Abstract

Among the leading consequences of corrosion in reinforced concrete structures (RCS) the cross section reduction in steel bars should be mentioned, coupled to a decay of their mechanical material properties. This paper recalls the main literature findings on the topic and describes a wide collected database of experimental tensile tests performed on naturally corroded reinforcements. The principal predictive degradation laws available in the scientific literature to assess the residual mechanical properties of the corroded reinforcements are synthesized. A first attempt to evaluate the reliability of the literature decay laws to simulate the mechanical performance of naturally corroded steel reinforcement subjected to both uniform and pitting corrosion is performed. Finally, some remarks are suggested on both the tested naturally corroded steel reinforcement and the available degradation laws.

1. Introduction

Corrosion is one of the most common causes of deterioration in reinforced concrete structures (RCS), affecting 70–90% of building heritage [1]. The main macroscopic effects of corrosion in RCS are [2]: (i) steel-to-concrete interaction variation, (ii) cracking and spalling of the concrete cover, and (iii) reinforcement cross section reduction. Each factor corresponds to a mechanical performance deterioration at the material level (i.e., the bond-slip law [3], the strength of the cracked concrete [4], and the reinforcement constitutive law [5]). Consequently, the structural response of corroded RCS gradually worsens over time (increasing the corrosion level) and their service life can be compromised [6].

A deep understanding of the materials’ mechanical properties decay is essential to assess and foresee the performance of existing corroded RCS. With specific reference to the performance of corroded reinforcements, several experimental studies have been carried out in the last few decades [7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43], most of the time analyzing the behavior of artificially corroded specimens. In the pioneering work by Almusallam [7], steel reinforcement embedded in concrete was subjected to a high anodic current (2 mA/cm2), obtaining a considerable pitting corrosion. Apostolopulos et al. [8,9,10,11,12,13,14,15,16,17,18,19,20] carried out several experimental campaigns on steel reinforcements differing in technical classes and diameters, damaged by means of laboratory salt spray corrosion. The research involved steel reinforcements, bare or embedded in concrete, exposed to different salt spray environments for variable time slots, and tested in both monotonic and low-fatigue tests. Chemical, metallographic, and fractographic analyses were typically performed. In some cases, the pits formed on the reinforcement surface were measured and statistically analyzed. Moreover, the effects of a plastic deformation applied before the corrosion were investigated [9], as well as the performance of naturally corroded reinforcements [12]. In the latter case, efforts were made to correlate the mass loss due to the artificial corrosion process with the one measured in exposed rebars subjected to natural corrosion. Caprili et al. [21,22,23,24] analyzed the corrosion effects on reinforcements belonging to the most representative typologies of the actual European scenario. The experimental research included tensile and low-cycle fatigue tests, different specimen diameters, and exposure conditions. Moreover, the performance of dual-phase steel grades reinforcements subjected to corrosion degradation was investigated. Monotonic and fatigue tests were performed by Ref. [25] on corroded reinforcement extracted from beams exposed to an electrolytic procedure. The weight loss and the pit geometrical characteristics (depth and length) were measured. A trend for the mechanical properties decay of the corroded reinforcements was identified and related to the corrosion penetration; unfortunately, no formulation relating mechanical degradation and corrosion damage was provided. In Ref. [26], the mechanical performance of naturally and artificially corroded reinforcements embedded in concrete was compared, finding significant differences attributable to the different corrosion morphology. In fact, according to tensile test results performed on mechanically indented bars [27,28], the pit geometry influences the reinforcements mechanical performance.

Starting from the experimental outcomes, different degradation laws for the mechanical properties in tension of corroded steel reinforcements have been statistically assessed [26,27,28,29,30,31,32,33,34,35] to define a useful tool for estimating the residual performance of corroded RCS. In the present paper, the studies on the topic available in the scientific scene are recalled, and a database of naturally corroded steel reinforcement subjected to tensile tests is collected. Finally, a comparison between the database and the literature degradation laws is performed [26,27,28,29,30,31,32,33,34,35], with the main aim to give a first indication on their reliability in assessing the structural performance of existing corroded RCS.

2. Mechanical Performance of Corroded Ribbed Reinforcements

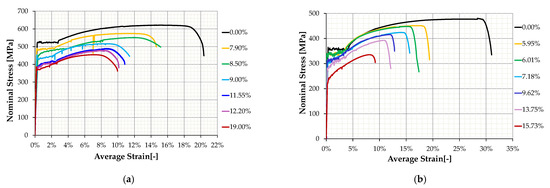

There is a general agreement about the reduction in the nominal constitutive law when a steel reinforcement corrodes: as the load capacity reduces together with the reinforcement cross section loss, the nominal stresses necessary decrease. The first work concerning the mechanical performance of corroded reinforcement was performed by Almusallam, on 6 mm and 12 mm diameters bars affected by highly localized corrosion [7]. A slight decrease in the yield and ultimate strengths and a significant reduction in the collapse elongation was detected. Subsequently, the Hellenic school analyzed the mechanical performance corroded steel reinforcements [8,9,10,11,12,13,14,15,16,17,18,19,20], finding that specimens embedded in concrete present stronger superficial severe localized pitting corrosion in contrast to the bare specimens. Moreover, the experimental outcomes [8,9,10,11,12,13,14,15,16,17,18,19,20] highlight a trend for the mechanical properties decay as a function of the corrosion level: both the residual ductility and the collapse strength reduce, and the yield plateau progressively disappears. It is worth noting that in Refs. [8,9,10,11,12,13,14,15,16,17,18,19,20] the specimens were artificially corroded through a laboratory salt spray chamber, with the main aim to simulate the effects of a natural coastal environment, rich in chlorides. Similar outcomes were observed in other studies analyzing the mechanical performance of reinforcements artificially damaged by accelerated electrolytic corrosion [25,26,29,30,31,32,33,34,35]. An example of constitutive law obtained for reinforcements subjected to uniform corrosion is reported in Figure 1, where a comparison between the performance of ribbed and smooth bars is moreover reported. Excepting the obvious differences in terms of both strength and ductility in absence of the corrosion, the performance of the two reinforcement typologies is similar once the degradation occurs.

Figure 1.

Comparison between the mechanical performance of steel reinforcements subjected to uniform corrosion: (a) ribbed bars, (b) smooth bars. The corrosion level is expressed in terms of mass loss.

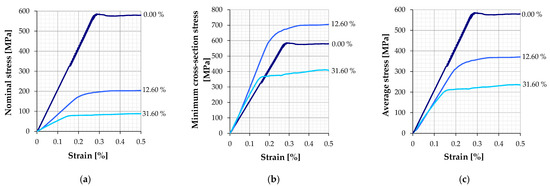

The mechanical properties decay can be observed in both the nominal and effective stresses (evaluated referring to the corroded cross section). Obviously, in the latter case the reduction is less evident. Regarding this aim, it is worth noting that a proper definition of the reference cross section plays a key role for a correct evaluation of the stress of a corroded reinforcement (Figure 2). Even if the minimum cross section governs the collapse, the adoption of this parameter is evidently not eligible in evaluating the constitutive law of the corroded reinforcement; this choice meant obtaining strength and elastic modulus higher than the uncorroded reinforcements (Figure 2b). By adopting the average cross section (evaluated on the gauge length), reasonable constitutive laws could instead be obtained (Figure 2c).

Figure 2.

Local constitutive laws referred to the most corroded zone: (a) stress evaluated by considering the nominal cross section, (b) stress evaluated by considering the most corroded cross section, and (c) stress evaluated by considering the average cross section in the gauge length.

The variation of the reinforcement constitutive laws after the corrosion degradation is ascribed to the steel bar microstructure [14,15,16,17,18,19,20,26,27,28,29,30,31,32,33]. However, it should be noted that the studies introducing this topic are based on specimens realized with steel reinforcements belonging to the actual manufacturing scenario, therefore characterized by a layered microstructure. As each layer has a proper mechanical behavior [36,37], the reinforcement constitutive law depends on the proportions between the layers’ volume: depending on the residual corroded layers, the constitutive law inevitably changes. A quite homogeneous layer reduction occurs in case of uniform corrosion, and a smooth degradation of the mechanical properties increasing the corrosion level can be observed. If, instead, the pitting corrosion develops, a greater dispersion of mechanical properties can also be detected for the same corrosion level or pit depth, due to the variable shape of pits affecting different layers at the same time. To better understand how pitting corrosion affects the reinforcement mechanical properties, experimental studies were performed on mechanically indented bars [27,28]. Together with the well assessed reduction in residual ductility and collapse strength, it was found that the deeper and more asymmetrical the pitting is, the worse the mechanical behavior of the corroded reinforcement. The latter outcome is confirmed observing reinforcements extracted from naturally corroded beams subjected to static loads and characterized by high pit depth [38].

3. Literature’s Degradation Laws for Corroded Ribbed Reinforcements and Comparison with the Mechanical Properties of Naturally Corroded Reinforcements

The experimental results on artificially corroded reinforcements allowed the derivation of some degradation laws, characterized by statistical errors depending on the considered database as well as on the corrosion morphology: the mechanical properties of corroded reinforcement are slightly scattered in case of uniform corrosion, while pitting corrosion is typically characterized by more dispersed results. In the scientific literature, different relationships can be found, derived for: (i) mechanically indented bars [27,28], (ii) artificially corroded bars by means of salt spray or electrolytic procedures [26,29,30,31,32,33,35], and (iii) naturally corroded bars [26,34,35]. In all cases, linear correlations between the strength and the corrosion level (CL) expressed in terms of mass loss are derived for both uniform and localized corroded reinforcements, that can be generalized as:

where β is a coefficient statistically defined by means of the ordinary least squares method (OLS), and its values calibrated by different researchers is reported in Table 1.

Table 1.

Yield and Ultimate Strength correlation coefficients β for degradation laws (EQ. 1) derived for uniform and pitting corrosion.

Concerning the ultimate deformation, the decay laws assessed in the scientific literature can follow a linear or an exponential trend, as synthesized in Table 2.

Table 2.

Ultimate Strain degradation laws for uniform and pitting corrosion.

With the purpose of evaluating the reliability of the available predictive laws in assessing the performance of naturally corroded reinforcements, a database of 398 experimental tests performed on bars extracted from deteriorated structural elements has been collected. In detail, the following cases are considered:

- n. 7 rebars from an offshore house (about 40 years old) located the coastal area of Athens, Greece [13]. The specimens (ribbed bars) had a nominal diameter of 10 mm, a mass loss varying between 9.67% and 16.00%, and the technical class comparable with the BSt 420 of DIN 488-1.

- n. 16 rebars from an industrial building (about 30 years old) located in the Aegion area, Greece, mainly subjected to carbonation and high humidity environment [13]. The specimens (ribbed bars) belong to a technical class comparable with the BSt 420 of DIN 488-1 and are characterized by a nominal diameter of 10 mm and mass losses variable between 0.25% and 9.74.

- n. 24 rebars from structures aged up to 96 years old and located less than 10 km from the coastal area of the Corinthian gulf in Greece [17]. The specimens (ribbed bars) are characterized by 8 mm and 10 mm diameters and belonged to the technical classes comparable with Grades B St III S (according to Din 488) and BSt I (according to DIN 1045). The corrosion attack rate varies between 0.013 and 0.024 mm/year.

- n. 18 rebars extracted from a residential building complex located close to the coastline of northern Taiwan [26]. The specimens’ diameters were 13, 16, and 19 mm, the mass loss ranged from 27% to 82% for specimen characterized by a nominal diameter of 13 mm (D13), and 6% to 39% and 23% to 51% for D16 and D19 steel bars, respectively.

- n. 74 rebars extracted from a real bridge after 30 years of service [34]. The structure, located in Sweden, was exposed to chlorides from deicing salts and showed signs of frost deterioration. The specimens (ribbed bars with 16 mm nominal diameter with a corrosion level ranging between 0 and 19%) belong to the steel class Ks60 and are divided into two typologies according to the rib pattern (straight and skewed).

- n. 40 rebars extracted from an inland building (54 years old) located in Mumbai, India, mainly subjected to carbonation [35]. Collected specimens belong to different technical class (22 rebars of MS 250 and 16 rebars of MS 350 grade), all having a nominal diameter and 12.7 mm and a round cross section.

- n. 103 rebars extracted from the deck of an overpass in Montreal, Canada, subjected to freezing and thawing cycles coupled to chloride attack due to deicing salts [39]. The specimens are characterized by a pitting corrosion, cross section reductions up 80%, and residual section shapes varying from roughly elliptic to quadrilateral.

- n. 45 rebars extracted from an existing building (more than 30 years old) mainly subjected to carbonation [40]. The specimen consisted of plain round rebars with a nominal diameter of 6.5 mm, the measured mass loss ranged between 15.6% and 31.2%.

- n. 13 rebars extracted from a beam subjected to 27 years of exposition in aggressive chloride environment and wetting–drying cycles [41]. In detail, after applying a constant load twice the design one for Service Limit State, the beams were first stored in a saline fog for 6 years and then subjected to wetting–drying cycles for 13 years; subsequently, the load was removed and exposed to the climate of southwest France for the rest of the time. The diameter losses vary between 9% and 22%.

- n. 17 rebars covered with a layer of soft clay containing chlorides for a period of 60 years [42]. The specimens (ribbed bars) are characterized by pit depth varying between 0.13 and 2.07 mm, maximum pit length between 4.07 and 23.46 mm, and maximum pit area between 12.55 and 276.01 mm2. Corrosion rates ranging between 0.01 and 0.05 mm/year were evaluated.

- n. 41 rebars extracted from a reinforced concrete bridge located in eastern Shenzhen, China, and subjected to 30 years of exposition in a marine environment [43]. The collected specimens (ribbed bars) belong to reinforcement located in the “underwater zone”, “tidal zone”, “splash zone”, and “atmosphere zone”. The mass loss ratio of the tested rebar was in a range from 3.41% to 49.09%.

The naturally corroded reinforcements are different in terms of: (i) corrosion morphology, (ii) chemical composition, and (iii) manufacturing process and initial mechanical properties. Considering the collected database, no studies state the manufacturing process, but differences are expected as naturally corroded rebars can present different chemical composition (listed in Table 3, where available) and different initial mechanical properties. Differences in terms of manufacturing process could be a key issue in interpreting the mechanical performance of naturally corroded reinforcements, as Ref. [12] demonstrate that the mechanical decay is most significant in TEMPCORE bars containing high proportions of carbon. Concerning the corrosion morphology, some authors discuss the occurrence of the pitting corrosion [17,34,35,39,41,42], but few works give a measurement of the pit features such as the pitting factor [42], or the pit dimensions [34,41].

Table 3.

Chemical composition of naturally corroded reinforcements (% of mass).

Not all collected data dispose of sufficient data to perform a comparison with the degradation laws available in the scientific literature. In the dataset, the majority of the samples are correlated to the average mass loss, with some exceptions. Only 24 naturally corroded reinforcements are categorized by means of the age of exposition [17]; for 103 samples, the corrosion level is defined by comparing the minimum and maximum cross-sectional areas on the gauge length by the measured diameter [39]. In several cases (61 experimental data) no mechanical properties are defined as initial reference [13,42,43], therefore the outcomes cannot be made nondimensional with the aim to perform proper comparisons. Only Ref. [34] considers a number of uncorroded reinforcement sufficient to statistically assess the initial mechanical characteristics, while in all other cases nominal [35], average [40,41], or estimated [13,26,39] values are available. Finally, it is important to underline that the ultimate strain values are provided only for 132 rebars of all the 203 naturally corroded reinforcements belonging to the complete sets [26,34,35].

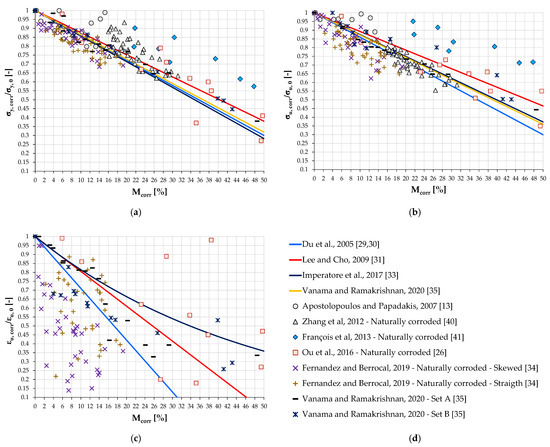

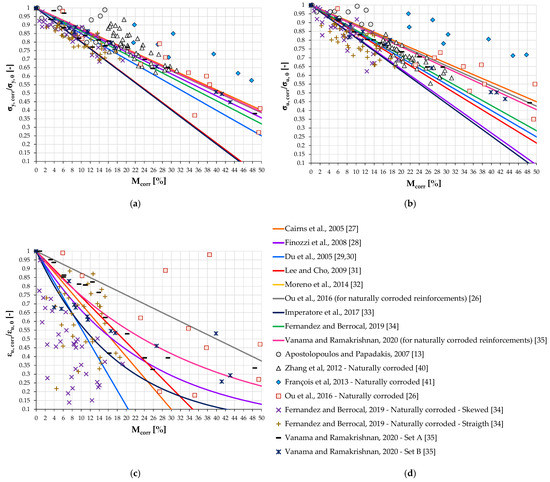

The comparison between the literature degradation laws and the performance of naturally corroded reinforcements is presented in Figure 3 and Figure 4 for the uniform and the pitting corrosion, respectively. If all sets are considered together, the mechanical properties of naturally corroded reinforcements do not follow a systematic trend. In fact, environmental aggressiveness differently affects the mechanical performance of corroded reinforcements. As demonstrated in Refs. [18,33], reinforced concrete elements subjected to chloride environments are characterized by the worst deterioration, in terms of both pit depth and mechanical properties decay. On the contrary, carbonation induces a less severe degradation [33,35]. This is one of the reasons for which the collected dataset is characterized by scattered mechanical properties.

Figure 3.

Comparison between the literature decay laws for uniform corrosion and the mechanical properties of naturally corroded rebars [13,26,29,30,31,33,34,35,40,41]: (a) yielding and (b) ultimate strength and (c) ultimate strain; (d) charts’ legend.

Figure 4.

Comparison between the literature decay laws for pitting corrosion and the mechanical properties of naturally corroded rebars [13,26,27,28,29,30,31,32,33,34,35,40,41]: (a) yielding and (b) ultimate strength and (c) ultimate strain; (d) charts’ legend.

Analyzing the entire dataset, the yielding and ultimate strength of naturally corroded reinforcements fit into bands containing the decay laws developed for uniform or pitting corrosion. Concerning the ultimate strain, instead, an excessive dispersion of the experimental results can be observed, which prevent any general consideration. Probably, as suggested in Ref. [26], the pit features (the minimum cross section and the pits distribution along the bar) are the main parameters affecting the deformation capacity of the naturally corroded reinforcements. Therefore, the ultimate strength is the most scattered mechanical parameter in natural corrosion and requires additional investigations.

If single sets of naturally corroded reinforcements are considered, the most scattered yielding and ultimate strength results are obtained by Ref. [13], while the tests presented in Ref. [26] are characterized by the higher dispersion of the ultimate strain. Concerning the remaining outcomes, each series follows its own trend, characterized by a variable standard deviation of the experimental results. In detail, the yielding strengths obtained by Ref. [40] have the greater dispersion. Regarding this aim, it should be noted that the considered samples have the lower diameter of whole database. Concerning the ultimate strength and strain, instead, the most scattered results are referred to the straight reinforcements presented in Ref. [34], characterized by a high carbon content. The same dispersion can also be observed by considering the pit dimensions as identification parameter of the suffered corrosion. It is worth noting that scattered ultimate strains also characterize skewed samples. Therefore, the mechanical performance variability should be ascribed to the manufacturing process, i.e., differences in terms of carbon content and rebar microstructure.

4. Conclusions and Final Remarks

This work presents a synthesis of the main findings available in the scientific literature on the mechanical performance of corroded reinforcement in concrete. Experimental studies performed over the years on both naturally and artificially corroded steel reinforcements demonstrate that corrosion not only reduces the steel cross section, but also changes the material constitutive law. Therefore, the evaluation of the corrosion effects on the mechanical performance of deteriorated steel reinforcement is a crucial aspect for assessing the effective structural capacity of existing corroded RCS. With this purpose, some degradation laws have been proposed by different authors to estimate the residual mechanical properties in tension, starting from the knowledge of the corrosion level and the morphology of the deterioration phenomenon. All the decay laws available for the monotonic tensile behavior of corroded steel reinforcement are recalled in the present paper. Moreover, a wide database of 398 tensile tests performed on corroded reinforcements extracted from reinforced concrete elements subjected to different aggressive environments for several years has been collected. The comparison between the mechanical properties of naturally corroded bars highlights that, with some exceptions, each set of reinforcements follows its own trend, not simulated by any literature degradation law. In detail, the scattering observed among the experimental results of the same series depends on the corrosion morphology, which itself is related to the environmental attack: severe pitting corrosion, such as the one occurring for a chloride attack from deicing salts coupled to frost damages [34], can result in a significant scattering of the experimental results; on the contrary, more uniform corrosion, occurring in case of concrete carbonation, induces a smooth degradation of the reinforcement mechanical properties, as can be observed in Ref. [35]. Moreover, the carbon content and the manufacture process seem to influence the residual mechanical performance. As observed in Ref. [12] and confirmed by the naturally corroded reinforcements presented in Ref. [34], high carbon contents promote a higher deterioration in terms of material properties.

Therefore, the proper assessment of the residual mechanical characteristics of naturally corroded reinforcements cannot be separated from:

- The evaluation of corrosion morphology due to the specific environmental attack, including the measurement of the pit features.

- The declaration of the reinforcement manufacturing process, including the carbon content, that affects the rebars microstructure and consequently the material properties decay.

- The exact evaluation of the initial mechanical properties, disregarding the nominal characteristics and hopefully assessing the sound mechanical parameters according to statistical approaches.

All points listed above would allow the achievement of a correct interpretation of the experimental results on naturally corroded reinforcements. This should be a key issue to assess decay laws appropriate in case of natural corrosion. In fact, those available are defined according to the results obtained for artificially corroded rebars, that in some cases seem to be unconservative, probably due to the less variable distribution of corrosion along the length of the specimens.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

Acknowledgments

The paper is part of the research “OPTION—The corrosion effects on the structural integrity of reinforced concrete beams” between Niccolò Cusano University and Oslo Metropolitan University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Angst, U.M. Challenges and opportunities in corrosion of steel in concrete. Mater. Struct. 2018, 51, 4. [Google Scholar] [CrossRef] [Green Version]

- Andrade, C. Corrosion of steel reinforcement. In Environmental Degradation of Materials; Moncmanovà, A., Ed.; WIT Press: Southampton, UK, 2007; pp. 185–231. [Google Scholar]

- Lin, H.; Zhao, Y.; Feng, P.; Ye, H.; Ozbolt, J.; Jiang, C.; Yang, J.Q. State-of-the-art review on the bond properties of corroded reinforcing steel bar. Constr. Build. Mater. 2019, 213, 216–233. [Google Scholar] [CrossRef]

- Andisheh, K.; Scott, A.; Palermo, A. Experimental evaluation of the residual compression strength and ultimate strain of chloride corrosion-induced damaged concrete. Struct. Concr. 2019, 20, 296–306. [Google Scholar] [CrossRef] [Green Version]

- Benenato, A.; Imperatore, S.; Ferracuti, B. Mechanical Behaviour of Steel Reinforcement Damaged by Corrosion: A Review. In Proceedings of the 5th Workshop on the New Boundaries of Structural Concrete, Milan, Italy, 19–20 September 2019. [Google Scholar]

- Bertolini, L. Steel corrosion and service life of reinforced concrete structures. Struct. Infrastruct. Eng. 2008, 4, 123–137. [Google Scholar] [CrossRef]

- Almusallam, A.A. Effect of degree of corrosion on the properties of reinforcing steel bars. Constr. Build. Mater. 2001, 15, 361–368. [Google Scholar] [CrossRef]

- Apostolopoulos, C.A.; Papadopoulos, M.P.; Pantelakis, S.G. Tensile behavior of corroded reinforcing steel bars BSt 500s. Constr. Build. Mater. 2006, 20, 782–789. [Google Scholar] [CrossRef]

- Apostolopoulos, C.A.; Michalopoulos, D. The impact of corrosion on the mechanical behavior of steel undergoing plastic deformation. Mater. Corros. 2007, 58, 5–12. [Google Scholar] [CrossRef]

- Apostolopoulos, C.A.; Papadopoulos, M.P. Tensile and low cycle fatigue behavior of corroded reinforcing steel bars S400. Constr. Build. Mater. 2007, 21, 855–864. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Apostolopoulos, C.A.; Papadopoulos, M.P.; Pantelakis, S.G. Mechanical performance of BStIV grade steel bars with regard to the long-term material degradation due to corrosion damage. Constr. Build. Mater. 2007, 21, 1362–1369. [Google Scholar] [CrossRef]

- Papadopoulos, M.P.; Apostolopoulos, C.A.; Alexopoulos, N.D.; Pantelakis, S.G. Effect of salt spray corrosion exposure on the mechanical performance of different technical class reinforcing steel bars. Mater. Des. 2007, 28, 2318–2328. [Google Scholar] [CrossRef]

- Apostolopoulos, C.A.; Papadakis, V.G. Consequences of steel corrosion on the ductility properties of reinforcement bar. Constr. Build. Mater. 2008, 22, 2316–2324. [Google Scholar] [CrossRef]

- Apostolopoulos, C.A.; Koutsoukos, P.G. Study of the corrosion of reinforcement in concrete elements used for the repair of monuments. Constr. Build. Mater. 2008, 22, 1583–1593. [Google Scholar] [CrossRef]

- Apostolopoulos, C. The effect of ribs on the mechanical behavior of corroded reinforcing steel bars S500s under low-cycle fatigue. Mater. Struct. 2008, 41, 991–999. [Google Scholar] [CrossRef]

- Apostolopoulos, C. The influence of corrosion and cross-section diameter on the mechanical properties of B500c steel. J. Mater. Eng. Perform. 2009, 18, 190–195. [Google Scholar] [CrossRef]

- Papadopoulos, M.P.; Apostolopoulos, C.A.; Zervaki, A.D.; Haidemenopoulos, G.N. Corrosion of exposed rebars, associated mechanical degradation and correlation with accelerated corrosion tests. Constr. Build. Mater. 2011, 25, 3367–3374. [Google Scholar] [CrossRef]

- Apostolopoulos, C.A.; Demis, S.; Papadakis, V.G. Chloride-induced corrosion of steel reinforcement–Mechanical performance and pit depth analysis. Constr. Build. Mater. 2013, 38, 139–146. [Google Scholar] [CrossRef]

- Apostolopoulos, C.A.; Diamantogiannis, G.; Apostolopoulos, A.C. Assessment of the mechanical behavior in dual-phase steel B400C, B450C, and B500B in a marine environment. J. Mater. Civ. Eng. 2016, 28, 04015097. [Google Scholar] [CrossRef]

- Apostolopoulos, A.; Matikas, T.E. Corrosion of bare and embedded in concrete steel bar-impact on mechanical behavior. Int. J. Struct. Integr. 2016, 7, 240–259. [Google Scholar] [CrossRef] [Green Version]

- Caprili, S.; Salvatore, W. Cyclic behaviour of uncorroded and corroded steel reinforcing bars. Constr. Build. Mater. 2015, 76, 168–186. [Google Scholar] [CrossRef]

- Caprili, S.; Moersch, J.; Salvatore, W. Mechanical performance versus corrosion damage indicators for corroded steel reinforcing bars. Adv. Mater. Sci. Eng. 2015, 2015, 739625. [Google Scholar] [CrossRef] [Green Version]

- Caprili, S.; Salvatore, W. Mechanical performance of steel reinforcing bars in uncorroded and corroded conditions. Data Brief 2018, 18, 1677–1695. [Google Scholar] [CrossRef] [PubMed]

- Caprili, S.; Salvatore, W.; Valentini, R. Corroded TempCore® vs. dual-phase steel reinforcing bars. Constr. Build. Mater. 2021, 277, 122301. [Google Scholar] [CrossRef]

- Fernandez, I.; Bairán, J.M.; Marí, A.R. Corrosion effects on the mechanical properties of reinforcing steel bars. Fatigue and σ–ε behavior. Constr. Build. Mater. 2015, 101, 772–783. [Google Scholar] [CrossRef]

- Ou, Y.C.; Susanto, Y.T.T.; Roh, H. Tensile behavior of naturally and artificially corroded steel bars. Constr. Build. Mater. 2016, 103, 93–104. [Google Scholar] [CrossRef]

- Cairns, J.; Plizzari, G.A.; Du, Y.; Law, D.W.; Franzoni, C. Mechanical properties of corrosion-damaged reinforcement. ACI Mater. J. 2005, 102, 256. [Google Scholar]

- Finozzi, I.; Saetta, A.; Budelmann, H. Structural response of reinforcing bars affected by pitting corrosion: Experimental evaluation. Constr. Build. Mater. 2018, 192, 478–488. [Google Scholar] [CrossRef]

- Du, Y.G.; Clark, L.A.; Chan, A.H.C. Residual capacity of corroded reinforcing bars. Mag. Concr. Res. 2005, 57, 135–147. [Google Scholar] [CrossRef]

- Du, Y.G.; Clark, L.A.; Chan, A.H.C. Effect of corrosion on ductility of reinforcing bars. Mag. Concr. Res. 2005, 57, 407–419. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.S.; Cho, Y.S. Evaluation of the mechanical properties of steel reinforcement embedded in concrete specimen as a function of the degree of reinforcement corrosion. Int. J. Fract. 2009, 157, 81–88. [Google Scholar] [CrossRef]

- Moreno, E.; Cobo, A.; Palomo, G.; González, M.N. Mathematical models to predict the mechanical behavior of reinforcements depending on their degree of corrosion and the diameter of the rebars. Constr. Build. Mater. 2014, 61, 156–163. [Google Scholar] [CrossRef]

- Imperatore, S.; Rinaldi, Z.; Drago, C. Degradation relationships for the mechanical properties of corroded steel rebars. Constr. Build. Mater. 2017, 148, 219–230. [Google Scholar] [CrossRef]

- Fernandez, I.; Berrocal, C.G. Mechanical properties of 30 year-old naturally corroded steel reinforcing bars. Int. J. Concr. Struct. Mater. 2019, 13, 9. [Google Scholar] [CrossRef]

- Vanama, R.K.; Ramakrishnan, B. Improved degradation relations for the tensile properties of naturally and artificially corroded steel rebars. Constr. Build. Mater. 2020, 249, 118706. [Google Scholar] [CrossRef]

- Kozlov, É.V.; Plevkov, A.V.; Yur’ev, A.B.; Gromov, V.E. Stress-strain curves, fracture mechanisms, and size effect for low-carbon low-alloyed steels with a quasi-composite structure. Russ. Phys. J. 2002, 45, 261–273. [Google Scholar] [CrossRef]

- Haefliger, S.; Kaufmann, W. Influence of cross section loss on the stress-strain characteristics of corroded quenched and self-tempered reinforcing bars. Constr. Build. Mater. 2021, 282, 122598. [Google Scholar] [CrossRef]

- Zhu, W.; François, R. Corrosion of the reinforcement and its influence on the residual structural performance of a 26-year-old corroded RC beam. Constr. Build. Mater. 2014, 51, 461–472. [Google Scholar] [CrossRef]

- Palsson, R.; Mirza, M.S. Mechanical response of corroded steel reinforcement of abandoned concrete bridge. Struct. J. 2002, 99, 157–162. [Google Scholar]

- Zhang, W.; Song, X.; Gu, X.; Li, S. Tensile and fatigue behavior of corroded rebars. Constr. Build. Mater. 2012, 34, 409–417. [Google Scholar] [CrossRef]

- François, R.; Khan, I.; Dang, V.H. Impact of corrosion on mechanical properties of steel embedded in 27-year-old corroded reinforced concrete beams. Mater. Struct. 2013, 46, 899–910. [Google Scholar] [CrossRef]

- Balestra, C.E.; Lima, M.G.; Silva, A.R.; Medeiros-Junior, R.A. Corrosion degree effect on nominal and effective strengths of naturally corroded reinforcement. J. Mater. Civ. Eng. 2016, 28, 04016103. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, S.; Du, Y.; Lin, Z.; Liang, X.; Liu, J.; Xing, F. Field test of a reinforced concrete bridge under marine environmental corrosion. Eng. Fail. Anal. 2020, 115, 104669. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).