Fabrication of Cobalt-Based Nano-Composite Film for Corrosion Mitigation of Copper in Flow Chloride Medium

Abstract

:1. Introduction

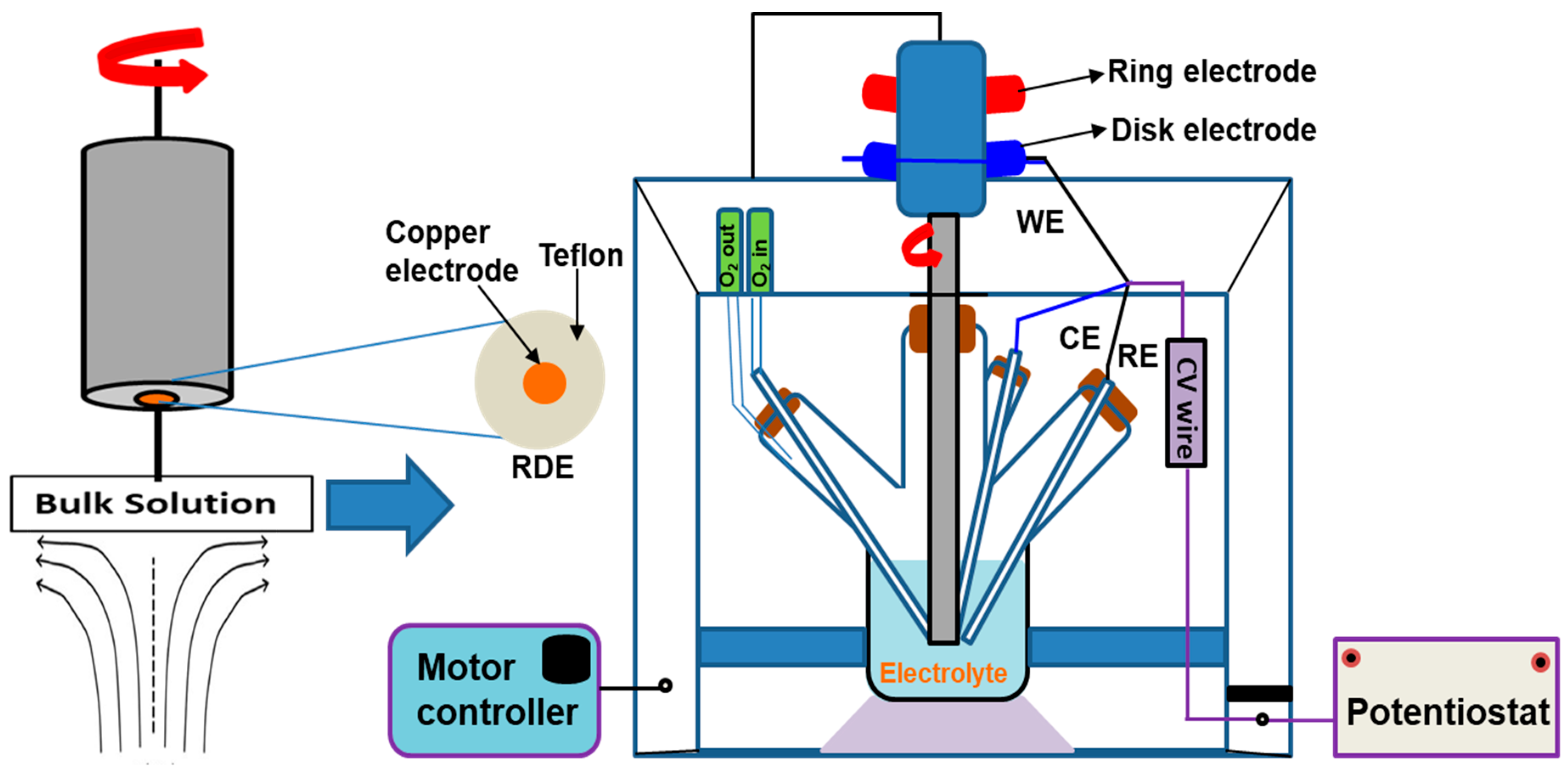

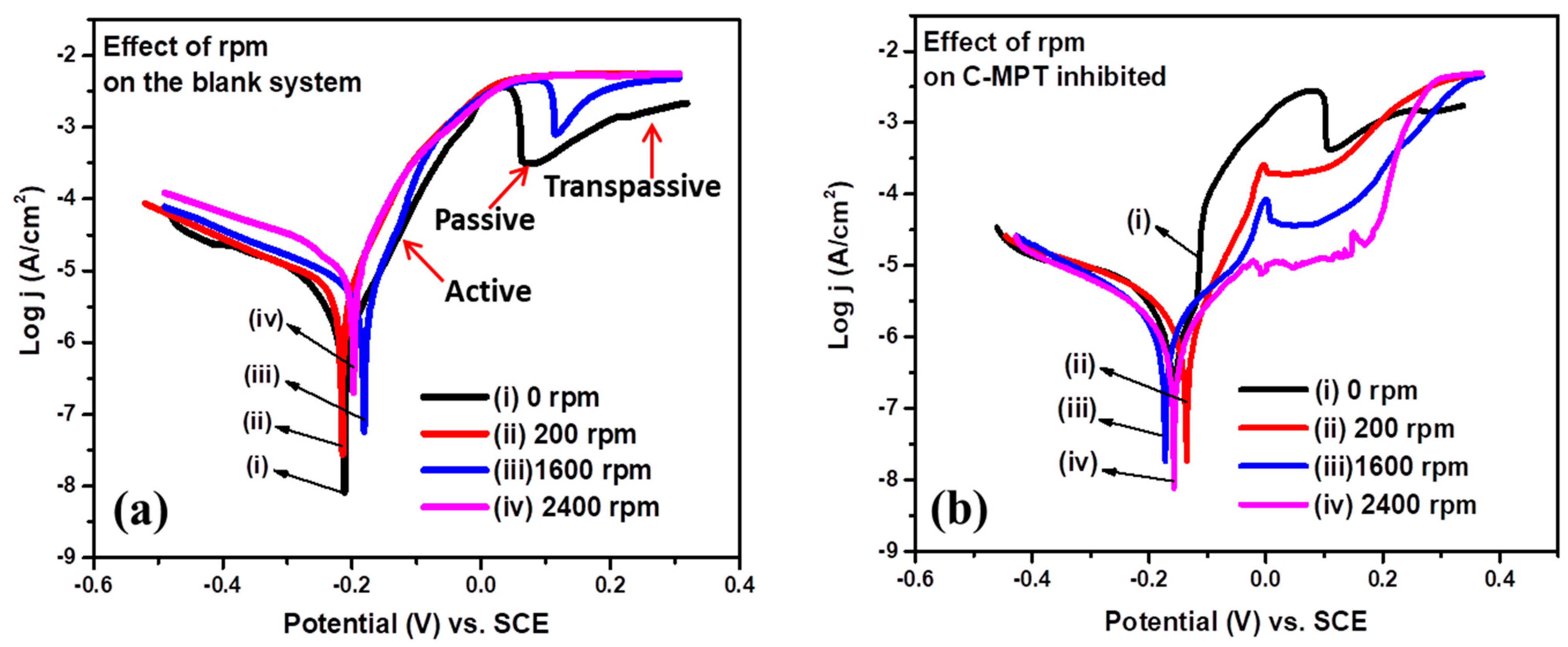

2. Materials and Methods

3. Results

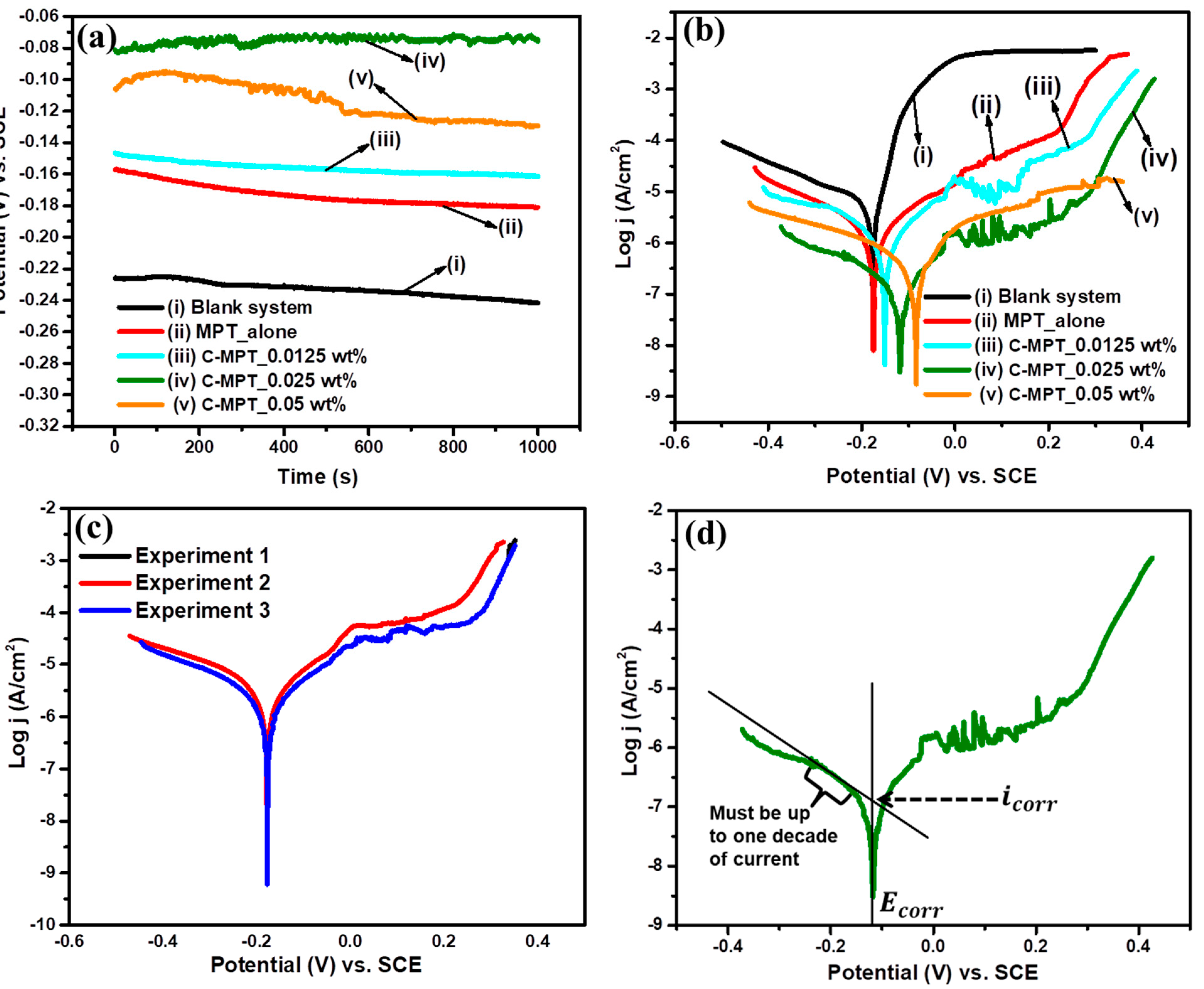

3.1. The Evolution of the Corrosion Potential

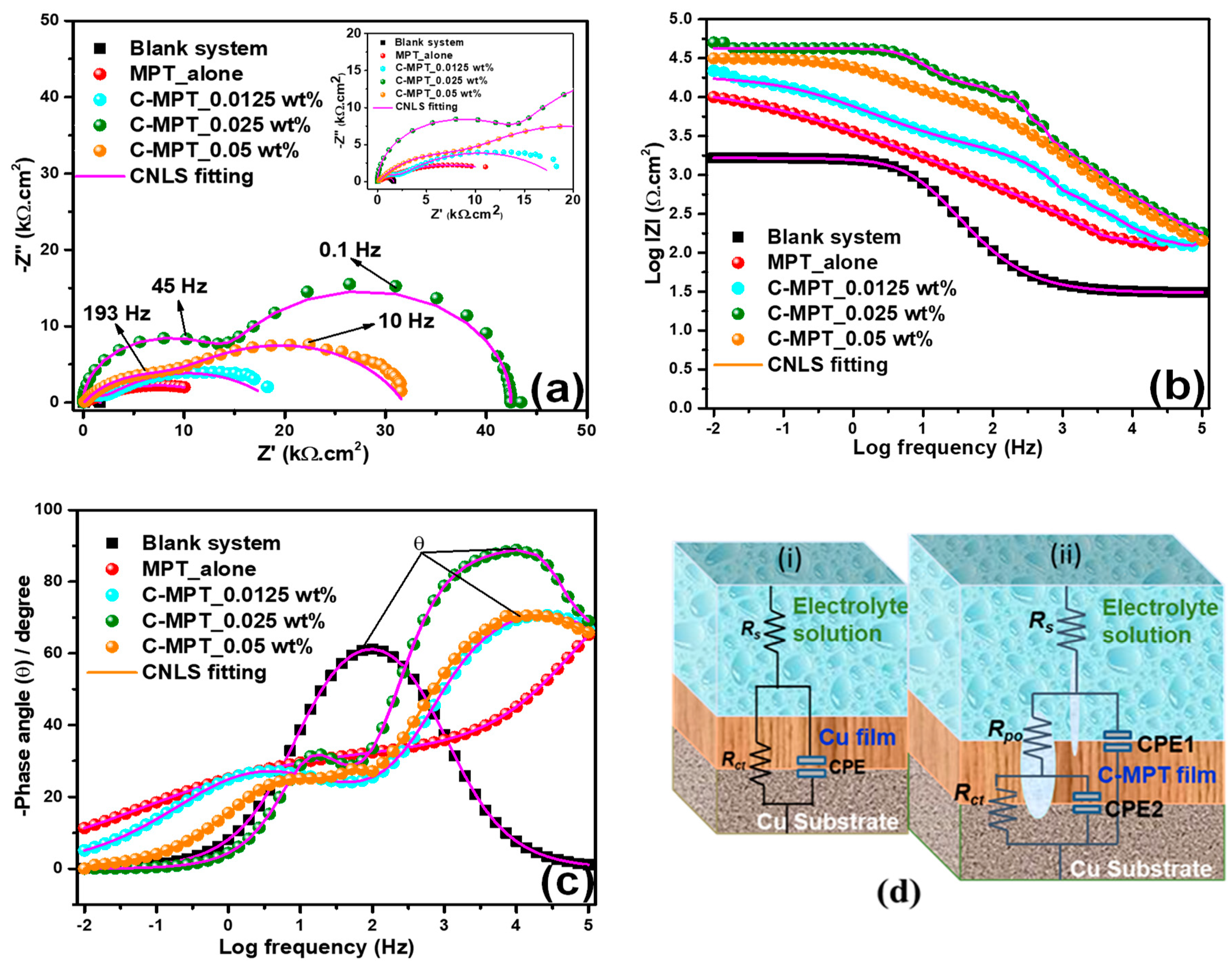

3.2. Electrochemical Impedance Spectroscopy (EIS) Analyses

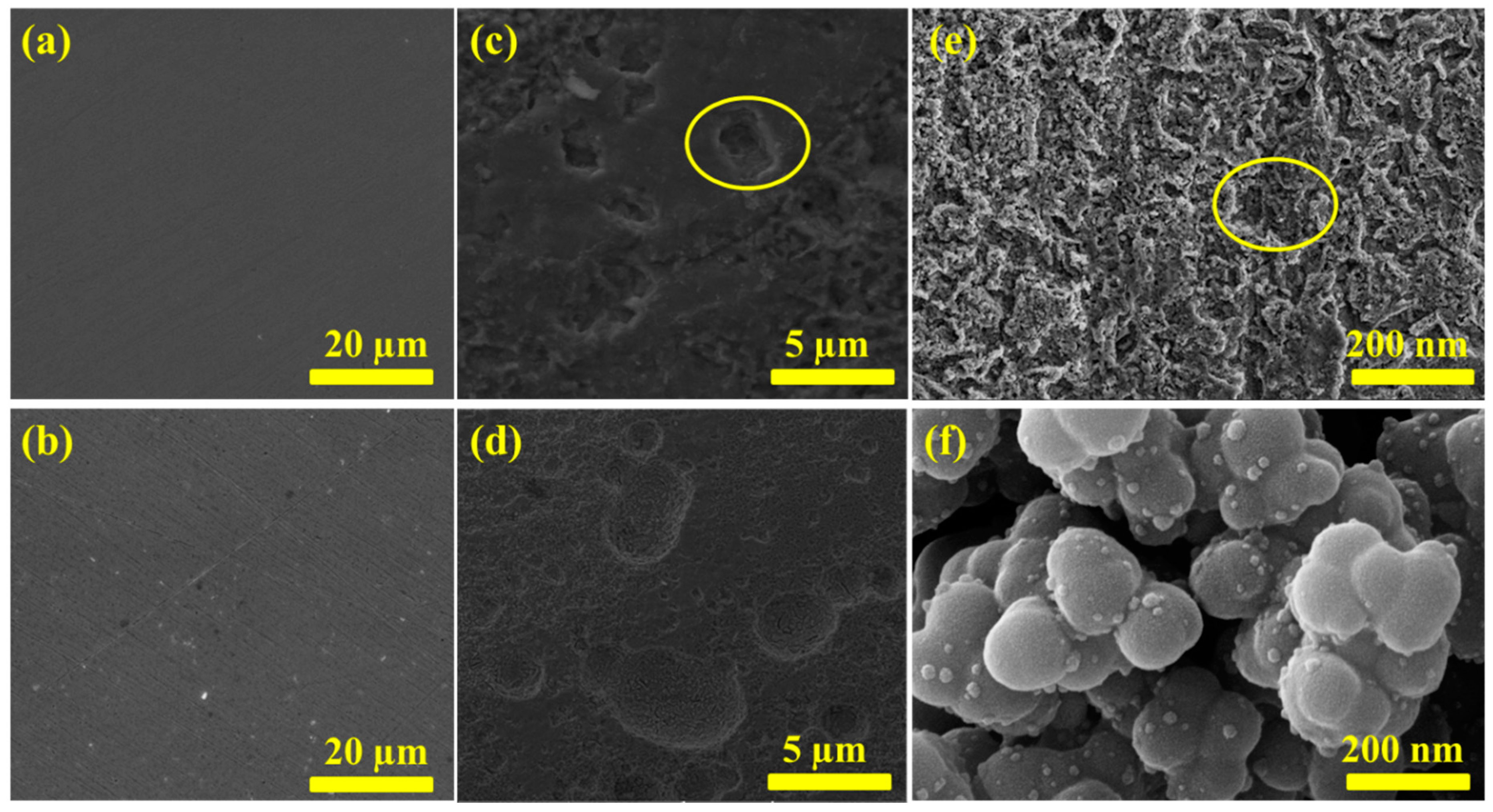

3.3. Post Corrosion SEM and FE-SEM Analyses of Immersed Surfaces

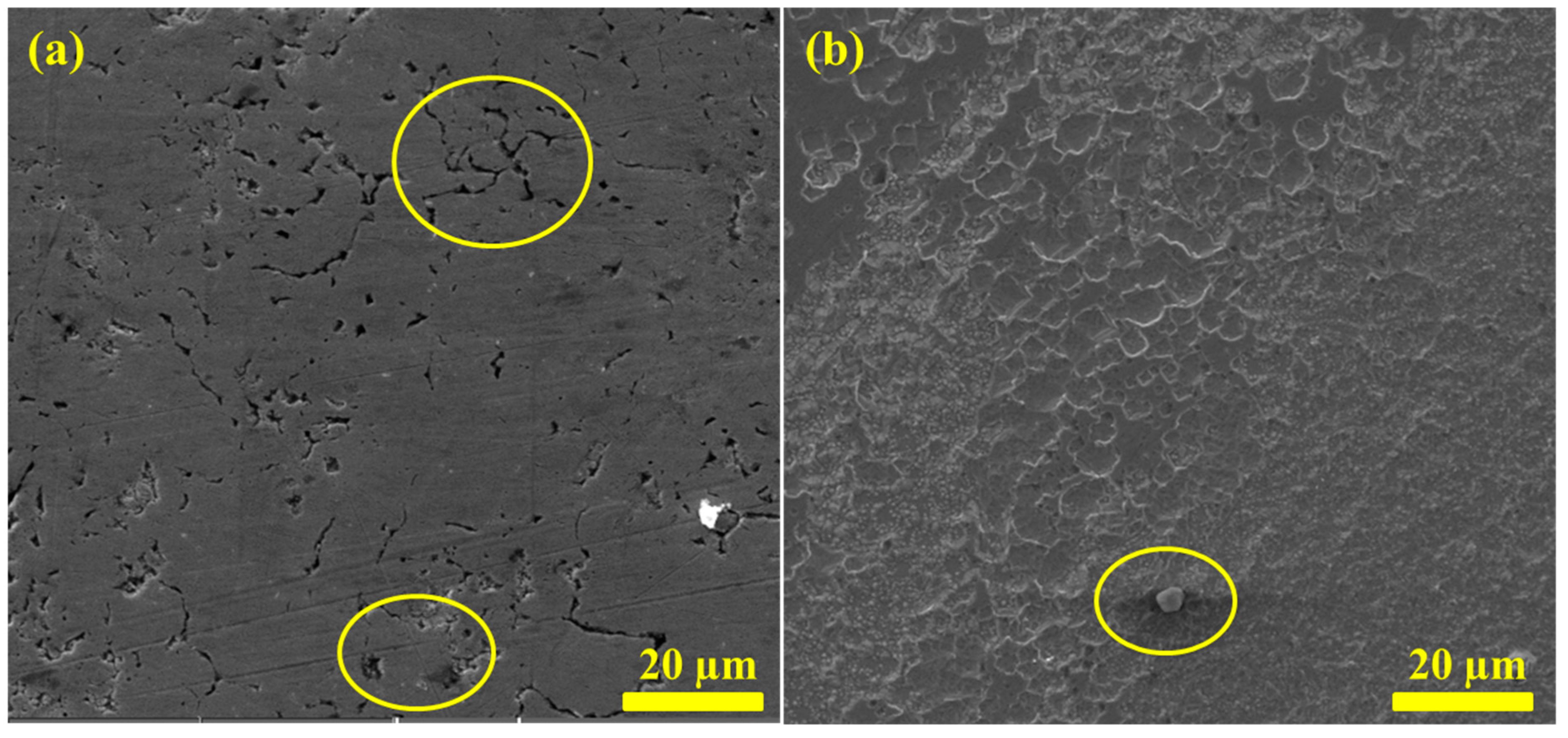

3.4. Effect of Immersion Duration on Coating Performance

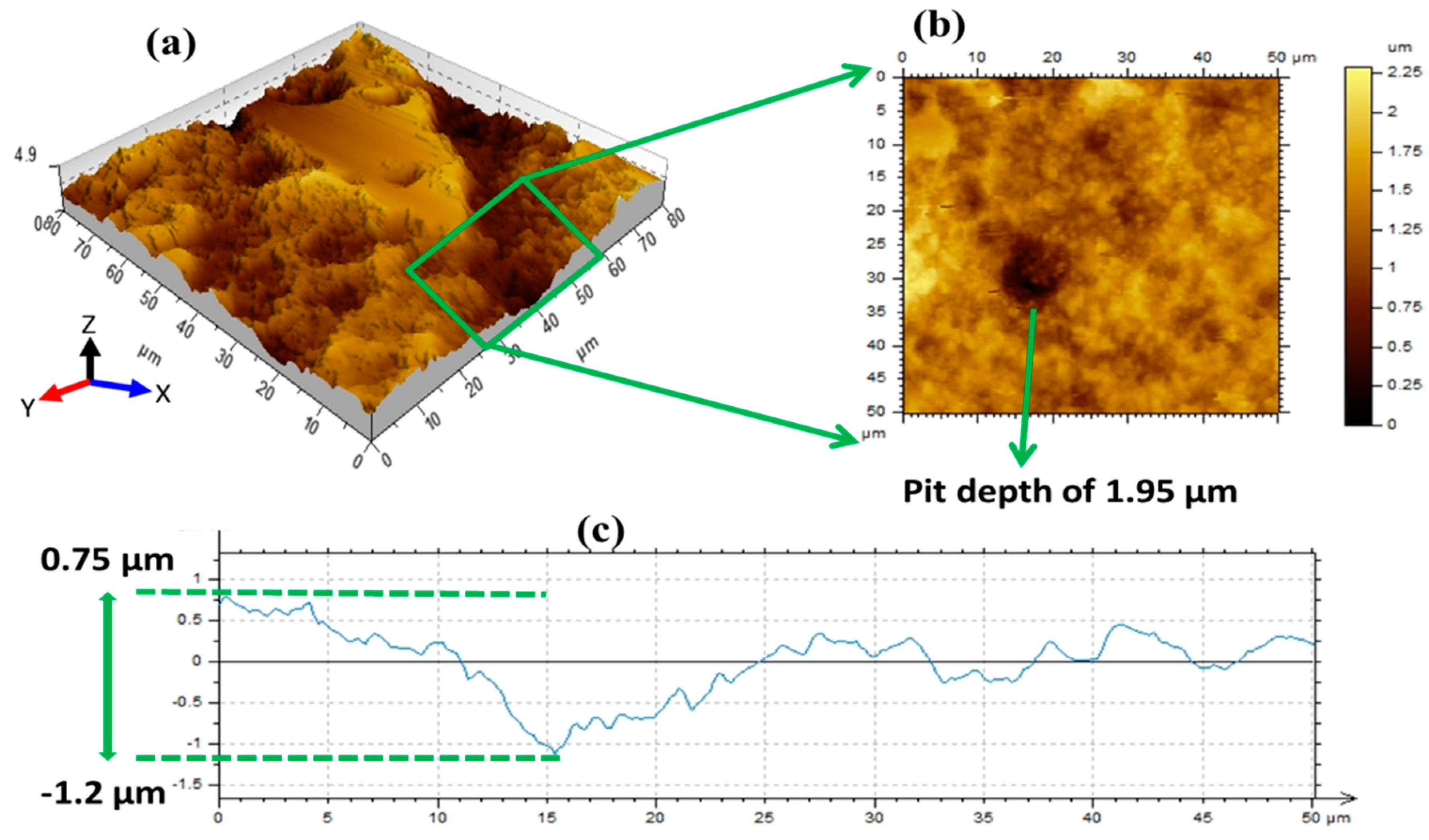

3.5. AFM Analyses of the Coated and Uncoated Cu Surfaces

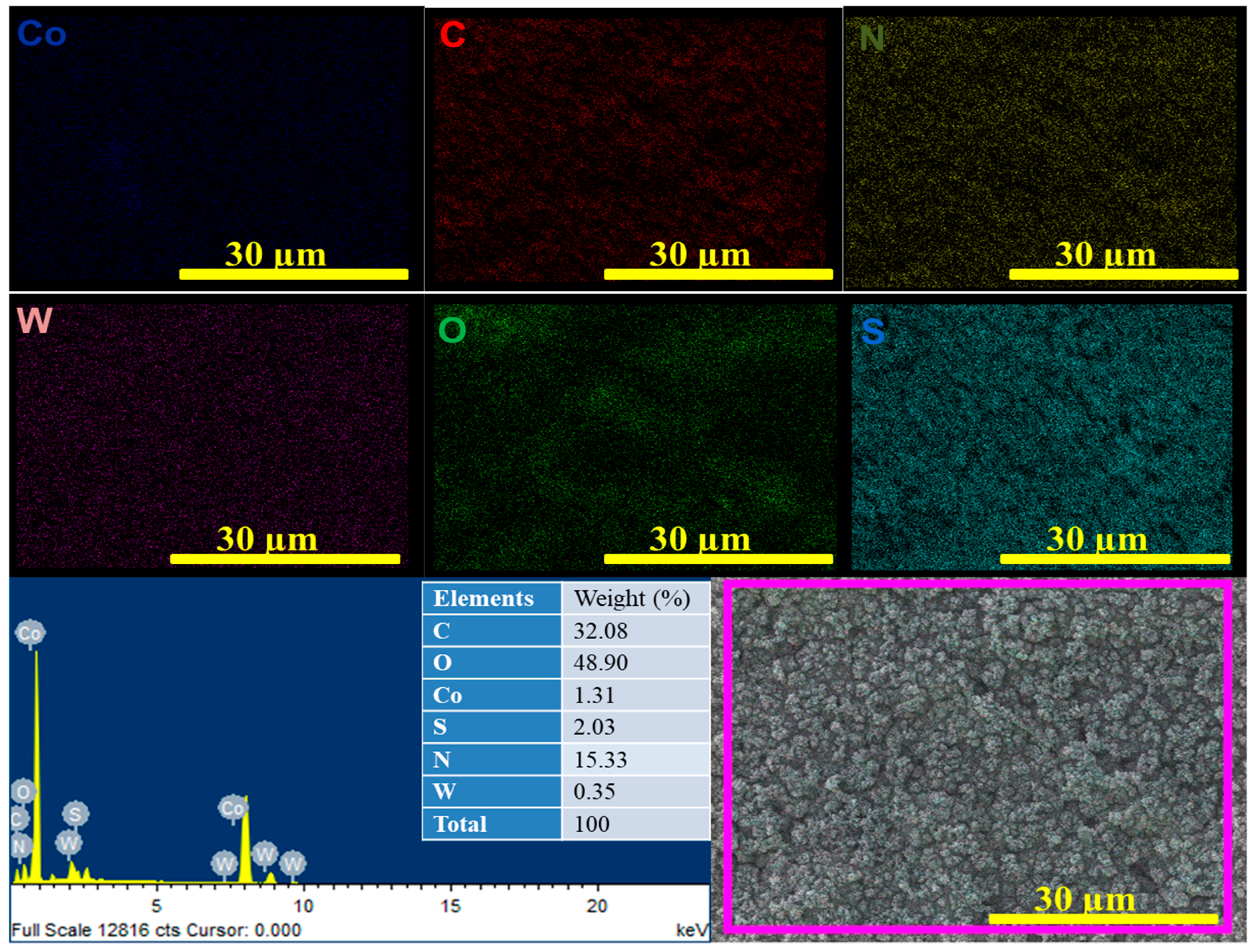

3.6. Elemental Color Mapping and EDAX Analyses of Coated Surfaces

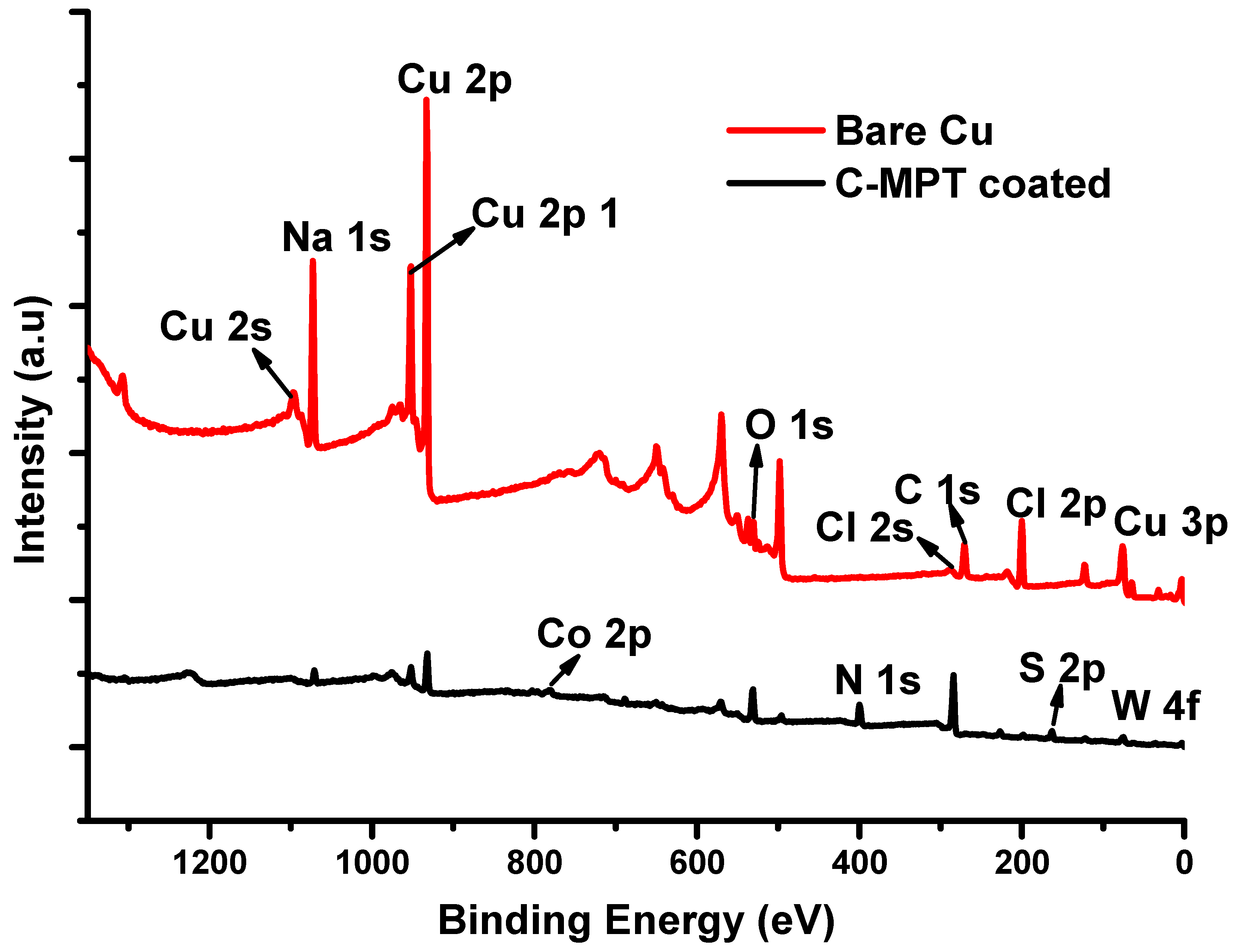

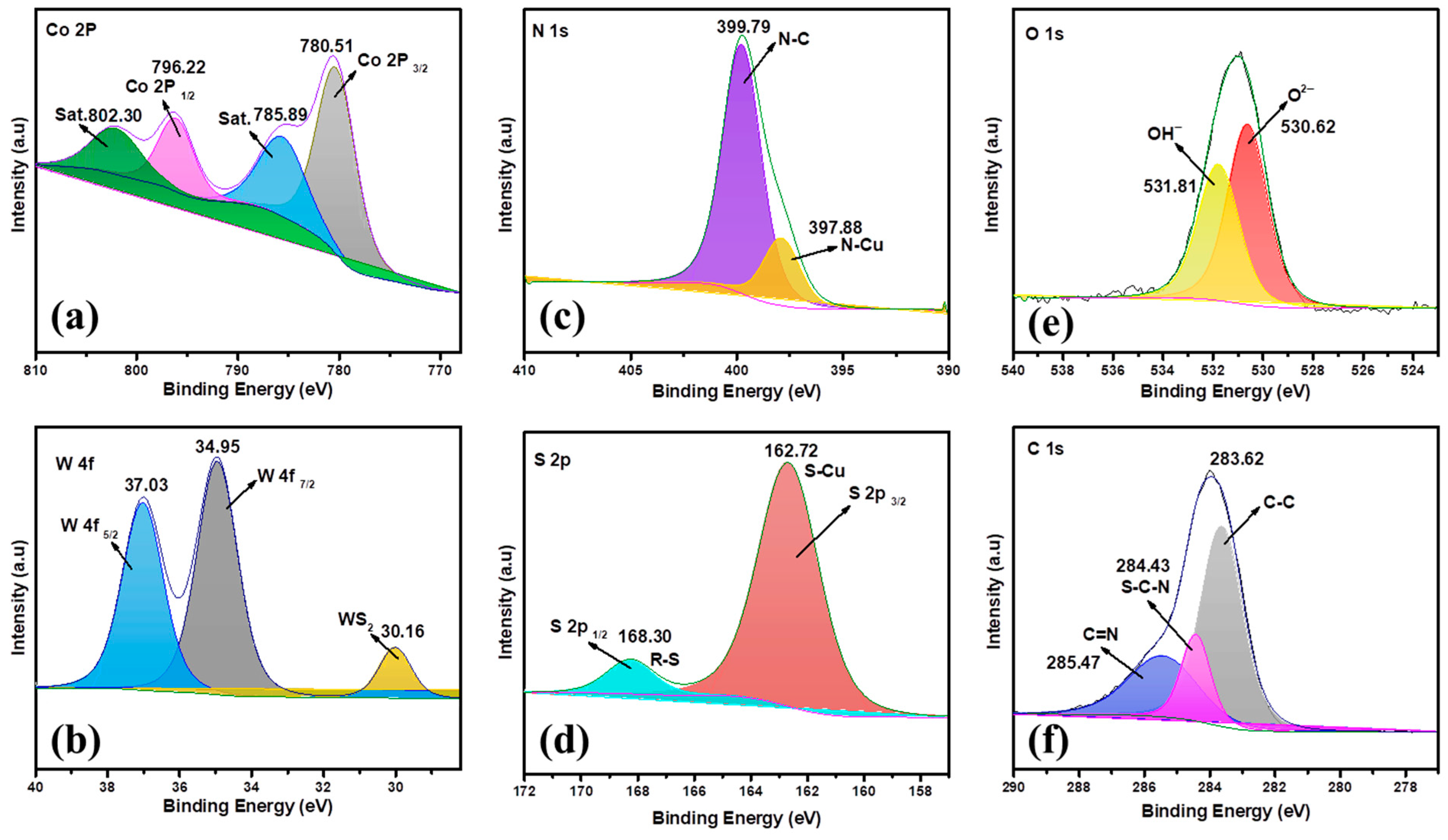

3.7. Post Corrosion XPS Analysis of Coated and Uncoated Cu Surfaces

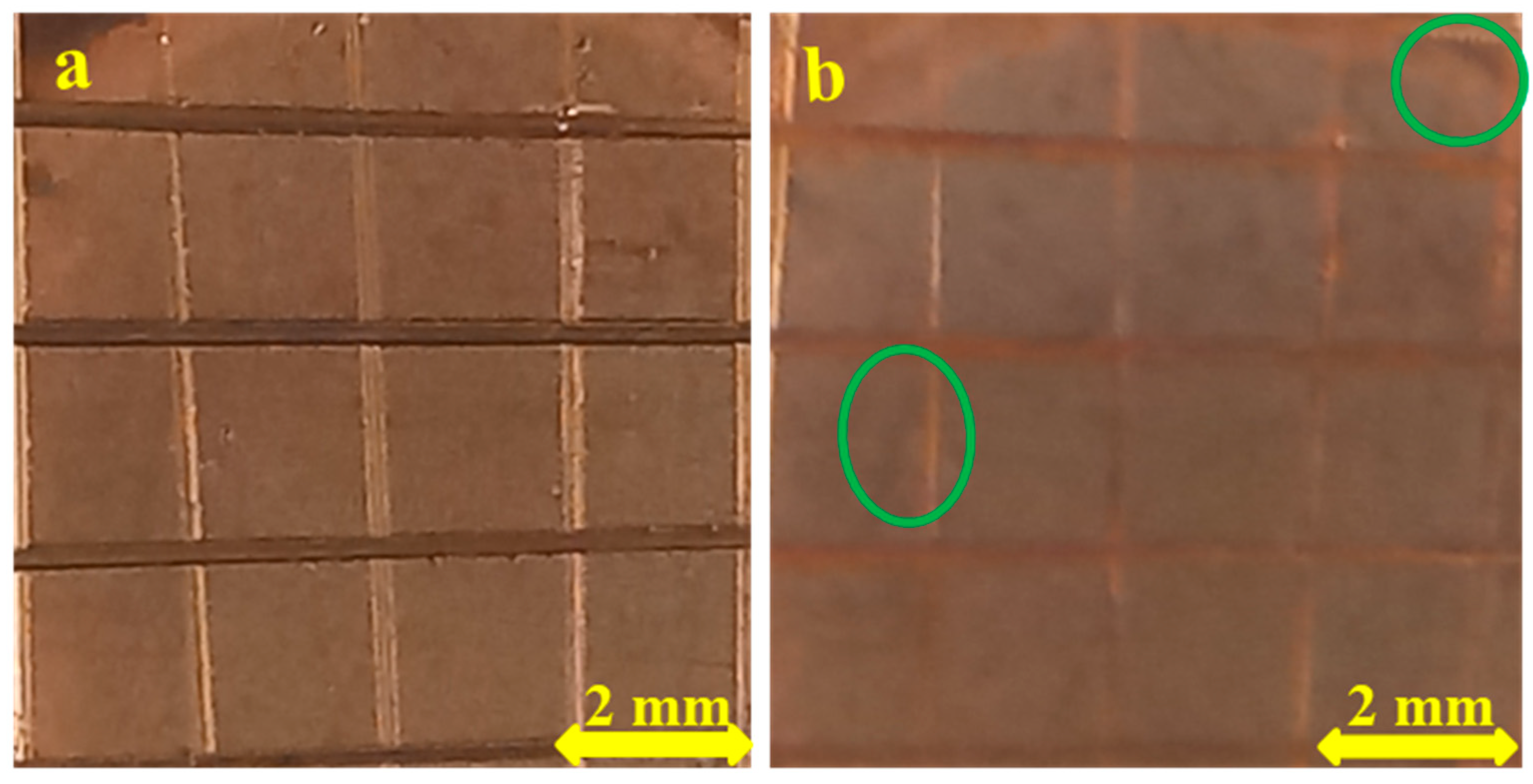

3.8. ASTM Standard Adhesion Tape Test

4. Discussion

5. Conclusions

- Nano-composite film was successfully fabricated on the copper surface using synthesized CoWO4 in synergy with 5-mercapto-1-phenyl-1H-tetrazole (MPT) via a wet chemical coating method.

- SEM and AFM analysis revealed the development of corrosion pits with a maximum depth of 1.95 µm on the uncoated copper after 2 h immersion duration due to chloride ion penetration which was aggravated by mass transport under hydrodynamic flow conditions.

- However, by the introduction of C-MPT nano-composite corrosion inhibitor, there was a facile and natural fabrication of film, which grew into a stable barrier coating on Cu surface leading to zero pit formation as evidence of effective protection.

- Electrochemical investigation showed that the inhibitor reduced the corrosion rate by inhibiting both cathodic and anodic reactions with a consequent reduction in corrosion current density from 34.5 to 1.02 µA cm−2, with a potential shift of less than 85 mV vs. SCE, which defines it as a mixed-type inhibitor.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arjmand, F.; Adriaens, A. Influence of pH and chloride concentration on the corrosion behavior of unalloyed copper in NaCl solution: A comparative study between the micro and macro scales. Materials 2012, 5, 2439–2464. [Google Scholar] [CrossRef] [Green Version]

- Sarver, E.; Edwards, M. Inhibition of copper pitting corrosion in aggressive potable waters. Int. J. Corros. 2012, 2012, 857823. [Google Scholar] [CrossRef] [Green Version]

- Frankel, G.S. Pitting Corrosion of Metals: A Review of the Critical Factors. J. Electrochem. Soc. 1998, 145, 2186–2198. [Google Scholar] [CrossRef]

- De Chialvo, M.R.G.; Salvarezza, R.C.; Vasquez Moll, D.; Arvia, A.J. Kinetics of passivation and pitting corrosion of polycrystalline copper in borate buffer solutions containing sodium chloride. Electrochim. Acta 1985, 30, 1501–1511. [Google Scholar] [CrossRef] [Green Version]

- Ha, H.M.; Scully, J.R. Effects of phosphate on pit stabilization and propagation in copper in synthetic potable waters. Corrosion 2013, 69, 703–718. [Google Scholar] [CrossRef]

- Loto, R.T. Electrochemical analysis of the corrosion inhibition effect of trypsin complex on the pitting corrosion of 420 martensitic stainless steel in 2M H2SO4 solution. PLoS ONE 2018, 13, e0195870. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El Warraky, A.; El Shayeb, H.A.; Sherif, E.M. Pitting corrosion of copper in chloride solutions. Anti-Corros. Methods Mater. 2004, 51, 52–61. [Google Scholar] [CrossRef]

- Marcus, P.; Maurice, V.; Strehblow, H.H. Localized corrosion (pitting): A model of passivity breakdown including the role of the oxide layer nanostructure. Corros. Sci. 2008, 50, 2698–2704. [Google Scholar] [CrossRef]

- Li, S.; Teague, M.T.; Doll, G.L.; Schindelholz, E.J.; Cong, H. Interfacial corrosion of copper in concentrated chloride solution and the formation of copper hydroxychloride. Corros. Sci. 2018, 141, 243–254. [Google Scholar] [CrossRef]

- Cong, H.; Scully, J.R. Effect of Chlorine Concentration on Natural Pitting of Copper as a Function of Water Chemistry. J. Electrochem. Soc. 2010, 157, C200–C211. [Google Scholar] [CrossRef]

- Dartmann, J.; Sadlowsky, B.; Dorsch, T.; Johannsen, K. Copper corrosion in drinking water systems—Effect of pH and phosphate-dosage. Mater. Corros. 2010, 61, 189–198. [Google Scholar] [CrossRef]

- Tang, Y.; Zuo, Y.; Wang, J.; Zhao, X.; Niu, B.; Lin, B. The metastable pitting potential and its relation to the pitting potential for four materials in chloride solutions. Corros. Sci. 2014, 80, 111–119. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, G.; Bobaru, F. The Influence of Passive Film Damage on Pitting Corrosion. J. Electrochem. Soc. 2016, 163, C19–C24. [Google Scholar] [CrossRef]

- Papadopoulou, O.; Vassiliou, P. The Influence of Archaeometallurgical Copper Alloy Castings Microstructure towards Corrosion Evolution in Various Corrosive Media. Corros. Mater. Degrad. 2021, 2, 227–247. [Google Scholar] [CrossRef]

- Croll, S.G. Surface roughness profile and its effect on coating adhesion and corrosion protection: A review. Prog. Org. Coat. 2020, 148, 105847. [Google Scholar] [CrossRef]

- Song, G.-L.; Feng, Z. Modification, degradation and evaluation of a few organic coatings for some marine applications. Corros. Mater. Degrad. 2020, 1, 408–442. [Google Scholar] [CrossRef]

- Chen, K.; Zhou, S.; Wu, L. Self-healing underwater superoleophobic and antibiofouling coatings based on the assembly of hierarchical microgel spheres. ACS Nano 2016, 10, 1386–1394. [Google Scholar] [CrossRef] [PubMed]

- Balbo, A.; Chiavari, C.; Martini, C.; Monticelli, C. Effectiveness of corrosion inhibitor films for the conservation of bronzes and gilded bronzes. Corros. Sci. 2012, 59, 204–212. [Google Scholar] [CrossRef]

- Chen, W.; Hong, S.; Li, H.B.; Luo, H.Q.; Li, M.; Li, N.B. Protection of copper corrosion in 0.5M NaCl solution by modification of 5-mercapto-3-phenyl-1,3,4-thiadiazole-2-thione potassium self-assembled monolayer. Corros. Sci. 2012, 61, 53–62. [Google Scholar] [CrossRef]

- Tian, H.; Li, W.; Cao, K.; Hou, B. Potent inhibition of copper corrosion in neutral chloride media by novel non-toxic thiadiazole derivatives. Corros. Sci. 2013, 73, 281–291. [Google Scholar] [CrossRef]

- Wei, N.; Jiang, Y.; Liu, Z.; Ying, Y.; Guo, X.; Wu, Y.; Wen, Y.; Yang, H. 4-Phenylpyrimidine monolayer protection of a copper surface from salt corrosion. RSC Adv. 2018, 8, 7340–7349. [Google Scholar] [CrossRef] [Green Version]

- Shevtsov, D.; Kozaderov, O.; Shikhaliev, K.; Komarova, E.; Kruzhilin, A.; Potapov, A.; Prabhakar, C.; Zartsyn, I. 3-Sulphinyl-5-amino-1H-1,2,4-triazoles as inhibitors of copper corrosion. Appl. Sci. 2019, 9, 4882. [Google Scholar] [CrossRef] [Green Version]

- Martinović, I.; Zlatić, G.; Pilić, Z.; Šušić, L.; Kowalska, O.; Petrović, D.; Falak, F.; Mišković, J. Self assembled monolayers of alkanethiol as inhibitors against copper corrosion in synthetic acid rain. Int. J. Electrochem. Soc. 2019, 14, 4206–4215. [Google Scholar]

- Durainatarajan, P.; Prabakaran, M.; Ramesh, S. Self-assembled monolayers of novel imidazole derivative on copper surface for anticorrosion protection in neutral medium. J. Adhes. Sci. Technol. 2021, 35, 2580–2601. [Google Scholar] [CrossRef]

- Chukwuike, V.I.; Sam Sankar, S.; Kundu, S.; Barik, R.C. Nanostructured cobalt tungstate (CoWO4: A highly promising material for fabrication of protective oxide film on copper in chloride medium. J. Electrochem. Soc. 2019, 166, 631–641. [Google Scholar] [CrossRef]

- Mihit, M.; Salghi, R.; El Issami, S.; Bazzi, L.; Hammouti, B.; Addi, E.A.; Kertit, S. A study of tetrazoles derivatives as corrosion inhibitors of copper in nitric acid. Pigment Resin Technol. 2006, 35, 151–157. [Google Scholar] [CrossRef]

- Jafari, H.R.; Davoodi, A.; Hosseinpour, S. Effect of Fluid Flow on the Corrosion Performance of as-Cast and Heat-Treated Nickel Aluminum Bronze Alloy (UNS C95800) in Saline Solution. Corros. Mater. Degrad. 2021, 2, 61–77. [Google Scholar] [CrossRef]

- Kumaravel, S.; Thiruvengetam, P.; Ede, S.R.; Karthick, K.; Anantharaj, S.; Sam Sankar, S.; Kundu, S. Cobalt tungsten oxide hydroxide hydrate (CTOHH) on DNA scaffold: An excellent bi-functional catalyst for oxygen evolution reaction (OER) and aromatic alcohol oxidation. Dalton Trans. 2019, 48, 17117–17131. [Google Scholar] [CrossRef]

- Zhang, X.L.; Jiang, Z.H.; Yao, Z.P.; Song, Y.; Wu, Z.D. Effects of scan rate on the potentiodynamic polarization curve obtained to determine the Tafel slopes and corrosion current density. Corros. Sci. 2009, 51, 581–587. [Google Scholar] [CrossRef]

- McCafferty, E. Validation of corrosion rates measured by the Tafel extrapolation method. Corros. Sci. 2005, 47, 3202–3215. [Google Scholar] [CrossRef]

- Kear, G.; Barker, B.D.; Stokes, K.R.; Walsh, F.C. Corrosion and impressed current cathodic protection of copper-based materials using a bimetallic rotating cylinder electrode (BRCE). Corros. Sci. 2005, 47, 1694–1705. [Google Scholar] [CrossRef]

- Deslouis, C.; Tribollet, B.; Mengoli, G.; Musiani, M.M. Electrochemical behavior of copper in neutral aerated chloride solution II. Impedance investigation. J. Appl. Elelctrochem. 1988, 18, 384–393. [Google Scholar] [CrossRef]

- Sabet Bokati, K.; Dehghanian, C.; Yari, S. Corrosion inhibition of copper, mild steel and galvanically coupled copper-mild steel in artificial sea water in presence of 1H-benzotriazole, sodium molybdate and sodium phosphate. Corros. Sci. 2017, 126, 272–285. [Google Scholar] [CrossRef]

- Tan, B.; Xiang, B.; Zhang, S.; Qiang, Y.; Xu, L.; Chen, S.; He, J. Papaya leaves extract as a novel eco-friendly corrosion inhibitor for Cu in H2SO4 medium. J. Colloid Interface Sci. 2021, 582, 918–931. [Google Scholar] [CrossRef] [PubMed]

- Qiang, Y.; Zhang, S.; Xu, S.; Yin, L. The effect of 5-nitroindazole as an inhibitor for the corrosion of copper in a 3.0% NaCl solution. RSC Adv. 2015, 5, 63866–63873. [Google Scholar] [CrossRef]

- Verma, C.B.; Quraishi, M.A.; Singh, A. 2-Aminobenzene-1,3-dicarbonitriles as green corrosion inhibitor for mild steel in 1 M HCl: Electrochemical, thermodynamic, surface and quantum chemical investigation. J. Taiwan Inst. Chem. Eng. 2015, 49, 229–239. [Google Scholar] [CrossRef]

- Petrović Mihajlović, M.B.; Radovanović, M.B.; Tasić, Ž.Z.; Antonijević, M.M. Imidazole based compounds as copper corrosion inhibitors in seawater. J. Mol. Liq. 2017, 225, 127–136. [Google Scholar] [CrossRef]

- Wang, D.; Xiang, B.; Liang, Y.; Song, S.; Liu, C. Corrosion control of copper in 3.5 wt.% NaCl solution by domperidone: Experimental and theoretical study. Corros. Sci. 2014, 85, 77–86. [Google Scholar] [CrossRef]

- Wang, Z.; Gong, Y.; Jing, C.; Huang, H.; Li, H.; Zhang, S.; Gao, F. Synthesis of dibenzotriazole derivatives bearing alkylene linkers as corrosion inhibitors for copper in sodium chloride solution: A new thought for the design of organic inhibitors. Corros. Sci. 2016, 113, 64–77. [Google Scholar] [CrossRef]

- Chen, W.; Hong, S.; Luo, H.Q.; Li, N.B. Inhibition effect of 2,4,6-trimercapto-1,3,5-triazine self-assembled monolayers on copper corrosion in NaCl solution. J. Mater. Eng. Perform. 2014, 23, 527–537. [Google Scholar] [CrossRef]

- Durainatarajan, P.; Prabakaran, M.; Ramesh, S.; Periasamy, V. Self-assembly on copper surface by using imidazole derivative for corrosion protection. J. Adhes. Sci. Technol. 2018, 32, 1733–1749. [Google Scholar] [CrossRef]

- Vida, T.A.; Freitas, E.S.; Cheung, N.; Garcia, A.; Osório, W.R. Electrochemical Corrosion Behavior of as-cast Zn-rich Zn-Mg Alloys in a 0.06 M NaCl Solution. Int. J. Electrochem. Sci. 2017, 12, 5264–5283. [Google Scholar] [CrossRef]

- Meyer, Y.A.; Bonatti, R.S.; Bortolozo, A.D.; Osório, W.R. Electrochemical behavior and compressive strength of Al-Cu/xCu composites in NaCl solution. J. Solid State Electrochem. 2021, 25, 1203–1317. [Google Scholar] [CrossRef]

- Hirschorn, B.; Orazem, M.E.; Tribollet, B.; Vivier, V.; Frateur, I.; Musiani, M. Constant-Phase-Element Behavior Caused by Resistivity Distributions in Films. J. Electrochem. Soc. 2010, 157, C458–C463. [Google Scholar] [CrossRef]

- Hirschorn, B.; Orazem, M.E.; Tribollet, B.; Vivier, V.; Frateur, I.; Musiani, M. Determination of effective capacitance and film thickness from constant-phase-element parameters. Electrochim. Acta 2010, 55, 6218–6227. [Google Scholar] [CrossRef]

- Wang, C.; Chen, S.; Zhao, S. Inhibition effect of AC-treated, mixed self-assembled film of phenylthiourea and 1-dodecanethiol on copper corrosion. J. Electrochem. Soc. 2004, 151, B11–B15. [Google Scholar] [CrossRef]

- Chukwuike, V.I.; Sankar, S.S.; Kundu, S.; Barik, R.C. Capped and uncapped nickel tungstate (NiWO4) nanomaterials: A comparison study for anti-corrosion of copper metal in NaCl solution. Corros. Sci. 2019, 158, 108101. [Google Scholar] [CrossRef]

- Wu, X.; Wiame, F.; Maurice, V.; Marcus, P. 2-Mercaptobenzothiazole corrosion inhibitor deposited at ultra-low pressure on model copper surfaces. Corros. Sci. 2020, 166, 108464. [Google Scholar] [CrossRef]

- Deslouis, C.; Tribollet, B.; Mengoli, G.; Musiani, M.M. Electrochemical behavior of copper in neutral aerated chloride solution. I. Steady-state investigation. J. Appl. Elelctrochem. 1988, 18, 374–383. [Google Scholar] [CrossRef]

| Metal Sample | Inhibitor | Electrolyte | Temperature (°C) | Nature of Film | Hydrodynamic Condition | η (%) | Authors | Ref. |

|---|---|---|---|---|---|---|---|---|

| Bronzes | 3-Mercaptopropyl-trimethoxysilane | 3.5% NaCl | Room temperature | Coated with Prop S-SH film | static | 99.8 | Balbo et al. | [18] |

| Copper | 5-Mercapto-3-phenyl-1,3,4-thiadiazole-2-thione potassium (MPTT) | 3.0% or 0.5 M NaCl | 25 °C | Coated via SAM | static | 93.7 | Chen et al. | [19] |

| Copper | 5-Phenyl-1,3,4-thiadiazole-2-thiol (PTT) | 3.5% NaCl | 303 K or 30 °C | Coated with thiadiazole–Cu complex. from PTT | static | 97.5 | Tian et al. | [20] |

| Copper | 2-(5-Mercapto- 1,3,4-thiadiazole-2-yl)- phenol (MTP) | 3.5% NaCl | 303 K or 30 °C | Coated with thiadiazole–Cu complex. from MTP | static | 97.1 | Tian et al. | [20] |

| Copper | 4-Phenylpyrimidine (4-PPM) | 3.0% NaCl | - | Coated with 4- PPM layer | static | 83.2 | Wei et al. | [21] |

| Copper | 3-Phenylsulphinyl-5-amino-1H-1,2,4-triazole | 1% HCl | 25 °C | Coated with inhibitor film | static | 91.7 | Shevtsovet al. | [22] |

| Copper | 1-Octadecanethiol (ODT) | Simulated acid rain | 25 °C | Coated via SAM | static | 85.8 | Martinović et al. | [23] |

| Copper | 1-(3-Aminopropyl)-2- methyl-1-imidazole (APMI) | 3.0% NaCl | - | Coated via SAM | static | 95.1 | Durainatarajan et al. | [24] |

| Copper | CoWO4 (nanoparticles NPs) + 5-mercapto-1-phenyl-1H-tetrazole (MPT) | 3.5% NaCl | 32 °C | Coated with nano-composite film | Flow | 97.4 | Present work | - |

| Concentration (wt%) | (V) | (µA cm−2) | βc (mV/decade) | Corrosion Rate (mmpy) | η (%) |

|---|---|---|---|---|---|

| Blank(0.0 C-MPT) | −0.203 | 34.50 ± 2.4 | 218.2 | 0.147 | - |

| MPT_alone_0.018 | −0.201 | 5.29 ± 0.5 | 162.8 | 0.039 | 84.7 ± 1 |

| C-MPT_0.0125 | −0.182 | 3.41 ± 0.2 | 123.6 | 0.028 | 90.1 ± 3 |

| C-MPT_0.025 | −0.137 | 1.02 ± 0.4 | 116.1 | 0.007 | 97.4 ± 2 |

| C-MPT_0.05 | −0.095 | 1.56 ± 0.7 | 89.3 | 0.009 | 95.5 ± 4 |

| Concentration of Inhibitors (wt%) | CPE1 | CPE2 | η (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| n1 | n2 | ||||||||

| Blank | 22 ± 0.3 | - | 27.1 ± 0.2 | 0.76 | 1401 ± 23 | - | - | 1.5 | - |

| MPT_alone | 25 ± 0.3 | 4988 ± 54 | 13.2 ± 0.3 | 0.74 | 5986 ± 89 | 10.3 ± 0.1 | 0.83 | 1.1 | 87.2± 5 |

| C-MPT_0.0125 | 26 ± 0.2 | 4997 ± 47 | 6.6 ± 0.1 | 0.86 | 15096 ± 201 | 8.3 ± 0.2 | 0.85 | 10.2 | 93.0 ± 4 |

| C-MPT_0.025 | 26 ± 0.5 | 20103 ± 101 | 4.3 ± 0.2 | 0.89 | 22897 ± 211 | 3.9 ± 0.3 | 0.90 | 7.1 | 97.0 ± 1 |

| C-MPT_0.05 | 28 ± 0.4 | 14431 ±104 | 4.7 ± 0.4 | 0.88 | 17580 ± 105 | 4.3 ± 0.4 | 0.80 | 6.6 | 96.0 ± 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chukwuike, V.I.; Barik, R.C. Fabrication of Cobalt-Based Nano-Composite Film for Corrosion Mitigation of Copper in Flow Chloride Medium. Corros. Mater. Degrad. 2021, 2, 743-761. https://doi.org/10.3390/cmd2040040

Chukwuike VI, Barik RC. Fabrication of Cobalt-Based Nano-Composite Film for Corrosion Mitigation of Copper in Flow Chloride Medium. Corrosion and Materials Degradation. 2021; 2(4):743-761. https://doi.org/10.3390/cmd2040040

Chicago/Turabian StyleChukwuike, Vitalis I., and Rakesh C. Barik. 2021. "Fabrication of Cobalt-Based Nano-Composite Film for Corrosion Mitigation of Copper in Flow Chloride Medium" Corrosion and Materials Degradation 2, no. 4: 743-761. https://doi.org/10.3390/cmd2040040

APA StyleChukwuike, V. I., & Barik, R. C. (2021). Fabrication of Cobalt-Based Nano-Composite Film for Corrosion Mitigation of Copper in Flow Chloride Medium. Corrosion and Materials Degradation, 2(4), 743-761. https://doi.org/10.3390/cmd2040040