1. Introduction

In Europe, heating and cooling account for almost 50% of the total final energy consumption [

1]. Most of the heating and cooling demands are in buildings and industries. Despite rising cooling demand in Europe, most of the energy consumed is still for heating purposes with fossil fuels used as the dominant primary energy source. The building stock is responsible for 40% of total energy consumption and 36% of all greenhouse gas (GHG) emissions in the European Union (EU) [

2]. Therefore, the decarbonization of the heating and cooling sector is crucial to reaching the EU’s climate neutrality goal by 2050 and the prior target set to reduce net GHG emissions by at least 55% by 2030 [

1]. The replacement of fossil fuels with renewable energy sources and deployment of low-carbon technologies, such as heat pumps (HPs), in the heating and cooling sector has been slower to date, especially in contrast to renewable electricity generation. Furthermore, the transition to sustainable heating and cooling is an appealing challenge considering the current geopolitics in the EU energy landscape. Thus, heat pumping technology is key to linking the use of renewable energy sources and energy efficiency in the heating and cooling sectors. Thereby, the implementation of HPs enables a faster transition of buildings and industrial users from dependence on fossil fuels for heating and cooling applications.

Heat pumping technologies are often limited to either the provision of heating or cooling (as a refrigerator or chiller) even though HPs can be designed to supply heating and cooling simultaneously with the right choice of working fluid (refrigerant) and the design of system components. Moreover, a considerable amount of heating and cooling are required simultaneously or within a short span in the building sector, food processing industries, and other applications. For instance, simultaneous heat and cold productions are required in hotels for space cooling and domestic hot water (DHW) production [

3,

4]; in office buildings for server room cooling and space heating; swimming pool heating and ice rink cooling in sports complexes [

5]; in the food processing industries (e.g., the dairy processing industry) for product refrigeration, process heating and cooling, and hot water for cleaning purposes [

6,

7,

8]; and other applications, such as space cooling and seawater desalination, for example, in coastal areas [

9]. Therefore, HPs capable of delivering heat and cold simultaneously have advantages in these types of buildings and industrial applications compared to separate production of heat and cold from the viewpoint of efficient utilization of primary energy sources. Besides, conventional heating and cooling systems (e.g., natural gas boiler and electricity-driven vapor compression chiller, respectively) used in these types of applications consume more primary energy than the combined production of heating and cooling using a single heat pump.

The heat pumping technologies are classified as work-driven and heat-driven HPs based on the type of driving input energy, which is electrical/mechanical energy and thermal energy, respectively. Among the heat-driven HPs, this study is focused on absorption heat pumps (AHPs) for simultaneous heating and cooling supply for potential applications in the building and industrial sectors. In the literature, various researchers have carried out theoretical and experimental studies on AHP cycles that combine cooling and heating (or water purification using the heating output to drive thermal separation processes) applications, and consequently, before presenting the proposed AHP concept in this paper, selected related studies are highlighted below.

The earliest AHP cycle configuration proposed for the combined heating and cooling production dates back to the 1980s, using an H

2O/LiBr working pair by Eisa et al. [

10]. The thermodynamic design data for the potential combinations of operating temperatures of the absorber (30–50 °C), condenser (50–100 °C), evaporator (2–15 °C), and generator (70–170 °C) of the single-effect H

2O/LiBr AHP cycle were obtained using simulation and reported taking into consideration of the LiBr crystallization limit in the absorber and generator. Further, Kumar et al. [

11] carried out an experimental study on the single-effect H2O/LiBr AHP for combined heating and cooling production taking advantage of the heat released during the absorption and condensation processes. Best et al. [

12] also conducted a similar study using an NH

3/LiNO

3 working pair and obtained the AHP cycle thermodynamic design data for the feasible combination of operating temperatures of the absorber (50–100 °C), condenser (50–100 °C), evaporator (−10–+15 °C), and generator (90–170 °C) with NH

3 concentration in the range of 30 to 55%. The same type of study was continued for the single-effect AHP cycle with H

2O/Carrol (LiBr + ethylene glycol, ratio 4.5) working pair by Best et al. [

13] and the corresponding thermodynamic design data were obtained for the feasible operating temperature range of the absorber (30–50 °C), condenser (50–100 °C), evaporator (2–14 °C), and generator (80–160 °C). These studies examined the potential of the single-stage AHP cycle using several types of working fluid mixtures (H

2O/LiBr, H

2O/Carrol, and NH

3/LiNO

3) for the combined production of heating and cooling for a range of operating conditions. In these AHP cycles, the condenser heat is released at temperature levels suitable for various applications, while the cooling is delivered by the evaporator for a range of temperatures.

The use of heat rejected by the condenser of the AHPs for desalination and water purification applications using thermal separation processes in closed- and open-loop integrated AHPs was studied by some researchers. Solar-driven H

2O/LiBr AHP coupled with a multi-effect distillation (MED) system with up to eight effects was proposed and modeled for both cooling production and water purification [

14]. The vapor leaving the desorber (generator) of the H

2O/LiBr AHP was used to drive the MED system and the condensate from the first three effects of the MED system was utilized in the evaporator of the AHP to provide the cooling output. The cooling COP of the AHP cycle reaches about 0.743, and the overall COP of the combined AHP–MED system could reach 1.44. The heat rejected from the absorber and condenser of a solar-driven H

2O/LiBr AHP was used to deliver the required warm water for the humidification–dehumidification (HDH) process to provide water purification while delivering a cooling effect at the evaporator [

15]. Using this coupled system, a daily water production of 5–9 L was obtained per unit area of solar collector array during the summer season, which is about twice the water production capacity of typical solar still. Another desalination system, based on a vacuum-enhanced distillation process, using the heat rejected from the H

2O/LiBr AHP as a driving heat source was theoretically investigated [

16]. This hybrid solar-assisted cooling and desalination system was able to provide 3.25 kW of cooling with a desalinated water production capacity of 4.5 kg/h.

The vapor generated by the desorber of H

2O/LiBr AHP was utilized to drive a MED system with six effects in the cycle configuration developed by Wang and Lior [

17,

18,

19]. In this combined AHP–MED system, the MED system’s first effect was utilized as a condenser of the AHP with the condensate provided to the AHP’s evaporator for obtaining the cooling output. Furthermore, they studied a cycle modification in which a second absorber was utilized for absorbing the vapor generated in the last effect of the MED system, and the heat rejected by this absorption process was used as extra steam to drive the MED system [

17,

18]. The modified system was capable of providing flexibility in the ratio of cooling to freshwater production. Ibrahim and Dincer [

20] designed and developed a combined system comprising an intermittent H

2O/LiBr AHP and a solar still to provide both cooling and desalinated water for domestic applications in rural areas. The combination between the seawater desalination system and the AHP system (i.e., for cooling production) is by using seawater as a coupling fluid for the condenser, evaporator, and absorber. The produced cooling effect, as chilled water, was stored in a storage tank to supply the cooling for a conditioned space during the day due to the intermittent operation of the AHP. This solar-driven combined system operated with an energy efficiency of around 13.8% and maximum desalination unit efficiency of about 40%.

Boman and Garimella [

21,

22] recently investigated an open-loop H

2O/LiBr AHP cycle combined with membrane-based water purification processes (i.e., membrane distillation (MD) and forward osmosis (FO)) to provide simultaneous graywater purification and space cooling/heating. The thermodynamic model of combined open-loop cycles (i.e., H

2O/LiBr AHP-MD or H

2O/LiBr AHP-FO) was developed and applied to analyze the performance of the cycle over a wider range of water loads [

21]. Moreover, the performance of the combined cycle in cooling and heating modes of operation were studied at varied evaporator temperatures (3–25 °C), water loads (up to 1000 kg/day), and graywater inlet temperatures (5–23 °C) of the cycle based on MD process [

21]. The performance of the MD-based cycle was higher than the FO-based cycle at a high-water demand regime in both heating and cooling modes of operation. Moreover, they designed, modeled, and experimentally validated a horizontal-tube (length of 0.24 m) falling-film heat exchanger to serve as absorber (or desorber) of the open-loop H

2O/LiBr AHP with a small-scale cooling output (0.3 kW) and a water purification capacity of ~10.5 kg/day [

22]. Two feed solutions (i.e., synthetic graywater and 3.5 wt% NaCl solution) representative of unconventional water sources were tested in their experimental study to evaluate the performance of the proposed water purifying H

2O/LiBr AHP concept, and it allows for the removal of 90% of contaminants from the synthetic graywater and 99% of NaCl from the feed NaCl solution.

Based on the above-reviewed studies, the following research gaps were identified: • The performance of a single-stage H2O/LiBr AHP for simultaneous heating and cooling supplies for different types of potential end-use applications was not investigated; • The feasibility of utilizing heat rejected during the condensation process of a single-effect H2O/LiBr chiller for heating applications at different temperature levels was not analyzed except in some previous cycle thermodynamic studies; • The majority of previously studied H2O/LiBr AHP cycles for combined heating and cooling have been focused on energy analysis in terms of COPs, and this type of system requires the consideration of both quantity and quality of the dual useful outputs (i.e., heating and cooling capacities and heating and cooling supply temperatures) in their performance evaluation.

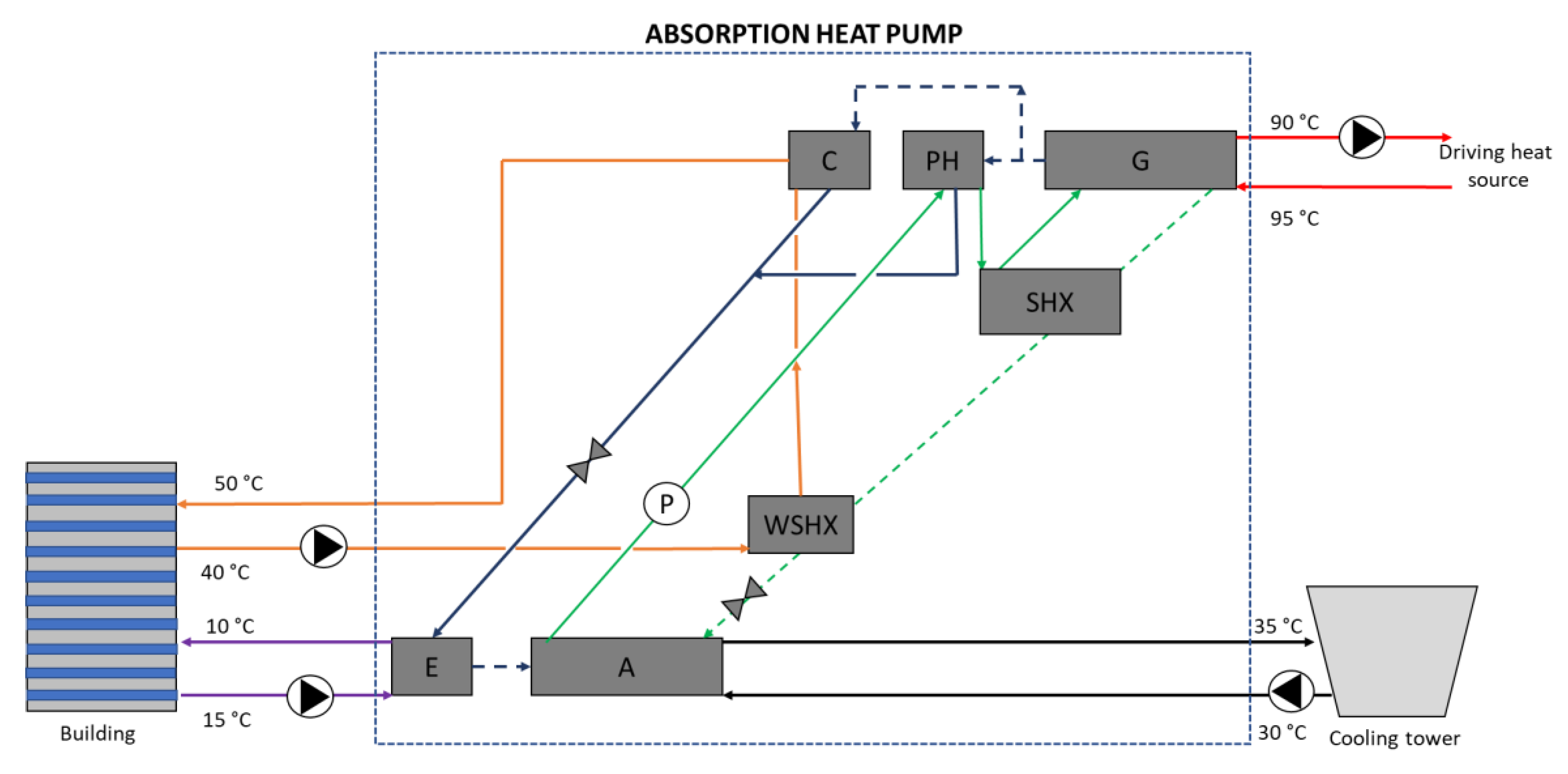

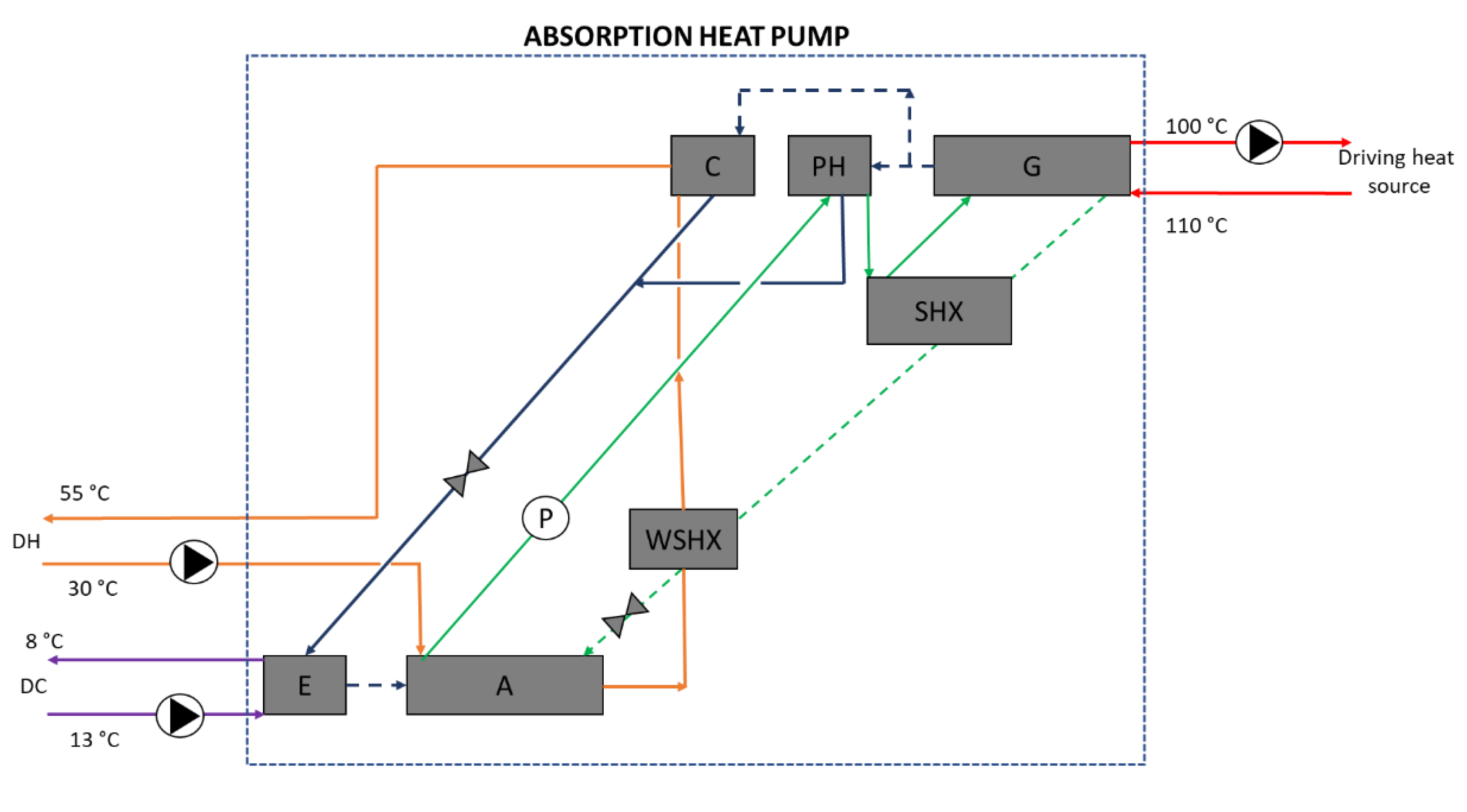

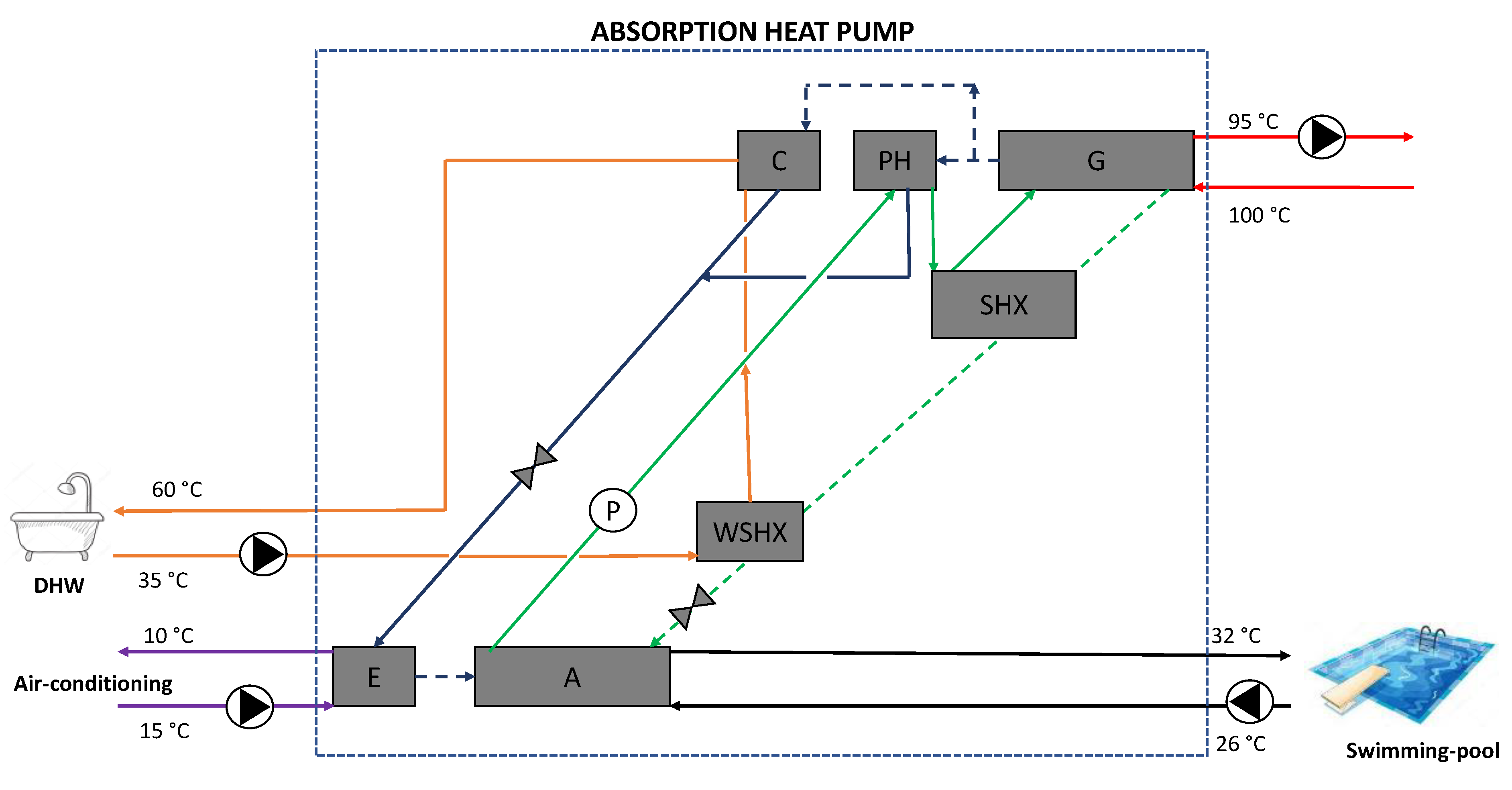

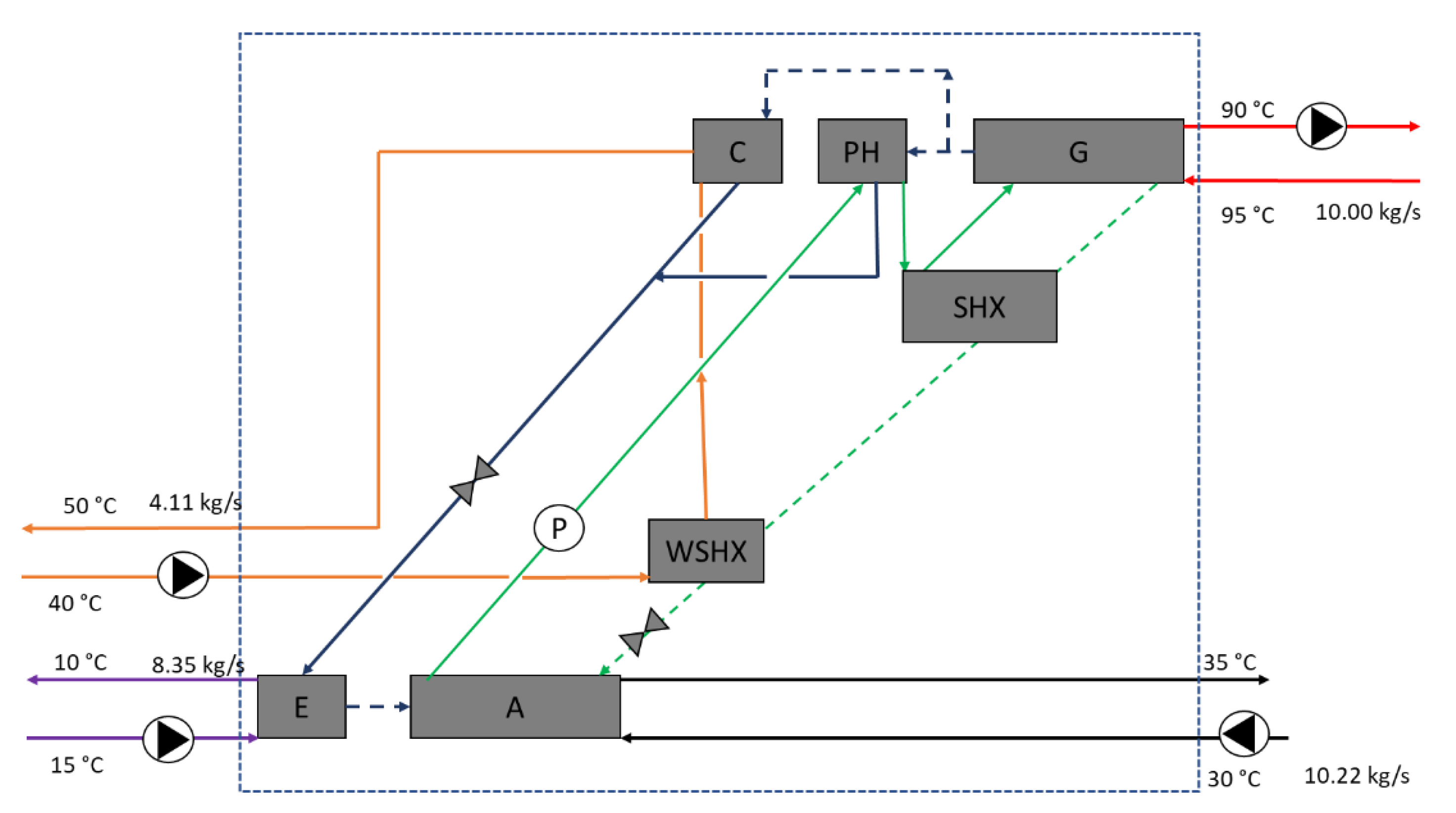

In this paper, the feasibility of a new single-effect H2O/LiBr AHP cycle configuration for the combined production of cooling and heating at several temperature levels is investigated. Thereby, the new H2O/LiBr AHP cycle can be integrated with several types of end-use applications. First, the main difference of this AHP cycle configuration is described in contrast to the conventional single-effect H2O/LiBr chiller. Then, the numerical model of the AHP cycle is developed and the operational limits of the cycle in terms of temperatures are identified; thus, it is used to set the suitable potential applications of the proposed cycle configuration. Finally, the performance of the AHP for various applications is evaluated based on its cooling capacity, heating capacity, coefficient of performance (COP), and exergy COP (ECOP).

6. Conclusions and Future Works

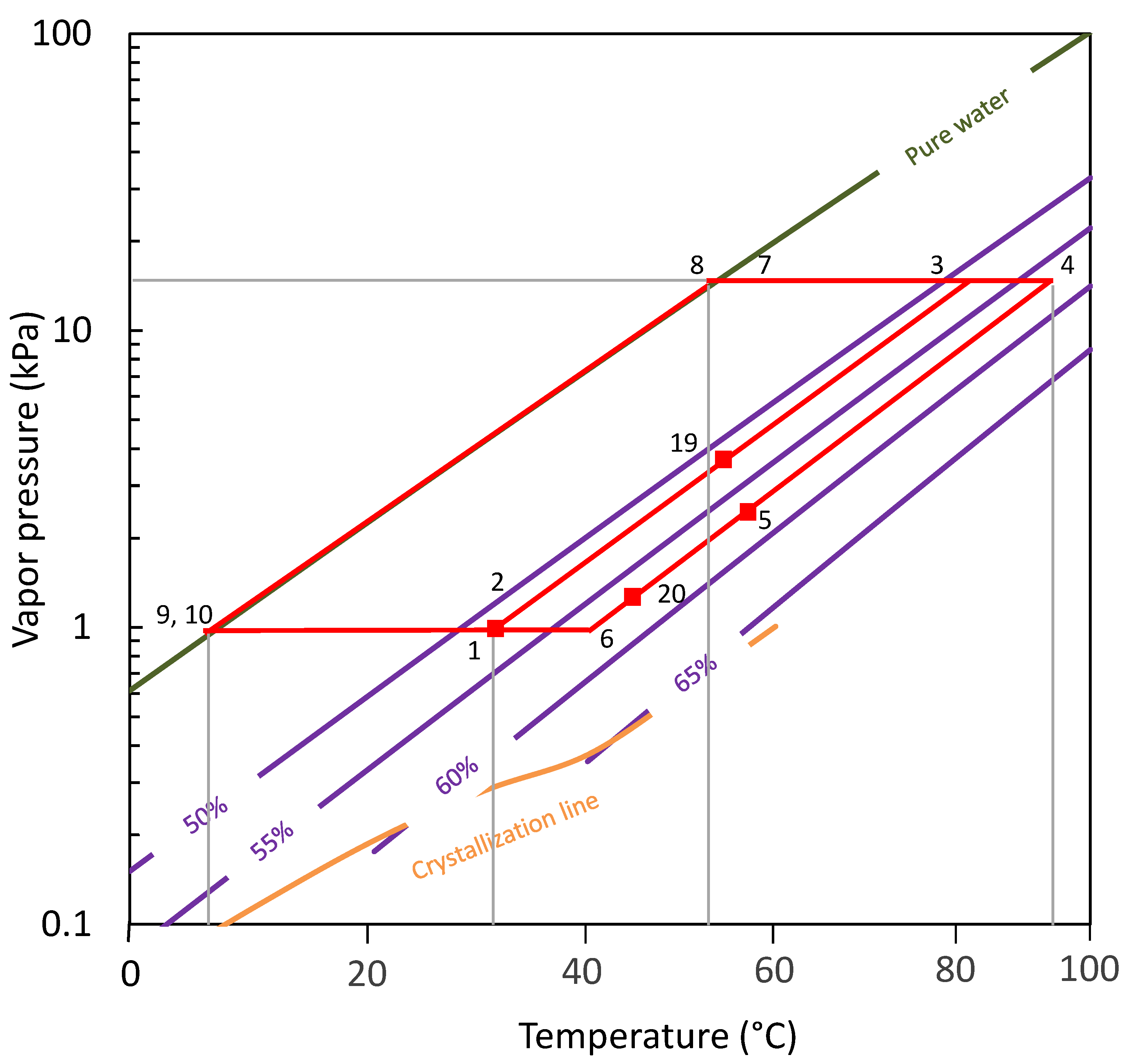

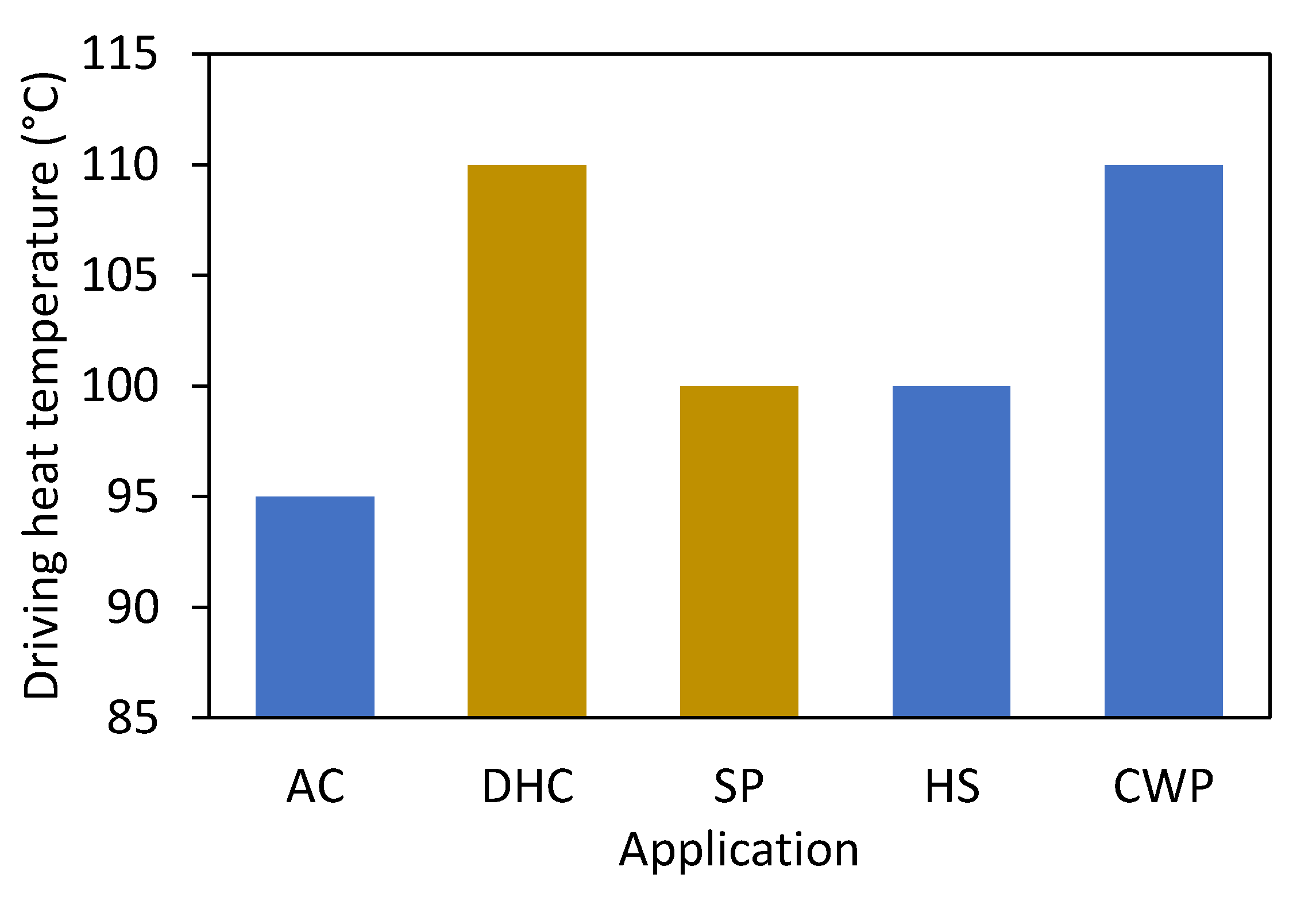

A novel AHP was proposed in this paper. This heat pump was based on a single-effect H2O/LiBr absorption chiller and was modified for the combined production of cooling and heating by recovering the condensation heat at a useful temperature level instead of rejecting it to ambient air, as in the case of a conventional single-effect absorption chiller. Furthermore, part of the heat of condensation was recovered internally to preheat the weak H2O/LiBr solution. The main changes that the AHP cycle requires in comparison with the conventional single-effect absorption chiller were described. Operational limitations of the cycle were set in terms of maximum and minimum driving heat temperatures for different set chilled and hot water supply temperatures. The minimum and maximum driving heat temperatures required by this AHP are from 85 °C to 120 °C, which are, in general, higher than those required by the conventional single-effect H2O/LiBr absorption chiller.

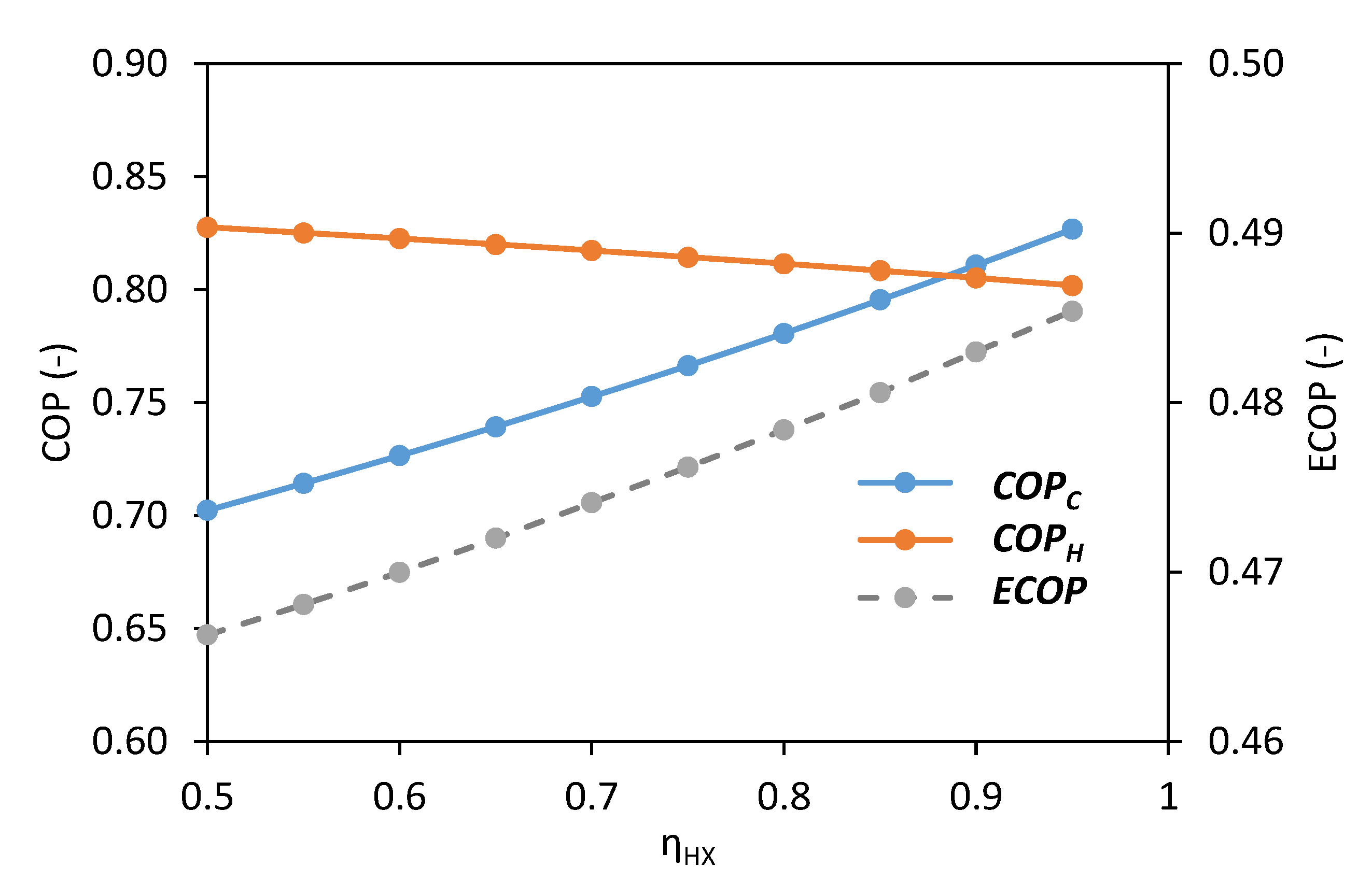

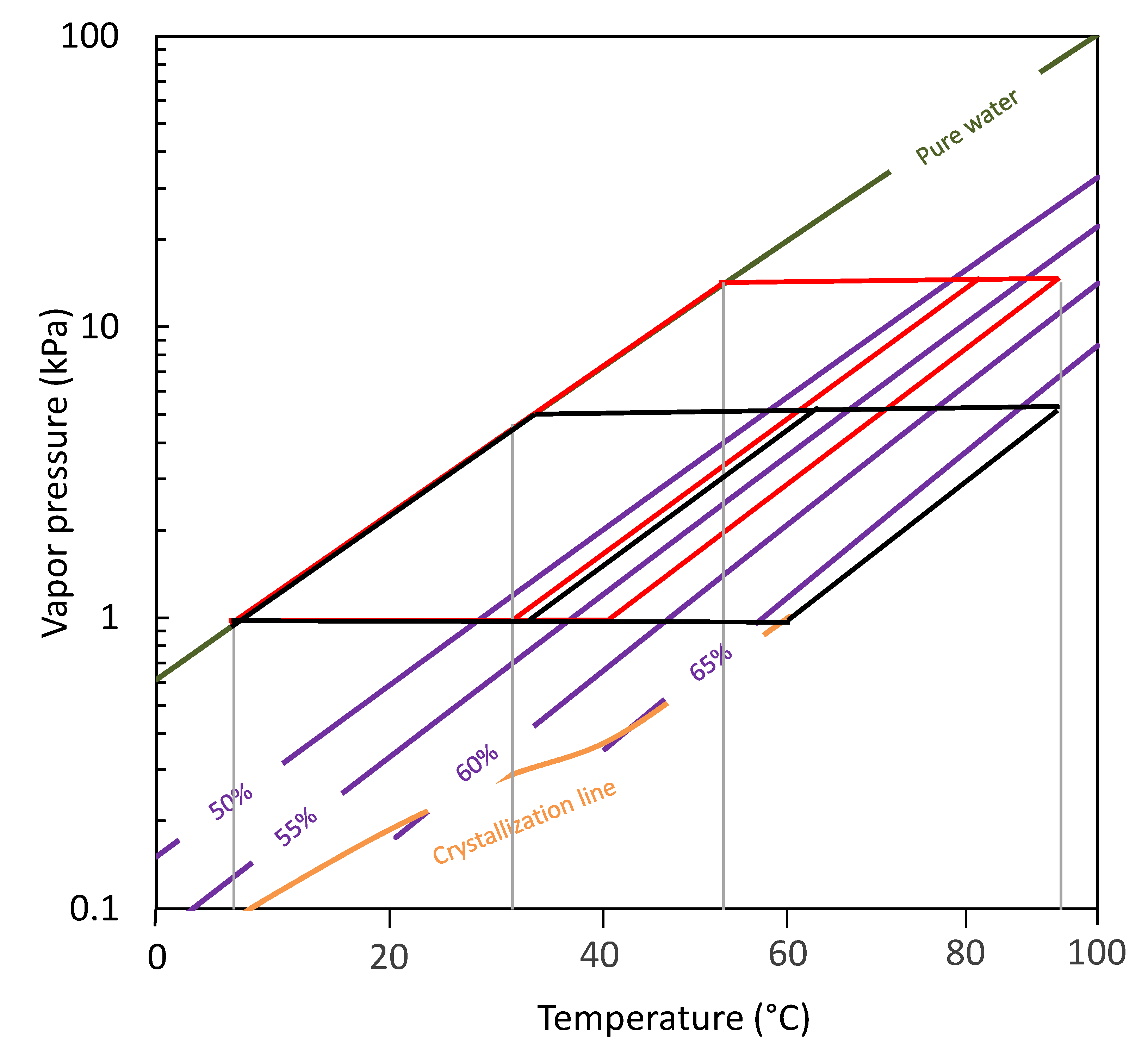

Increasing the solution heat exchanger effectiveness allows for an increase of the AHP performance, especially the , which increases from 0.7 to 0.83. The novel H2O/LiBr AHP was evaluated under five potential applications that require simultaneous heating and cooling: an air conditioning application, a 4th generation DHC network, a sports center with an indoor swimming pool, a hybrid air conditioning system with an AHP and a desiccant evaporative cooling system, and a simultaneous cooling and water purification application. For these five applications, the novel AHP showed promising results, especially for the 4th generation DHC, and the sports center with an indoor swimming pool, where heat rejected from the absorber can also be used for the heating application. In these two applications the is 0.812 and 0.842, the is 1.812 and 1.842, and the is 0.667 and 0.54, respectively. In the other three applications, where the heat rejected from the absorber cannot be used, the ranges between 0.832 and 0.840. The is smaller in these cases: 0.58 in the CWP, 0.72 in the HS, and 0.82 in the AC. The ECOP ranges between 0.451 and 0.485.

Future work will be an experimental evaluation at the laboratory level of a complete AHP. This evaluation will be helpful to validate the novel AHP and identify possible issues to be solved before its integration in a demonstration site.