Environmental Impacts Associated with the Production and Packing of Persian Lemon in Mexico through Life-Cycle Assessment

Abstract

1. Introduction

2. Materials and Methods

2.1. Definition of Goal and Scope

2.2. Life-Cycle Inventory

2.3. Life-Cycle Impact Assessment

2.4. Life-Cycle Interpretation

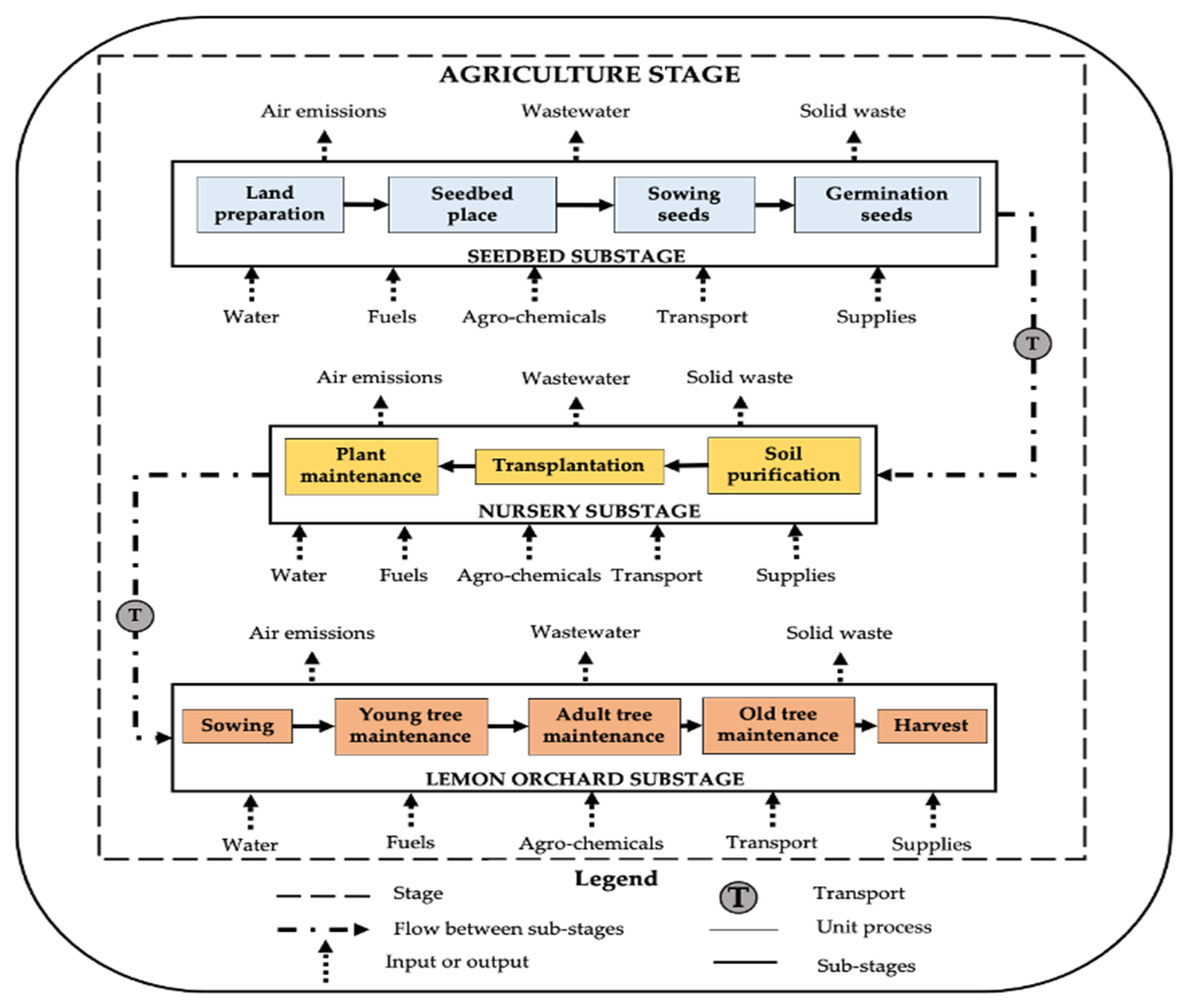

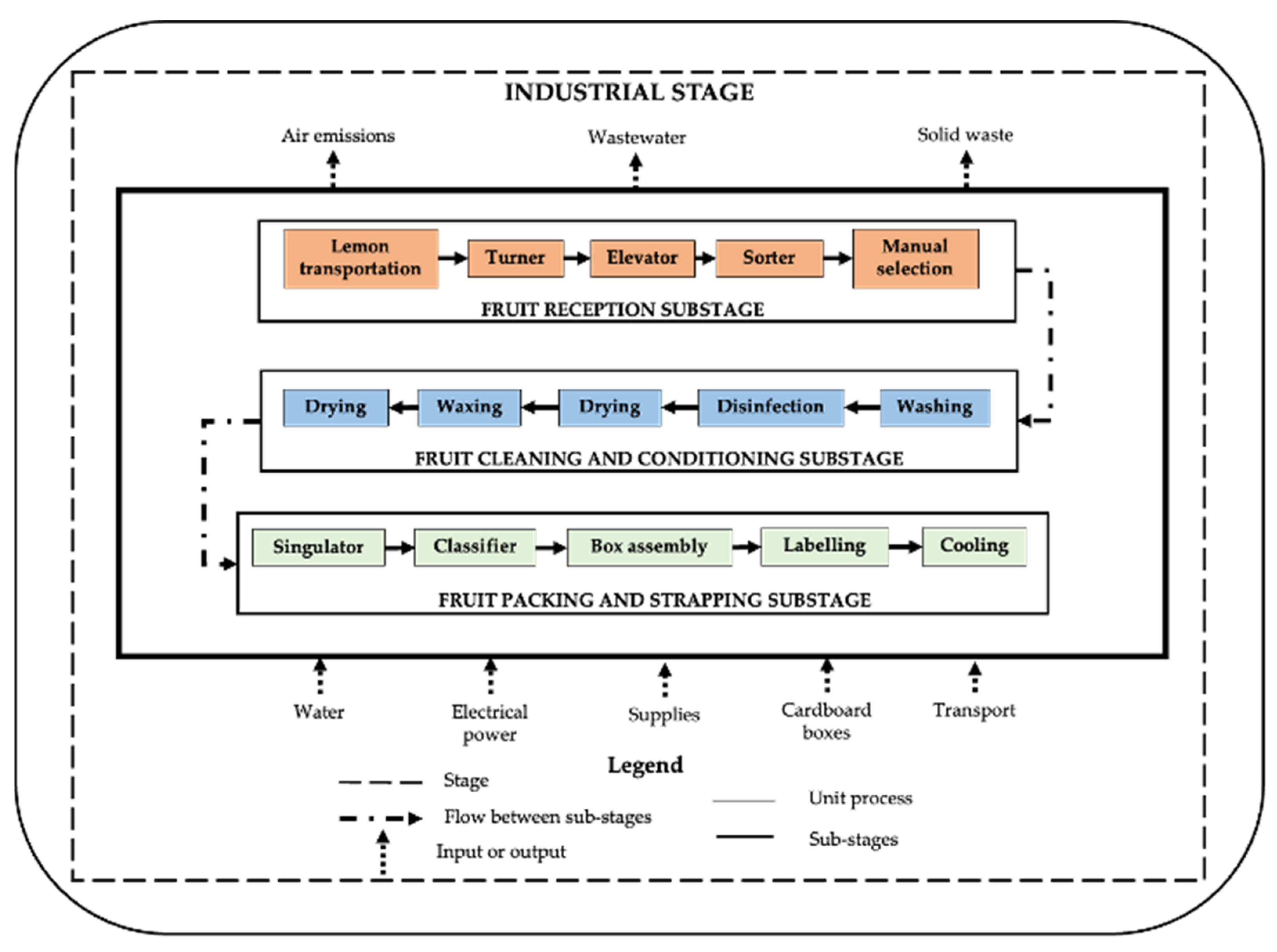

3. LCA of Persian Lemon Production

3.1. Goal and Scope Definition

3.2. Description of the Product System

3.2.1. Nursery and Seedbed

3.2.2. Lemon Orchard

3.2.3. Packing Plant

3.3. Life-Cycle Inventory

3.3.1. Energy Supply

3.3.2. Water Supply

3.3.3. Balance of Trees and Fruits in Lemon Orchard

3.3.4. Transportation

3.3.5. Foreground Data Collection for the LCI

4. Results and Discussion

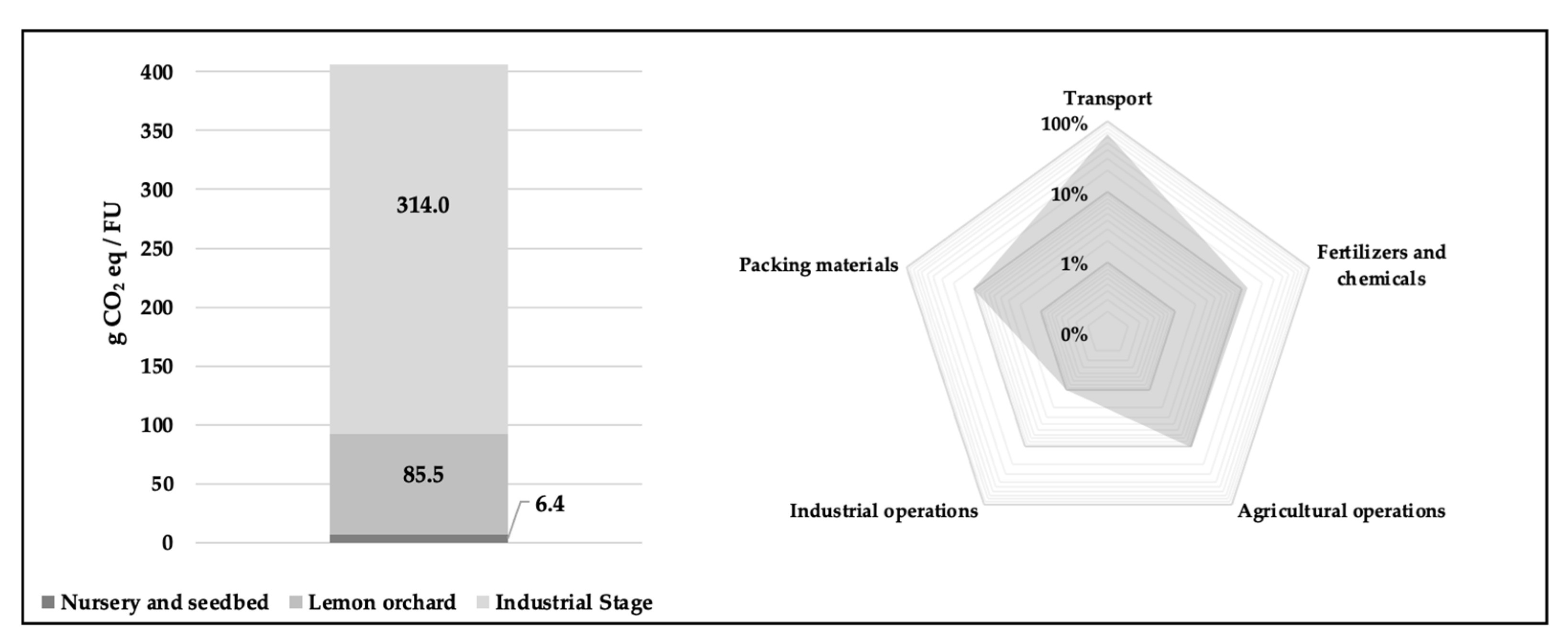

4.1. Life-Cycle Impact Assessment

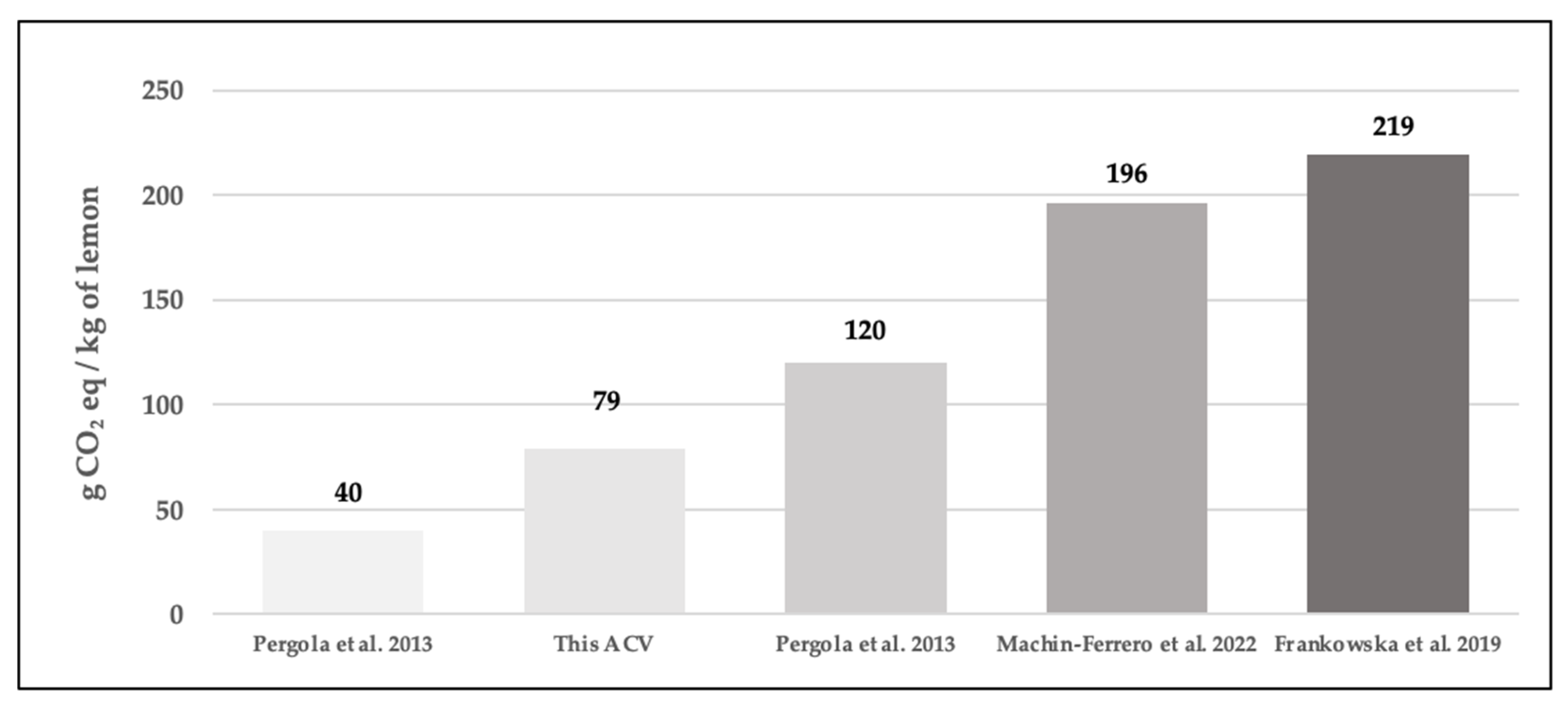

4.2. Carbon Footprint

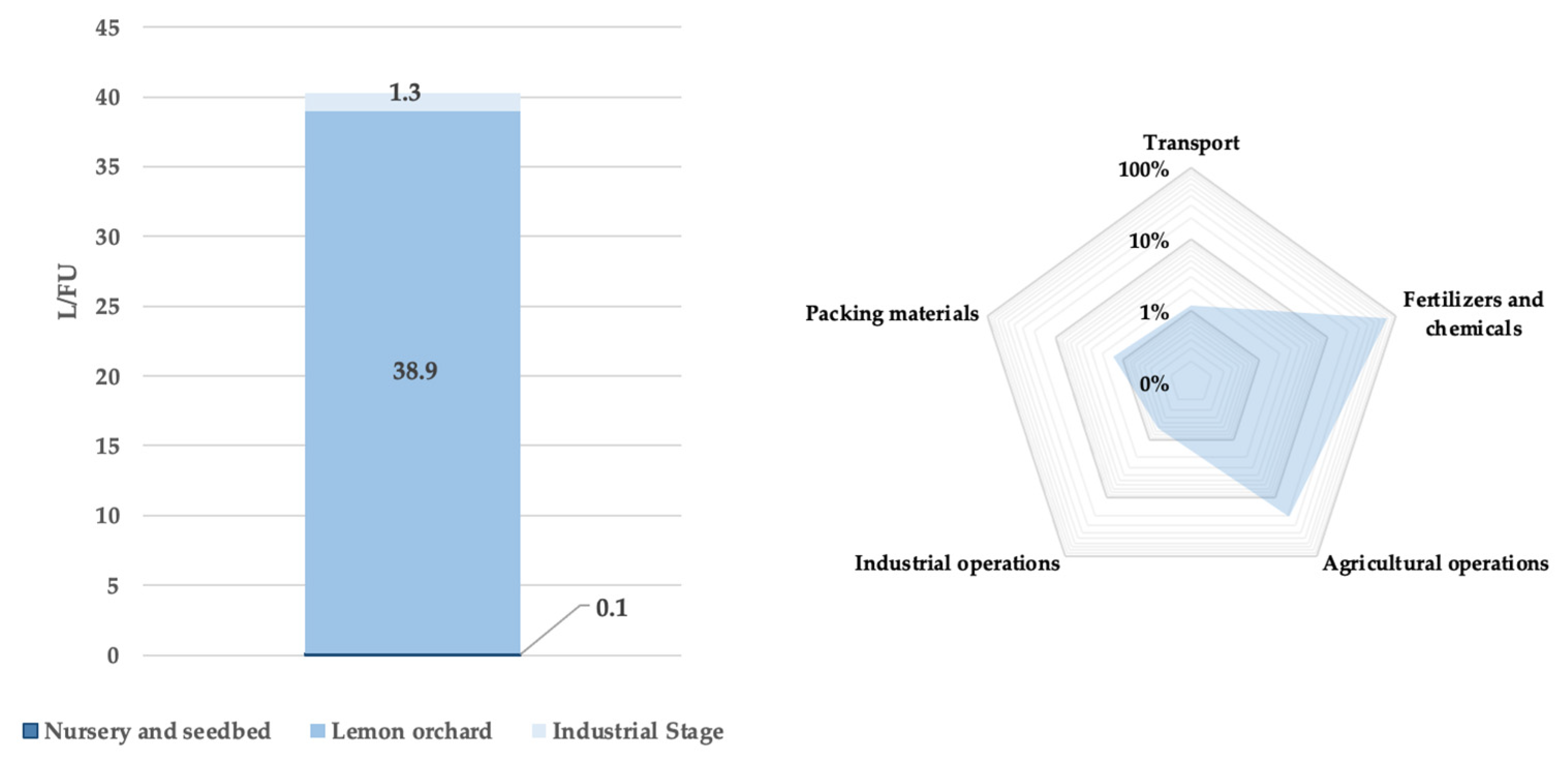

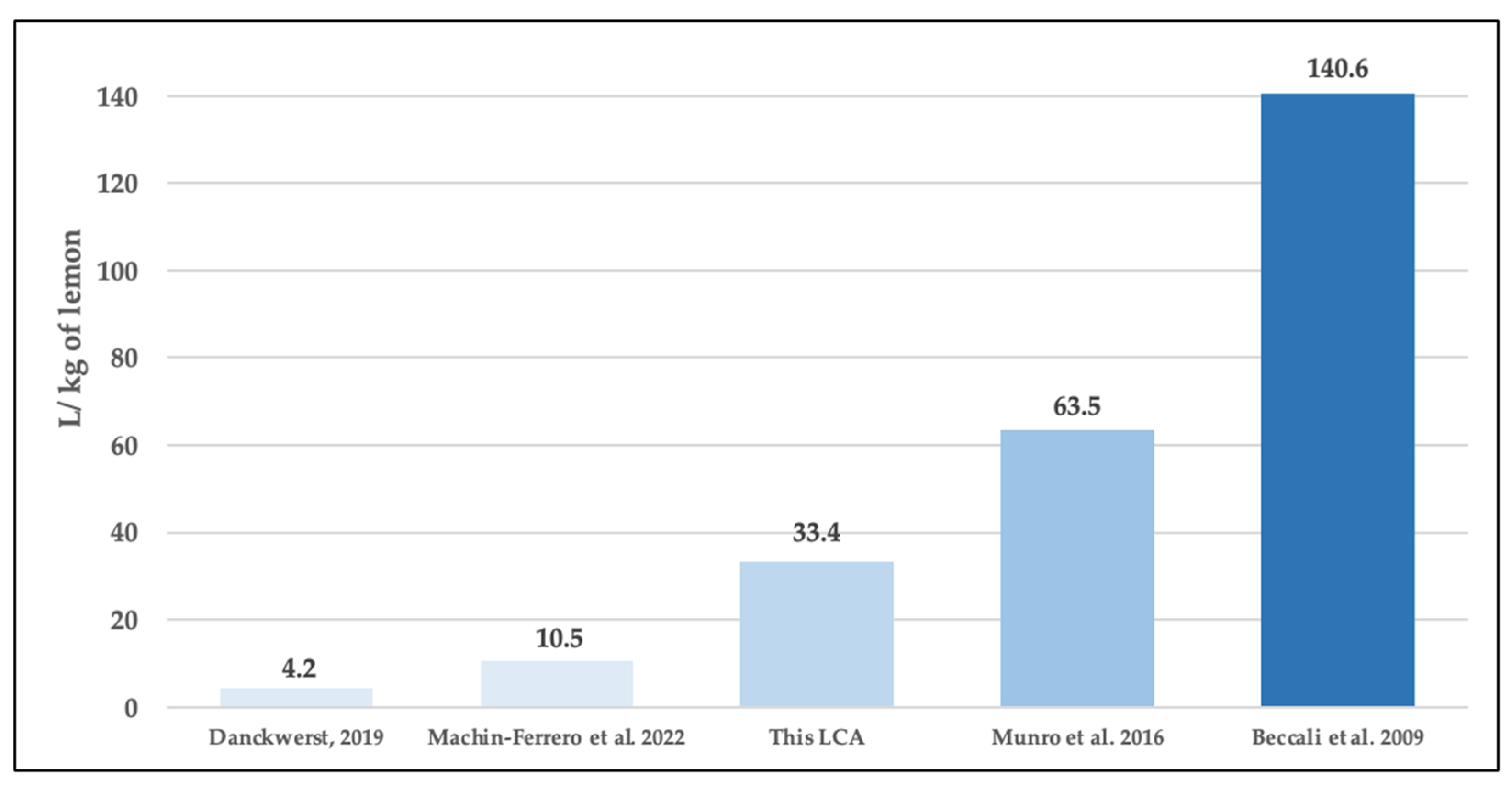

4.3. Water Footprint

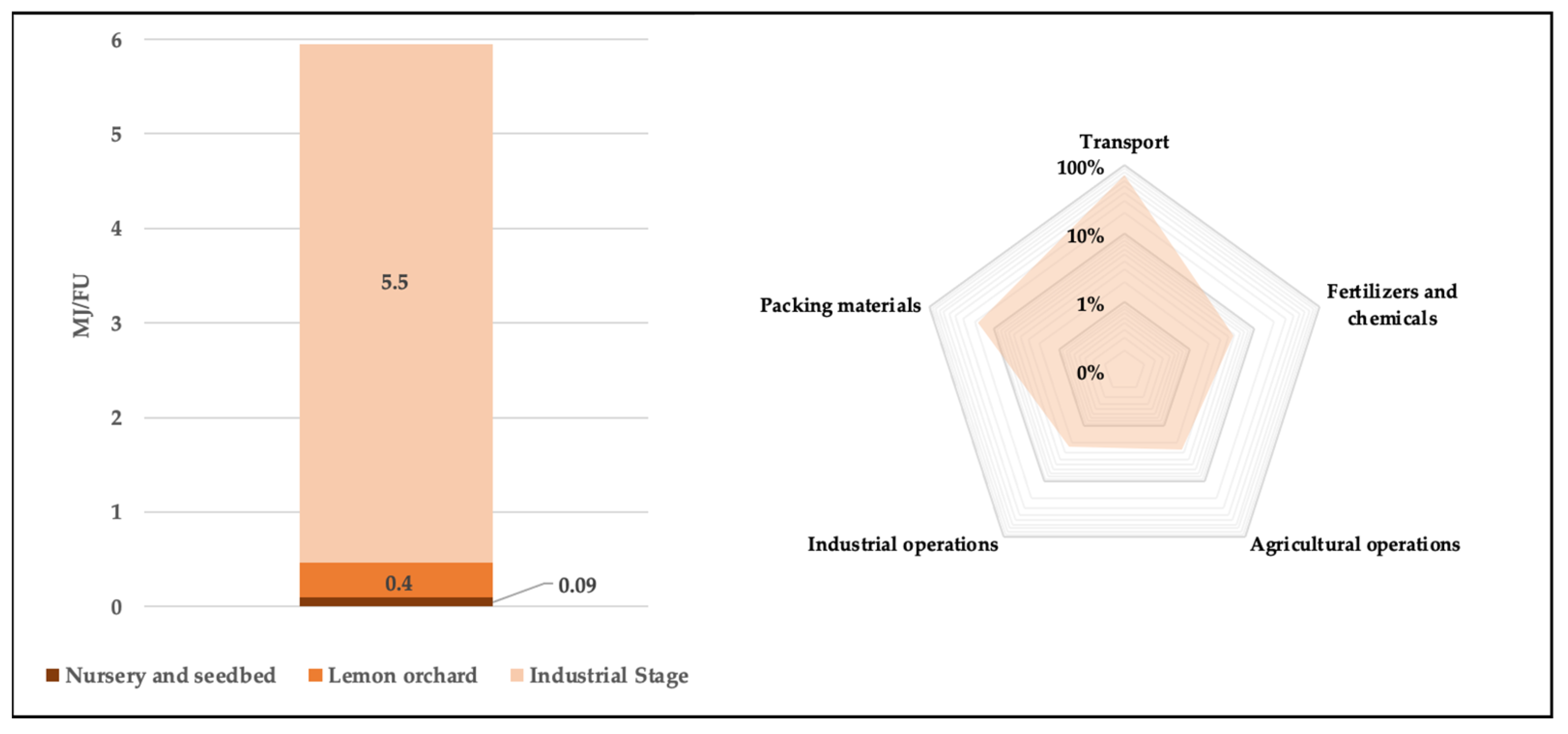

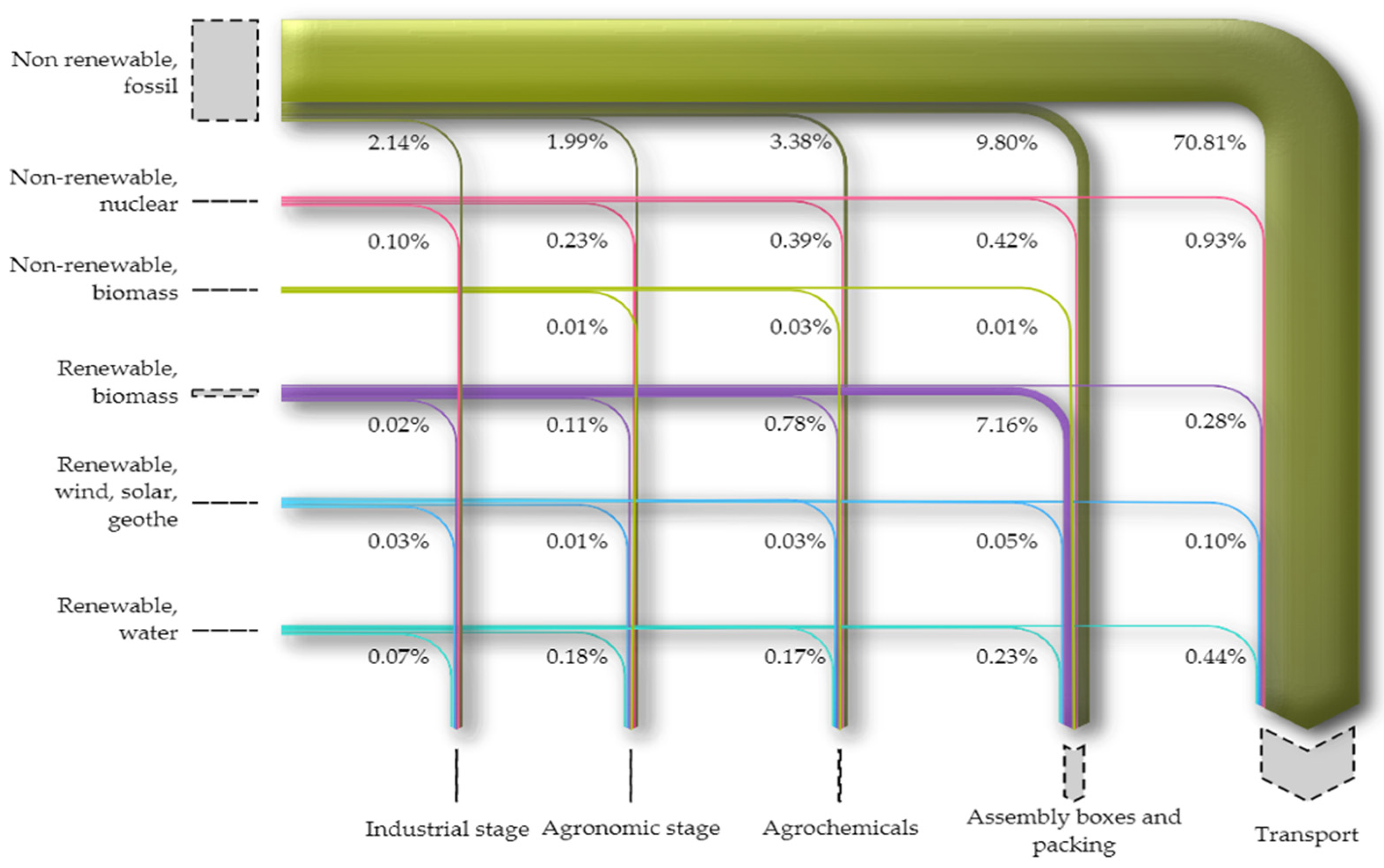

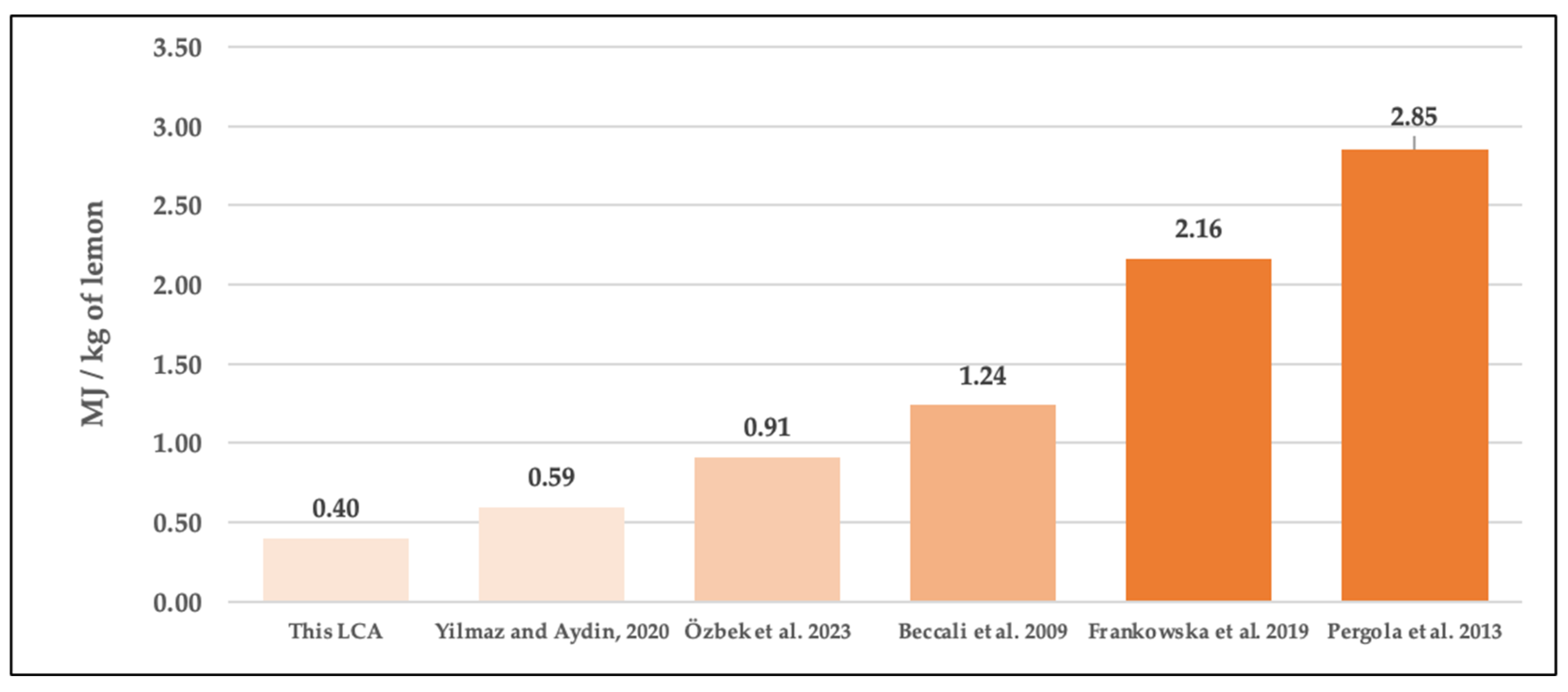

4.4. Energy Footprint

4.5. Analysis by Tree Yield in the Lemon Orchard

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, M.M.; Al-Yahyai, R.; Al-Said, F. The Lime: Botany, Production and Uses, 1st ed.; CAB International: Wallingford, UK, 2017; pp. 1–273. ISBN 9781780647845. [Google Scholar]

- Vargas-Canales, J.M.; Guido-López, D.L.; Rodríguez-Haros, B.; Bustamante-Lara, T.I.; Camacho-Vera, J.H.; Orozco-Cirilo, S. Evolution of the specialization and competitiveness of lemon production in Mexico. Rev. Mex. Cienc. Agríc. 2020, 11, 1043–1056. [Google Scholar] [CrossRef]

- Food and Agriculture Organization. Crops and Livestock Products. Available online: https://www.fao.org/faostat/es/#data/QCL (accessed on 1 March 2024).

- Food and Agriculture Organization. Citrus Fruit Statistical Compendium 2020. Available online: https://www.fao.org/3/cb6492en/cb6492en.pdf (accessed on 1 April 2023).

- Organization for Economic Cooperation and Development; Food and Agriculture Organization. Environmental Sustainability in Agriculture 2023; FAO: Rome, Italy, 2023; pp. 1–24. [Google Scholar]

- Tubiello, F.N.; Rosenzweig, C.; Conchedda, G.; Karl, K.; Gütschow, J.; Xueyao, P.; Sandalow, D. Greenhouse gas emissions from food systems: Building the evidence base. Environ. Res. Lett. 2021, 16, 065007. [Google Scholar] [CrossRef]

- Hoogeveen, J.; Faurès, J.-M.; Peiser, L.; Burke, J.; Van de Giesen, N. GlobWat—A global water balance model to assess water use in irrigated agriculture. Hydrol. Earth Syst. Sci. 2015, 19, 3829–3844. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. The State of Food and Agriculture 2020: Overcoming Water Challenges in Agriculture; FAO: Rome, Italy, 2020; pp. 1–210. ISBN 978-92-5-133441-6. [Google Scholar]

- United Nations. The United Nations World Water Development Report 2022: Groundwater: Making the Invisible Visible; UNESCO: Paris, France, 2022; pp. 1–225. ISBN 978-92-3-100507-7. [Google Scholar]

- Boretti, A.; Rosa, L. Reassessing the projections of the World Water Development Report. npj Clean Water 2019, 2, 15. [Google Scholar] [CrossRef]

- Naciones Unidas. Informe Mundial de las Naciones Unidas Sobre el Desarrollo de los Recursos Hídricos 2021: El Valor del Agua; UNESCO: París, France, 2021; pp. 1–207. ISBN 978-92-3-300164-0. [Google Scholar]

- International Energy Agency. Statistics Report: Key World Energy Statistics 2021. Available online: https://www.iea.org/reports/key-world-energy-statistics-2021 (accessed on 4 February 2023).

- International Renewable Energy Agency; Food and Agriculture Organization of the United Nations. Renewable Energy for Agri-Food Systems—Towards the Sustainable Development Goals and the Paris Agreement; FAO: Rome, Italy, 2021; pp. 1–89. ISBN 978-92-5-135235-9. [Google Scholar]

- Food and Agriculture Organization. Greenhouse Gas Emissions from Agri-Food Systems—Global, Regional And Country Trends, 2000–2020; FAOSTAT Analytical Brief No. 50; FAO: Rome, Italy, 2022; pp. 1–12. [Google Scholar]

- Flammini, A.; Pan, X.; Tubiello, F.N.; Qiu, S.Y.; Rocha Souza, L.; Quadrelli, R.; Sims, R. Emissions of greenhouse gases from energy use in agriculture, forestry and fisheries: 1970–2019. Earth Syst. Sci. Data 2022, 14, 811–821. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development; Food and Agriculture Organization. OECD-FAO Agricultural Outlook 2022–2031; FAO: Rome, Italy; OECD: Paris, France, 2022; pp. 1–363. ISBN 978-92-5-136313-3. [Google Scholar]

- Rosa, L.; Rulli, M.C.; Ali, S.; Chiarelli, D.D.; Dell’Angelo, J.; Mueller, N.D.; D’Odorico, P. Energy implications of the 21st century agrarian transition. Nat. Commun. 2021, 12, 2319. [Google Scholar] [CrossRef]

- Tubiello, F.; Karl, K.; Flammini, A.; Conchedda, G.; Oblylayrea, G. Food Systems Emissions Shares, 1990–2019 (Nov 2021 FAOSTAT Update). 2021. Available online: https://zenodo.org/records/5615082 (accessed on 5 March 2023). [CrossRef]

- Nicolo, B.F.; De Luca, A.I.; Stillitano, T.; Iofrida, N.; Falcone, G.; Gulisano, G. Environmental and economic sustainability assessment of navel oranges from the cultivation to the packinghouse according to environmental product declarations system. Calitatea 2017, 18, 108–112. [Google Scholar]

- ISO 14040; Environmental Management-Life Cycle Assessment-Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/obp/ui#iso:std:iso:14040:ed-2:v1:es (accessed on 29 July 2023).

- ISO 14044; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14044:ed-1:v1:es (accessed on 29 July 2023).

- ISO 14067; Greenhouse Gases. Carbon Footprint of Products. Requirements and Guidelines for Quantification. International Organization for Standardization: Geneva, Switzerland, 2018. Available online: https://www.iso.org/obp/ui#iso:std:iso:14067:ed-1:v1:en (accessed on 29 July 2023).

- Jolliet, O.; Antón, A.; Boulay, A.M.; Cherubini, F.; Fantke, P.; Levasseur, A.; McKone, T.; Michelsen, O.; Milà i Canals, L.; Motoshita, M.; et al. Global guidance on environmental life cycle impact assessment indicators: Impacts of climate change, fine particulate matter formation, water consumption and land use. Int. J. Life Cycle Assess 2018, 23, 2189–2207. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F. ReCiPe2016: A harmonized life cycle impact assessment method at mid- point and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- ISO 14046; Environmental Management—Water Footprint—Principles, Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/obp/ui#iso:std:iso:14046:ed-1:v1:es (accessed on 29 July 2023).

- Huijbregts, M.A.J.; Rombouts, L.J.A.; Hellweg, S.; Frischknecht, R.; Hendriks, A.J.; Van De Meent, D.; Ragas, A.M.J.; Reijnders, L.; Struijs, J. Is Cumulative Fossil Energy Demand a Useful Indicator for the Environmental Performance of Products? Environ. Sci. Technol. 2006, 40, 641–648. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Hellweg, S.; Frischknecht, R.; Hendriks, H.W.M.; Hungerbühler, K.; Hendriks, A.J. Cumulative Energy Demand as Predictor for the Environmental Burden of Commodity Production. Environ. Sci. Technol. 2010, 44, 2189–2196. [Google Scholar] [CrossRef] [PubMed]

- Puig, R.; Fullana, I.P.P.; Baquero, G.; Riba, J.-R.; Gala, A.B. A Cumulative Energy Demand indicator (CED), life cycle based, for industrial waste management decision making. Waste Manag. 2013, 33, 2789–2797. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Knöpfel, S.B.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Hischier, R.; Weidema, B.; Althaus, H.-J.; Bauer, C.; Doka, G.; Dones, R.; Frischknecht, R.; Hellweg, S.; Humbert, S.; Jungbluth, N.; et al. Implementation of Life Cycle Impact Assessment Methods, Final Report Ecoinvent v2; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2010. [Google Scholar]

- Arango, E.; Capote, M.; Morera, S.; Clemente, J. Viveros protegidos de cítricos. Manejo Técnico. In Taller Regional Sobre Viveros de Cítricos; IIFT: Havana, Cuba, 2010; pp. 1–18. [Google Scholar]

- Berdeja-Arbeu, R.; Aguilar-Méndez, L.; Moreno-Velazquez, D.; Vázquez-Huerta, G.; Ibáñez-Martínez, A.; Ontiveros-Capurata, R. Calidad de fruta de lima “Persa” en diferentes portainjertos en Veracruz, México. Acta Agríc. Pecu. 2016, 2, 17–22. [Google Scholar]

- Estrada-Venegas, E.G.; Acuña-Soto, J.A.; Chaires-Grijalva, M.P.; Equihua-Martínez, A. Ácaros Asociados y de Importancia Económica a los “Sistemas Producto” en México, y la Relevancia de Algunas Especies que Afectan Estos Cultivos con Importancia Cuarentenaria. Sociedad Mexicana de Entomología: Texcoco, México, 2013; pp. 151–236.

- Flores Contreras, C.; (Citrus producer, Emiliano Zapata, Veracruz, Mexico). Personal communication, 2022.

- García, A.; Rodríguez, K.; Puente, A.; Valero, L.; Rodríguez, G. Evaluación de alternativas para disminuir los niveles de hongos fitopatógenos del suelo en áreas de replantación de cítricos. Cent. Agríc. 2011, 38, 5–7. [Google Scholar]

- Irigoyen, J.N.; Cruz Vela, M.A. Guía Ténica de Semilleros y Viveros Frutales; Ministerio de Agricultura y Ganadería: San Salvador, El Salvador, 2005; pp. 1–40. [Google Scholar]

- Jaramillo, J.; Rodríguez, V.P.; Guzmán, M.; Zapata, M.; Renfigo, T. En la Producción de Tomate Bajo Condiciones Protegidas; FAO: Santiago de Chile, Chile, 2007; pp. 1–316. [Google Scholar]

- Luis, M.; Peña, M.; Collazo, C.; Ramos, P.; Llauger, R. Enfermedades Bacterianas y Fungosas en Viveros de Cítricos: Características y Control. In Taller Regional Sobre Viveros de Cítricos; IIFT: Havana, Cuba, 2010; pp. 1–42. [Google Scholar]

- Macías-Rodríguez, L.; Santillan-Ortega, C.; Robles-Bermúdez, A.; Isidora-Aquino, N.; Ortíz-Catón, M. Insecticidas de Bajo Impacto Ambiental para el Control de Diaphorina citri (Hemiptera: Psyllidae) en Limón Persa en “La Fortuna”, Nayarit, México. Bio Cienc. 2013, 2, 154–161. [Google Scholar]

- Sandoval-Rincón, J.A.; Curti-Díaz, S.A. Producción de Planta Certificada en Vivero; Instituto Nacional de Investigaciones Forestales, Agricolas y Pecuarias, Martínez de la Torre: Veracruz, Mexico, 2011; pp. 1–43. ISBN 978-607-425-654-3. [Google Scholar]

- Steduto, P.; Hslao, T.C.; Fereres, E.; Raes, D. Respuesta del Rendimiento de los Cultivos al Agua; FAO: Roma, Italy, 2012; pp. 1–531. [Google Scholar]

- Trinidad Santos, A.; Aguilar Manjarrez, D. Fertilización foliar, un respaldo importante en el rendimiento de los cultivos. Terra Latinoam. 1999, 17, 247–255. [Google Scholar]

- Mayorga-Castañeda, F.J. Manejo Agronómico para la Producción de Limón Persa en el Estado de Morelos; Secretaría de Agricultura, Ganadería, Desarrollo Forestal, Pesca y Alimentación: Morelos, Mexico, 2009. [Google Scholar]

- Jiménez Pérez, M.; (Citrus producer, Emiliano Zapata, Veracruz, Mexico). Personal communication, 2022.

- Rodríguez-Cedillos, M. Cultivo de Limón Pérsico; Centro Nacional de Tecnología Agropecuaria y Forestal: San Salvador, El Salvador, 2002; pp. 1–32. [Google Scholar]

- Vanegas, M. Guía Técnica Cultivo del Limón Persa, 1st ed.; Escobar-de-León, J., Alas, F.A., Eds.; Editorial Maya: San Salvador, El Salvador, 2002; pp. 1–46. [Google Scholar]

- Curti-Díaz, S.A.; Laredo-Salazar, X.; Díaz-Zorrilla, U.; Sandoval-Rincón, J.A.; Hernández-Hernández, J. Tecnología para Producir Limón Persa; Instituto Nacional de Investigaciones Forestales, Agricolas y Pecuarias: Veracruz, Mexico, 2000; pp. 1–166. [Google Scholar]

- González-Mancilla, A.; Rivera-Cruz, M.d.; Ortíz-García, C.F.; Almaraz-Suárez, J.J.; Trujillo-Narcía, A.; Cruz-Navarro, G. Use of organic fertilisers to improve soil chemical and microbiological properties and citric Citrage troyer growth. Univ. Cienc. 2013, 29, 123–139. [Google Scholar]

- Velazquez, P. Momento óptimo de aplicación de pulverizaciones cúpricas para el control de la cancrosis de los cítricos en hojas de limonero en Famaillana, Tucumán. Hortic. Argent. 2008, 27, 5–10. [Google Scholar]

- Vargas, F.; Viera, M.; Anteparra, M. Efecto comparativo de paraquat, glifosato y gramocil para el control de malezas en cítricos en Tulumayo, Loncio Prado. Investig. Amaz. 2012, 2, 20–26. [Google Scholar]

- Vegas-Rodríguez, U.; Narrea Cango, M. Manejo Integrado del Cultivo de Limón; Universidad Nacional Agraria la Molina: Piura, Peru, 2011; pp. 1–43. [Google Scholar]

- Alia-Tejacal, I.; Lugo-Alonso, A.; Ariza-Flores, R.; Valdez-Aguilar, L.A.; Víctor, L.M.; Pacheco-Hernández, P. Manual de Tecnología de Producción en Limón “Persa” y Naranja “Valencia” en el Estado de Morelos; Instituto Nacional de Investigaciones Forestales, Agricolas y Pecuarias: Morelos, Mexico, 2011; pp. 1–99. [Google Scholar]

- Hernández Ruíz, A.; (Persian Lime Packing Facility, Emiliano Zapata, Veracruz, Mexico); Contreras Mejía, A.K.; (Persian Lime Packing Facility, Emiliano Zapata, Veracruz, Mexico); Morales Navarro, A.; (Persian Lime Packing Facility, Emiliano Zapata, Veracruz, Mexico). Personal communication, 2022.

- Ecoinvent. The Ecoinvent Database. Available online: https://www.ecoinvent.org/database/database.html (accessed on 31 January 2023).

- Secretaría de Energía. Balance Nacional de Energía. Gobierno de México. 2021. Available online: https://www.gob.mx/cms/uploads/attachment/file/805509/BNE-2021.pdf (accessed on 3 March 2023).

- Secretaría de Energía. Informe Pormenorizado Sobre el Desempeño y las Tendencias de la Industria Eléctrica Nacional 2021. Gobierno de México. Available online: http://base.energia.gob.mx/InfPormenorizado/IP2021.pdf (accessed on 15 March 2023).

- Secretaría de Energía. Reporte Anual del Potencial de Mitigación de GEI en el Sector Eléctrico. Gobierno de México. Available online: https://www.gob.mx/cms/uploads/attachment/file/754392/Reporte_Anual_Pot__Mit_SE__VF.pdf (accessed on 30 January 2023).

- Giraldi-Díaz, M.R.; Castillo-González, E.; De Medina-Salas, L.; Velasquez-De la Cruz, R.; Huerta-Silva, H.D. Environmental impacts associated with intensive production in pig farms in Mexico through life cycle assessment. Sustainability 2021, 13, 11248. [Google Scholar] [CrossRef]

- Sistema Meteorológico Nacional. Normales Climatológica por Estado. Comisión Nacional del Agua, Gobierno de México. Available online: https://smn.conagua.gob.mx/es/informacion-climatologica-por-estado?estado=ver (accessed on 15 November 2022).

- Janse-van Vuuren, P.F. Regional Resource Flow Model Fruit Sector Report; GreenCape, Department of Economic Development and Tourism, Western Cape Government: Cape Town, South Africa, 2015. [Google Scholar]

- Frankowska, A.; Jeswani, H.K.; Azapagic, A. Life cycle environmental impacts of fruits consumption in the UK. J. Environ. Manag. 2019, 248, 109111. [Google Scholar] [CrossRef] [PubMed]

- Machin Ferrero, L.M.; Wheeler, J.; Mele, F.D. Life cycle assessment of the Argentine lemon and its derivatives in a circular economy context. Sustain. Prod. Consum. 2022, 29, 672–684. [Google Scholar] [CrossRef]

- Machin Ferrero, L.M.; Araujo, P.Z.; Nishihara Hun, A.L.; Valdeón, D.H.; Mele, F.D. Water footprint assessment of lemon and its derivatives in Argentina: A case study in the province of Tucumán. Int. J. Life Cycle Assess. 2021, 26, 1505–1519. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Iudicello, M.; Mistretta, M. Resource consumption and environmental impacts of the agrofood sector: Life cycle assessment of Italian citrus-based products. Environ. Manag. 2009, 43, 707–724. [Google Scholar] [CrossRef] [PubMed]

- Bell, E.M.; Horvath, A. Modeling the carbon footprint of fresh produce: Effects of transportation, localness, and seasonality on US orange markets. Environ. Res. Lett. 2020, 15, 034040. [Google Scholar] [CrossRef]

- Pergola, M.; D’Amico, M.; Celano, G.; Palese, A.M.A.; Scuderi, A.; Di Vita, G.; Inglese, P. Sustainability evaluation of Sicily’s lemon and orange production: An energy, economic and environmental analysis. J. Environ. Manag. 2013, 128, 674–682. [Google Scholar] [CrossRef] [PubMed]

- Basset-Mens, C.; Vannière, H.; Grasselly, D.; Heitz, H.; Braun, A.; Payen, S.; Biard, Y. Environmental impacts of imported and locally grown fruits for the French market: A cradle-to-farm-gate LCA study. Fruits 2016, 71, 93–104. [Google Scholar] [CrossRef]

- Aguilera, E.; Guzmán, G.; Alonso, A. Greenhouse gas emissions from conventional and organic cropping systems in Spain. I. Herbaceous crops. Agron. Sustain. Dev. 2015, 35, 713–724. [Google Scholar] [CrossRef]

- Danckwerts, L. Water Footprint and Economic Water Productivity of Citrus Production: A Comparison across Three River Valleys in the Eastern Cape Midlands. Master’s Thesis, Rhodes University Grahamstown South Africa, Makhanda, South Africa, 2019. [Google Scholar]

- Munro, S.A.; Fraser, G.C.; Snowball, J.D.; Pahlow, M. Water footprint assessment of citrus production in South Africa: A case study of the Lower Sundays River Valley. J. Clean. Prod. 2016, 135, 668–678. [Google Scholar] [CrossRef]

- Machin Ferrero, L.M.; Araujo, P.Z.; Valdeón, D.H.; Hun, A.L.N.; Mele, F.D. Water footprint of lemon production in Argentina. Sci. Total Environ. 2022, 816, 151614. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, S.P.; Meena, R.S.; Lalotra, S.; Parihar, R.K.; Mitra, B. Reduction of Energy Consumption in Agriculture for Sustainable Green Future. In Input Use Efficiency for Food and Environmental Security; Bhatt, R., Meena, R.S., Hossain, A., Eds.; Springer: Singapore, 2021. [Google Scholar]

- Fardet, A.; Rock, E. Ultra-processed foods and food system sustainability: What are the links? Sustainability 2020, 12, 6280. [Google Scholar] [CrossRef]

- Tubiello, F.N.; Karl, K.; Flammini, A.; Gütschow, J.; Obli-Laryea, G.; Conchedda, G.; Torero, M. Pre-and post-production processes increasingly dominate greenhouse gas emissions from agri-food systems. Earth Syst. Sci. Data 2022, 14, 1795–1809. [Google Scholar] [CrossRef]

- Yilmaz, H.; Aydin, B. Comparative input-output energy analysis of citrus production in Turkey: Case of Adana province. Erwerbs-Obstbau 2020, 62, 29–36. [Google Scholar] [CrossRef]

- Özbek, O.; Dokumacı, K.Y.; Gökdoğan, O. Analysis of Energy Use Efficiency and Greenhouse Gas Emissions of Lemon (Citrus lemon L.) Production in Turkey. Erwerbs-obstbau 2023, 65, 1705–1712. [Google Scholar] [CrossRef] [PubMed]

| Footprint | Equation | Description |

|---|---|---|

| Carbon | Expressed in units of kg CO2 eq, the carbon footprint (CF) equation epitomizes the aggregate global warming potential (GWP) of all substances tallied within the inventory. Herein, G denotes the quantity of the examined gas emission, and GWPgas represents its global warming potential [23]. | |

| Water | The application of the water footprint (WF) equation was based on the model proposed by Huijbregts et al. [24], which assesses the cumulative impact of water consumption measured in cubic meters (m3). The utilized weighting parameters associate (Characterization factor) the volume of consumed water with water extracted from either surface or subterranean sources, multiplied by the water flows accounted (water consumption) for in the inventory pertinent to each process within the product system. | |

| Energy | The energy footprint (EF) equation was derived from the accumulated energy model, aggregating energy flows provided within the product system. Conversion factors (energy factor) for each type of primary energy source, as proposed by Hischier et al. [30], were applied, and multiplied by the fuel consumption computed in the inventory. |

| Type of Energy | Primary Fuel Supplied | Net Calorific Value Conversion Factor | Primary Energy Share b (%) | Energy Efficiency (%) | Self-Consumption c (%) | Electric Power Generation (%) |

|---|---|---|---|---|---|---|

| Natural gas | 9.43 × 109 m3 | 39.08 MJ/m3 | 35.98 | 43.3 | 0.94 | 37.03 |

| Coal | 8.44 × 109 kg | 19.43 MJ/kg | 16.01 | 41.1 | 7.79 | 14.56 |

| Fuel oil | 3.36 × 109 L | 40.74 MJ/L | 13.35 | 37.1 | 7.29 | 11.02 |

| Diesel | 4.55 × 108 L | 37.68 MJ/L | 1.67 | 36.6 | 4.41 | 1.41 |

| Uranium | 3.82 × 104 kg | 3.29 GJ/g | 12.26 | 34.6 | 2.76 | 9.90 |

| Hydro-energy | 8.90 | 91.9 | 0.89 | 19.45 | ||

| Geothermal | 10.75 | 16.7 | 5.55 | 4.07 | ||

| Wind | 1.07 | 99.6 | 0.05 | 2.56 | ||

| Solar (photovoltaic) | 0.001 | 99.2 | 1.00 | 0.001 |

| Tree/Ha | Lemons | ||

|---|---|---|---|

| Sprouted lemon plants | 117 | Fruits on the tree | 1126 |

| Seeded lemon plants | 115 | Harvested fruits | 113 |

| Plants in the lemon orchard | 110 | Selected fruits | 111 |

| Young lemon trees | 106 | Packed fruits | 100 |

| Adult lemon trees | 100 |

| Stages | Input/Output | Quantity | Unit | |

|---|---|---|---|---|

| Seedbed and nursery | Seedbed place | Fertilizers | 3.5217 × 10−9 | kg |

| Fossil fuels | 3.7122 × 10−4 | kg | ||

| Metals-supply | 9.0671 × 10−10 | kg | ||

| Pesticides | 1.2586 × 10−7 | kg | ||

| Plastics supplies | 3.5093 × 10−10 | kg | ||

| Transport | 3.4262 × 10−6 | kg | ||

| Water | 4.6984 × 10−6 | m3 | ||

| Emissions | 1.0905 × 10−3 | kg | ||

| Residual agrochemicals | 1.7165 × 10−8 | kg | ||

| Wastewater | 3.6647 × 10−6 | m3 | ||

| Nursery | Fertilizers | 7.8513 × 10−4 | kg | |

| Metals-supply | 7.0949 × 10−7 | kg | ||

| Pesticides | 3.5100 × 10−6 | kg | ||

| Plastics supplies | 2.1933 × 10−6 | kg | ||

| Transport | 4.6157 × 10−4 | tkm | ||

| Water | 4.0749 × 10−3 | m3 | ||

| Emissions | 2.5625 × 10−4 | kg | ||

| Residual agrochemicals | 9.7375 × 10−6 | kg | ||

| Wastewater | 1.3002 × 10−5 | m3 | ||

| Lemon orchard | Overall maintenance | Fossil fuels | 1.0142 × 10−5 | kg |

| Metals-supply | 9.8954 × 10−10 | kg | ||

| Plastics supplies | 1.5851 × 10−10 | kg | ||

| Transport | 5.1763 × 10−6 | tkm | ||

| Water | 2.1285 × 10−3 | m3 | ||

| Emissions | 4.9574 × 10−5 | kg | ||

| Wastewater | 1.6602 × 10−3 | m3 | ||

| Young lemon tree | Fertilizers | 4.9365 × 10−6 | kg | |

| Pesticides | 7.3265 × 10−6 | kg | ||

| Transport | 5.9616 × 10−5 | tkm | ||

| Water | 1.4782 × 10−3 | m3 | ||

| Residual agrochemicals | 1.6381 × 10−6 | kg | ||

| Wastewater | 1.3714 × 10−7 | m3 | ||

| Adult lemon tree | Fertilizers | 1.1664 × 10−2 | kg | |

| Pesticides | 2.6366 × 10−5 | kg | ||

| Transport | 1.8929 × 10−3 | tkm | ||

| Water | 1.0274 × 10−3 | m3 | ||

| Residual agrochemicals | 2.9263 × 10−3 | kg | ||

| Wastewater | 7.8694 × 10−9 | m3 | ||

| Long-lived lemon tree | Fertilizers | 2.2067 × 10−3 | kg | |

| Pesticides | 1.5095 × 10−5 | kg | ||

| Transport | 3.9766 × 10−4 | tkm | ||

| Water | 4.6616 × 10−4 | m3 | ||

| Residual agrochemicals | 7.3416 × 10−4 | kg | ||

| Wastewater | 7.8694 × 10−9 | m3 | ||

| Industrialized | Packing house | Chemical supplies | 2.5995 × 10−3 | kg |

| Electric power | 5.5441 × 10−3 | MJ | ||

| Packing materials | 1.6057 × 10−1 | kg | ||

| Transport | 3.4466 × 100 | tkm | ||

| Water | 1.6400 × 10−5 | m3 | ||

| Wastewater | 9.3620 × 10−6 | m3 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo-González, E.; De Medina-Salas, L.; Giraldi-Díaz, M.R.; Velásquez-De La Cruz, R.; Jiménez-Ochoa, J.R. Environmental Impacts Associated with the Production and Packing of Persian Lemon in Mexico through Life-Cycle Assessment. Clean Technol. 2024, 6, 551-571. https://doi.org/10.3390/cleantechnol6020029

Castillo-González E, De Medina-Salas L, Giraldi-Díaz MR, Velásquez-De La Cruz R, Jiménez-Ochoa JR. Environmental Impacts Associated with the Production and Packing of Persian Lemon in Mexico through Life-Cycle Assessment. Clean Technologies. 2024; 6(2):551-571. https://doi.org/10.3390/cleantechnol6020029

Chicago/Turabian StyleCastillo-González, Eduardo, Lorena De Medina-Salas, Mario Rafael Giraldi-Díaz, Raúl Velásquez-De La Cruz, and José Rafael Jiménez-Ochoa. 2024. "Environmental Impacts Associated with the Production and Packing of Persian Lemon in Mexico through Life-Cycle Assessment" Clean Technologies 6, no. 2: 551-571. https://doi.org/10.3390/cleantechnol6020029

APA StyleCastillo-González, E., De Medina-Salas, L., Giraldi-Díaz, M. R., Velásquez-De La Cruz, R., & Jiménez-Ochoa, J. R. (2024). Environmental Impacts Associated with the Production and Packing of Persian Lemon in Mexico through Life-Cycle Assessment. Clean Technologies, 6(2), 551-571. https://doi.org/10.3390/cleantechnol6020029