Metallographic Analyses of 19th-Century Steel Semi-Finished Products from Slovenia

Abstract

1. Introduction

1.1. Historical Background

1.2. Research Aims

2. Materials and Methods

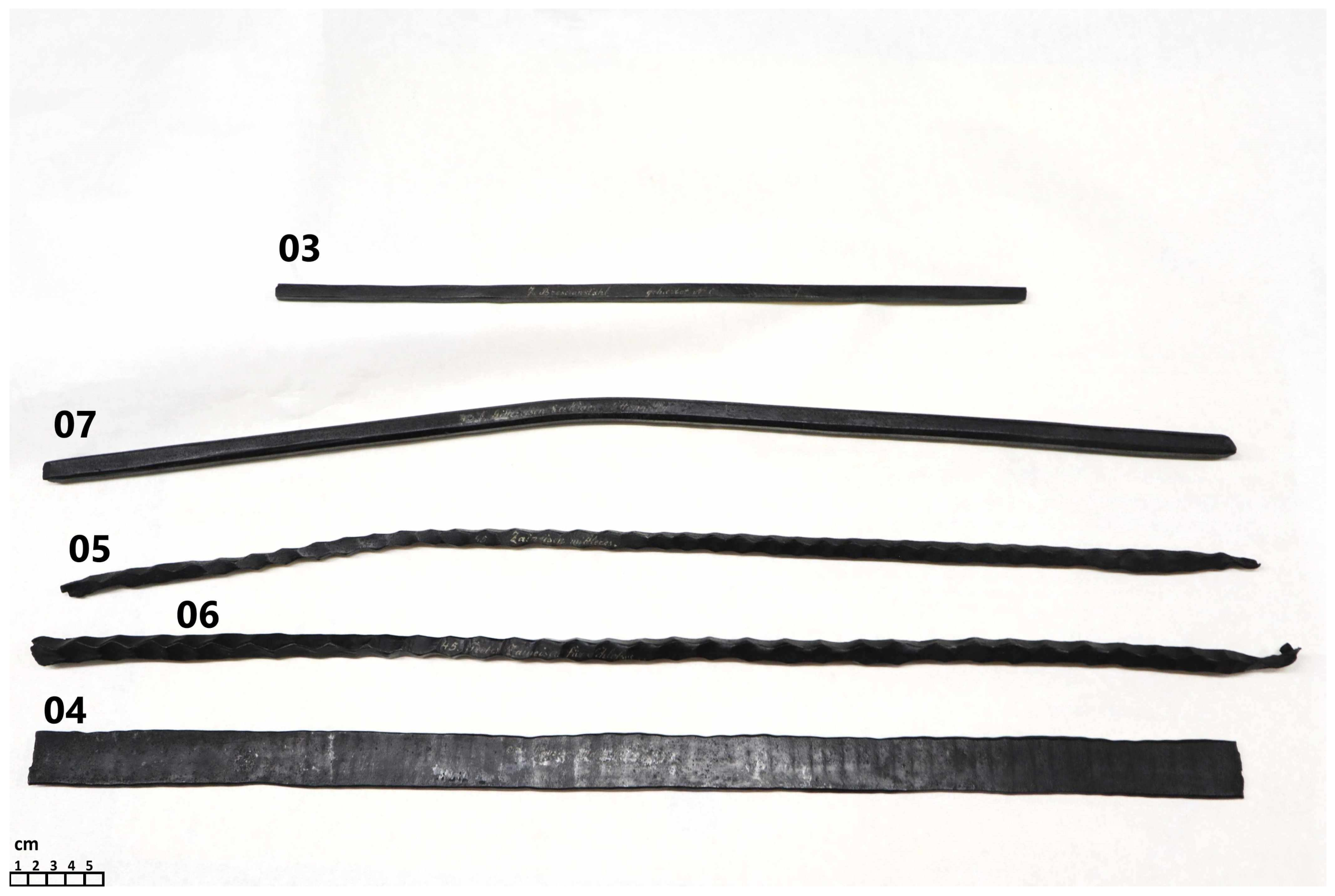

2.1. Materials

2.2. Investigation Methods

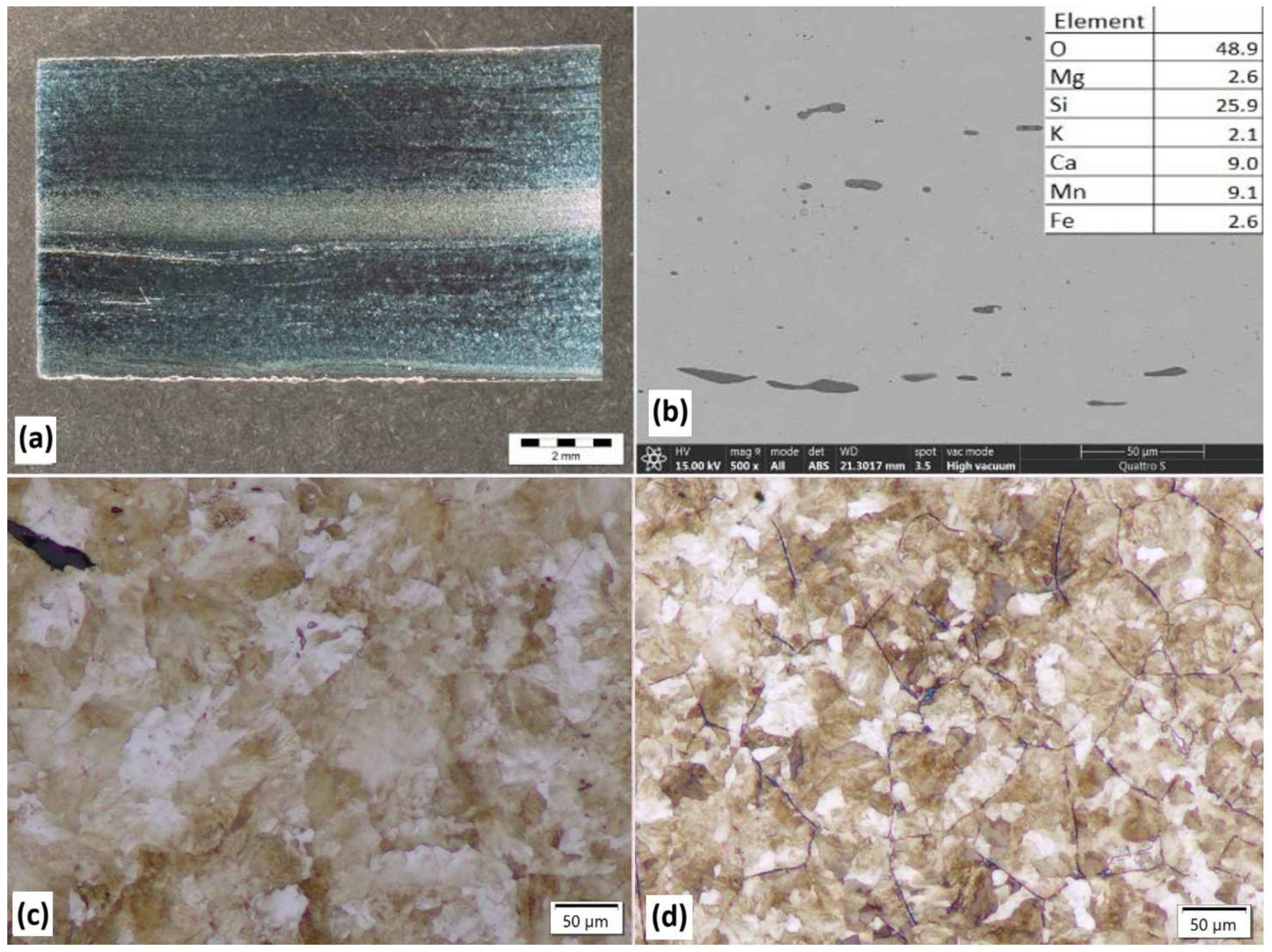

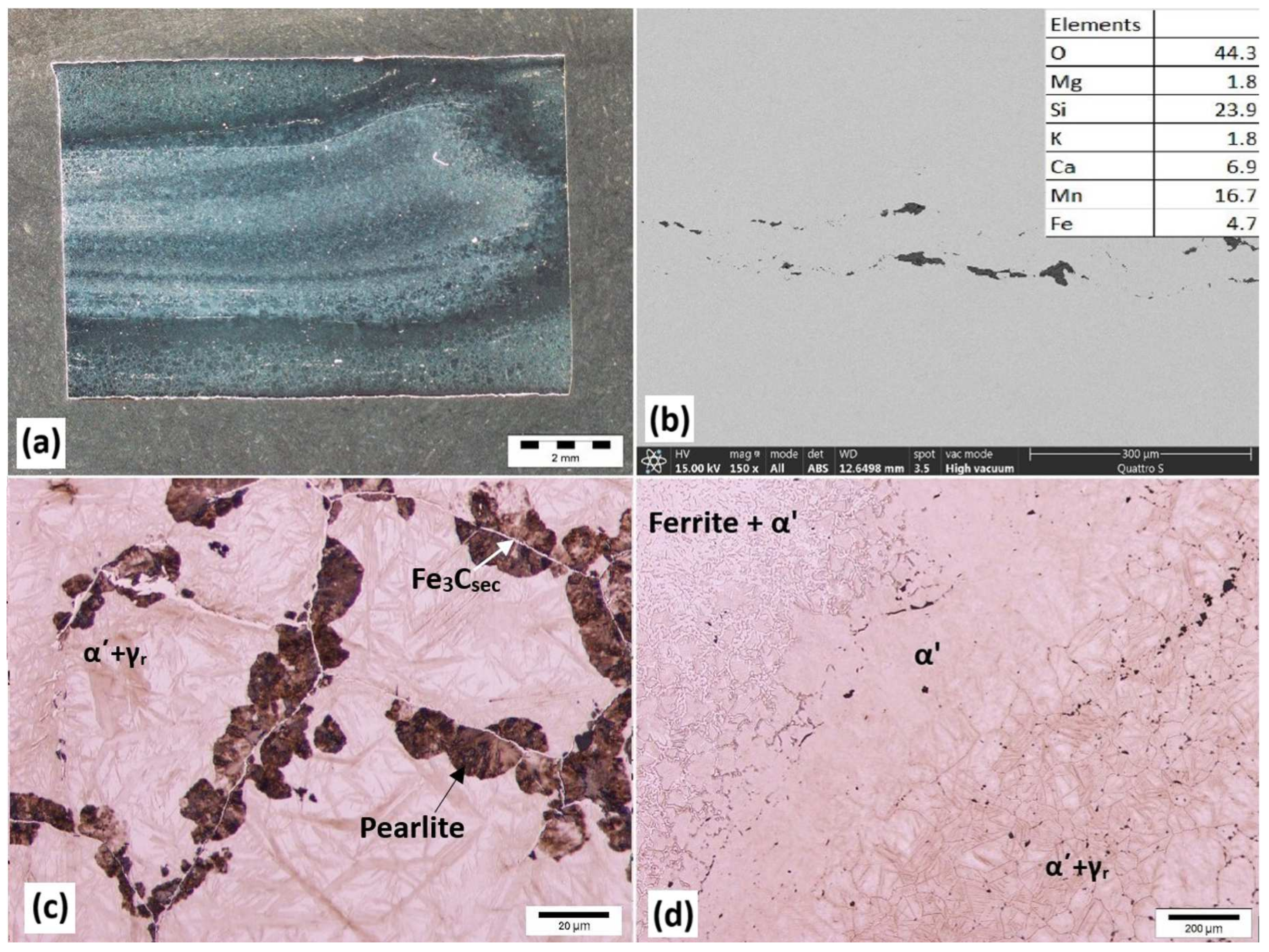

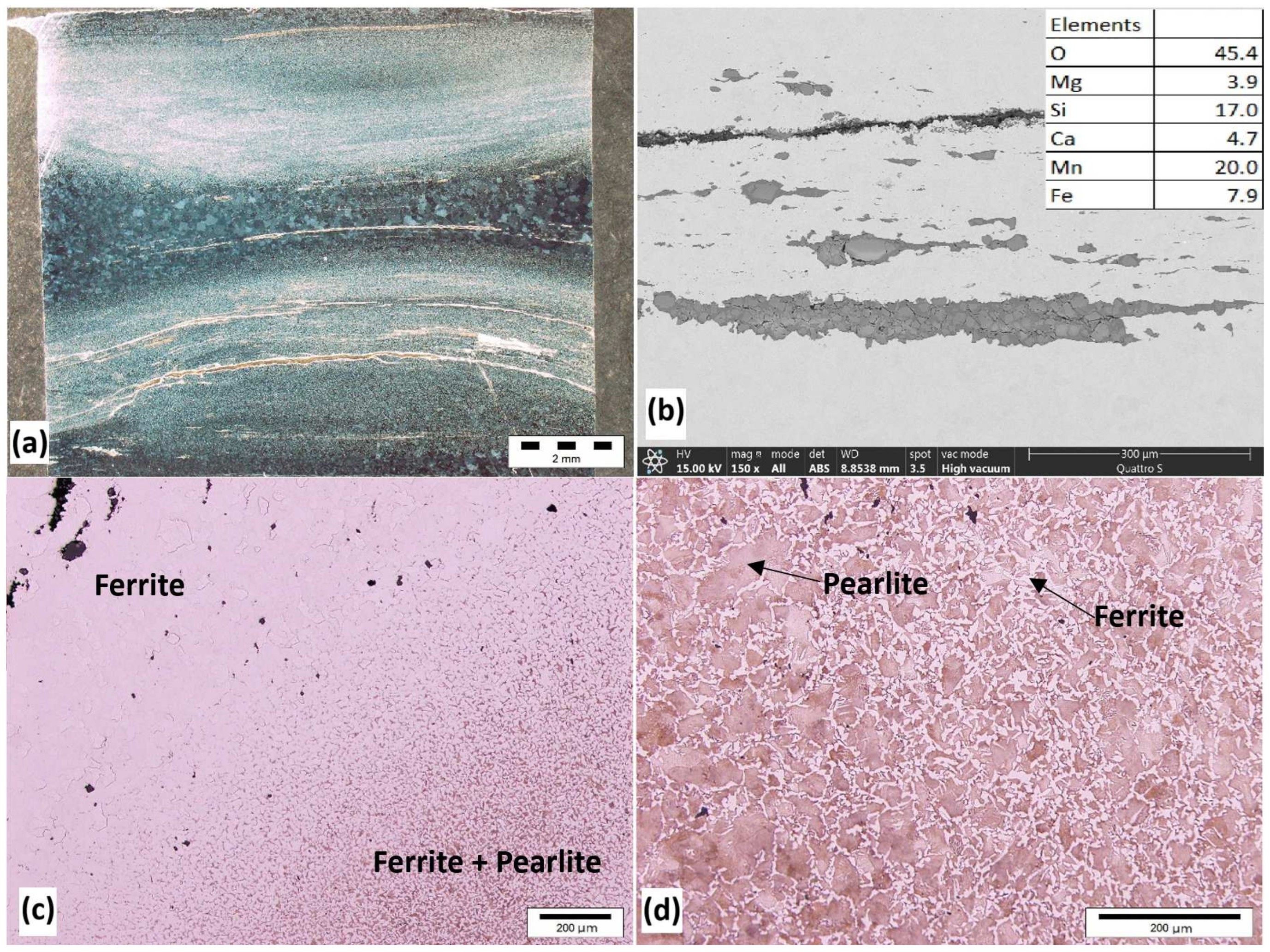

3. Results

3.1. Chemical Composition

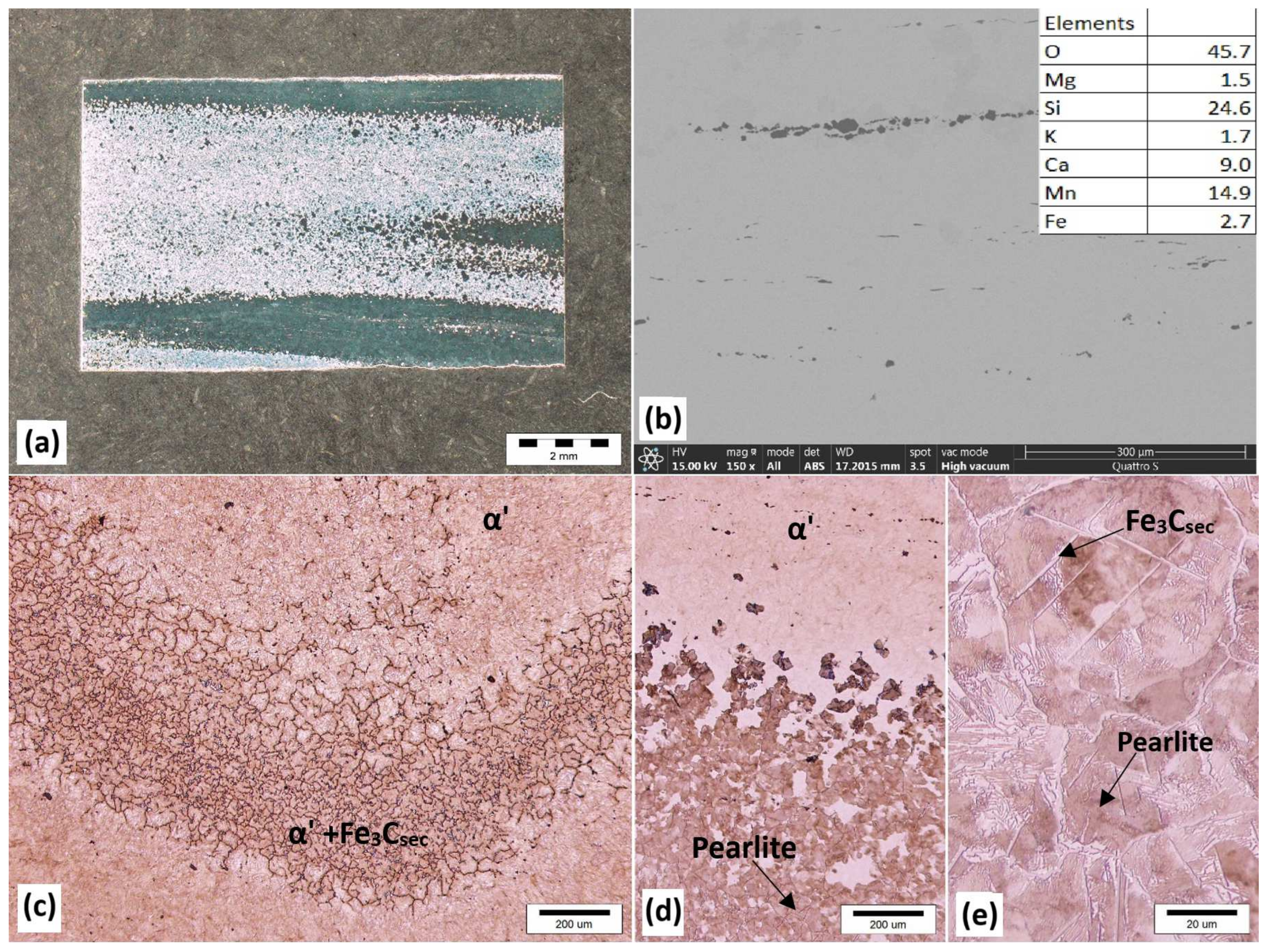

3.2. Microstructure Characterisation

3.3. Hardness

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hobsbawm, E. The Age of Revolution. Europe 1789–1848; Weidenfeld & Nicholson: London, UK, 1962. [Google Scholar]

- Luthar, O. (Ed.) The Land Between. A History of Slovenia; Peter Lang GmbH: Frankfurt am Main, Germany, 2008. [Google Scholar]

- Tylecote, R.F. A History of Metallurgy, 2nd ed.; The Institute of Materials: London, UK, 1992. [Google Scholar]

- Francis Von Rosthorn. Nature 1877, 17, 11. [CrossRef][Green Version]

- Oitzl, G. Between Traditional Ironworking and Industrialisation. Key Aspects of Metallurgy in Slovenian Territory in the “Long Nineteenth Century”. In The Song of Metal. Millennia of Metallurgy in Slovenia; Kotar, J., Lazar, T., Fajfar, P., Eds.; National Museum of Slovenia: Ljubljana, Slovenia, 2019; pp. 118–165. [Google Scholar]

- Oitzl, G. Zapuščina tržiških kovačev v Narodnem muzeju Slovenije. Kronika 2020, 68, 553–580. [Google Scholar]

- Bericht Über die Zweite Allgemeine Österreichische Gewerbs-Producten-Ausstellung im Jahre 1839; K. k. Hof- und Staats-Aerarial-Druckerei: Wien, Austria, 1840.

- Steiermärkisches Gewerbeverein. Bericht über Sämmtliche Erzeugnisse, Welche für die Dritte, zu Laibach im Jahre 1844 Veranstaltete und bei Gelegenheit der Anwesenheit Allerhöchst Ihrer Majestäten des Kaisers und der Kaiserin Eröffnete Industrie-Ausstellung des Vereines zur Beförderung und Unterstützung der Industrie und Gewerbe in Innerösterreich, dem Lande ob der Enns und Salzburg Eingeschickt Worden Sind; Vereins Direction: Grätz, Austria, 1845. [Google Scholar]

- Hacquet, B. Oryctographia Carniolica, oder Physikalische Erdbeschreibung des Herzogthums Krain, Istrien und zum Teil der Benachbarten Länder; Johann Gottlob Immanuel Breitkopf: Leipzig, Germany, 1784; pp. 1778–1789. [Google Scholar]

- Oitzl, G. The Transfer of Ironworking Technologies in Slovenian Territory between the 14th and 16th Centuries. In Secrets of Iron—From Raw Material to an Iron Object. Proceedings of the 7th International Conference of Medieval Archaeology of the Institute of Archaeology, Zagreb, Criatia, 10–11 September 2020; Sekelj Ivančan, T., Karavidović, T., Tkalčec, T., Krznar, S., Belaj, J., Eds.; Institute of Archaeology: Zagreb, Croatia, 2022; pp. 207–220. [Google Scholar]

- von Scheuchenstuel, C. Idioticon der Österreichischen Berg- und Hüttensprache. Zum Besseren Verständnisse der Österreichisch Berg-Gesetzes und deren Motive für Nicht-Montanisten; W. Braumüller: Wien, Austria, 1856. [Google Scholar]

- Verzeichniß Nro. 3 der eingegangenen Museums-Beiträge. Laibacher Zeitung 1835, 14.

- Steiermärkisches Gewerbeverein. Bericht Über Sämmtliche Erzeugnisse, Welche für die Erste, zu Klagenfurt im Jahre 1838 Veranstaltete, und bei Gelegenheit der Anwesenheit Sr. Majestät des Kaisers Eröffnete Industrie-Ausstellung des Vereines zur Beförderung und Unterstützung der Industrie und der Gewerbe in Innerösterreich Eingeschickt Worden Sind; Vereins Direction: Grätz, Austria, 1839. [Google Scholar]

- Lazar, T. Department of History and Applied Arts and Its Predecessors. In National Museum of Slovenia. 200 Years; Lazar, T., Kotar, J., Oitzl, G., Eds.; National Museum of Slovenia: Ljubljana, Slovenia, 2022; pp. 335–356. [Google Scholar]

- de Bouw, M.; Wouters, I.; Vereecken, J.; Lauriks, L. Iron and Steel Varieties in Building Industry between 1860 and 1914—A Complex and Confusing Situation Resolved. Constr. Build. Mater. 2009, 23, 2775–2787. [Google Scholar] [CrossRef]

- Di Lorenzo, G.; Formisano, A.; Terracciano, G.; Landolfo, R. Iron Alloys and Structural Steels from XIX Century until Today. Evolution of Mechanical Properties and Proposal of a Rapid Identification Method. Constr. Build. Mater. 2021, 302, 124132. [Google Scholar] [CrossRef]

- Benini, L.; Pardal, J.M.; Tavares, S.S.M.; Renni, Y.S.; Oliveira, I.G.; Noris, L.F.; Coreia, J.A.F.O. Effects of Normalizing Heat Treatment on the Mechanical and Magnetic Properties of the Puddled Iron. Eng. Fail. Anal. 2023, 146, 107082. [Google Scholar] [CrossRef]

- Hotała, E.; Ignatowicz, R.; Lachowicz, M.B. Metallographic Testing of 19th Century Steel in an Operating Water Tower. Materials 2021, 14, 2204. [Google Scholar] [CrossRef] [PubMed]

- Lesiuk, G.; Correia, J.A.F.O.; De Jesus, A.M.P.; Kucharski, P. Fatigue Crack Propagation Behaviour of Old Puddle Iron Including Crack Closure Effects. Procedia Struct. Integr. 2016, 2, 3218–3225. [Google Scholar] [CrossRef]

- Pardal, J.M.; Gripp, I.; Tavares, S.S.M.; Cardoso, A.S.M.; Pereira, A.M.; Carneiro da Cunha, R.P.; Barbosa, C. Failure Characterization of a Structural Welded Component of an Ancient Bridge. Eng. Fail. Anal. 2020, 116, 104751. [Google Scholar] [CrossRef]

- Lucchetta, M.C.; Gutiérrez, G.; De Rosa, H. Studies on Wrought Iron Pieces from the Villarino Ship, 1880 (Argentina). J. Archaeol. Sci. Rep. 2021, 39, 103179. [Google Scholar] [CrossRef]

- Matteis, P.; Scavino, G. Mechanical Performance of Historical Wrought Iron Rods. Archaeometry 2019, 61, 1053–1065. [Google Scholar] [CrossRef]

| Sample No. | Grade of Semi-Product | Original Name of the Grade | Origin | Manufacture Date | Length [cm] | Width [mm] | Inv. No. |

|---|---|---|---|---|---|---|---|

| 1 | Rod iron | Feines Zaineisen | Tržič | 1821 | 64 | 9.4 | N 39295 |

| 2 | Steel | x | Carniola (?) | 1st half of the 19th c. | 47 | 15 | N 38902 |

| 3 | Brescian steel | Brescianstahl, gehärtet Nr. 0 | Tržič | 1821 | 43.5 | 8.8 | N 38924 |

| 4 | Strip iron | Wannen- oder Kübelesien | Tržič | 1821 | 64.2 | 30 | N 38897 |

| 5 | Rod iron | Zaineisen Mittleres | Tržič | 1821 | 66.2 | 10 | N 38900 |

| 6 | Rod iron | Groben Zaineisen für Schlosser | Tržič | 1821 | 68.3 | 18 | N 38899 |

| 7 | Rod iron for artistic forging | Gittereisen, 8eckiges (Ottangoli) | Tržič | 1821 | 67.3 | 17 | N 38898 |

| 8 | Rod iron | x | Carniola (?) | 1st half of the 19th c. | 65 | 10 | N 38901 |

| 9 | Rod iron | x | Carniola (?) | 1st half of the 19th c. | 13 | 82 | N 39598 |

| 10 | Steel | No. 0 | Sava | 1834 | 27.2 | 85 | N 39599 |

| 11 | Steel | No. 00 | Sava | 1834 | 25.3 | 72 | N 38597 |

| 12 | Iron plate | x | ? | 1st half of the 19th c. | 33 | 550 | N 38587 |

| Sample No. | C | S | N | Fe |

|---|---|---|---|---|

| 2 | 0.83 | 0.00 | 0.00 | rest |

| 3 | 1.13 | 0.00 | 0.01 | rest |

| 7 | 0.10 | 0.01 | 0.00 | rest |

| 11 | 1.36 | 0.00 | 0.00 | rest |

| Sample No. | Site 1 | Site 2 | Site 3 | Average |

|---|---|---|---|---|

| 2 | 311 | 316 | 303 | 310 |

| 3 | 891 | 901 | 882 | 891 |

| 7 | 147 | 145 | 138 | 143 |

| 11 | 870 | 886 | 901 | 886 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oitzl, G.; Nagode, A.; Cvek, Ž.; Fajfar, P. Metallographic Analyses of 19th-Century Steel Semi-Finished Products from Slovenia. Heritage 2025, 8, 119. https://doi.org/10.3390/heritage8040119

Oitzl G, Nagode A, Cvek Ž, Fajfar P. Metallographic Analyses of 19th-Century Steel Semi-Finished Products from Slovenia. Heritage. 2025; 8(4):119. https://doi.org/10.3390/heritage8040119

Chicago/Turabian StyleOitzl, Gašper, Aleš Nagode, Žiga Cvek, and Peter Fajfar. 2025. "Metallographic Analyses of 19th-Century Steel Semi-Finished Products from Slovenia" Heritage 8, no. 4: 119. https://doi.org/10.3390/heritage8040119

APA StyleOitzl, G., Nagode, A., Cvek, Ž., & Fajfar, P. (2025). Metallographic Analyses of 19th-Century Steel Semi-Finished Products from Slovenia. Heritage, 8(4), 119. https://doi.org/10.3390/heritage8040119