Co-Simulation-Based Verification of Torsional Vibration Protection of Electric-Driven Railway Vehicle Wheelsets

Abstract

:1. Introduction

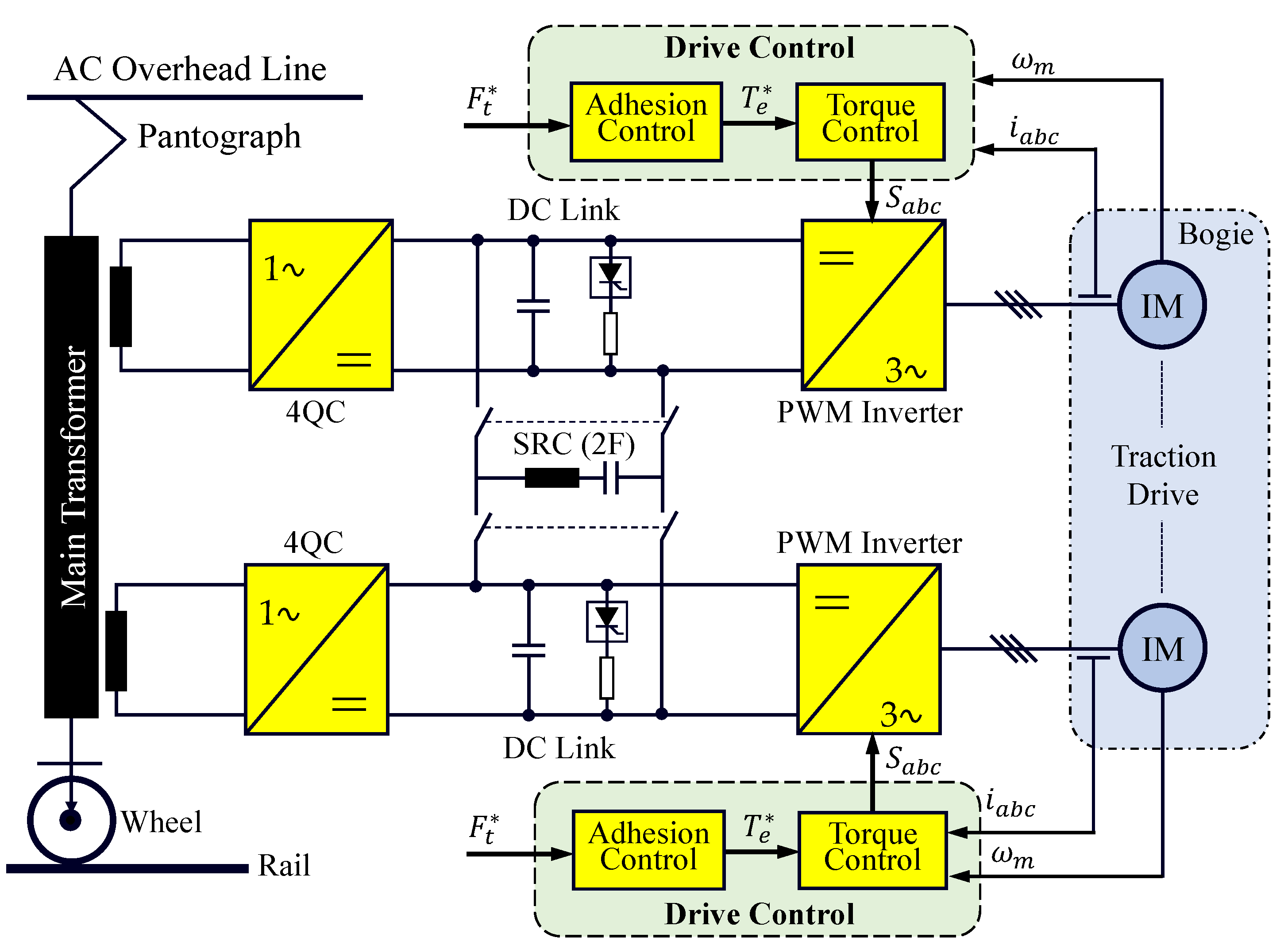

2. System Description

- the four-quadrant chopper (4QC),

- the DC-link,

- the switched inverter.

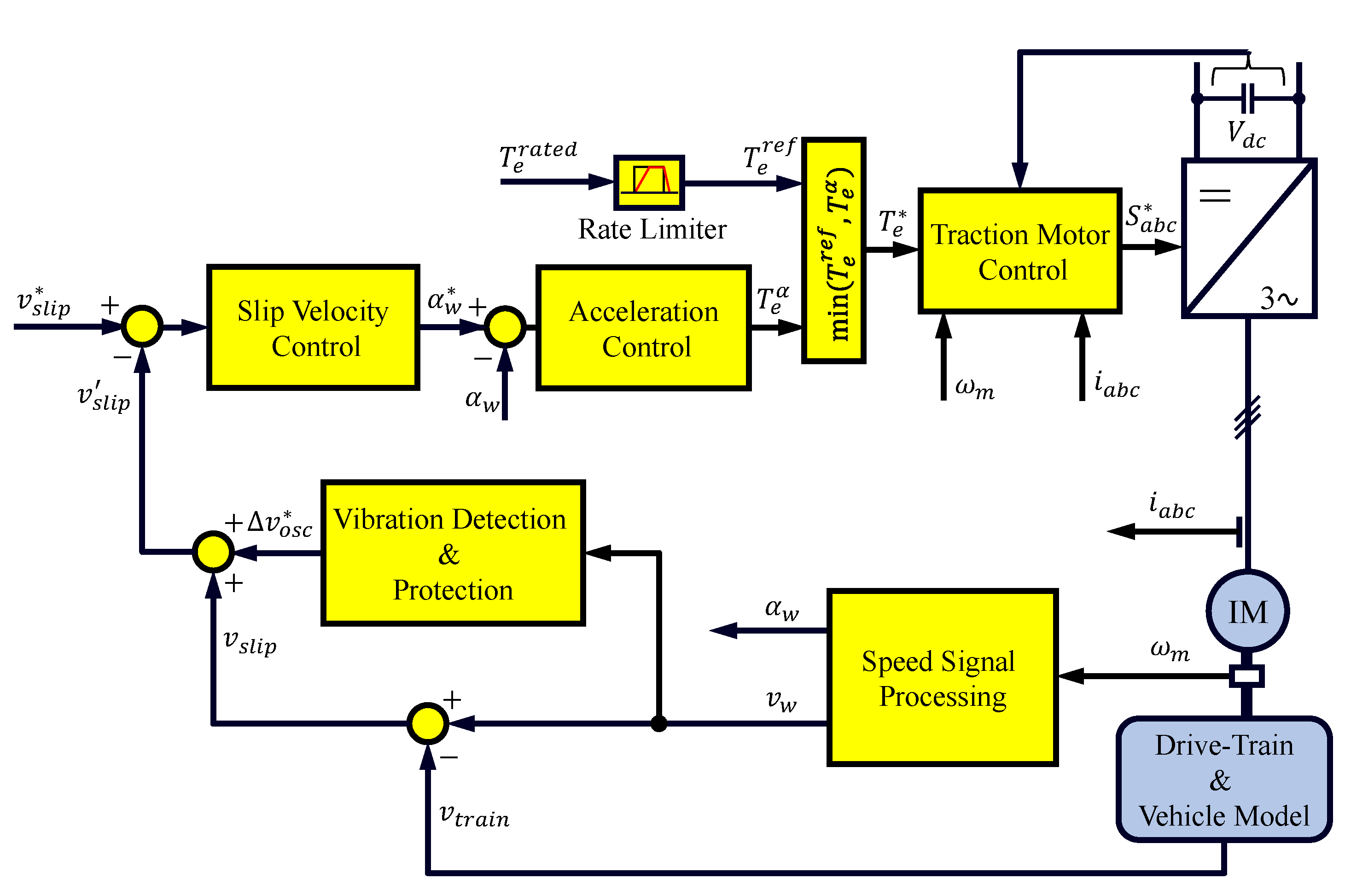

2.1. Electric Drive

- Adhesion control. This control loop aims to adapt the wheel–rail adhesion level (i.e., the tractive/breaking force) besides preventing the wheel from slipping during acceleration/deceleration of the locomotive or due to changing of the wheel–rail contact conditions caused by slippery rails. More details will be discussed in Section 3.1.

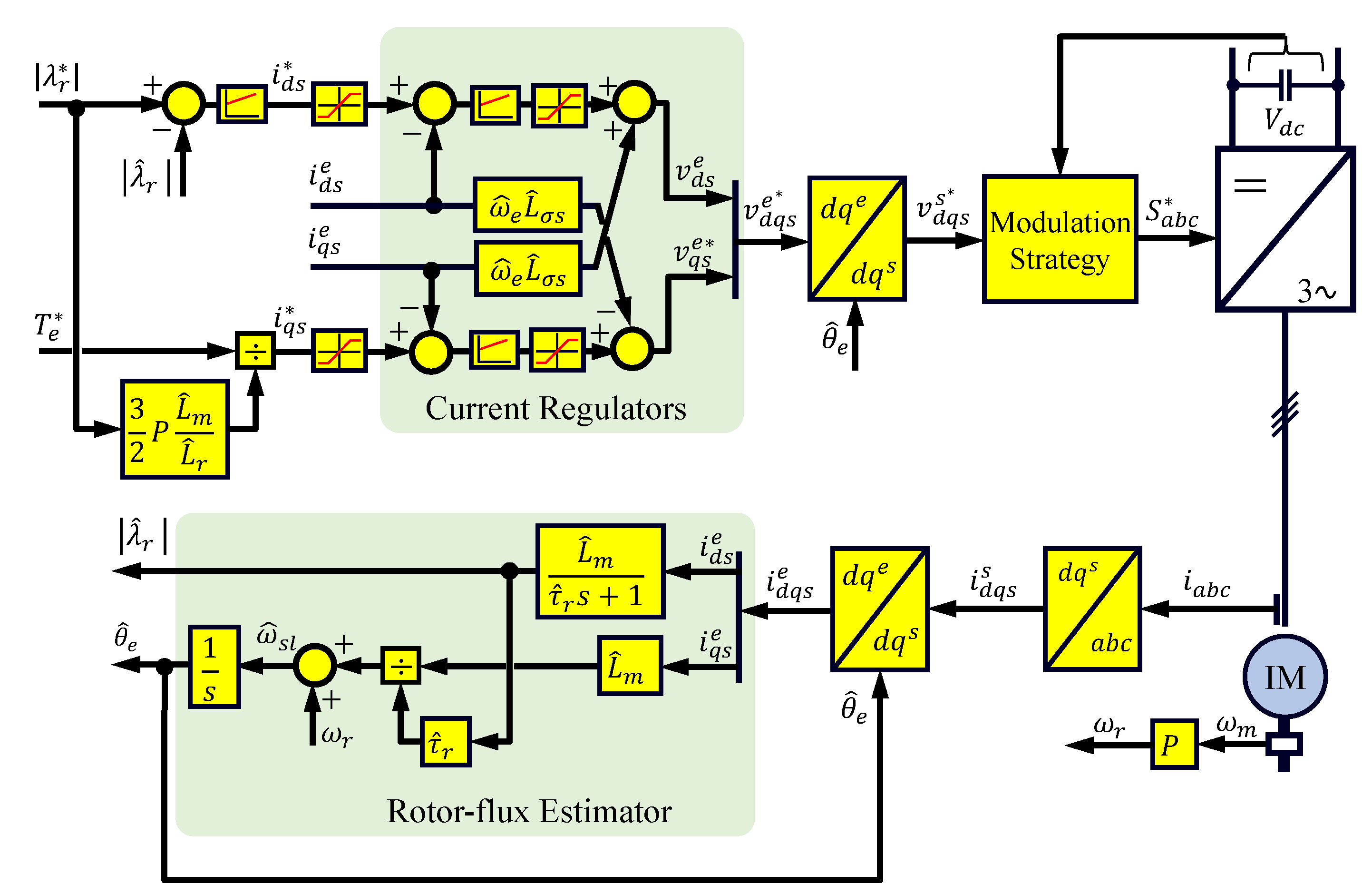

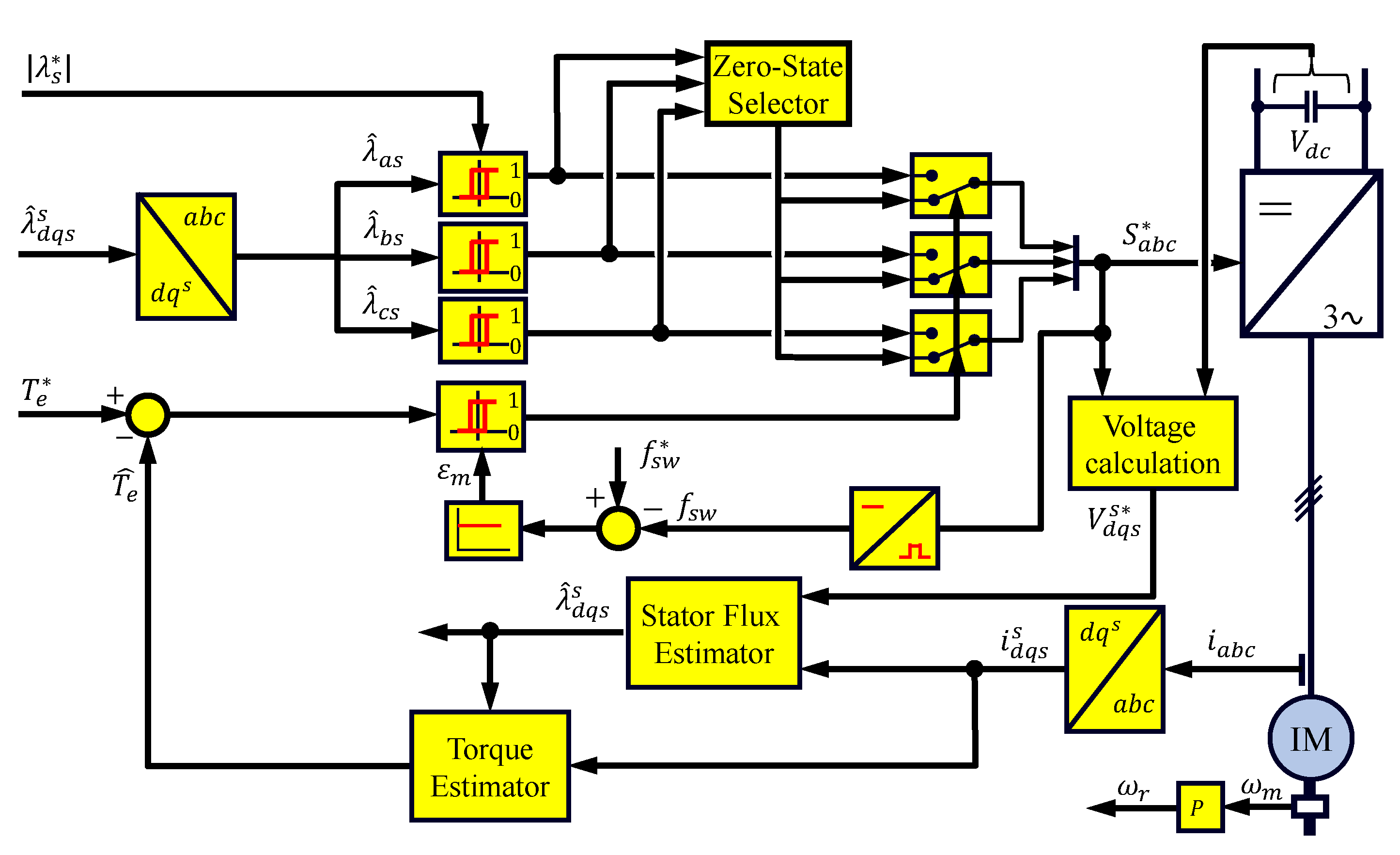

- Torque control. A precise, high dynamic torque control is needed to assure that the machines’ actual torque follows the demanded torque by the outer adhesion controller. Modern traction drives are equipped with different control strategies, which can change dynamically based on the operating speed [18]. Mainly, vector control schemes are used to decouple the torque and flux components of the machine’s current, which allows to fully exploit machine torque capability without surpassing machine or power converter current limits. Typically rotor flux field-oriented control (RFOC) tuned with a high bandwidth is used (see Figure 2). In this scheme, the d-axis of the rotating reference frame is aligned with the rotor flux, i.e., , the stator voltage and the stator flux equations become (1) and (2), where is the angular speed in electrical units of the synchronous reference.Thus, the electromagnetic torque can be represented by (4) in terms of q-axis of stator current and the estimated rotor flux.The main concerns regarding RFOC methods are their sensitivity to rotor resistance, and the degradation of current regulator performance when the inverter operates near its voltage limit. Alternatively, the stator-flux orientation can be used to overcome these limitations, especially at high speeds. Direct Self-Control (DSC) was proposed for high power drives operating with low switching to fundamental frequency ratio (see Figure 3) [21]. Three hysteresis controllers determine the voltage applied to the machine by comparing the command flux magnitude and the estimated one for each phase. A two-level hysteresis torque controller determines the amount of zero voltage vector to be used. Moreover, the switching frequency is controlled by adapting the torque controller hysteresis band using either proportional or proportional-integral (P/PI) controller. DSC produces a symmetrical hexagonal stator flux trajectory to the origin increasing the robustness against input voltage disturbances. From ≈ to ≈ of base speed, DSC offers a high dynamic response and reduced switching losses, but at the price of a high current ripple. At high speeds ( of base speed), zero voltage vectors are not selected anymore, DSC providing, therefore, a natural transition into overmodulation and eventually into six-step [22]. Below ≈ of the base speed there is a degradation of the control performance, a detailed description and potential remedial actions can be found in [23,24].

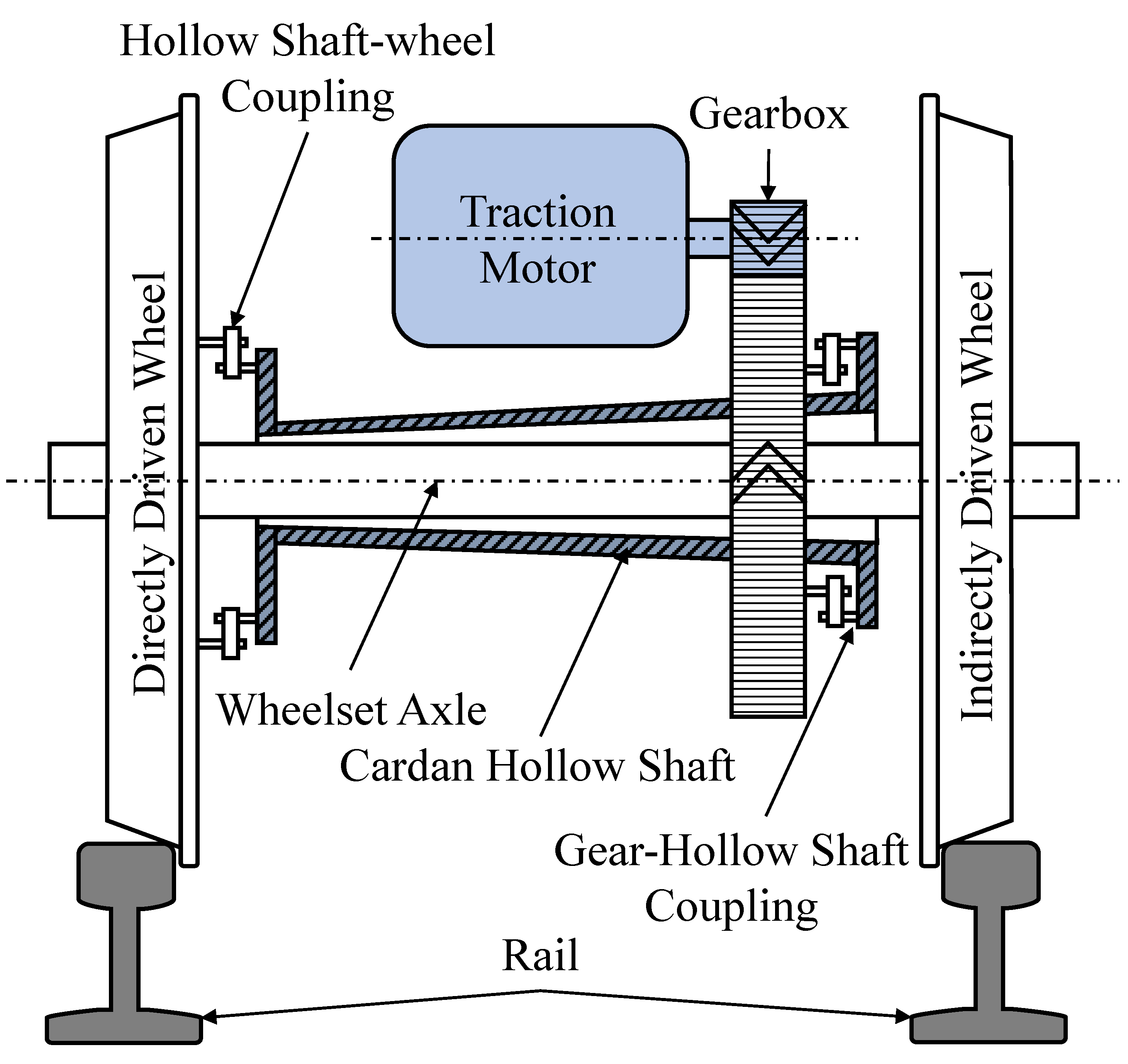

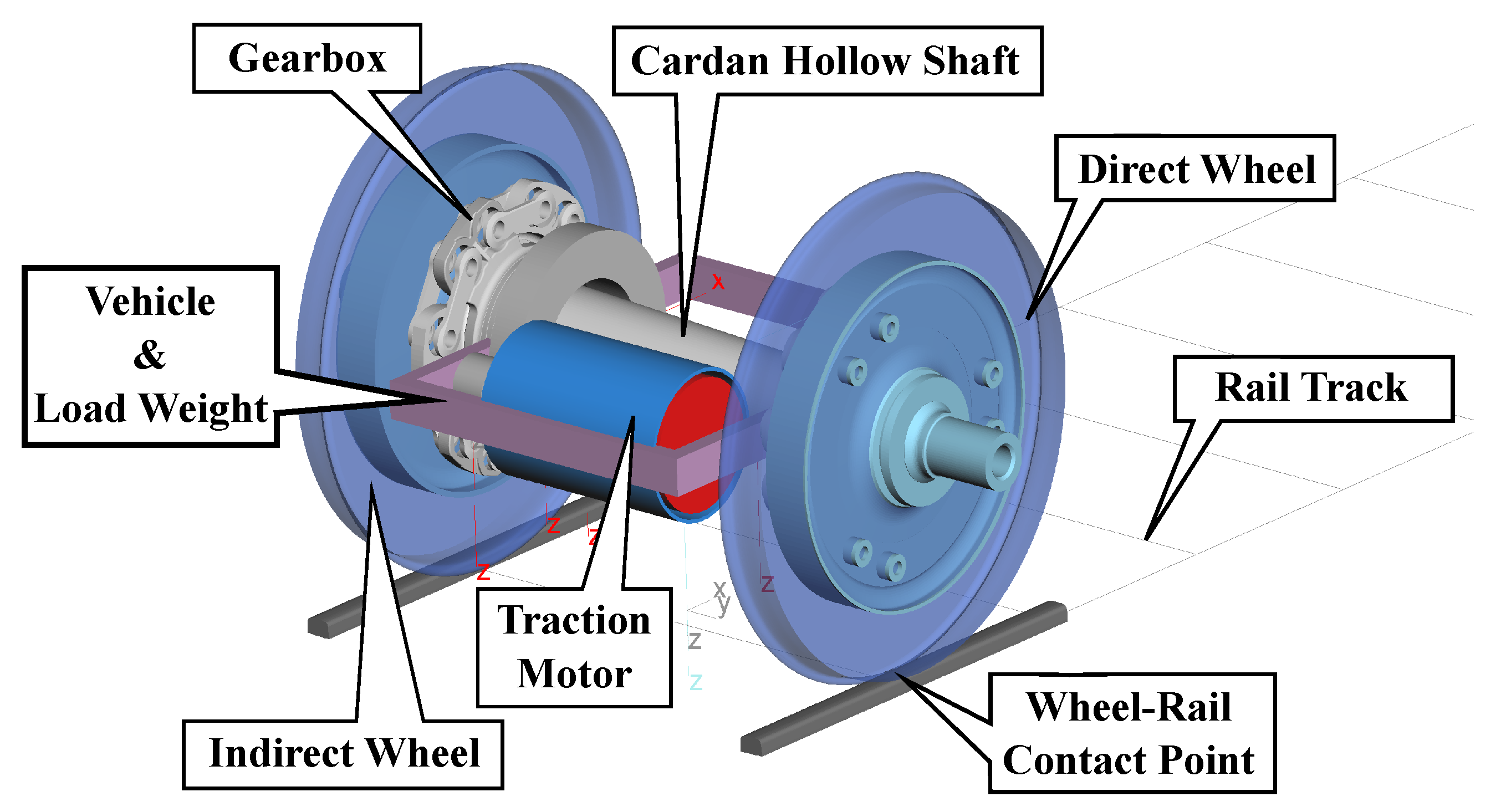

2.2. Mechanical Model of the Drive Train

2.2.1. Simulation Model

2.2.2. Linear Analysis

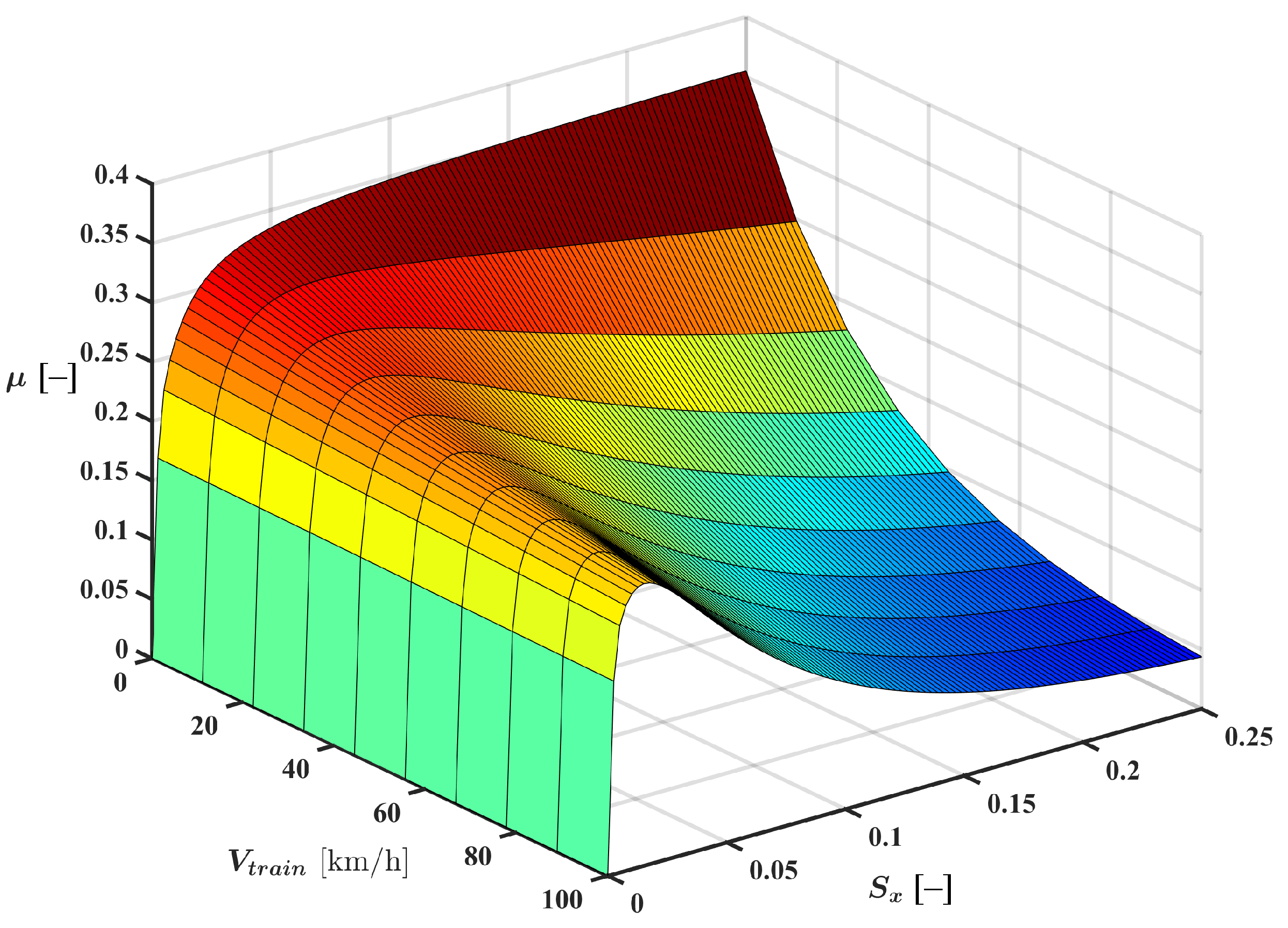

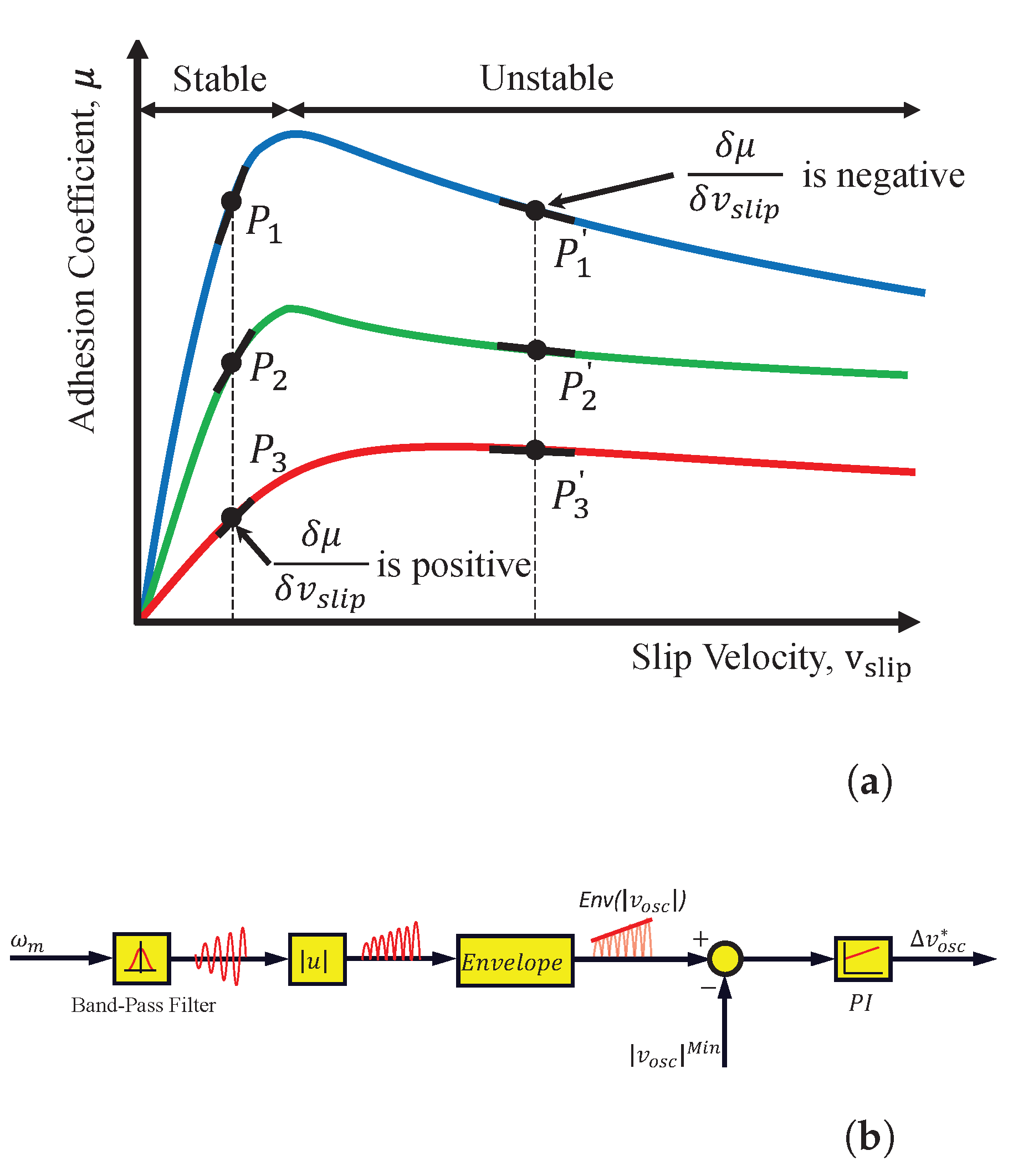

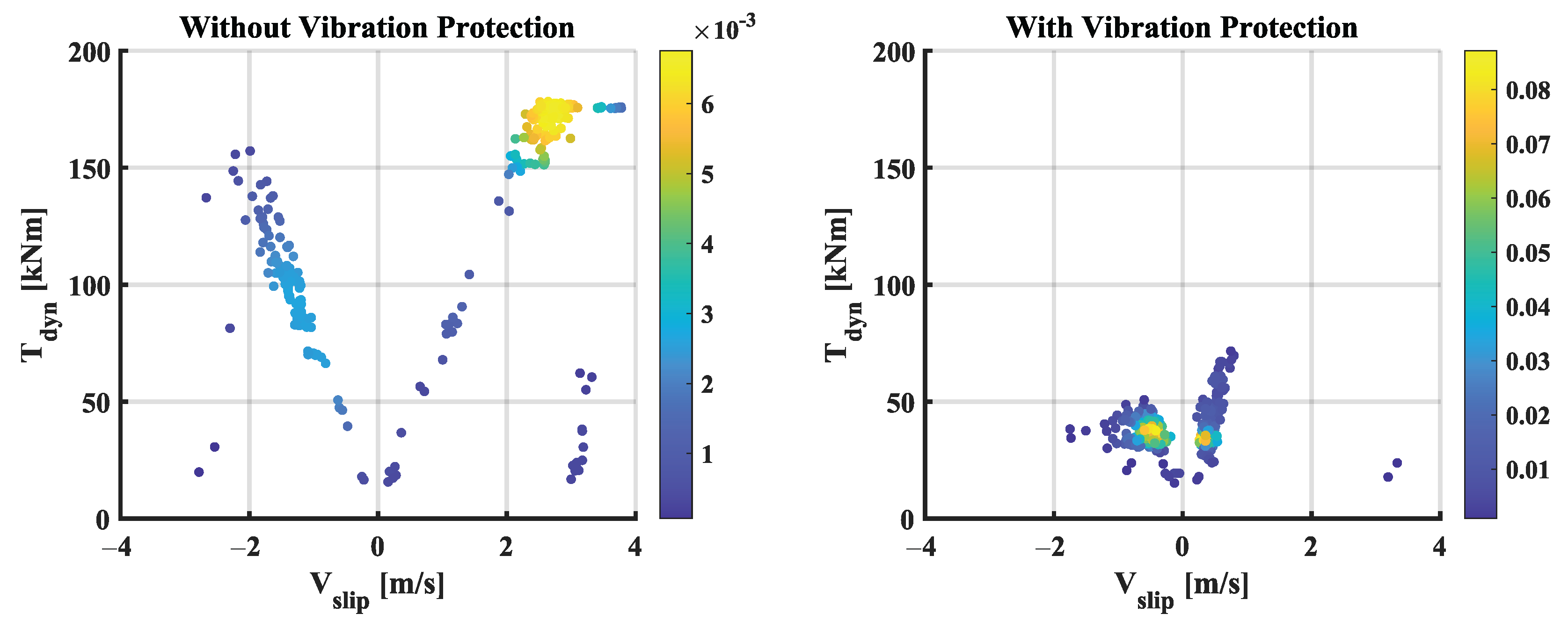

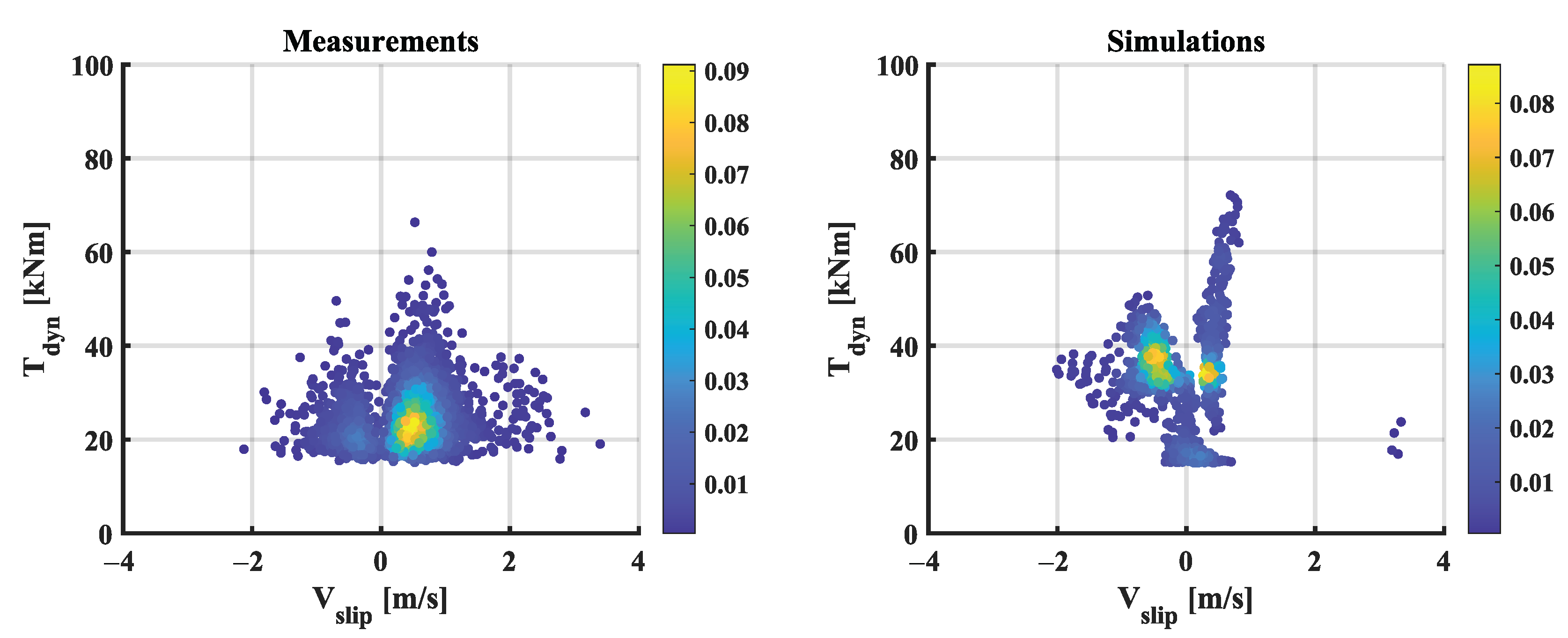

3. Slip Control and Torsional Vibration Protection

3.1. Overview of Slip Control

- Traditional slip controllers, also known as re-adhesion controllers. They are one of the simplest and stablest solutions to limit the wheel–rail slippage to a predefined value [27,28,29]. The slip velocity reference can be kept at a constant value or varied with the train speed based on previous field-tests and train’ driver experience [30].

3.2. Torsional Vibration Control

4. Simulation Results and Experimental Verification

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fridrichovskỳ, T.; Šulc, B. Occurrence of Torsional Oscillations in Railway Wheelsets. WSEAS Trans. Syst. 2016, 15, 252–261. [Google Scholar]

- Yu, M.; Breuer, W. Energie-Methode zur Beurteilung von Kraftschlussinduzierten Eigenschwingungen von Radsatzwellen; DVV Media Group, Eurailpress: Hamburg, Germany, 2018; Volume 142. [Google Scholar]

- Weinhardt, M. Torsionsschwingungen in Radsätzen—Fakten und Thesen zur Anregung durch den Rad-Schiene-Kraftschluss. In Proceedings of the 15. Internationale Schienenfahrzeugtagung 2017 in Dresden, Dresden, Germany, 1 March 2017; pp. 49–51. [Google Scholar]

- Szolc, T. Simulation of bending-torsional-lateral vibrations of the railway wheelset-track system in the medium frequency range. Veh. Syst. Dyn. 1998, 30, 473–508. [Google Scholar] [CrossRef]

- Schneider, R. Torsionsschwingungen von Radsatzwellen—Systemanalyse Teil 1: System- und Modellbeschreibung. ZEVrail 2017, 141, 452–461. [Google Scholar]

- Saur, F.; Weber, J. Selbsterregte Radsatz-Torsionsschwingungen in Schienenfahrzeugen: Analyse, Berechnung und Simulation. In Proceedings of the Dresdner Maschinenelemente Kolloquium (DMK 2019), Dresden, Germany, 26–27 December 2019; Technische Universität Dresden, Sierke Verlag: Göttingen, Germany, 2019; pp. 633–650. [Google Scholar]

- Saur, F.; Weber, J. Analytische Berechnung des maximalen, dynamischen Radsatz-Torsionsmoments von Schienenfahrzeugen mit Tatzlagerantrieb. Eisenbahntechnische Rundsch. 2021, 4, 69–73. [Google Scholar]

- Saur, F.; Weber, J. Auslegung von Radsatzwellen unter Berücksichtigung des maximalen, dynamischen Torsionsmoments. Eisenbahntechnische Rundsch. 2021, 10, 86–90. [Google Scholar]

- Liu, J.; Zhao, H.; Zhai, W. Mechanism of self-excited torsional vibration of locomotive driving system. Front. Mech. Eng. China 2010, 5, 465–469. [Google Scholar] [CrossRef]

- Xu, K.; Zeng, J.; Wei, L. An analysis of the self-excited torsional vibration of high-speed train drive system. J. Mech. Sci. Technol. 2019, 33, 1149–1158. [Google Scholar] [CrossRef]

- Meierhofer, A.; Simon, G.; Simunek, D.; Weber, F.J.; Six, K. Welche Worst-Case-Kraftschluss Szenarien verursachen die maximale Rollierschwingung? In Proceedings of the 18 Internationale Schienenfahrzeugtagung 2021 in Dresden, Dresden, Germany, 22 September 2021; pp. 42–43. [Google Scholar]

- Fridrichovskỳ, T.; Šulc, B. Investigation of Torsional Oscillations in Railway Vehicles. In Proceedings of the MATEC Web of Conferences in Corfu Island, Greece; EDP Sciences: Les Ulis, France, 2016; Volume 76, p. 02052. [Google Scholar]

- Körner, E. Reibschwingungen Eines Elektrischen Triebfahrzeuges an der Haftwertgrenze; TU Graz: Graz, Austria, 1988. [Google Scholar]

- Schwartz, H.J. Regelung der Radsatzdrehzahl zur maximalen Kraftschlussausnutzung bei elektrischen Triebfahrzeugen; VDI-Verlag: Düsseldorf, Germany, 1992. [Google Scholar]

- Buscher, M. Radschlupfregelung zur maximalen Kraftschlussausnutzung bei elektrischen Traktionsantrieben; Verlag Shaker: Herzogenrath, Germany, 1995. [Google Scholar]

- Trimpe, F.; Salander, C. Wheel—Rail adhesion during torsional vibration of driven railway wheelsets. Veh. Syst. Dyn. 2021, 59, 785–799. [Google Scholar] [CrossRef]

- Trimpe, F.; Lück, S.; Naumann, R.; Salander, C. Simulation of torsional vibration of driven railway wheelsets respecting the drive control response on the vibration excitation in the wheel–rail contact point. Vibration 2020, 4, 30–48. [Google Scholar] [CrossRef]

- Fathy Abouzeid, A.; Guerrero, J.M.; Endemaño, A.; Muniategui, I.; Ortega, D.; Larrazabal, I.; Briz, F. Control strategies for induction motors in railway traction applications. Energies 2020, 13, 700. [Google Scholar] [CrossRef]

- El-Refaie, A.M. Motors/generators for traction/propulsion applications: A review. IEEE Veh. Technol. Mag. 2013, 8, 90–99. [Google Scholar] [CrossRef]

- Fleischer, M.; de Doncker, R.W.; Abel, D. Traction Control for Railway Vehicles; Technical Report; Institut für Stromrichtertechnik und Elektrische Antriebe: Brighton, The Netherlands, 2019. [Google Scholar]

- Depenbrock, M. Direct self-control (DSC) of inverter fed induktion machine. In Proceedings of the 1987 IEEE Power Electronics Specialists Conference, Blacksburg, VA, USA, 21–26 June 1987; pp. 632–641. [Google Scholar]

- Buja, G.S.; Kazmierkowski, M.P. Direct torque control of PWM inverter-fed AC motors-a survey. IEEE Trans. Ind. Electron. 2004, 51, 744–757. [Google Scholar] [CrossRef]

- Spichartz, M.; Heising, C.; Staudt, V.; Steimel, A. Indirect Stator-Quantities control as benchmark for highly dynamic induction machine control in the full operating range. In Proceedings of the 14th International Power Electronics and Motion Control Conference EPE-PEMC 2010, Ohrid, North Macedonia, 6–8 September 2010; pp. T3–T13. [Google Scholar]

- Steimel, A. Direct self-control and synchronous pulse techniques for high-power traction inverters in comparison. IEEE Trans. Ind. Electron. 2004, 51, 810–820. [Google Scholar] [CrossRef]

- Abouzeid, A.F.; Guerrero, J.M.; Vicente-Makazaga, I.; Muniategui-Aspiazu, I.; Endemaño-Isasi, A.; Briz, F. Torsional Vibration Suppression in Railway Traction Drives. IEEE Access 2022, 10, 32855–32869. [Google Scholar] [CrossRef]

- Polach, O. Creep forces in simulations of traction vehicles running on adhesion limit. Wear 2005, 258, 992–1000. [Google Scholar] [CrossRef]

- Watanabe, T. Anti-slip readhesion control with presumed adhesion force-Method of presuming adhesion force and running test results of High-speed shinkansen train. Q. Rep. RTRI 2000, 41, 32–36. [Google Scholar] [CrossRef]

- Park, D.Y.; Kim, M.S.; Hwang, D.H.; Lee, J.H.; Kim, Y.J. Hybrid re-adhesion control method for traction system of high-speed railway. In Proceedings of the ICEMS’2001. Proceedings of the Fifth International Conference on Electrical Machines and Systems (IEEE Cat.No. 01EX501); Shenyang, China, 18–20 August 2001, Volume 2, pp. 739–742.

- Yamashita, M.; Soeda, T. Anti-slip re-adhesion control method for increasing the tractive force of locomotives through the early detection of wheel slip convergence. In Proceedings of the 2015 17th European conference on power electronics and applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015; pp. 1–10. [Google Scholar]

- Cheok, A.D.; Shiomi, S. Combined heuristic knowledge and limited measurement based fuzzy logic antiskid control for railway applications. IEEE Trans. Syst. Man Cybern. Part Appl. Rev. 2000, 30, 557–568. [Google Scholar] [CrossRef]

- Spiryagin, M.; Lee, K.S.; Yoo, H.H. Control system for maximum use of adhesive forces of a railway vehicle in a tractive mode. Mech. Syst. Signal Process 2008, 22, 709–720. [Google Scholar] [CrossRef]

- Ohishi, K.; Hata, T.; Sano, T.; Yasukawa, S. Realization of anti-slip/skid re-adhesion control for electric commuter train based on disturbance observer. IEEJ Trans. Electr. Electron. Eng. 2009, 4, 199–209. [Google Scholar] [CrossRef]

- Sadr, S.; Khaburi, D.A.; Rodríguez, J. Predictive slip control for electrical trains. IEEE Trans. Ind. Electron. 2016, 63, 3446–3457. [Google Scholar] [CrossRef]

- Ishrat, T.; Ledwich, G.; Vilathgamuwa, M.; Borghesani, P. Identification scheme of maximum traction force using recursive least square for traction control in electric locomotives. In Proceedings of the 2017 IEEE 12th International Conference on Power Electronics and Drive Systems (PEDS), Honolulu, HI, USA, 12–15 December 2017; pp. 1–120. [Google Scholar]

- Fang, X.; Lin, S.; Yang, Z.; Lin, F.; Sun, H.; Hu, L. Adhesion control strategy based on the wheel–rail adhesion state observation for high-speed trains. Electronics 2018, 7, 70. [Google Scholar] [CrossRef] [Green Version]

- Can, K.; Jingchun, H.; Wenqi, D.; Xiaokang, W. Adhesion control method based on optimal slip velocity searching and tracking. In Proceedings of the 2019 14th IEEE International Conference on Electronic Measurement & Instruments (ICEMI), Changsha, China, 1–3 November 2019; pp. 1200–1207. [Google Scholar]

- Trimpe, F.; Friedrich, S.; Traupe, M. Untersuchung der Gleitgeschwindigkeit während dynamischer Torsionsbelastungen von Radsatzwellen. In Proceedings of the 17 Internationale Schienenfahrzeugtagung 2020 in Dresden, Dresden, Germany, 26–28 February 2020; pp. 61–63. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abouzeid, A.F.; Trimpe, F.F.; Lück, S.; Traupe, M.; Guerrero, J.M.; Briz, F. Co-Simulation-Based Verification of Torsional Vibration Protection of Electric-Driven Railway Vehicle Wheelsets. Vibration 2022, 5, 613-627. https://doi.org/10.3390/vibration5030036

Abouzeid AF, Trimpe FF, Lück S, Traupe M, Guerrero JM, Briz F. Co-Simulation-Based Verification of Torsional Vibration Protection of Electric-Driven Railway Vehicle Wheelsets. Vibration. 2022; 5(3):613-627. https://doi.org/10.3390/vibration5030036

Chicago/Turabian StyleAbouzeid, Ahmed Fathy, Fritz Felix Trimpe, Sönke Lück, Markus Traupe, Juan Manuel Guerrero, and Fernando Briz. 2022. "Co-Simulation-Based Verification of Torsional Vibration Protection of Electric-Driven Railway Vehicle Wheelsets" Vibration 5, no. 3: 613-627. https://doi.org/10.3390/vibration5030036

APA StyleAbouzeid, A. F., Trimpe, F. F., Lück, S., Traupe, M., Guerrero, J. M., & Briz, F. (2022). Co-Simulation-Based Verification of Torsional Vibration Protection of Electric-Driven Railway Vehicle Wheelsets. Vibration, 5(3), 613-627. https://doi.org/10.3390/vibration5030036