equilibrium. Int. J. Fract. 2024, 246, 47–57. [Google Scholar] [CrossRef]

- Varias, A.G. Hydride induced embrittlement and fracture of non-hardening metals under hydrogen chemical equilibrium. Int. J. Solids Struct. 2024, 305, 113073. [Google Scholar] [CrossRef]

- Voisey, K.T. The Engineer’s Guide to Materials. An Applications-Focused Introduction to Materials Science; Springer Nature: Cham, Switzerland, 2024. [Google Scholar]

- Joshi, S.; Martukanitz, R.P.; Nassar, A.R.; Michaleris, P. Additive manufacturing with Metals. Design, Processes, Materials, Quality Assurance, and Applications; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

- Coleman, C.E. The Metallurgy of Zirconium; International Atomic Energy Agency: Vienna, Austria, 2022; Volume 3. [Google Scholar]

- Teter, D.F.; Robertson, I.M.; Birnbaum, H.K. The effect of hydrogen on the deformation and fracture of β-Titanium. Acta Mater. 2001, 49, 4313–4323. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Fu, Q.; Akiyama, E.; Song, X.; Wang, Y.; Li, Q.; Zou, N. Tensile mechanical properties and fracture behaviors of nickel-based superalloy 718 in the presence of hydrogen. Int. J. Hydrog. Energy 2018, 43, 20118–20132. [Google Scholar] [CrossRef]

- Martin, M.L.; Dadfarnia, M.; Nagao, A.; Wang, S.; Sofronis, P. Enumeration of the hydrogen-enhanced localized plasticity mechanism for hydrogen embrittlement in structural materials. Acta Mater. 2019, 165, 734–750. [Google Scholar] [CrossRef]

- Troiano, A.R. The role of hydrogen and other interstitials in the mechanical behavior of metals. Trans. ASM 1960, 52, 54–80. [Google Scholar] [CrossRef]

- Oriani, R.A.; Josephic, P.H. Equilibrium aspects of hydrogen-induced cracking of steels. Acta Metall. 1974, 22, 1065–1074. [Google Scholar] [CrossRef]

- Oriani, R.A.; Josephic, P.H. Equilibrium and kinetic studies of hydrogen assisted cracking of steel. Acta Metall. 1977, 25, 979–988. [Google Scholar] [CrossRef]

- Birenis, D.; Ogawa, Y.; Matsunaga, H.; Takakuwa, O.; Yamabe, J.; Prytz, Ø.; Thøgersen, A. Hydrogen-assisted crack propagation in α-iron during elasto-plastic fracture toughness tests. Mater. Sci. Eng. A 2019, 756, 396–404. [Google Scholar] [CrossRef]

- Symons, D.M.; Thompson, A.W. The effect of hydrogen on the fracture of alloy X-750. Metall. Mater. Trans. A 1996, 27A, 101–110. [Google Scholar] [CrossRef]

- Beachem, C.D. A new model for hydrogen assisted cracking (hydrogen embrittlement). Metall. Trans. 1972, 3, 437–451. [Google Scholar] [CrossRef]

- Birnbaum, H.K.; Sofronis, P. Hydrogen enhanced localized plasticity—A mechanism for hydrogen related fracture. Mater. Sci. Eng. 1994, A176, 191–202. [Google Scholar] [CrossRef]

- Zhang, Z.; Obasi, G.; Morana, R.; Preuss, M. In-situ observation of hydrogen induced crack initiation in a nickel-based superalloy. Scr. Mater. 2017, 140, 40–44. [Google Scholar] [CrossRef]

- Robertson, I.M.; Birnbaum, H.K. An HVEM study of hydrogen effects on the deformation and fracture of nickel. Acta Metall. 1986, 34, 353–366. [Google Scholar] [CrossRef]

- Lynch, S.P. Environmentally assisted cracking: Overview of evidence for an adsorption-induced localized-slip process. Acta Metall. 1988, 36, 2639–2661. [Google Scholar] [CrossRef]

- Sofronis, P.; McMeeking, R.M. Numerical analysis of hydrogen transport near a blunting crack tip. J. Mech. Phys. Solids 1989, 37, 317–350. [Google Scholar] [CrossRef]

- Lufrano, J.; Sofronis, P.; Symons, D. Hydrogen transport and large strain elastoplasticity near a notch in alloy X-750. Eng. Fract. Mech. 1998, 59, 827–845. [Google Scholar] [CrossRef]

- Krom, A.H.M.; Koers, R.W.J.; Bakker, A. Hydrogen transport near a blunting crack tip. J. Mech. Phys. Solids 1999, 47, 971–992. [Google Scholar] [CrossRef]

- Varias, A.G.; Warren, R. Distribution of Hydrogen in Interstitial Lattice Sites and Saturable Traps, Ahead of a Steadily Growing Crack—Mathematical Model and Numerical Algorithm; Malmö University: Malmö, Sweden, 2001; PA-06-12-01. [Google Scholar] [CrossRef]

- Kanayama, H.; Ndong-Mefane, S.; Ogino, M.; Miresmaeili, R. Reconsideration of the Hydrogen Diffusion Model Using the McNabb-Foster Formulation; Memoirs of the Faculty of Engineering, Kyushu University: Fukuoka, Japan, 2009; Volume 69, pp. 149–161. [Google Scholar]

- Di Leo, C.V.; Anand, L. Hydrogen in metals: A coupled theory for species diffusion and large elastic–plastic deformations. Int. J. Plast. 2013, 43, 42–69. [Google Scholar] [CrossRef]

- Dadfarnia, M.; Martin, M.L.; Nagao, A.; Sofronis, P.; Robertson, I.M. Modeling hydrogen transport by dislocations. J. Mech. Phys. Solids 2015, 78, 511–525. [Google Scholar] [CrossRef]

- Zhang, Z.; Peeters, J.; Popovich, V.; Ayas, C. Combined effects of stress and temperature on hydrogen diffusion in non-hydride forming alloys applied in gas turbines. Int. J. Hydrog. Energy 2022, 47, 30687–30706. [Google Scholar] [CrossRef]

- Varias, A.G. Hydrogen Distribution in Metals Under Chemical Equilibrium and Steady-State Heat Conduction; EH-29122022; Euro Harmonization and Engineering: N. Iraklio, Greece, 2022. [Google Scholar] [CrossRef]

- Denbigh, K.G. The Thermodynamics of the Steady State; Methuen & CO.: London, UK, 1951. [Google Scholar]

- Shewmon, P. Diffusion in Solids; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1989. [Google Scholar]

- Nagumo, M. Fundamentals of Hydrogen Embrittlement; Springer Nature: Singapore, 2023. [Google Scholar]

- Johnson, H.H.; Quick, N.; Kumnick, A.J. Hydrogen trapping mechanisms by permeation techniques. Scr. Metall. 1979, 13, 67–72. [Google Scholar] [CrossRef]

- Oriani, R.A. The diffusion and trapping of hydrogen in steel. Acta Metall. 1970, 18, 147–157. [Google Scholar] [CrossRef]

- Krom, A.H.M.; Bakker, A.D. Hydrogen trapping models in steel. Metall. Mater. Trans. B 2000, 31B, 1475–1482. [Google Scholar] [CrossRef]

- Shi, R.; Nie, Z.; Fan, Q.; Wang, F.; Zhou, Y.; Liu, X. Correlation between dislocation-density-based strain hardening and microstructural evolution in dual phase TC6 titanium alloy. Mater. Sci. Eng. A 2018, 715, 101–107. [Google Scholar] [CrossRef]

- Nabarro, F.R.N. The strains produced by precipitation in alloys. Proc. R. Soc. 1940, A175, 519–538. [Google Scholar]

- Eshelby, J.D. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. 1957, A241, 376–396. [Google Scholar]

- Lee, J.K.; Earmee, Y.Y.; Aaronson, H.I.; Russell, K.C. Plastic relaxation of the transformation strain energy of a misfitting spherical precipitate: Ideal plastic behavior. Metall. Trans. A 1980, 11A, 1837–1847. [Google Scholar] [CrossRef]

- Earmee, Y.Y.; Johnson, W.C.; Lee, J.K. Plastic relaxation of the transformation strain energy of a misfitting spherical precipitate: Linear and power-law strain hardening. Metall. Trans. A 1981, 12A, 1521–1530. [Google Scholar]

- Broberg, K.B. Cracks and Fracture; Academic Press: London, UK, 1999. [Google Scholar]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 2: An Introduction to Microstructures, Processing and Design; Pergamon: Oxford, UK, 1986. [Google Scholar]

- Hertzberg, R.W. Deformation and Fracture Mechanics of Engineering Materials; John Wiley & Sons: New York, NY, USA, 1983. [Google Scholar]

- Hirth, J.P. Effects of hydrogen on the properties of iron and steel. Metall. Trans. A 1980, 11A, 861–890. [Google Scholar] [CrossRef]

- Kumnick, A.J.; Johnson, H.H. Deep trapping states for hydrogen in deformed iron. Acta Metall. 1980, 28, 33–39. [Google Scholar] [CrossRef]

- Special Metals Alloy Technical Bulletins. Available online: https://www.specialmetals.com/documents/technical-bulletins/inconel/inconel-alloy-x-750.pdf (accessed on 31 October 2024).

- Baranowski, B.; Majchrzak, S.; Flanagan, T.B. The volume increase of fcc metals and alloys due to interstitial hydrogen over a wide range of hydrogen contents. J. Phys. F Met. Phys. 1971, 1, 258–261. [Google Scholar] [CrossRef]

- Senkov, O.N.; Dubois, M.; Jonas, J.J. Elastic moduli of titanium-hydrogen alloys in the temperature range 20 °C to 1100 °C. Metall. Mater. Trans. A 1996, 27A, 3963–3970. [Google Scholar] [CrossRef]

- Alvarez, A.M.; Robertson, I.M.; Birnbaum, H.K. Hydrogen embrittlement of a metastable β-titanium alloy. Acta Mater. 2004, 52, 4161–4175. [Google Scholar] [CrossRef]

- Waisman, J.L.; Sines, G.; Robinson, L.B. Diffusion of hydrogen in titanium alloys due to composition, temperature, and stress gradients. Metall. Trans. 1973, 4, 291–302. [Google Scholar] [CrossRef]

- Vitt, R.S.; Ono, K. Hydrogen solubility in alpha titanium. Metall. Trans. 1971, 2, 608–609. [Google Scholar] [CrossRef]

- Pardee, W.J.; Paton, N.E. Model of sustained load cracking by hydride growth in Ti alloys. Metall. Trans. A 1980, 11A, 1391–1400. [Google Scholar] [CrossRef]

- Chen, C.Q.; Li, S.X.; Zheng, H.; Wang, L.B.; Lu, K. An investigation on structure, deformation and fracture of hydrides in titanium with a large range of hydrogen contents. Acta Mater. 2004, 52, 3697–3706. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Singular behaviour at the end of a tensile crack in a hardening material. J. Mech. Phys. Solids 1968, 16, 13–31. [Google Scholar] [CrossRef]

- Rice, J.R.; Rosengren, G.F. Plane strain deformation near a crack tip in a power-law hardening material. J. Mech. Phys. Solids 1968, 16, 1–12. [Google Scholar] [CrossRef]

- San Marchi, C.; Somerday, B.P.; Robinson, S.L. Permeability, solubility and diffusivity of hydrogen isotopes in stainless steels at high gas pressures. Int. J. Hydrog. Energy 2007, 32, 100–116. [Google Scholar] [CrossRef]

- Symington, M.; Shih, C.F.; Ortiz, M. Tables of Plane Strain Mixed-Mode Plastic Crack Tip Fields; Brown University: Providence, RI, USA, 1988; MRG/DMR-8714665/1. [Google Scholar]

- Rice, J.R. A path independent integral and the approximate analysis of strain concentration by notches and cracks. J. Appl. Mech. 1968, 35, 379–387. [Google Scholar] [CrossRef]

- Williams, M.L. On the stress distribution at the base of a stationary crack. J. Appl. Mech. 1957, 24, 109–114. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Plastic stress and strain fields at a crack tip. J. Mech. Phys. Solids 1968, 16, 337–347. [Google Scholar] [CrossRef]

| Material Property (Units) | Reference | |

|---|---|---|

| E (GPa) | 210 | [62] |

| ν | 0.3 | [63] |

| (MPa) | 250 | |

| 20 | calculation | |

| (m3/mol) | 2 × 10−6 | [64] |

| (m3/mol) | 7.1 × 10−6 | calculation |

| (kJ/mol) | 59.9 | [65] |

| (m−3 · mol−1) | [65] | |

| β | 6 | [55] |

| Material Property (Units) | Reference | |

|---|---|---|

| E (GPa) | 214 (at 25 °C) 196 (at 285 °C) | [66] |

| ν | 0.29 | [66] |

| (MPa) | 810 (at 25 °C) 735 (at 285 °C) | [35] |

| 15 | calculation | |

| (m3/mol) | 1.72 × 10−6 | [35,42,67] |

| (m3/mol) | 6.87 × 10−6 | [42] |

| (kJ/mol) | 15.1 | [35,42] |

| (m−3 · mol−1) | [42] | |

| β | 1 | [42,55] |

| Material Property (Units) | Reference | |

|---|---|---|

| E (GPa) | 110 | [68] |

| ν | 0.34 | [68] |

| (MPa) | 140 1 | |

| (m3/mol) | 1.7 × 10−6 | [69,70] |

| (m3/mol) | 10.62 × 10−6 | calculation |

| (mol/m3) | 3.8478 × 105 exp(−20,951.28/RT) | [71] |

| (m3/mol) | 13.17 × 10−6 | calculation |

| 0.24 | [72] | |

| 1.5 2 | e.g., [73] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varias, A.G. Chemical Equilibrium Fracture Mechanics—Hydrogen Embrittlement Application. Corros. Mater. Degrad. 2025, 6, 5. https://doi.org/10.3390/cmd6010005

Varias AG. Chemical Equilibrium Fracture Mechanics—Hydrogen Embrittlement Application. Corrosion and Materials Degradation. 2025; 6(1):5. https://doi.org/10.3390/cmd6010005

Chicago/Turabian StyleVarias, Andreas G. 2025. "Chemical Equilibrium Fracture Mechanics—Hydrogen Embrittlement Application" Corrosion and Materials Degradation 6, no. 1: 5. https://doi.org/10.3390/cmd6010005

APA StyleVarias, A. G. (2025). Chemical Equilibrium Fracture Mechanics—Hydrogen Embrittlement Application. Corrosion and Materials Degradation, 6(1), 5. https://doi.org/10.3390/cmd6010005