A Conceptual Framework for Biointelligent Production—Calling for Systemic Life Cycle Thinking in Cellular Units

Abstract

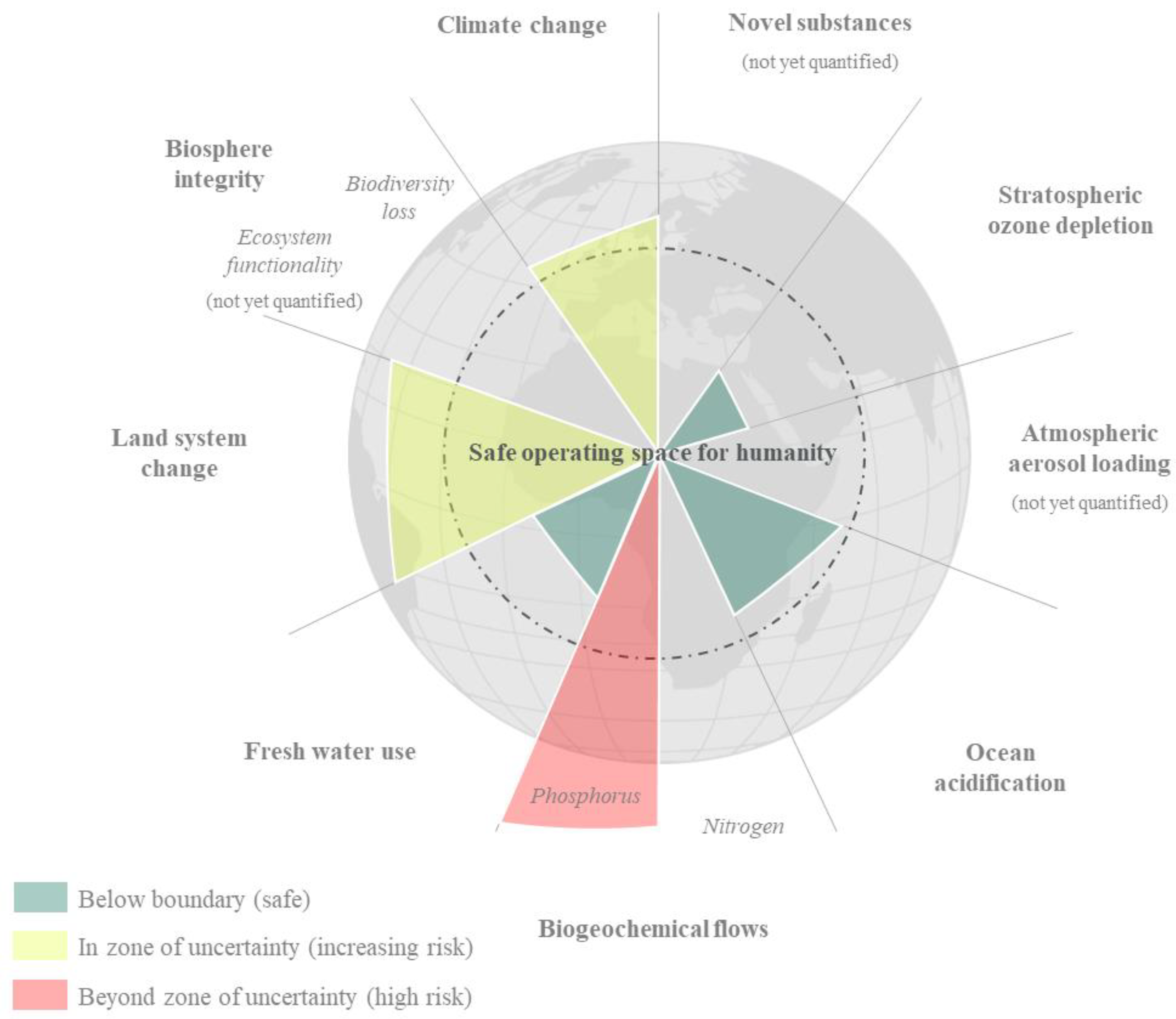

:1. Introduction

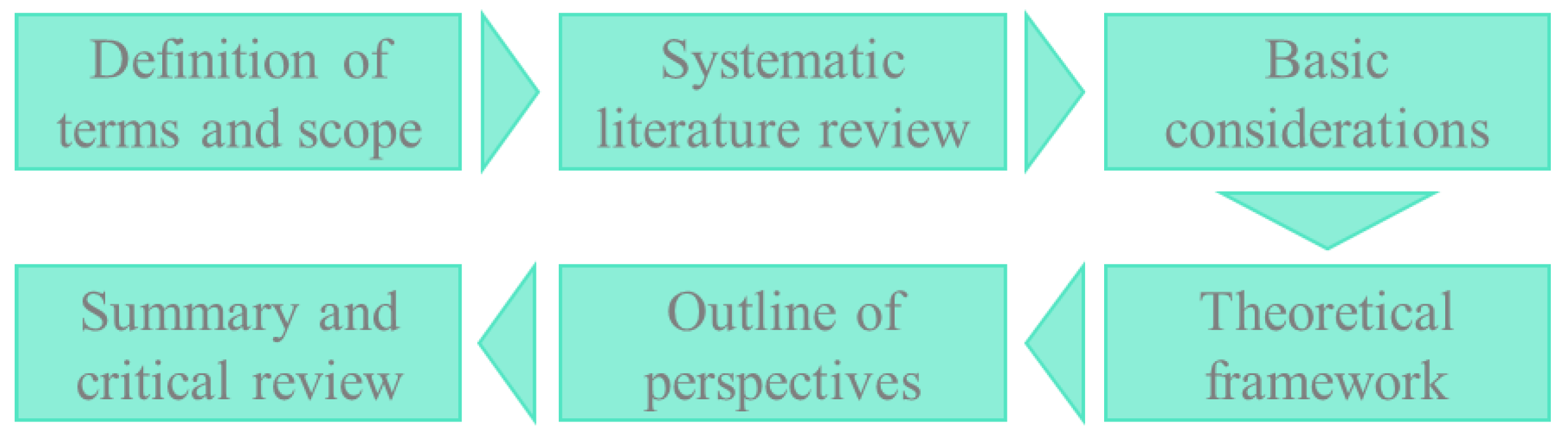

2. Materials and Methods

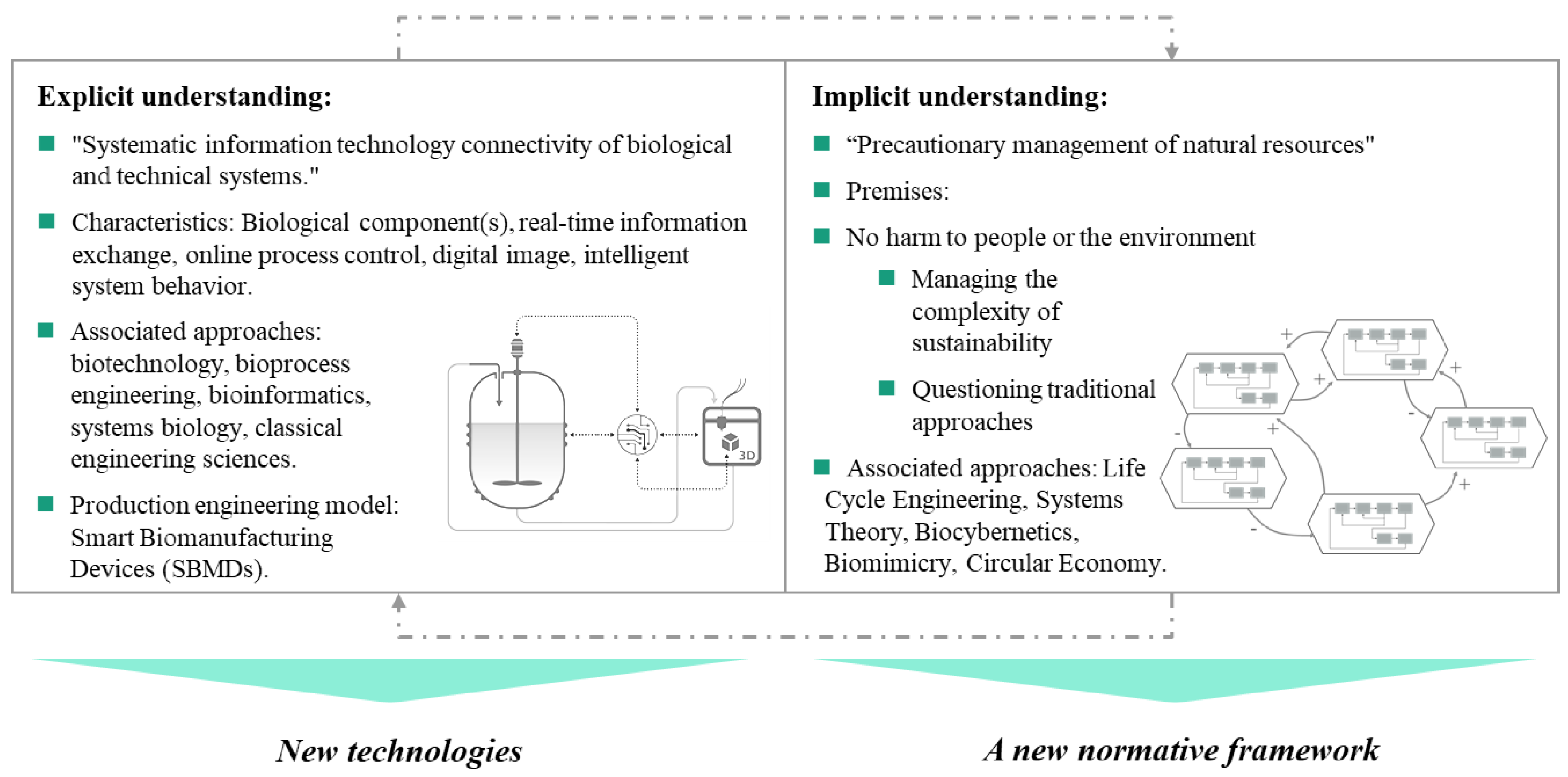

3. Basic Considerations on Implicit Biointelligence

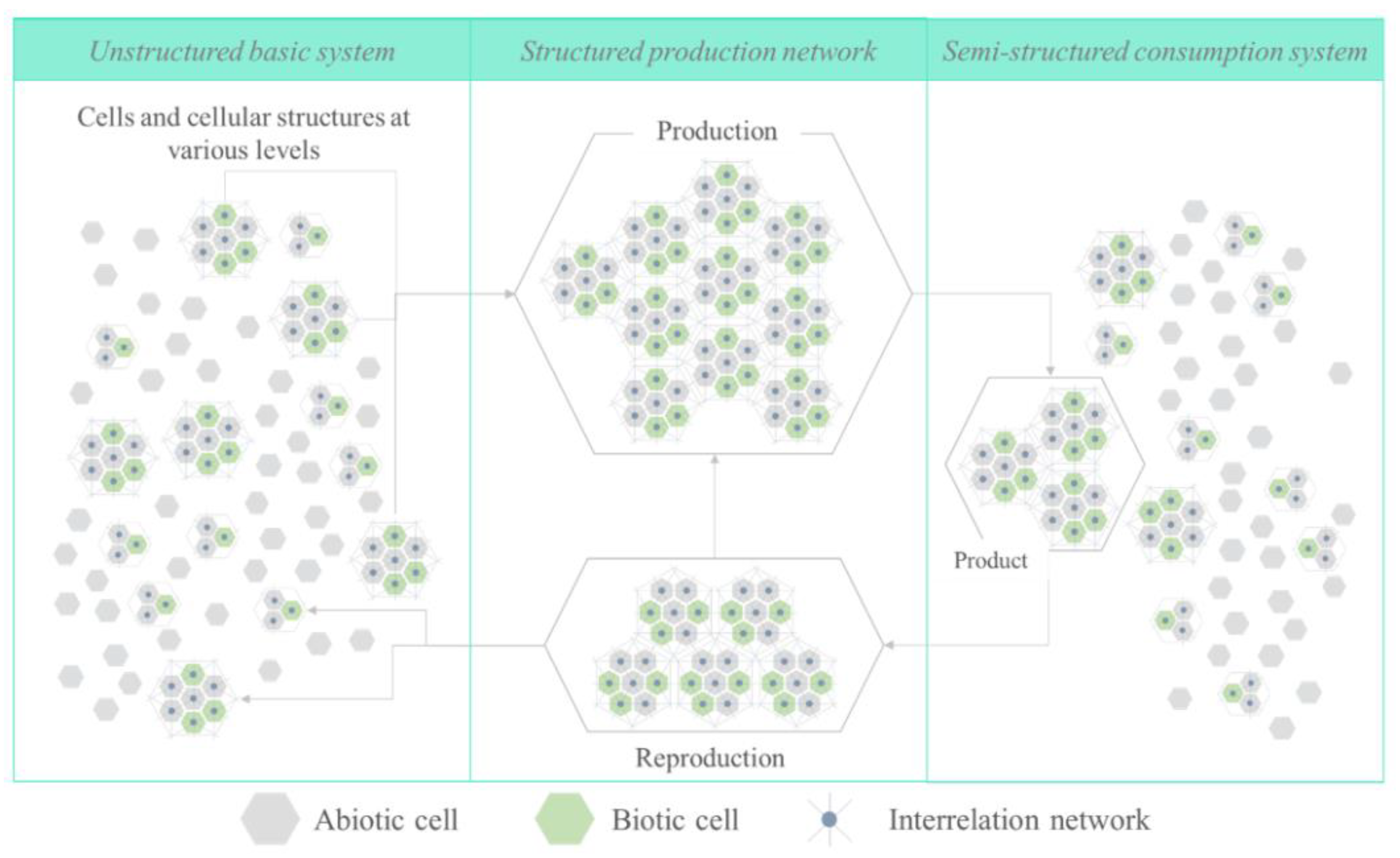

4. Conceptual Framework of Biointelligent Production

5. Perspectives for the Management of Biointelligent Systems

5.1. Markets and Customers

5.2. Strategies and Business Models

- Production of conventional products with conventional production technologies

- Production of biointelligent products with conventional production technologies

- Production of conventional products with biointelligent production technologies

- Production of biointelligent products with biointelligent production technologies

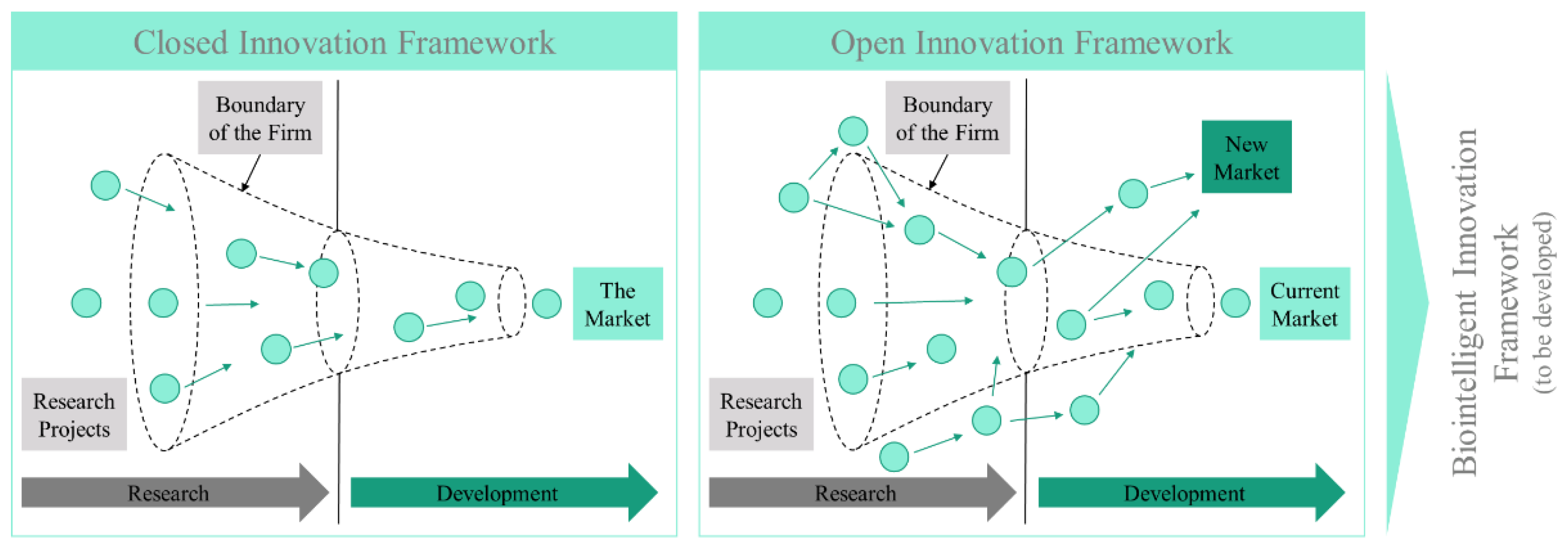

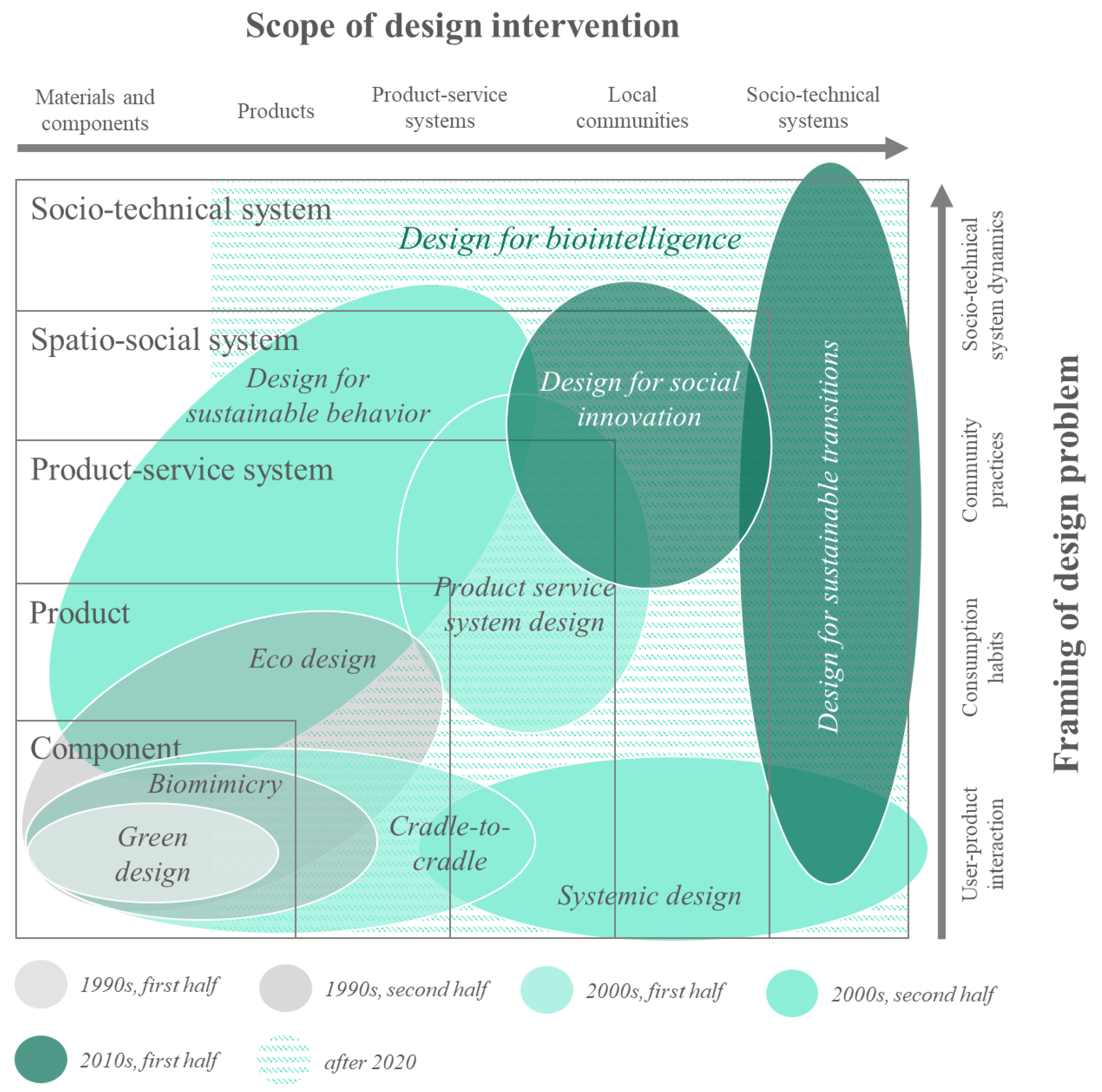

5.3. Innovation and Product Development

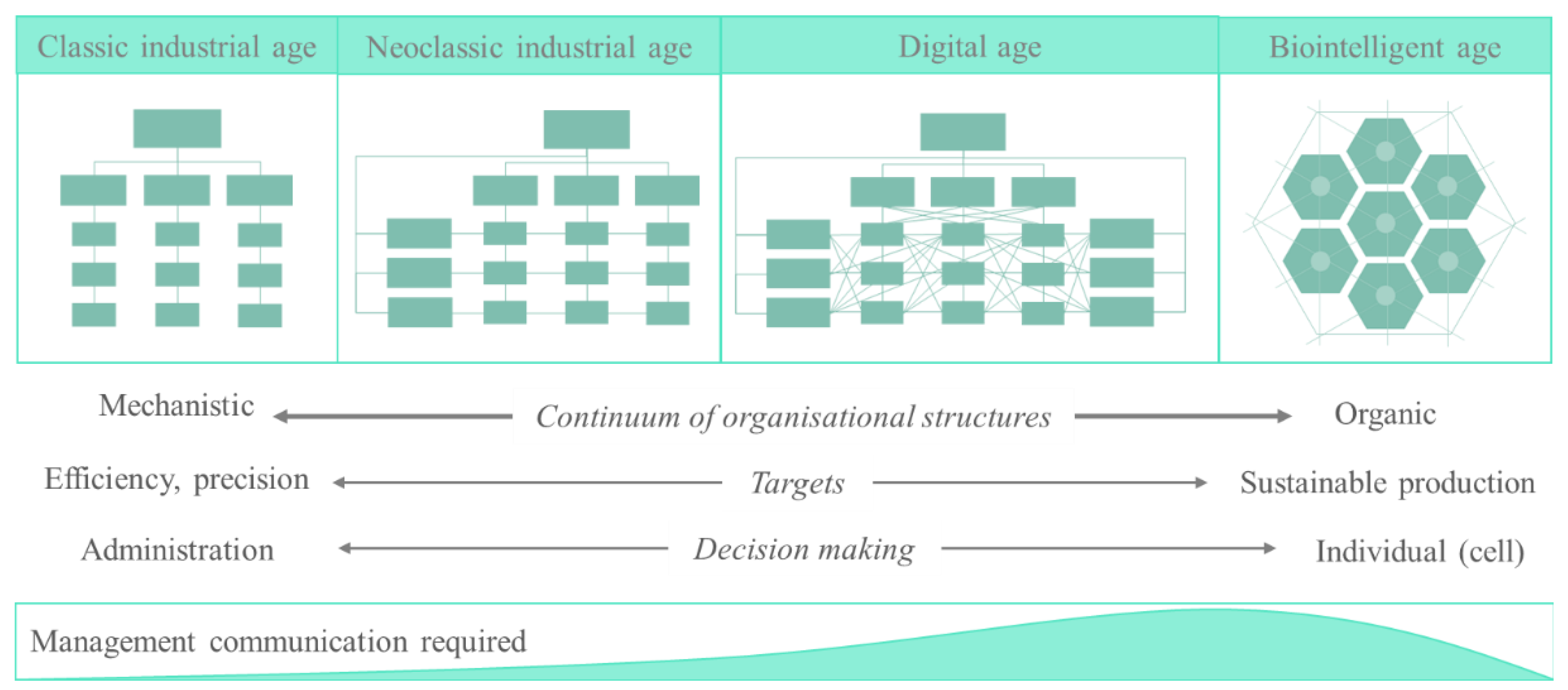

5.4. Organization and Management

5.5. Responsibility

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hagedorn, G.; Loew, T.; Seneviratne, S.I.; Lucht, W.; Beck, M.-L.; Hesse, J.; Knutti, R.; Quaschning, V.; Schleimer, J.-H.; Mattauch, L.; et al. The concerns of the young protesters are justified: A statement by Scientists for Future concerning the protests for more climate protection. GAIA Ecol. Perspect. Sci. Soc. 2019, 28, 79–87. [Google Scholar] [CrossRef]

- Umweltbundesamt. Nachhaltigkeit in der Politik. 2019. Available online: https://www.umweltbundesamt.de/themen/nachhaltigkeit-strategien-internationales/nachhaltigkeit-in-der-politik (accessed on 13 October 2021).

- Haessler, P. Strategic Decisions between Short-Term Profit and Sustainability. Adm. Sci. 2020, 10, 63. [Google Scholar] [CrossRef]

- Revell, A.; Stokes, D.; Chen, H. Small businesses and the environment: Turning over a new leaf? Bus. Strategy Environ. 2010, 19, 273–288. [Google Scholar] [CrossRef]

- Miehe, R.; Baumgarten, Y.; Bauernhansel, T. Biointelligenz: Definition und Kategorisierung—Ein Diskussionspaper. WT WERKSTATTSTECHNIK 2020, 110, 58–63. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; de Vries, W.; de Wit, C.A.; et al. Sustainability. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347, 6223. [Google Scholar] [CrossRef] [Green Version]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, F.S., III; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary Boundaries: Exploring the Safe Operating Space for Humanity. Ecol. Soc. 2009, 14, 1–33. [Google Scholar] [CrossRef]

- Europäische Kommission (n.d.) Umsetzung des Europäischen Grünen Deals. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_de (accessed on 15 September 2021).

- McKinsey & Company. How the European Union Could Achieve Net-Zero Emissions at Net-Zero Cost. 2020. Available online: https://www.mckinsey.com/business-functions/sustainability/our-insights/how-the-european-union-could-achieve-net-zero-emissions-at-net-zero-cost (accessed on 13 October 2021).

- Miehe, R.; Full, J.; Scholz, P.; Demmer, A.; Bauernhansl, T.; Sauer, A.; Schub, G. The Biological Transformation of Industrial Manufacturing-Future Fields of Action in Bioinspired and Bio-based Production Technologies and Organization. Procedia Manuf. 2019, 39, 737–744. [Google Scholar] [CrossRef]

- Miehe, R.; Bauernhansl, T.; Beckett, M.; Brecher, C.; Demmer, A.; Drossel, W.-G.; Elfert, P.; Full, J.; Hellmich, A.; Hixlage, J.; et al. The biological transformation of industrial manufacturing—Technologies, status and scenarios for a sustainable future of the German manufacturing industry. J. Manuf. Syst. 2020, 54, 50–61. [Google Scholar] [CrossRef]

- Byrne, G.; Damm, O.; Monostori, L.; Teti, R.; van Houten, F.; Wegener, K.; Wertheim, R.; Sammler, F. Towards high performance living manufacturing systems—A new convergence between biology and engineering. CIRP J. Manuf. Sci. Technol. 2021, 34, 6–21. [Google Scholar] [CrossRef]

- Byrne, G.; Dimitrov, D.; Monostori, L.; Teti, R.; van Houten, F.; Wertheim, R. Biologicalisation: Biological transformation in manufacturing. CIRP J. Manuf. Sci. Technol. 2018, 21, 1–32. [Google Scholar] [CrossRef]

- BIOPRO Baden-Württemberg GmbH. Potenzialanalyse und Roadmapping Biointelligenz für Baden-Württemberg; BIOPRO Baden-Württemberg GmbH: Stuttgart, Germany, 2021. [Google Scholar]

- Wegener, K.; Spierings, A.B.; Teti, R.; Caggiano, A.; Knuttel, D.; Staub, A. A conceptual vision for a bio-intelligent manufacturing cell for Selective Laser Melting. CIRP J. Manuf. Sci. Technol. 2021, 34, 61–83. [Google Scholar] [CrossRef]

- Whitford, W. Biologicalisation: A Nature-Based Digital Manufacturing Revolution. In Proceedings of the ECI Digital Archieves, Biochemical and Molecular Engineering XXI, Mont-Tremblant, QC, Canada, 14–18 July 2019. [Google Scholar]

- Drossel, W.; Dani, I.; Wertheim, R. Biological transformation and technologies used for manufacturing of multifunctional metal-based parts. Procedia Manuf. 2019, 33, 115–122. [Google Scholar] [CrossRef]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, F.S., III; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A safe operating space for humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef] [PubMed]

- Borowski, P.F. Digitization, digital twins, blockchain, and industry 4.0 as elements of management process in enterprises in the energy sector. Energies 2021, 14, 1885. [Google Scholar] [CrossRef]

- Köhl, U.; Abken, H. CAR-T-Zellen als Arzneimittel für neuartige Therapien (Advanced Therapy Medicinal Products) (CAR T cells as drugs for novel therapies (advanced therapy medicinal products)). Der Internist 2021, 62, 449–457. [Google Scholar] [CrossRef]

- Dankar, I.; Haddarah, A.; Omar, F.E.; Sepulcre, F.; Pujola, M. 3D printing technology: The new era for food customization and elaboration. Trends Food Sci. Technol. 2018, 75, 231–242. [Google Scholar] [CrossRef]

- Kiemel, S.; Smolinka, T.; Lehner, F.; Full, J.; Sauer, A.; Miehe, R. Critical materials for water electrolysers at the example of the energy transition in Germany. Int. J. Energy Res. 2021, 45, 9914–9935. [Google Scholar] [CrossRef]

- Miehe, R.; Waltersmann, L.; Sauer, A.; Bauernhansl, T. Sustainable production and the role of digital twins–Basic reflections and perspectives. J. Adv. Manuf. Process. 2021, 3, e10078. [Google Scholar] [CrossRef]

- Bauernhansel, T.; Beckett, M.; Breyer, C.; Gumbsch, P.; ten Hompel, M.; Wolperdinger, M.; Miehe, R.; Beckett, M.; Demmer, A.; Elfert, P.; et al. Biointelligenz: Eine Neue Perspektive für Nachhaltige Industrielle Wertschöpfung. Ergebnisse der Voruntersuchung zur Biologischen Transformation der Industriellen Wertschöpfung (BIOTRAIN); Stuttgart Fraunhofer Verlag: Stuttgart, Germany, 2019. [Google Scholar]

- Full, J.; Miehe, R.; Kiemel, S.; Bauernhansl, T.; Sauer, A. The Biological Transformation of Energy Supply and Storage—Technologies and Scenarios for Biointelligent Value Creation. Procedia Manuf. 2019, 39, 1204–1214. [Google Scholar] [CrossRef]

- Ulrich, P.; Hill, W. Wissenschaftstheoretische Grundlagen der Betriebswirtschaftslehre—Teil I. Wirtschaftswissenschaftliches Studium—Zeitschrift für Ausbildung und Hochschulkontakt 1976, 5, 304–309. [Google Scholar]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- United Nations. Report of the World Commission on Environment and Development: Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Birner, R. Bioeconomy Concepts: Changing Perspectives on the Bioeconomy. In Bioeconomy: Shaping the Transition to a Sustainable, Biobased Economy; Lewandowski, I., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 22–38. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Jonas, H. Das Prinzip der Verantwortung: Versuch einer Ethik für die Technologische Zivilisation, 3rd ed.; Suhrkamp: Frankfurt am Main, Germany, 1993. [Google Scholar]

- Forrester, J.W. Counterintuitive Behaviour of Social Systems. Technol. Rev. 1971, 2, 52–68. [Google Scholar]

- Forrester, J.W. System Dynamics and the Lessons of 35 Years. In A Systems-Based Approach to Policymaking; de Greene, K.B., Ed.; Springer: Boston, MA, USA, 1993; pp. 199–240. [Google Scholar]

- Forrester, J.W. System dynamics, systems thinking, and soft OR. Syst. Dyn. Rev. 1994, 10, 245–256. [Google Scholar] [CrossRef]

- Vester, F. Neuland des Denkens—Vom technokratischen zum Kybernetischen Zeitalter; DTV: München, Germany, 1993. [Google Scholar]

- Vester, F. Die Kunst Vernetzt zu Denken: Ideen und Werkzeuge für Einen Neuen Umgang mit Komplexität. Ein Bericht an den Club of Rome, 8th ed.; DTV: München, Germany, 2011. [Google Scholar]

- Heiskanen, E. The Institutional Logic of Life Cycle Thinking. J. Clean. Prod. 2002, 10, 427–437. [Google Scholar] [CrossRef]

- Thabrew, L.; Wiek, A.; Ries, R. Environmental decision making in multi-stakeholder contexts: Applicability of life cycle thinking in development planning and implementation. J. Clean. Prod. 2009, 17, 67–76. [Google Scholar] [CrossRef]

- Westkämper, E. Einführung in Die Organisation der Produktion; Springer: Berlin, Germany, 2006. [Google Scholar]

- Rüegg-Stürm, J.; Grand, S. Das St. Galler Management-Modell, 2nd ed.; Haupt: Bern, Switzerland, 2015. [Google Scholar]

- Hauschild, M.Z.; Herrmann, C.; Kara, S. An Integrated Framework for Life Cycle Engineering. Procedia CIRP 2017, 61, 2–9. [Google Scholar] [CrossRef] [Green Version]

- Hauschild, M.Z.; Kara, S.; Røpke, I. Absolute sustainability: Challenges to life cycle engineering. CIRP Ann. 2020, 69, 533–553. [Google Scholar] [CrossRef]

- Stead, J.; Stead, W.E. Sustainable strategic management: An evolutionary perspective. Int. J. Sustain. Strateg. Manag. 2008, 1, 62–81. [Google Scholar] [CrossRef]

- Rathnayaka, A.D.; Potdar, V.M.; Kuruppu, S.J. An Innovative Approach to Manage Prosumers in Smart Grid; IEEE: Washington, DC, USA, 2011. [Google Scholar]

- Espe, E.; Potdar, V.; Chang, E. Prosumer Communities and Relationships in Smart Grids: A Literature Review, Evolution and Future Directions. Energies 2018, 11, 2528. [Google Scholar] [CrossRef] [Green Version]

- Morris, M.; Schindehutte, M.; Allen, J. The entrepreneur’s business model: Toward a unified perspective. J. Bus. Res. 2005, 58, 726–735. [Google Scholar] [CrossRef]

- Zott, C.; Amit, R.; Massa, L. The Business Model: Recent Developments and Future Research. J. Manag. 2011, 37, 1019–1042. [Google Scholar] [CrossRef] [Green Version]

- Burkhart, T.; Krumeich, J.; Werth, D.; Loos, P. Analyzing the business model concept—A comprehensive classification of literature. In Proceedings of the Thirty Second International Conference on Information Systems, Shanghai, China, 4–7 December 2011; pp. 1–19. [Google Scholar]

- Balzer, V.; Schrodi, T.; Wiendahl, H.-H. Strategien und Struktur Produzierender Unternehmen. In Fabrikbetriebslehre 1: Management in der Produktion; Bauernhansl, T., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 35–66. [Google Scholar]

- Mintzberg, H.; Ahlstrand, B.; Lampel, J. Strategy Safari: The Complete Guide through the Wilds of Strategic Management, 2nd ed.; Pearson Education: London, UK, 2008. [Google Scholar]

- Mintzberg, H.; Pascale, R.T.; Goold, M.; Rumelt, R.P. The Honda effec revisited. Calif. Manag. Rev. 1996, 38, 77–117. [Google Scholar] [CrossRef]

- Mintzberg, H.; Waters, J.A. Of strategies, deliberate and emergent. Strateg. Manag. J. 1985, 6, 257–272. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; The Free Press: New York, NY, USA, 1985. [Google Scholar]

- Porter, M.E. The five competitive forces that shape strategy. Harv. Bus. Rev. 2008, 86, 25–40. [Google Scholar]

- Lavie, D. The Competitive Advantage of Interconnected Firms: An Extension of the Resource-Based View. Acad. Manag. Rev. 2006, 31, 638–658. [Google Scholar] [CrossRef]

- Stokes, R. Network-based strategy making for events tourism. Eur. J. Mark. 2006, 40, 682–695. [Google Scholar] [CrossRef]

- Weiblen, T. Opening Up the Business Model: Business Model Innovation through Collaboration. Ph.D. Thesis, Univeristät St. Gallen, Gallen, Switzerland, 2015. [Google Scholar]

- Schumpeter, J.A. Kapitalismus, Sozialismus und Demokratie, 8th ed.; UTB: Stuttgart, Germany, 2005. [Google Scholar]

- Schumpeter, J.A. Geschichte der Ökonomischen Analyse, Neuauflage; Vandenhoeck & Ruprecht: Göttingen, Germany, 2007. [Google Scholar]

- Gassmann, O.; Enkel, E.; Chesbrough, H. The future of open innovation. RD Manag. 2010, 40, 213–221. [Google Scholar] [CrossRef]

- Chesbrough, H.W.; Appleyard, M.M. Open Innovation and Strategy. Calif. Manag. Rev. 2007, 50, 57–76. [Google Scholar] [CrossRef] [Green Version]

- Simic, D. Applied Open Innovation—A Case Study Analysis based on Electric Drive Technology Projects in the Automotive Industry. Ph.D. Thesis, Technische Universität Wien, Wien, Austria, 2013. [Google Scholar]

- Schloske, A. Innovation und Produktentwicklung. In Fabrikbetriebslehre 1: Management in der Produktion; Bauernhansl, T., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 67–104. [Google Scholar]

- Graessler, I.; Hentze, J.; Bruckmann, T. V-models for interdisciplinary systems engineering. In Proceedings of the DESIGN 2018 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 747–756. [Google Scholar] [CrossRef]

- Ceschin, F.; Gaziulusoy, I. Design for Sustainability: A Multi-level Framework from Products to Socio- Technical Systems; Routledge: New York, NY, USA, 2020. [Google Scholar]

- Beer, S. Diagnosing the System for Organizations, 2nd ed.; John Wiley & Sons Ltd: Chichester, UK, 1995. [Google Scholar]

- Beer, S. Cybernetics and Management; John Wiley & Sons: Hoboken, NJ, USA, 1967. [Google Scholar]

- Beer, S. Brain of the Firm: A Development in Management Cybernetics; Verlag Herder GmbH: Munich, Germany, 1972. [Google Scholar]

- Warnecke, H.-J. Die Fraktale Fabrik: Revolution der Unternehmenskultur; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar]

- Ehrlich, P.R.; Holden, J.P. Impact of population growth. Science 1971, 171, 1212–1217. [Google Scholar] [CrossRef] [PubMed]

| Traditional Understanding of Production | Biointelligent Understanding of Production | |

|---|---|---|

| Definition | Production as a planned combination of input factors enabling satisfaction of individual customer needs | Production as a spontaneous or planned combination and recombination of cellular units to create or dismantle a cellular structure capable of intelligent behavior, enabling satisfaction of individual, social and environmental needs |

| Scope | Production (enterprises) as individual units for the purpose of economic benefit to the shareholders | Entirety of production as an organism aligned with planetary boundaries, individuals, communities and enterprises as subsystem production units |

| Scale | Mostly medium sized or large enterprises | Networks of cellular units in the form of small enterprises, communities, individuals and households |

| Volume | Mostly centralized production units operating in series and mass production processes; partly small series production; individual production only in few cases | On-site production of single products in individual spontaneous production networks as standard model |

| Decision Context | Free, i.e., fully independent decision making | Normative, i.e., regulated decision making directed to planetary boundaries/budgets |

| Decision Parameter | Mostly efficiency and costs | Increasingly effectivity and sufficiency-driven |

| Scientific Basis | Engineering and information science | Engineering, information and life sciences |

| Business Model | Value Proposition | Provider | Buyer | Earnings Model |

|---|---|---|---|---|

| Know-how as a service | Providing know-how, design plans and skills | All market participants | All market participants | Common advisory and consultancy models, pay-per-unit |

| Labour as a service | Providing necessary staffing | Individuals | All other market participants | Pay-per-hour, common employment models |

| Equipment as a service | Providing equipment and infrastructure for production task | All market participants | All market participants | Common contracting models |

| Capital as a service | Providing required capital for production task and/or spontaneous emergence of production networks | Individuals, companies | All market participants | Common investment and financing models |

| Platform as a service | Providing platforms, either technological or as mechanism for input factor allocation | All market participants | All market participants | Participant fee, pay-per-use |

| Product as a service | Providing products that have to be returned after use | All market participants | All market participants | Common leasing models |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miehe, R.; Buckreus, L.; Kiemel, S.; Sauer, A.; Bauernhansl, T. A Conceptual Framework for Biointelligent Production—Calling for Systemic Life Cycle Thinking in Cellular Units. Clean Technol. 2021, 3, 844-857. https://doi.org/10.3390/cleantechnol3040049

Miehe R, Buckreus L, Kiemel S, Sauer A, Bauernhansl T. A Conceptual Framework for Biointelligent Production—Calling for Systemic Life Cycle Thinking in Cellular Units. Clean Technologies. 2021; 3(4):844-857. https://doi.org/10.3390/cleantechnol3040049

Chicago/Turabian StyleMiehe, Robert, Lorena Buckreus, Steffen Kiemel, Alexander Sauer, and Thomas Bauernhansl. 2021. "A Conceptual Framework for Biointelligent Production—Calling for Systemic Life Cycle Thinking in Cellular Units" Clean Technologies 3, no. 4: 844-857. https://doi.org/10.3390/cleantechnol3040049

APA StyleMiehe, R., Buckreus, L., Kiemel, S., Sauer, A., & Bauernhansl, T. (2021). A Conceptual Framework for Biointelligent Production—Calling for Systemic Life Cycle Thinking in Cellular Units. Clean Technologies, 3(4), 844-857. https://doi.org/10.3390/cleantechnol3040049