Efficient Management of Sewage Sludge from Urban Wastewaters with the Addition of Inorganic Waste: Focus on Rheological Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sludges Characteristics and Conditioning Procedure

2.2. Analytical Methods

2.3. Rheological Measurements

2.4. Mathematical Modeling

3. Results and Discussion

3.1. Effective Management of ADS Using GLDs

- (i).

- a reduction in the OM and nitrogen content is observed after GLDs incorporation, while the phosphorus and potassium concentrations are not significantly changed.

- (ii).

- the germination index increased slightly by mixing ADS with GLDs, while caution is recommended for both material applications during the seed germination phase.

- (iii).

- GLDs allowed a significant reduction of E. coli contamination below the legal limit established by Portuguese legislation for applying SS on the soil (<3 log CFU/g). On the other hand, biomass production during a growth test is not influenced negatively by the application of GLDs.

- (iv).

- the levels of potentially toxic metals in both materials are below the Portuguese legal limit (Portuguese Decree-Law No. 276/2009) established for the direct use of sludge in soil [27].

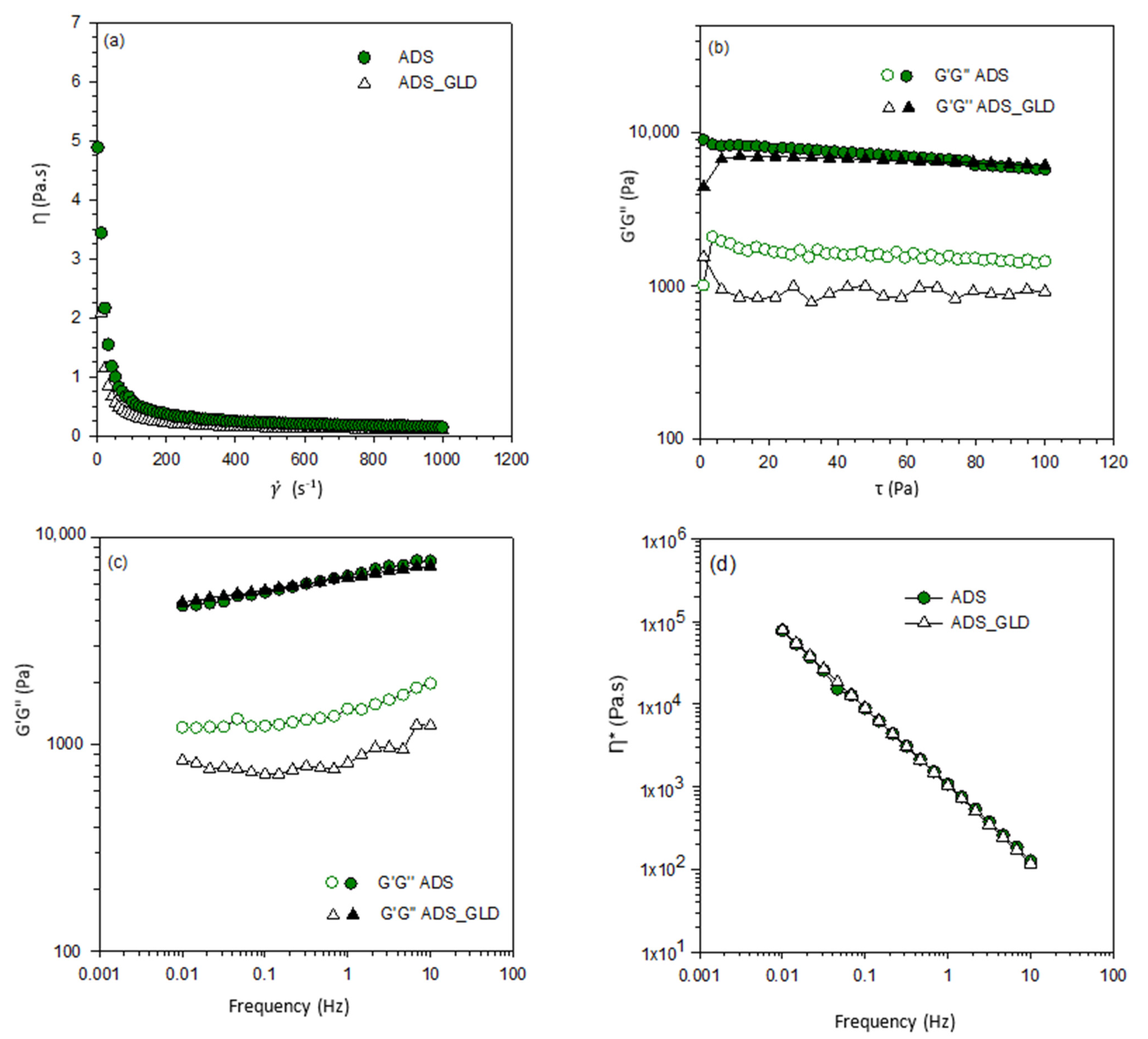

3.2. Rheological Characteristics of Raw and Conditioned ADS

3.2.1. Rheology of Raw ADS

3.2.2. Rheology of ADS Mixed with GLDs

3.2.3. Mathematical Modeling

3.3. Practical Applications

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bennamoun, L.; Crine, M.; Léonard, A. Convective Drying of Wastewater Sludge: Introduction of Shrinkage Effect in Mathematical Modeling. Dry. Technol. 2013, 31, 643–654. [Google Scholar] [CrossRef]

- Collard, M.; Teychené, B.; Lemée, L. Comparison of three different wastewater sludge and their respective drying processes: Solar, thermal and reed beds—Impact on organic matter characteristics. J. Environ. Manag. 2017, 203, 760–767. [Google Scholar] [CrossRef] [PubMed]

- Gomes, L.A.; Santos, A.F.; Góis, J.C.; Quina, M.J. Thermal dehydration of urban biosolids with green liquor dregs from pulp and paper mill. J. Environ. Manag. 2020, 261, 109944. [Google Scholar] [CrossRef]

- Santos, A.F.; Santos, C.P.; Matos, A.M.; Cardoso, O.; Quina, M.J. Effect of Thermal Drying and Chemical Treatments with Wastes on Microbiological Contamination Indicators in Sewage Sludge. Microorganisms 2020, 8, 376. [Google Scholar] [CrossRef]

- Gomes, L.A.; Santos, A.F.; Pinheiro, C.T.; Góis, J.C.; Quina, M.J. Screening of waste materials as adjuvants for drying sewage sludge based on environmental, technical and economic criteria. J. Clean. Prod. 2020, 259, 120927. [Google Scholar] [CrossRef]

- Santos, A.F.; Gomes, L.A.; Góis, J.C.; Quina, M.J. Improvement of Thermal Dehydration and Agronomic Properties of Products Obtained by Combining Sewage Sludge with Industrial Residues. Waste Biomass Valorization 2021, 12, 5087–5097. [Google Scholar] [CrossRef]

- Markis, F.; Baudez, J.; Rajarathinam, P.; Slatter, P.; Eshtiaghi, N. Rheological characterisation of primary and secondary sludge: Impact of solids concentration. Chem. Eng. J. 2014, 253, 526–537. [Google Scholar] [CrossRef]

- Wang, H.; Hu, H.; Yang, H.; Zeng, R.J. Characterization of anaerobic granular sludge using a rheological approach. Water Res. 2016, 106, 116–125. [Google Scholar] [CrossRef]

- Baudez, J. About peak and loop in sludge rheograms. J. Environ. Manag. 2006, 78, 232–239. [Google Scholar] [CrossRef]

- Kumaran, V. Rheology of Complex Fluids: Chapter 2—Fundamentals of Rheology; Springer: New York, NY, USA, 2011. [Google Scholar]

- Dai, X.; Gai, X.; Dong, B. Rheology evolution of sludge through high-solid anaerobic digestion. Bioresour. Technol. 2014, 174, 6–10. [Google Scholar] [CrossRef]

- Seyssiecq, I.; Ferrasse, J.; Roche, N. State-of-the-art: Rheological characterisation of wastewater treatment sludge. Biochem. Eng. J. 2003, 16, 41–56. [Google Scholar] [CrossRef]

- Eshtiaghi, N.; Markis, F.; Dong, S.; Baudez, J.; Slatter, P. Rheological characterisation of municipal sludge: A review. Water Res. 2013, 47, 5493–5510. [Google Scholar] [CrossRef] [PubMed]

- Chhabra, R.; Richardson, J. Non-Newtonian Flow and Applied Rheology, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2008; ISBN 9788578110796. [Google Scholar]

- Cross, M.M. Rheology of non-Newtonian fluids: A new flow equation for pseudoplastic systems. J. Colloid Sci. 1965, 20, 417–437. [Google Scholar] [CrossRef]

- Baudez, J.; Ayol, A.; Coussot, P. Practical determination of the rheological behavior of pasty biosolids. J. Environ. Manag. 2004, 72, 181–188. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Jiang, K.; Wang, X.; Xu, G. Effect of total suspended solids and various treatment on rheological characteristics of municipal sludge. Res. Chem. Intermed. 2018, 44, 5123–5138. [Google Scholar] [CrossRef]

- Pevere, A.; Guibaud, G.; Van Hullebusch, E.; Lens, P.; Baudu, M. Viscosity evolution of anaerobic granular sludge. Biochem. Eng. J. 2006, 27, 315–322. [Google Scholar] [CrossRef]

- Baudez, J.-C.; Coussot, P. Rheology of aging, concentrated, polymeric suspensions: Application to pasty sewage sludges. J. Rheol. 2001, 45, 1123–1139. [Google Scholar] [CrossRef]

- Wang, H.-F.; Bai, Y.-N.; Zhang, W.; Wang, H.-J.; Zeng, R.J. Supplementary In-Depth Analysis of the Waste Activated Sludge Dewatering Process Using a Rheological Analysis. ACS ES&T Eng. 2021, 1, 289–297. [Google Scholar]

- Baroutian, S.; Eshtiaghi, N.; Gapes, D.J. Rheology of a primary and secondary sewage sludge mixture: Dependency on temperature and solid concentration. Bioresour. Technol. 2013, 140, 227–233. [Google Scholar] [CrossRef]

- Lotito, V.; Lotito, A.M. Rheological measurements on different types of sewage sludge for pumping design. J. Environ. Manag. 2014, 137, 189–196. [Google Scholar] [CrossRef]

- Baudez, J.C.; Gupta, R.K.; Eshtiaghi, N.; Slatter, P. The viscoelastic behaviour of raw and anaerobic digested sludge: Strong similarities with soft-glassy materials. Water Res. 2013, 47, 173–180. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quina, M.J.; Pinheiro, C.T. Inorganic waste generated in kraft pulp mills: The transition from landfill to industrial applications. Appl. Sci. 2020, 10, 2317. [Google Scholar] [CrossRef]

- Mäkitalo, M.; Maurice, C.; Jia, Y.; Öhlander, B. Characterization of green liquor dregs, potentially useful for prevention of the formation of acid rock drainage. Minerals 2014, 4, 330–344. [Google Scholar] [CrossRef]

- Wang, R.; Zhao, Z.; Yin, Q.; Liu, J. Effects of the low-temperature thermo-alkaline method on the rheological properties of sludge. J. Environ. Manag. 2016, 177, 74–83. [Google Scholar] [CrossRef] [PubMed]

- Santos, A.F.; Veríssimo, A.M.; Brites, P.; Baptista, F.M.; Góis, J.C.; Quina, M.J. Greenhouse Assays with Lactuca sativa for Testing Sewage Sludge-Based Soil Amendments. Agronomy 2022, 12, 209. [Google Scholar] [CrossRef]

- Forster, C.F. The rheological and physico-chemical characteristics of sewage sludges. Enzym. Microb. Technol. 2002, 30, 340–345. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook, 4th ed.; Vincentz Network: Hanover, Germany, 2012; ISBN 9783866306509. [Google Scholar]

- Cao, X.; Jiang, Z.; Cui, W.; Wang, Y.; Yang, P. Rheological Properties of Municipal Sewage Sludge: Dependency on Solid Concentration and Temperature. Procedia Environ. Sci. 2016, 31, 113–121. [Google Scholar] [CrossRef]

- Liu, J.; Wang, R.; Gao, F.; Zhou, J.; Cen, K. Rheology and thixotropic properties of slurry fuel prepared using municipal wastewater sludge and coal. Chem. Eng. Sci. 2012, 76, 1–8. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, J.; Poncin, S.; Li, H.Z. Rheological characteristics of highly concentrated anaerobic digested sludge. Biochem. Eng. J. 2014, 86, 57–61. [Google Scholar] [CrossRef]

- Liu, J.; Wang, R.; Hu, Y.; Zhou, J.; Cen, K. Improving the properties of slurry fuel preparation to recycle municipal sewage sludge by alkaline pretreatment. Energy Fuels 2013, 27, 2883–2889. [Google Scholar] [CrossRef]

- Xiao, B.; Liu, C.; Liu, J.; Guo, X. Evaluation of the microbial cell structure damages in alkaline pretreatment of waste activated sludge. Bioresour. Technol. 2015, 196, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Gürses, A.; Açikyildiz, M.; Doǧar, Ç.; Karaca, S.; Bayrak, R. An investigation on effects of various parameters on viscosities of coal-water mixture prepared with Erzurum-Aşkale lignite coal. Fuel Process. Technol. 2006, 87, 821–827. [Google Scholar] [CrossRef]

- Neyens, E.; Baeyens, J.; Creemers, C. Alkaline thermal sludge hydrolysis. J. Hazard. Mater. 2003, 97, 295–314. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, H. Rheological behavior of sewage sludge with high solid content. Water Sci. Technol. 2015, 71, 1686–1693. [Google Scholar] [CrossRef] [PubMed]

- Edifor, S.Y.; Nguyen, Q.D.; Van Eyk, P.; Biller, P.; Lewis, D.M. Rheological studies of municipal sewage sludge slurries for hydrothermal liquefaction biorefinery applications. Chem. Eng. Res. Des. 2021, 166, 148–157. [Google Scholar] [CrossRef]

- Wang, H.-F.; Hu, H.; Wang, H.-J.; Bai, Y.-N.; Shen, X.-F.; Zhang, W.; Zeng, R.J. Comprehensive investigation of the relationship between organic content and waste activated sludge dewaterability. J. Hazard. Mater. 2020, 394, 122547. [Google Scholar] [CrossRef]

- Miryahyaei, S.; Olinga, K.; Ayub, M.S.; Jayaratna, S.S.; Othman, M.; Eshtiaghi, N. Rheological measurements as indicators for hydrolysis rate, organic matter removal, and dewaterability of digestate in anaerobic digesters. J. Environ. Chem. Eng. 2020, 8, 103970. [Google Scholar] [CrossRef]

- Papa, M.; Pedrazzani, R.; Nembrini, S.; Bertanza, G. Should Rheological Properties of Activated Sludge be Measured? Appl. Rheol. 2015, 25, 24590. [Google Scholar]

| ADS | ADS_GLDs | |

|---|---|---|

| General parameters * | ||

| pH | 6.71 | 8.40 |

| OM (%) | 63.7 | 56.7 |

| NKjeldahl (%) | 3.90 | 2.38 |

| P2O5 (%) | 3.83 | 3.35 |

| K2O (%) | 0.22 | 0.20 |

| Technical parameters | ||

| Drying rate (gH2O/min.kgwb) | 16.81 | 17.78 |

| Diffusion coefficient (m2/s) | 6.92 × 10−8 | 6.49 × 10−8 |

| Acid neutralization capacity (g CaCO3/g) | 0.06 | 0.38 |

| Environmental parameters | ||

| Germination index (%) ** | 5.53 | 6.43 |

| E. coli contamination (log CFU/g) | 4.28 | 2.32 |

| Biomass production (g) *** | 0.38 | 0.39 |

| Herschel–Bulkley Model | Cross Model | |||||||

|---|---|---|---|---|---|---|---|---|

| TSs (%) | K (Pa·sn) | τy (Pa) | n | R2 | Ƞ0 (Pa·s) | Ƞꝏ (Pa·s) | (s−1) | R2 |

| 5 | 5.317 × 10−4 | 0.319 | 1.400 | 0.9984 | 0.7773 | 0.0050 | 10.34 | 0.8859 |

| 10 | 1.728 × 10−3 | 1.941 | 1.276 | 0.9841 | 0.0463 | 0.0134 | 104.3 | 0.6538 |

| 15 | 2.225 | 22.19 | 0.595 | 0.9920 | 4.927 | 0.1692 | 16.70 | 0.9978 |

| 20 | 10.88 | 178.3 | 0.963 | 0.9770 | 40,004 | 0.5102 | 1.503 | 0.9999 |

| Herschel–Bulkley Model | Cross Model | |||||||

|---|---|---|---|---|---|---|---|---|

| K (Pa·sn) | τy (Pa) | n | R2 | Ƞꝏ (Pa·s) | Ƞ0 (Pa·s) | (s−1) | R2 | |

| ADS | 2.225 | 22.19 | 0.5952 | 0.992035 | 0.1692 | 4.927 | 16.70 | 0.9978 |

| ADS_GLDs | 1.080 | 13.33 | 0.6337 | 0.993015 | 0.0712 | 2.356 | 4.832 | 0.9995 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, A.F.; Ferreira, A.G.M.; Quina, M.J. Efficient Management of Sewage Sludge from Urban Wastewaters with the Addition of Inorganic Waste: Focus on Rheological Properties. Clean Technol. 2022, 4, 841-853. https://doi.org/10.3390/cleantechnol4030052

Santos AF, Ferreira AGM, Quina MJ. Efficient Management of Sewage Sludge from Urban Wastewaters with the Addition of Inorganic Waste: Focus on Rheological Properties. Clean Technologies. 2022; 4(3):841-853. https://doi.org/10.3390/cleantechnol4030052

Chicago/Turabian StyleSantos, Andreia F., Abel G. M. Ferreira, and Margarida J. Quina. 2022. "Efficient Management of Sewage Sludge from Urban Wastewaters with the Addition of Inorganic Waste: Focus on Rheological Properties" Clean Technologies 4, no. 3: 841-853. https://doi.org/10.3390/cleantechnol4030052

APA StyleSantos, A. F., Ferreira, A. G. M., & Quina, M. J. (2022). Efficient Management of Sewage Sludge from Urban Wastewaters with the Addition of Inorganic Waste: Focus on Rheological Properties. Clean Technologies, 4(3), 841-853. https://doi.org/10.3390/cleantechnol4030052