A Testbench for Measuring the Dynamic Force-Displacement Characteristics of Shockmounts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Investigated Shockmounts

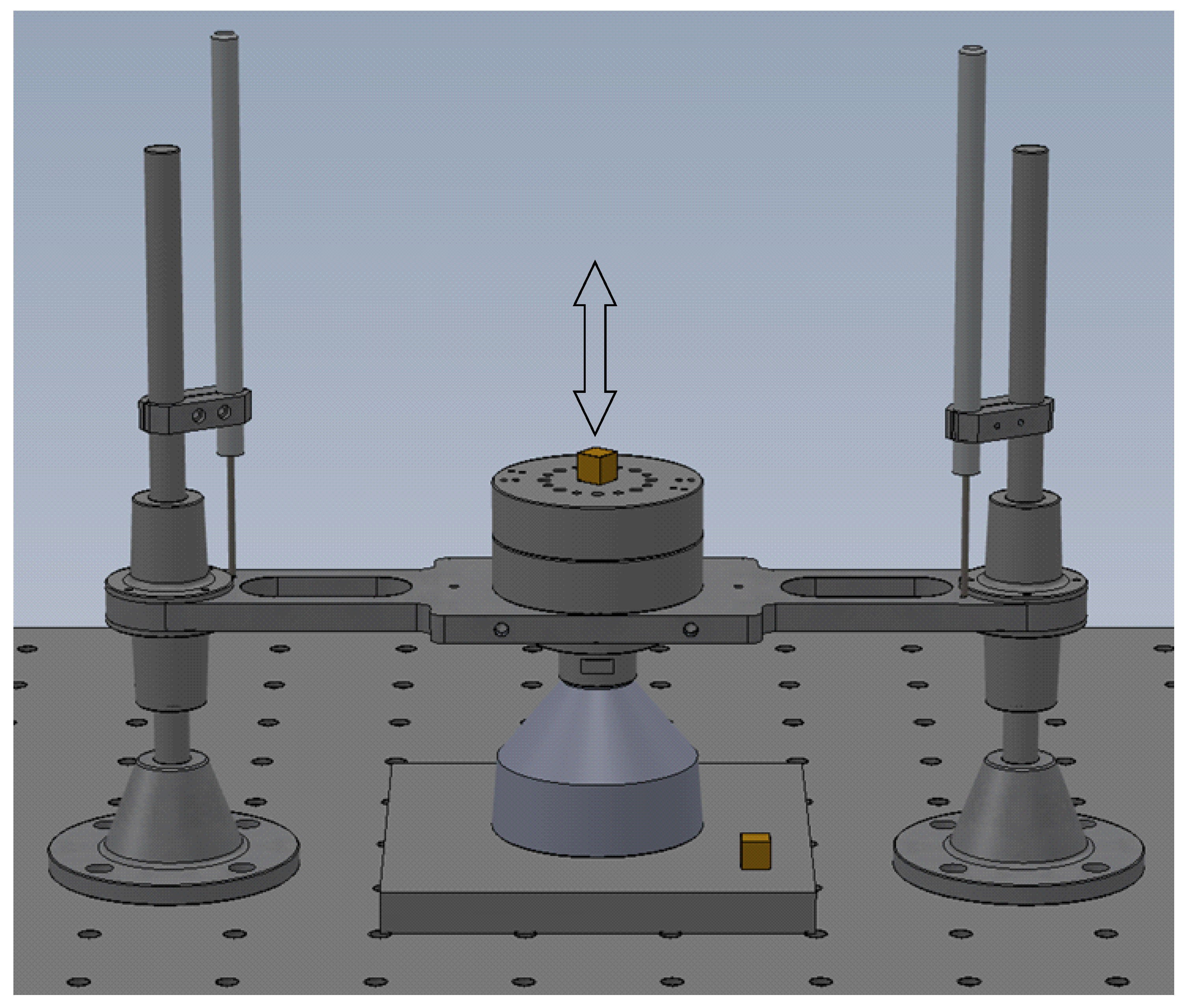

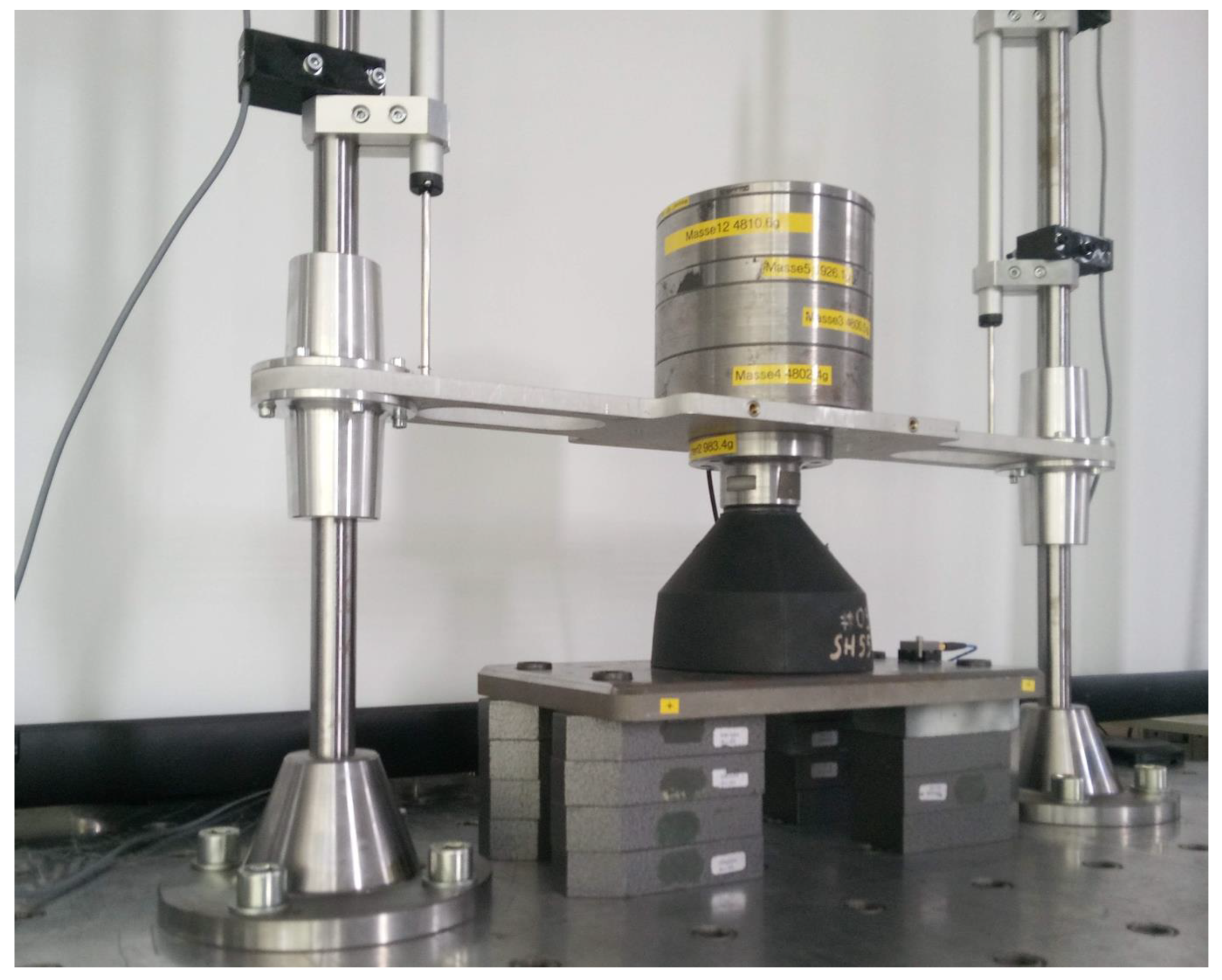

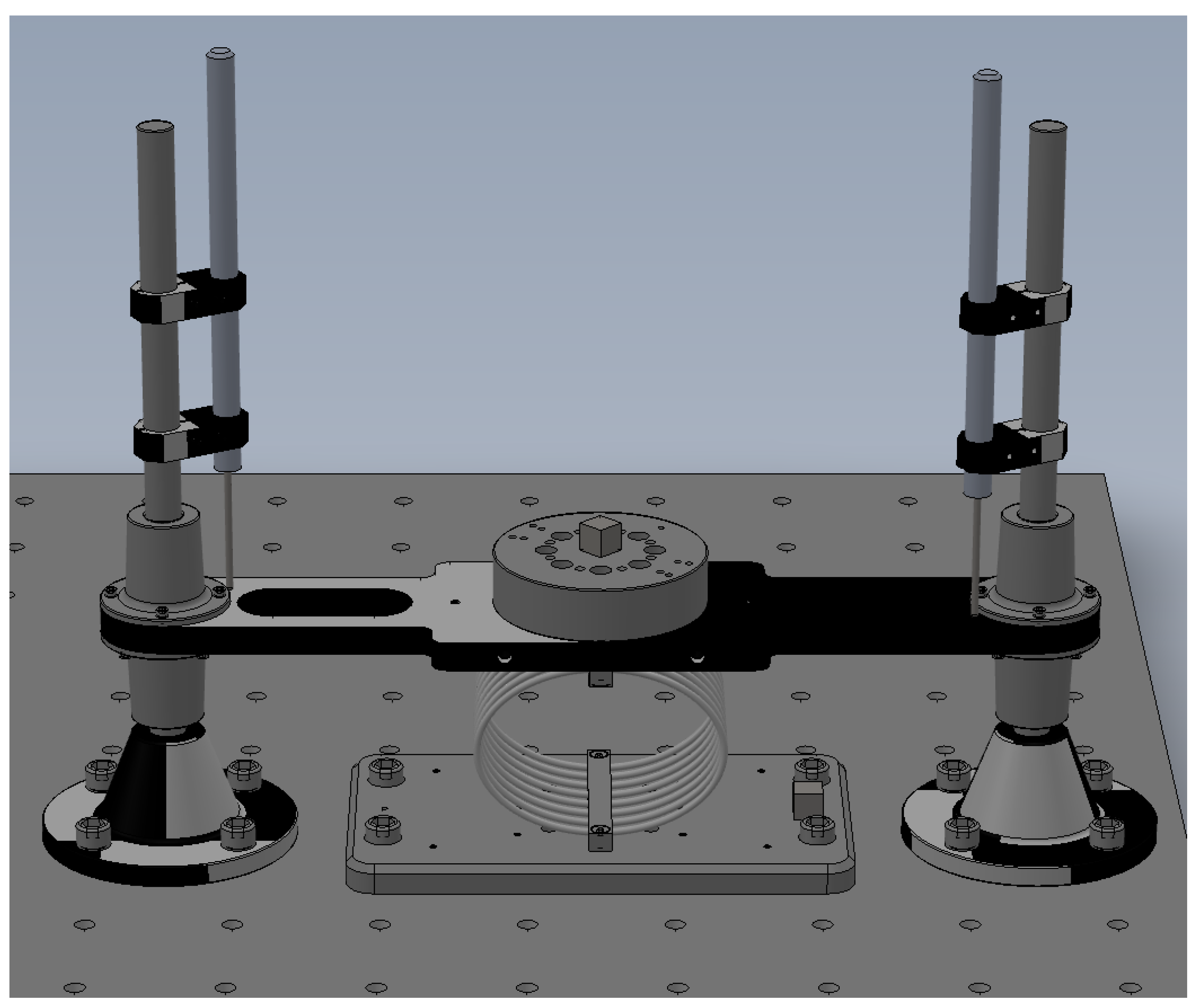

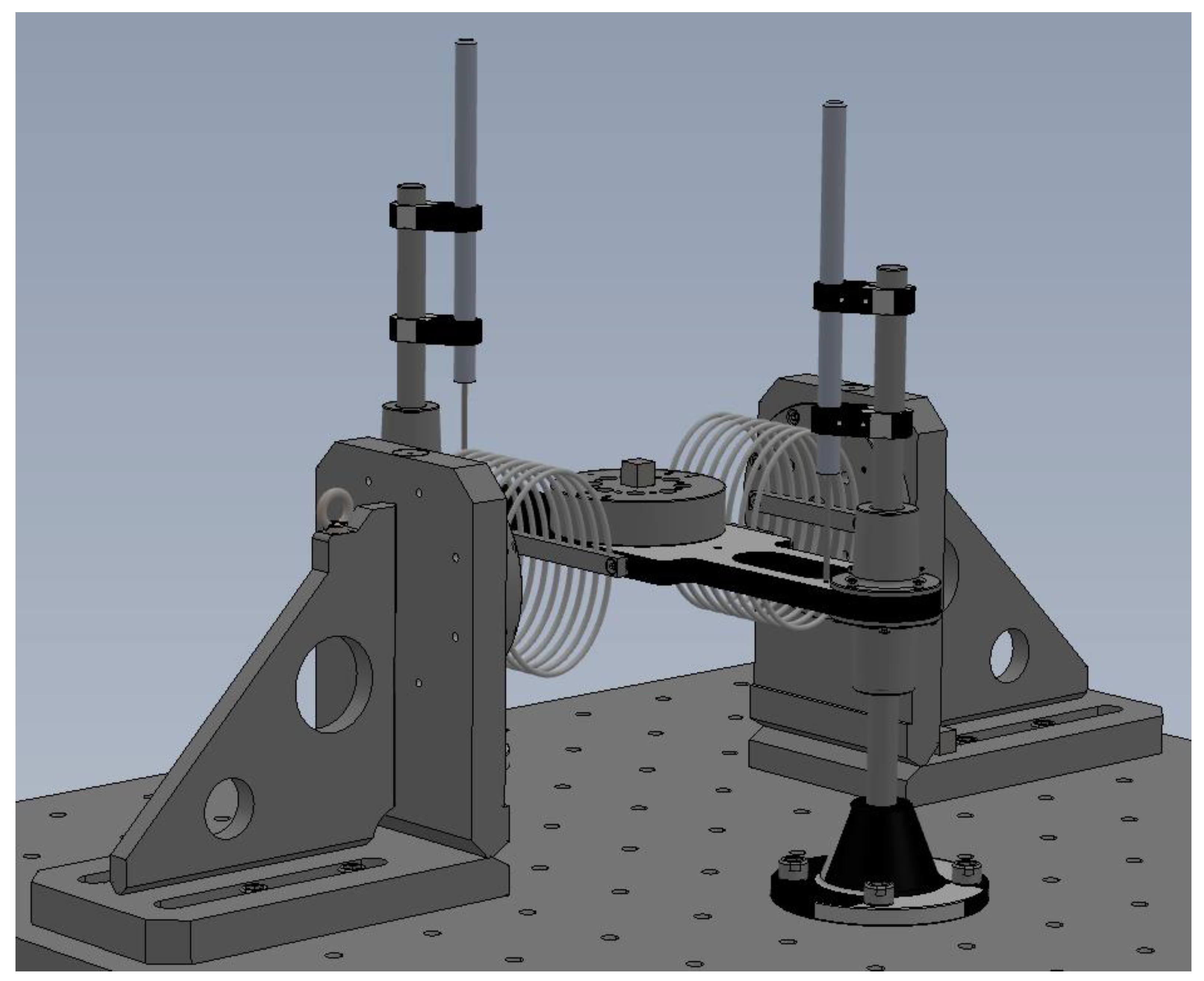

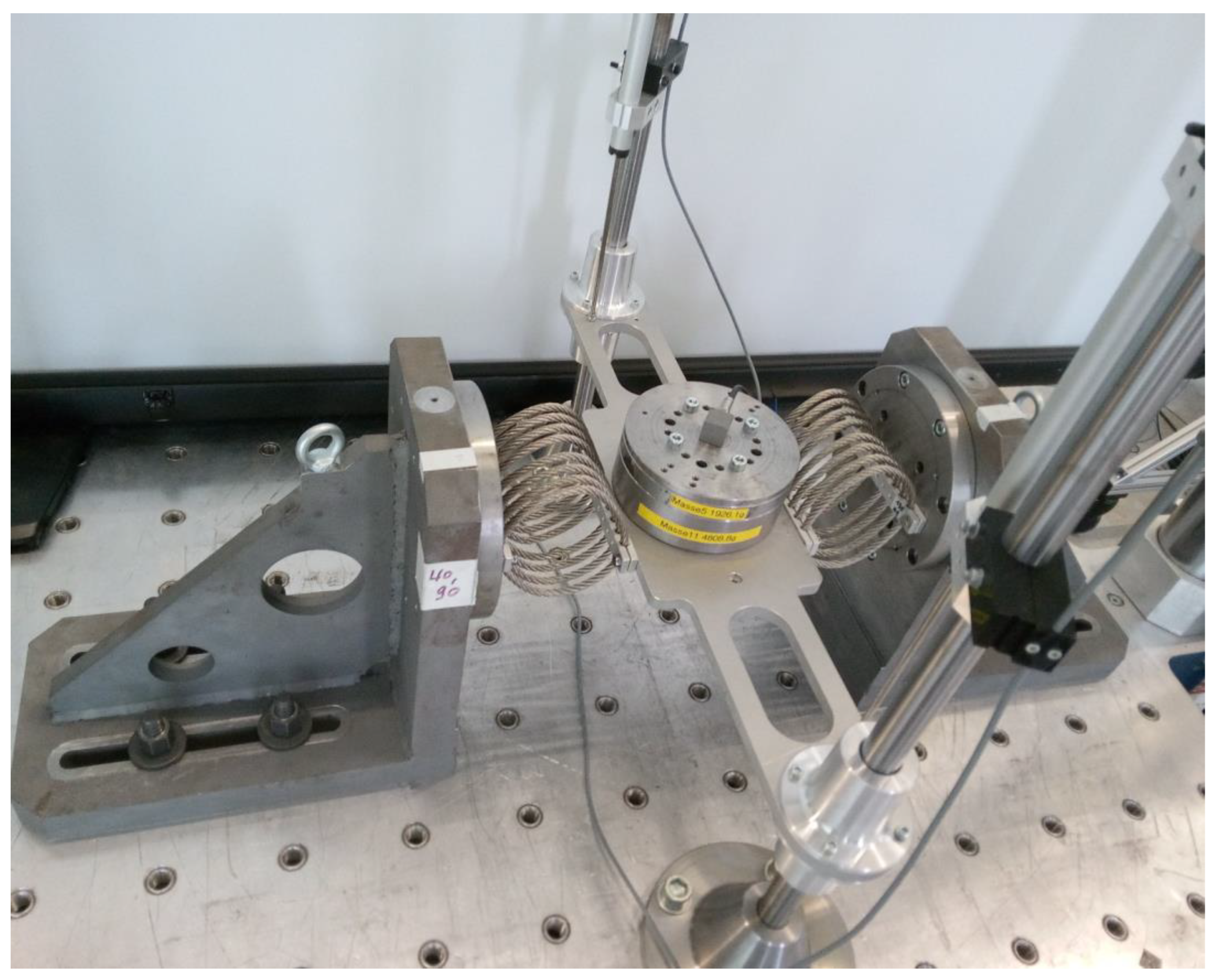

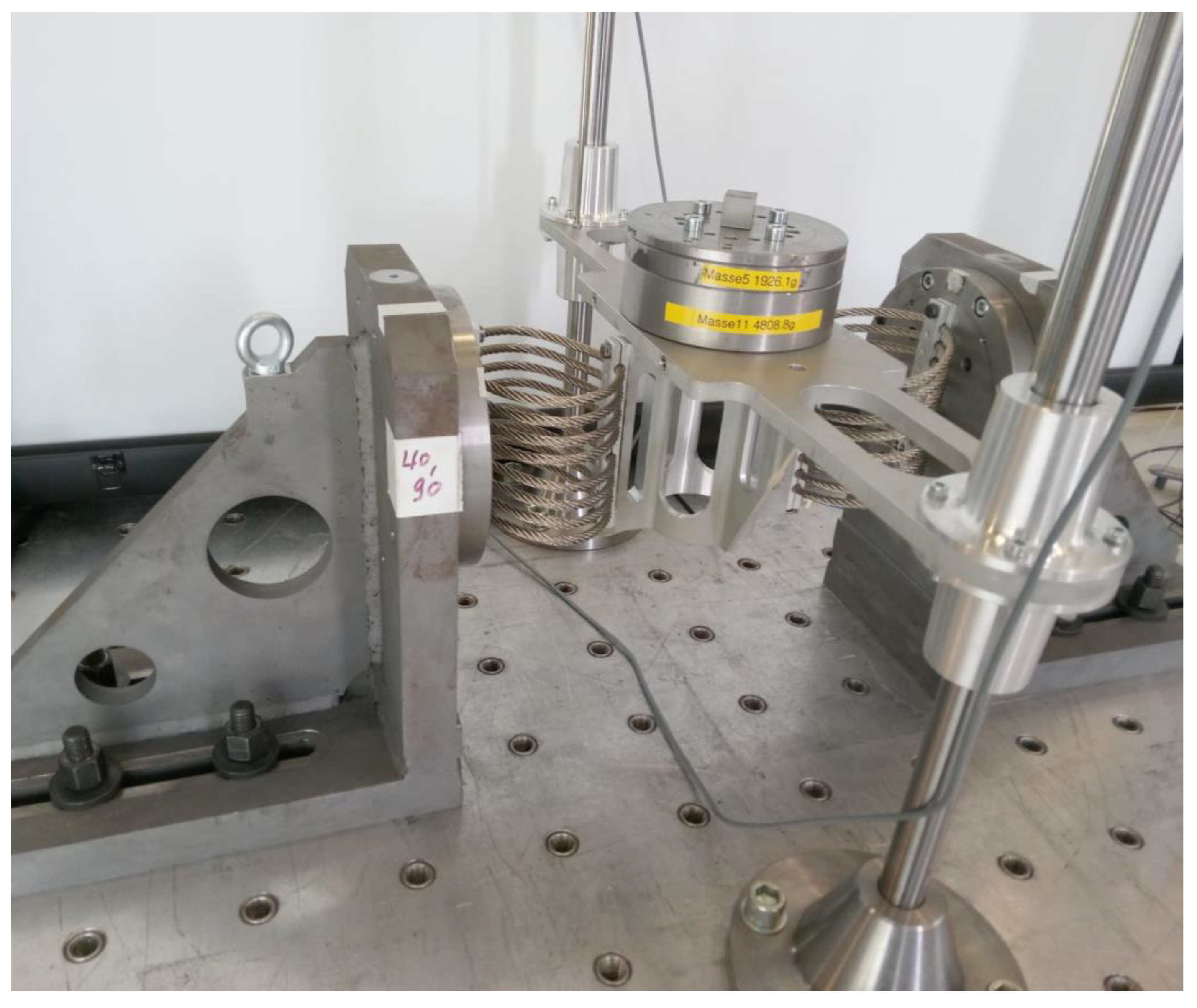

2.2. Description of the Testbench

2.2.1. Shock Test Machine

2.2.2. Displacement Measuring Devices

- Measurement range 250 mm.

- Maximum power supply 60 V

- Displacement speed 10 m/s

- Shock resistance 50 g, 11 ms

- Up to ± 13° tilt

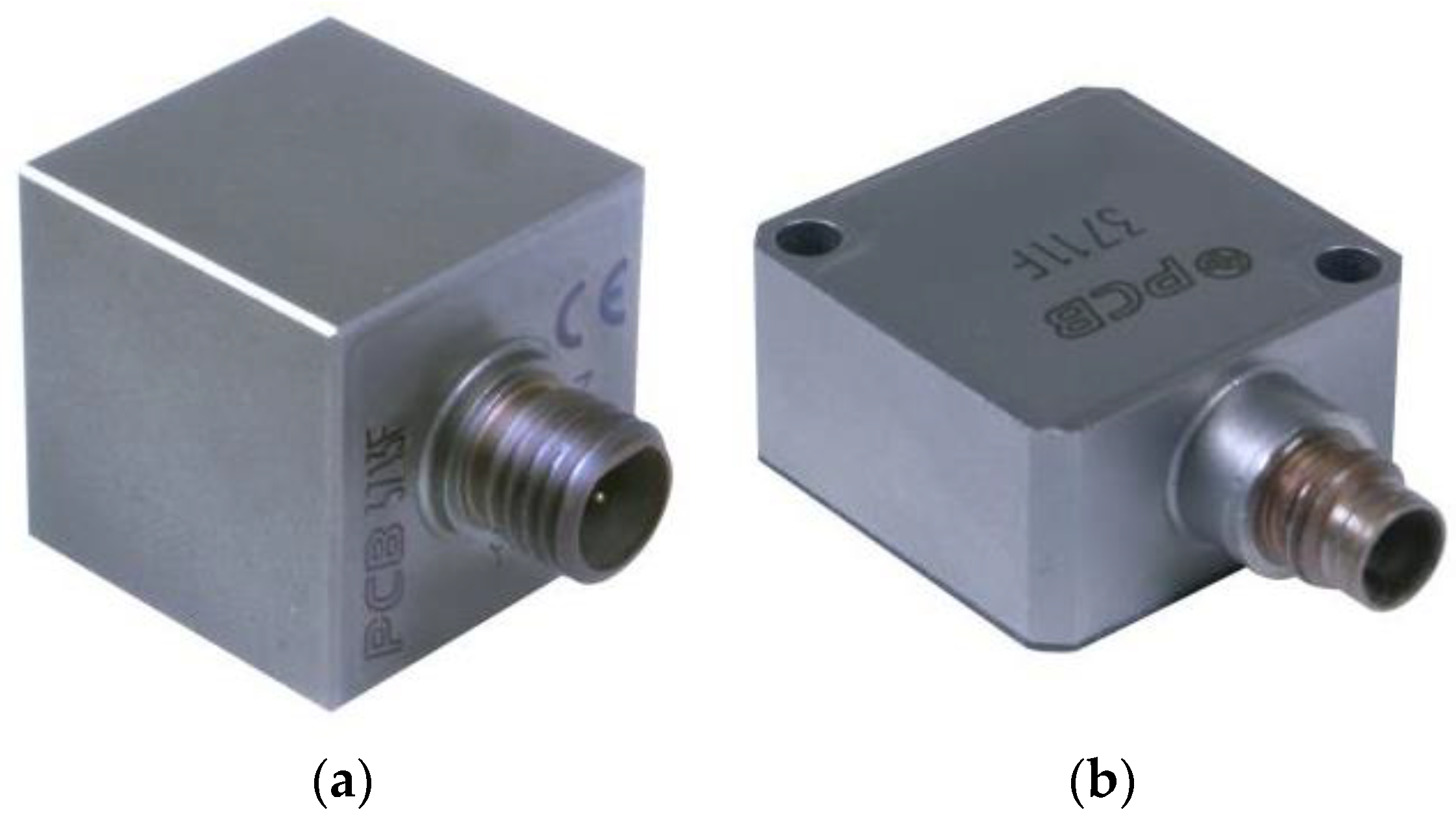

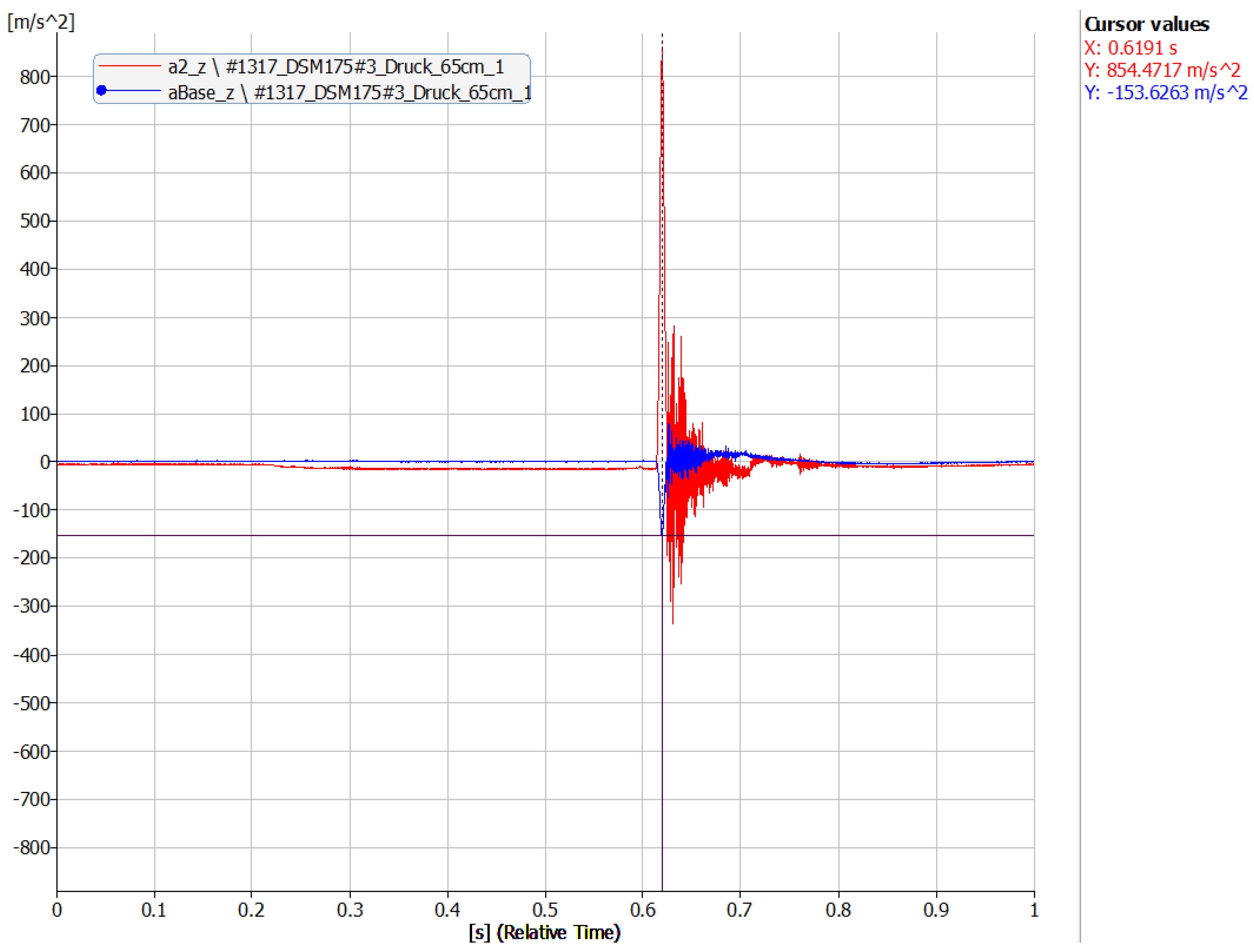

2.2.3. Acceleration Sensors

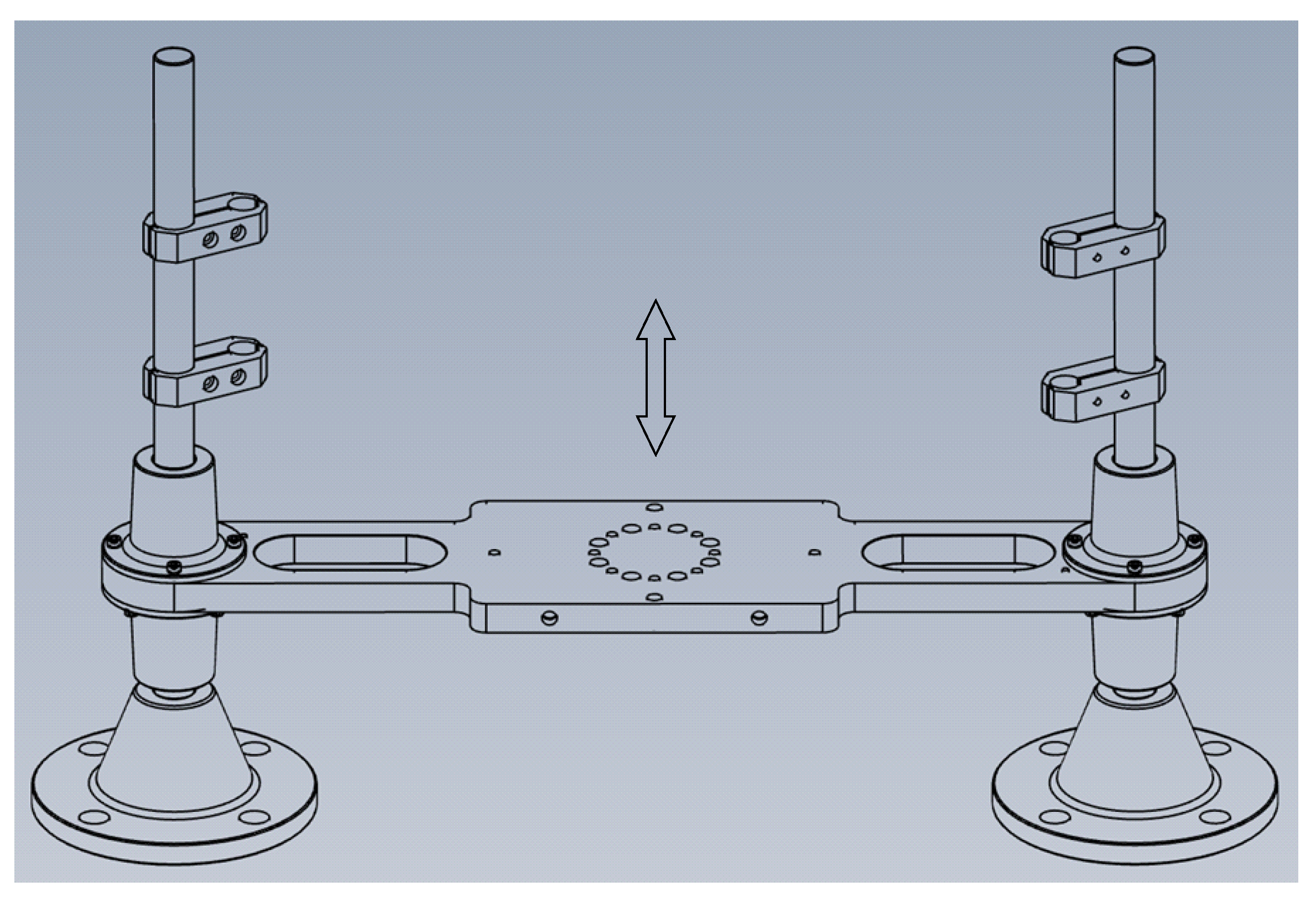

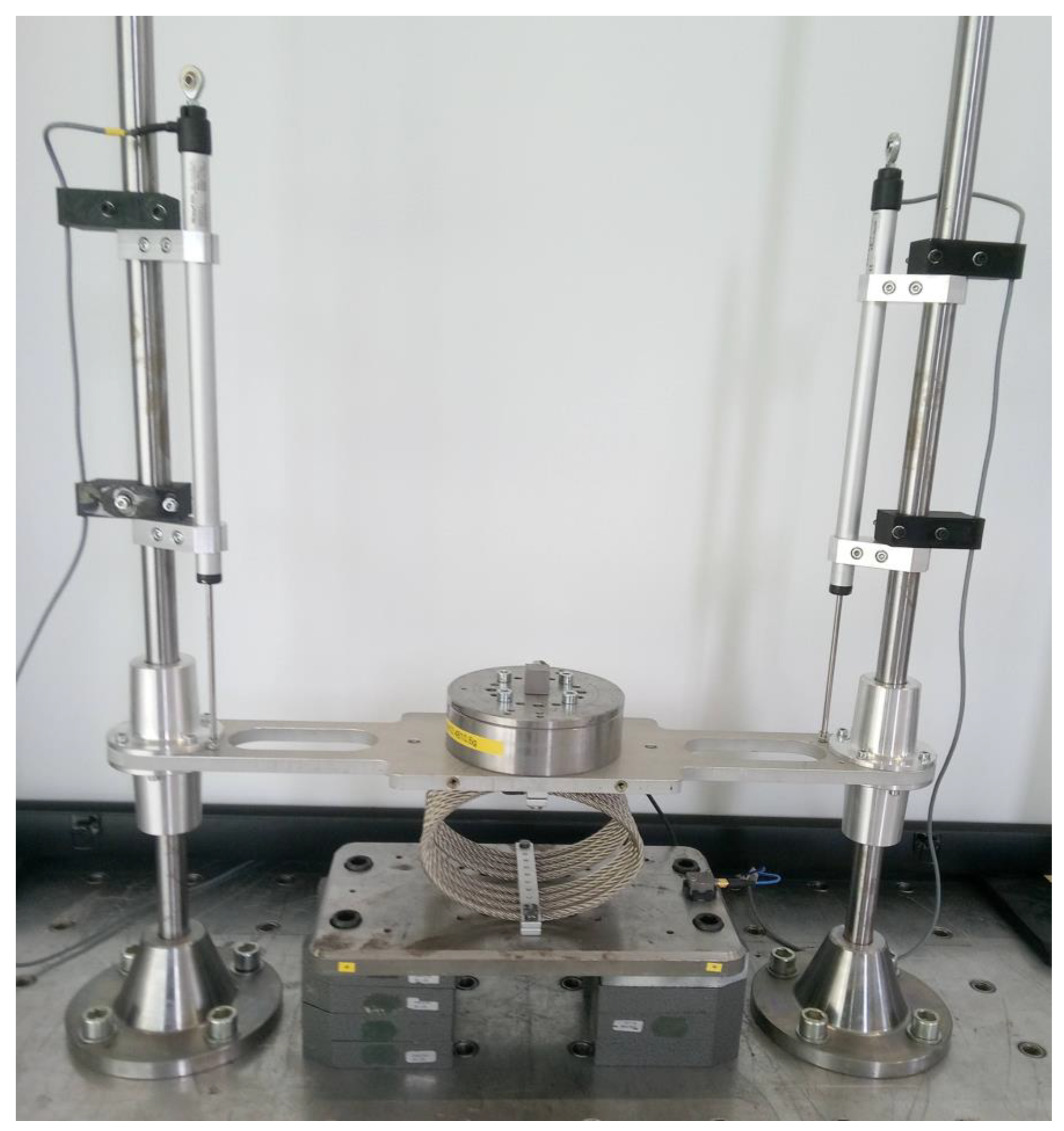

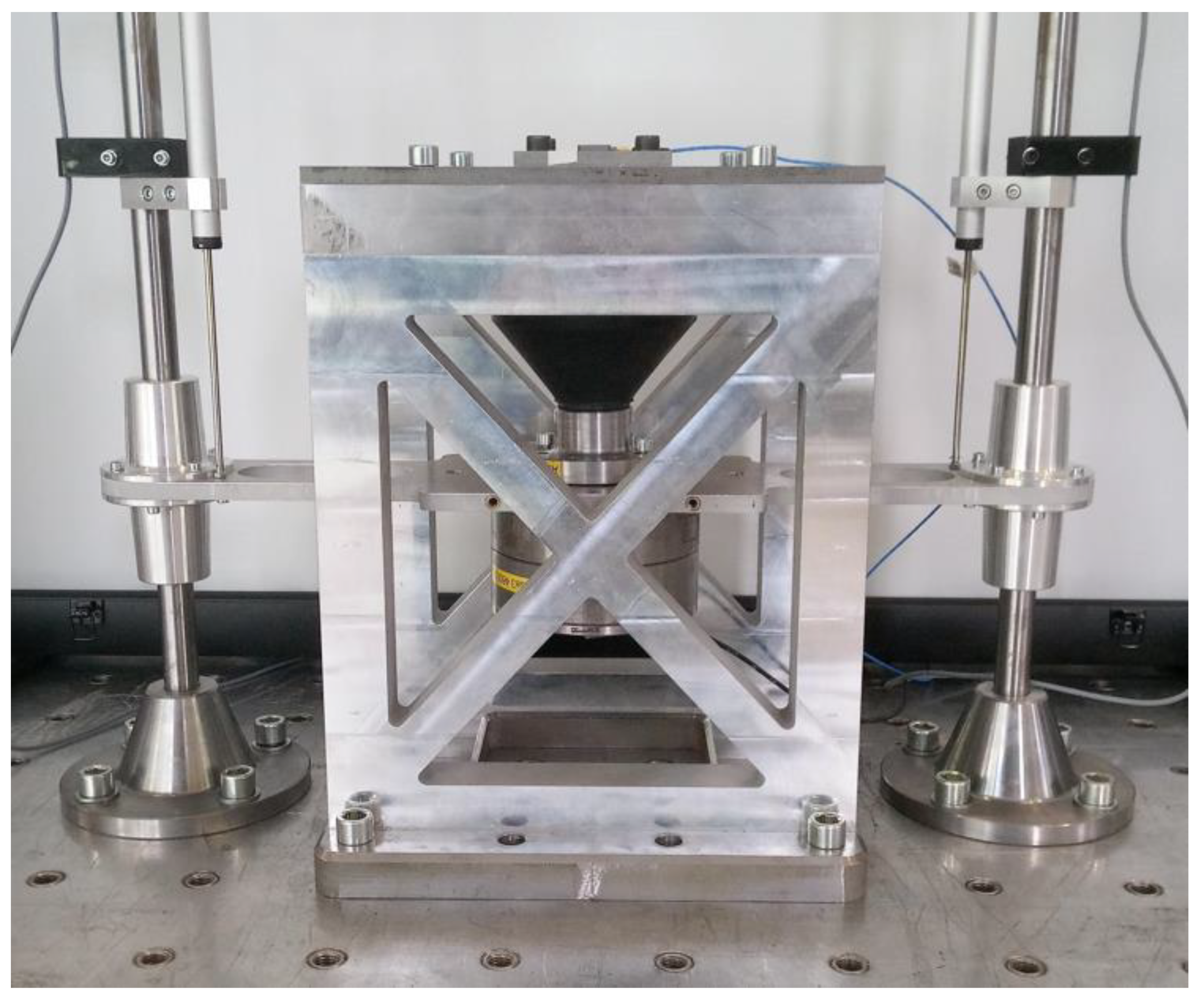

2.2.4. Improved Guiding System and Loading Mass

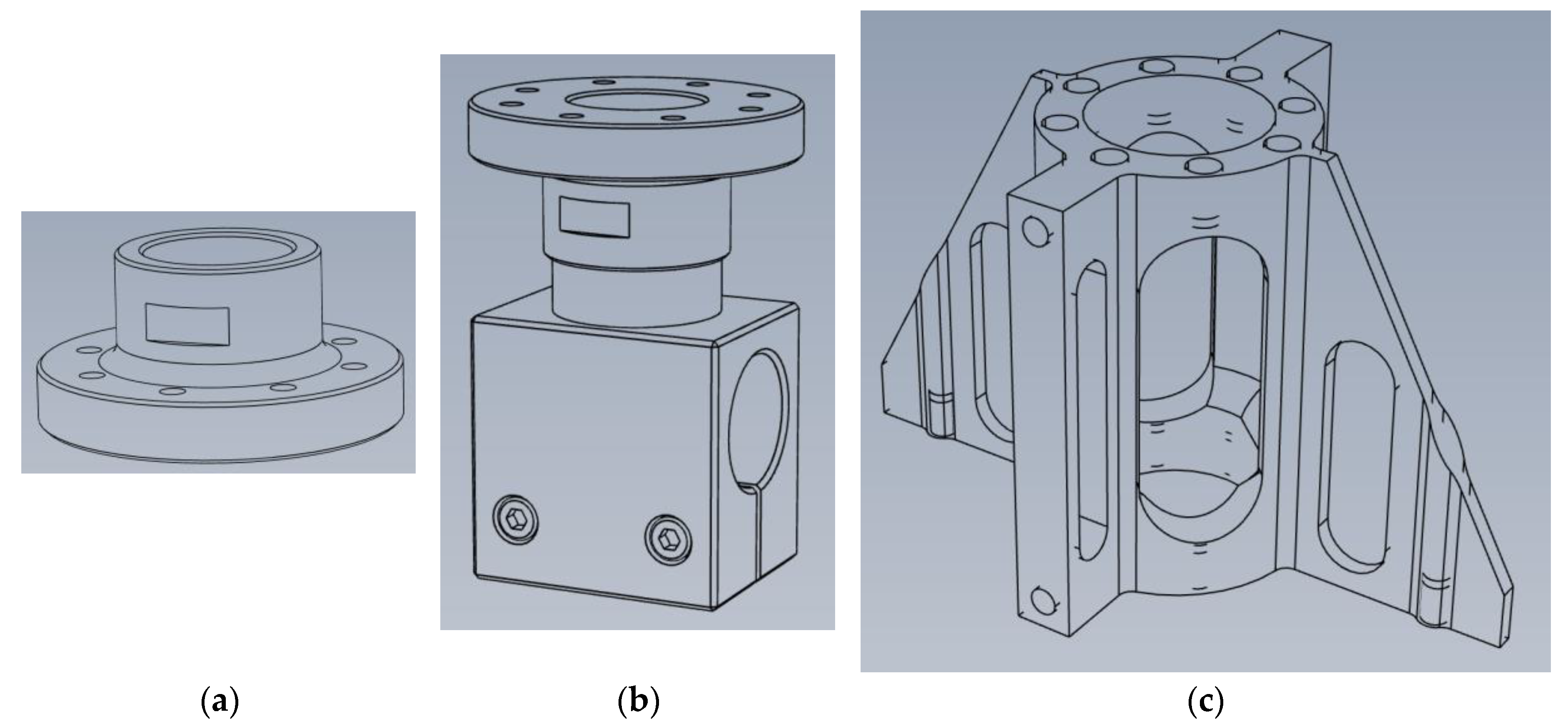

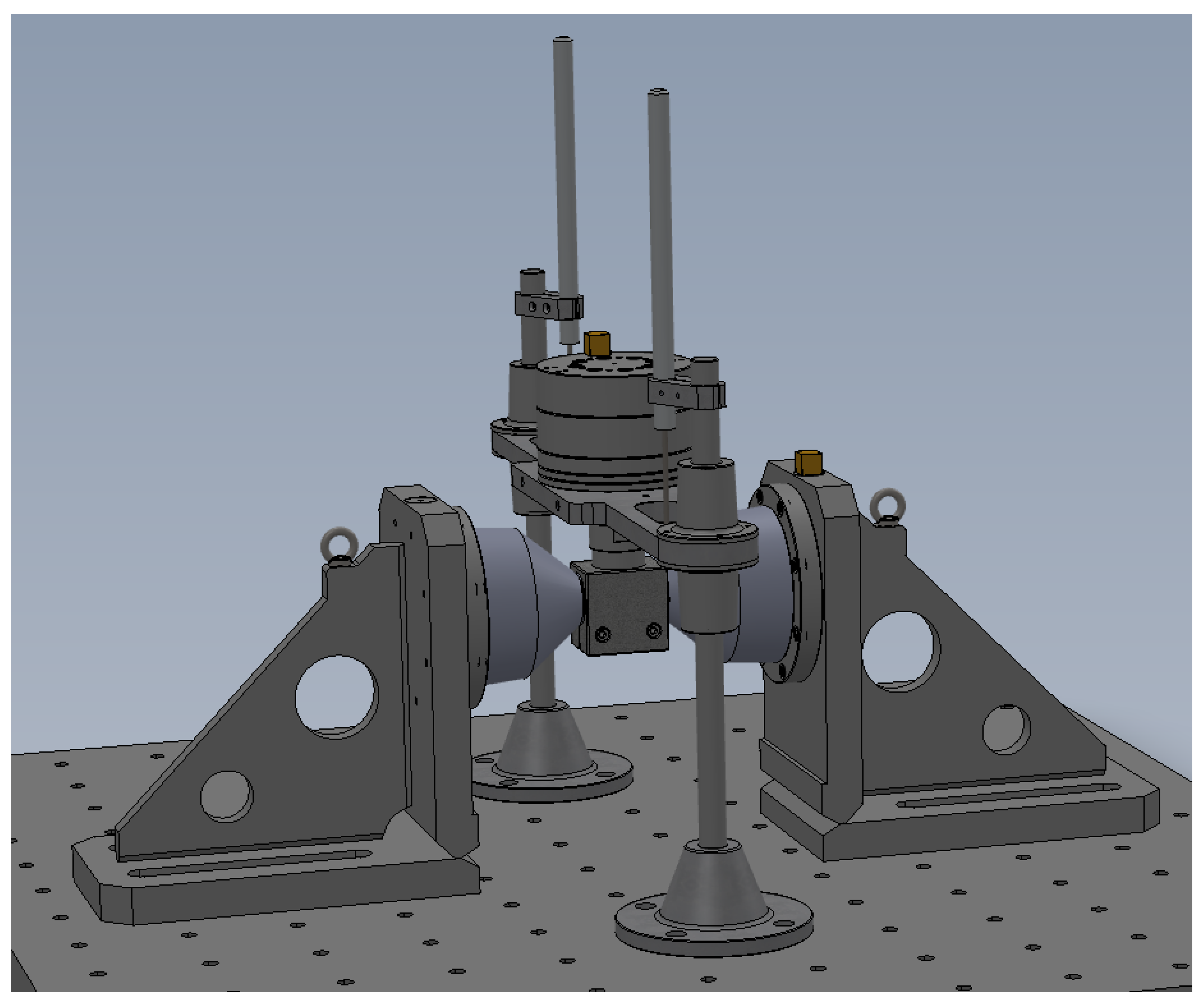

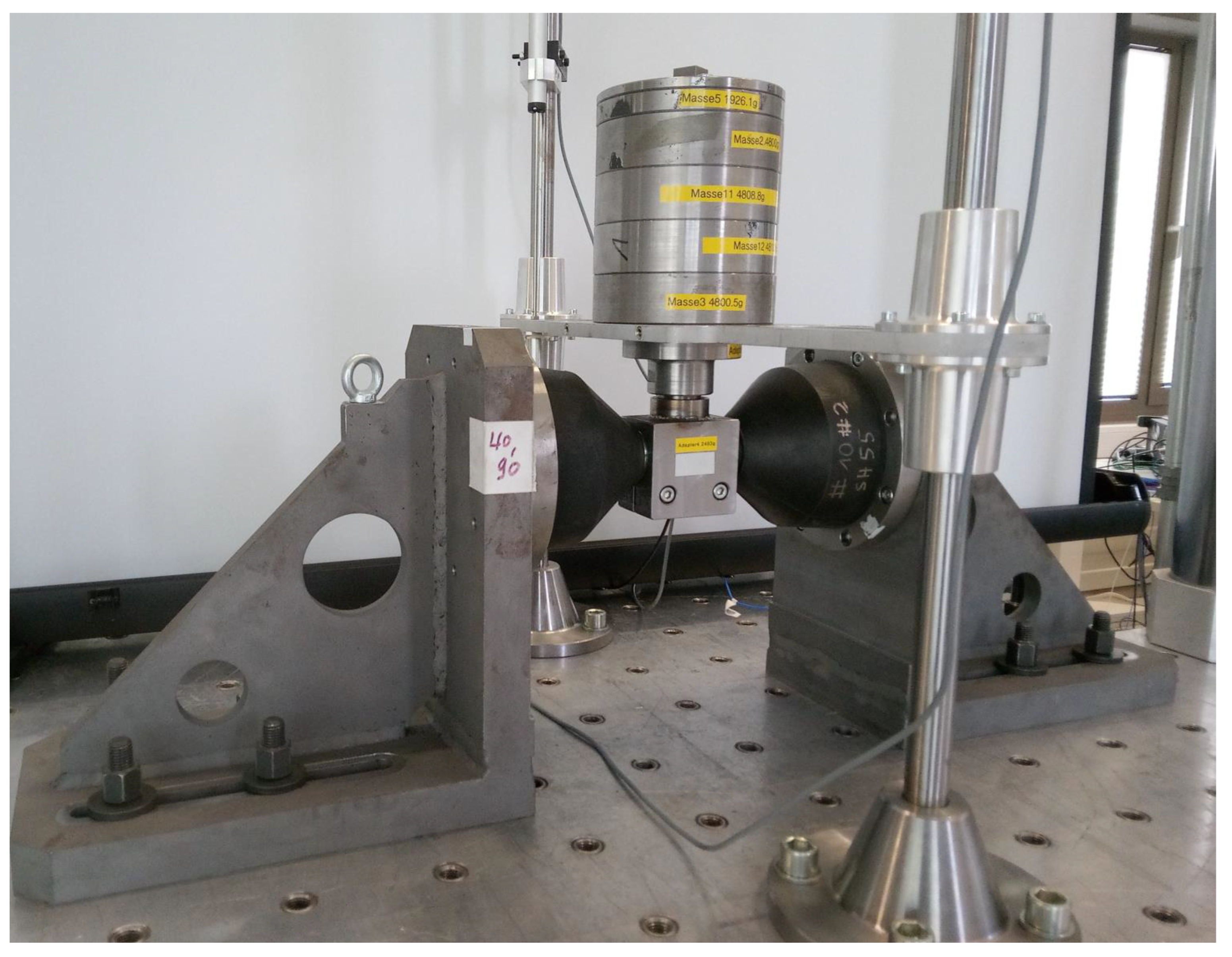

2.2.5. Measuring Adapters

2.2.6. Complete Setup

2.2.7. Highspeed Camera

2.2.8. Data Acquisition

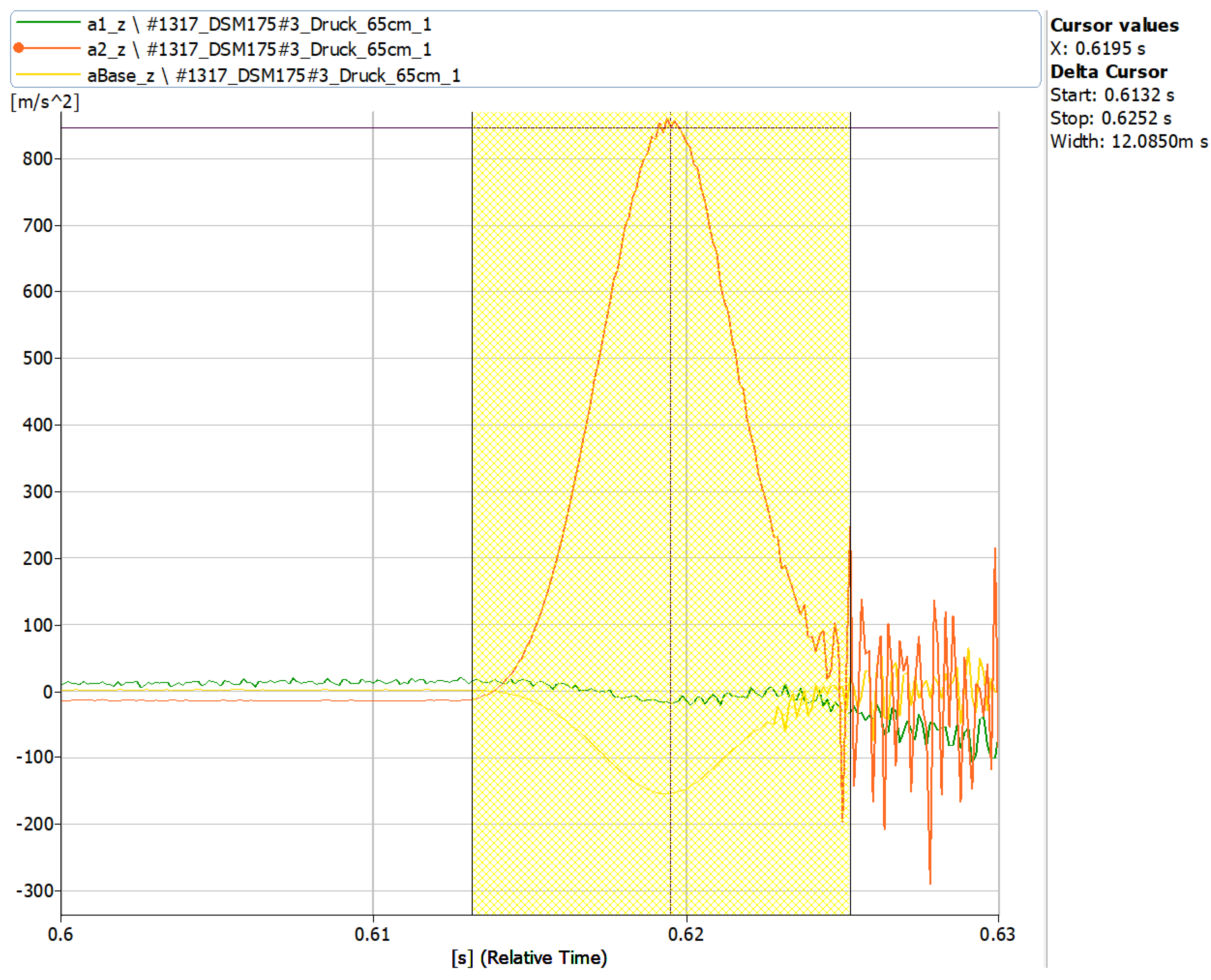

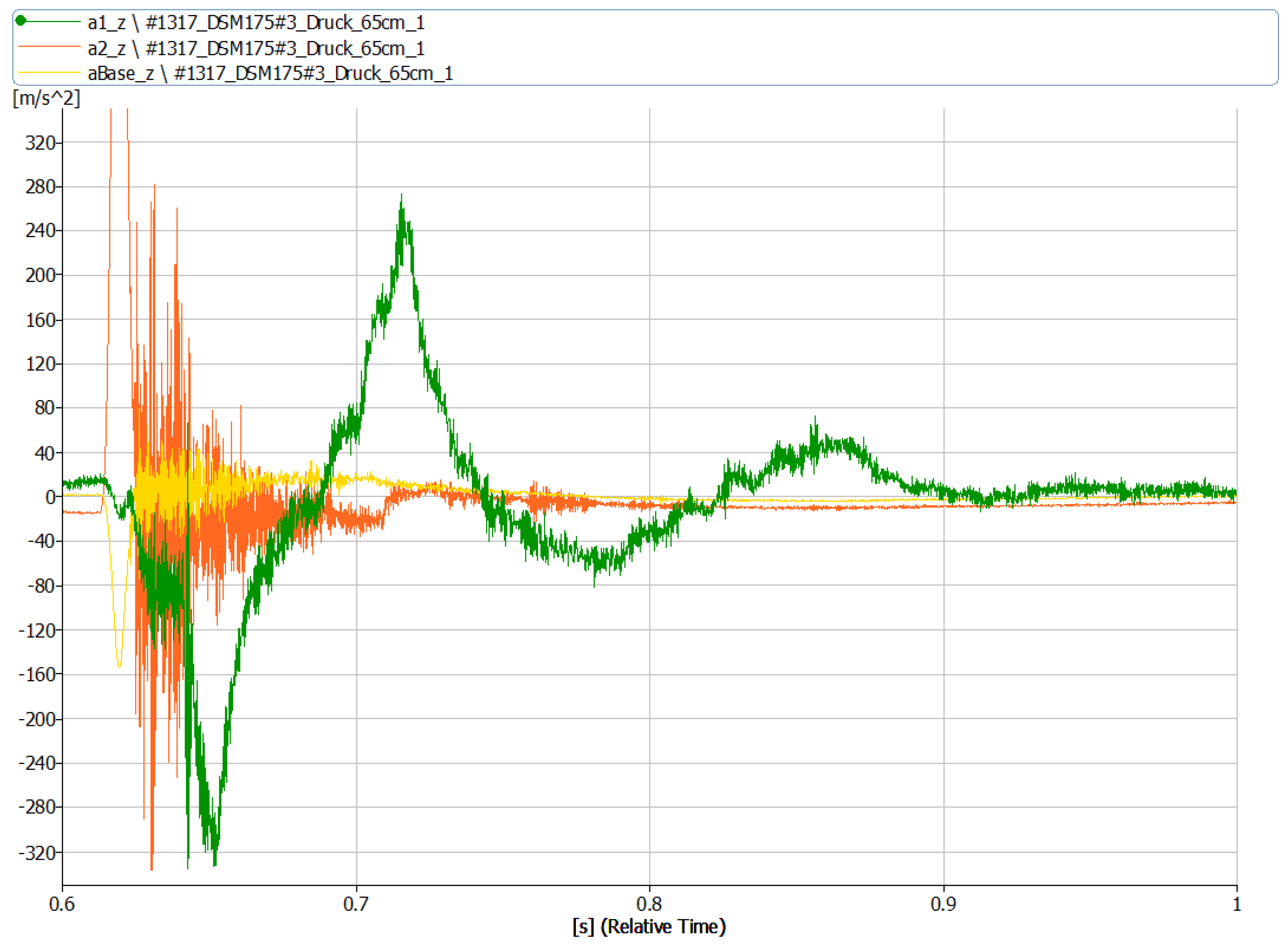

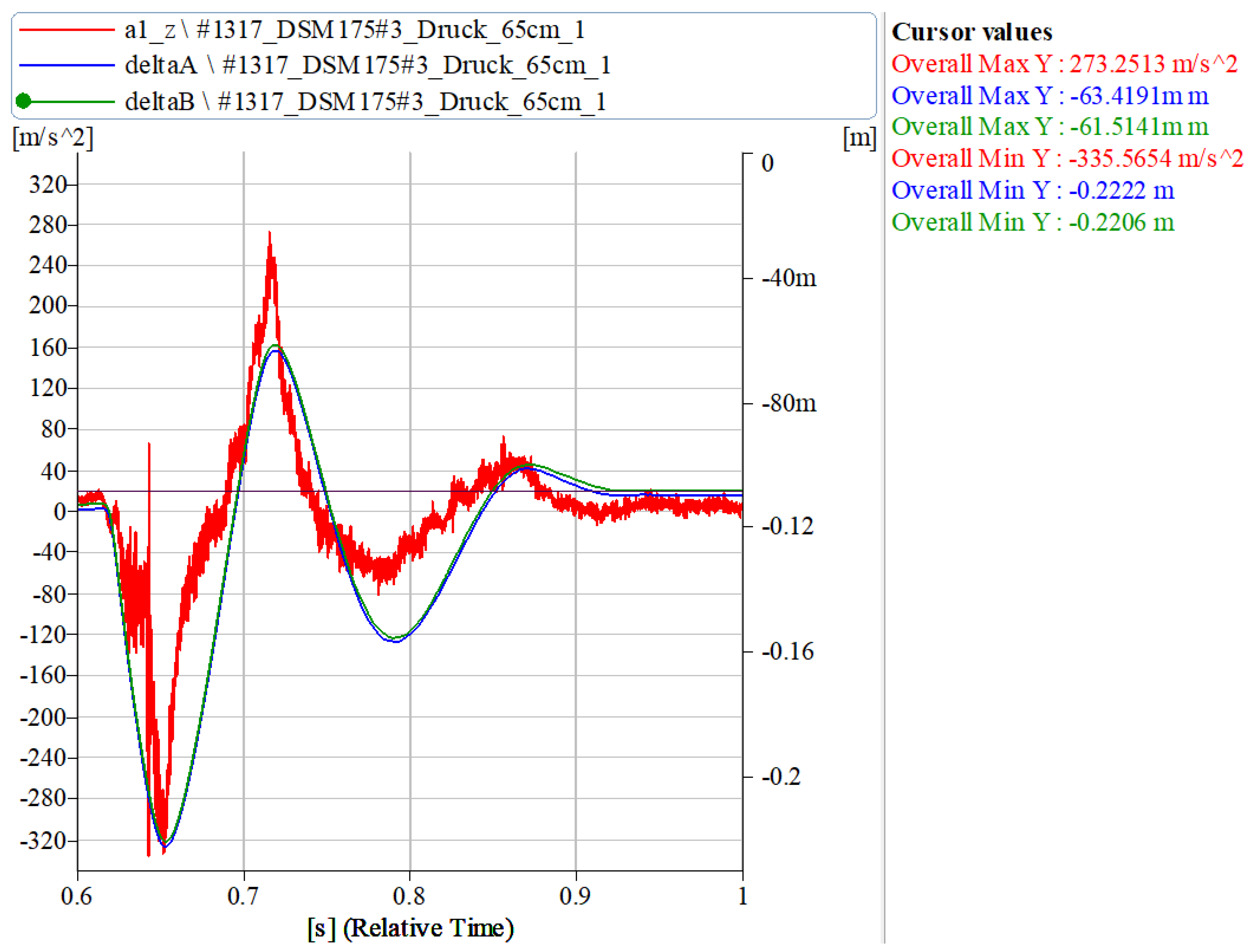

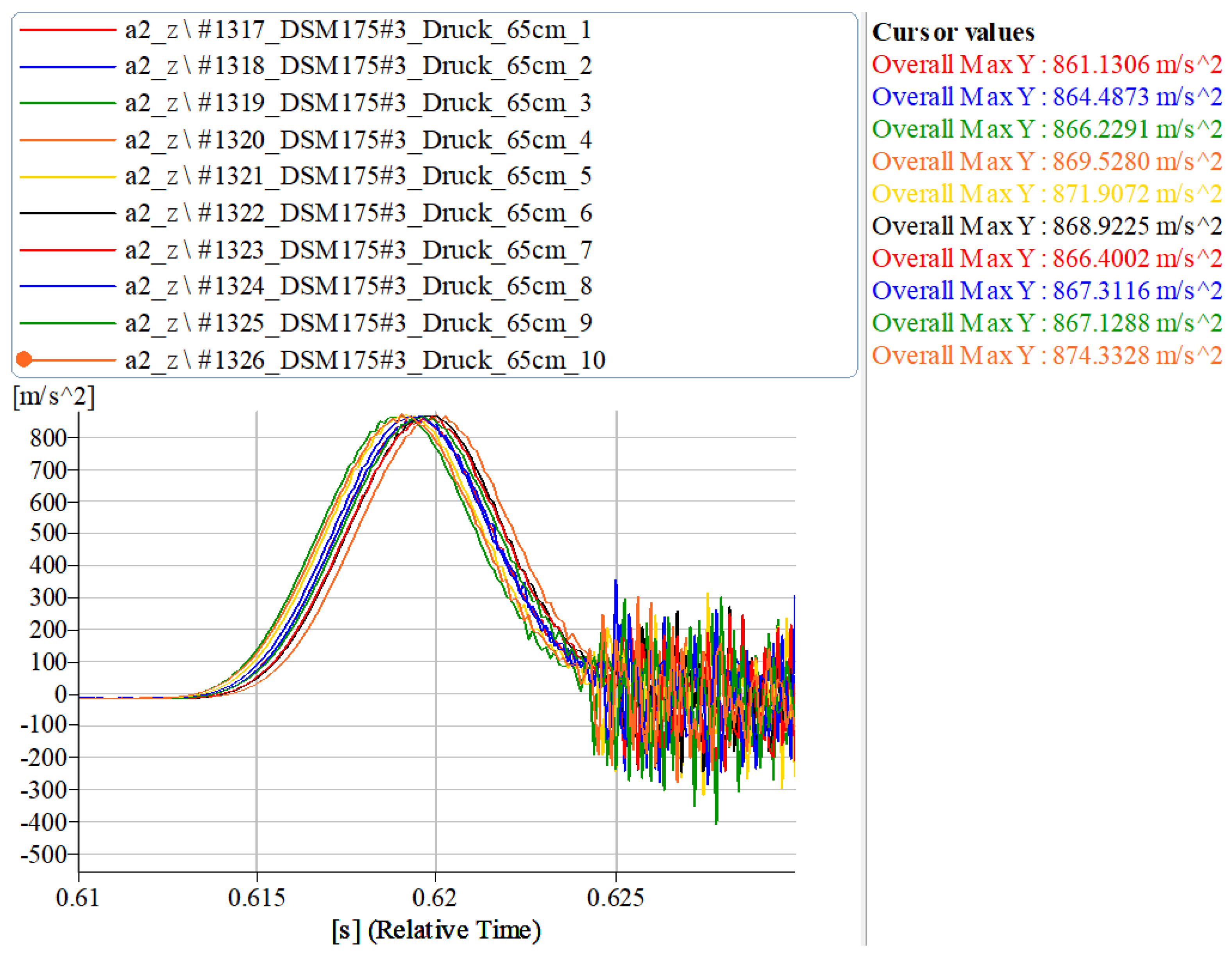

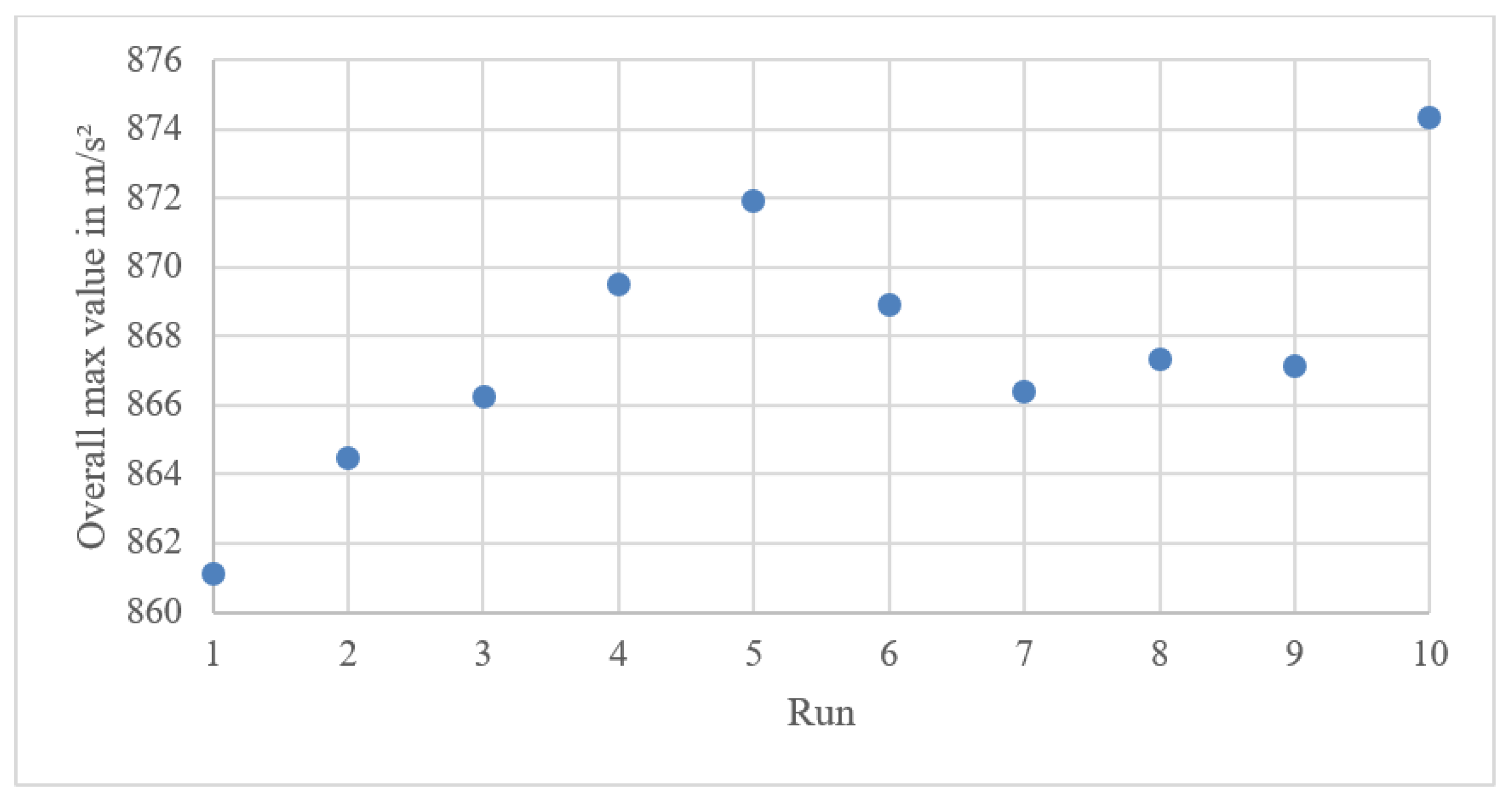

2.2.9. Reproducibility

2.3. Advanced Kelvin–Voigt Model and Parameter Identification

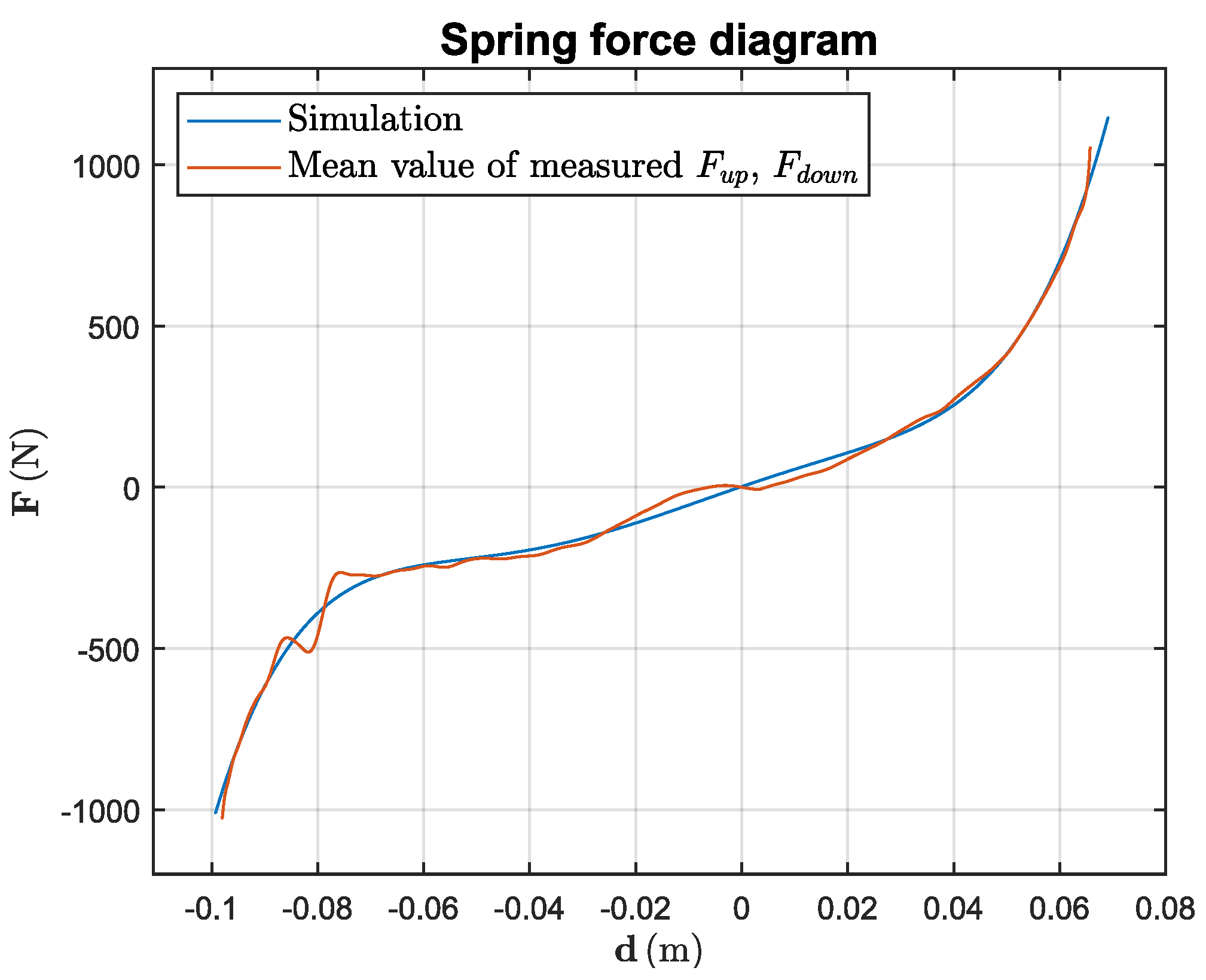

2.3.1. Non-Linear Spring Force

2.3.2. Damping Coefficient

2.4. Simulation

2.4.1. State Vectors

2.4.2. Basepoint Excitation

2.4.3. Numerical ODE45 Solver in MATLAB

3. Results and Discussion

3.1. Testbench

- The horizontal traverse of the guiding system, including the housings of the plain bearing bushes, contribute to the loading mass that loads the shockmount. For very soft shockmounts, such as the WSM 175 in shear or roll configurations, almost no additional loading mass is required to displace the shockmount dynamically. In these cases, the mass of the traverse should be as small as possible. Nevertheless, the stiffness of the traverse must be high enough to prevent the bearing housings from oscillating around the middle of the traverse.

- Even if the linear potentiometers in the proposed setup are attached to the guiding traverse, the displacement could be measured, for example, by non-contact evaluation of highspeed camera images. However, the guiding system is required to prevent shockmount-mass combination from tilting. This is especially true for configurations with wire rope shockmounts, which usually show an asymmetric construction, or for configurations with a high center of gravity when using multiple stacked mass modules.

- The linear potentiometers for measuring the displacement have a specified shock capability of only 50 g at 11 ms. In the conducted measurement series, basepoint excitations up to 165 g at 10 ms were applied. As long as the potentiometers were loaded axial to the piston rod, they showed good usability without any failure.

- The intention for using triaxial accelerometers for measuring acceleration of the loading mass was to observe if there is motion of the loading mass in the two directions orthogonally to excitation. Evaluation of measurements showed that there is no significant motion in these directions.

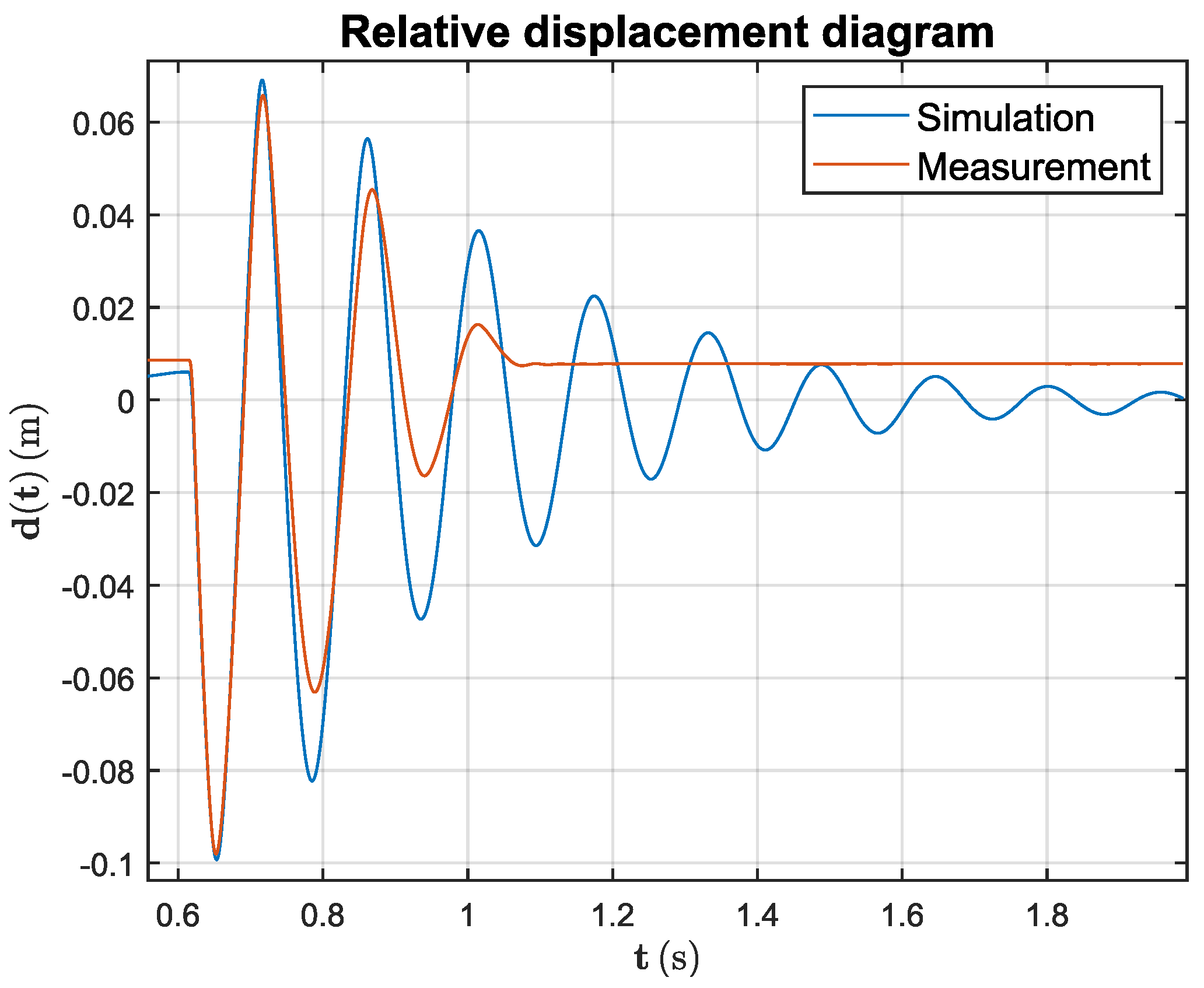

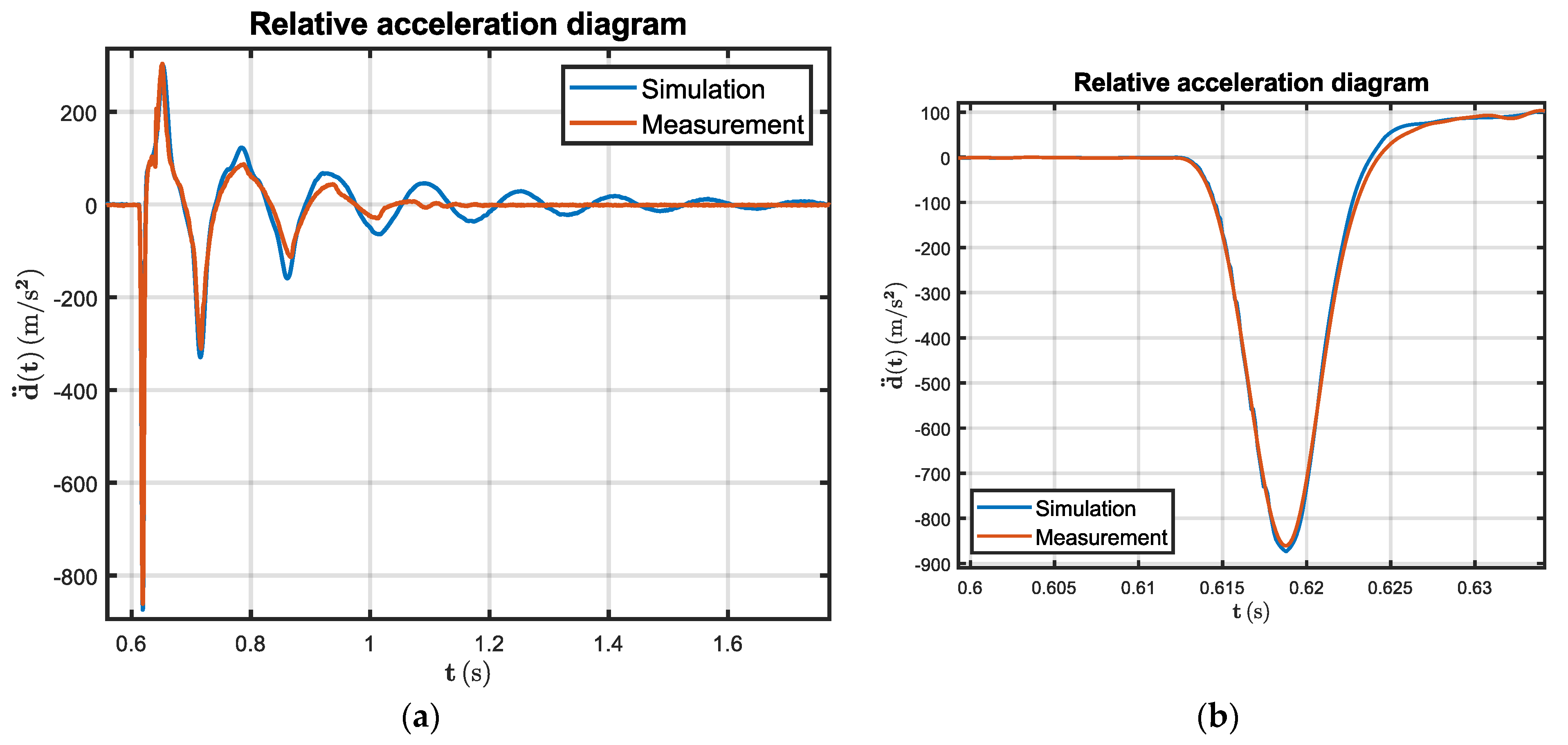

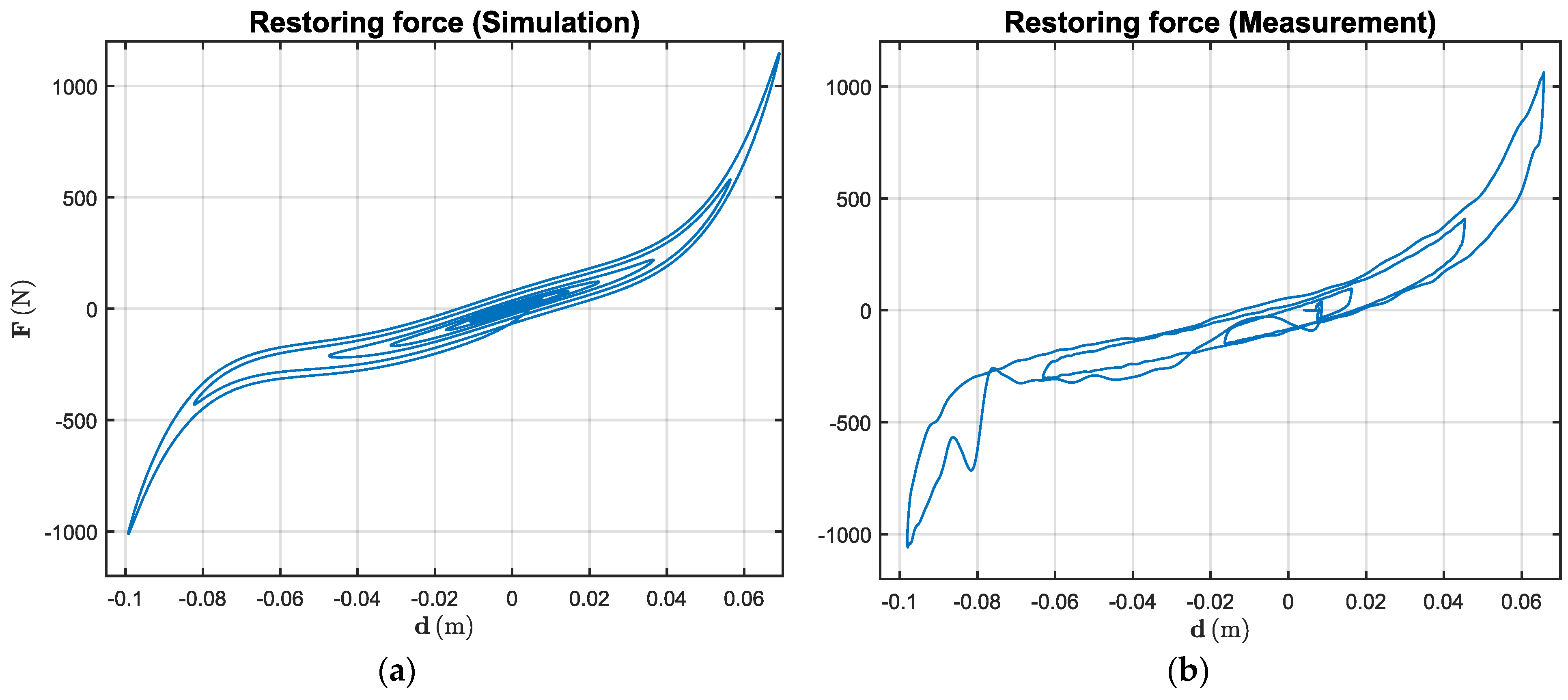

3.2. Exemplary Simulation

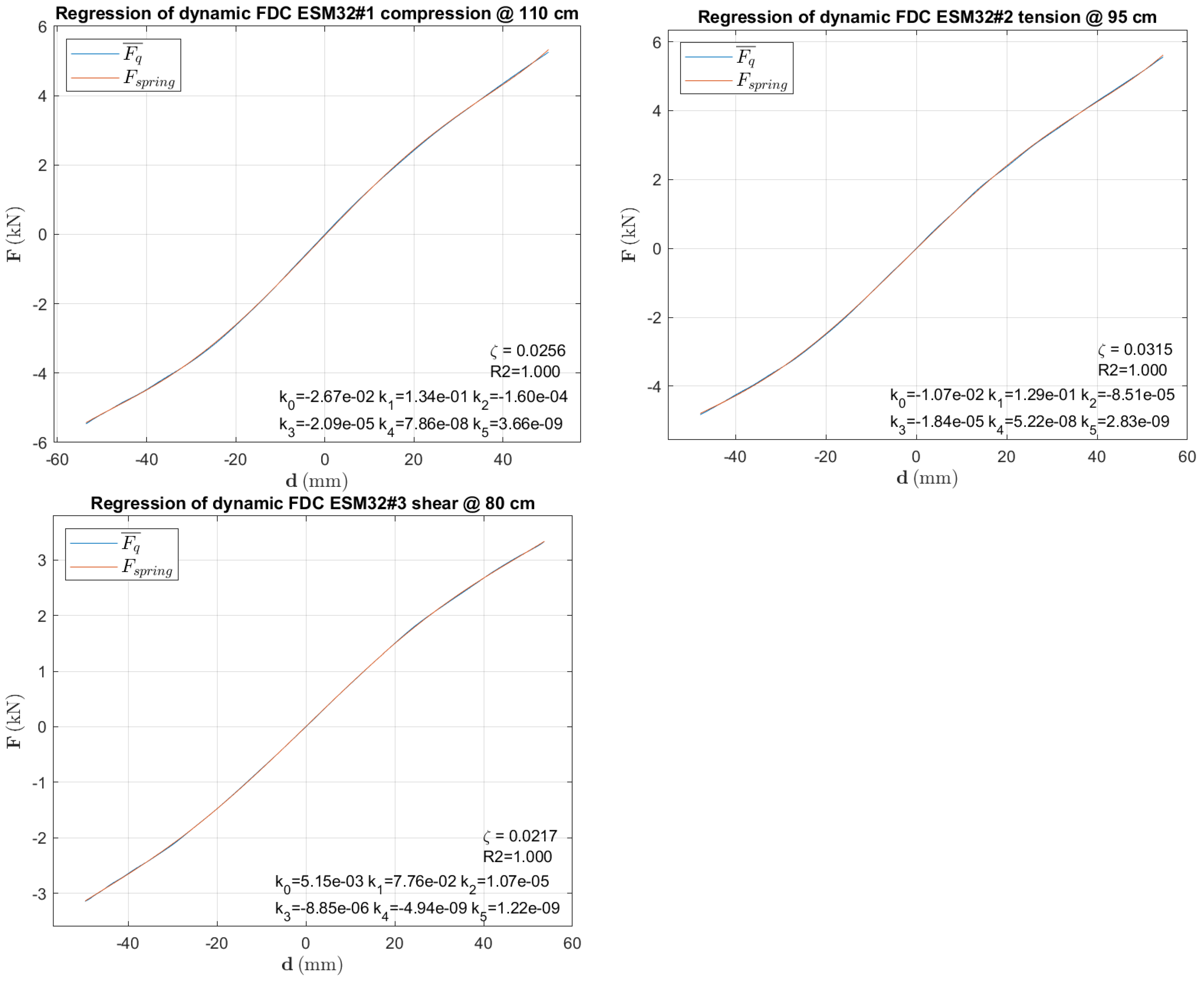

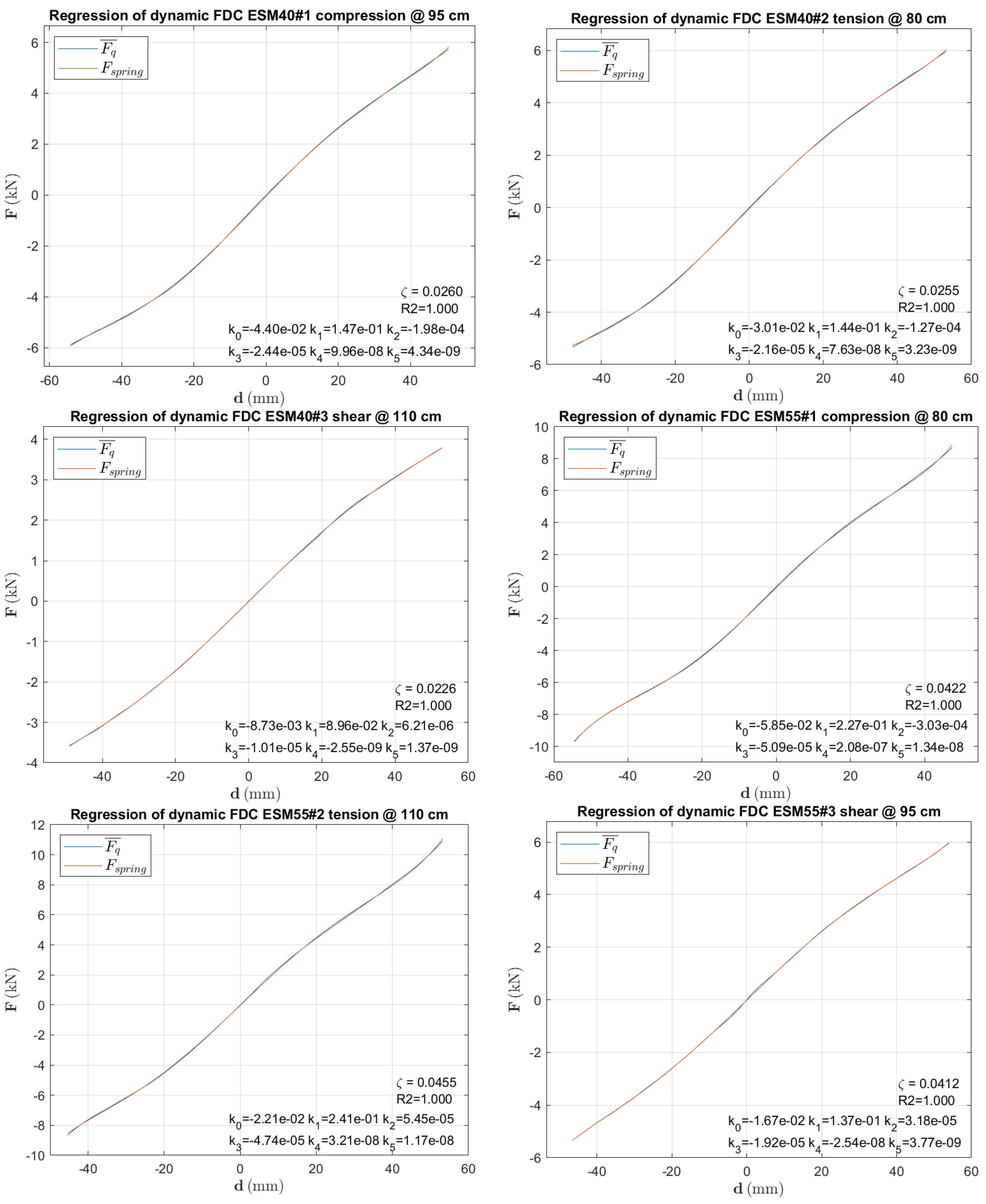

3.3. Parameter Sets for the Advanced Kelvin–Voigt Model

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- Shockmount type (ESM32, ESM40, ESM 55, WSM125, WSM135, WSM175, according to Section 2.1)

- Specimen number (#1, #2, #3) out of three specimens of a shockmount type

- Load directions (compression, tension, shear, roll)

- Drop height (in cm)

Appendix A.1. Elastomer Shockmounts

Appendix A.2. Wire Rope Shockmounts

References

- Sisemore, C.; Babuska, V. The Science and Engineering of Mechanical Shock, 1st ed.; Imprint; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Akram, P.A.; John, B.M.; Madathil, T.S.; Shija, C.; Abhirami, P.; Mathiazhagan, A.; Tide, P.S.; Ebenezer, D.D. Numerical Model of a Multi-layer Shock and Vibration Isolator. In Proceedings of the OCEANS 2022, Chennai, India, 21–24 February 2022; pp. 1–6. [Google Scholar]

- Prost, C.; Abdelnour, B. Influence and Enhancement of Damping Properties of Wire Rope Isolators for Naval Applications. Sound Vib. 2018, 52, 1–4. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, K.; Zhang, L.; Yan, M.; Zhang, Y. Experimental study on mechanical properties of new biaxial compression wire rope isolator. Sci. Sin.-Phys. Mech. Astron. 2021, 51, 124612. [Google Scholar] [CrossRef]

- Grządziela, A.; Kluczyk, M. Shock Absorbers Damping Characteristics by Lightweight Drop Hammer Test for Naval Machines. Materials 2021, 14, 772. [Google Scholar] [CrossRef] [PubMed]

- Kluczyk, M.; Grządziela, A.; Pająk, M.; Muślewski, Ł.; Szeleziński, A. The Fatigue Wear Process of Rubber-Metal Shock Absorbers. Polymers 2022, 14, 1186. [Google Scholar] [CrossRef] [PubMed]

- Mannacio, F.; Barbato, A.; Di Marzo, F.; Gaiotti, M.; Rizzo, C.M.; Venturini, M. Shock effects of underwater explosion on naval ship foundations: Validation of numerical models by dedicated tests. Ocean. Eng. 2022, 253, 111290. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, H.; Dong, T.; Xu, X. Dumbbell-Shaped Damage Effect of Closed Cylindrical Shell Subjected to Far-Field Side-On Underwater Explosion Shock Wave. J. Mar. Sci. Eng. 2022, 10, 1874. [Google Scholar] [CrossRef]

- Gargano, A.; Mouritz, A.P. Comparative study of the explosive blast resistance of metal and composite materials used in defence platforms. Compos. Part C Open Accesss 2023, 10, 100345. [Google Scholar] [CrossRef]

- DIN 95415:2020-11; Drahtseil-Federelemente—Technische Spezifikation. Deutsches Institut für Normung e.V.: Berlin, Germany, 2020.

- DIN 95360:2009-06; Elastomer-Federelemente—Technische Spezifikation. Deutsches Institut für Normung e.V.: Berlin, Germany, 2009.

- Heinemann, B.; Dreesen, J.; Sachau, D. Dynamic measuring of force-displacement-characteristics of shockmounts. Heliyon 2023, 9, e16743. [Google Scholar] [CrossRef] [PubMed]

- ANEP 63; Shock Mount Characterisation NATO Naval Armaments Group NG6/SG7 on Ship Combat Survivability. NATO: Washington, DC, USA, 2001.

- Clasen, M.; Sachau, D. Simulation models investigating the dynamic characteristics of shock isolators. Proc. Appl. Math. Mech. 2023, 22, e202200017. [Google Scholar] [CrossRef]

- Willbrandt, K.G. (Ed.) CAVOFLEX Drahtseil-Federelemente, Product Catalogue. Available online: https://www.willbrandt.com/willbrandt/en/imprint/imprint.php?test=1 (accessed on 29 September 2023).

- Willbrandt, K.G. (Ed.) Schockdämpfer: Produkte—Daten-Anwendungen, Product Catalogue. Available online: https://www.willbrandt.de/willbrandt/de/schwingungstechnik/schockdaempfer_SES6000.php (accessed on 29 September 2023).

- Lansmont Corporation (Ed.) Half Sine Pulse Capacity: Model M122, 12 inch (30.5 cm) Extended Height with Load Spreader and Low Frequency Base; Lansmont Corporation: Monterey, CA, USA, 2020. [Google Scholar]

- WayCon Positionsmesstechnik GmbH (Ed.) Linearpotentiometer: Serie LZW2; WayCon Positionsmesstechnik GmbH: Taufkirchen, Germany, 2020. [Google Scholar]

- PCB Piezotronics (Ed.) 3710 Series DC Accelerometer Operating Guide; PCB Piezotronics: Depew, NY, USA. Available online: https://www.pcbpiezotronics.fr/wp-content/uploads/3713f1250g.pdf (accessed on 29 September 2023).

- PCB Piezotronics. 3713F11—Online Photo. Available online: https://www.pcb.com/contentStore/images/pcb_corporate/vibration/products/photo/400/3713f11.jpg (accessed on 5 August 2022).

- PCB Piezotronics. 3711F11—Online Photo. Available online: https://www.pcb.com/contentStore/images/pcb_corporate/vibration/products/photo/400/3711f11.jpg (accessed on 5 August 2022).

- PCB Piezotronics (Ed.) Triaxial DC Response Accelerometer: Model 3713F11200G; Spec 70528; PCB Piezotronics: Depew, NY, USA, 2019. [Google Scholar]

- Shampine, L.; Reichelt, M. The MATLAB ODE Suite. SIAM J. Sci. Comput. 1997, 18, 1–22. Available online: https://www.mathworks.com/help/pdf_doc/otherdocs/ode_suite.pdf (accessed on 29 September 2023). [CrossRef]

| Type | Manufacturer and Model | Max. Static Load (kg) | Natural Frequency (Hz) @ Max. Static Load | Max. Displacement (mm) in Direction of | |

|---|---|---|---|---|---|

| Tension (+) Compression (−) | Shear, Roll | ||||

| ESM | Willbrandt KG SES 1500 SH32 | 90 | 5 … 6 | 55 | 55 |

| ESM | Willbrandt KG SES 1500 SH40 | 125 | 5 … 6 | 55 | 55 |

| ESM | Willbrandt KG SES 1500 SH55 | 260 | 5 … 6 | 55 | 55 |

| WSM | Willbrandt KG CAVOFLEX H 63-146-135-175-8 | 22 … 120 | 6.2 … 6.7 | +65/−100 | 86 |

| WSM | Willbrandt KG CAVOFLEX H 63-146-110-135-8 | 30 … 150 | 6 … 6.5 | +50/−82 | 65 |

| WSM | Willbrandt KG CAVOFLEX H63-146-95-125-8 | 50 … 170 | 7.1 … 7.6 | +45/−67 | 60 |

| Signal Name | Sensor Type | Position | Purpose |

|---|---|---|---|

| a1_z | Triaxial MEMS accelerometer | Loading mass | Measuring vertical acceleration of upper part |

| a2_z | Uniaxial MEMS accelerometer | Basepoint | Measuring vertical acceleration of lower part |

| aBase_z | Uniaxial MEMS accelerometer | Seismic base | Measuring vertical acceleration of base |

| deltaA | Linear potentiometer | Between rod and traverse of guide system | Measuring displacement between basepoint and loading mass |

| deltaB | Linear potentiometer | Between rod and traverse of guide system | Measuring displacement between basepoint and loading mass |

| Parameter | ||||||

|---|---|---|---|---|---|---|

| Value | − | − |

| Parameter | ||||

|---|---|---|---|---|

| Value | 3.449 |

| Compr. | Tension | Shear | Roll | Damp. | Stiffness from Parameter Identification | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SM | H | M | L | H | M | L | H | M | L | H | M | L | |||||||

| ESM32#1 | X | 2.6 | −2.67 × 102 | 1.34 × 10−1 | −1.60 × 10−4 | −2.09 × 10−5 | 7.86 × 10−8 | 3.66 × 10−9 | |||||||||||

| #2 | X | 3.2 | −1.07 × 10−2 | 1.29 × 10−1 | −8.51 × 10−5 | −1.84 × 10−5 | 5.22 × 10−8 | 2.83 × 10−9 | |||||||||||

| #3 | X | 2.2 | 5.15 × 10−3 | 7.76 × 10−2 | 1.07 × 10−5 | −8.85 × 10−6 | −4.94 × 10−9 | 1.22 × 10−9 | |||||||||||

| ESM40#1 | X | 2,6 | −4.40 × 10−2 | 1.47 × 10−2 | −1.98 × 10−4 | −2.44 × 10−5 | 9.96 × 10−8 | 4.34 × 10−9 | |||||||||||

| #2 | X | 2.6 | −3.01 × 10−2 | 1.44 × 10−1 | −1.27 × 10−4 | −2.16 × 10−5 | 7.63 × 10−8 | 3.23 × 10−9 | |||||||||||

| #3 | X | 2.3 | −8.73 × 10−3 | 8.96 × 10−2 | 6.21 × 10−6 | −1.01 × 10−5 | −2.55 × 10−9 | 1.37 × 10−9 | |||||||||||

| ESM55#1 | X | 4.2 | −5.85 × 10−2 | 2.2 × 10−1 | −3.03 × 10−4 | −5.09 × 10−5 | 2.08 × 10−7 | 1.34 × 10−8 | |||||||||||

| #2 | X | 4.6 | −2.21 × 10−2 | 2.41 × 10−1 | 5.45 × 10−5 | −4.74 × 10−5 | 3.21 × 10−8 | 1.17 × 10−8 | |||||||||||

| #3 | X | 4.1 | −1.67 × 10−2 | 1.37 × 10−1 | 3.18 × 10−5 | −1.92 × 10−5 | −2.54 × 10−8 | 3.77 × 10−9 | |||||||||||

| WSM125#1 | X | 5.0 | 1.27 × 10−2 | 1.28 × 10−2 | 9.97 × 10−6 | 4.91 × 10−7 | 1.50 × 10−7 | 2.44 × 10−9 | |||||||||||

| #2 | X | 4.3 | 1.23 × 10−2 | 1.58 × 10−2 | 3.35 × 10−5 | −6.05 × 10−6 | 1.42 × 10−7 | 6.07 × 10−9 | |||||||||||

| #3 | X | 9.8 | −5.03 × 10−3 | 2.94 × 10−3 | 2.81 × 10−5 | 1.01 × 10−6 | −5.11 × 10−8 | 7.55 × 10−10 | |||||||||||

| WSM135#1 | X | 6.9 | 8.92 × 10−3 | 1.04 × 10−2 | 5.99 × 10−5 | 1.93 × 10−6 | 8.90 × 10−8 | 1.03 × 10−9 | |||||||||||

| #2 | X | 5.0 | −1.11 × 10−2 | 1.38 × 10−2 | 2.16 × 10−4 | −1.14 × 10−5 | −1.01 × 10−7 | 8.91 × 10−9 | |||||||||||

| #3 | X | 9.6 | −2.34 × 10−4 | 2.52 × 10−3 | 5.50 × 10−6 | 2.80 × 10−7 | −4.80 × 10−9 | 1.32 × 10−10 | |||||||||||

| WSM175#1 | X | 6.4 | 9.12 × 10−3 | 5.16 × 10−3 | 1.18 × 10−7 | −3.09 × 10−7 | 2.02 × 10−8 | 2.84 × 10−10 | |||||||||||

| #2 | X | 5.0 | 3.84 × 10−3 | 6.15 × 10−3 | −3.78 × 10−6 | −1.23 × 10−6 | 2.14 × 10−8 | 4.90 × 10−10 | |||||||||||

| #3 | X | 11.3 | 3.68 × 10−4 | 9.26 × 10−4 | 1.72 × 10−6 | 1.34 × 10−7 | −1.70 × 10−9 | 2.03 × 10−11 | |||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heinemann, B.; Simanowski, K.; Clasen, M.; Dreesen, J.; Sachau, D. A Testbench for Measuring the Dynamic Force-Displacement Characteristics of Shockmounts. Vibration 2024, 7, 1-35. https://doi.org/10.3390/vibration7010001

Heinemann B, Simanowski K, Clasen M, Dreesen J, Sachau D. A Testbench for Measuring the Dynamic Force-Displacement Characteristics of Shockmounts. Vibration. 2024; 7(1):1-35. https://doi.org/10.3390/vibration7010001

Chicago/Turabian StyleHeinemann, Bernhard, Kai Simanowski, Michael Clasen, Jan Dreesen, and Delf Sachau. 2024. "A Testbench for Measuring the Dynamic Force-Displacement Characteristics of Shockmounts" Vibration 7, no. 1: 1-35. https://doi.org/10.3390/vibration7010001

APA StyleHeinemann, B., Simanowski, K., Clasen, M., Dreesen, J., & Sachau, D. (2024). A Testbench for Measuring the Dynamic Force-Displacement Characteristics of Shockmounts. Vibration, 7(1), 1-35. https://doi.org/10.3390/vibration7010001