Feasibility Study of Biodegradable Vegetable Peels as Sustainable Fluid Loss Additives in Water-Based Drilling Fluids

Abstract

1. Introduction

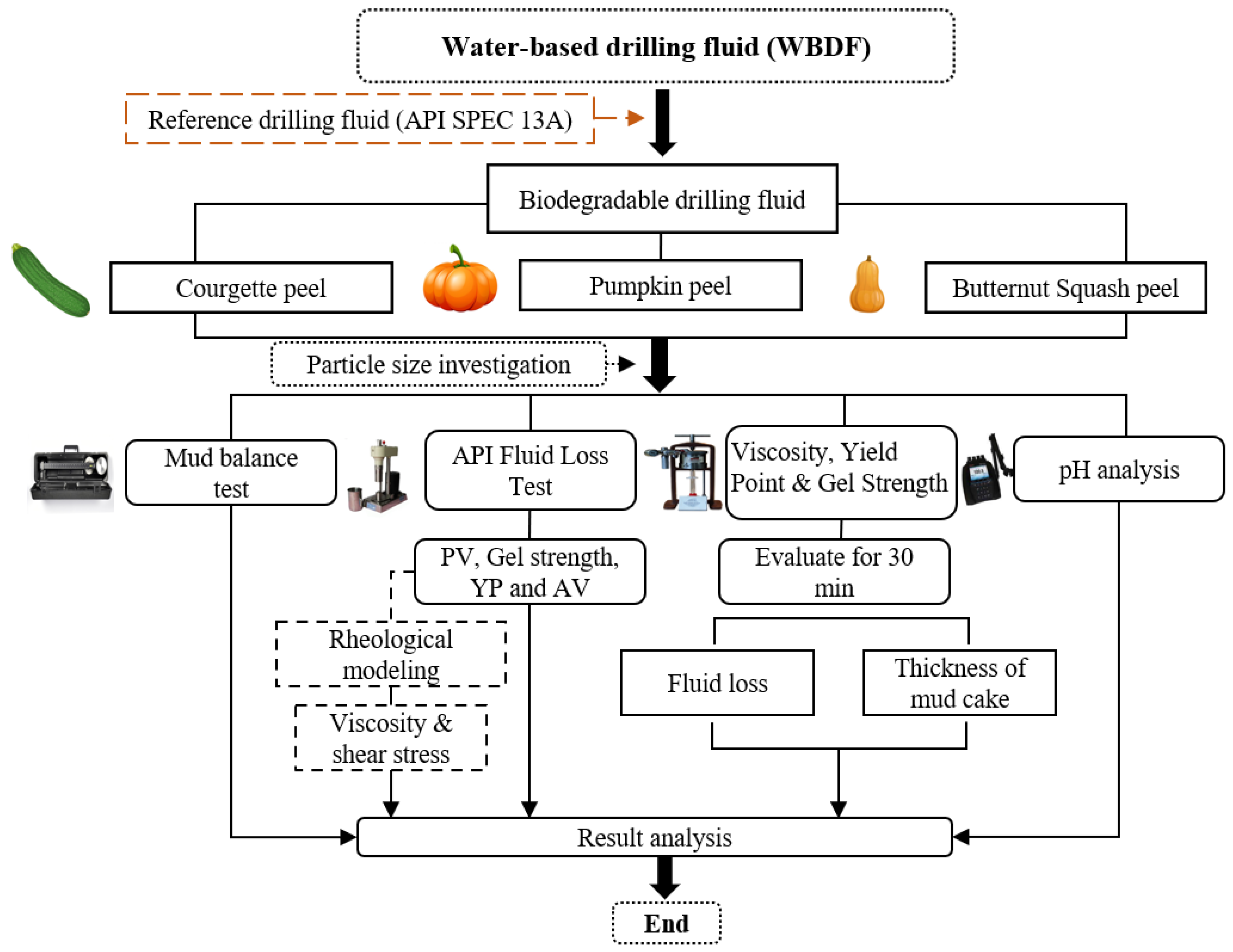

2. Materials and Methodology

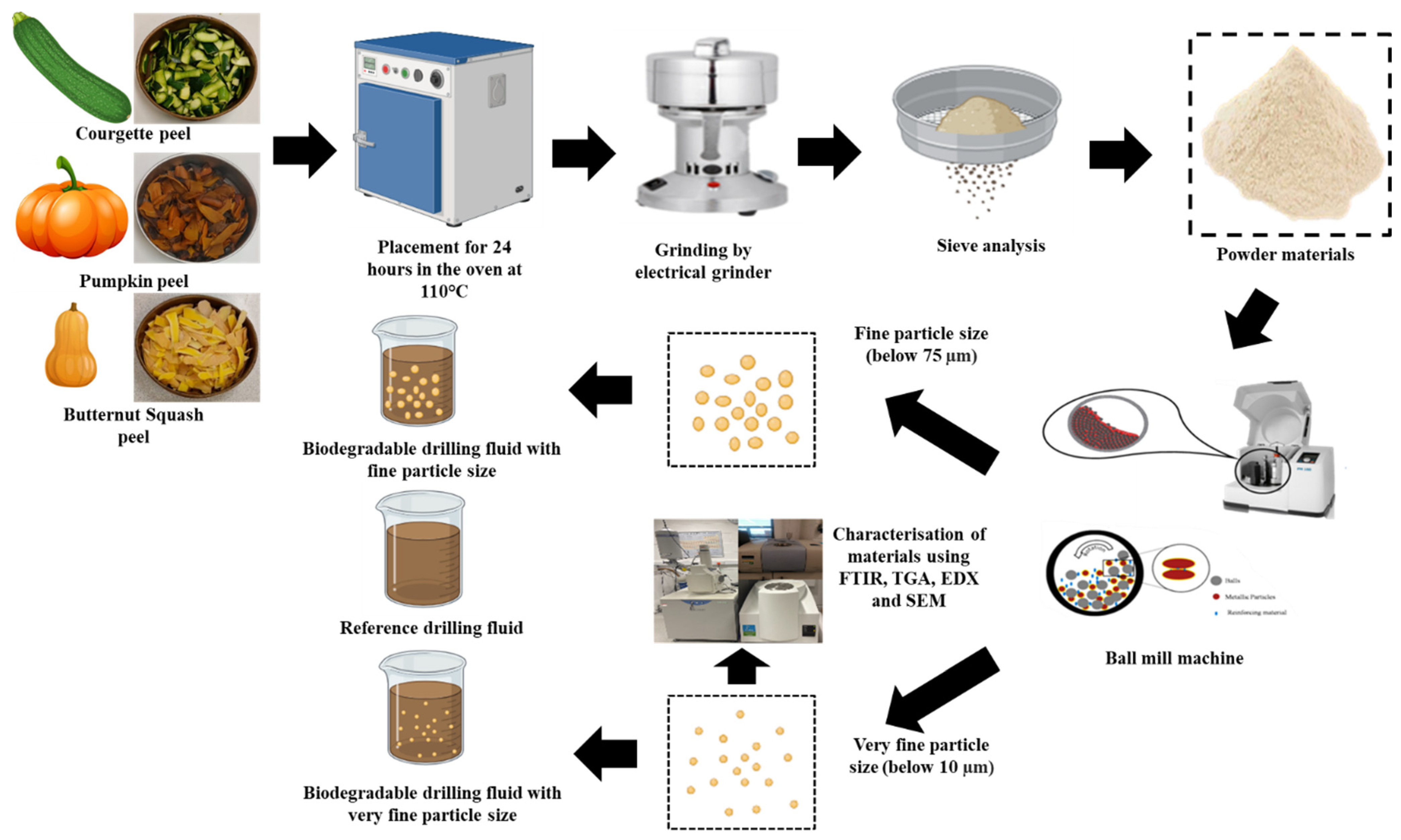

2.1. Preparation of Biodegradable Materials and Drilling Fluids

2.2. Fluid Circulation Loss and Filter Cake Thickness Measurements

2.3. Measurement of the Rheological Properties of Drilling Fluid

2.4. Relationship Between Shear Rate, Viscosity, and Shear Stress

3. Results and Discussion

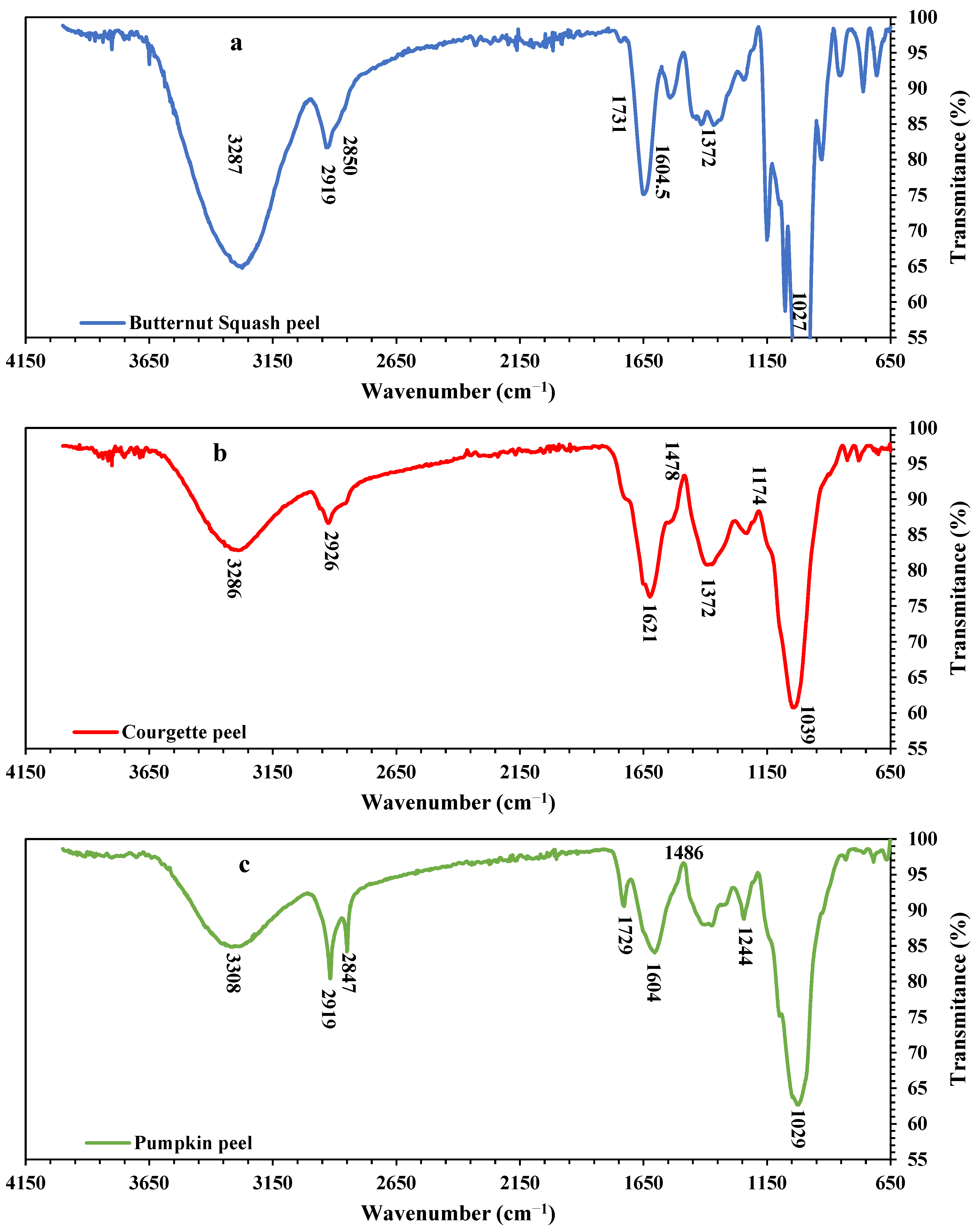

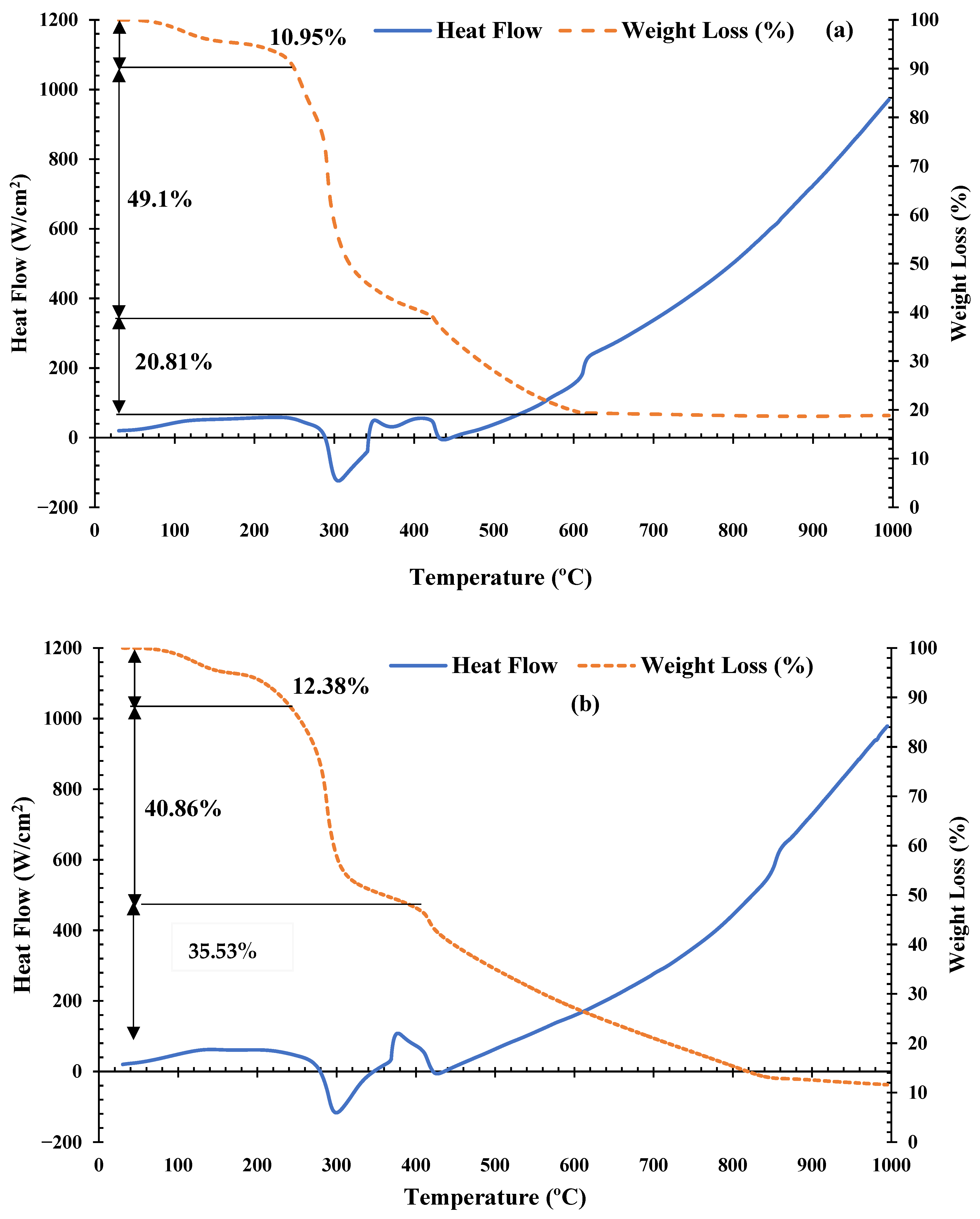

3.1. Characterization of Wasted Vegetable Peels

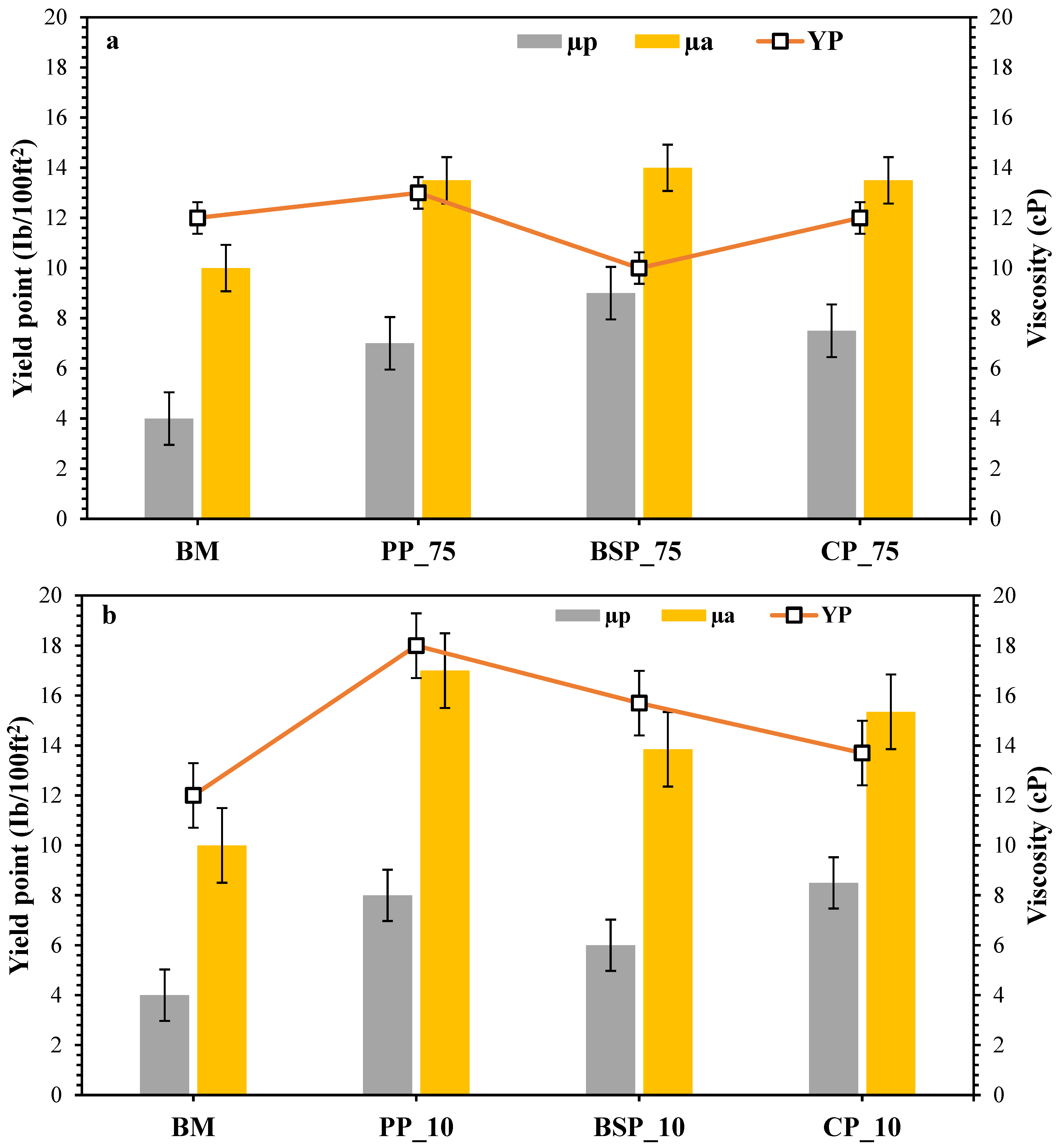

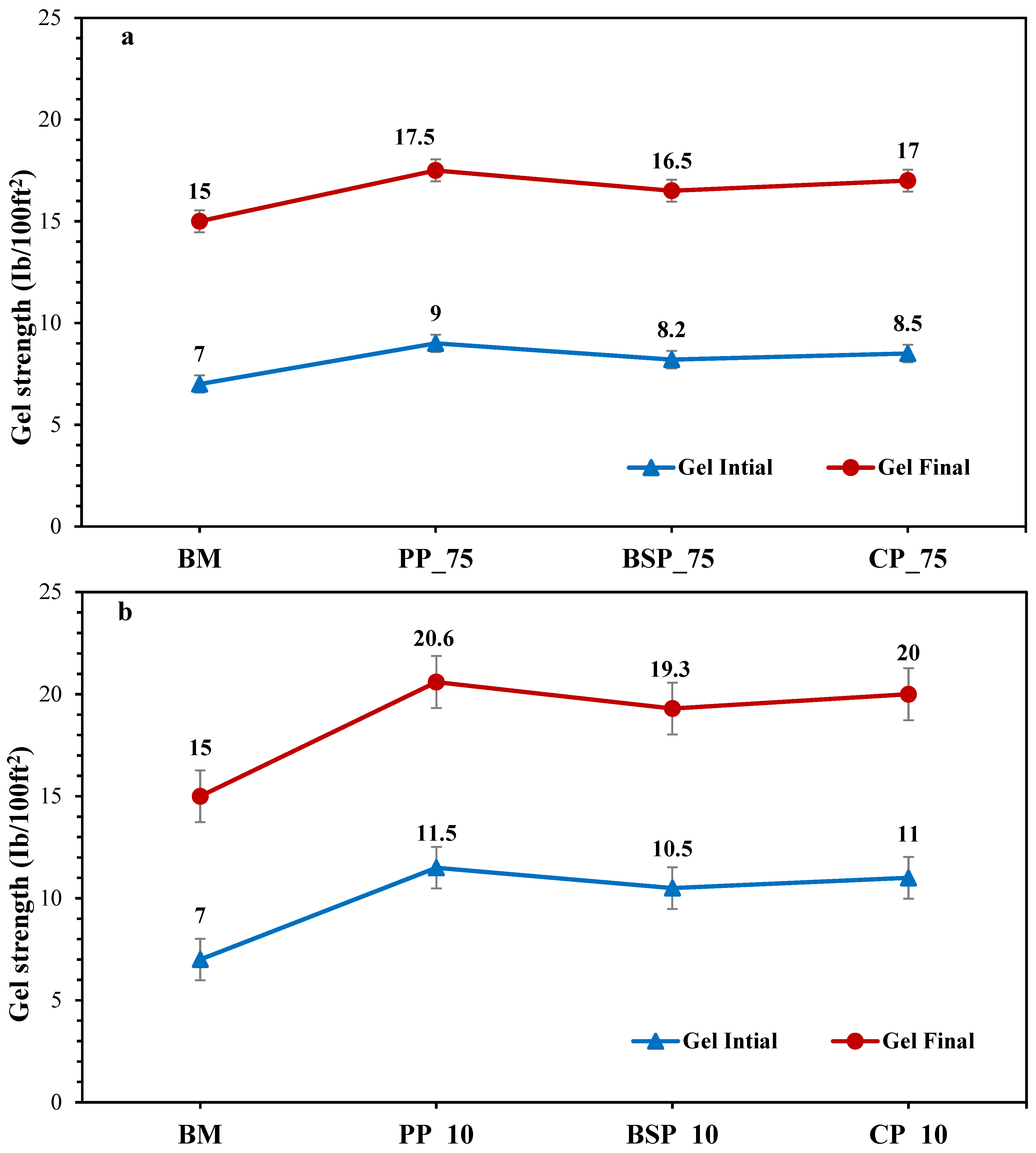

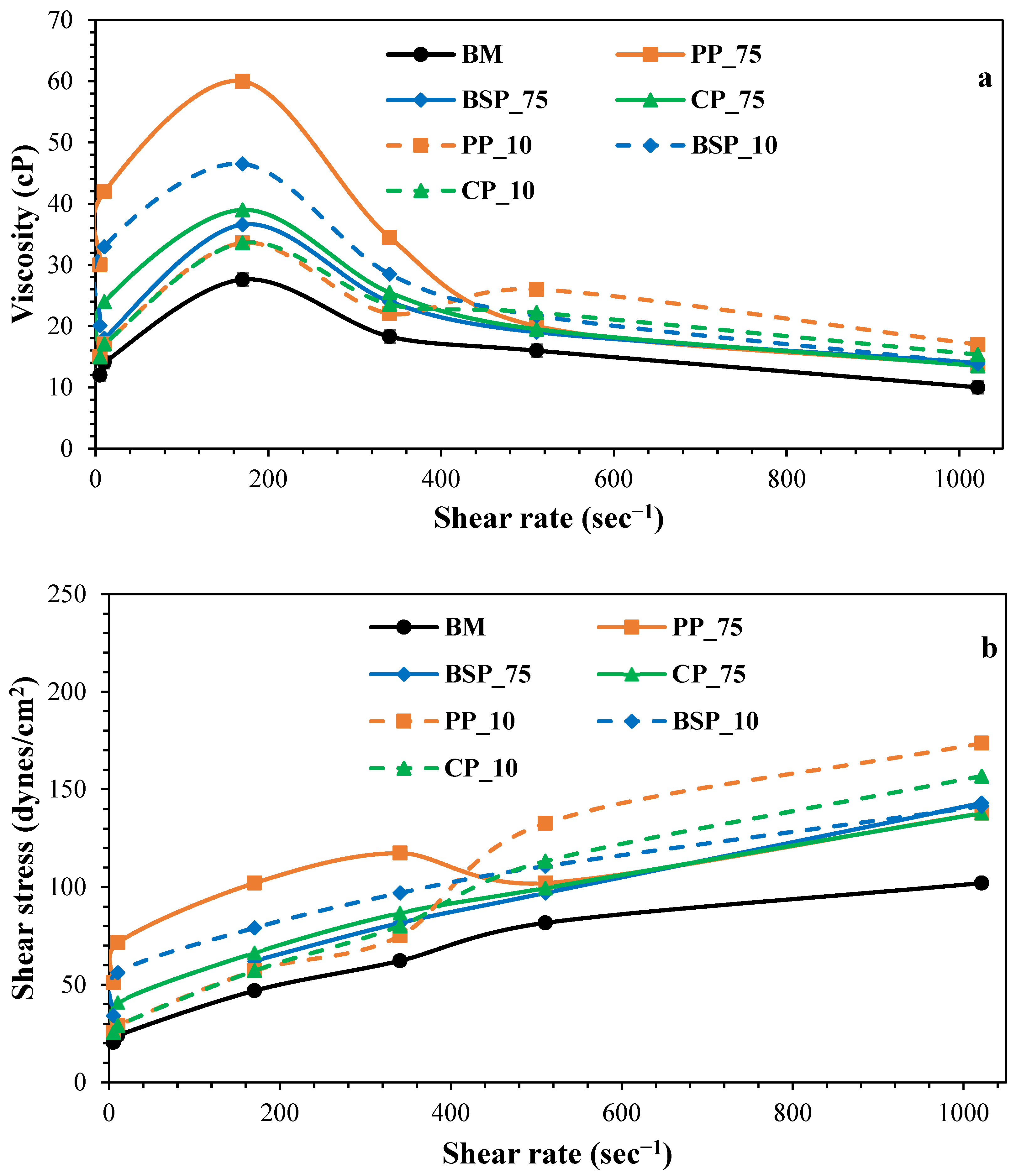

3.2. Rheological Property

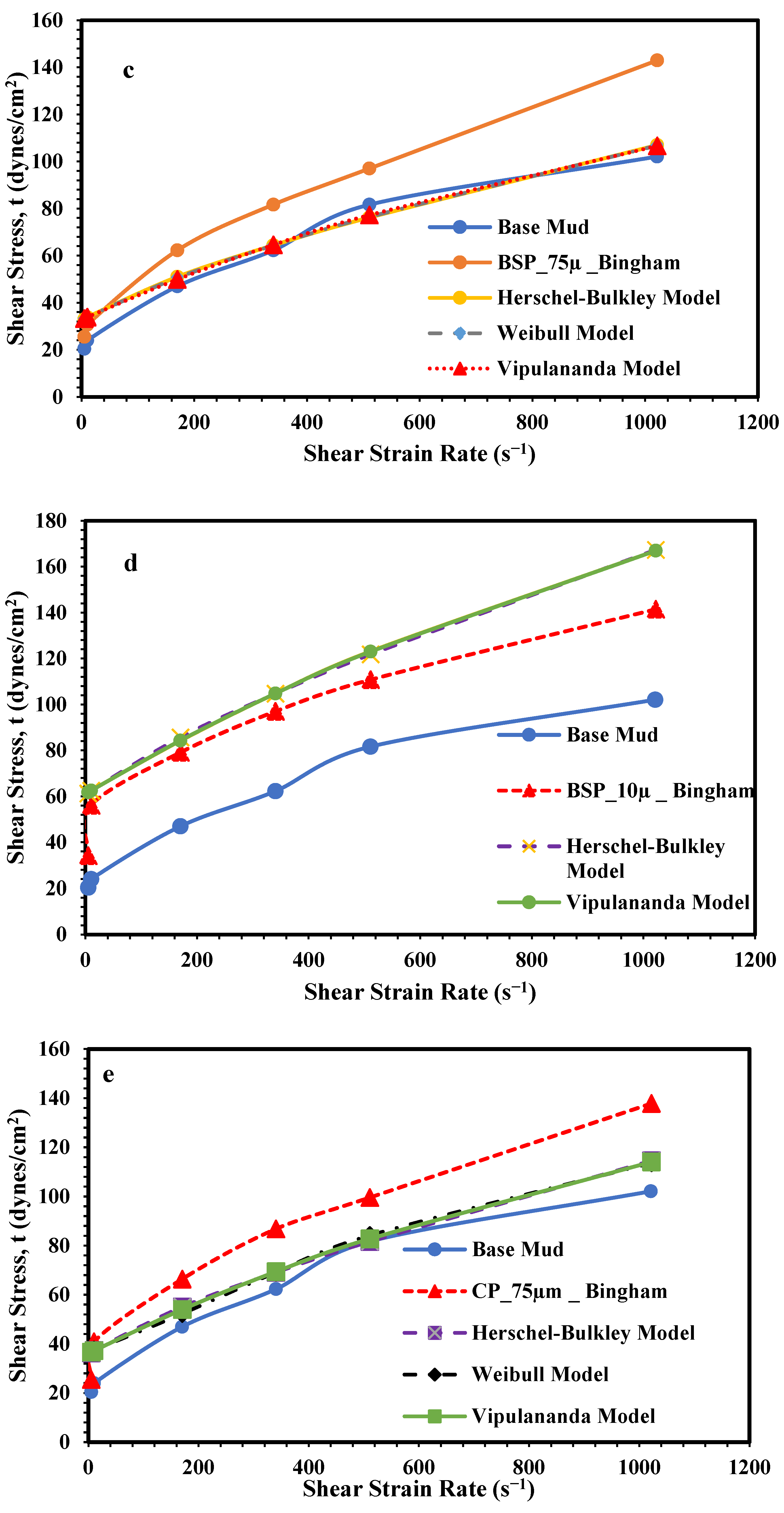

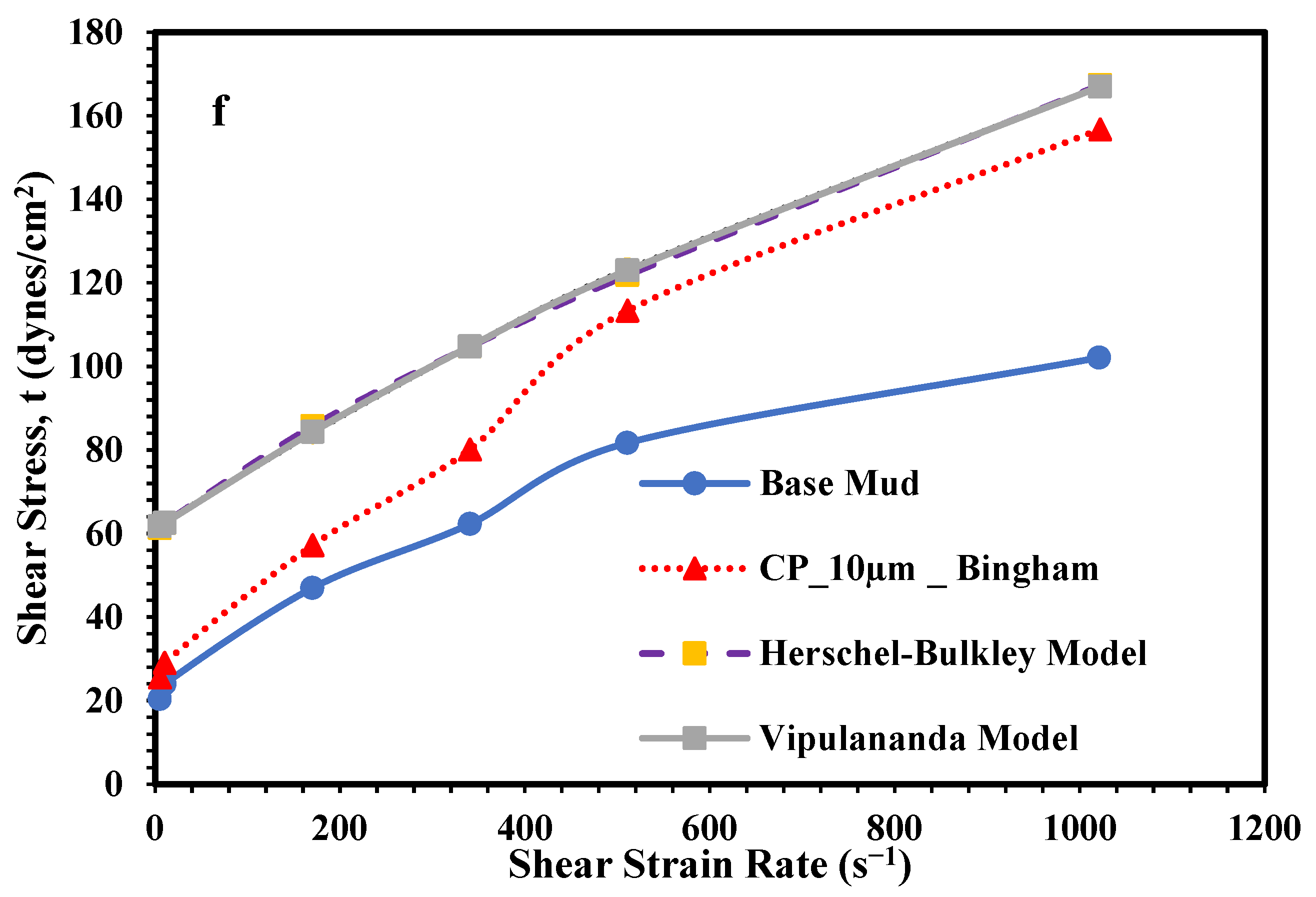

3.3. Rheological Modelling

3.4. Relationship Between Shear Rate, Viscosity, and Shear Stress

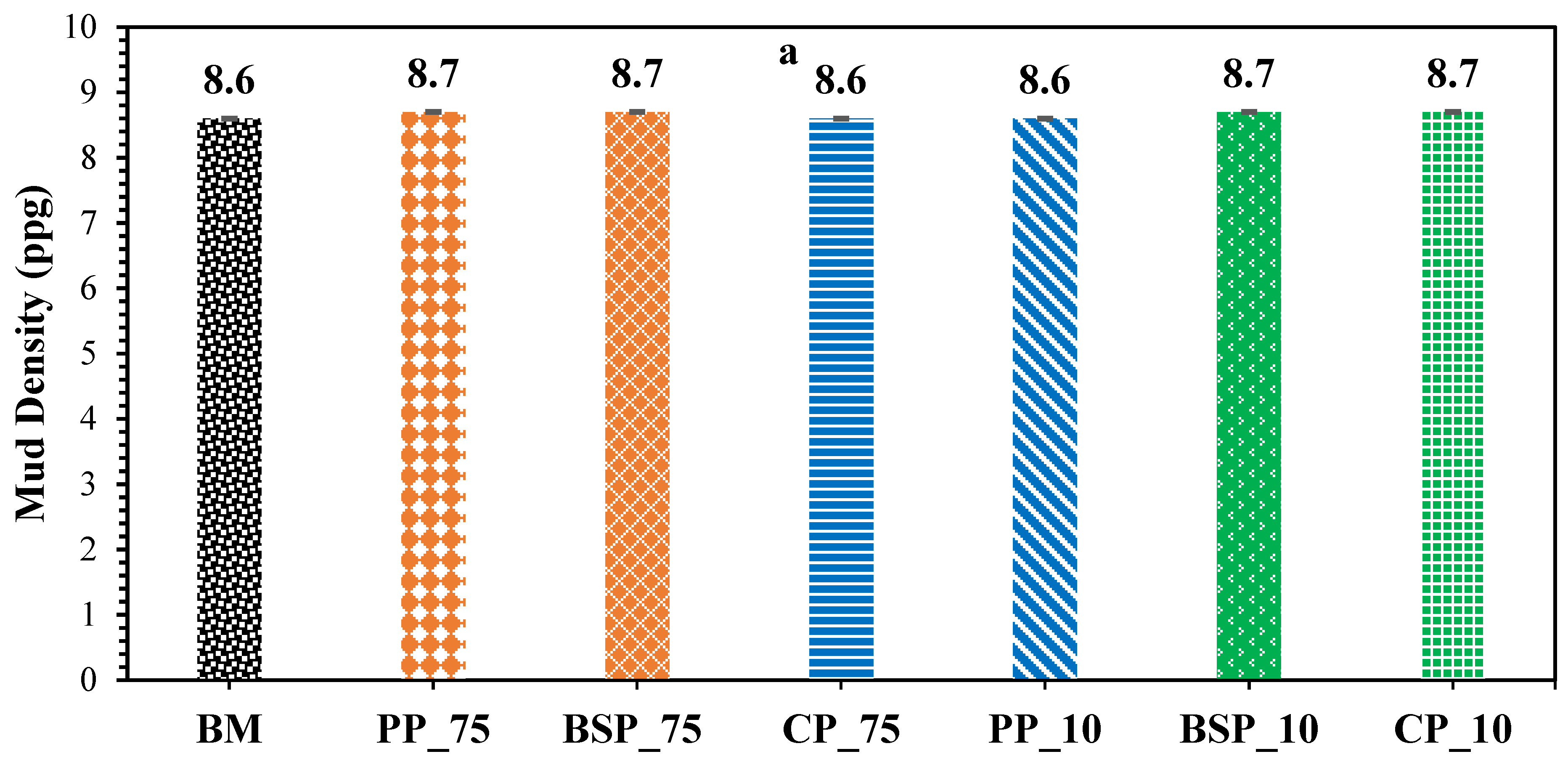

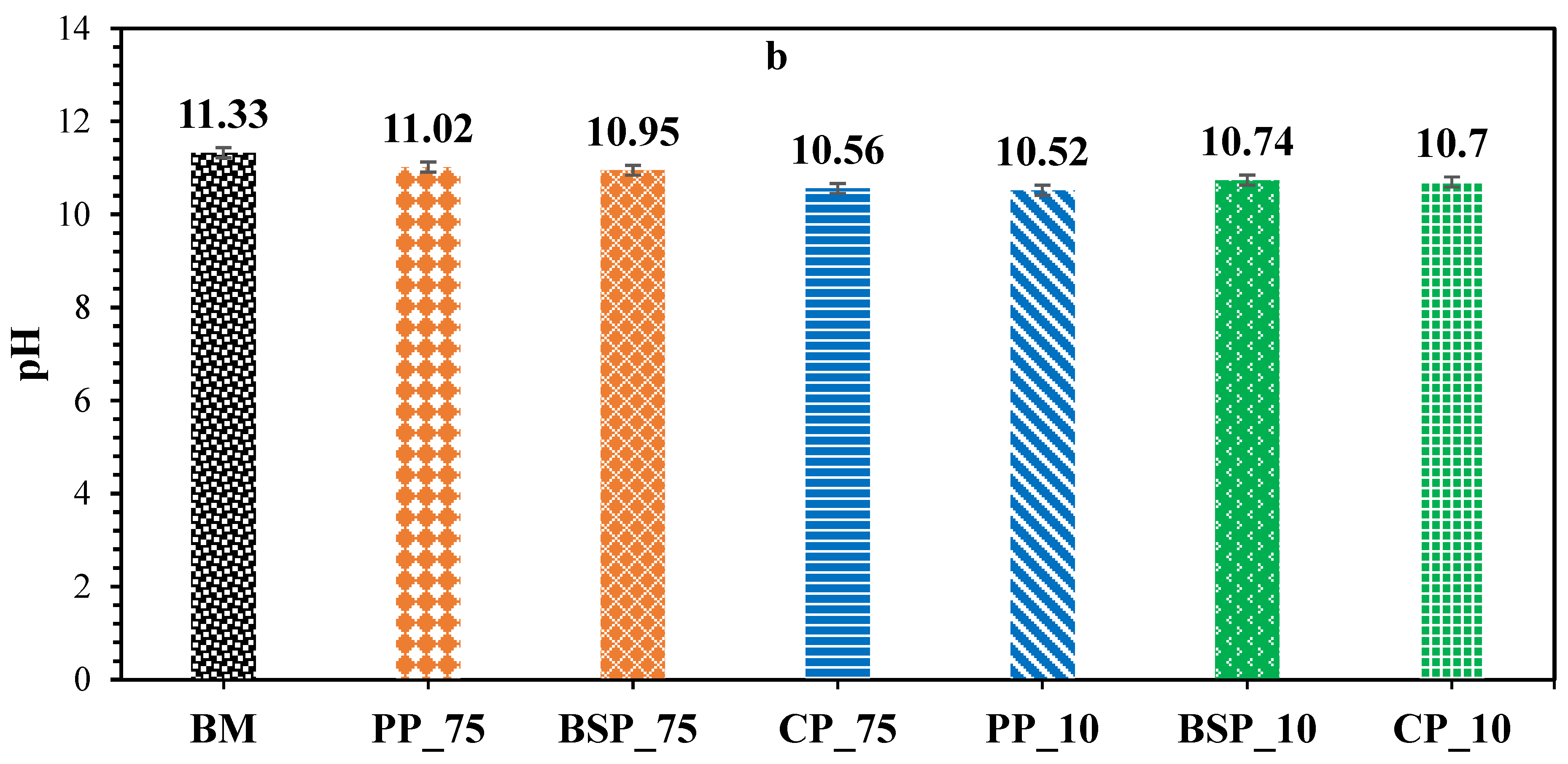

3.5. pH Analysis and Mud Balance Test of Drilling Fluids

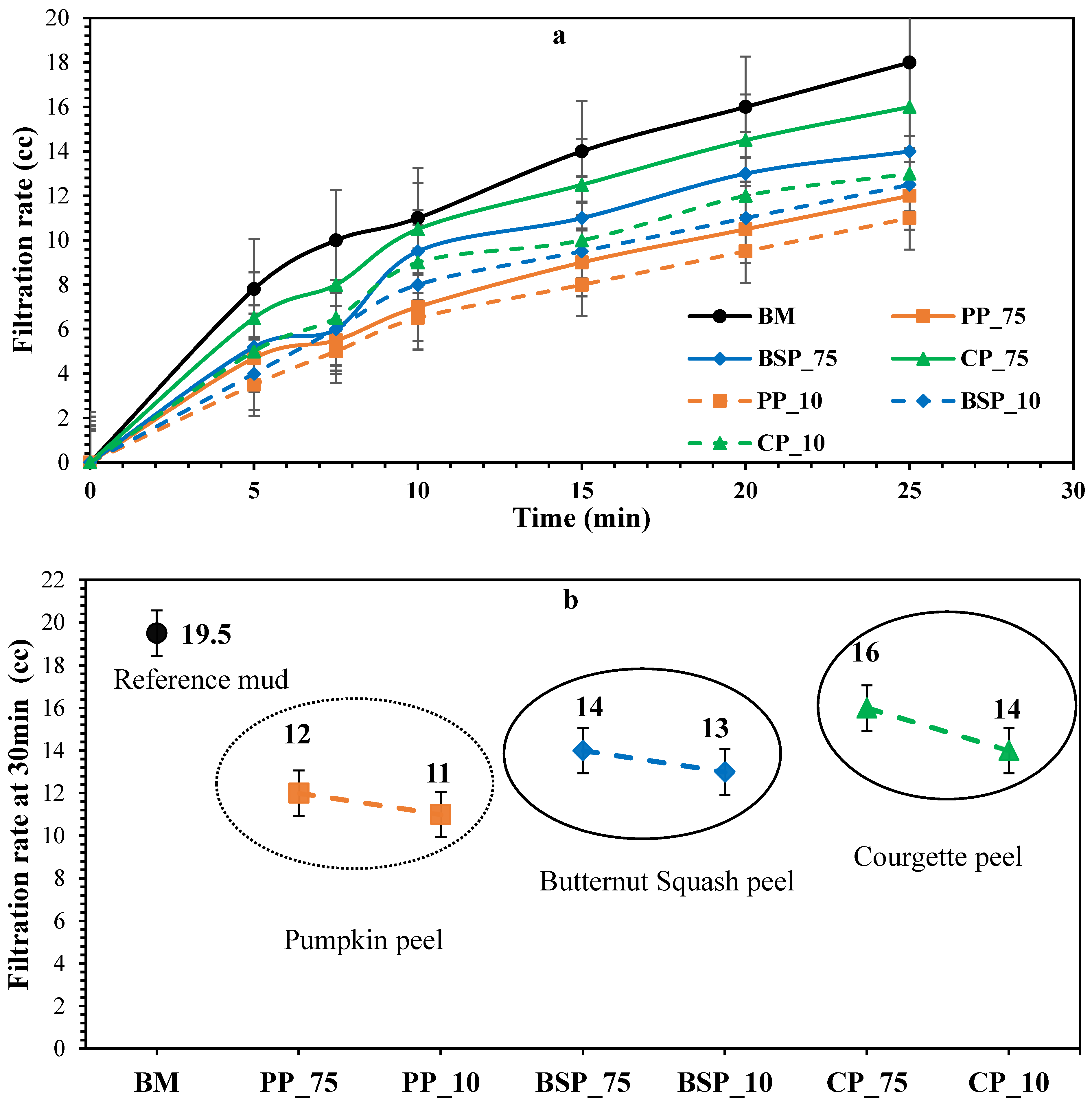

3.6. Filtration Properties

4. Conclusions

- Adding 3 wt% of very fine particle size pumpkin peel powder (PP_10) to the WBDF reduce the fluid loss and filter cake thickness by 43.5% and 50% in comparison to the reference mud;

- The minimum fluid loss of 3.5 cc at 5 min and capping at 11 cc by 30 min was obtained using very fine (10 µm) pumpkin peel powder (PP_10), outperforming other additives, including PP_75, CP_10, and BSP_10;

- The results showed the yield point of base mud was increased from 12 lb/100 ft2 to 18 lb/100 ft2 by adding 3% of finer particle size pumpkin peel powder, indicating the higher ability of the drilling fluid to transport cutting from the wellbore and maintain its stability;

- Adding biodegradable additives from courgette, butternut squash, and pumpkin peel powders keep the pH level of the drilling mud above 10, which is important for corrosion protection of the drilling equipment.

- Vegetable peel additives, particularly pumpkin peel at 10 µm (PP_10), enhance shear stress across all shear rates. PP_10 demonstrates higher shear stress compared with the 75 µm counterpart (PP_75), indicating that finer particles provide better shear resistance;

- Incorporation of 3 wt% fine particle size (10 µm) pumpkin powder (PP_10) enhances rheological properties, increasing plastic viscosity to 8 cP, apparent viscosity to 17 cP, yield point to 18 lb/100 ft2, and gel strength to 11.5 lb/100 ft2 at 10 s and 20.6 lb/100 ft2 at 10 min;

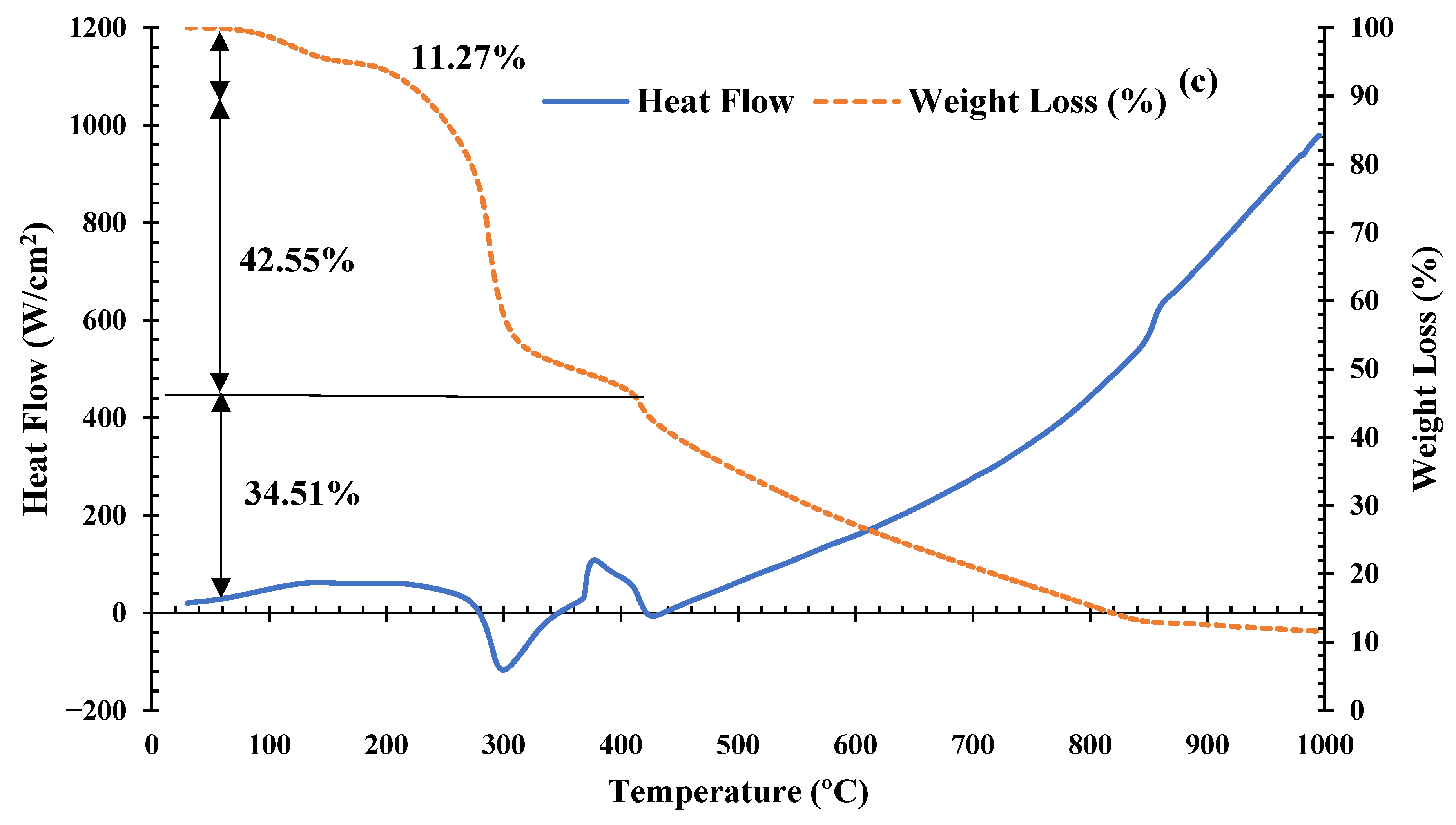

- The TGA results showed that all utilized additives (pumpkin, courgette, and butternut squash) exhibited similar thermal stability, with three weight loss phases: 10–12% in the first (0–245 °C), 40–50% in the second (210–420 °C), and 20–35% in the third phase. These results indicate good thermal stability, making the powders suitable for high-temperature drilling applications;

- This research provides a fundamental understanding of using biodegradable vegetable peels as WBDF additives. Future studies could explore the application of these materials under high-pressure and high-temperature conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BSP_10 and BSP_75 | Butternut squash peel with particle size of 10 μm and 75 μm |

| CMC | Carboxy methylcellulose |

| CPP_10 and CCP_75 | Courgette peel powder with particle size of 10 μm and 75 μm |

| cP | Centipoise |

| EDX | Energy dispersive X-ray spectroscopy |

| FTIR | Fourier transform infrared spectroscopy |

| NaOH | Sodium hydroxide (caustic soda) |

| PP_10 and PP_75 | Pumpkin peel with particle size of 10 μm and 75 μm |

| pH | Potential of Hydrogen |

| ppg | Pounds per gallon |

| TGA | Thermogravimetric analysis |

| YP | Yield point |

| Shear stress | |

| µ | Viscosity |

| µa | Apparent viscosity |

| µp | Plastic viscosity |

| ϴ100,200,300,400,600 | Viscometer reading at different rate |

References

- Apaleke, A.S.; Al-Majed, A.; Hossain, M.E. Drilling Fluid: State of The Art and Future Trend. In Proceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 20–22 February 2012; Volume 1, pp. 101–113. [Google Scholar] [CrossRef]

- Madu, C.; Faraji, F.; Abdalqadir, M.; Gomari, S.R.; Chong, P.L. Feasibility Study of Biodegradable Coffee Ground Waste and Watermelon Rind as Water-Based Drilling Fluid Additives. Gas Sci. Eng. 2024, 125, 205322. [Google Scholar] [CrossRef]

- Davoodi, S.; Ramazani, S.A.A.; Jamshidi, S.; Fellah Jahromi, A. A Novel Field Applicable Mud Formula with Enhanced Fluid Loss Properties in High Pressure-High Temperature Well Condition Containing Pistachio Shell Powder. J. Pet. Sci. Eng. 2018, 162, 378–385. [Google Scholar] [CrossRef]

- Shakib, J.T.; Kanani, V.; Pourafshary, P. Nano-Clays as Additives for Controlling Filtration Properties of Water–Bentonite Suspensions. J. Pet. Sci. Eng. 2016, 138, 257–264. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Y.; Luo, P.; Tian, Y.; Lin, Y.; Guo, Q. Poly (Sodium p-Styrene Sulfonate) Modified Fe3O4 Nanoparticles as Effective Additives in Water-Based Drilling Fluids. J. Pet. Sci. Eng. 2018, 165, 786–797. [Google Scholar] [CrossRef]

- Ali, J.A.; Abdalqadir, M.; Najat, D.; Hussein, R.; Jaf, P.T.; Simo, S.M.; Abdullah, A.D. Application of Ultra-Fine Particles of Potato as Eco-Friendly Green Additives for Drilling a Borehole: A Filtration, Rheological and Morphological Evaluation. Chem. Eng. Res. Des. 2024, 206, 89–107. [Google Scholar] [CrossRef]

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Dunn-Norman, S.; Al-Alwani, M.A.; Alshammari, A.F.; Albazzaz, H.W.; Alkhamis, M.M.; Alashwak, N.F.; Mutar, R.A. Insights into the Application of New Eco-Friendly Drilling Fluid Additive to Improve the Fluid Properties in Water-Based Drilling Fluid Systems. J. Pet. Sci. Eng. 2019, 183, 106424. [Google Scholar] [CrossRef]

- Amanullah, M.; Yu, L. Environment Friendly Fluid Loss Additives to Protect the Marine Environment from the Detrimental Effect of Mud Additives. J. Pet. Sci. Eng. 2005, 48, 199–208. [Google Scholar] [CrossRef]

- Medved, I.; Gaurina-Medimurec, N.; Mavar, K.N.; Mijić, P. Waste Mandarin Peel as an Eco-Friendly Water-Based Drilling Fluid Additive. Energies 2022, 15, 2591. [Google Scholar] [CrossRef]

- Amanullah, M.; Ramasamy, J.; Al-Arfaj, M.K. Application of an Indigenous Eco-Friendly Raw Material as Fluid Loss Additive. J. Pet. Sci. Eng. 2016, 139, 191–197. [Google Scholar] [CrossRef]

- Sweet, F.; Kauffman, M.; Pellerin, T.; Espy, D.; Mills, M. An Estimate of the National Cost for Remediation of Mtbe Releases from Existing Leaking Underground Storage Tank Sites. In Proceedings of the Annual International Conference on Soils, Sediments, Water and Energy, Amherst, MA, USA, 18–21 October 2010; Volume 11. [Google Scholar]

- Zhao, X.; Li, D.; Zhu, H.; Ma, J.; An, Y. Advanced Developments in Environmentally Friendly Lubricants for Water-Based Drilling Fluid: A Review. RSC Adv. 2022, 12, 22853–22868. [Google Scholar] [CrossRef]

- Li, W.; Zhao, X.; Peng, H.; Guo, J.; Ji, T.; Chen, B.; You, Z.; Liu, L. A Novel Environmentally Friendly Lubricant for Water-Based Drilling Fluids as a New Application of Biodiesel. In Proceedings of the Society of Petroleum Engineers—IADC/SPE Asia Pacific Drilling Technology Conference, Singapore, 22–24 August 2016; OnePetro: Singapore, 2016. [Google Scholar]

- Haut, R.C.; Rogers, J.D.; McDole, B.W. Minimizing Waste during Drilling Operations. In Proceedings of the AADE National Technical Conference and Exhibition held at the Wyndam Greenspoint Hotel, Houston, TX, USA, 10–12 April 2007; American Association of Drilling Engineers: Houston, TX, USA, 2007; pp. 1–10. [Google Scholar]

- Zhou, G.; Qiu, Z.; Zhong, H.; Zhao, X.; Kong, X. Study of Environmentally Friendly Wild Jujube Pit Powder as a Water-Based Drilling Fluid Additive. ACS Omega 2021, 6, 1436–1444. [Google Scholar] [CrossRef]

- Ali, J.A.; Abbas, D.Y.; Abdalqadir, M.; Nevecna, T.; Jaf, P.T.; Abdullah, A.D.; Rancová, A. Evaluation the Effect of Wheat Nano-Biopolymers on the Rheological and Filtration Properties of the Drilling Fluid: Towards Sustainable Drilling Process. Colloids Surfaces A Physicochem. Eng. Asp. 2023, 683, 133001. [Google Scholar] [CrossRef]

- Yalman, E.; Depci, T.; Federer-Kovacs, G.; Hani, K.A. A New Eco-Friendly and Low Cost Additive in Water Based Drilling Fluids. Pet. Eng. Energ. 2021, 36, 1–12. [Google Scholar] [CrossRef]

- Novrianti; Khalid, I.; Yuliastini; Novriansyah, A. Experimental Analysis of Cassava Starch as a Fluid Loss Control Agent on Drilling Mud. Mater. Today Proc. 2021, 39, 1094–1098. [Google Scholar] [CrossRef]

- Abdullah, A.D.; Ali, J.A.; Abdalqadir, M. Exploring the Role of Hydrophobic Nanofluids in Reducing Shale Swelling during Drilling: A Step towards Eco-Friendly and Sustainable Practices. Colloids Surfaces A Physicochem. Eng. Asp. 2024, 694, 134164. [Google Scholar] [CrossRef]

- Hossain, M.E.; Wajheeuddin, M. The Use of Grass as an Environmentally Friendly Additive in Water-Based Drilling Fluids. Pet. Sci. 2016, 13, 292–303. [Google Scholar] [CrossRef]

- Song, K.; Wu, Q.; Li, M.C.; Wojtanowicz, A.K.; Dong, L.; Zhang, X.; Ren, S.; Lei, T. Performance of Low Solid Bentonite Drilling Fluids Modified by Cellulose Nanoparticles. J. Nat. Gas Sci. Eng. 2016, 34, 1403–1411. [Google Scholar] [CrossRef]

- Nestle, A. Drilling Fluid. U.S. Patent 2601050, 17 June 1952. Assigned to Texaco Development Corporation. [Google Scholar]

- Morris, G.R. Drilling Fluid. U.S. Patent 3042607, 3 July 1962. [Google Scholar]

- Burts, B. Lost Circulation Material with Rice Fraction. U.S. Patent 5118664A, 2 June 1992. [Google Scholar]

- Burts, B.D., Jr. Well Fluid Additive, Well Fluid Made There from, Method of Treating a Well Fluid, Method of Circulating a Well Fluid. U.S. Patent 6323158, 27 November 2001. Assigned to Bottom Line Industries. [Google Scholar]

- Sampey, J.A. Sugar Cane Additive for Filtration Control in Well Working Compositions. U.S. Patent 7094737B1, 22 August 2006. [Google Scholar]

- Amadi, K.; Alsaba, M.; Dushaishi, M.F.A.; Al-Hameedi, A.; Alkinani, H. Empirical Studies of the Effectiveness of Bio-Enhancers (Food Waste Products) as Suitable Additives in Environmental Friendly Drilling Fluid Systems. In Proceedings of the Fluids Technical Conference and Exhibition, Houston, TX, USA, 10–11 April 2018; American Association of Drilling Engineers: Houston, TX, USA, 2018. [Google Scholar]

- Nik Ab Lah, N.; Ngah, K.; Sauki, A. Study on the Viability of Egg Shell as a Lost Circulation Material in Synthetic Based Drilling Fluid. In Proceedings of the International Conference on Nanomaterials: Science, Engineering and Technology (ICoNSET), Penang Island, Malaysia, 5–6 August 2019. [Google Scholar]

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Alkhamis, M.M.; Dunn-Norman, S. Utilizing a New Eco-Friendly Drilling Mud Additive Generated from Wastes to Minimize the Use of the Conventional Chemical Additives. J. Pet. Explor. Prod. Technol. 2020, 10, 3467–3481. [Google Scholar] [CrossRef]

- Yaseer, A.; Khan, M.; Mugni, S.A.; Kummetha, M.; Prakash, V.; Bhattacharya, M. Evaluation of Wheat Husk as Environment Friendly Fluid Loss Additive as a Substitute of CMC(LVG) in Water Based Drilling Fluid up to 100 OC. Int. Res. J. Eng. Technol. 2020, 7, 4899–4904. [Google Scholar]

- Akmal, I.A.N.; Jamaludin, S.K.; Sauki, A.; Hassan, H.; Ilham, W.M.A. Potential of Banana Peels and Sugarcane Bagasse as Lost Circulation Material Additives in Drilling Mud Application. In Proceedings of the 4th International Sciences, Technology and Engineering Conference (ISTEC) 2020: Exploring Materials for the Future, Arau, Malaysia, 8 October 2020. [Google Scholar]

- Dotto, J.M.; Chacha, J.S. The Potential of Pumpkin Seeds as a Functional Food Ingredient: A Review. Sci. Afr. 2020, 10, e00575. [Google Scholar] [CrossRef]

- Surucu-Balci, E.; Berberoglu, B. Wasted Pumpkins: A Real Halloween Horror Story. Br. Food J. 2022, 124, 4718–4735. [Google Scholar] [CrossRef]

- Theguardian Over Half UK’s 24m Halloween Pumpkins Destined for Food Waste | Food Waste | The Guardian. Available online: https://www.theguardian.com/environment/2020/oct/08/over-half-uks-24m-halloween-pumpkins-destined-for-food-waste (accessed on 18 March 2024).

- Hha, M.; Sh, U.; Kv, J. Glycemic Response and Antioxidant Activity of Pumpkin Seed Powder (Cucurbita Maxima) Blended Biscuits. J. Pharmacogn. Phytochem. 2018, 7, 1877–1882. [Google Scholar]

- Kidoń, M.; Uwineza, P.A. New Smoothie Products Based on Pumpkin, Banana, and Purple Carrot as a Source of Bioactive Compounds. Molecules 2022, 27, 3049. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.F.Y.; Barakat, H.; Hassan, M.F.Y.; Barakat, H. Effect of Carrot and Pumpkin Pulps Adding on Chemical, Rheological, Nutritional and Organoleptic Properties of Ice Cream. Food Nutr. Sci. 2018, 9, 969–982. [Google Scholar] [CrossRef][Green Version]

- Wu, Y.; Wang, L.; Ding, X.; Wang, W.; Zhao, L. Preparation of High Internal Phase Emulsions Based on Pumpkin Seed Oil Body and Its Physicochemical Properties. LWT 2023, 189, 115533. [Google Scholar] [CrossRef]

- Tomczyńska-Mleko, M.; Terpiłowski, K.; Pérez-Huertas, S.; Sapiga, V.; Polischuk, G.; Sołowiej, B.; Nastaj, M.; Wesołowska-Trojanowska, M.; Mleko, S. Co-Gelation of Pumpkin-Seed Protein with Egg-White Protein. Foods 2023, 12, 2030. [Google Scholar] [CrossRef]

- Ventour, L. The Food We Waste; Waste & Resources Action Programme (WRAP): Banbury, UK, 2008. [Google Scholar]

- Eissa, H.A.; Bareh, G.F.; Ibrahim, A.A.; Moawad, R.K.; Ali, H.S. The Effect of Different Drying Methods on the Nutrients and Non-Nutrients Composition of Zucchini (Green Squash) Rings. J. Appl. Sci. Res. 2013, 09, 5380–5389. [Google Scholar]

- Li, H. Evaluation of Bioactivity of Butternut Squash (Cucurbita moschata D.) Seeds and Skin. Food Sci. Nutr. 2020, 8, 3252–3261. [Google Scholar] [CrossRef]

- API SPEC 13A; Specification for Drilling Fluid Materials. American Petroleum Institute: Washington, DC, USA, 1993.

- Ali, J.A.; Kolo, K.; Mohammad Sajadi, S.; Hamad, K.H.; Salman, R.; Wanli, M.; Manshad, A.K.; Hamad, S.M.; Raihana, B.; Hama, S.M. Modification of Rheological and Filtration Characteristics of Water-Based Mud for Drilling Oil and Gas Wells Using Green SiO2 @ZnO@Xanthan Nanocomposite. IET Nanobiotechnology 2019, 13, 748–755. [Google Scholar] [CrossRef]

- Awl, M.; Sabir Mahmood, B.; Tahsin Mohammed, P.; Fakhradin Mohammed, H.; Mhedin Hamad, A.; Hussen Abdulqadir, A.; Omer Abdalqadir, M. Performance Evaluation of the New Environmentally Friendly Additive for Enhanced Fluid Loss and Rheological Properties of Drilling Fluid. J. Chem. Pet. Eng. 2023, 57, 189–202. [Google Scholar] [CrossRef]

- Ali, J.A.; Ahmed, R.N.; Abdullah, A.D.; Ali, N.H.; Kalhury, A.M.; Sabir, A.N.; Khaksar Manshad, A.; Keshavarz, A.; Mohammadi, A.H. Development of a Nanobiodegradable Drilling Fluid Using Prosopis Farcta Plant and Pomegranate Peel Powders with Metal Oxide Nanoparticles. ACS Omega 2022, 7, 31327–31337. [Google Scholar] [CrossRef]

- Ali, J.A.; Gailani, R.; Abdullah, A.D.; Jaf, P.T.; Simo, S.M.; Abdalqadir, M.; Faris, V.M. Performance Evaluation of the Nano-Biodegradable Drilling Fluid Using the Greenly Synthesized Zinc Nanorods and Gundelia Seed Waste. Environ. Sci. Pollut. Res. 2024, 31, 51381–51400. [Google Scholar] [CrossRef] [PubMed]

- Bair, S. Shear Dependence of Viscosity. In Encyclopedia of Tribology; Springer: Boston, MA, USA, 2013; pp. 3074–3078. [Google Scholar] [CrossRef]

- Piroozian, A.; Ismail, I.; Yaacob, Z.; Babakhani, P.; Ismail, A. Impact of Drilling Fluid Viscosity, Velocity and Hole Inclination on Cuttings Transport in Horizontal and Highly Deviated Wells. J. Pet. Explor. Prod. Technol. 2012, 2, 149–156. [Google Scholar] [CrossRef]

- Bagum, M.; Ahammad, J.M.; Husain, T.; Hossain, M.E. An Experimental Study to Develop an Environmental Friendly Mud Additive of Drilling Fluid Using Aloe Vera. J. Pet. Sci. Eng. 2022, 211, 110135. [Google Scholar] [CrossRef]

- Lee, Y.G.; Shin, J.; Kwak, J.; Kim, S.; Son, C.; Cho, K.H.; Chon, K. Effects of NaOH Activation on Adsorptive Removal of Herbicides by Biochars Prepared from Ground Coffee Residues. Energies 2021, 14, 1297. [Google Scholar] [CrossRef]

- Singh, A.K.; Basireddy, T.; Moran, J.L. Eliminating Waste with Waste: Transforming Spent Coffee Grounds into Microrobots for Water Treatment. Nanoscale 2023, 15, 17494–17507. [Google Scholar] [CrossRef]

- Chou, W.-L.; Wang, C.-T.; Huang, K.-Y.; Chang, Y.-C.; Shu, C.-M. Investigation of Indium Ions Removal from Aqueous Solutions Using Spent Coffee Grounds. Int. J. Phys. Sci. 2012, 7, 2445–2454. [Google Scholar] [CrossRef]

- Ajithram, A.; Winowlin Jappes, J.T.; Siva, I.; Brintha, N.C. Experimental Investigation on Aquatic Waste Water Hyacinth (Eichhorniacrassipes) Plant into Natural Fibre Polymer Composite—Biological Waste into Commercial Product. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 620–629. [Google Scholar] [CrossRef]

- Saadatkhah, N.; Carillo Garcia, A.; Ackermann, S.; Leclerc, P.; Latifi, M.; Samih, S.; Patience, G.S.; Chaouki, J. Experimental Methods in Chemical Engineering: Thermogravimetric Analysis—TGA. Can. J. Chem. Eng. 2020, 98, 34–43. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Criado, J.M.; Pérez-Maqueda, L.A.; Popescu, C.; Sbirrazzuoli, N. ICTAC Kinetics Committee Recommendations for Performing Kinetic Computations on Thermal Analysis Data. Thermochim. Acta 2011, 520, 1–19. [Google Scholar] [CrossRef]

- Bensharada, M.; Telford, R.; Stern, B.; Gaffney, V. Loss on Ignition vs. Thermogravimetric Analysis: A Comparative Study to Determine Organic Matter and Carbonate Content in Sediments. J. Paleolimnol. 2022, 67, 191–197. [Google Scholar] [CrossRef]

- Abdelrahman, H.E.; Wahba, M.H.; Refaey, H.A.; Moawad, M.; Berbish, N.S. Performance Enhancement of Photovoltaic Cells by Changing Configuration and Using PCM (RT35HC) with Nanoparticles Al2O3. Sol. Energy 2019, 177, 665–671. [Google Scholar] [CrossRef]

- Herschel, W.H.; Bulkley, R. Konsistenzmessungen von Gummi-Benzollösungen. Kolloid-Zeitschrift 1926, 39, 291–300. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Theory of the Strength of Materials; Ingeniörsvetenskapsakademiens Handlingar: Stockholm, Sweden, 1939; No. 151. [Google Scholar]

- Vipulanandan, C.; Mohammed, A.S. Hyperbolic Rheological Model with Shear Stress Limit for Acrylamide Polymer Modified Bentonite Drilling Muds. J. Pet. Sci. Eng. 2014, 122, 38–47. [Google Scholar] [CrossRef]

- Caenn, R.; Darley, H.; Gray, G. Composition and Properties of Drilling and Completion Fluids; Elsevier Science & Technology: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Peretomode, J. Plantain Peels Powder, Burnt Palm Head Powder and Commercial Sodium Hydroxide as Additives for Water Based Drilling Mud. J. Appl. Sci. Environ. Manag. 2018, 22, 1009–1012. [Google Scholar] [CrossRef]

- Denney, D. Well Planning for Shallow Water Flows and Overpressures. J. Pet. Technol. 2001, 54, 44. [Google Scholar] [CrossRef]

- Muhayyidin, A.H.M.; Bakar, N.F.A.; Sauki, A.; Ghazali, N.A.; Jan, B.M.; Ibrahim, W.A.; Naimi, F.M. Rheological and Filtration Performances of Rhizophora Mucronata Tannin Water-Based Drilling Fluid. Mater. Today Proc. 2019, 17, 768–777. [Google Scholar] [CrossRef]

- Dejtaradon, P.; Hamidi, H.; Chuks, M.H.; Wilkinson, D.; Rafati, R. Impact of ZnO and CuO Nanoparticles on the Rheological and Filtration Properties of Water-Based Drilling Fluid. Colloids Surfaces A Physicochem. Eng. Asp. 2019, 570, 354–367. [Google Scholar] [CrossRef]

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Dunn-Norman, S.; Al-Alwani, M.A.; Al-Bazzaz, W.H.; Alshammari, A.F.; Albazzaz, H.W.; Mutar, R.A. Experimental Investigation of Bio-Enhancer Drilling Fluid Additive: Can Palm Tree Leaves Be Utilized as a Supportive Eco-Friendly Additive in Water-Based Drilling Fluid System? J. Pet. Explor. Prod. Technol. 2020, 10, 595–603. [Google Scholar] [CrossRef]

| Study | Material | Combination | Purpose |

|---|---|---|---|

| [22] | Tree bark (douglas fir) | Unknown | Control Fluid Lost |

| [23] | Ground peach seeds | Unknown | Control Fluid Lost |

| [24] | Rice fraction (rice hulls, rice tips, rice straw and rice bran) | N/A | Control Fluid Lost |

| [25] | Corn cub outers | N/A | Control Fluid Lost |

| [26] | Sugar cane ash (300 microns) | 0.1, 0.4, and 0.5 wt% of sugar cane ash was mixed with WBDF | Control Fluid Lost |

| [20] | Grass (300 µm, 90 µm and 35 µm particle sizes) | 0.25, 0.50, 0.75 and 1.0 g of grass with different particle sizes added to WBDF | Control Fluid Lost and water control agent |

| [27] | 21 types of food and green waste | Between 0 to 10 ppb concentrations of different green and food waste materials added to the WBDF | Control Fluid Lost |

| [28] | Eggshell waste | 15 g added to the total WBDF mud | Control Fluid Lost |

| [7] | Grass powder (GP) | 1% and 2% GP added to the WBDF | Control Fluid Lost |

| [29] | Black sunflower seeds’ shell powder | 0.5, 1.5, 2.5, and 3.5 wt% added to WBDF | Fluid Lost Control |

| [30] | Wheat Husk Powder (WHP) | Concentrations of 1, 2, 3, and 4 wt% WHP were added to the WBDF | Control Fluid Lost |

| [31] | Waste banana peels | Various percentages were added to the WBDF | Control Fluid Lost |

| [15] | Wild Jujube Pit Powder (WJPP) | 0.5, 1, 2, 3 and 5 wt% WJPP were added to WBDF | Control Fluid Lost |

| [18] | Cassava starch | 0 to 10 g was added to the WBDF | Control Fluid Lost |

| [9] | Waste Mandarin Peel | concentrations of 0.5, 1, 1.5, and 2wt% | Shale swelling inhibitor |

| [16] | Wheat nano-biopolymers | 2 wt% concentrations added to WBDF | Fluid loss control |

| Drilling Fluid | Additives | Acronym | Particle Size (µm) | Concentration (%) | Caustic Soda (gm) | Bentonite (gm) | Distilled Water (mL) |

|---|---|---|---|---|---|---|---|

| Reference | BM | - | 1 | 40 | 700 | ||

| Biodegradable drilling fluids | Pumpkin Peel | PP_10 | 10 | 3 | 1 | 40 | 700 |

| PP_75 | 75 | 3 | 1 | 40 | 700 | ||

| Courgette peel | CP_10 | 10 | 3 | 1 | 40 | 700 | |

| CP_75 | 75 | 3 | 1 | 40 | 700 | ||

| Butternut Squash peel | BSP_10 | 10 | 3 | 1 | 40 | 700 | |

| BSP_75 | 75 | 3 | 1 | 40 | 700 |

| Biodegradable Material | Element (wt%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| O | Na | Mg | Si | P | S | Cl | K | Ca | |

| Butternut Squash peel | 78.2 | 0.3 | 1.7 | 1.4 | 2.3 | 0.9 | 1.3 | 12.1 | 1.9 |

| Courgette peel | 74.4 | 0.6 | 1.6 | 0.7 | 1.7 | 1.2 | 5.0 | 13.0 | 1.8 |

| Pumpkin peel | 76.0 | 0.4 | 1.8 | 1.9 | 2.0 | 1.3 | 2.3 | 12.0 | 2.4 |

| Material | Reduction in Fluid Loss After 30 min (%) | Reduction in Filter Cake Thickness (%) | Reference |

|---|---|---|---|

| Best performed additive (very fine particle pumpkin peel powder PP_10) | 43.5 | 50 | Current study |

| Broad bean peel powder | 31.86 | 28.57 | [45] |

| Potato peel powder | 30 | 40 | [7] |

| Grass powder | 42 | 33.33 | [7] |

| Nanoparticle (CuO) | 30.20 | 27.60 | [66] |

| Pistachio Shell Powder | 38.57 | 20.54 | [3] |

| Palm Tree leaves powder | 28 | 36.67 | [67] |

| Rice husk ash | 10 | Increased | [17] |

| Wild Jujube Pit Powder (WJPP) | 42.5 | Not provided | [15] |

| Biopolymer (Rhizophora, Mucronata Tannin) | 33.33 | 3.33 | [65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oladipo, O.I.; Faraji, F.; Habibi, H.; Abdalqadir, M.; Ali, J.A.; Chong, P.L. Feasibility Study of Biodegradable Vegetable Peels as Sustainable Fluid Loss Additives in Water-Based Drilling Fluids. J 2025, 8, 10. https://doi.org/10.3390/j8010010

Oladipo OI, Faraji F, Habibi H, Abdalqadir M, Ali JA, Chong PL. Feasibility Study of Biodegradable Vegetable Peels as Sustainable Fluid Loss Additives in Water-Based Drilling Fluids. J. 2025; 8(1):10. https://doi.org/10.3390/j8010010

Chicago/Turabian StyleOladipo, Olajide Ibrahim, Foad Faraji, Hossein Habibi, Mardin Abdalqadir, Jagar A. Ali, and Perk Lin Chong. 2025. "Feasibility Study of Biodegradable Vegetable Peels as Sustainable Fluid Loss Additives in Water-Based Drilling Fluids" J 8, no. 1: 10. https://doi.org/10.3390/j8010010

APA StyleOladipo, O. I., Faraji, F., Habibi, H., Abdalqadir, M., Ali, J. A., & Chong, P. L. (2025). Feasibility Study of Biodegradable Vegetable Peels as Sustainable Fluid Loss Additives in Water-Based Drilling Fluids. J, 8(1), 10. https://doi.org/10.3390/j8010010