Mould Growth Risk for Internal Retrofit Insulation of Heritage-Protected Timber Plank Frame Walls

Abstract

1. Introduction

1.1. Climate Goals and Energy Consumption

1.2. Heritage Protection

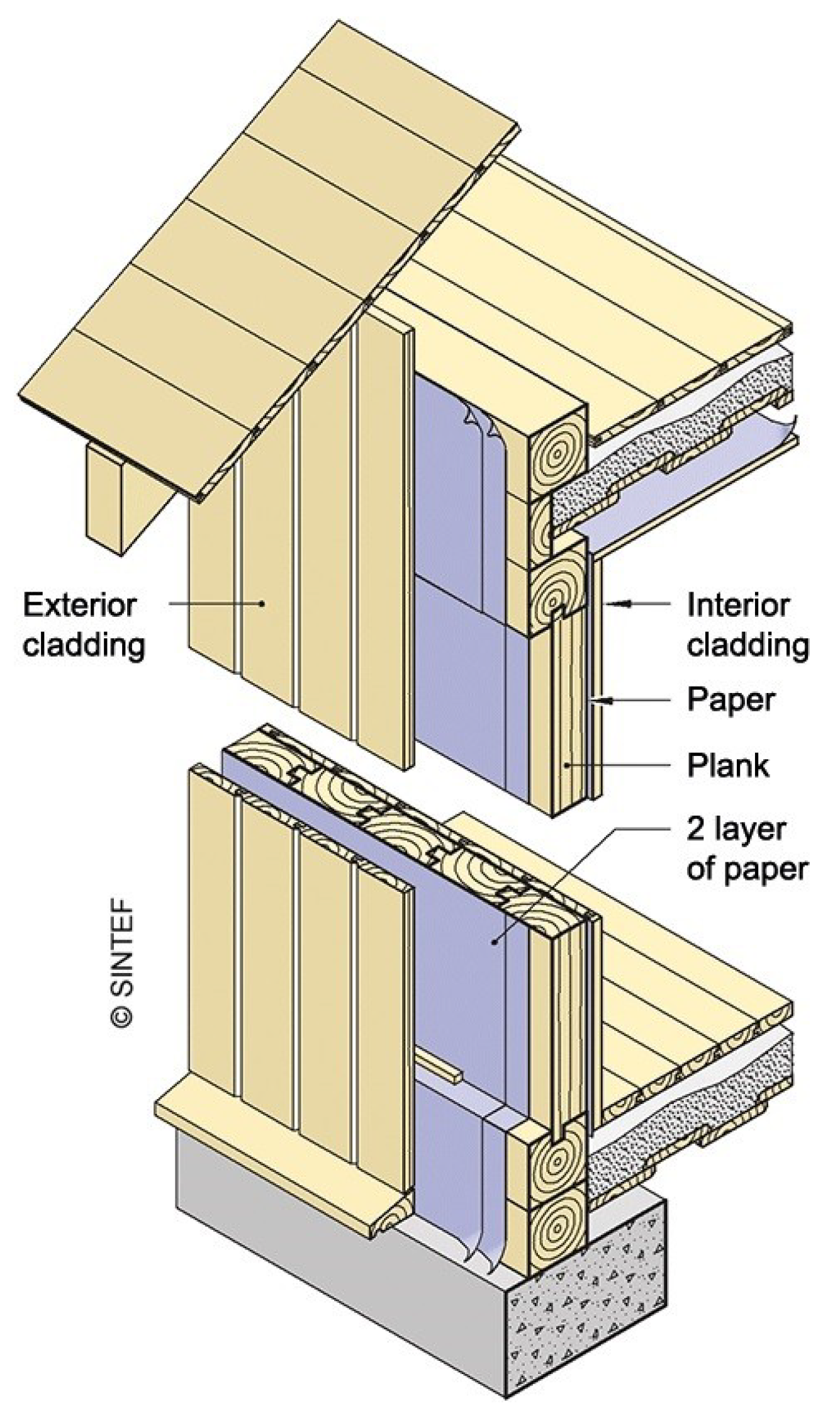

1.3. Historical Timber Plank Frame Buildings in Norway

1.4. Internal Insulation and Moisture Damage

1.5. Mould Growth Risk

1.6. Objective and Scope

- 1.

- What is the range of water vapour resistance for commonly used building papers in heritage-worthy buildings?

- 2.

- What are the effects of the water vapour resistance of building paper on the moisture performance of internally insulated timber plank frame walls?

- 3.

- What is the effect of moisture-adaptive vapour barriers on the possibilities for internal insulated timber plank frame walls?

2. Materials and Methods

2.1. Laboratory Measurements

2.1.1. Selection of Products

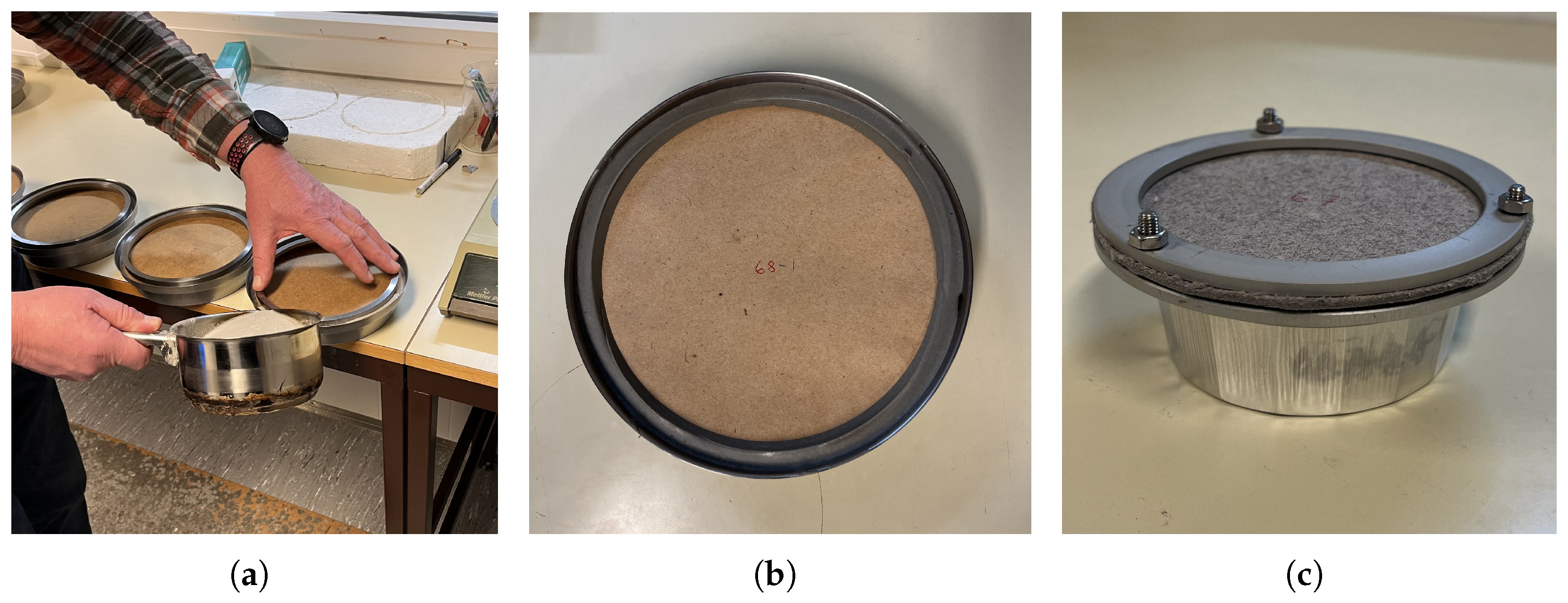

2.1.2. Preparation of Samples

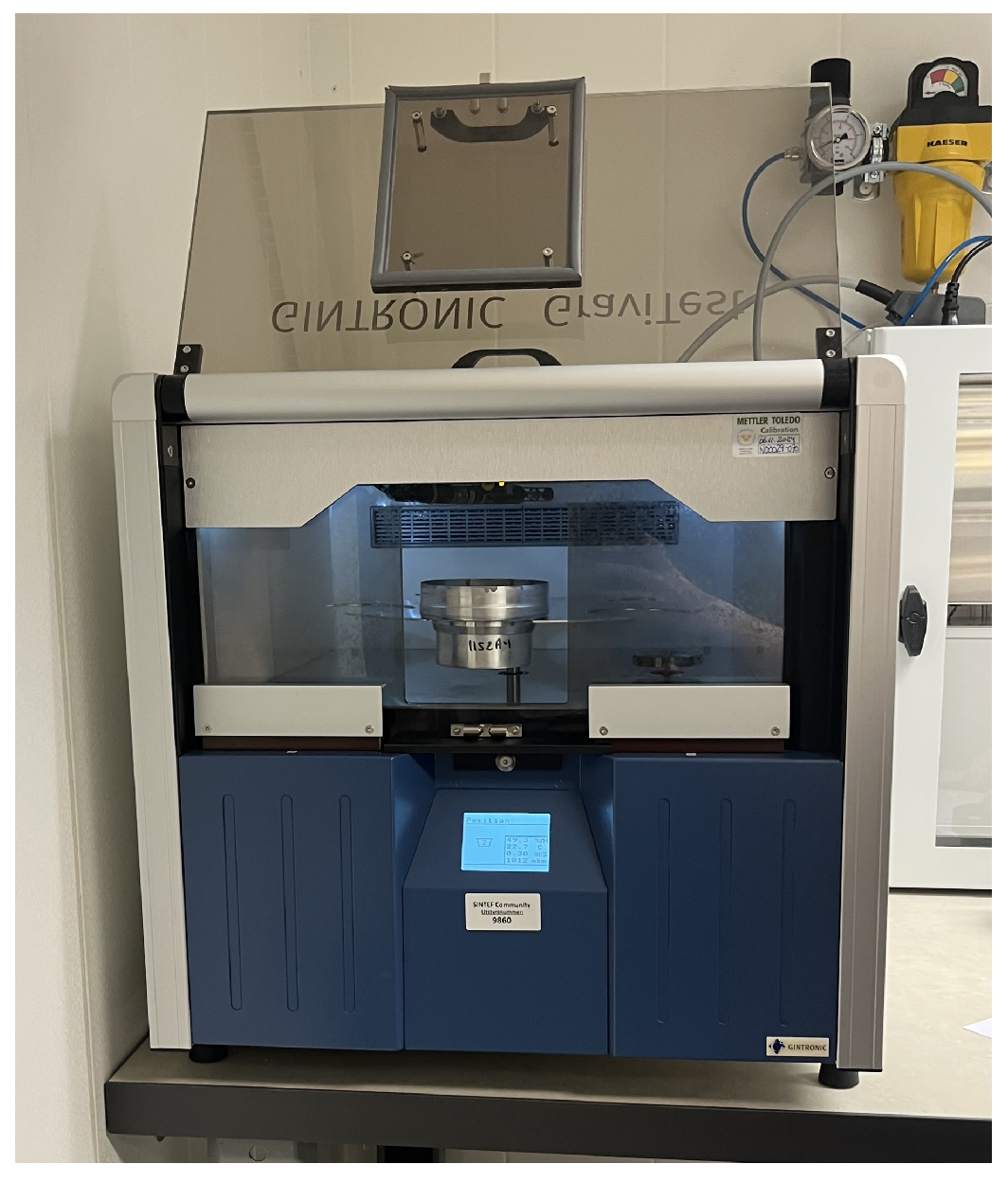

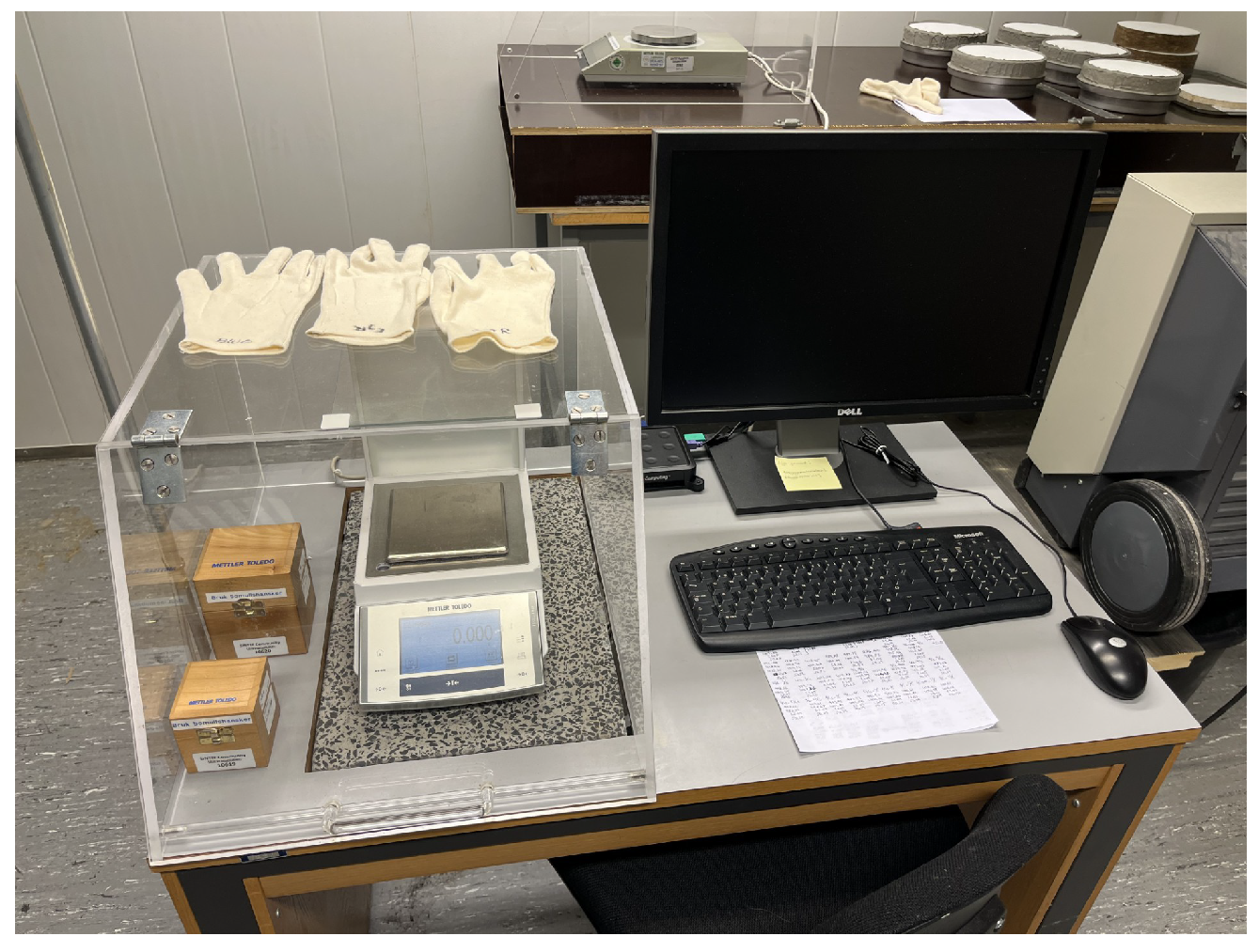

2.1.3. Test Procedure

2.2. WUFI® Pro Simulations

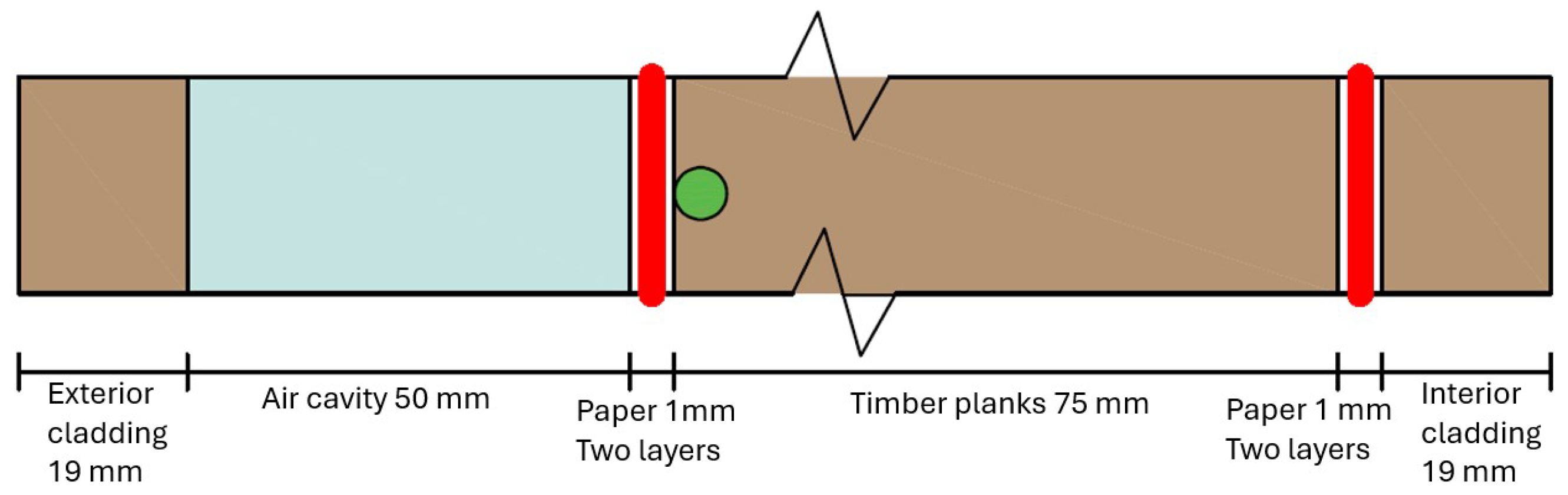

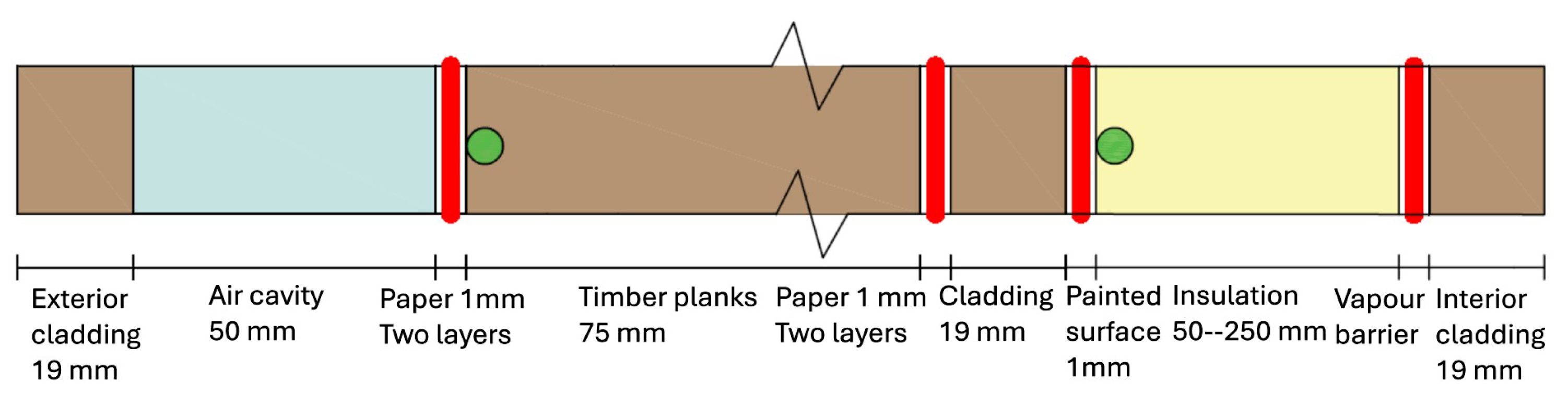

2.2.1. Geometry and Materials of the Original Wall

2.2.2. Geometry and Materials of Internally Retrofitted Wall

2.2.3. Simulation Input Data

2.2.4. Assessment of Mould Growth Risk

3. Results

3.1. Values of Building Paper

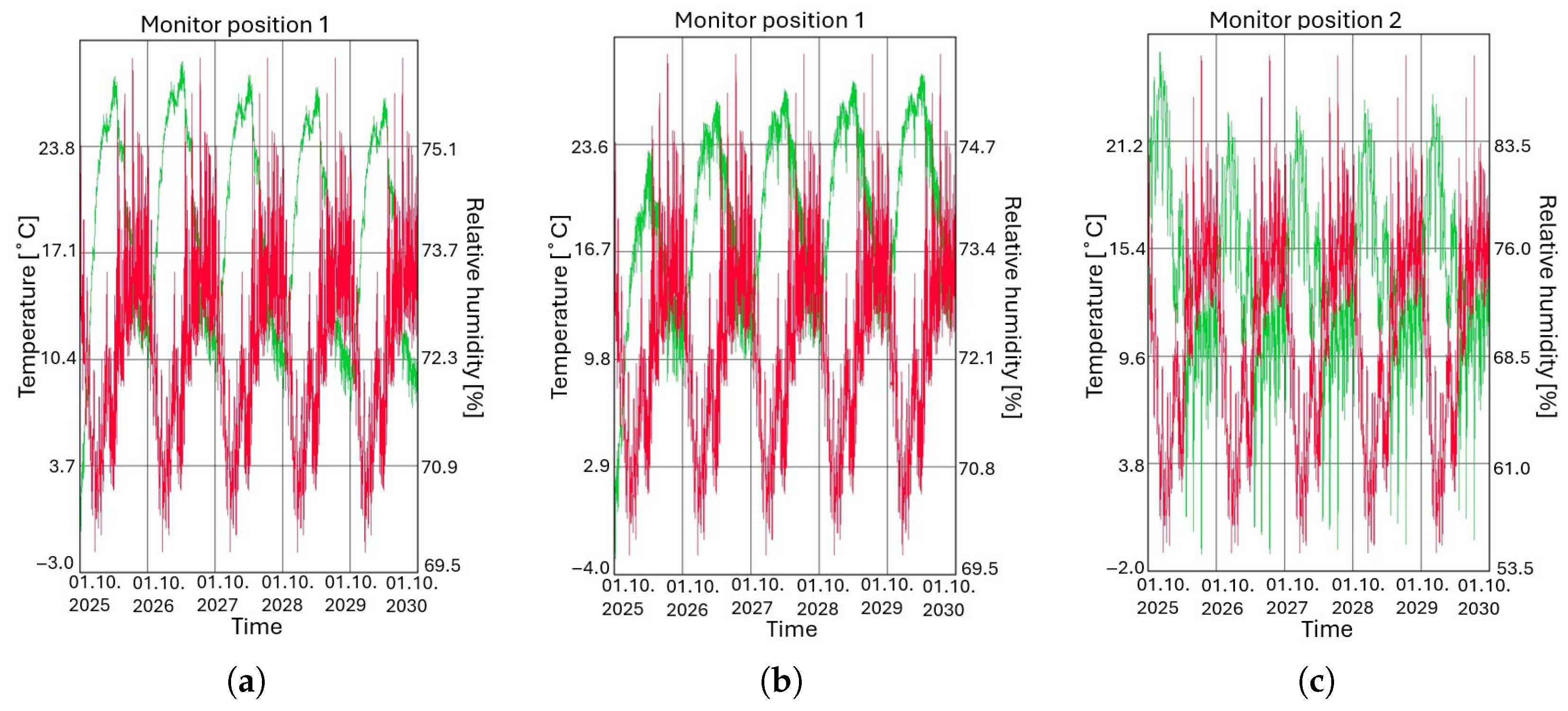

3.2. WUFI® Pro Simulations

- The exterior building paper was found to significantly affect the risk of mould growth for both the original wall and the internally retrofitted wall.

- Cases 1–4 were simulations of the original wall in different climates and with different types of exterior building paper. Cases 2 and 4, with vapour-permeable building paper (two layers of E1; value: 0.040 m) on the exterior side, revealed a reduced risk of mould growth compared to Cases 1 and 3, in which a more vapour-tight building paper was used (sample E3; value: 5.293 m).

- Cases 5–7 comprised different thicknesses of insulating mineral wool, with PE foil and building paper E3 ( value: 5.293 m) on the exterior side. From these simulations, it is clear that the thickness of the insulation has a large impact on the mould growth risk. An insulation thickness of 50 mm with a PE foil vapour barrier resulted in a low mould growth risk measure.

- Cases 8–9 demonstrate the effects of different thicknesses when a vapour-open exterior building paper (E1 with sd value 0.040 m) was applied. Such a vapour-open exterior building paper, together with a PE foil vapour barrier, allowed for an internal retrofit thickness of 100 mm.

- Case 10 demonstrated that the outdoor climate affects mould growth risk, as the location in Hamar had a lower mould growth risk than the location in Kristiansund (Case 7).

- Cases 11–13 had no vapour barrier on the interior side of the internally retrofit insulation. The simulation showed that the mould growth risk was high in all of these cases, independent of the climate and the vapour impermeability of the exterior building paper.

- Cases 14–16 included different thicknesses of wood fibre insulation in combination with exterior building paper E3 ( value: 5.293 m). This construction configuration allowed for an internal insulation thickness of 50 mm provided by a PE foil vapour barrier.

- Cases 17–19 revealed that the mould growth risk was high for all cases with MAVB, independent of the thickness of the insulation.

- Case 20 included a shortwave radiation absorptivity of 0.8, which matched the dark-coloured exterior cladding. This case revealed that the shortwave radiation absorptivity rate had a low impact on the mould growth risk of the wall, which was also the case when MAVB was applied. A shortwave radiation absorptivity of 0.8 did not contribute to a lower risk of mould growth compared to Case 17, with a shortwave radiation absorptivity rate of 0.4.

- Case 21 shows that an indoor climate with a lower humidity class (i.e., lowering from class 3 to class 2) significantly reduced the mould growth risk.

4. Discussion

4.1. Vapour Resistance of Types of Building Paper

4.2. Moisture Performance of Internally Insulated Timber Plank Frame Walls

4.3. Moisture Performance of the Internally Retrofitted Wall with MAVB

4.4. Assumptions for the Simulations

4.5. Limitations and Future Studies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. European Climate Law. 2024. Available online: https://climate.ec.europa.eu/eu-action/european-climate-law_en (accessed on 7 March 2025).

- Bjelland, D.; Gullbrekken, L.; Hrynyszyn, B.D.; Kvande, T. Is Heritage Protection a Limiting Factor for Passive Deep Energy Retrofitting? A Cold-Climate Case Study of University Buildings. Heritage 2025, 8, 88. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. DIRECTIVE (EU) 2023/1791 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 13 September 2023, on Energy Efficiency and Amending Regulation (EU) 2023/955 (Recast) (Text with EEA Relevance). 2023. Available online: https://eur-lex.europa.eu/eli/dir/2023/1791/oj/eng (accessed on 7 March 2025).

- Norwegian Technical Requirements for Construction Works (TEK17). 2017. Available online: https://lovdata.no/dokument/SF/forskrift/2017-06-19-840 (accessed on 7 March 2025).

- Grytli, E.; Andresen, I.; Hermstad, K.; Knudsen, W. Fiin Gammel Aargang; SINTEF Bygg og miljø: Trondheim, Norway, 2004; Available online: https://www.sintef.no/globalassets/upload/fiin_gammel_aargang.pdf (accessed on 1 October 2024).

- Riksantikvaren. Råd om Energisparing i Gamle Hus. 2022. Available online: https://www.riksantikvaren.no/veileder/rad-om-energisparing-i-gamle-hus/#section1 (accessed on 3 February 2025).

- European Commission. Final Report Summary—EFFESUS (ENERGY EFFICIENCY FOR EU HISTORIC DISTRICTS SUSTAINABILITY). 2024. Available online: https://cordis.europa.eu/project/id/314678/reporting/it (accessed on 7 March 2025).

- Lovdata. Plan- og Bygningsloven. Lov om Planlegging og Byggesaksbehandling. LOV-2008-06-27-71. 2025. Available online: https://lovdata.no/dokument/NL/lov/2008-06-27-71 (accessed on 9 March 2025).

- Trondheim kommune. Kriterier for A, B og C-klassifisering. 2022. Available online: https://www.trondheim.kommune.no/tema/bygg-kart-og-eiendom/bygging/byantikvaren/aktsomhetskart-kulturminner/kriterier-for-abc-klassifisering/#bygninger_med_antikvarisk_verdi_ab_og_c (accessed on 9 March 2025).

- Edvardsen, K.I.; Ramstad, T.Ø. Trehusbygging i Norge. In Trehus håNdbok 5; Haug, T., Ed.; SINTEF akademisk forlag: Oslo, Norway, 2018; ISBN 978-82-536-1391-8. [Google Scholar]

- Ritchie, T. The Use of Planks in Wall Construction. Bull. Assoc. Preserv. Technol. 1974, 6, 26–34. Available online: https://www.jstor.org/stable/1493482 (accessed on 21 March 2025). [CrossRef][Green Version]

- Drange, T.; Aanensen, H.O.; Brænne, J. Gamle Trehus; Universitetsforlaget AS: Oslo, Norway, 1996; pp. 117–118. ISBN 82-00-21389-7. [Google Scholar]

- Edvardsen, K.I. 723.305 Eldre Vegger av Reisverk. Metoder og Materialer; Byggforskserien; SINTEF: Trondheim, Norway, 2017; Available online: https://www.byggforsk.no/dokument/676/eldre_vegger_av_reisverk_metoder_og_materialer# (accessed on 3 February 2025).

- Bugge, A. Husbygningslære; H. Aschehoug & co: Oslo, Norway, 1918; pp. 381–428. Available online: https://www.nb.no/items/URN:NBN:no-nb_digibok_2016052707029?page=5 (accessed on 8 April 2025).

- Roede, L. Gode Råd om Yttervegger i Eldre Trehus; Fortidsminneforeningen: Oslo, Norway, 2009; ISSN 0332-7205. [Google Scholar]

- Bøhlerengen, T. 723.511 Etterisolering av Yttervegger av Tre; Byggforskserien: Oslo, Norway; SINTEF: Trondheim, Norway, 2023; Available online: https://www.byggforsk.no/dokument/679/etterisolering_av_yttervegger_av_tre#i9 (accessed on 9 April 2025).

- Bergheim, E.; Geving, S.; Gullbrekken, L. Bruk av Eldre Sperresjikt ved Etterisolering; Byggeindustrien: Oslo, Norway, 2020; p. 26. [Google Scholar]

- Tveit, A. Vanndampdiffusjonstall for Papp og Trefiberplater; Johan Grundt Tanum Forlag: Oslo, Norway, 1954; ISBN 532.72:691.14. [Google Scholar]

- Bottino-Leone, D.; Larcher, M.; Herrera-Avellansosa, D.; Haas, F. Evaluation of natural-based internal insulation systems in historic buildings through a holistic approach. Energy 2019, 181, 521–531. [Google Scholar] [CrossRef]

- NS-EN 16883:2017; Conservation of Cultural Heritage. Guidelines for Improving the Energy Performance of Historic Buildings. Standard Norge: Oslo, Norway, 2017.

- Lisø, K.R.; Kvande, T.; Thue, J.V. Learning from experience—An analysis of process induced building defects in Norway. In Proceedings of the 3rd International Building Physics Conference—Research in Building Physics and Building Engineering, Montreal, QC, Canada, 27–31 August 2006; Taylor & Francis: Montreal, QC, Canada, 2006; pp. 425–432. [Google Scholar]

- Knarud, J.I.B. Hygrothermal Modeling of Masonry with Interior Insulation Retrofit. Perspectives on Hygrothermal Performance and Modeling-Uncertainty. Doctoral Thesis, Norwegian University of Science and Technology, Faculty of Engineering, Department of Civil and Environmental Engineering, Trondheim, Norway, 2024. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/3115856 (accessed on 20 May 2025).

- Klõšeiko, P. Hygrothermal Performance of Masonry Walls Retrofitted with Interior Insulation in Cold Climate. Ph.D. Thesis, Department of Civil Engineering and Architecture, Tallinn University of Technology, Tallinn, Estonia, 2022. [Google Scholar]

- Gutland, M.J. Evaluating Uncertainty in Hygrothermal Modelling of Heritage Masonry Buildings. Ph.D. Thesis, Carleton University, Ottawa, Canada, 2022. [Google Scholar]

- Soulios, V. Hygrothermal Performance of Hydrophobized Brick and Mortar: Energy Renovation Through Internal Insulation-Can Hydrophobization Improve the Moisture Safety? Ph.D. Thesis, Department of the Build Environment, Aalborg University, Aalborg, Denmark, 2021. [Google Scholar]

- Jensen, N.F. Robust Solutions for Internal Retrofitting Solid Masonry Walls in Historic Buildings with Regards to Hygrothermal Performance. Ph.D. Thesis, Department of Civil Engineering, Technical University of Denmark, Lyngby, Denmark, 2021. [Google Scholar]

- Calle, K. Renovation of Historical Facades: The Rescue or the Kiss of Death? Doctoral Dissertation, Faculteit Ingenieurswetenschappen en Architectuur, Vakgroep Architectuur en Stedenbouw, Ghent University, Ghent, Belgium, 2020. [Google Scholar]

- Ruisinger, U. Das hygrothermische Verhalten von Balkenköpfen bei innen gedämmten Gebäuden. Ph.D. Thesis, Institut für Hochbau, Technischen Universität Graz, Dresden, Germany, 2019. [Google Scholar]

- Odgaard, T.R. Challenges When Retrofitting Multi-Storey Buildings with Interior Thermal Insulation. Ph.D. Thesis, Department of Civil Engineering, Technical University of Denmark, Lyngby, Denmark, 2019. [Google Scholar]

- Kolatis, D.I.; Malliotakis, E.; Kontogeorgos, D.A.; Mandilaras, I.; Katsourinis, D.I.; Founti, M.A. Comparative assessment of internal and external thermal insulation systems for energy efficient retrofitting of residential buildings. Energy Build. 2013, 64, 123–131. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Thermal performance of a selection of insulation materials suitable for historic buildings. Build. Environ. 2015, 94, 155–165. [Google Scholar] [CrossRef]

- Pagoni, P.; Møller, E.B.; Peuhkuri, R.H.; Jensen, N.F. Evaluation of the performance of different internal insulation systems in real-life conditions—A case study. Build. Environ. 2025, 267, 112319. [Google Scholar] [CrossRef]

- Lucchi, E.; Tabak, M.; Troi, A. The “Cost Optimality” Approach for the Internal Insulation of Historic Buildings. Energy Procedia 2017, 133, 412–423. [Google Scholar] [CrossRef]

- Harrestup, M.; Svendsen, S. Full-scale test of an old heritage multi-storey building undergoing energy retrofitting with focus on internal insulation and moisture. Build. Environ. 2015, 85, 123–133. [Google Scholar] [CrossRef]

- Finken, G.R.; Bjarløv, S.P.; Peuhkuri, R.H. Effect of façade impregnation on feasibility of capillary active thermal internal insulation for a historic dormitory—A hygrothermal simulation study. Constr. Build. Mater. 2016, 113, 202–214. [Google Scholar] [CrossRef]

- Alev, U.; Kalamees, T. Avoiding mould growth in an interiorly insulated log wall. Build. Environ. 2016, 105, 104–115. [Google Scholar] [CrossRef]

- Cho, H.M.; Wi, S.; Chang, S.J.; Kim, S. Hygrothermal properties analysis of cross-laminated timber wall with internal and external insulation systems. J. Clean. Prod. 2019, 231, 1353–1363. [Google Scholar] [CrossRef]

- Geving, S. 471.111 Beregningsmetode for å Unngå Kondens Eller Muggvekst på Innvendige Overflater; Byggforskserien; SINTEF: Trondheim, Norway, 1999; Available online: https://www.byggforsk.no/dokument/2758/beregningsmetode_for_aa_unngaa_kondens_eller_muggvekst_pa-a_innvendige_overflater#i8 (accessed on 20 February 2025).

- Viitanen, H. Factors affecting the development of biodeterioration in wooden constructions. Mater. Struct. 1994, 27, 483–493. [Google Scholar] [CrossRef]

- Mattsson, J. Råtesopp i Bygninger. Forekomst, Påvisning, Vurdering og Utbedring; Mycoteam AS: Oslo, Norway, 2010; pp. 70–78. ISBN 978-82-91070-14-8. [Google Scholar]

- Holme, J. Mould Growth in Buildings. Doctoral Thesis, Norwegian University of Science and Technology (NTNU), Trondheim, Norway, 2010. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/231669 (accessed on 19 May 2025).

- Gradeci, K.; Labonnote, N.; Time, B.; Köhler, J. Mould growth criteria and design avoidance approaches in wood-based materials—A systematic review. Constr. Build. Mater. 2017, 150, 77–88. [Google Scholar] [CrossRef]

- Ingebretsen, S.B.; Andenær, E.; Gullbrekken, L.; Kvande, T. Microclimate and Mould Growth Potential of Air Cavities in Ventilated Wooden Facade and Roof Systems—Case Studies from Norway. Buildings 2022, 12, 1739. [Google Scholar] [CrossRef]

- Mattsson, J.; Stensrød, O. Håndbok om Vannskader. Årsak, Undersøkelser, Tiltak og Gjenoppbygging; Mycoteam: Oslo, Norway, 2009; ISBN 978-82-91070-11-7. [Google Scholar]

- Viitanen, H.; Factors Affecting Mould Growth on Kiln Dried Wood. VTT Building and Transport, Finland, no Date. Available online: https://www.penthon.com/wp-content/uploads/2014/08/Vittanen-Mogelinex.pdf (accessed on 20 February 2025).

- NS-EN ISO 13788:2012; Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperture to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation Methods. Standard Norge: Oslo, Norway, 2012.

- Bøhlerengen, T. 421.132 Fukt i bygninger. Teorigrunnlag; Byggforskserien; SINTEF: Trondheim, Norway, 2018; Available online: https://www.byggforsk.no/dok-ument-/184/fukt_i_bygninger_teorigrunnlag (accessed on 13 February 2025).

- NS-EN ISO 12572:2016; Standard Norge. Hygrothermal Performance of Building Materials and Products. Determination of Water Vapour Transmission Properties. Cup Method. Standard Norge: Oslo, Norway, 2016.

- Fraunhofer Institute for Building Physics. WUFI® Pro|WUFI (En); Fraunhofer Institute for Building Physics: Stuttgart, Germany, 2024. [Google Scholar]

- Bergheim, E. Risiko for Muggvekst ved Utvendig Etterisolering av Eldre Bindingsverksvegger. Master’s Thesis, Norwegian University of Science and Technology, Faculty of Engineering, Department of Civil and Environmental Engineering, Trondheim, Norway, 2020. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/discover (accessed on 18 June 2025).

- HeriTACE Future-Proofing Heritage Buildings by Optimising Comfort and Energy in Time and Space. 2024. Available online: https://www.heritace.eu/home (accessed on 21 May 2025).

- Rambæk, I. Verneverdige Trehus bør Også Etterisoleres. Men det må gjøRes Riktig for å Unngå Skader på Bygningen. 2024. Available online: https://www.forskning.no/bygningsmaterialer-partner-resirkulering/verneverdige-trehus-bor-ogsa-etterisoleres/2433258 (accessed on 21 May 2025).

- Sande, Ø. Orkmannen. Store Norske Leksikon. 2024. Available online: https://snl.no/Orkmannen (accessed on 17 February 2025).

- Thue, J.V. Bygningsfysikk Grunnlag; Fagbokforlaget: Trondheim, Norway, 2020; ISBN 978-82-450-1994-0. [Google Scholar]

- NS-EN 15026:2023; Hygrothermal Performance of Building Components and Building Elements. Assessment of Moisture Transfer by Numerical Simulation. Standard Norge: Oslo, Norway, 2023.

- Lunde, E. Trefiberbasert Isolasjon i Bindingsverkvegger—Undersøkelse av Fuktforhold i et Laboratorieforsøk og Sammenligning med Simuleringer i WUFI®. Master’s Thesis, Norwegian University of Science and Technology, Faculty of Engineering, Department of Civil and Environmental Engineering, Trondheim, Norway, 2014. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/233197 (accessed on 2 May 2025).

- Skogstad, H.B. SINTEF Technical Approval TG 20440; SINTEF: Oslo, Norway, 2021; Available online: https://www.sintefcertification.-no/product/index/3217 (accessed on 12 May 2025).

- Sletfjerding, E.B. Smart Vapour Barriers in Compact Timber-Framed Roofs. Parameter Analysis and Field Measurements. Master’s Thesis, Norwegian University of Science and Technology, Faculty of Engineering, Department of Civil and Environmental Engineering, Trondheim, Norway, 2019. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/2621273 (accessed on 20 May 2025).

- Tomren, J.H.; Andenæs, E.; Geving, S.; Kvande, T. Water Vapour Resistance of Ceiling Paints—Implications for the Use of Smart Vapour Barriers in Compact Wooden Roofs. Buildings 2023, 13, 2185. [Google Scholar] [CrossRef]

- Knarud, J.I.; Kvande, T.; Geving, S. Hygrothermal Simulation of Interior Insulated Brick Wall — Perspectives on Uncertainty and Sensitivity. Buildings 2023, 13, 1701. [Google Scholar] [CrossRef]

- NS 3031:2025; Bygningers Energiytelse—Beregning av Energi- og Effektbehov. Standard Norge: Oslo, Norway, 2025.

- Direktoratet for byggkvalitet. Byggteknsik Forskrifte (TEK17) § 13-4. Termisk Inneklima. 2020. Available online: https://www.dibk.no/regelverk/byggteknisk-forskrift-tek17/13/ii/13-4?_t_q=temperatur (accessed on 26 April 2025).

- DIN 4108-3; Thermal Protection and Energy Economy in Buildings—Part 3: Protection Against Moisture Subject to Climate Conditions—Requirements, Calculation Methods and Directions for Planning and Construction. German National Standard: Berlin, Germany, 2024.

- Rossebø, K.B. Determination of Vapour Resistance of Exterior Coatings—Impact on Moisture Drying Conditions in Wooden Claddings. Master’s Thesis, Norwegian University of Science and Technology, Faculty of Engineering, Department of Civil and Environmental Engineering, Trondheim, Norway, 2024. [Google Scholar]

- Rossebø, K.B.; Kvande, T. Water Vapour Resistance of Exterior Coatings—Influence on Moisture Conditions in Ventilated Wooden Claddings. Buildings 2024, 14, 2202. [Google Scholar] [CrossRef]

- Geving, S.; Torgersen, S.E.; Klimadata for Fuktberegninger. Referanseår for 12 Steder i Norge og Klimadata for Konstruksjoner mot Grunnen. Prosjektrapport 227, Norges Byggforskningsinstitutt, Norway, 1997. Available online: https://sintef.brage.unit.no/sintef-xmlui/handle/11250/2416041 (accessed on 21 May 2025).

- Storaas, K. Smart Dampsperre i Kompakte Tretak—Vurdering av Fuktsikkerhet. Master’s Thesis, Norwegian University of Science and Technology, Faculty of Engineering, Department of Civil and Environmental Engineering, Trondheim, Norway, 2020. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/2779405 (accessed on 2 May 2025).

- Fuglestad, F.E.; Andenæs, E.; Geving, S.; Kvande, T. Determining the Vapour Resistance of Breather Membrane Adhesive Joints. Materials 2022, 15, 6619. [Google Scholar] [CrossRef] [PubMed]

- Geving, S. Praktisk Bygningsfysikk; Fagbokforlaget: Trondheim, Norway, 2021; pp. 105–107. ISBN 978-82-450-2801-0. [Google Scholar]

- Uvsløkk, S. 573.121 Materialer til luft- og Damptetting; Byggforskserien; SINTEF: Trondheim, Norway, 2003; Available online: https://www.byggforsk.no/dok-ument/598/materialer_til_luft_og_damptetting#i4 (accessed on 19 May 2025).

- Elvebakk, K.; Gullbrekken, L. 523.255 Yttervegger av bindingsverk. Varmeisolering og tetting; Byggforskserien; SINTEF: Trondheim, Norway, 2020; Available online: https://www.byggforsk.no/dokument/361/yttervegger_av_bindingsverk_varmeisolering_og_tetting# (accessed on 19 May 2025).

- Nore, K. Hygrothermal Performance of Ventilated Wooden Cladding. Doctoral Thesis, Norwegian University of Science and Technology, Faculty of Engineering, Department of Civil and Environmental Engineering, Trondheim, Norway, 2009. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/231575 (accessed on 2 May 2025).

- Gudum, C. Moisture Transport and Convection in Building Envelopes. Ventilation in Light Weight Outer Walls. Doctoral Thesis, Technical University of Denmark, Lyngby, Denmark, 2003. Byg Rapport R-047. Available online: https://orbit.dtu.dk/en/publications/moisture-transport-and-convection-in-building-envelopes (accessed on 28 April 2025).

| Material | Time ca. | Use | Data |

|---|---|---|---|

| Tar- or asphalt-impregnated sheathing paper and cellulose board | 1870– | Outside | Asphalt paper is available in both sanded and unsanded variants [14]. Sheathing paper is a thin type of paper produced as felt paper with added wood pulp, which is then impregnated. It weighs 250–300 g per m2. |

| Newspaper | 1850–1920 | Inside | Around 50 to 55 g per m2, according to a specialist in paper materials. |

| Felt boards | 1870–1920 | Inside | These weigh around 350 g per m2 [14]. |

| Unimpregnated cellulose boards | 1870–1950 | Inside | These are made from cellulose pulp [14] and used only in dry areas, as they absorb moisture. |

| Product | Picture | Year | Location | Description | |

|---|---|---|---|---|---|

| Exterior paper | E1 |  | 1908 | Orkanger train station | Brown paper. Taken from “the knee walls” on the outside. |

| E2 |  | 1938 | Belsnes | Asphalt-impregnated paper. Black. Not grainy. House built in 1938 and renovated in the 1950s. | |

| E3 |  | 1938 | Belsnes | Asphalt-impregnated paper. Black. More grainy than E2. House built in 1938 and renovated in the 1950s. | |

| E4 |  | 1938 | Vanvikan, Indre Fosen | Black paper, probably asphalt-impregnated. Unknown origin and use. One roll found in a barn from 1938. The associated house was renovated in the 1950s–1960s. | |

| Interior paper | I1 |  | 1908 | Orkanger train station | Brown-grey wool paper. Taken from “the knee walls” on the inside. |

| I2 |  | 1908 | Orkanger train station | Brown-grey wool paper. Taken from “the knee walls” on the inside. | |

| I3 |  | 1932 | “Orkmannen” newpaper | Newspaper from Orkdal in the south of Trøndelag in Norway [53]. A local newspaper from 1926 to 1945. | |

| I4 |  | 1933 | “Orkmannen” newspaper | Same as above. | |

| I5 |  | 1936 | “Orkmannen” newspaper | Same as above. | |

| I6 |  | 1880 | Northern Trøndelag, Norway | Brown paper. One smoother side and one rougher side. Found on the interior side of exterior walls in an 1880s log house. Assembly date unknown. | |

| I7 |  | No date | Oslo | Haakon paper. Brown. The entire roll was stored in a basement and had not been used. | |

| I8 |  | 1880 | Northern Trøndelag, Norway | Impregnated wool paper. Black-brown colour on one side, grey on the other side. Found inside an 1880s log house. Assembly date unknown. | |

| No. | E1 | E2 | E3 | E4 | I1 | I2 | I3 | I4 | I5 | I6 | I7 | I8 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness [mm] | 1 | 0.52 | 0.68 | 0.71 | 0.58 | 0.45 | 0.98 | 0.10 | 0.10 | 0.12 | 0.50 | 0.46 | 1.40 |

| 2 | 0.48 | 0.70 | 0.72 | 0.59 | 0.52 | 0.96 | 0.10 | 0.10 | 0.12 | 0.50 | 0.46 | 1.24 | |

| 3 | 0.50 | 0.75 | 0.72 | 0.59 | 0.54 | 0.96 | 0.10 | 0.10 | 0.12 | 0.50 | 0.43 | 1.24 | |

| 4 | 0.47 | 0.73 | 0.60 | 0.48 | 0.10 | 0.10 | 0.12 | 0.50 | 0.43 | ||||

| 5 | 0.48 | 0.75 | 0.59 | 0.50 | 0.10 | 0.10 | 0.12 | 0.50 | 0.44 | ||||

| Average [mm] | 0.49 | 0.72 | 0.72 | 0.59 | 0.50 | 0.97 | 0.10 | 0.10 | 0.12 | 0.50 | 0.44 | 1.29 | |

| Grammage | |||||||||||||

| [g/m2] | 322 | 541 | 541 | 574 | - | - | 57 | 58 | 57 | 377 | 261 | 767 | |

| Sample No. | Orientation |

|---|---|

| E1–E4, I1–I5, I7 | Identical on both sides. The orientation had no impact. |

| I6 | The smooth surface facing down to the salt solution. |

| I8 | The impregnated side facing down to the salt solution. |

| Time Interval | Samples | Test Chamber |

|---|---|---|

| Every 120 min | I1 and I2 | Gintronic GraviTest |

| Every 24 h | E1, E2, E3, E4, I6, I7, and I8 | Test enclosure with shelves |

| Every morning and afternoon | I3, I4, and I5 | Test enclosure with shelves |

| Parameter | Input | Comment |

|---|---|---|

| Air exchanges in cavity | 0 h−1 | See the Data Availability Statement. |

| Initial temperature | 21 °C [61,62] | |

| Initial RH | 0.7 | |

| Wall inclination | 90° | |

| Exterior surface heat resistance, Rse | 0.0588 (m2K/W) | Standard value in WUFI® Pro [63]. |

| Interior surface heat resistance, Rsi | 0.125 (m2K/W) | Standard value in WUFI® Pro [63]. |

| Ground shortwave reflectivity | 0.2 | Standard value in WUFI® Pro [63]. |

| Simulation start | October | Beginning of wet season |

| Simulation duration | 5 years | |

| Building height | <10 m | Short building |

| Driving rain coefficients | R1 = 0 R2 = 0.07 | Standard values in WUFI® Pro for short buildings [63]. |

| Surface treatment of interior and exterior cladding | Oil painting value: 1.35 m | Oil paint has the highest level of vapour resistance, as measured in [64,65]. Three layers of paint. |

| Indoor temperature | 21 °C [61,62] | |

| Orientation wall | South | |

| Timber cladding and timber planks | Scandinavian spruce, transversal direction II | Material in WUFI® Pro, taken from the NTNU database |

| Paper on interior side | To layers of I6 ( value: 0.046 m) | As all types of interior paper were vapour-permeable, the least vapour-permeable type was chosen. |

| Parameter | Basic Input | Variable (s) |

|---|---|---|

| Outdoor climate | Kristiansund | Hamar |

| Insulation thickness | 50 mm | 100 mm 250 mm None |

| Insulation material | Mineral wool ( = 0.034 W/(mK)) | Wood fibre insulation ( = 0.038 W/(mK)) |

| Vapour barrier | PE foil 0.2 mm ( value: 87 m) | MAVB No vapour barrier |

| Shortwave radiation absorptivity | 0.4 (white house) | 0.8 (dark house) |

| Paper on the exterior | E3 ( value: 5.293 m) | Two layers of E1 ( value: 0.040 m) |

| Humidity class inside | 3 | 2 |

| Colour | Risk |

|---|---|

| Red | High mould growth risk: RH over 80% and temperature between 5 and 30 °C for a continuous time period of minimum one day continuous. |

| Yellow | Medium mould growth risk: RH under 80% but exceeding 80 % for a short time period (<one day continuous); alternatively, RH increasing over the simulated 5-year time period (this needs to be investigated further over a longer time period); alternatively, RH over 80% at the beginning of the simulation but decreasing over the simulated 5-year time period. |

| Green | Low mould growth risk: RH under 80 %, and RH does not increase during the simulated 5-year time period. |

| No. | Description | Value [m] |

|---|---|---|

| E1 | Brown paper. | 0.020 |

| E2 | Asphalt-impregnated paper; not grainy. | 0.881 |

| E3 | Asphalt-impregnated paper; grainy. | 5.293 |

| E4 | Black; impregnated paper. | 0.435 |

| I1 | Wool paper. | 0.018 |

| I2 | Wool paper. | 0.021 |

| I3 | Newspaper from 1932. | 0.013 |

| I4 | Newspaper from 1933. | 0.014 |

| I5 | Newspaper from 1936. | 0.008 |

| I6 | Brown paper. | 0.023 |

| I7 | Haakon paper; brown. | 0.017 |

| I8 | Impregnated wool paper. | 0.022 |

| Case | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input Parameters | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| Insulation thickness | 0 mm (original wall) | x | x | x | x | |||||||

| 50 mm | x | x | ||||||||||

| 100 mm | x | x | ||||||||||

| 250 mm | x | x | x | |||||||||

| Outdoor climate | Kristiansund | x | x | x | x | x | x | x | x | |||

| Hamar | x | x | x | |||||||||

| Insulation material | Galva mineral wool | x | x | x | x | x | x | x | ||||

| Wood fibre insulation | ||||||||||||

| Vapour barrier | Normal | x | x | x | x | x | x | |||||

| MAVB | ||||||||||||

| None | x | x | x | x | x | |||||||

| Shortwave radiation | 0.4 | x | x | x | x | x | x | x | x | x | x | x |

| absorptivity | 0.8 | |||||||||||

| Paper exterior side | E3 | x | x | x | x | x | x | |||||

| Two layers of E1 | x | x | x | x | x | |||||||

| Humidity class | 3 | x | x | x | x | x | x | x | x | x | x | x |

| inside | 2 | |||||||||||

| Mould growth risk | ||||||||||||

| Case | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Input Parameters | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | |

| Insulation thickness | 0 mm (original wall) | x | |||||||||

| 50 mm | x | x | x | x | x | ||||||

| 100 mm | x | x | |||||||||

| 250 mm | x | x | |||||||||

| Outdoor climate | Kristiansund | x | x | x | x | x | x | x | x | ||

| Hamar | x | x | |||||||||

| Insulation material | Mineral wool | x | x | x | x | x | x | ||||

| Wood fibre insulation | x | x | x | ||||||||

| Vapour barrier | Normal | x | x | x | |||||||

| MAVB | x | x | x | x | |||||||

| None | x | x | x | ||||||||

| Shortwave radiation | 0.4 | x | x | x | x | x | x | x | x | x | |

| absorptivity | 0.8 | x | |||||||||

| Paper exterior side | E3 | x | x | x | x | x | x | x | x | x | |

| Two layers of E1 | x | ||||||||||

| Humidity class | 3 | x | x | x | x | x | x | x | x | x | |

| inside | 2 | x | |||||||||

| Mould growth risk | |||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harberg, M.E.; Asphaug, S.K.; Kvande, T. Mould Growth Risk for Internal Retrofit Insulation of Heritage-Protected Timber Plank Frame Walls. Heritage 2025, 8, 278. https://doi.org/10.3390/heritage8070278

Harberg ME, Asphaug SK, Kvande T. Mould Growth Risk for Internal Retrofit Insulation of Heritage-Protected Timber Plank Frame Walls. Heritage. 2025; 8(7):278. https://doi.org/10.3390/heritage8070278

Chicago/Turabian StyleHarberg, Martha Eilertsen, Silje Kathrin Asphaug, and Tore Kvande. 2025. "Mould Growth Risk for Internal Retrofit Insulation of Heritage-Protected Timber Plank Frame Walls" Heritage 8, no. 7: 278. https://doi.org/10.3390/heritage8070278

APA StyleHarberg, M. E., Asphaug, S. K., & Kvande, T. (2025). Mould Growth Risk for Internal Retrofit Insulation of Heritage-Protected Timber Plank Frame Walls. Heritage, 8(7), 278. https://doi.org/10.3390/heritage8070278