Microanalytical Determinations to Distinguish Maiolica and Mezza Majolica Ceramics from Faenza (Emilia-Romagna Region, Italy)

Abstract

1. Introduction

- -

- “majolica” or engobed terracotta, where the color of the ceramic body is hidden by a white or colored glass that waterproofs it on one side and highlights the painted decorations on the other side [20];

- -

2. Sampling and Analytical Methods

2.1. Samples and Sampling Site Description

- -

- -

2.2. Analytical Techniques

3. Results and Discussion

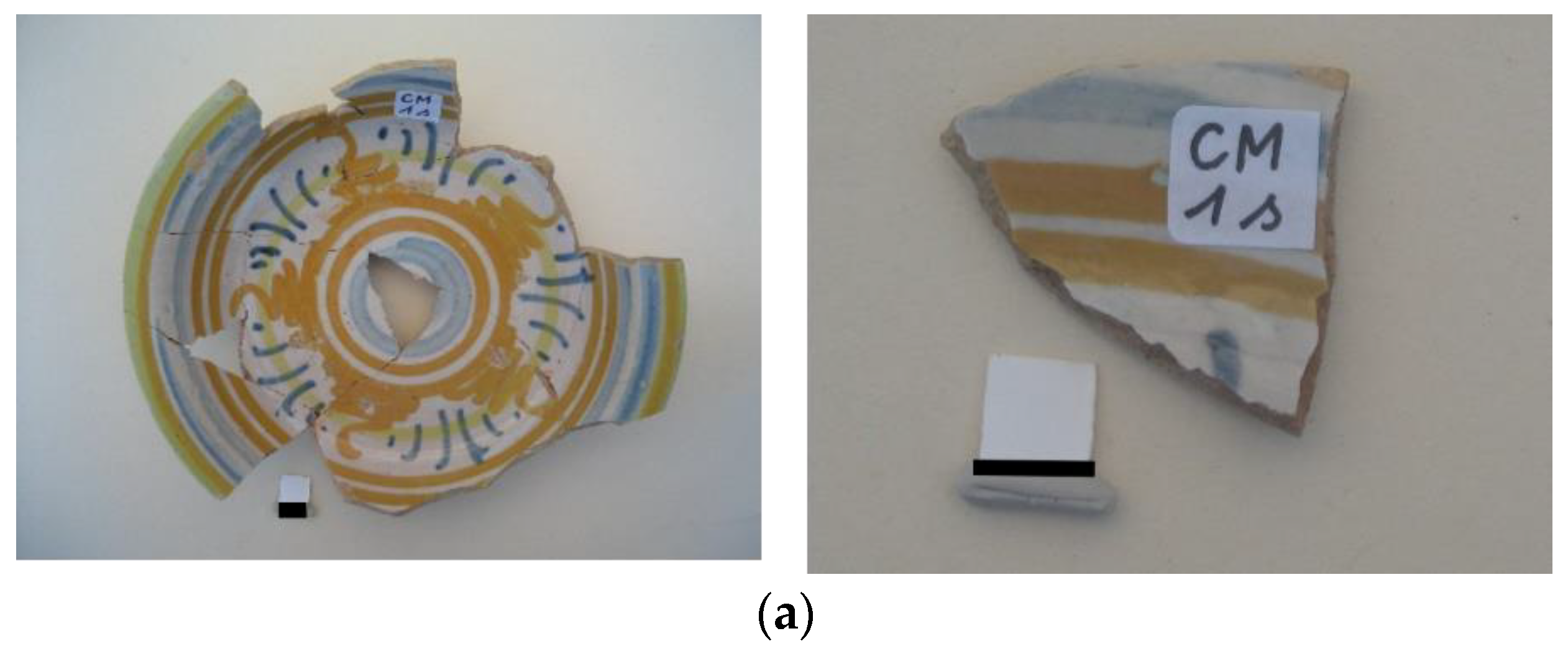

3.1. Macroscopic Observation of the Collected Ceramic Samples

- -

- Tableware for domestic use consisting of containers (Figure 2c,f). These samples were glazed engobed terracotta. The body was colored, and it seemed more porous than those of the other samples. The coating was a white engobed covered with a yellowish lead glaze.

- -

- Terracotta tableware for consuming food on a table, such as plates (Figure 2a,b,d,e). The bodies were porous, sometimes very crumbly, light yellow in color, and rarely pink in color. The coating was sometimes a white enamel or of bluish tones, or with a white engobed and with a glazed layer. In both cases, it completely covered the body. There were two different types of enamel: white (sometimes bluish) of considerable thickness (sometimes up to 2 mm) with a thin mesh; whitish of considerably less thickness than the other type with a much finer mesh. The first type was characterized by the engobed terracotta of the seventeenth century, and probably later production (Figure 2a–c). The second type of coating was influenced by an older production method (Figure 2e); the coating was probably not a unique layer, but it was a painted enamel and subsequently covered by a glazed layer, a technique probably used in the last 1300 years [33].

- -

- the color surface was generally white, milky, or blue;

- -

- the surface appeared brilliant;

- -

- the coating completely and homogeneously covered both the front and the back sections, except the foot;

- -

- if there were decorations, they were always painted in blue, yellow, orange, green, or manganese violet.

- -

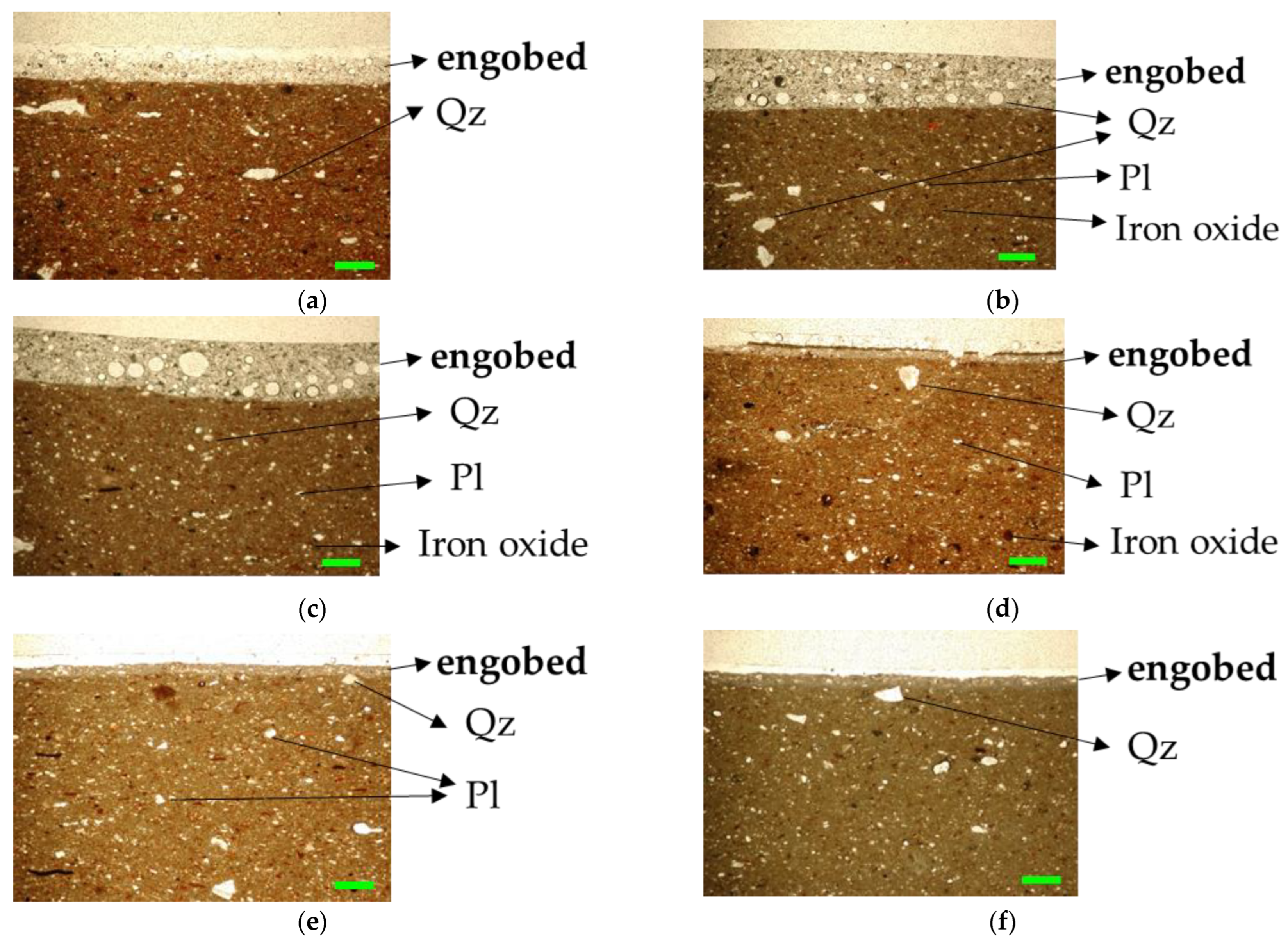

- Coating thickness: This was thicker in the engobed terracotta samples;

- -

- Coating color: The color of the engobed terracotta samples appeared milky white when the thickness of the enamel was thicker (Figure 3a) and pink where the thicknesses were thinner (Figure 3b). In the glazed engobed terracotta samples, the color was yellowish-ivory and none had pink tones (Figure 3c);

- -

- Coating luster: This was more visible in the glazed engobed terracotta;

- -

- Touch sensitivity on the painted ornaments: No sensitivity was detected in the engobed terracotta samples, except for the orange color. The opposite was true for the glazed engobed terracotta samples, in which the color had touch sensitivity.

- -

- Even alterations and degradation due to wear and/or laying in the subsoil could be used as indicators to identify the materials, for example:

- -

3.2. Microscopic Observation of the Selected Ceramic Samples

3.2.1. Engobed Terracottas

3.2.2. Glazed Engobed Terracottas

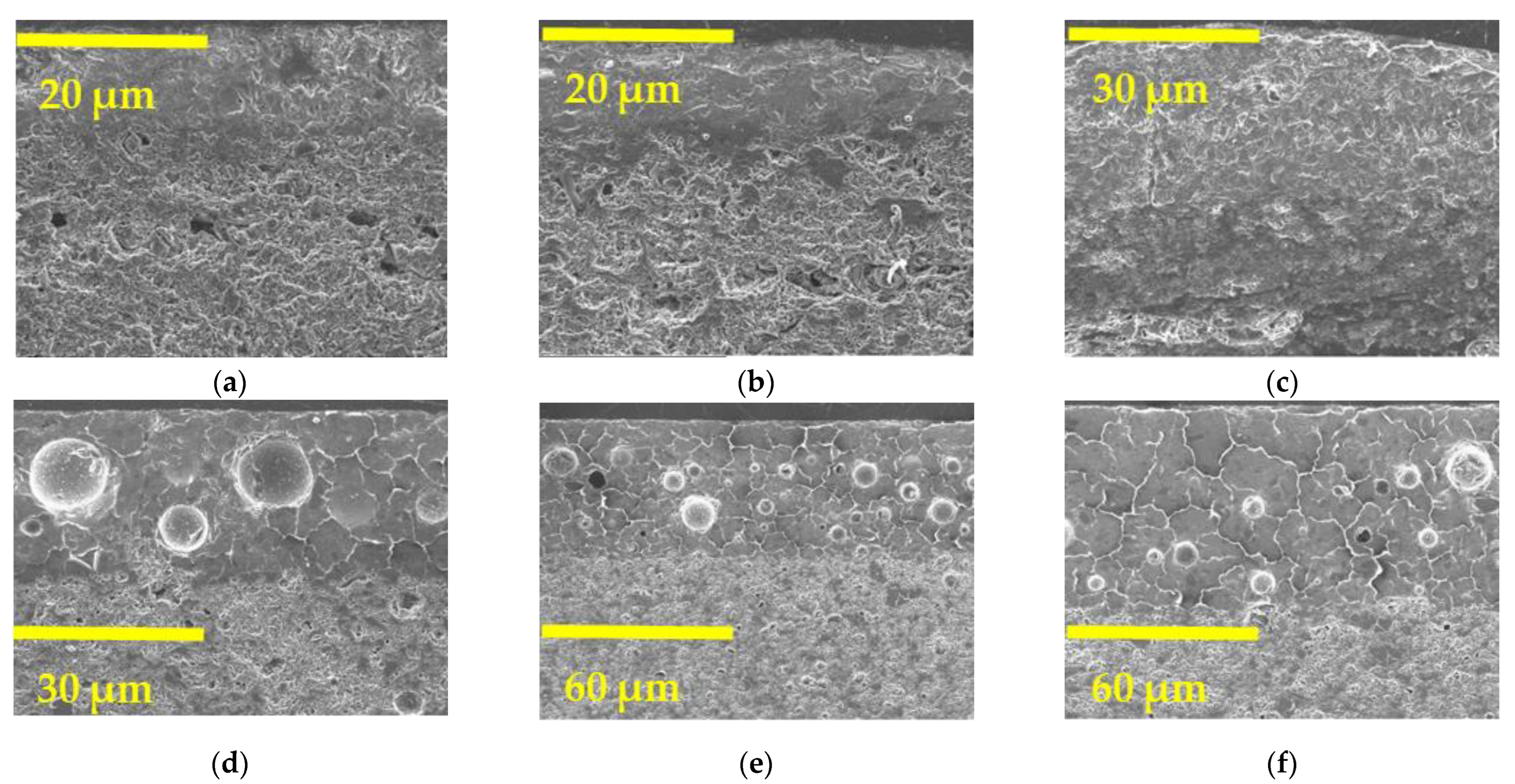

3.3. SEM-EDS Analyses of Selected Samples

3.3.1. Engobed Terracotta Samples

3.3.2. Glazed Engobed Terracotta Samples

3.4. Colorimetric Analyses

- -

- -

- Fe-enriched non-calcareous clay is characterized by a porous structure with a sandy appearance with regular inclusions and vacuoles. It is characterized by a reddish-brown color.

- -

- with a double coating consisting of an engobed (earthy, covering) and a colorless showcase (vitreous, transparent); the decoration was between the two coatings (samples CM1i, CM2i, CM3i represented the mezza-majolica finds);

- -

- with a double coating consisting of an enamel (vitreous, covering); the painted ornamentation was between the two coatings (as for the majolica sample CM1s);

- -

- with a single coating consisting of an enamel (vitreous, covering) on which the painted decoration was carried out (as for the majolica sample CM2s).

4. Conclusions

- -

- Fe-enriched carbonate clay, characterized by a more or less fine structure, free of inclusions and vacuoles, with a color ranging from light pink to more intense shades, but never reaching the deep red color;

- -

- Fe-enriched non-carbonate clay, characterized by a porous structure of sandy appearance with regular inclusions and vacuoles. It is characterized by a reddish-brown color.

- -

- one with a double coating consisting of an engobe (earthy, covering) and a colorless glaze (vitreous, transparent);

- -

- one with a double coating consisting of a glaze (vitreous, opaque); the painted ornament was between the two coatings;

- -

- another with a single coating consisting of an enamel (vitreous, opaque), on which the painted ornament was executed.

Author Contributions

Funding

Conflicts of Interest

References

- Fabbri, B.; Ravanelli Guidotti, C. Il Restauro della Ceramica; Nardini Editore: Firenze, Italy, 2003. [Google Scholar]

- Akgun, O. Damage Detection in Ceramic Materials Using Bicoherence Analysis. Balk. J. Electr. Comput. Eng. 2000, 8, 300–306. [Google Scholar] [CrossRef]

- Tirado-Hernandez, A.; Becerra, J.; Ortiz, R.; Ortiz, P.; Gomez-Moron, A.; Ghervase, L.; Cortea, I.; Angheluta, L.; Radvan, R. Non-destructive techniques applied to the study and diagnosis of ceramic and glazed terracotta tombs in Omnium Sanctorum church (Seville, Spain). In Science and Digital Technology for Cultural Heritage—Interdisciplinary Approach to Diagnosis, Vulnerability, Risk assessment and Graphic Information Models; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Quinn, P.; Yang, Y.; Xia, Y.; Li, X.; Ma, S.; Zhang, S.; Wilke, D. Geochemical evidence for the manufacture, logistics and supply-chain management of Emperor Qin Shihuang’s Terracotta Army, China. Archaeometry 2021, 63, 40–52. [Google Scholar] [CrossRef]

- Gültekin, E.E.M.; Topates, G.; Kurama, S. The effects of sintering temperature on phase and pore evolution in porcelain tiles. Ceram. Int. 2017, 43, 11511–11515. [Google Scholar] [CrossRef]

- Fontes, W.C.; de Carvalho, J.M.F.; Andrade, L.C.R.; Segadaes, A.M.; Peixoto, R.A.F. Assessment of the use potential of iron ore tailings in the manufacture of ceramic tiles: From tailings-dams to “brown porcelain”. Constr. Build. Mater. 2019, 206, 111–121. [Google Scholar] [CrossRef]

- Martin, D.; Aparicio, P.; Galan, E. Time evolution of the mineral carbonation of ceramic bricks in a simulated pilot plant using a common clay as sealing material at superficial conditions. Appl. Clay Sci. 2019, 180, 105191. [Google Scholar] [CrossRef]

- Vakalova, T.V.; Revva, I.B. Use of zeolite rocks for ceramic bricks based on brick clays and clay loams with high drying sensitivity. Constr. Build. Mater. 2020, 255, 119324. [Google Scholar] [CrossRef]

- Ricca, M.; Paladini, G.; Rovella, N.; Ruffolo, S.A.; Randazzo, L.; Crupi, V.; Fazio, B.; Majolino, D.; Venuti, V.; Galli, G.; et al. Archaeometric Characterisation of Decorated Pottery from the Archaeological Site of Villa dei Quintili (Rome, Italy): Preliminary Study. Geosciences 2019, 9, 172. [Google Scholar] [CrossRef]

- Antonelli, F.; Ermati, A.L.; Verita, M.; Raffaeli, G. An archaeometric contribution to the characterization of Renaissance maiolica from Urbino and a comparison with coeval maiolica from Pesaro (the Marches, Central Italy). Archaeometry 2014, 56, 784–804. [Google Scholar] [CrossRef]

- Dell’Aquila, C.; Laviano, R.; Vurro, F. Chemical and mineralogical investigations of majolicas (16th–19th centuries) from Laterza, southern Italy. Geol. Soc. 2006, 257, 151–162. [Google Scholar] [CrossRef]

- Fabbri, B.; Fassina, V.; Rattazzi, A.; Salvioni, D. The maiolica flooring of S. Sebastiano in Venice; an attempt of attribution by means of its composition and technology. In Proceedings of the 4th European Ceramic Society Conference, Riccione, Italy, 2–6 October 1995. [Google Scholar]

- Borzacconi, A. Technological Aspects of 16th Century Ceramics Production in Castelnovo del Friuli, Italy. Mater. Manuf. Process. 2009, 24, 1041–1047. [Google Scholar] [CrossRef]

- Law, J.E.; Østermark-Johansen, L. Victorian and Edwardian Responses to the Italian Renaissance; Routledge: London, UK, 2017. [Google Scholar]

- Matejkova, K.; Blazkova, G. Europa Postmediaevalis 2018: Post-Medieval Pottery between (Its) Borders; Archaeopress Publishing: London, UK, 2019; 310p. [Google Scholar]

- Ricci, C.; Borgia, I.; Brunetti, B.G.; Sgamellotti, A.; Fabbri, B.; Burla, M.C.; Polidori, G. A study on late medieval transparent-glazed pottery and archaic majolica from orvieto (central Italy). Archaeometry 2005, 47, 557–570. [Google Scholar] [CrossRef]

- Padeletti, G.; Fermo, P.; Bouquillon, A.; Aucouturier, M.; Barbe, F. A new light on a first example of lustred majolica in Italy. Appl. Phys. A 2010, 100, 747–761. [Google Scholar] [CrossRef]

- Kingery, W.D. Painterly Maiolica of the Italian Renaissance. Technol. Cult. 1993, 34, 28–48. [Google Scholar] [CrossRef]

- Falke, J. Majolica. In The Workshop: A Monthly Journal Devoted to Progress of the Useful Arts; Baumer, W., Schnorr, I., Eds.; E. Steiger: New York, NY, USA, 1869; Volume 2, pp. 145–148. [Google Scholar]

- Dias, M.I.; Prudencio, M.I.; Kasztovsky, Z.; Maroti, B.; Harsanyi, I.; Flor, P. Nuclear tech-niques applied to provenance and technological studies of Renaissance majolica roundels from Portuguese museums attributed to della Robbia Italian workshop. J. Radioanal. Nucl. Chem. 2017, 312, 205–219. [Google Scholar] [CrossRef]

- Douglas, R.L. The majolica and glazed earthenware of Tuscany. J. Soc. Arts 1904, 52, 853–862. [Google Scholar]

- Solon, M.L. The Ceramic Art of Orvieto during the Thirteenth and Fourteenth Centuries. Burlingt. Mag. Connoiss. 1909, 16, 10–13, 16–17. [Google Scholar]

- Bersani, D.; Lottici, P.P.; Virgenti, S.; Sodo, A.; Malvestuto, G.; Botti, A.; Salvioli-Mariani, E.; Tribaudino, M.; Ospitali, F.; Catarsi, M. Multi-technique investigation of archaeological pottery from Parma (Italy). J. Raman Spectrosc. 2010, 41, 1556–1561. [Google Scholar] [CrossRef]

- Marrocchino, E.; Telloli, C.; Pedrini, M.; Vaccaro, C. Natural stones used in the Or-si-Marconi palace façade (Bologna): A petro-mineralogical characterization. Heritage 2020, 3, 62. [Google Scholar] [CrossRef]

- Cuomo di Caprio, N. La Ceramica in Archeologia, Antiche Tecniche di Lavorazione e Moderni Metodi d’Indagine; Erma di Bretschneider: Rome, Italy, 1988. [Google Scholar]

- Telloli, C.; Chicca, M.; Pepi, S.; Vaccaro, C. Saharan dust particles in snow samples of Alps and Apennines during an exceptional event of transboundary air pollution. Environ. Monit. Assess. 2018, 190, 37. [Google Scholar] [CrossRef]

- Marrocchino, E.; Telloli, C.; Caraccio, S.; Guarnieri, C.; Vaccaro, C. Medieval Glassworks in the City of Ferrara (North Eastern Italy): The Case Study of Piazza Municipale. Heritage 2020, 3, 45. [Google Scholar] [CrossRef]

- NORMAL-43/93. Misure Colorimetriche di Superfici Opache. Raccomandazioni Normal; Comas Grafica Srl: Rome, Italy, 1994. [Google Scholar]

- Parvathy, U.; Nizam, K.M.; Zynudheen, A.A.; Ninan, G.; Panda, S.K.; Ravishankar, C.N. Characterization of fish protein hydrolysate from red meat of Euthynnus affinis and its application as an antioxidant in iced sardine. J. Sci. Ind. Res. 2018, 77, 111–119. [Google Scholar]

- Bautista-Ruiz, J.; Torres, N.; Aperador, W. Effect of the application technique on the colorimetric coordinates for a ceramic enamel. J. Phys. Conf. Ser. 2020, 1708, 012004. [Google Scholar] [CrossRef]

- Echarri-Iribarren, V.; Rizo-Maestre, C. Gloss, Light Reflection and Iridescence in Ceramic Tile Enamels Containing ZrO2 and ZnO. Coatings 2020, 10, 854. [Google Scholar] [CrossRef]

- Miller, G.L.; Samford, P.; Shlasko, E.; Madsen, A. Telling Time for Archaeologists. Northeast Hist. Archaeol. 2000, 29, 2. [Google Scholar] [CrossRef]

- Piccolpasso, C. I Tre Libri dell’Arte del Vasaio, 3rd ed.; Arnaldo Forni Editore: Sala Bolognese, Italy, 1879. [Google Scholar]

- Burzacchini, B. Colore, Pigmenti e Colorazione in Ceramica; Cierre Grafica: Verona, Italy, 2003. [Google Scholar]

- Amraoui, M.E.; Haddad, M.; Bejjit, L.; Ait Lyazidi, S.; Lakhal, R. On-site XRF characterization of archaeological materials in CERA center of Rissani (Morocco). IOP Conf. Ser. Mater. Sci. Eng. 2017, 186, 012029. [Google Scholar] [CrossRef]

- Aloupi-Siotis, E. Ceramic technology: How to characterise black Fe-based glass-ceramic coatings. Archaeol. Anthropol. Sci. 2020, 12, 191. [Google Scholar] [CrossRef]

- Quinn, P.S. Ceramic Petrography: The Interpretation of Archaeological Pottery & Related Artefacts in Thin Section; Archaeopress: Oxford, UK, 2013. [Google Scholar]

- Kazakou, T.; Zorba, T.; Vourlias, G.; Pavlidou, E.; Chrissafis, K. Combined studies for the determination of the composition and the firing temperature of ancient and contemporary ceramic artefacts. Thermochim. Acta 2019, 682, 178412. [Google Scholar] [CrossRef]

- Carretero, M.I.; Dondi, M.; Fabbri, B.; Raimondo, M. The influence of shaping and firing technology on ceramic properties of calcareous and non-calcareous illitic–chloritic clays. Appl. Clay Sci. 2002, 20, 301–306. [Google Scholar] [CrossRef]

- Ryan, W. Properties of Ceramic Raw Materials, 2nd ed.; Pergamon Press: Oxford, UK, 2013. [Google Scholar]

- Pereira, S.L.C. The production of faience in Portuguese workshops (15th–18th century). E-J. Port. Hist. 2019, 17, 49–150. [Google Scholar]

- Baldisserri, G. Rilievo delle Tecniche Ceramiche in Uso a Castelli tra le Due Guerre; Istituto Statale d’Arte per la Ceramica “G. Ballardini”: Faenza, Italy, 1988. [Google Scholar]

- Liverani, G. Una nota sulla “Mezzamaiolica”. Boll. Del Mus. Int. Ceram. Faenza 1977, 63, 99–107. [Google Scholar]

| Sample Name | Figure Reference | Classification | Daily Use | Engobed Color | Coating | Porous Body |

|---|---|---|---|---|---|---|

| CM1i | Figure 2a | engobed terracotta | Plats | White | white enamel | X |

| CM2i | Figure 2b | engobed terracotta | Plats | White | white enamel | X |

| CM3i | Figure 2c | engobed terracotta | containers (jug or pit) | White | yellow lead glaze | Less intense |

| CM1s | Figure 2d | glazed engobed terracotta | Plats | White | white enamel | X |

| CM2s | Figure 2e | glazed engobed terracotta | Plats | White | white enamel | X |

| CM3s | Figure 2f | glazed engobed terracotta | containers (jug or pit) | White | yellow lead glaze | Less intense |

| Coating Thickness | Coating Color | Coating Luster | Touch Sensitivity on the Painted Ornaments | Quibble | |

|---|---|---|---|---|---|

| Engobed terracotta | Thick | Milky white with thick enamel and pink with thin enamel | Less visible | Never, except for orange color. | Thin or thick depending on the thickness of the glaze. Always with round mesh |

| Glazed engobed terracotta | Thin | Yellowish-ivory | More visible | Always | Mesh with geometrical trend and always blackened |

| SiO2 | PbO | TiO2 | Al2O3 | Fe2O3 | MgO | CaO | Na2O | K2O | SO3 | SnO2 | TOT | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CM1s | G | 61.11 | 17.10 | 6.20 | 2.95 | 1.21 | 0.23 | 2.10 | 1.87 | 7.23 | 0.00 | 0.00 | 100 |

| Ena | 66.24 | 14.11 | 0.00 | 0.17 | 0.53 | 0.17 | 3.66 | 1.84 | 6.61 | 0.00 | 6.67 | 100 | |

| CB | 55.66 | 0.00 | 0.65 | 14.79 | 6.03 | 3.67 | 14.86 | 1.16 | 3.18 | 0.00 | 0.00 | 100 | |

| CM2s | G | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0 |

| Ena | 56.39 | 25.31 | 0.00 | 4.15 | 0.38 | 0.28 | 1.53 | 1.42 | 4.51 | 0.00 | 6.03 | 100 | |

| CB | 51.89 | 0.00 | 0.76 | 14.20 | 6.60 | 4.47 | 18.56 | 1.41 | 2.11 | 0.00 | 0.00 | 100 | |

| CM3s | G | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0 |

| Ena | 55.57 | 24.14 | 0.00 | 4.35 | 0.61 | 0.21 | 1.74 | 1.39 | 5.43 | 0.00 | 6.56 | 100 | |

| CB | 51.50 | 0.00 | 0.73 | 14.65 | 7.26 | 3.90 | 17.71 | 1.37 | 2.88 | 0.00 | 0.00 | 100 | |

| CM1i | G | 59.69 | 22.85 | 0.00 | 4.64 | 0.74 | 0.42 | 3.97 | 1.86 | 5.83 | 0.00 | 0.00 | 100 |

| Eng | 53.83 | 0.00 | 0.68 | 16.53 | 1.80 | 5.86 | 11.04 | 2.00 | 5.93 | 2.33 | 0.00 | 100 | |

| CB | 51.36 | 0.00 | 0.59 | 15.27 | 6.43 | 4.38 | 16.58 | 1.65 | 3.74 | 0.00 | 0.00 | 100 | |

| CM2i | G | 58.30 | 27.70 | 0.00 | 3.97 | 0.35 | 0.45 | 2.73 | 1.57 | 4.93 | 0.00 | 0.00 | 100 |

| Eng | 49.90 | 0.00 | 0.69 | 16.27 | 0.99 | 5.12 | 15.10 | 1.04 | 6.49 | 4.40 | 0.00 | 100 | |

| CB | 53.13 | 0.00 | 0.63 | 14.23 | 5.19 | 4.11 | 17.85 | 1.15 | 3.71 | 0.00 | 0.00 | 100 | |

| CM3i | G | 60.26 | 24.95 | 0.00 | 3.36 | 0.63 | 0.68 | 3.74 | 2.27 | 4.11 | 0.00 | 0.00 | 100 |

| Eng | 56.00 | 0.00 | 0.70 | 15.27 | 1.60 | 5.51 | 11.19 | 2.94 | 5.03 | 1.76 | 0.00 | 100 | |

| CB | 56.75 | 0.00 | 0.72 | 15.37 | 3.82 | 4.91 | 12.64 | 2.91 | 2.88 | 0.00 | 0.00 | 100 |

| L* | a* | b* | |

|---|---|---|---|

| CM 1s | 66.61 | 3.95 | 10.01 |

| CM 2s | 78.63 | 1.04 | 6.47 |

| CM 3s | 78.35 | 1.85 | 8.36 |

| CM 1i | 76.38 | 2.10 | 14.69 |

| CM 2i | 77.17 | 0.80 | 13.51 |

| CM 3i | 75.39 | 1.89 | 12.31 |

| Engobed Terracotta (Majolica) | Glazed Engobed Terracotta (Mezza-Majolica) | |

|---|---|---|

| 1 | Molding of the clay in a plastic state | Molding of clay in a plastic state |

| 2 | Engobed application on the raw artifact | |

| 3 | First firing | First firing |

| 4 | Enable application and decoration | Decoration |

| 5 | Glazed application | |

| 6 | Second firing | Second firing |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marrocchino, E.; Paletta, M.G.; Telloli, C. Microanalytical Determinations to Distinguish Maiolica and Mezza Majolica Ceramics from Faenza (Emilia-Romagna Region, Italy). Heritage 2022, 5, 3515-3529. https://doi.org/10.3390/heritage5040182

Marrocchino E, Paletta MG, Telloli C. Microanalytical Determinations to Distinguish Maiolica and Mezza Majolica Ceramics from Faenza (Emilia-Romagna Region, Italy). Heritage. 2022; 5(4):3515-3529. https://doi.org/10.3390/heritage5040182

Chicago/Turabian StyleMarrocchino, Elena, Maria Grazia Paletta, and Chiara Telloli. 2022. "Microanalytical Determinations to Distinguish Maiolica and Mezza Majolica Ceramics from Faenza (Emilia-Romagna Region, Italy)" Heritage 5, no. 4: 3515-3529. https://doi.org/10.3390/heritage5040182

APA StyleMarrocchino, E., Paletta, M. G., & Telloli, C. (2022). Microanalytical Determinations to Distinguish Maiolica and Mezza Majolica Ceramics from Faenza (Emilia-Romagna Region, Italy). Heritage, 5(4), 3515-3529. https://doi.org/10.3390/heritage5040182