Measurement and Analysis of Crowdsourced Vehicle Vibration Levels during Last Mile Delivery Segments for Parcel Shipments

Abstract

1. Introduction

2. Materials and Methods

2.1. Instrumentation and Recording Parameters

- Sample rate: 1000 Hz;

- Anti-aliasing filter frequency: 500 Hz;

- Record time: 2.048 s;

- Sample size: 2048;

- Frequency resolution for PSD: 0.48 Hz;

- Signal pre-trigger: 10%;

- Signal trigger level: 0.1 g.

2.2. Vehicle Types and Travel Conditions

2.3. Analysis Method for Collected Data

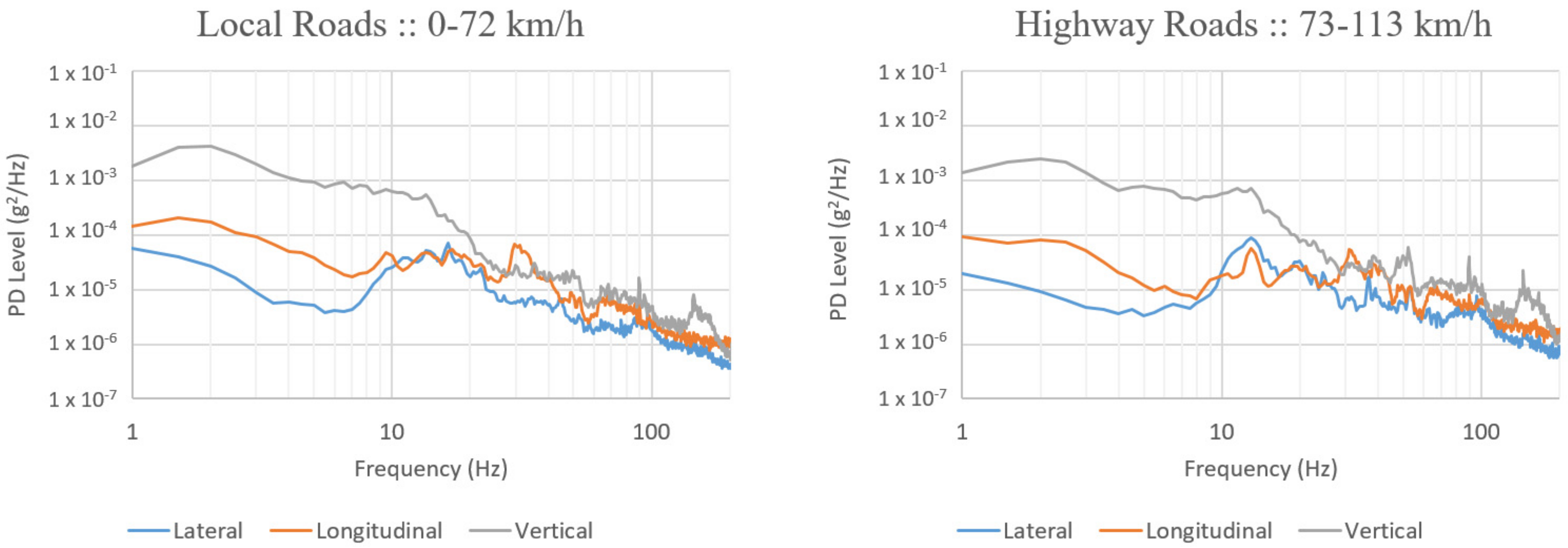

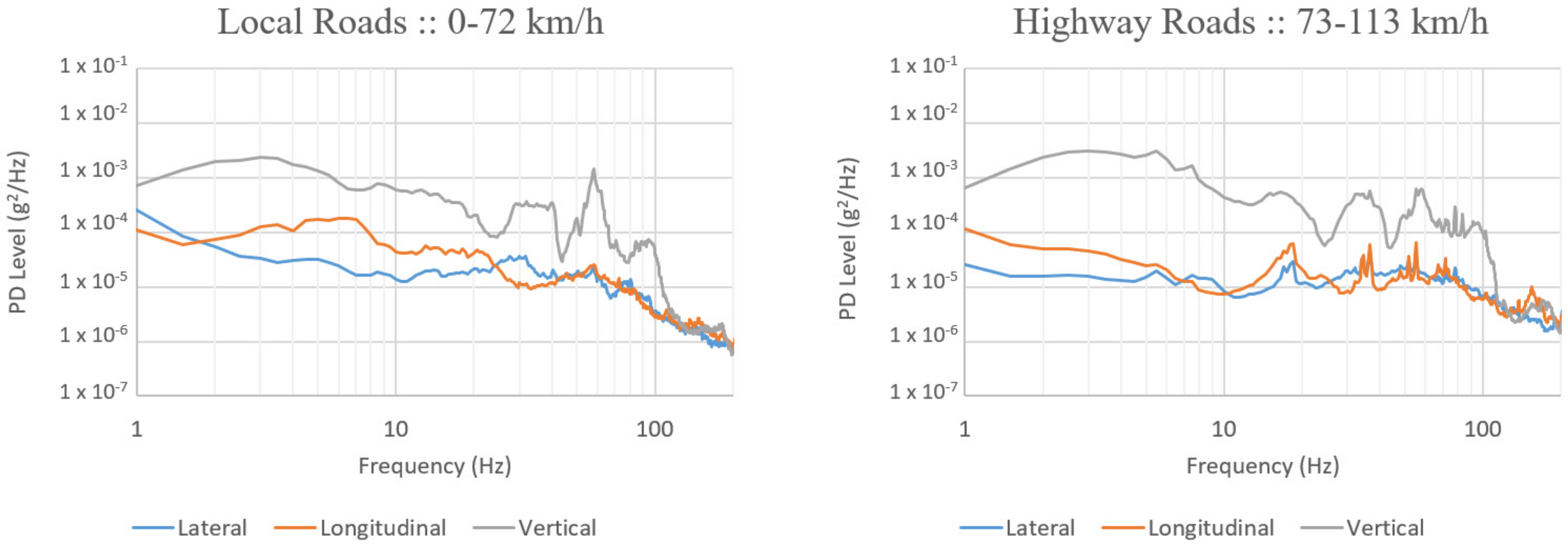

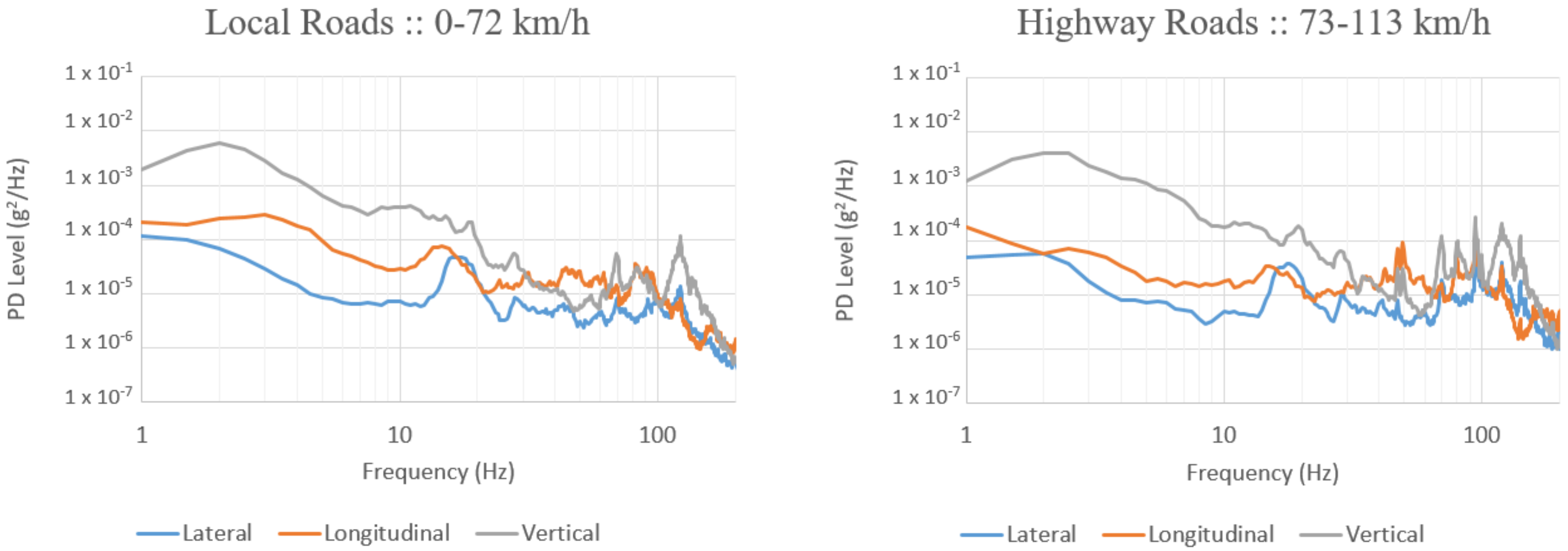

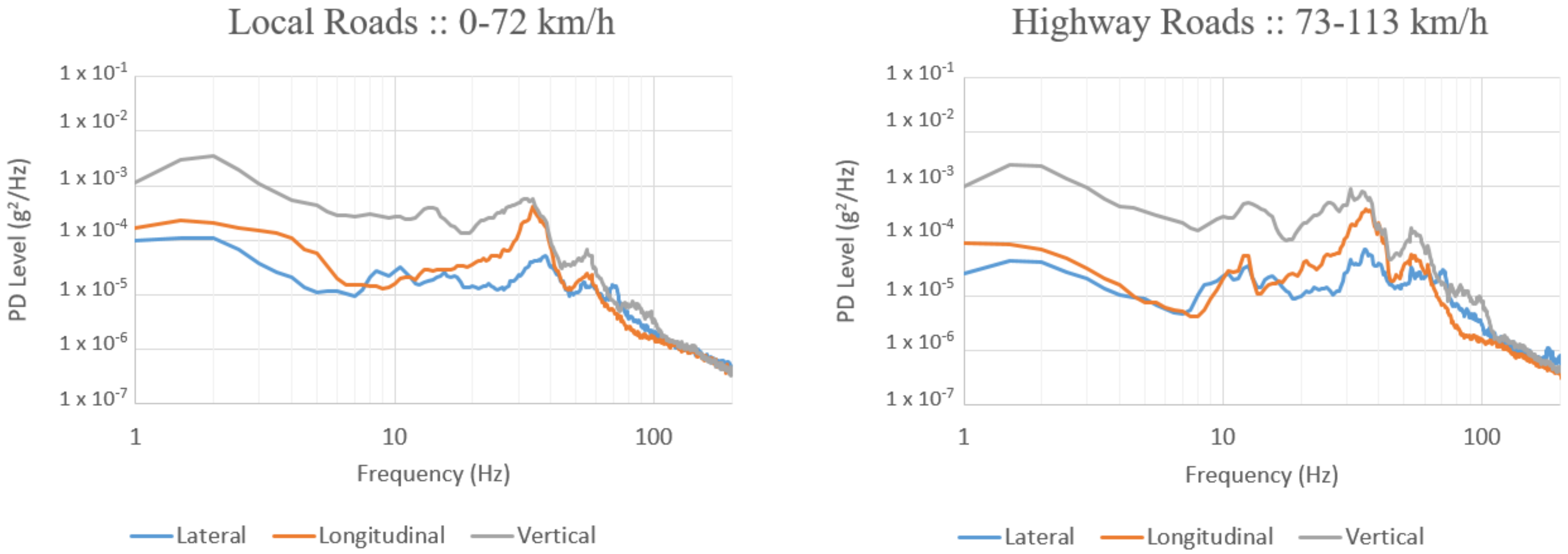

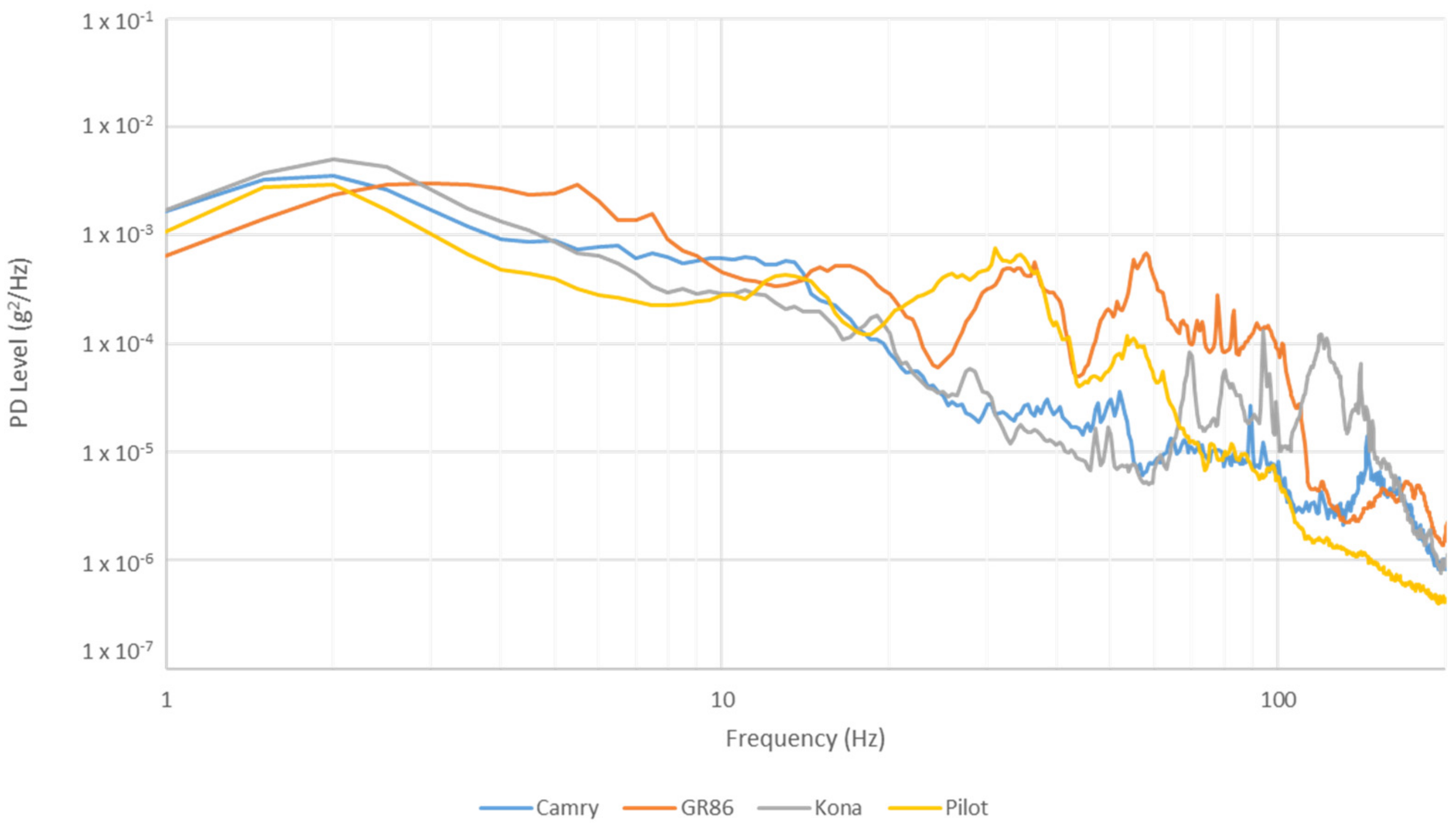

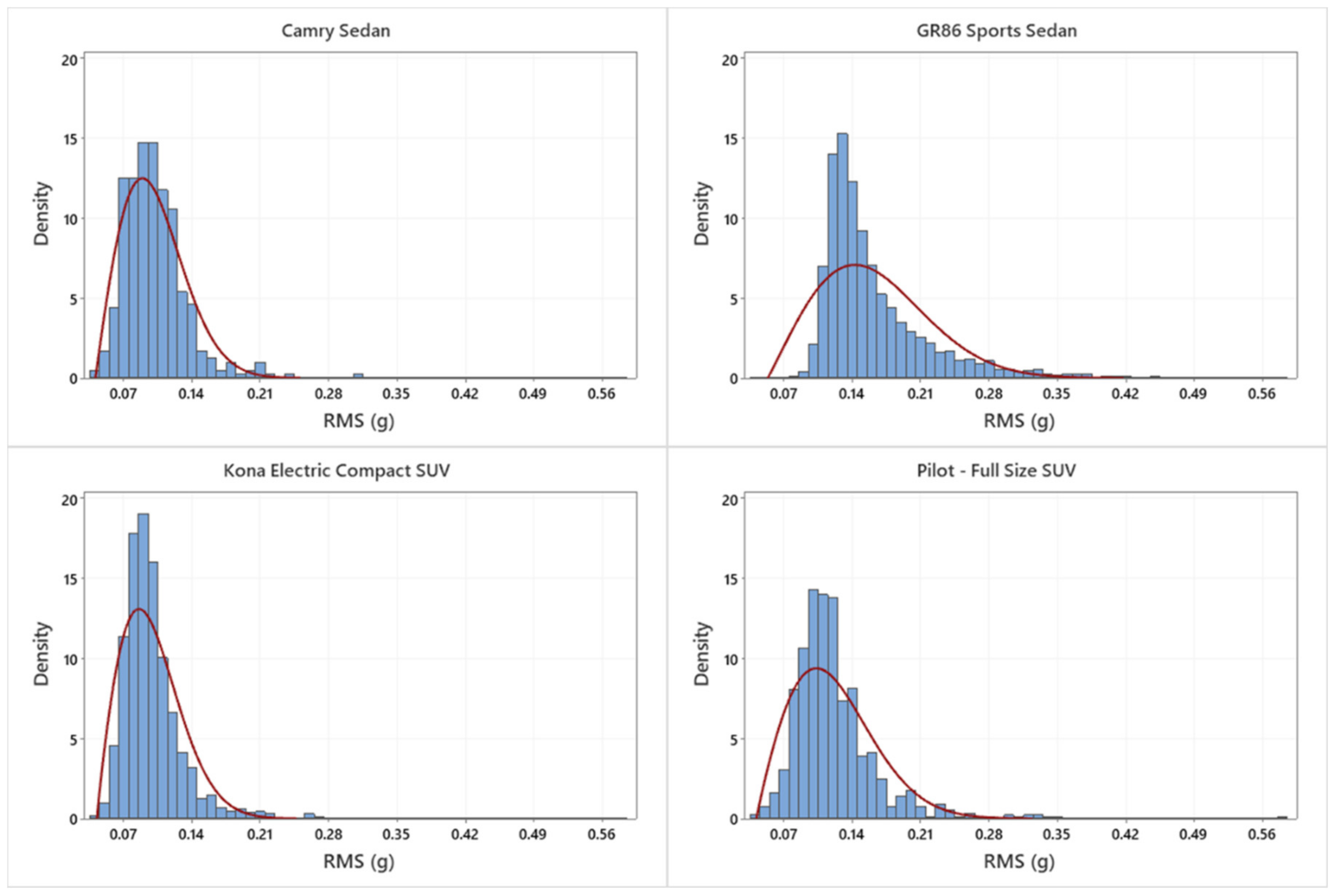

3. Results and Discussion

Limitations of this Study

- This study did not evaluate the observed roadway conditions or the changes in the payload inside the cargo area and their impact on the vibration levels. Further studies can measure the road roughness and can include various payload capacities to determine the impact on the experienced vibration levels.

- The ISTA vibration test standards are accelerated (time compressed), which artificially amplifies the vibration magnitude. Therefore, the field measured levels for the overall GRMS values of this study should be evaluated carefully against standard test levels.

- The observations for this study were made in good driving conditions. However, many parts of the US and the globe have adverse weather, which can alter driving conditions. This can be another area of further exploration.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sampaio, A.; Savelsbergh, M.; Veelenturf, L.P.; Van Woensel, T. Delivery Systems with Crowd-sourced Drivers: A Pickup and Delivery Problem with Transfers. Networks 2020, 76, 232–255. [Google Scholar] [CrossRef]

- Le, T.V.; Ukkusuri, S.V. Crowd-Shipping Services for Last Mile Delivery: Analysis from American Survey Data. Transp. Res. Interdiscip. Perspect. 2019, 1, 100008. [Google Scholar] [CrossRef]

- Boysen, N.; Fedtke, S.; Schwerdfeger, S. Last-Mile Delivery Concepts: A Survey from an Operational Research Perspective. OR Spectr. 2021, 43, 1–58. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.P.; Joneson, E. Measurement and Analysis of US Truck Vibration for Leaf Spring and Air Ride Suspensions, and Development of Tests to Simulate These Conditions. Packag. Technol. Sci. 2006, 19, 309–323. [Google Scholar] [CrossRef]

- Singh, S.P.; Sandhu, A.P.S.; Singh, J.; Joneson, E. Measurement and Analysis of Truck and Rail Shipping Environment in India. Packag. Technol. Sci. 2007, 20, 381–392. [Google Scholar] [CrossRef]

- Rissi, G.O.; Singh, S.P.; Burgess, G.; Singh, J. Measurement and Analysis of Truck Transport Environment in Brazil. Packag. Technol. Sci. 2008, 21, 231–246. [Google Scholar] [CrossRef]

- Böröcz, P.; Singh, S.P. Measurement and Analysis of Delivery van Vibration Levels to Simulate Package Testing for Parcel Delivery in Hungary. Packag. Technol. Sci. 2018, 31, 342–352. [Google Scholar] [CrossRef]

- Böröcz, P. Vibration Levels in Vans as a Function of Payload and Leaf Spring Sheet Number. J. Test. Eval. 2017, 46, 20160538. [Google Scholar] [CrossRef]

- Dunno, K. Measurement and Analysis of Vehicle Vibration for Bottled Water Delivery Trucks. Int. J. Adv. Packag. Technol. 2014, 2, 75–83. [Google Scholar] [CrossRef]

- Dunno, K. Experimental Evaluation of Techniques Designed to Reduce Vibration Simulation Test Time. J. Appl. Packag. Res. 2014, 6, 1. [Google Scholar] [CrossRef]

- Cano-Moreno, J.D.; Cabanellas Becerra, J.M.; Arenas Reina, J.M.; Islán Marcos, M.E. Analysis of E-Scooter Vibrations Risks for Riding Comfort Based on Real Measurements. Machines 2022, 10, 688. [Google Scholar] [CrossRef]

- Boglietti, S.; Ghirardi, A.; Zanoni, C.T.; Ventura, R.; Barabino, B.; Maternini, G.; Vetturi, D. First Experimental Comparison between E-Kick Scooters and e-Bike’s Vibrational Dynamics. Transp. Res. Procedia 2022, 62, 743–751. [Google Scholar] [CrossRef]

- Govers, M.E.; Nolan, A.J.; Hassan, M.; Oliver, M.L. Relationships between Height, Mass, Body Mass Index, and Trunk Muscle Activation during Seated Whole-Body Vibration Exposure. Vibration 2021, 4, 822–835. [Google Scholar] [CrossRef]

- Maravich, M.M.; Altinsoy, E. Influence of Seat Vibration Frequency on Total Annoyance and Interaction Effects Caused by Simultaneous Noise and Seat Vibrations in Commercial Vehicles. Vibration 2022, 5, 183–199. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, Z.-W. Measurement and Analysis of Vibration Levels for Express Logistics Transportation in South China. Packag. Technol. Sci. 2018, 31, 665–678. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Singh, S.P.; Singh, J.J.; Stallings, J.; Grewal, G. Measurement and Analysis of Vehicle Vibration for Delivering Packages in Small-Sized and Medium-Sized Trucks and Automobiles: Small and medium truck and automobile vibration levels. Packag. Technol. Sci. 2012, 25, 31–38. [Google Scholar] [CrossRef]

- Rouillard, V.; Sek, M. Creating Transport Vibration Simulation Profiles from Vehicle and Road Characteristics: Vibration simulation schedules from vehicle and road characteristics. Packag. Technol. Sci. 2013, 26, 82–95. [Google Scholar] [CrossRef]

- Zhou, R.; Yan, L.; Li, B.; Xie, J. Measurement of Truck Transport Vibration Levels in China as a Function of Road Conditions, Truck Speed and Load Level: Vibration as a Function of Road Conditions, Truck Speed and Load Mass. Packag. Technol. Sci. 2015, 28, 949–957. [Google Scholar] [CrossRef]

- Garcia-Romeu-Martinez, M.-A.; Singh, S.P.; Cloquell-Ballester, V.-A. Measurement and Analysis of Vibration Levels for Truck Transport in Spain as a Function of Payload, Suspension and Speed. Packag. Technol. Sci. 2008, 21, 439–451. [Google Scholar] [CrossRef]

- Lu, F.; Ishikawa, Y.; Kitazawa, H.; Satake, T. Effect of Vehicle Speed on Shock and Vibration Levels in Truck Transport. Packag. Technol. Sci. 2010, 23, 101–109. [Google Scholar] [CrossRef]

- Młyńczak, J.; Celiński, I.; Burdzik, R. Effect of Vibrations on the Behaviour of a Vehicle Driver. Vibroeng. Procedia 2015, 6, 243–247. [Google Scholar]

- Xiang, H.; Zhu, J.; Liang, G.; Shen, Y. Prediction of Dangerous Driving Behavior Based on Vehicle Motion State and Passenger Feeling Using Cloud Model and Elman Neural Network. Front. Neurorobot. 2021, 15, 641007. [Google Scholar] [CrossRef] [PubMed]

- Wallin, B. Developing a Random Vibration Profile Standard. In Proceedings of the 2007 IAPRI Symposium, Windsor, UK, 3–5 September 2007. [Google Scholar]

- Böröcz, P. Vibration and Acceleration Levels of Multimodal Container Shipping Physical Environment. Packag. Technol. Sci. 2019, 32, 269–277. [Google Scholar] [CrossRef]

- Böröcz, P.; Singh, S.P. Measurement and Analysis of Vibration Levels in Rail Transport in Central Europe. Packag. Technol. Sci. 2017, 30, 361–371. [Google Scholar] [CrossRef]

- Rouillard, V. Quantifying the Non-Stationarity of Vehicle Vibrations with the Run Test. Packag. Technol. Sci. 2014, 27, 203–219. [Google Scholar] [CrossRef]

- ISTA. Standard 3A: Packaged-Products for Parcel Delivery System Shipment 70 Kg (150 Lb) or Less; ISTA: East Lansing, MI, USA, 2018. [Google Scholar]

- Park, J.; Choi, S.; Jung, H.M. Measurement and Analysis of Vibration Levels for Truck Transport Environment in Korea. Appl. Sci. 2020, 10, 6754. [Google Scholar] [CrossRef]

- Rouillard, V.; Sek, M.A. Synthesizing Nonstationary, Non-Gaussian Random Vibrations. Packag. Technol. Sci. 2010, 23, 423–439. [Google Scholar] [CrossRef]

- Otari, S.; Odof, S.; Nolot, J.B.; Vasseur, P.; Pellot, J.; Krajka, N.; Erre, D. Statistical Characterization of Acceleration Levels of Random Vibrations during Transport: Random vibration characterization. Packag. Technol. Sci. 2011, 24, 177–188. [Google Scholar] [CrossRef]

- Rouillard, V.; Lamb, M.J. Using the Weibull Distribution to Characterise Road Transport Vibration Levels. Packag. Technol. Sci. 2020, 33, 255–266. [Google Scholar] [CrossRef]

| Parameter | Toyota Camry | Honda Pilot | Hyundai Kona | Toyota GR86 |

|---|---|---|---|---|

| Model Year | 2011 | 2015 | 2021 | 2022 |

| Engine | 2.5 L Gas | 3.5 L Gas | Electric | 2.4 L Gas |

| Drive Train | Front Wheel | Front Wheel | Front Wheel | Rear Wheel |

| Gross Vehicle Weight | 1501 kg | 1896 kg | 1315 kg | 1275 kg |

| Suspension/Type | Independent/Coil Spring | Independent/Coil Spring | Independent/Coil Spring | Independent/Coil Spring |

| Overall GRMS Values | |||||||

|---|---|---|---|---|---|---|---|

| Vehicle | Road Type | Speed (km/h) | Vertical | Longitudinal | Lateral | Kurtosis | Skewness |

| Camry—Sedan | Local | 0–72 | 0.135 | 0.046 | 0.032 | 6.22 | 1.86 |

| Highway | 73–113 | 0.124 | 0.043 | 0.034 | 3.20 | 1.56 | |

| GR86—Sport Sedan | Local | 0–72 | 0.176 | 0.054 | 0.047 | 2.81 | 1.29 |

| Highway | 73–113 | 0.197 | 0.048 | 0.044 | 6.71 | 2.26 | |

| Kona—Electric Compact SUV | Local | 0–72 | 0.140 | 0.059 | 0.036 | 10.19 | 2.29 |

| Highway | 73–113 | 0.142 | 0.057 | 0.420 | 9.21 | 2.11 | |

| Pilot—Gas Full-sized SUV | Local | 0–72 | 0.137 | 0.068 | 0.042 | 15.68 | 2.78 |

| Highway | 73–113 | 0.146 | 0.070 | 0.044 | 6.46 | 2.05 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dunno, K.; Chavan, P. Measurement and Analysis of Crowdsourced Vehicle Vibration Levels during Last Mile Delivery Segments for Parcel Shipments. Vibration 2022, 5, 792-802. https://doi.org/10.3390/vibration5040046

Dunno K, Chavan P. Measurement and Analysis of Crowdsourced Vehicle Vibration Levels during Last Mile Delivery Segments for Parcel Shipments. Vibration. 2022; 5(4):792-802. https://doi.org/10.3390/vibration5040046

Chicago/Turabian StyleDunno, Kyle, and Purushottam Chavan. 2022. "Measurement and Analysis of Crowdsourced Vehicle Vibration Levels during Last Mile Delivery Segments for Parcel Shipments" Vibration 5, no. 4: 792-802. https://doi.org/10.3390/vibration5040046

APA StyleDunno, K., & Chavan, P. (2022). Measurement and Analysis of Crowdsourced Vehicle Vibration Levels during Last Mile Delivery Segments for Parcel Shipments. Vibration, 5(4), 792-802. https://doi.org/10.3390/vibration5040046