Traction Performance of Common Formal Footwear on Slippery Surfaces

Abstract

1. Introduction

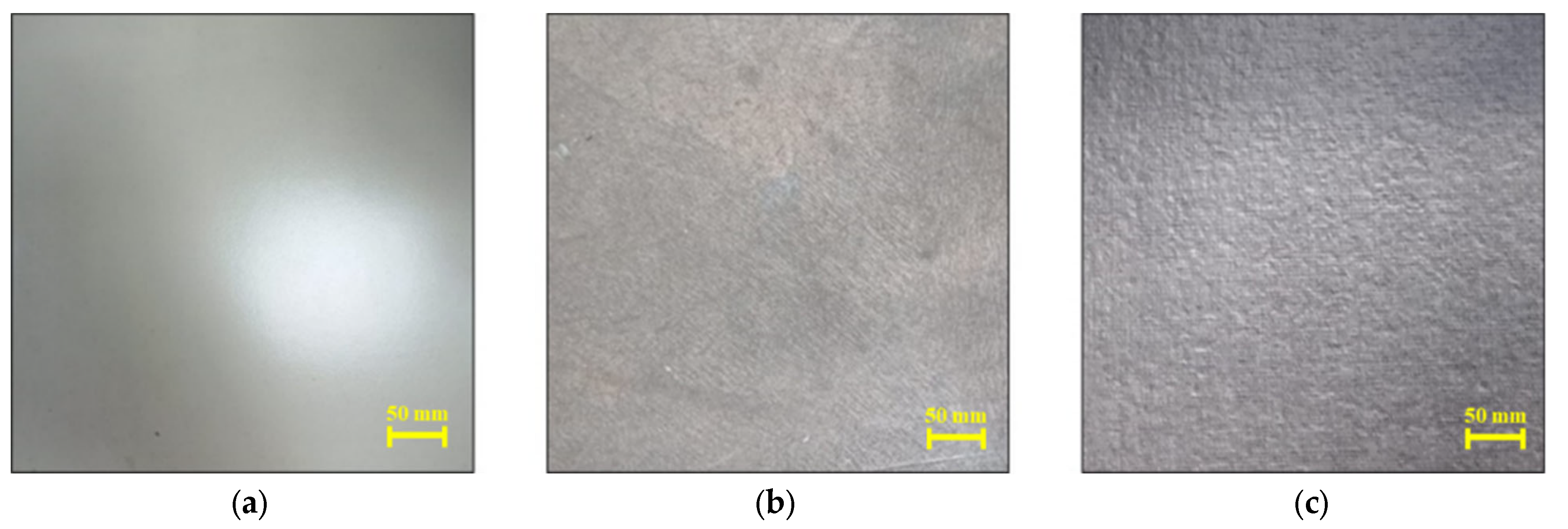

2. Materials and Methods

3. Results

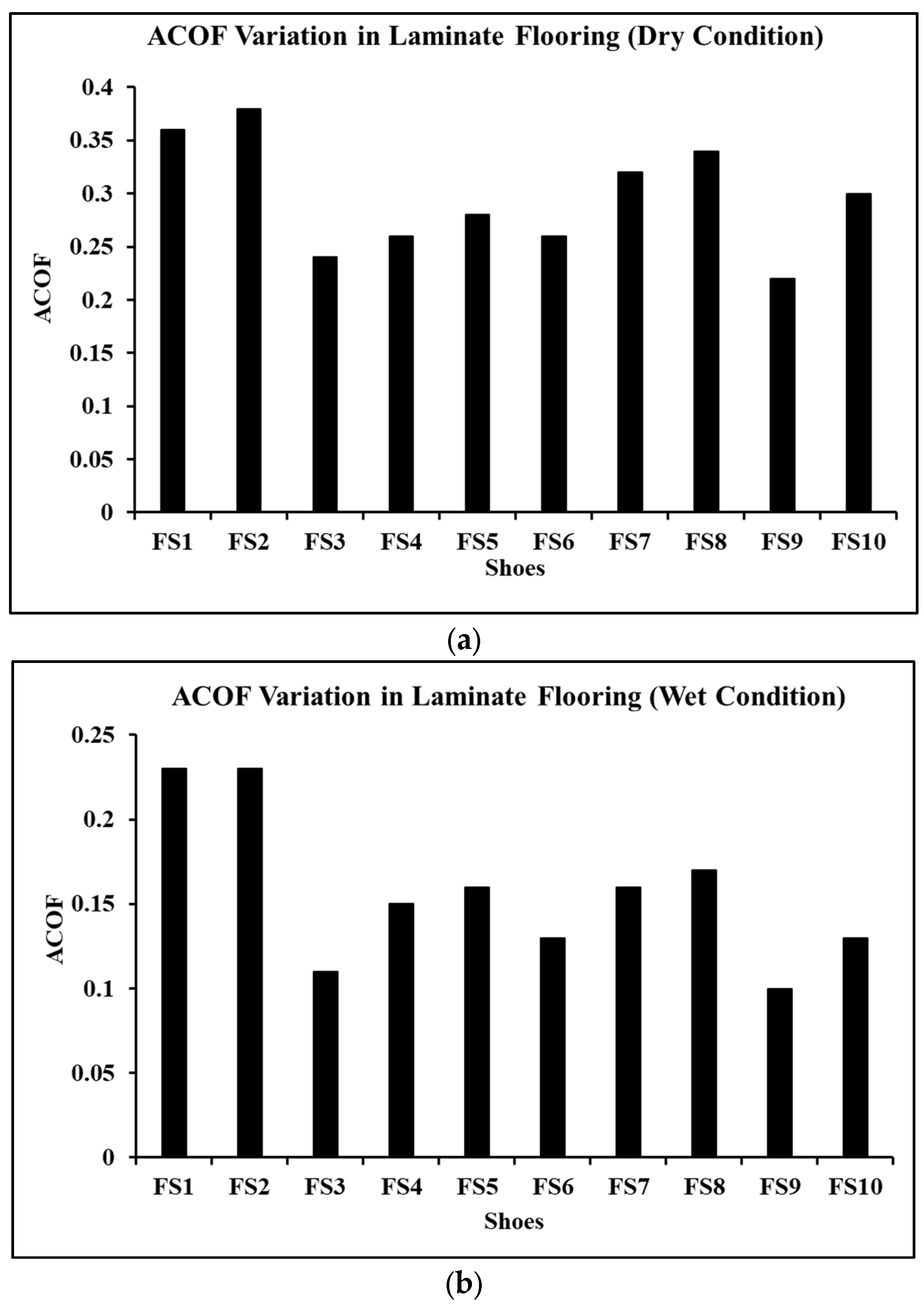

3.1. Traction Performance of Shoes across Laminate Flooring

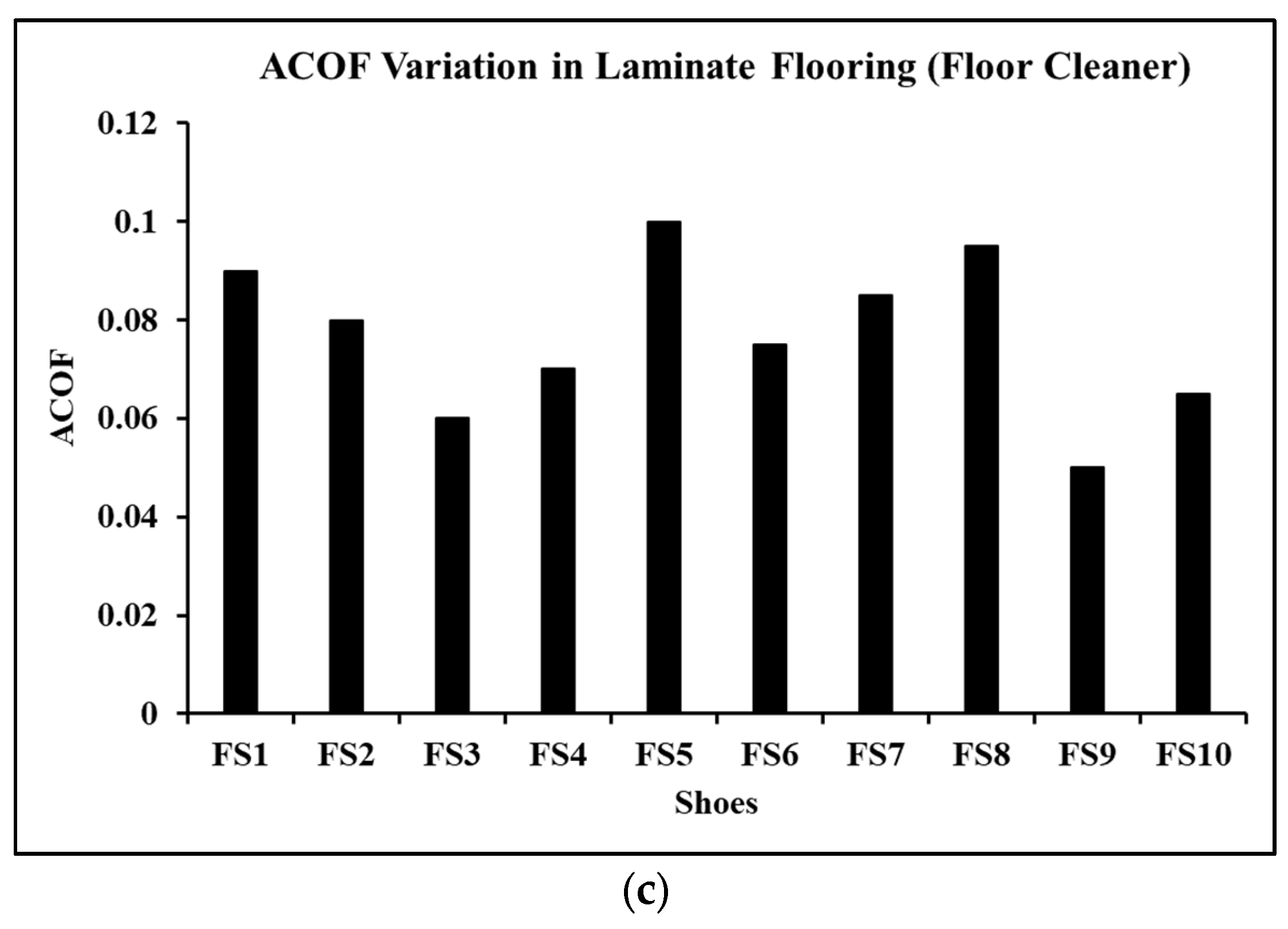

3.2. Traction Performance of Shoes across Matt Flooring

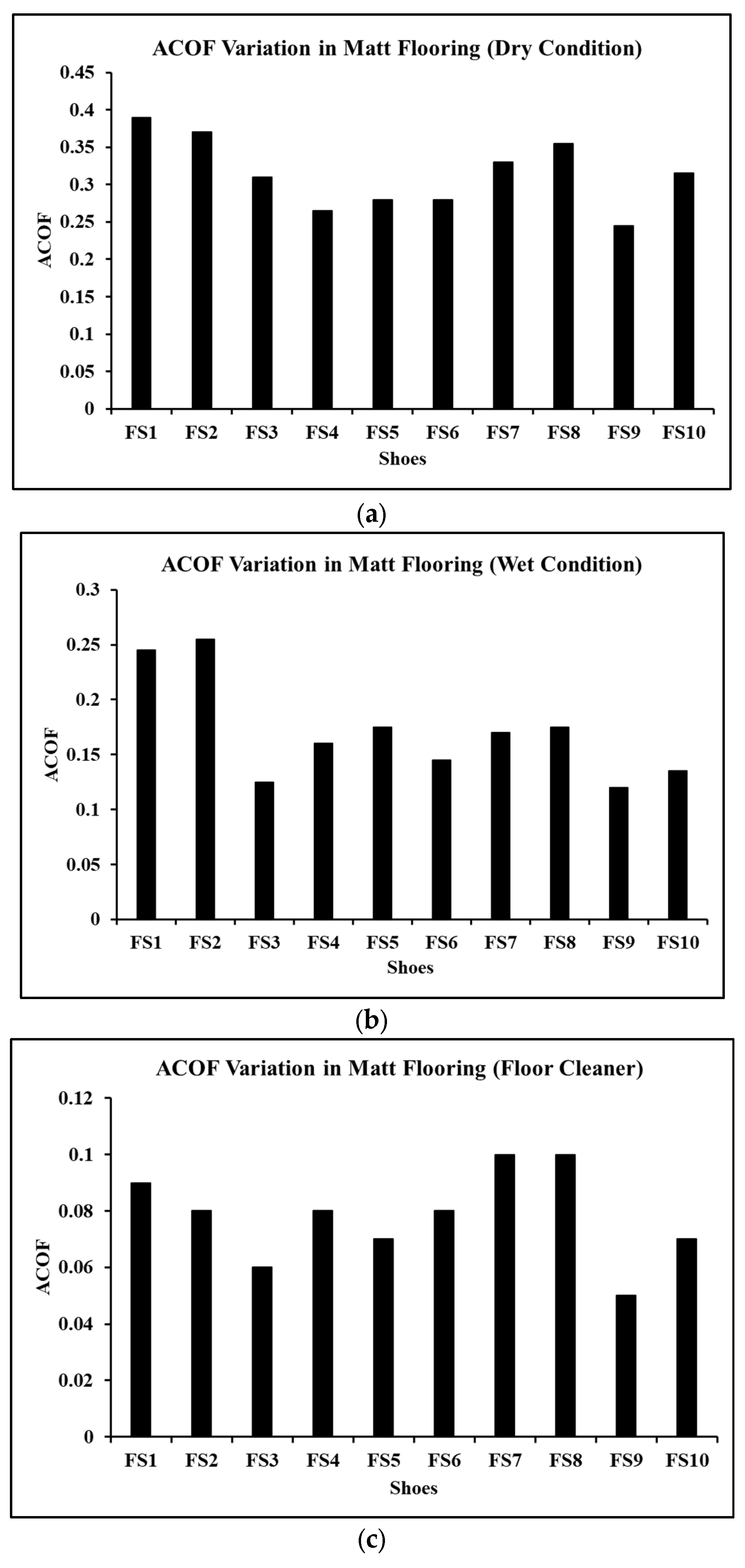

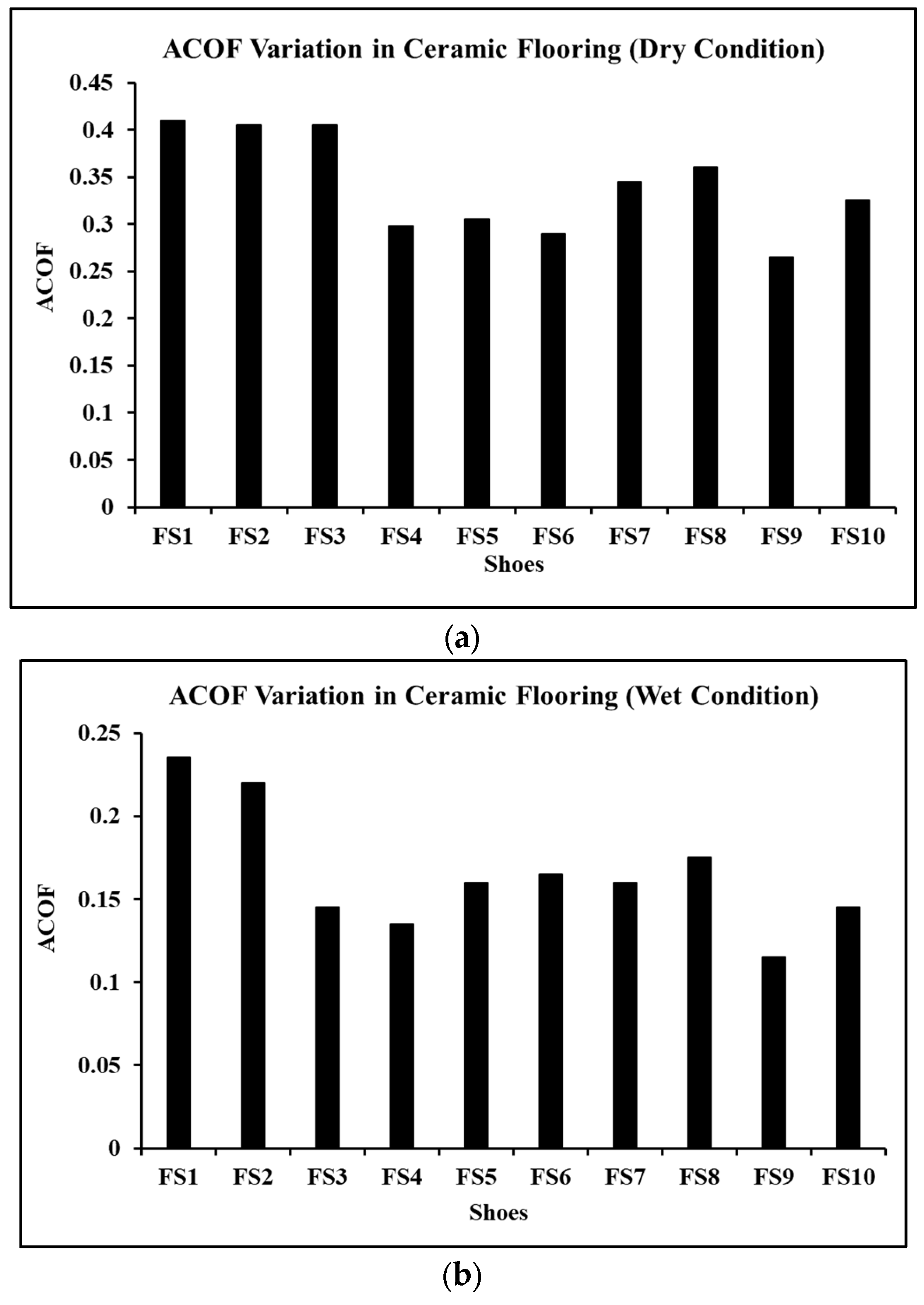

3.3. Traction Performance of Shoes across Ceramic Flooring

3.4. Effect of Footwear Characteristics on the Traction Performance

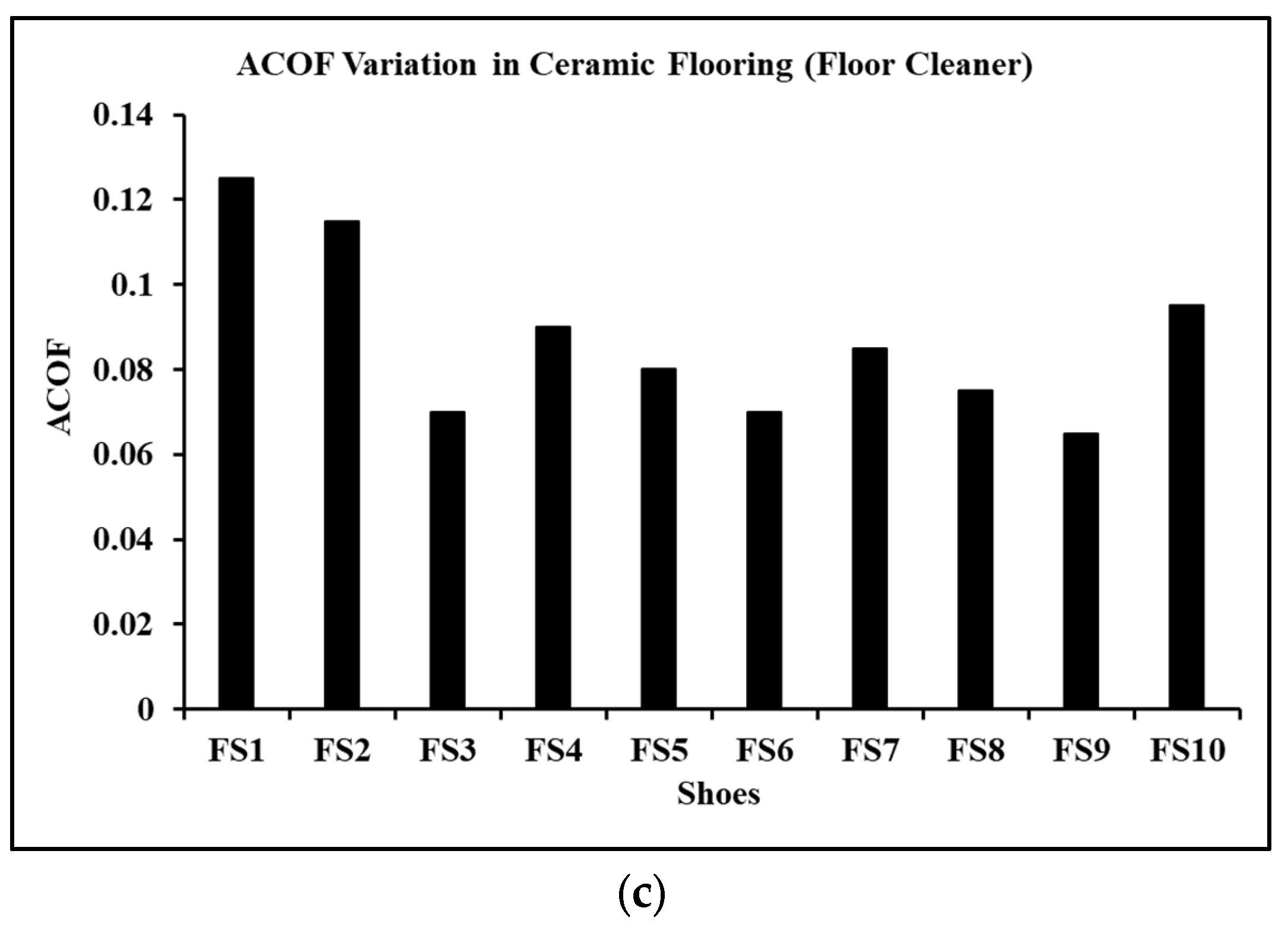

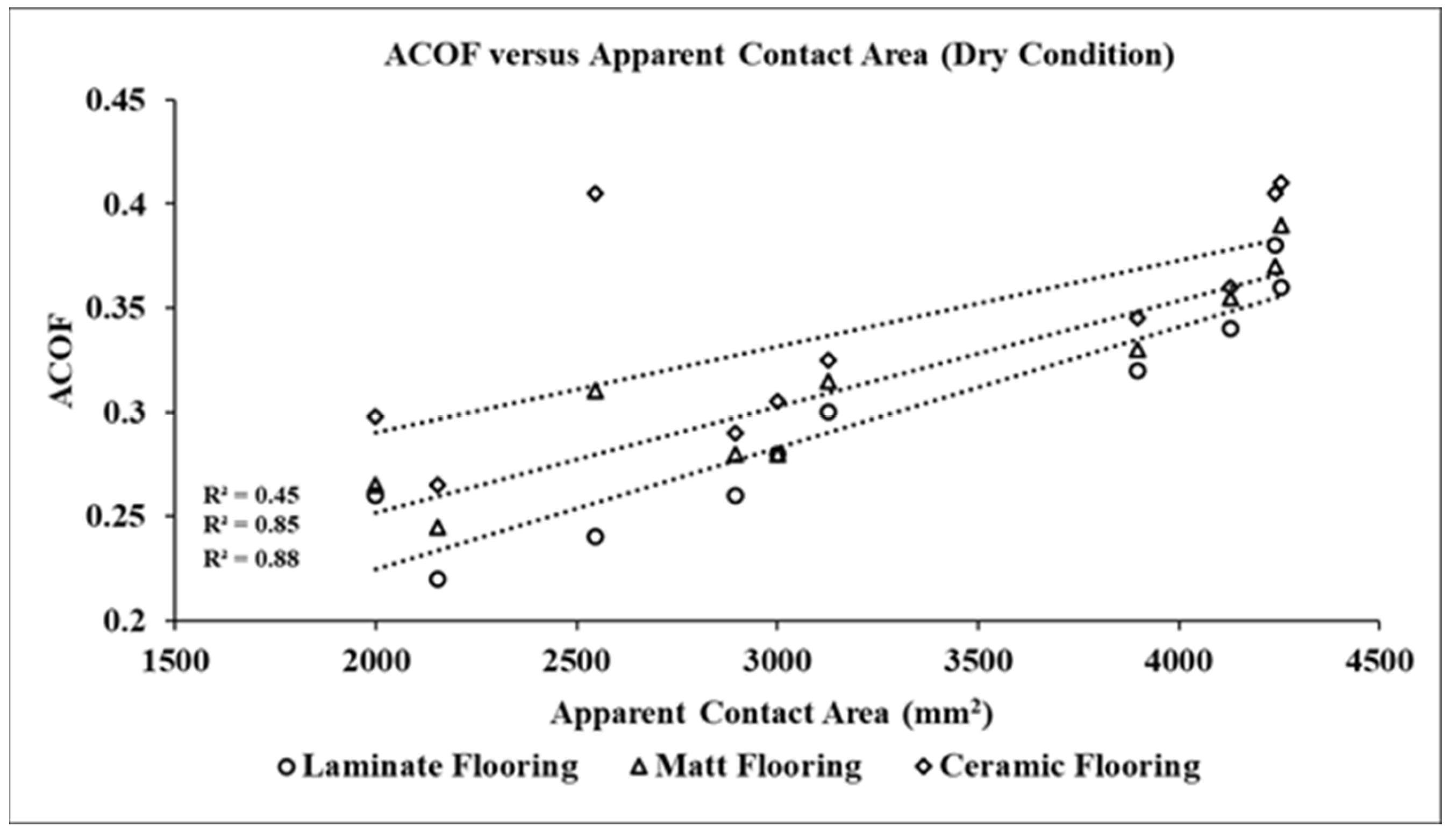

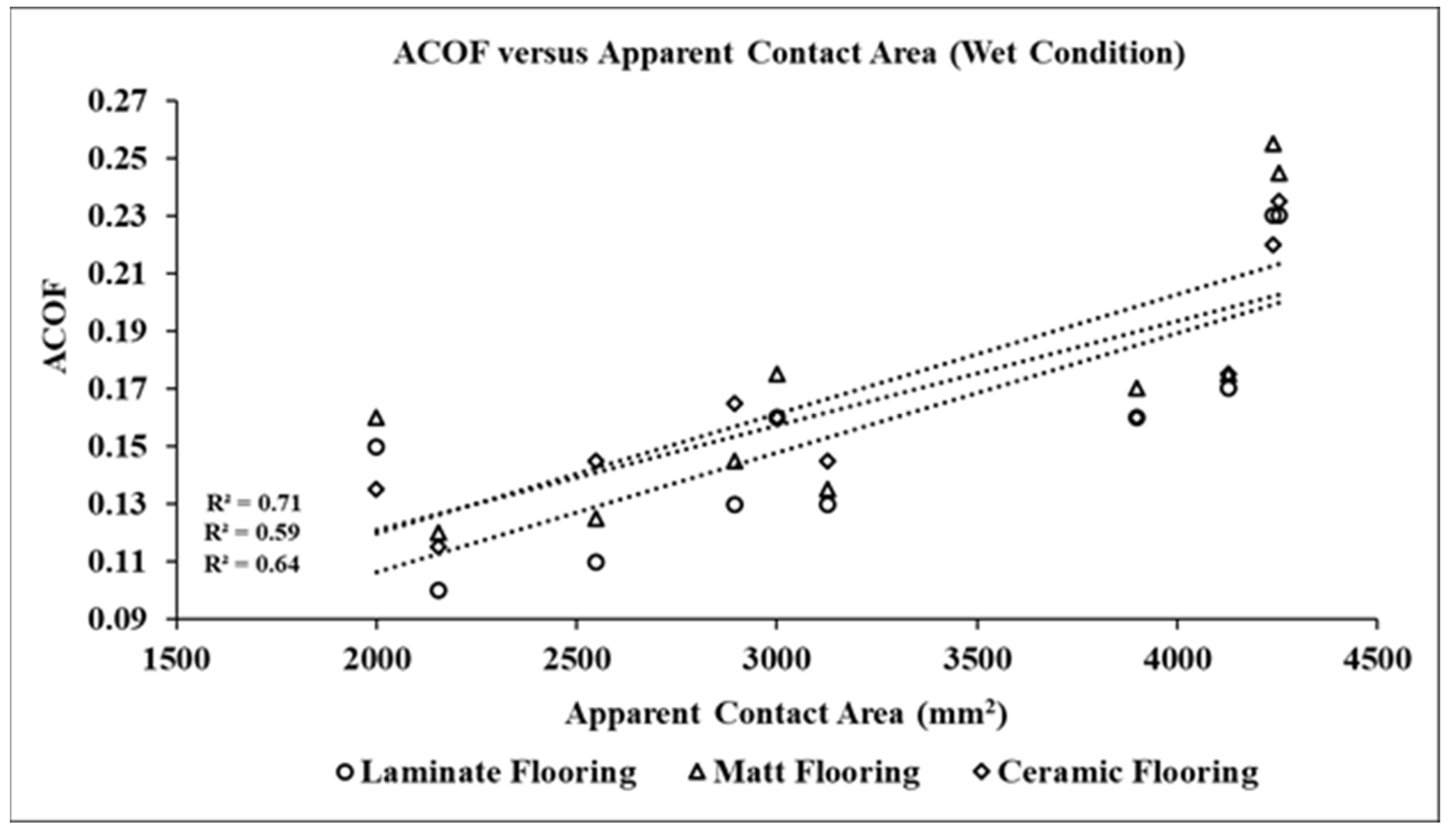

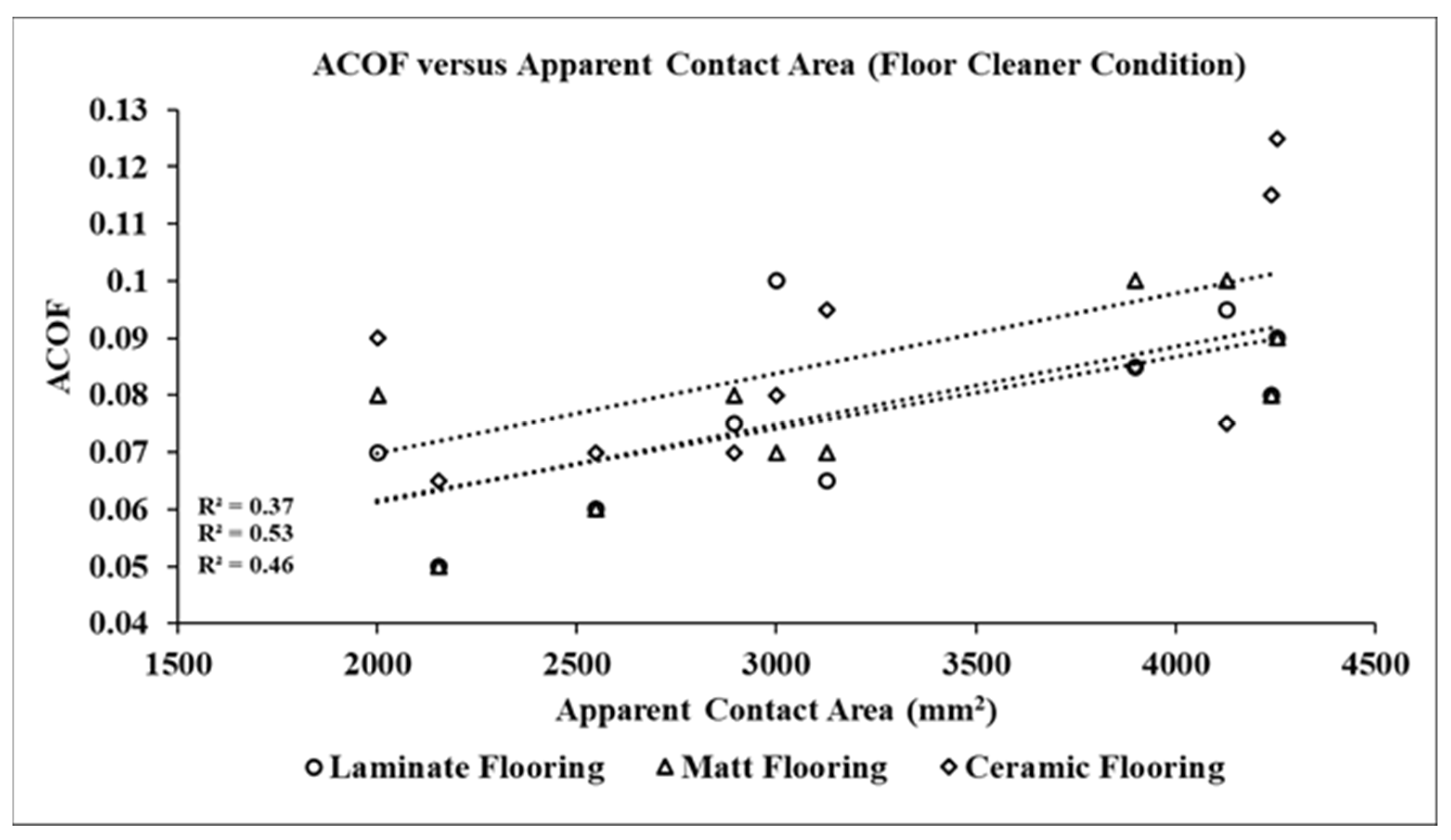

3.4.1. Effect of Apparent Contact Area on ACOF

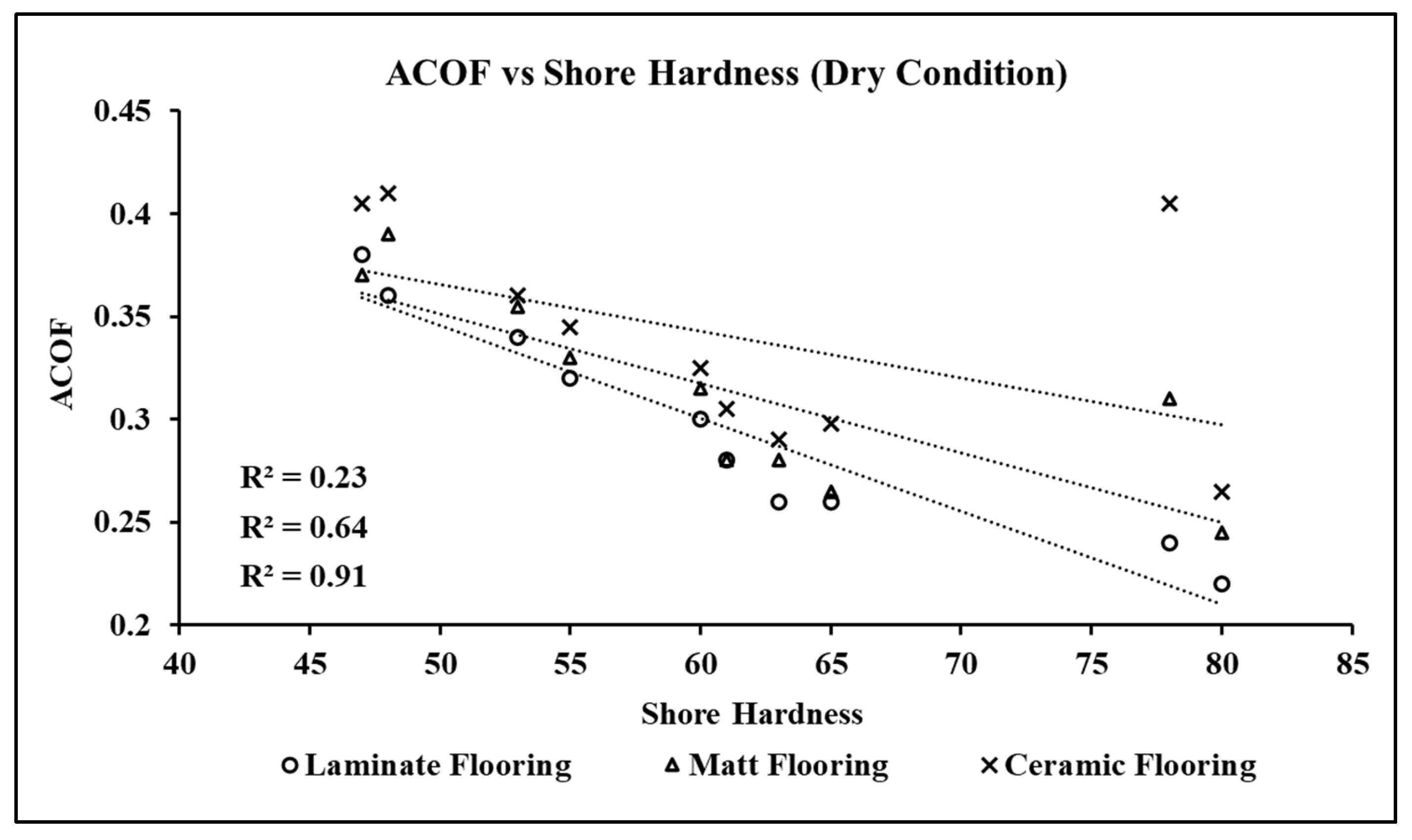

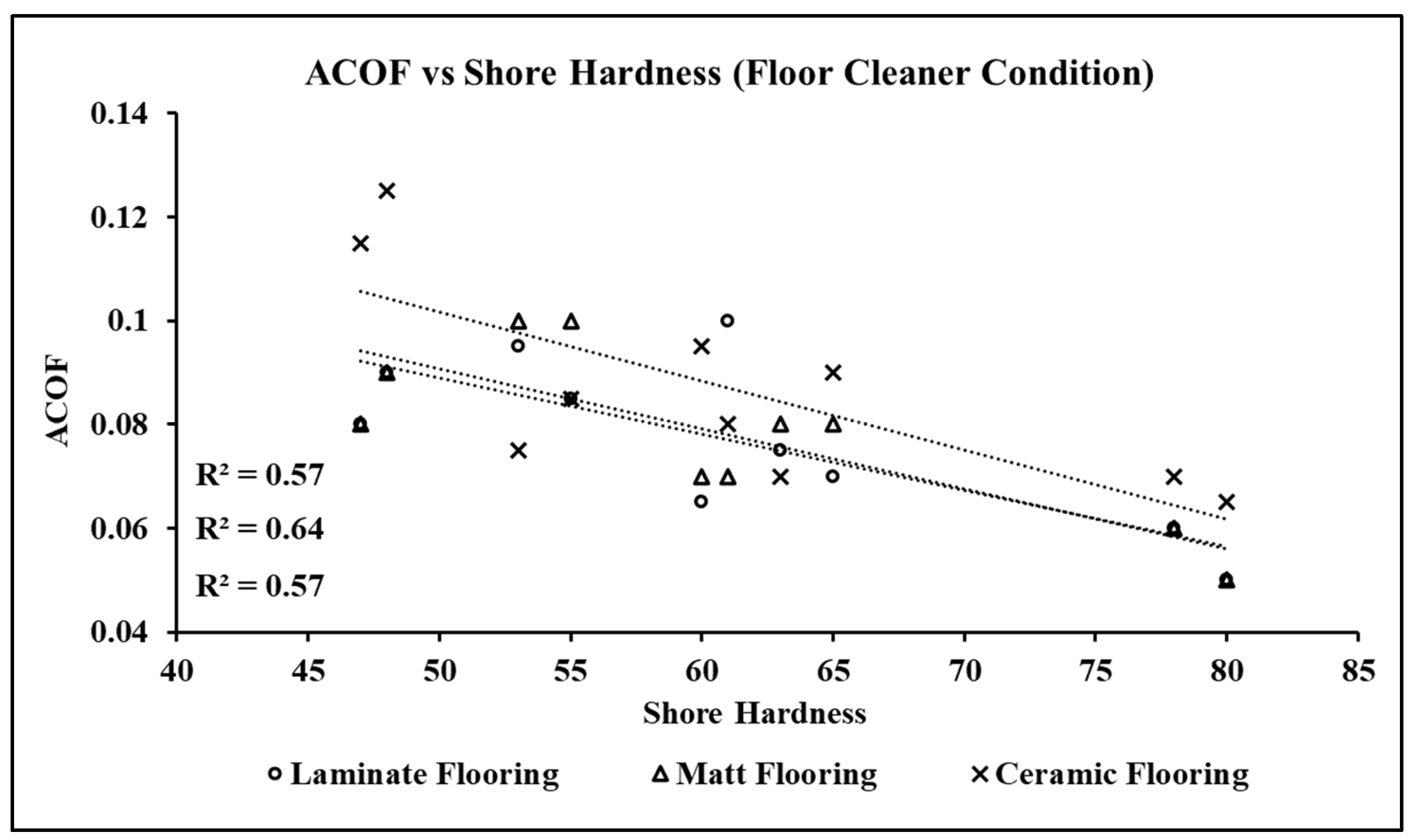

3.4.2. Effect of Shore Hardness on ACOF

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- WHO—World Health Organization. Falls. Available online: https://www.who.int/news-room/fact-sheets/detail/falls (accessed on 30 July 2022).

- Berg, W.P.; Alessio, H.M.; Mills, E.M.; Tong, C. Circumstances and consequences of falls in independent community-dwelling older adults. Age Ageing 1997, 26, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Bell, J.L.; Collins, J.W.; Wolf, L.; Grönqvist, R.; Chiou, S.; Chang, W.-R.; Sorock, G.S.; Courtney, T.; Lombardi, D.A.; Evanoff, B.A. Evaluation of a comprehensive slip, trip and fall prevention programme for hospital employees. Ergonomics 2009, 51, 1906–1925. [Google Scholar] [CrossRef] [PubMed]

- Campbell, A.J.; Borrie, M.J.; Spears, G.F.; Jackson, S.L.; Brown, J.S.; Fitzgerald, J.L. Circumstances and Consequences of Falls Experienced by a Community Population 70 Years and over during a Prospective Study. Age Ageing 1990, 19, 136–141. [Google Scholar] [CrossRef] [PubMed]

- Joseph, A.; Kumar, D.; Bagavandas, M. A Review of Epidemiology of Fall among Elderly in India. Indian J. Community Med. 2019, 44, 166. [Google Scholar] [CrossRef] [PubMed]

- Sirohi, A.; Kaur, R.; Goswami, A.K.; Mani, K.; Nongkynrih, B.; Gupta, S.K. A study of falls among elderly persons in a rural area of Haryana. Indian J. Public Health 2017, 61, 99–104. [Google Scholar] [CrossRef]

- Chacko, P.H.V. Epidemiology of fall and its risk factors among elders in a rural area of Coimbatore, India. Int. J. Community Med. Public Health 2017, 4, 3864–3869. [Google Scholar] [CrossRef][Green Version]

- Sharma, P.K.; Bunker, C.H.; Singh, T.; Ganguly, E.; Reddy, P.S.; Newman, A.B.; Cauley, J.A. Burden and Correlates of Falls among Rural Elders of South India: Mobility and Independent Living in Elders Study. Curr. Gerontol. Geriatr. Res. 2017, 2017, 1290936. [Google Scholar] [CrossRef]

- Bhatt, H.; Sharma, P. Slip, trip and falls among women of different age groups: A case study from the northern hills of India. J. Appl. Nat. Sci. 2017, 9, 614–620. [Google Scholar] [CrossRef][Green Version]

- Liberty Manual Insurance. Liberty Mutual Workplace Safety Index; Liberty Manual Insurance: Boston, MA, USA, 2017. [Google Scholar]

- Di Pilla, S. Slip, Trip, and Fall Prevention: A Practical Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Jabbour, R.; Turner, S.; Hussey, L.; Page, F.; Agius, R. Workplace injury data reported by occupational physicians and general practitioners. Occup. Med. 2015, 65, 296–302. [Google Scholar] [CrossRef]

- Strandberg, L.; Lanshammar, H. The dynamics of slipping accidents. J. Occup. Accid. 1981, 3, 153–162. [Google Scholar] [CrossRef]

- Hanson, J.P.; Redfern, M.S.; Mazumdar, M. Predicting slips and falls considering required and available friction. Ergonomics 2010, 42, 1619–1633. [Google Scholar] [CrossRef]

- Beschorner, K.E.; Li, Y.S.; Yamaguchi, T.; Ells, W.; Bowman, R. The Future of Footwear Friction. In Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2021; Volume 223, pp. 841–855. [Google Scholar] [CrossRef]

- Beschorner, K.E.; Iraqi, A.; Redfern, M.S.; Cham, R.; Li, Y. Predicting slips based on the STM 603 whole-footwear tribometer under different coefficient of friction testing conditions. Ergonomics 2019, 62, 668–681. [Google Scholar] [CrossRef]

- Beschorner, K.E.; Redfern, M.S.; Porter, W.L.; Debski, R.E. Effects of slip testing parameters on measured coefficient of friction. Appl. Ergon. 2007, 38, 773–780. [Google Scholar] [CrossRef]

- Chang, W.-R.; Grönqvist, R.; Leclercq, S.; Myung, R.; Makkonen, L.; Strandberg, L.; Brungraber, R.J.; Mattke, U.; Thorpe, S.C. The role of friction in the measurement of slipperiness, Part 1: Friction mechanisms and definition of test conditions. Ergonomics 2001, 44, 1217–1232. [Google Scholar] [CrossRef]

- Sundaram, V.H.; Hemler, S.L.; Chanda, A.; Haight, J.M.; Redfern, M.S.; Beschorner, K.E. Worn region size of shoe outsole impacts human slips: Testing a mechanistic model. J. Biomech. 2020, 105, 109797. [Google Scholar] [CrossRef]

- Chang, W.-R.; Grönqvist, R.; Leclercq, S.; Brungraber, R.J.; Mattke, U.; Strandberg, L.; Thorpe, S.C.; Myung, R.; Makkonen, L.; Courtney, T. The role of friction in the measurement of slipperiness, Part 2: Survey of friction measurement devices. Ergonomics 2001, 44, 1233–1261. [Google Scholar] [CrossRef]

- Aschan, C.; Hirvonen, M.; Mannelin, T.; Rajamäki, E. Development and validation of a novel portable slip simulator. Appl. Ergon. 2005, 36, 585–593. [Google Scholar] [CrossRef]

- Beschorner, K.E.; Siegel, J.L.; Hemler, S.L.; Sundaram, V.H.; Chanda, A.; Iraqi, A.; Haight, J.M.; Redfern, M.S. An observational ergonomic tool for assessing the worn condition of slip-resistant shoes. Appl. Ergon. 2020, 88, 103140. [Google Scholar] [CrossRef]

- Gupta, S.; Sidhu, S.S.; Chatterjee, S.; Malviya, A.; Singh, G.; Chanda, A. Effect of Floor Coatings on Slip-Resistance of Safety Shoes. Coatings 2022, 12, 1455. [Google Scholar] [CrossRef]

- Beschorner, K.E.; Chanda, A.; Moyer, B.E.; Reasinger, A.; Griffin, S.C.; Johnston, I.M. Validating the ability of a portable shoe-floor friction testing device, NextSTEPS, to predict human slips. Appl. Ergon. 2022, 106, 103854. [Google Scholar] [CrossRef]

- Jakobsen, L.; Lysdal, F.G.; Bagehorn, T.; Kersting, U.G.; Sivebaek, I.M. Evaluation of an actuated force plate-based robotic test setup to assess the slip resistance of footwear. Int. J. Ind. Ergon. 2022, 88, 103253. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Katsurashima, Y.; Hokkirigawa, K. Effect of rubber block height and orientation on the coefficients of friction against smooth steel surface lubricated with glycerol solution. Tribol. Int. 2017, 110, 96–102. [Google Scholar] [CrossRef]

- Singh, G.; Beschorner, K.E. A Method for Measuring Fluid Pressures in the Shoe–Floor–Fluid Interface: Application to Shoe Tread Evaluation. IIE Trans. Occup. Ergon. Hum. Factors 2014, 2, 53–59. [Google Scholar] [CrossRef] [PubMed]

- Li, K.W.; Chen, C.J. The effect of shoe soling tread groove width on the coefficient of friction with different sole materials, floors, and contaminants. Appl. Ergon. 2004, 35, 499–507. [Google Scholar] [CrossRef] [PubMed]

- Li, K.W.; Chin, J.C. Effects of tread groove orientation and width of the footwear pads on measured friction coefficients. Saf. Sci. 2005, 43, 391–405. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Umetsu, T.; Ishizuka, Y.; Kasuga, K.; Ito, T.; Ishizawa, S.; Hokkirigawa, K. Development of new footwear sole surface pattern for prevention of slip-related falls. Saf. Sci. 2012, 50, 986–994. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Hokkirigawa, K. Development of a High Slip-resistant Footwear Outsole Using a Hybrid Rubber Surface Pattern. Ind. Health 2014, 52, 414–423. [Google Scholar] [CrossRef]

- Jakobsen, L.; Lysdal, F.G.; Bagehorn, T.; Kersting, U.G.; Sivebaek, I.M. The effect of footwear outsole material on slip resistance on dry and contaminated surfaces with geometrically controlled outsoles. Ergonomics 2022. ahead of print. [Google Scholar] [CrossRef]

- Nishi, T.; Yamaguchi, T.; Hokkirigawa, K. Development of high slip-resistant footwear outsole using rubber surface filled with activated carbon/sodium chloride. Sci. Rep. 2022, 12, 267. [Google Scholar] [CrossRef]

- Gupta, S.; Chatterjee, S.; Chanda, A. Effect of footwear material wear on slips and falls. Mater. Today Proc. 2022, 62, 3508–3515. [Google Scholar] [CrossRef]

- Hemler, S.L.; Pliner, E.M.; Redfern, M.S.; Haight, J.M.; Beschorner, K.E. Effects of natural shoe wear on traction performance: A longitudinal study. Footwear Sci. 2021, 14, 1–12. [Google Scholar] [CrossRef]

- Iraqi, A.; Vidic, N.S.; Redfern, M.S.; Beschorner, K.E. Prediction of coefficient of friction based on footwear outsole features. Appl. Ergon. 2020, 82, 102963. [Google Scholar] [CrossRef]

- Derler, S.; Huber, R.; Kausch, F.; Meyer, V.R. Effectiveness, durability and wear of anti-slip treatments for resilient floor coverings. Saf. Sci. 2015, 76, 12–20. [Google Scholar] [CrossRef]

- Chatterjee, S.; Gupta, S.; Chanda, A. Barefoot Slip Risk in Indian Bathrooms: A Pilot Study. Tribol. Trans. 2022, 1–15. [Google Scholar] [CrossRef]

- Chatterjee, S.; Gupta, S.; Chanda, A. Barefoot slip risk assessment of Indian manufactured ceramic flooring tiles. Mater. Today Proc. 2022, 62, 3699–3706. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chanda, A. Development of a Tribofidelic Human Heel Surrogate for Barefoot Slip Testing. J. Bionic Eng. 2022, 19, 429–439. [Google Scholar] [CrossRef]

- Strobel, C.M.; Menezes, P.L.; Lovell, M.R.; Beschorner, K.E. Analysis of the contribution of adhesion and hysteresis to shoe-floor lubricated friction in the boundary lubrication regime. Tribol. Lett. 2012, 47, 341–347. [Google Scholar] [CrossRef]

- Chanda, A.; Jones, T.G.; Beschorner, K.E. Generalizability of Footwear Traction Performance across Flooring and Contaminant Conditions. Tribol. Lett. 2018, 6, 98–108. [Google Scholar] [CrossRef]

- Jones, T.; Iraqi, A.; Beschorner, K. Performance testing of work shoes labeled as slip resistant. Appl. Ergon. 2018, 68, 304–312. [Google Scholar] [CrossRef]

- Albert, D.; Moyer, B.; Beschorner, K.E. Three-Dimensional Shoe Kinematics During Unexpected Slips: Implications for Shoe–Floor Friction Testing. IISE Trans. Occup. Ergon. Hum. Factors 2017, 5, 1–11. [Google Scholar] [CrossRef]

- Redfern, M.S.; Cham, R.; Gielo-Perczak, K.; Grönqvist, R.; Hirvonen, M.; Lanshammar, H.; Marpet, M.; Pai, C.Y.C.; Powers, C.J. Biomechanics of slips. Ergonomics 2001, 44, 1138–1166. [Google Scholar] [CrossRef] [PubMed]

- ASTM F2913-19; Standard Test Method for Measuring the Coefficient of Friction for Evaluation of Slip Performance of Footwear and Test Surfaces/Flooring Using a Whole Shoe Tester. ASTM International: West Conshohocken, PA, USA, 2019.

- Iraqi, A.; Cham, R.; Redfern, M.S.; Beschorner, K.E. Coefficient of friction testing parameters influence the prediction of human slips. Appl. Ergon. 2018, 70, 118–126. [Google Scholar] [CrossRef] [PubMed]

- Hemler, S.L.; Charbonneau, D.N.; Iraqi, A.; Redfern, M.S.; Haight, J.M.; Moyer, B.E.; Beschorner, K.E. Changes in under-shoe traction and fluid drainage for progressively worn shoe tread. Appl. Ergon. 2019, 80, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Meehan, E.E.; Vidic, N.; Beschorner, K.E. In contrast to slip-resistant shoes, fluid drainage capacity explains friction performance across shoes that are not slip-resistant. Appl. Ergon. 2022, 100, 103663. [Google Scholar] [CrossRef]

- Hemler, S.L.; Pliner, E.M.; Redfern, M.S.; Haight, J.M.; Beschorner, K.E. Traction performance across the life of slip-resistant footwear: Preliminary results from a longitudinal study. J. Saf. Res. 2020, 74, 219–225. [Google Scholar] [CrossRef]

- Grönqvist, R. Mechanisms of friction and assessment of slip resistance of new and used footwear soles on contaminated floors. Ergonomics 2007, 38, 224–241. [Google Scholar] [CrossRef]

| Formal Footwear | Shore Hardness |

|---|---|

| FS1 | 48A |

| FS2 | 47A |

| FS3 | 78A |

| FS4 | 65A |

| FS5 | 61A |

| FS6 | 63A |

| FS7 | 55A |

| FS8 | 53A |

| FS9 | 80A |

| FS10 | 60A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, S.; Chatterjee, S.; Malviya, A.; Chanda, A. Traction Performance of Common Formal Footwear on Slippery Surfaces. Surfaces 2022, 5, 489-503. https://doi.org/10.3390/surfaces5040035

Gupta S, Chatterjee S, Malviya A, Chanda A. Traction Performance of Common Formal Footwear on Slippery Surfaces. Surfaces. 2022; 5(4):489-503. https://doi.org/10.3390/surfaces5040035

Chicago/Turabian StyleGupta, Shubham, Subhodip Chatterjee, Ayush Malviya, and Arnab Chanda. 2022. "Traction Performance of Common Formal Footwear on Slippery Surfaces" Surfaces 5, no. 4: 489-503. https://doi.org/10.3390/surfaces5040035

APA StyleGupta, S., Chatterjee, S., Malviya, A., & Chanda, A. (2022). Traction Performance of Common Formal Footwear on Slippery Surfaces. Surfaces, 5(4), 489-503. https://doi.org/10.3390/surfaces5040035