1. Introduction

Coal, as a globally significant energy source, makes thick coal seam mining a crucial component of extraction operations. In China, thick coal seams (≥3.5 m) constitute a substantial proportion of coal reserves. Fully mechanized top-coal caving (FMTC) mining is widely employed for thick coal seams due to its high efficiency and productivity. However, during the FMTC mining of extra-thick coal seams in high-gas mines, large volumes of gas flow from the goaf, coupled with complex migration patterns, readily lead to gas concentration exceedances in the working face and return airway, and may even trigger major accidents such as gas explosions. As one of the primary sources of mine gas, the gas migration within the goaf is a complex process influenced by multiple factors, including geological conditions, mining parameters, ventilation methods, and gas drainage technologies. Therefore, in-depth research into the gas migration patterns within the goaf of FMTC faces in high-gas extra-thick coal seams is essential for ensuring safe and efficient coal mining.

Significant progress has been made in recent years by domestic and international scholars, utilizing field measurements, physical simulations, and numerical simulations, concerning the mechanisms of gas migration in goafs, influencing factors, and control techniques.

Gas migration in the goaf is jointly controlled by permeability distribution, overlying strata fractures, and the ventilation mode. Yuehan Wang et al. [

1], through CFD modeling, found that vertical borehole drainage causes uneven oxygen distribution in the goaf, with the oxygen concentration being significantly higher on the tailgate side than on the maingate side. The airflow recirculates into the boreholes via the “high-permeability flow channel” on the tailgate side. Zongyi Qin et al. [

2] indicated that gas flow in the goaf is influenced by gas emission characteristics, fracture zone height, and borehole location, with boreholes placed within the annular fracture zone exhibiting higher drainage efficiency. Jie Cao et al. [

3], using UDEC-COMSOL to simulate gas migration in fracture networks, pointed out that gas flux in the fracture zone is far higher than that found in the matrix zone, providing theoretical support for optimizing drainage processes. Jun Nian et al. [

4], focusing on gob side entry retaining with roof cutting, revealed the formation of an asymmetric “double equilibrium arch” fracture structure in the overburden, leading to significant gas accumulation in high-level fracture zones. Li Jia et al. [

5] constructed a deformation-gas pressure–temperature-coupled experimental setup to study permeability evolution during parallel borehole drainage. They discovered that permeability near the borehole declines rapidly but recovers substantially, and a noticeable drainage superposition effect occurs at a borehole spacing of 250 mm. Karacan C. Ö. [

6], analyzing data from US longwall mines, confirmed that gob gas ventholes (GGVs) effectively control gas from overlying strata fractures, with an influence radius of 330–380 m. Zunguo Zhang et al. [

7], studying the 97312 fully mechanized face in Sihe Mine No. 2, found that the sealing quality of the airtight wall in the gob side retained entry directly impacts the gas concentration within it. As the porosity of the airtight wall increases, the gas concentration at the return corner gradually decreases, while the concentration within the retained entry gradually increases.

The high-intensity mining and large residual coal volume associated with FMTC in extra-thick coal seams exacerbate gas emission and accumulation risks. Pengxiang Zhao et al. [

8] investigated the influence of pseudo-inclined length (PSL), noting that PSL induces airflow disorder and local gas accumulation. Effective control of upper corner gas concentration (≤0.46%) was achieved when PSL = 25 m and buried pipe depth = 20 m. Huaming An et al. [

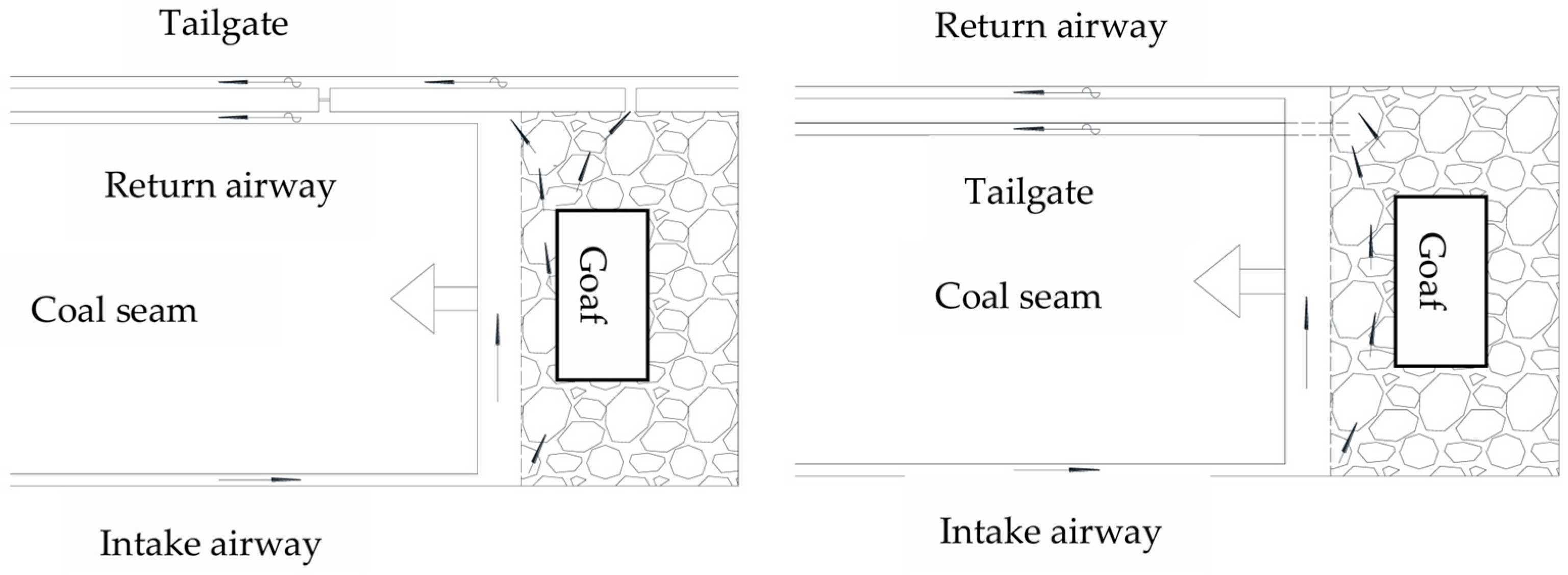

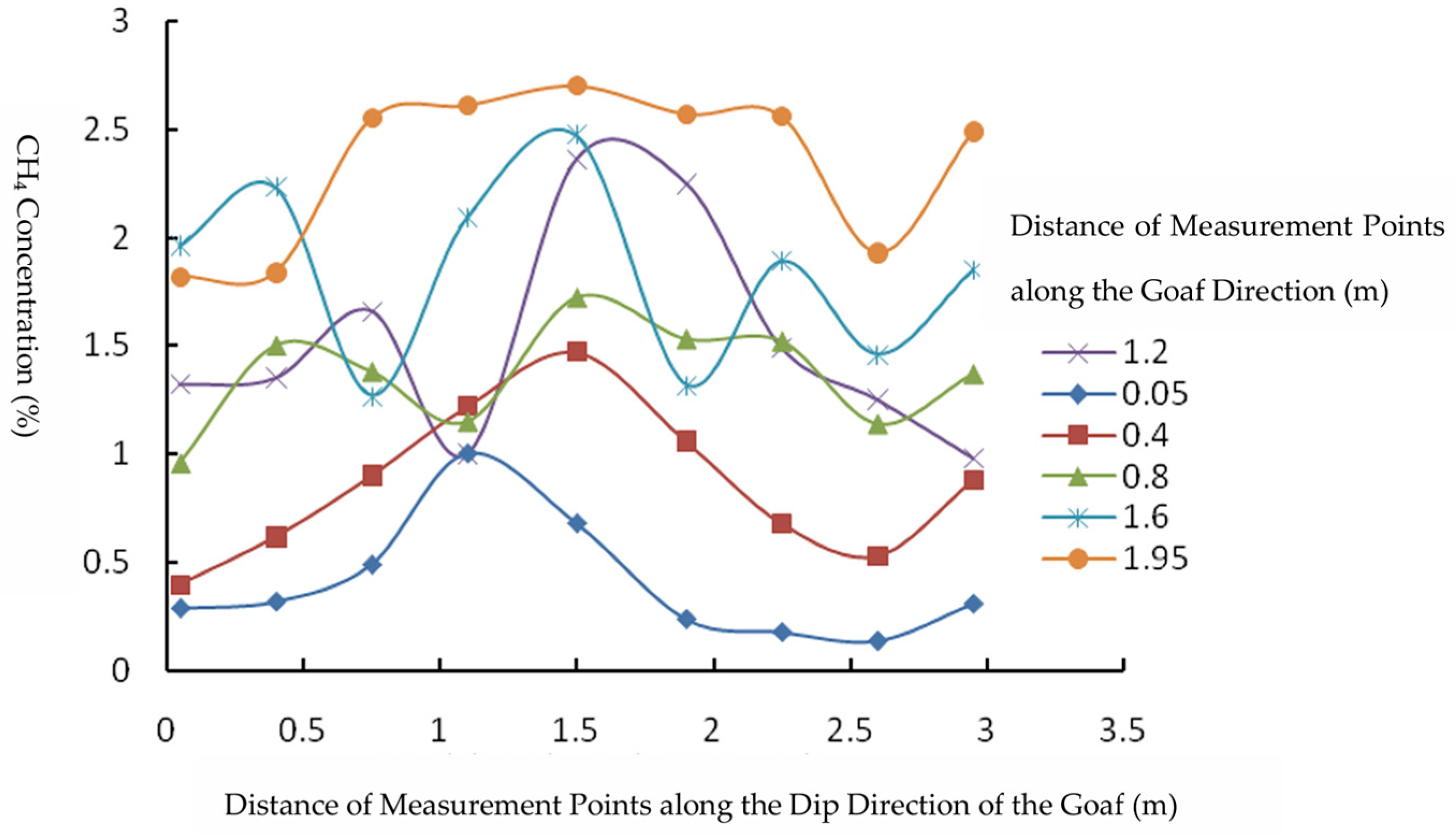

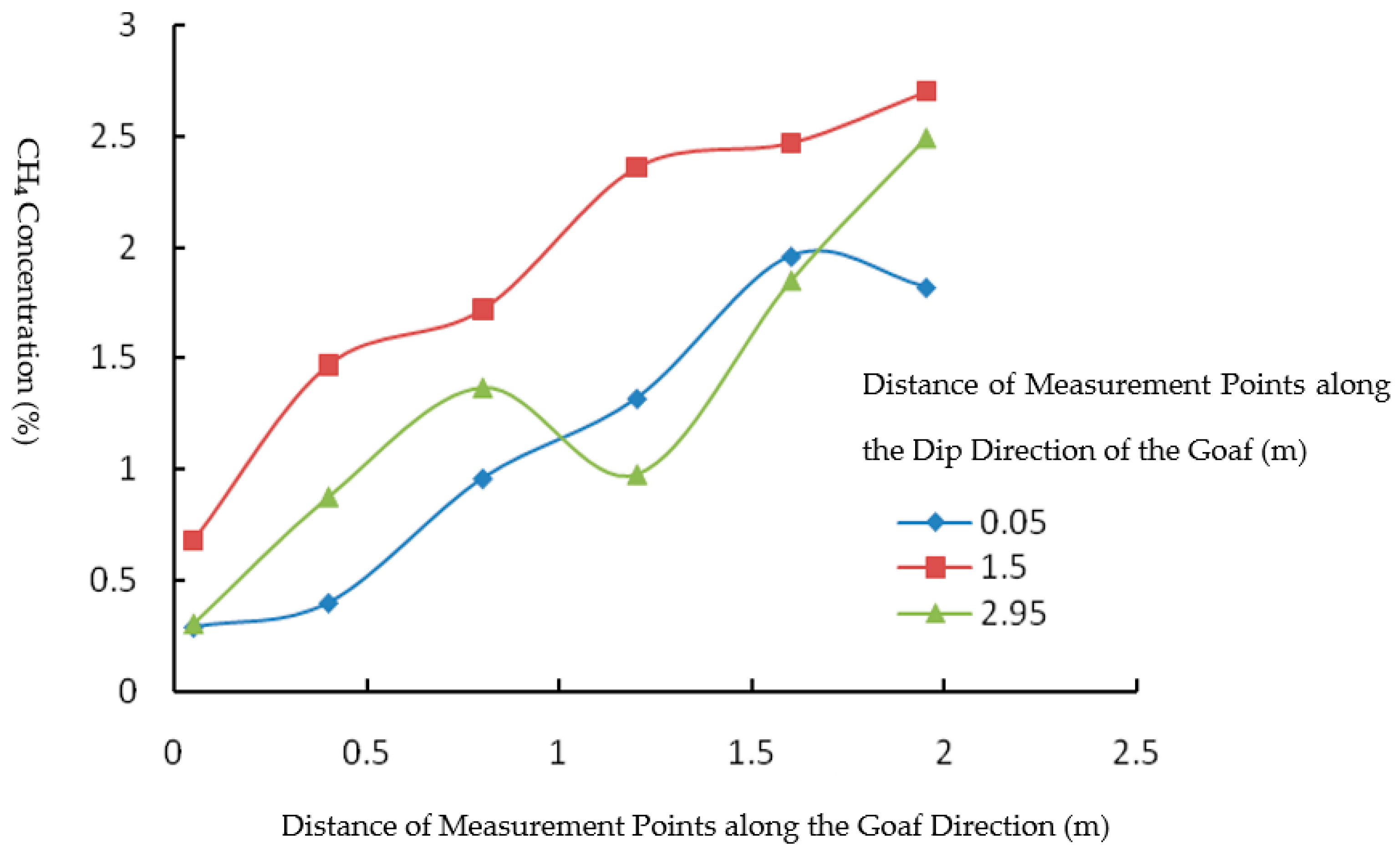

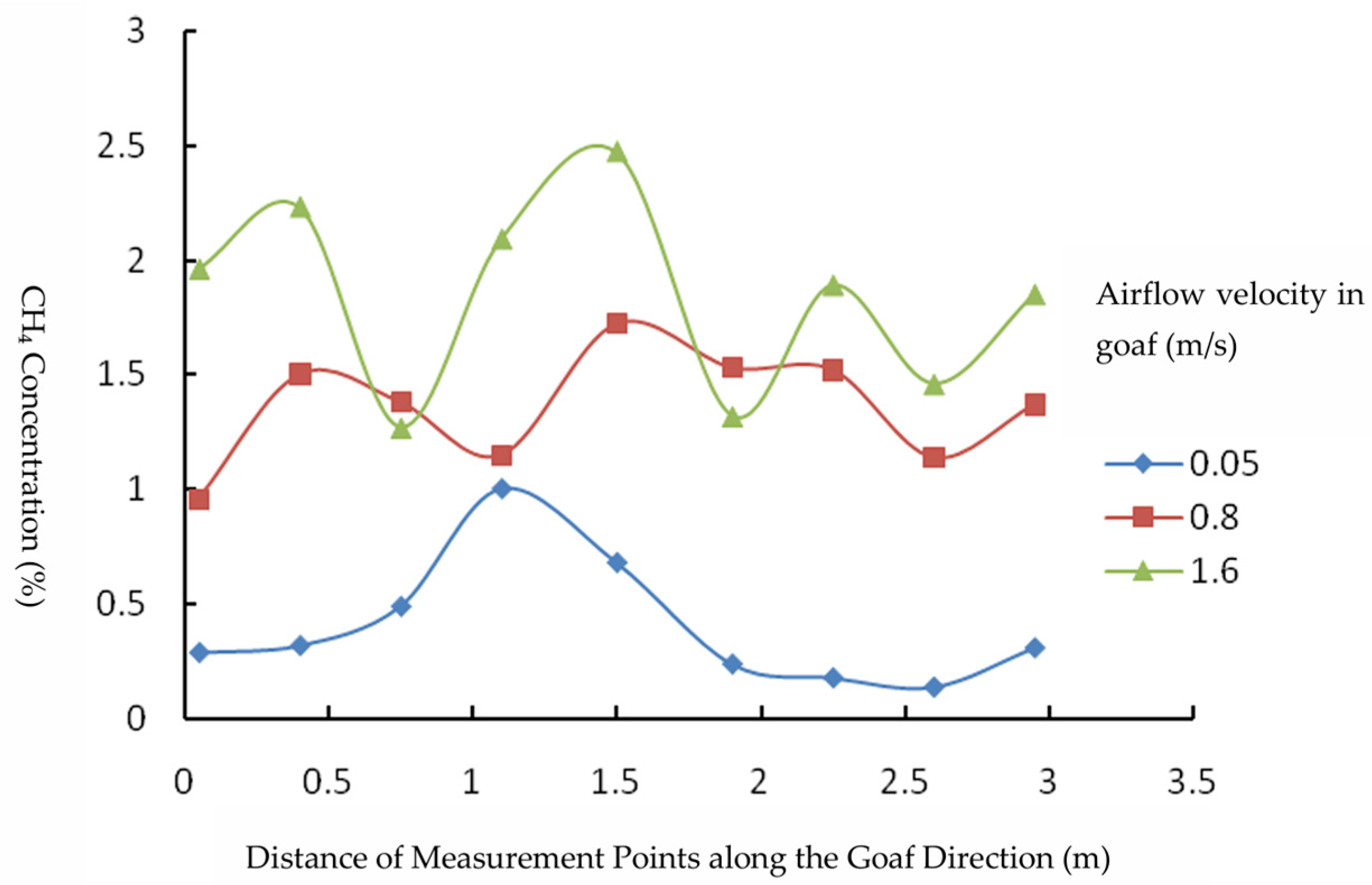

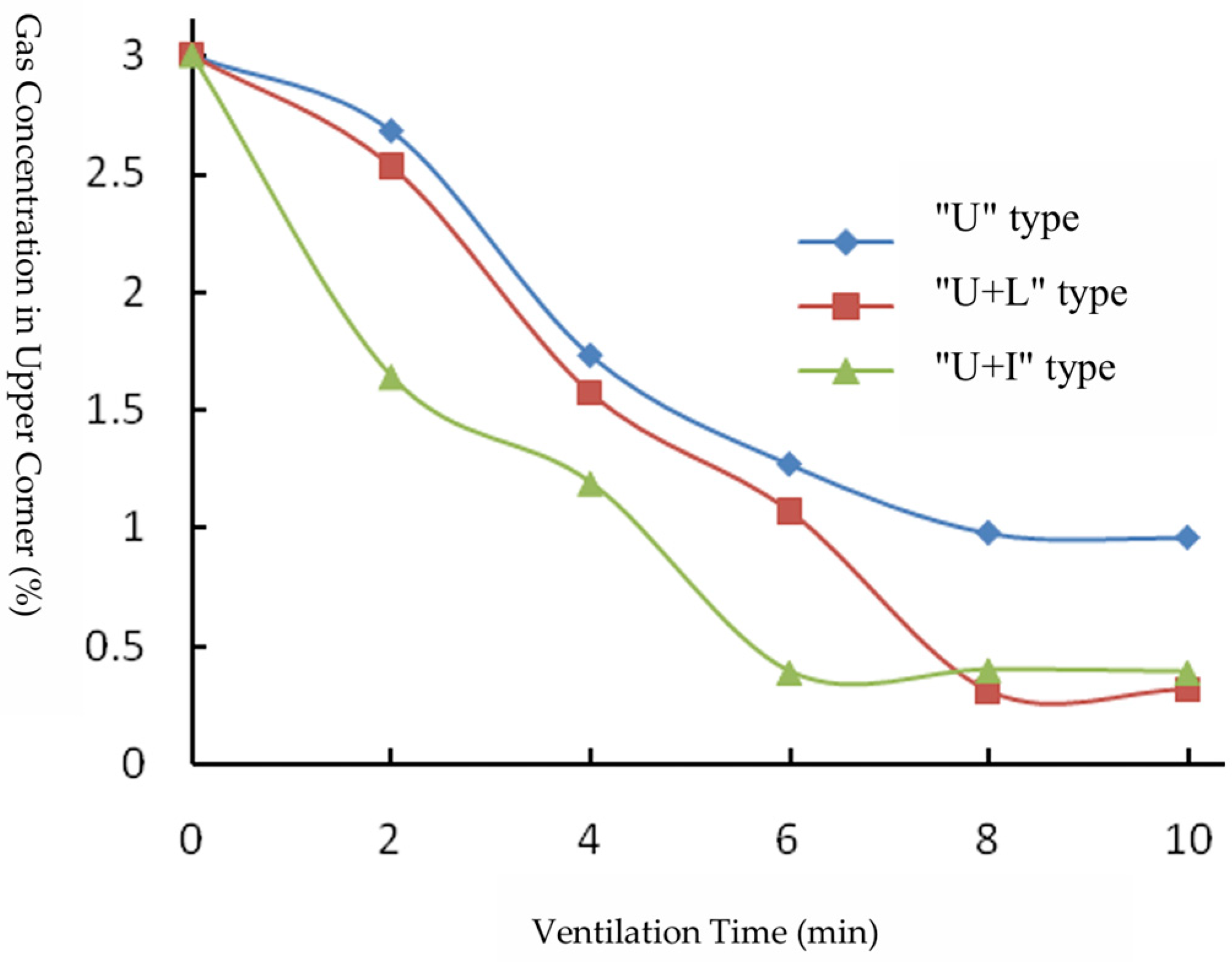

9], simulating different ventilation modes for the N2105 working face, concluded that the ventilation mode significantly affects gas seepage patterns in the goaf. U + I and U + Itype ventilation substantially reduce upper corner gas concentration. Wenlin Wang et al. [

10] demonstrated through testing that gas volume fraction along the coal wall in high-gas extra-thick coal seam faces follows an asymmetric concave curve, with absolute gas emission peaking during the first weighting. Haijun Guo et al. [

11], using the Taishan Mine in China as an example under ultra-thick seam FMTC conditions, found that lamprophyre fracturing during roof weighting significantly increases gas emission into the return airway and upper corner.

Seam dip angle, fault structures, and mining speed significantly alter gas migration pathways. Xiangtao Kang et al. [

12] found that normal faults cause active gas circulation within the mining-induced fracture field, making gas concentration more prone to accumulation at higher fault positions. Pengxiang Zhao et al. [

13] confirmed through physical simulation that an increase in the coal seam dip angle reduces the height of the “three zones,” narrowing the scope of gas migration channels. The field results showed that high-level borehole drainage efficiency reached 49.94–89.88%. Xiangjun Chen et al. [

14], via field measurements and numerical simulation, determined the optimal intake air velocity (2 m/s) and advance rate (3 m/d) for the 215101 working face in Yue Nan Mine. They identified the 0–50 m region behind the face as a strong disturbance zone and the main gas source. Dapeng Wang et al. [

15], taking Shaping Mine as an example, studied toxic gas migration in the goafs of upper and lower seams during close-distance coal seam group mining and proposed prevention and control technologies for gas accumulation at the return corner. Chuantian Li et al. [

16] proposed a spatio-temporal evolution model of the “three zones and five regions” in the overburden during the initial mining stage, emphasizing that the fracture development zone is the key area for gas drainage.

Drainage parameter design is a core strategy for controlling goaf gas. Cheng Cheng et al. [

17], using Wangjialing Mine as an example and combining physical and numerical simulation, clarified the distribution patterns of overburden fracture zone height and gas enrichment zones under mining influence. They proposed that high-level directional boreholes should be installed in the middle of the fracture zone. Kai Han et al. [

18], through microseismic monitoring, determined the overburden fracture zone height in a soft coal seam to be 70–75 m and provided optimal spatial parameters for high-level boreholes accordingly. Chong Li et al. [

19], when studying the 7607 working face in Wuyang Mine via field measurement and numerical simulation, found that high-level drainage roadway technology significantly mitigates gas exceedance. Lei Wang et al. [

20], using Fluent simulation, proposed optimal parameters for buried pipe drainage (pipe length 30 m, diameter 0.3 m, flow rate 80 m

3/min) and suggested combining high-level boreholes with upper corner drainage to reduce the concentration to below the safe threshold. Hongzhe Jia et al. [

21], for a W-type ventilation face, determined the optimal placement height for high-level directional boreholes in the roof to be 25–35 m. The post-drainage gas concentration in the return airway stabilized at 0.42–0.75%. Aitao Zhou et al. [

22], based on COMSOL simulation and field tests at the Buertai Mine 42201 face, proposed the following optimal parameters: pipe spacing 50–70 m and drainage negative pressure 12–18 kPa. Karacan C. Ö. [

23], conducting a comprehensive study for a Pocahontas No. 3 metallurgical coal longwall mine in Virginia, USA, aimed to predict gas emissions and propose mitigation strategies. They found that extending the pre-drainage time or increasing borehole density significantly reduces ventilation and goaf gas emissions. Leilin Zhang et al. [

24], optimizing buried pipe parameters for the Baode Mine 81307 face (sealed roadway spacing 100 m, suction pressure -32 kPa, pipe diameter 800 mm, flow rate 600 m

3/min), reduced upper corner gas concentration to 0.38% in field trials. Zhe Li et al. [

25] proposed a combined drainage technology using buried pipes and inserted pipes at the upper corner. Simulations showed this reduced the concentration from 1.2% to 0.6%, recommending a buried pipe length of 20 m.

CFD has become a key tool for studying gas flow in goafs. Janoszek Tomasz [

26,

27] conducted CFD simulations with field validation for Poland’s Jankowice Mine and a “short-Y-” type ventilation face, providing a basis for shearer speed control. Zhongwei Wang et al. [

28,

29] systematically simulated six mining scenarios, consistently finding methane concentration to be higher at the tailgate drum than that found at the maingate drum, with accumulated gas in the upper corner primarily originating from goaf emission. Mishra D.P. et al. [

30] performed CFD simulations of methane layer diffusion in the tailgate of a retreating longwall face at an Indian underground mine, based on methane emission rates. The results indicated that an air velocity ≥3.0 m/s effectively reduces tailgate methane concentration. Gang Wang et al. [

31] quantified goaf porosity distribution using a DEM-CFD-coupled model, identifying the most significant air leakage flow field within 0–10 m along the dip direction. Xu Zheng et al. [

32] simulated gas distribution under different ventilation modes using a DEM-CFD model, proposing that 3D gas drainage technology effectively controls roadway gas accumulation. Jinzhao Liu et al. [

33] established a “Z-type” ventilation DEM-CFD model, dividing the goaf into a strong air leakage zone (0–10 m) and a weak disturbance zone (45–190 m), providing a basis for seal design. Shuailong Feng et al. [

34], using Fluent to simulate airflow patterns in the working face and goaf of the Chengjiao Mine 21304 test face, concluded that the leakage patterns differ significantly from those of traditional longwall mining.

Despite the progress made in gas control, high-gas thick coal seams during mining, influenced by fully mechanized top-coal caving techniques, face challenges such as long preparation times, fast advancement speeds, and high gas emissions, leading to frequent gas overruns at the working face, upper corner, and gob area. Due to the complexity of fully mechanized top-coal caving techniques, once operational parameters are set, they are difficult to change. On-site conditions are complex, and real-time monitoring of airflow and gas distribution migration is challenging, hazardous, costly, and lacks repeatability. On-site studies often focus on single ventilation modes or specific conditions, lacking systematic comparisons of gas migration patterns under multiple ventilation modes. Experimental simulation studies, by adjusting the experimental platform structure and parameters, can address the shortcomings of on-site research, providing a robust framework for systematically studying airflow and gas migration patterns in the gob area of the working face. Therefore, conducting experimental studies offers theoretical foundations and technical support for optimizing fully mechanized top-coal caving process parameters and improving gas control effectiveness.

This study utilizes similarity principles and Darcy’s law for porous media seepage to derive similarity criteria for simulating gas migration patterns in the gob area of a fully mechanized top-coal caving face. Using a specific coal mine as a prototype, a similarity model experimental platform was designed and constructed to enable adjustments to ventilation modes, working face airflow velocity, and gas emission rates in the gob area. Experimental studies were conducted on airflow movement, gas migration, and changes in gas concentration at the upper corner under the “U,” “U + L”, and “U + I” ventilation modes at different airflow velocities.

2. Materials and Methods

2.1. Similarity Principles

Using the similarity principle, similarity criteria were derived to guide the construction of an experimental platform for simulating airflow and gas migration patterns in the gob under “U,” “U + L,” and “U + I” ventilation modes, ensuring that the model results accurately reflect actual field conditions.

Under specific conditions, if the similarity model of the prototype can comprehensively reproduce the prototype’s dynamics, these conditions are referred to as similarity conditions. In the model of gas migration in the gob of a mining face, these conditions include geometric similarity, kinematic similarity, and dynamic similarity as fundamental requirements.

- (1)

Geometric Similarity

Geometric similarity requires that the ratios of corresponding lengths between objects in the two systems under study are identical. These ratios are referred to as the length similarity ratio. Let

,

, and

represent certain length parameters in the prototype, and

,

, and

represent the corresponding parameters in the model. The similarity ratios are defined as:

where

denotes the ratio of a value in the model to the corresponding value in the prototype.

For strict geometric similarity, the following condition must hold:

where

represents any arbitrary length dimension.

Consequently, the area similarity ratio

between the two systems is:

The volume similarity ratio

is:

Geometric similarity ensures that the experimental platform model proportionally replicates the spatial structure of the gob and working face, providing accurate geometric boundaries for simulating gas migration under “U,” “U + L,” and “U + I” ventilation modes.

- (2)

Kinematic Similarity

Kinematic similarity presupposes geometric similarity. The steady-state flow vector relationships in the model and prototype flow fields must be geometrically similar, and the trajectories of unsteady flows should also be geometrically similar. In simple terms, kinematic similarity means that the motion paths at corresponding points in the model and prototype are geometrically similar, and the ratio of the time taken to traverse corresponding paths is constant. This is expressed as:

Since , it follows that the time similarity ratio is .

However, in a deformable model, the length similarity ratio

varies with direction. As a result, the velocity similarity ratio also varies with the direction of flow, expressed as:

Kinematic similarity ensures that the motion paths of airflow and gas in the experimental platform model are consistent with those in the prototype gob, facilitating the analysis of gas concentration distribution patterns under different ventilation modes.

- (3)

Dynamic Similarity

Dynamic similarity requires both geometric and kinematic similarity. For two dynamically similar systems, the forces acting at corresponding points must have equal similarity ratios and act in the same direction. These forces include gravity, pressure, friction, inertial forces, elastic forces, and surface tension. The force similarity ratio is given by:

Dynamic similarity ensures that the force characteristics (e.g., pressure, viscous forces) of airflow and gas in the model are consistent with those in the prototype gob, providing a mechanical basis for studying the impact of ventilation modes on gas migration.

2.2. Dimensional Analysis

Gas migration in the gob is influenced by the seepage characteristics of porous media and ventilation modes. Dimensional analysis quantifies similarity conditions through dimensionless numbers (e.g., Froude number, Euler number), ensuring that the experimental platform model accurately replicates the gas flow patterns under “U,” “U + L,” and “U + I” ventilation modes.

In theory, any fluid flow can be uniquely determined by the fundamental differential equations governing the flow and their corresponding boundary conditions. For two flow phenomena to be similar, their differential equations must be identical, ensuring that they adhere to the same objective laws. Additionally, to obtain a specific solution for a particular flow, the uniqueness conditions—such as internal boundary conditions, external boundary conditions, and initial conditions—must also be similar. Therefore, in fluid mechanics problems involving six forces—gravity (), pressure (), viscous force (), inertial force (), elastic force (), and surface tension ()—and for satisfying dynamic similarity, five dimensionless numbers must be introduced. These are defined as follows:

- (1)

Froude Number: The ratio of inertial force to gravity:

- (2)

Euler Number: The ratio of inertial force to the pressure (or pressure gradient) force:

- (3)

Reynolds Number: The ratio of inertial force to viscous force:

- (4)

Mach Number: The ratio of inertial force to elastic force:

- (5)

Weber Number: The ratio of inertial force to surface tension:

In the equation, represents gravitational acceleration, m/s2; denotes density, kg/m3; indicates fluid velocity, m/s; is the viscosity coefficient, kg/(m·s); represents surface tension, N/m; is the elastic coefficient; and is the characteristic length, m.

2.3. Derivation of Similarity Criteria

The five dimensionless numbers— (Froude number), (Euler number), (Reynolds number), (Mach number), and (Weber number)—serve as the basis for determining whether two phenomena are similar and are referred to as similarity criteria or similarity conditions. Therefore, in similarity simulation studies, it is sufficient to ensure that the conditions playing a decisive role in the process satisfy the similarity principles.

The similarity criteria are derived using a two-dimensional mathematical model of gas migration in porous media. The gas flow in the gob area satisfies the extended Darcy’s law, yielding the continuity equation and momentum differential equations [

35]. These equations are expressed as:

where

, : velocities in the and directions, respectively, in m/s;

δ: porosity of the gob area;

: kinematic viscosity of the fluid, in m2/s;

: fluid density, in kg/m3;

: fluid pressure, in Pa;

F: inertial coefficient of the fluid in the porous medium;

K: permeability of the gob area, in m2;

: a defined average particle diameter, in .

To determine the scaling ratios, the subscript

denotes the model, and

denotes the ratio of model variables and constants to their corresponding prototype values. These are defined as:

Substituting Equation (17) into Equations (13)–(15) and simplifying yields:

According to the requirement that the prototype and model equations should be identical or proportional, comparing the continuity equation shows that

, comparing the corresponding momentum and energy equations for the prototype and model, and expanding the coefficients of the diffusion terms in the energy equation. Therefore, the following proportional relationships are obtained:

If the physical properties of the fluid and porous medium in the model and prototype are similar, and the temperature variation is small, it can be approximated that

= 1,

= 1. The average particle diameter ratio

and porosity ratio

are known (accurately obtainable during the experimental setup). Thus, the relationships become:

Since achieving complete model similarity is challenging, the design of the experimental platform does not consider criteria with minor impacts. Specifically, the momentum equation neglects the diffusion term and satisfies similarity only for the Darcy and convective terms. Substituting Equation (17) into Equation (22) and simplifying yields:

Given that the porosity is small and the porosity of the model is close to that of the prototype, it can be approximated that

. Thus, Equation (23) further simplifies to:

This leaves five scaling factors: , , , , and , with only one independent relationship. Apart from the special constraint, = 1, there are three freely selectable variables: , , and . The velocity ratio can then be determined from the above independent relationship. In this study, the values are chosen as = 1:100, ≈ 1:30, and ≈ 2:1, which satisfy the requirements. The experimental results confirm that the platform constructed based on the similarity principle effectively simulates the airflow patterns in the mining face under actual “U,” “U + L,” and “U + I” ventilation modes.

4. Experimental Scheme for the Similarity Model of the Working Face and Gob Area

Due to the complex geological conditions of coal seams and significant variations in the physicochemical properties of coal, combined with diverse mining techniques, each fully mechanized top-coal caving face and its associated gob area exhibits unique process parameters and characteristics. Factors such as the intensity of air leakage at the actual working face, the amount of residual coal in the gob area, the desorbable gas content of the residual coal, and the porosity of the collapsed coal and rock in the gob area vary significantly. Consequently, it is impossible to fully replicate every detail of the production environment in a simulation experiment. Therefore, a simplified approach is adopted to simulate the distribution and migration patterns of gas in the gob area. In this experiment, a CH4 supply system is established to simulate gas in the gob area, with gas release rates adjusted via a flow control valve. Airflow generated by a fan is used to simulate ventilation at the fully mechanized top-coal caving face. Pre-installed measurement tubes within the experimental platform enable the measurement of airflow and gas under various operating conditions. The experiments include the measurement of CH4 concentration distribution and its migration patterns in the gob area of the working face, real-time monitoring of ventilation airflow in the gob area, and the control of boundary conditions such as ventilation mode, airflow velocity at the working face, and CH4 release rates in the gob area.

4.1. Auxiliary Systems of the Experimental Model

- (1)

CH4 Supply System Description

In this experiment, gas is introduced into the gob area through a supply pipeline in a controlled proportion. By varying the ventilation mode and airflow velocity at the working face, the airflow movement and CH4 concentration distribution in the gob area are observed in order to study the gas migration patterns.

Given the flammable and explosive nature of CH4 gas, strict control of CH4 concentration is maintained during the experiment, with comprehensive preparations to ensure safety. Firstly, a ventilation duct is installed at the outlet of the fan to direct the airflow outdoors. Additionally, an exhaust system is implemented to promptly replace the indoor air and reduce the CH4 concentration, ensuring that the CH4 concentration in the gob area of the experimental platform remains well below the lower explosive limit. This setup, while neglecting the influence of other factors on CH4 concentration, guarantees the accuracy and precision of the measurements. The gas is stored in specialized steel cylinders, with a dedicated pressure-reducing valve and flow meter installed at the outlet to monitor flow rates in real time and stabilize the gas flow.

The experimental platform utilizes φ16 mm PVC pipes as the tracer gas supply source. To ensure uniform gas distribution and minimize simulation errors, seven PVC pipes are strategically arranged within the model as follows: one pipe is placed at the working face (designated as No. 1), one in Zone I (No. 2), one in Zone II (No. 4), two in Zone III (Nos. 6 and 7), one in the transition zone between Zones I and II (No. 3), and one in the transition zone between Zones II and III (No. 5). Each pipe is uniformly perforated with four φ2 mm holes spaced every 10 mm along its length to serve as gas supply points. To account for the varying gas desorption patterns in the gob area, flow control valves are installed on each supply pipeline, enabling precise control of gas flow activation and adjustment, with flow rates ranging from 0 to 1 L/min.

- (2)

Ventilation System Description

The experimental model utilizes organic glass tubes as the intake airway, return airway, and gas drainage airway. Two axial flow fans, model SFG2-2R, manufactured by Shanghai Yulong Mechanical and Electrical Manufacturing Co., Ltd., Wenling Branch (Taizhou, China), with an airflow capacity of 1300 m3/h, serve as the power source for the model’s ventilation system.

In the experimental platform for the “U,” “U + L,” and “U + I” ventilation mining fields, the return airway or the combined return and gas drainage airway employs negative pressure ventilation to drive the airflow throughout the mining field. By controlling the ball valve at the air outlet, the airflow velocity can be continuously adjusted between 0 and 5 m/s, ensuring that the airflow velocity within the working face varies between 0 and 4 m/s. Airflow measurement is conducted using the total pressure method, with dynamic pressure measured using a micro-manometer, and the airflow velocity calculated based on the dynamic pressure–velocity relationship formula. The ventilation system and CH

4 supply system are shown in

Figure 4.

- (3)

Airtightness of the Experimental Platform

Studying the migration patterns of gases (air or methane) within the experimental platform requires extremely high airtightness, as even minor errors in measurement parameters can affect the reliability and accuracy of the experimental results. To minimize gas leakage, the baseplate, top plate, working face, and gob area of the experimental platform model are all made of impermeable acrylic glass. These structures are sealed with sealant in addition to mechanical connections. The intake and return air ducts, as well as the tailgate duct, are made of impermeable acrylic tubes, while the gas supply pipes and measurement points are constructed using impermeable PVC pipes, with all connections to the model body properly sealed. The ventilation ducts, tailgate ducts, gas supply pipes, and other pipelines connected to the external environment are equipped with sealed valves, which serve both to control flow and ensure airtightness. The measurement points within the model are connected to the top cover plate through drilled holes, which can be covered with transparent adhesive tape. During measurements, the tape covering the side holes is removed, reducing air leakage through these holes.

4.2. Arrangement of Measurement Points

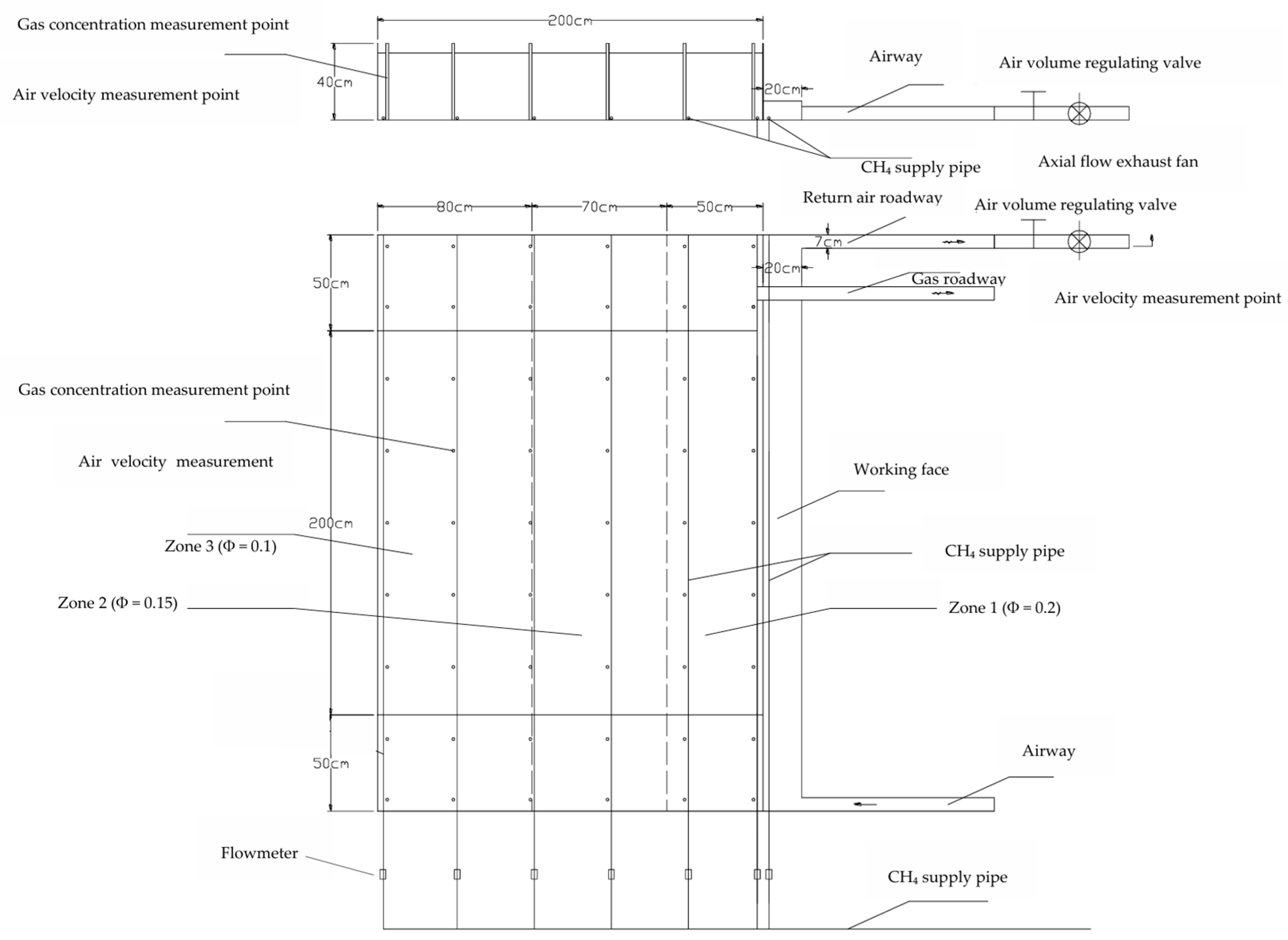

Based on the structure of the ventilation system in the gob area of the fully mechanized top-coal caving face, as well as the influence of airflow velocity on gas concentration at the working face and upper corner, and in accordance with the configuration of the similarity model, measurement points are strategically placed within the working face and gob area model. Four measurement points are selected at the working face, intake and return airways, and gas drainage airway to measure airflow velocity. Inside the gob area model, six rows of measurement points are evenly arranged along the strike direction, with nine points uniformly distributed in each row along the dip direction, resulting in a total of 54 measurement points for monitoring airflow velocity and gas concentration. The specific arrangement of these measurement points is shown in

Figure 2.

4.3. Experimental Scheme

The experimental platform was used to conduct a similarity simulation study on the airflow leakage and methane concentration variation patterns in the gob area of the working face under the “U,” ”U + L,” and “U + I” ventilation modes. The steps are as follows:

- (1)

CH4 Supply to the Gob Area: The gob area is supplied with CH4 gas uniformly to simulate the gas accumulation in an actual gob area. The supply method involves simultaneously opening all CH4 gas supply pipelines for a unified overall supply, adhering to the similarity ratio of the gas source term in the similarity model.

- (2)

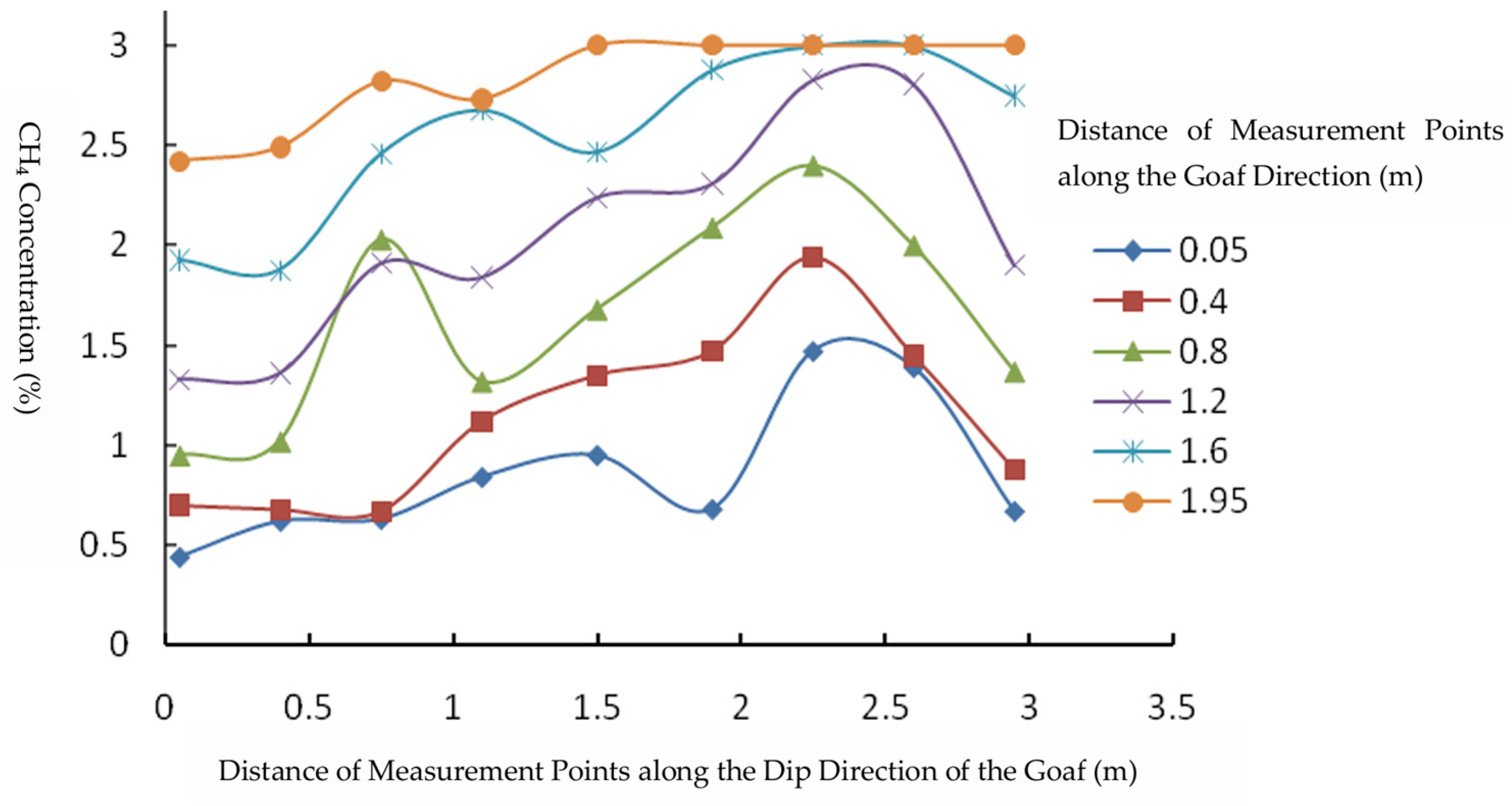

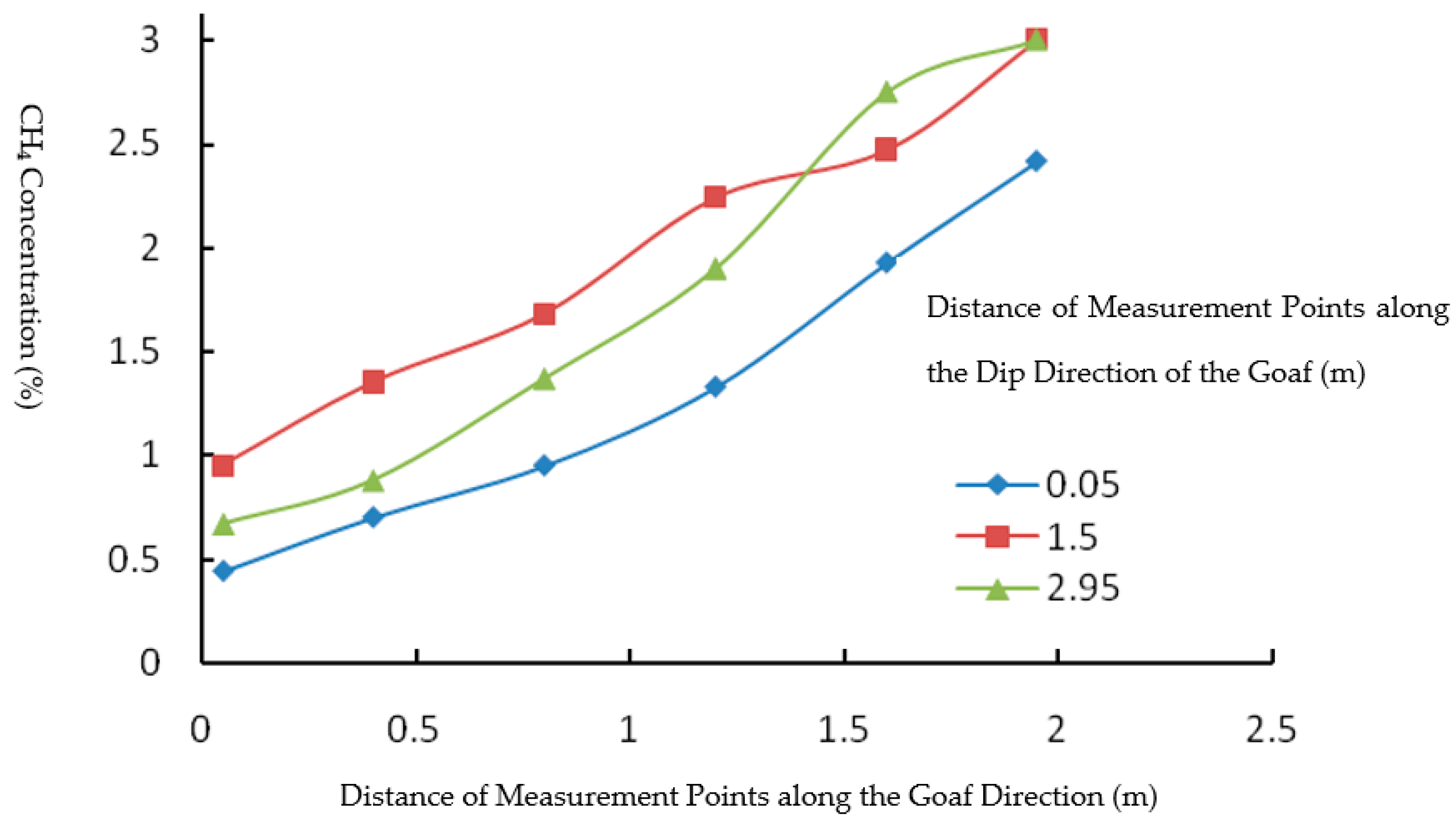

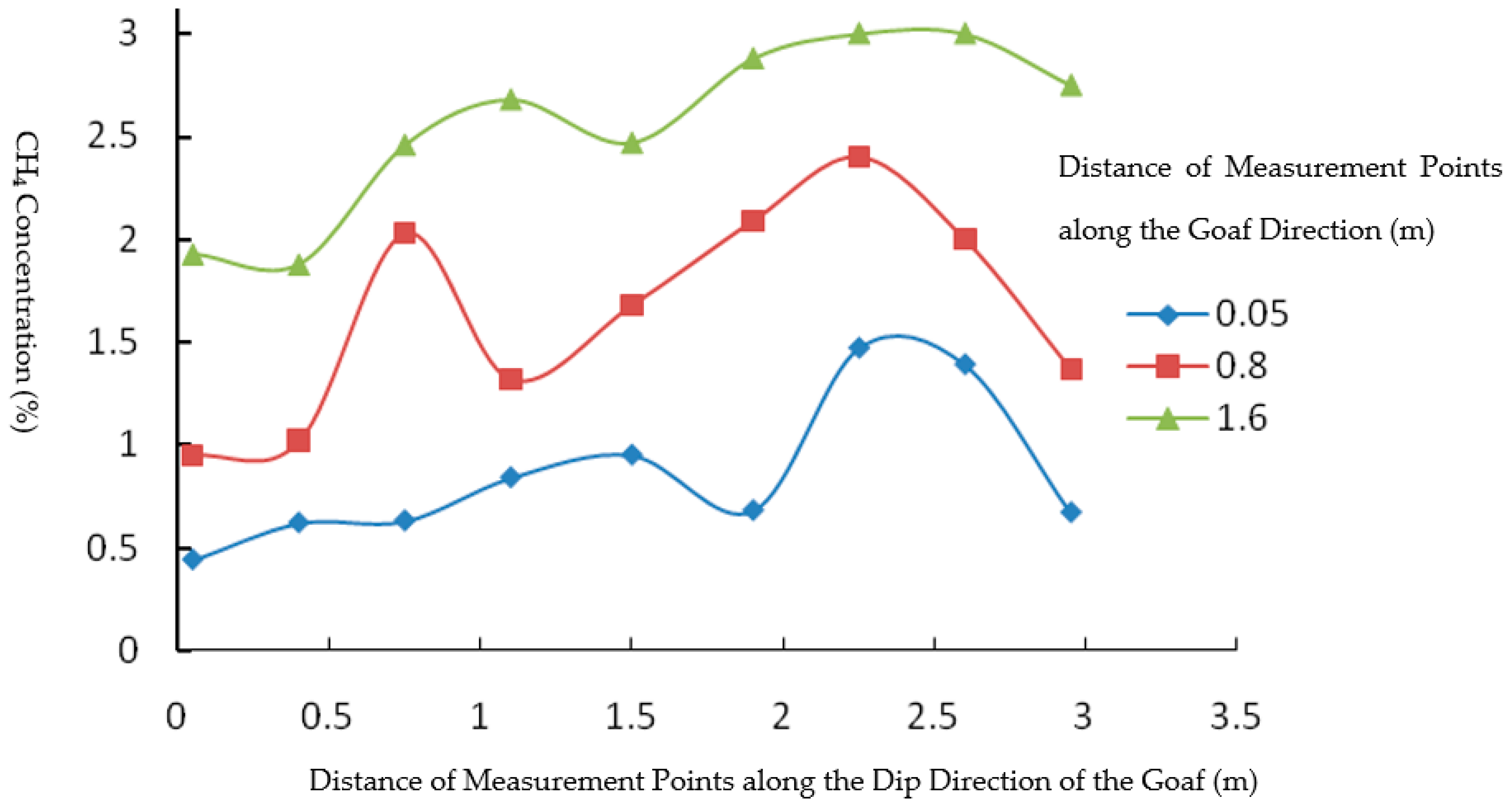

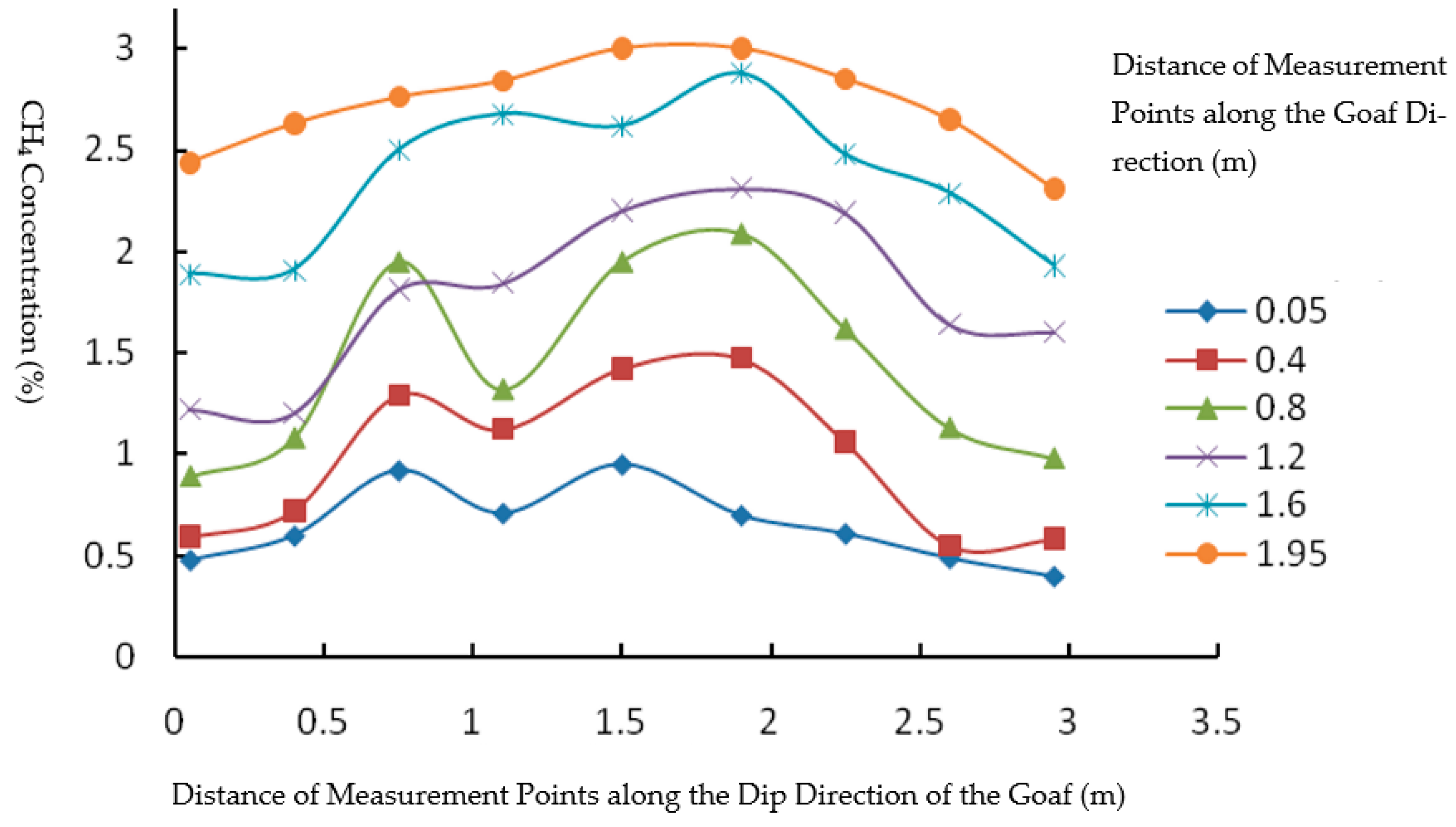

CH4 Concentration Determination: Due to variations in gas occurrence conditions, coal recovery rates, mining progress, and airflow velocities across different mines, the gas concentration distribution in the gob area and the “three zones” (heat dissipation zone, oxidation zone, and suffocation zone) differs. As the purpose of this experiment is to determine the gas migration patterns at different locations within the gob area, the CH4 concentration is selected to reflect its migration patterns in the simulated space, set at 3%. In the deep gob area of actual mines, oxygen is scarce, and the voids are primarily filled with gas, potentially reaching concentrations as high as 100%, largely unaffected by the working face advance rate or airflow velocity. Therefore, the CH4 concentration in Zone 3 is used as a reference to simulate the gas concentration in the suffocation zone.

- (3)

CH4 Concentration Supply and Adjustment: Under the conditions set in (1), CH4 concentration is supplied, and a methane detector is used to measure CH4 concentrations at the sampling points designed on the experimental platform. Once the concentration reaches 3%, the flow regulation devices on each supply pipeline are adjusted to ensure uniform flow rates across all pipelines. The gas release rate in the experimental model is scaled proportionally to the actual gas release rate in the gob area, simulating the continuous gas release process in the gob area.

- (4)

Airflow Velocity Variation and Measurements: By adjusting the airflow regulation valve in the return airway, the airflow velocity at the working face is varied within the range of 0–4 m/s. Tests are conducted in ascending order of airflow velocity to investigate the following: (a) the temporal variation of gas concentration in each zone, (b) the variation of gas concentration with airflow velocity, and (c) the spatial variation of gas concentration from Zone 1 to Zone 3. This examines the influence of airflow at the working face on gas distribution and migration patterns in the gob area.

Since air leakage occurs in both actual mine gob areas and the experimental model, only the actual CH

4 supply rate in the model is considered, neglecting the impact of air leakage in the experimental platform. In the similarity model, gas released from residual coal and surrounding rock fracture zones is simulated through supply pipelines installed at the base of the experimental platform. The experimental parameters are shown in

Table 2.

The CH4 supply rates for each zone are determined according to the similarity ratio of gas release rates between the model and the prototype. By adjusting the control valves on pipelines Nos. 1, 2, and 3, the CH4 supply rate for Zone I is set at 1.5 L/min; by adjusting the control valves on pipelines Nos. 4 and 5, the CH4 supply rate for Zone II is set at 1.0 L/min; and by adjusting the control valves on pipelines Nos. 6 and 7, the CH4 supply rate for Zone III is set at 0.6 L/min. To mitigate the randomness of CH4 concentration measurements, multiple sets of experiments are conducted for comparison. The experiment is considered repeatable if the CH4 concentration errors at all measurement points do not exceed 10%.

- 2.

CH4 Concentration Measurement

To determine the concentration distribution and migration patterns of CH4 in the gob area of the working face, measurements of CH4 concentration variations within the gob area are conducted to simulate the gas movement process in a porous medium. The gas in the gob area is influenced by multiple factors, including the following: gas release from residual coal, gas inflow from the surrounding rock and adjacent layers, the occurrence conditions of the coal seam roof, the particle size and porosity of collapsed coal and rock, the intensity of air leakage in the gob area, and the process parameters of the working face mining operations. Accurately describing the distribution of gas sources is highly challenging due to these factors. Therefore, in this experiment, the gas source in the gob area of the working face is simplified, assuming that all gas in the gob area originates from residual coal and is supplied through the gas supply pipelines. Based on the experimental requirements, six rows of measurement points are evenly arranged along the strike direction of the gob area, with nine CH4 concentration measurement points per row. The CH4 concentration at each measurement point is detected using a methane detector, and the measurement data are recorded on site.

- 3.

Flow Field Measurement

Initially, the “U” ventilation mode is employed, and a ventilation experiment is conducted on the gob area model of the working face using negative pressure extraction. The airflow velocity is measured using micro-pressure differential devices installed in the return airway and gas drainage airway. The airflow velocity in the mining field is controlled by adjusting the airflow regulation valve according to pre-specified parameter values. The CH4 concentration at each measurement point is measured using a methane detector. During the ventilation process, CH4 concentrations at each measurement point are recorded at specified time intervals, and all data are documented.

- 4.

Boundary Conditions Measurement

Boundary conditions are critical for similarity simulation experiments, as accurate and realistic boundary conditions are fundamental to ensuring the reliability of the experimental results. In this similarity simulation experiment, the required boundary conditions include the ventilation mode of the working face, the airflow velocity at the working face, and the CH4 release rate in the gob area of the working face.