Systematic Design of Ancient Machines’ Models: Leonardo da Vinci’s Glider

Abstract

1. Introduction

2. Materials and Methods

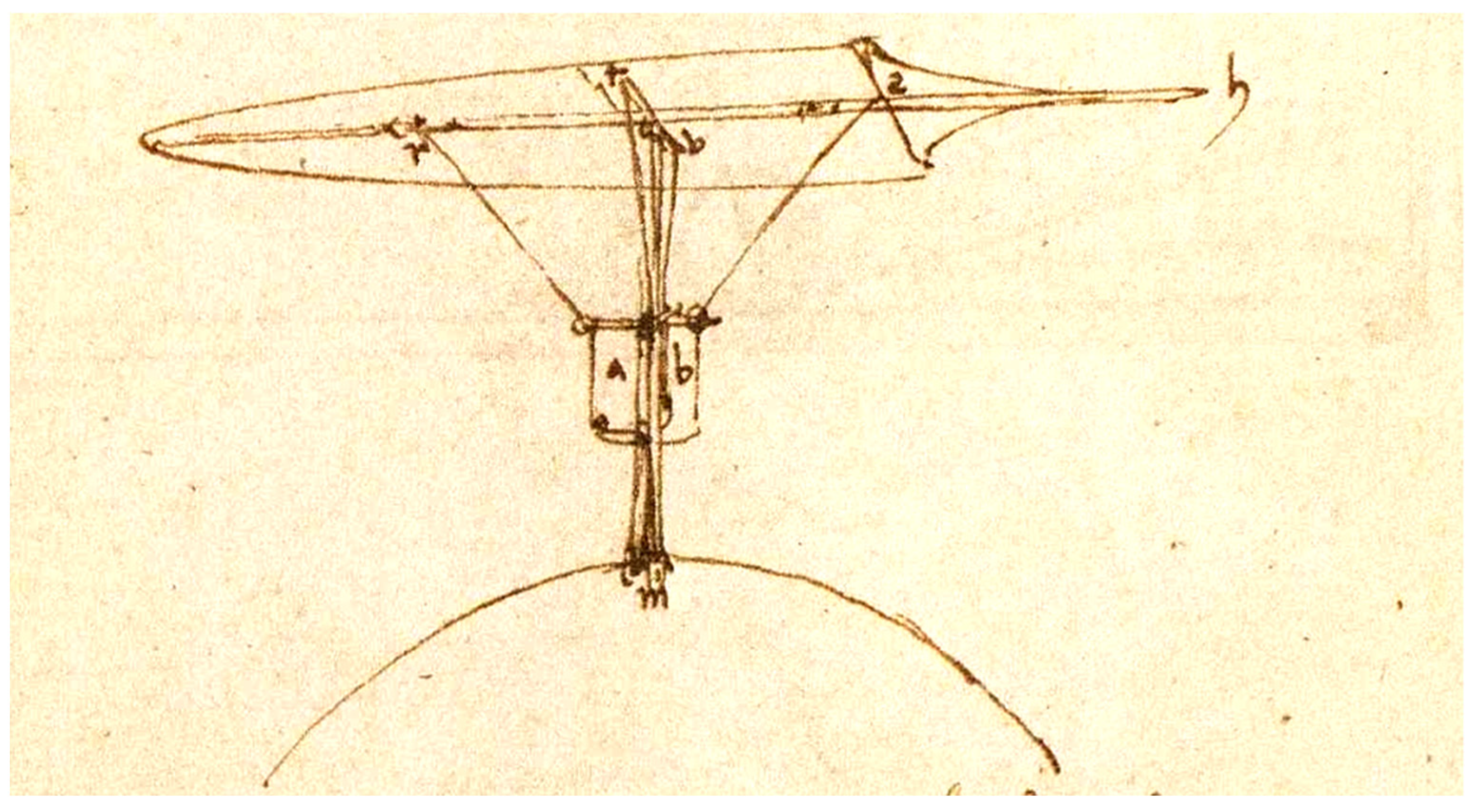

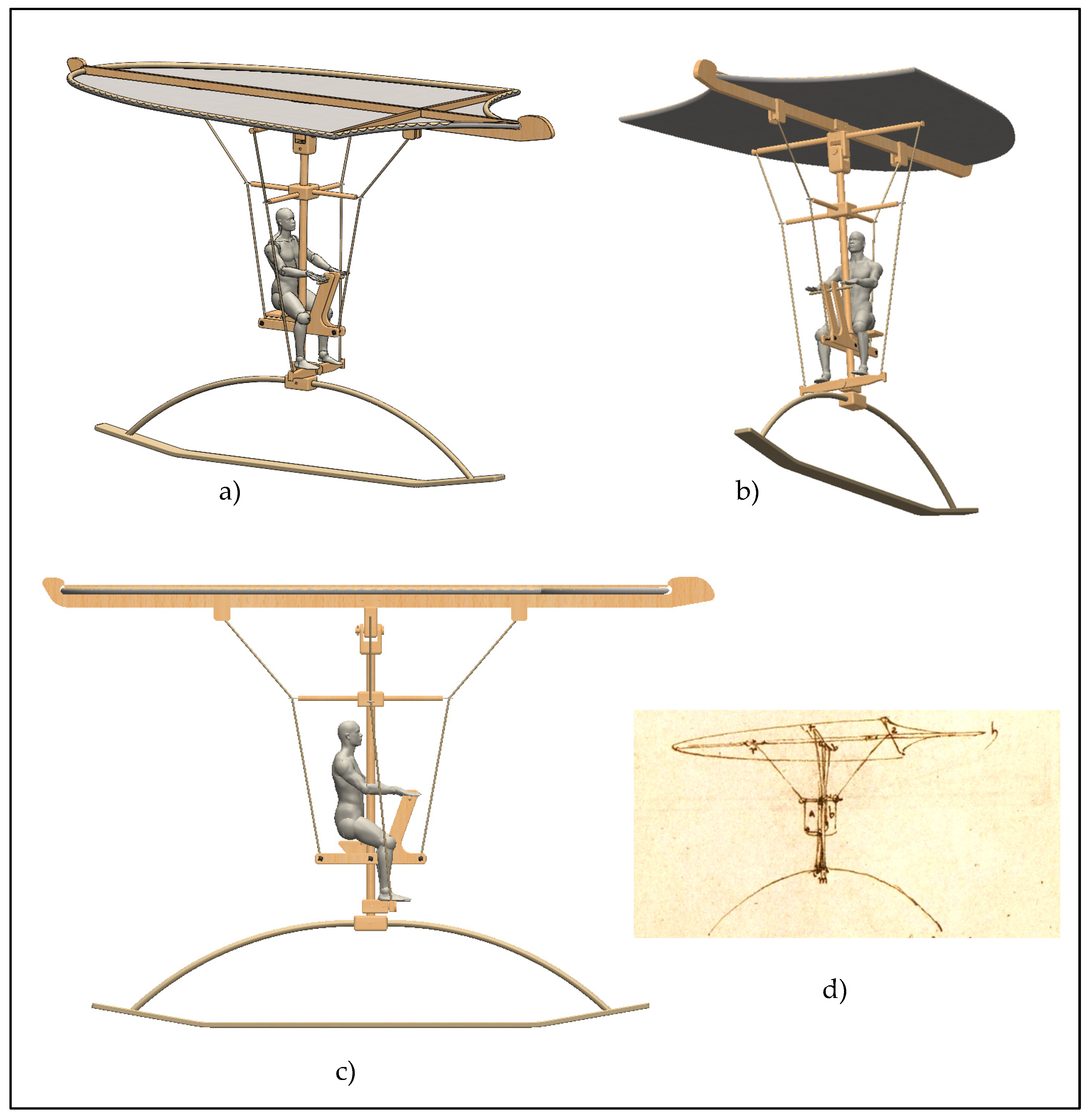

2.1. The “Delta wing” of Leonardo

2.2. The Problem-Solution-Network

- Allows to visualize the explored design space in a single graphical representation.

- Allows to solve each main design problem independently, thus enhancing multidisciplinary teamwork.

- Allows to keep track of information-gathering activities for both problems and solutions.

- The concept generation (CG), where the design space is explored in terms of problems and solutions sequences, leading to network hierarchically organized according to related abstraction levels.

- The concept composition (CC), where a variety of possible combinations are proposed between the solutions from different PSN branches. In this phase, sketches are created by the designer to generate and visualize different overall concept variants.

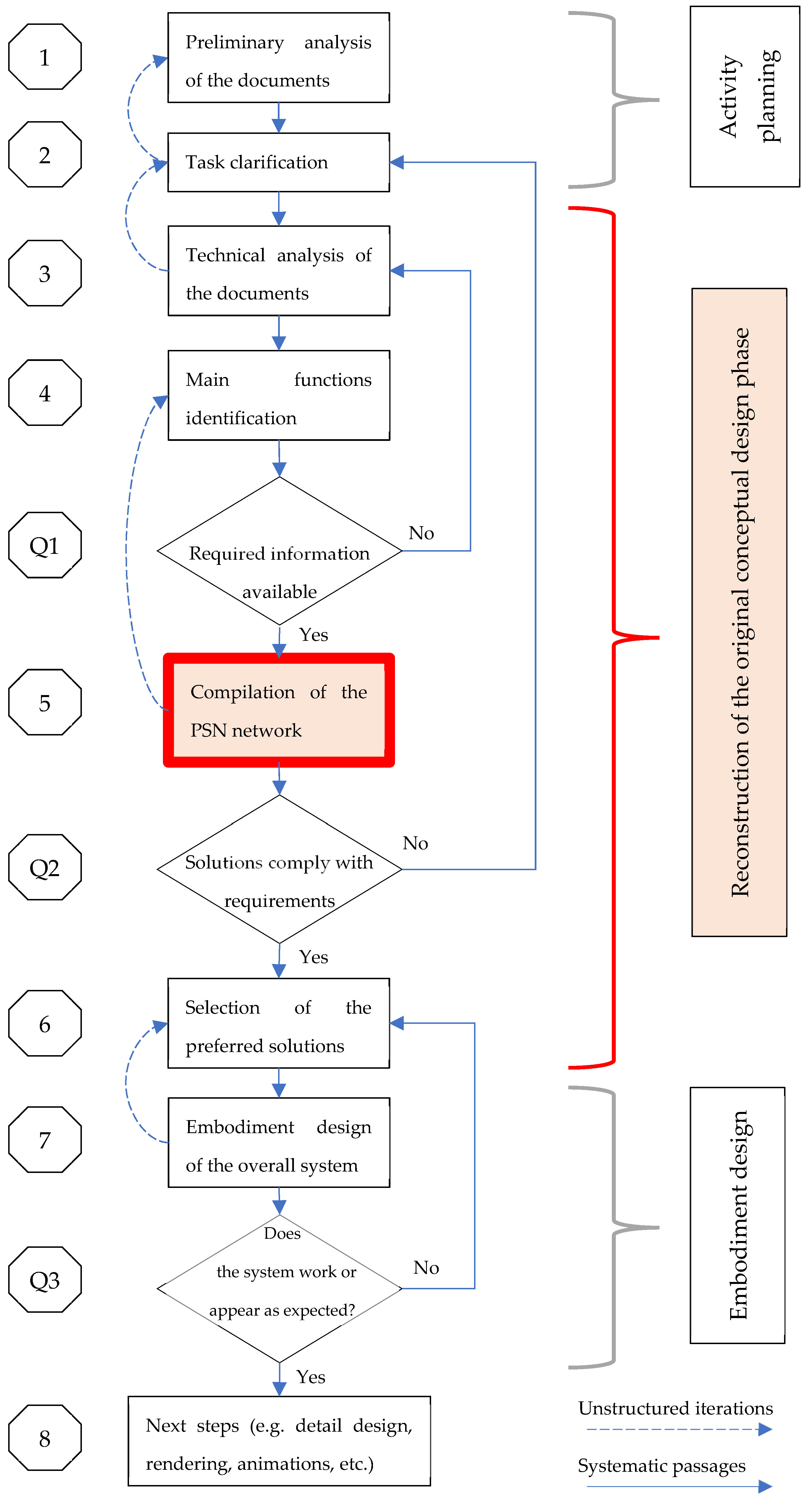

2.3. The Proposed Approach

2.3.1. Description of the Steps

2.3.2. Systematic Iterations and Unstructured Passages

3. Application to a Case and Obtained Results

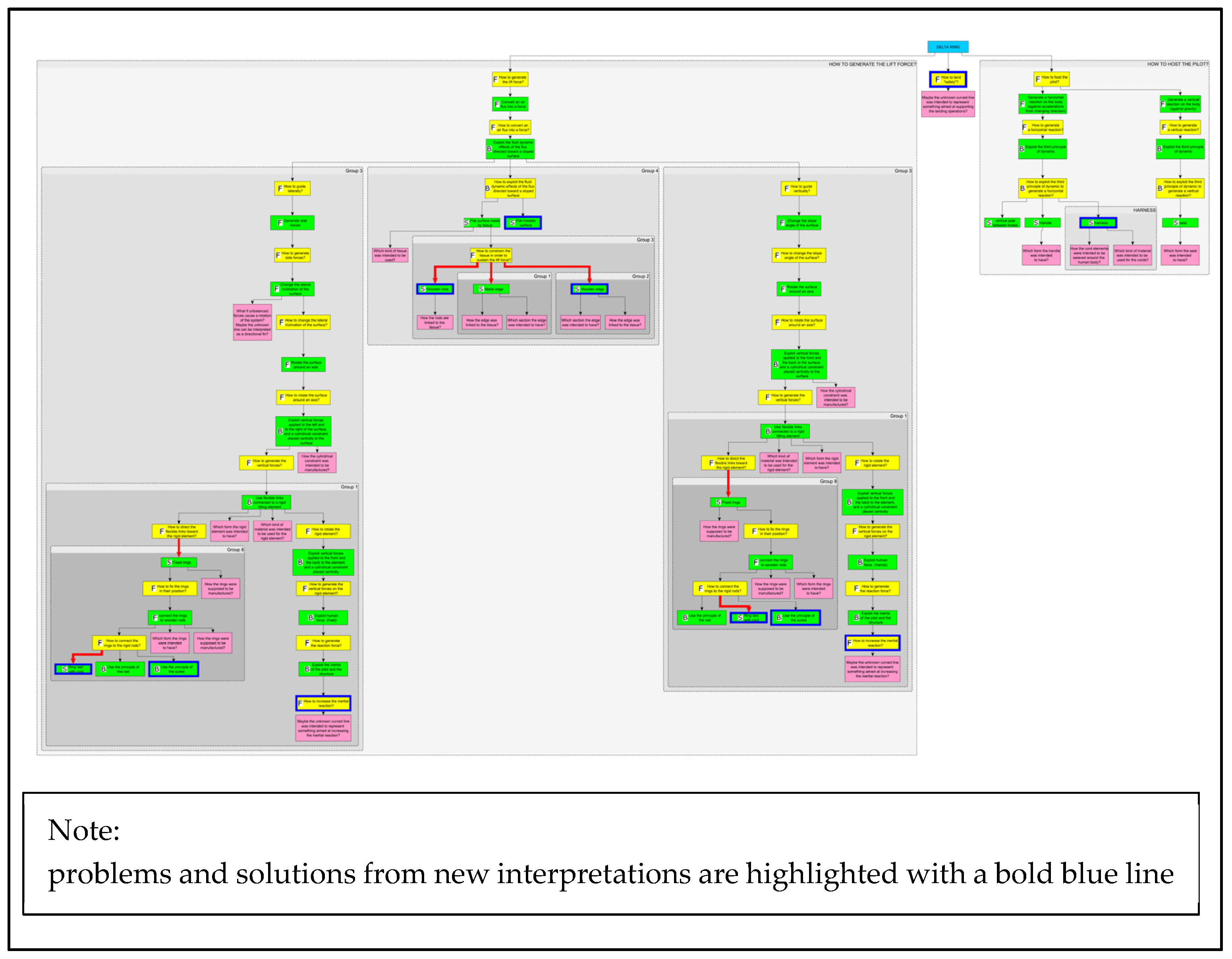

3.1. Problem–Solution–Network of Leonardo’s Delta Wing

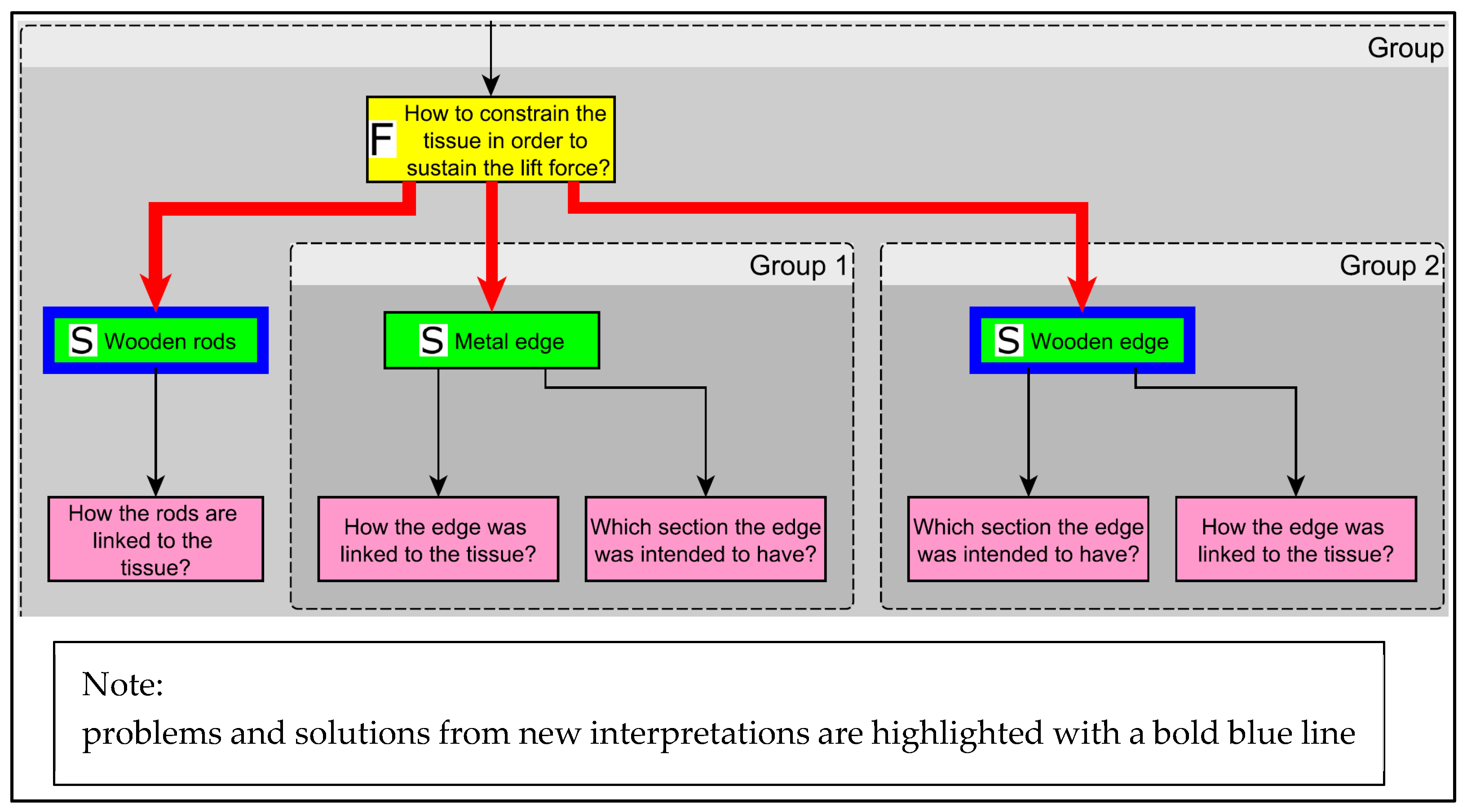

3.2. Example of Alternative Intepretations: How to Constrain the Tissue of the Wing

3.3. Example of Alternative Intepretations: Another Possible Purpose of the Ambiguous Line?

3.4. Embodiment-Design Model

4. Discussion

4.1. About the Obtained Results

4.2. Limitations of the Work and Research Hints

4.3. Expected Impact

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moon, F.C. The Machines of Leonardo da Vinci and Franz Reuleaux; Kinematics of Machines from the Renaissance to Machines of Leonardo Da Vinci (History of Mechanism and Machine Science); Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Galluzzi, P. Leonardo da Vinci: From the “elementi macchinali” to the man-machine. Hist. Technol. Int. J. 1987, 4, 235–265. [Google Scholar] [CrossRef]

- Hollister-Short, G. Relating to Leonardo da Vinci’ s Work on Textile Machines. J. Renaiss. 2007, 5, 77–115. [Google Scholar] [CrossRef]

- Innocenzi, P. The Innovators Behind Leonardo; Springer: Cham, Switzerland, 2019; ISBN 9783319904481. [Google Scholar]

- Padfield, G. Leonardo da Vinci Glider. Available online: https://www.liverpool.ac.uk/flight-science/fs/fshistory/leonardo/ (accessed on 18 April 2022).

- Laurenza, D. Leonardo on Flight. Aircr. Eng. Aerosp. Technol. 2008, 80. [Google Scholar] [CrossRef]

- Giacomelli, R. The Aerodynamics of Leonardo Da Vinci. J. R. Aeronaut. Soc. 1930, 34, 1016–1038. [Google Scholar] [CrossRef]

- Parra, R.B. Leonardo da Vinci Interdisciplinarity. In Proceedings of the 31st Congress of the International Council of the Aeronautical Sciences (ICAS 2018), Belo Horizonte, Brazil, 9–14 September 2018. [Google Scholar]

- Le Masson, P.; Weil, B. Design theories as languages of the unknown: Insights from the German roots of systematic design (1840–1960). Res. Eng. Des. 2012, 24, 105–126. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design, 3rd ed.; Springer: London, UK, 2007; ISBN 9781846283185. [Google Scholar]

- Mossa, M. The recent 500th anniversary of Leonardo da Vinci’s death: A reminder of his contribution in the field of fluid mechanics. Environ. Fluid Mech. 2021, 21, 1–10. [Google Scholar] [CrossRef]

- Tarelko, W. Leonardo da Vinci—Precursor of Engineering Design. In Proceedings of the DS 36: DESIGN 2006, the 9th International Design Conference, Dubrovnik, Croatia, 15–18 May 2006; pp. 139–146. [Google Scholar]

- Güss, C.D.; Ahmed, S.; Dörner, D. From da Vinci’s Flying Machines to a Theory of the Creative Process. Perspect. Psychol. Sci. 2021, 16, 1184–1197. [Google Scholar] [CrossRef]

- E-Leo Digital Archive—Madrid Codex 1—Sheet 64r. Available online: https://www.leonardodigitale.com/en/browse/madrid-I/0064-r/ (accessed on 4 March 2022).

- Fiorineschi, L.; Barsanti, R.; Cascini, G.; Rotini, F. Application of Systematic Design Methods to Cultural Heritage Preservation. In Proceedings of the Heritech 2020, Florence, Italy, 14–16 October 2020. [Google Scholar]

- Fiorineschi, L.; Rotini, F.; Rissone, P. A new conceptual design approach for overcoming the flaws of functional decomposition and morphology. J. Eng. Des. 2016, 27, 438–468. [Google Scholar] [CrossRef]

- Purcell, A.T.; Gero, J.S. Design and other types of fixation. Des. Stud. 1996, 17, 363–383. [Google Scholar] [CrossRef]

- Jansson, D.G.; Smith, S.M. Design fixation. Des. Stud. 1991, 12, 3–11. [Google Scholar] [CrossRef]

- Crilly, N.; Cardoso, C. Where next for research on fixation, inspiration and creativity in design? Des. Stud. 2017, 50, 1–38. [Google Scholar] [CrossRef]

- Fiorineschi, L. Abstraction framework to support students in learning creative conceptual design. J. Eng. Des. Technol. 2018, 16, 616–636. [Google Scholar] [CrossRef]

- Vermaas, P.E.; Dorst, K. On the conceptual framework of John Gero’s FBS-model and the prescriptive aims of design methodology. Des. Stud. 2007, 28, 133–157. [Google Scholar] [CrossRef]

- Gero, J.S. Design Prototypes: A Knowledge Representation Schema for Design. AI Mag. 1990, 11, 26–36. [Google Scholar]

- Pugh, S. Total Design. Integrated Methods for Succesfull Product Engineering; Addison Wesley Publishing Company: Reading, MA, USA, 1991. [Google Scholar]

- Akao, Y. Quality Function Deployment: Integrating Customer Requirements into Product Design; Productivity Press: Cambridge, UK, 1990. [Google Scholar]

- Fiorineschi, L.; Frillici, F.S.; Rotini, F. Challenging COVID-19 with Creativity: Supporting Design Space Exploration for Emergency Ventilators. Appl. Sci. 2020, 10, 4955. [Google Scholar] [CrossRef]

- YWorks. YWorks Yed Graph Editor. Available online: https://www.yworks.com/products/yed (accessed on 4 April 2022).

- Fiorineschi, L. Problem-Solution-Network of the Leonardo da Vinci’s Glider. Mendeley Data 2022, 1. [Google Scholar] [CrossRef]

- Ulrich, K.T.; Eppinger, S.D. Product Design and Development, 5th ed.; Mc Graw Hill Irwin: New York, NY, USA, 2012; ISBN 9780073404776. [Google Scholar]

- Ullman, D.G. The Mechanical Design Process, 4th ed.; Mc Graw HIll: New York, NY, USA, 2010; ISBN 978-0-07-297574-1. [Google Scholar]

- Shah, J.J.; Smith, S.M.; Vargas-Hernandez, N. Metrics for measuring ideation effectiveness. Des. Stud. 2003, 24, 111–134. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Rotini, F. Novelty metrics in engineering design. J. Eng. Des. 2021, 32, 590–620. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Frillici, F.S.; Rotini, F. Refined metric for a-posteriori novelty assessments. J. Eng. Des. 2021, 33, 39–63. [Google Scholar] [CrossRef]

- Sarkar, P.; Chakrabarti, A. Assessing design creativity. Des. Stud. 2011, 32, 348–383. [Google Scholar] [CrossRef]

- Hennessey, B.A.; Amabile, T.M.; Mueller, J.S. Consensual Assessment, 2nd ed.; Academic Press: San Diego, CA, USA, 2011; Volume 1. [Google Scholar]

- Jagtap, S. Design creativity: Refined method for novelty assessment. Int. J. Des. Creat. Innov. 2019, 7, 99–115. [Google Scholar] [CrossRef]

- Lopez-Mesa, B.; Vidal, R. Novelty Metrics in Engineering Design Experiments. In Proceedings of the 9th International Design Conference, DESIGN 2006, Dubrovnik, Croatia, 15–18 May 2006; pp. 557–564. [Google Scholar]

- Geijo, J.M.; Sanchez-Lite, A.; Zulueta, P.; Sampaio, A.Z. Study of an “Artefact” of the Castilla Canal: Reconstruction of the Missing Machinery. Machines 2022, 10, 239. [Google Scholar] [CrossRef]

- Cascini, G.; Russo, D.; Nanni, R. A Contribution to History of Technology: Analyzing Leonardo’s Textile Machines and His Inventive Process by TRIZ Methods; Firenze University Press: Florence, Italy, 2004; ISBN 88-8453-221-3. [Google Scholar]

- Reich, Y. My method is better! Res. Eng. Des. 2010, 21, 137–142. [Google Scholar] [CrossRef][Green Version]

- Kroll, E. Design theory and conceptual design: Contrasting functional decomposition and morphology with parameter analysis. Res. Eng. Des. 2013, 24, 165–183. [Google Scholar] [CrossRef]

- Shai, O.; Reich, Y. Infused design. I. Theory. Res. Eng. Des. 2004, 15, 93–107. [Google Scholar] [CrossRef]

- Altshuller, G.S. Creativity as an Exact Science; Gordon and Breach Science: Amsterdam, The Netherlands, 1984; ISBN 0677212305. [Google Scholar]

- Cavallucci, D.; Khomenko, N. From TRIZ to OTSM-TRIZ: Addressing complexity challenges in inventive design Denis Cavallucci, Nikolaï Khomenko. Int. J. Prod. Dev. 2007, 4, 4–21. [Google Scholar] [CrossRef]

- Nakagawa, T. A New Paradigm for Creative Problem Solving: Six-Box Scheme in USIT without Depending on Analogical Thinking. Available online: https://triz-journal.com/new-paradigm-creative-problem-solving-six-box-scheme-usit-without-depending-analogical-thinking/ (accessed on 2 January 2017).

- Vermaas, P.E.; Eckert, C. My functional description is better! Artif. Intell. Eng. Des. Anal. Manuf. 2013, 27, 187–190. [Google Scholar] [CrossRef]

| Type of Box | Abstraction Level | Graphical Representation | Description |

|---|---|---|---|

| Problem | Function |  | Problems about how to implement an action that the system is supposed to perform (e.g., “how to move the object?”) |

| Behavior |  | Problems about how to exploit specific behaviors to implement a required function (e.g., “How to use gravity to move objects?”) | |

| Solution | Function |  | Solution representing an action that the system could perform in order to solve a problem (e.g., “Move the object laterally”). |

| Behavior |  | Solution representing a behavior that could be used to solve a functional problem (e.g., “Exploit the thermal expansion of metallic materials”). | |

| Structure |  | Solution representing the specific structure that can be used for implementing a function by exploiting specific behaviors (e.g., “Torque spring”). | |

| Arrows | F to S passage |  | When a solution to an “F” problem is formulated at the “S” level, thus neglecting the “B” level, the passage is highlighted by a bold red line |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiorineschi, L.; Rotini, F.; Barsanti, R. Systematic Design of Ancient Machines’ Models: Leonardo da Vinci’s Glider. Heritage 2022, 5, 1593-1611. https://doi.org/10.3390/heritage5030083

Fiorineschi L, Rotini F, Barsanti R. Systematic Design of Ancient Machines’ Models: Leonardo da Vinci’s Glider. Heritage. 2022; 5(3):1593-1611. https://doi.org/10.3390/heritage5030083

Chicago/Turabian StyleFiorineschi, Lorenzo, Federico Rotini, and Roberta Barsanti. 2022. "Systematic Design of Ancient Machines’ Models: Leonardo da Vinci’s Glider" Heritage 5, no. 3: 1593-1611. https://doi.org/10.3390/heritage5030083

APA StyleFiorineschi, L., Rotini, F., & Barsanti, R. (2022). Systematic Design of Ancient Machines’ Models: Leonardo da Vinci’s Glider. Heritage, 5(3), 1593-1611. https://doi.org/10.3390/heritage5030083