Synergistic Enhancement of Fire Retardancy and Mechanical Performance in Silicone Foams Using Halogen-Free Fillers

Abstract

1. Introduction

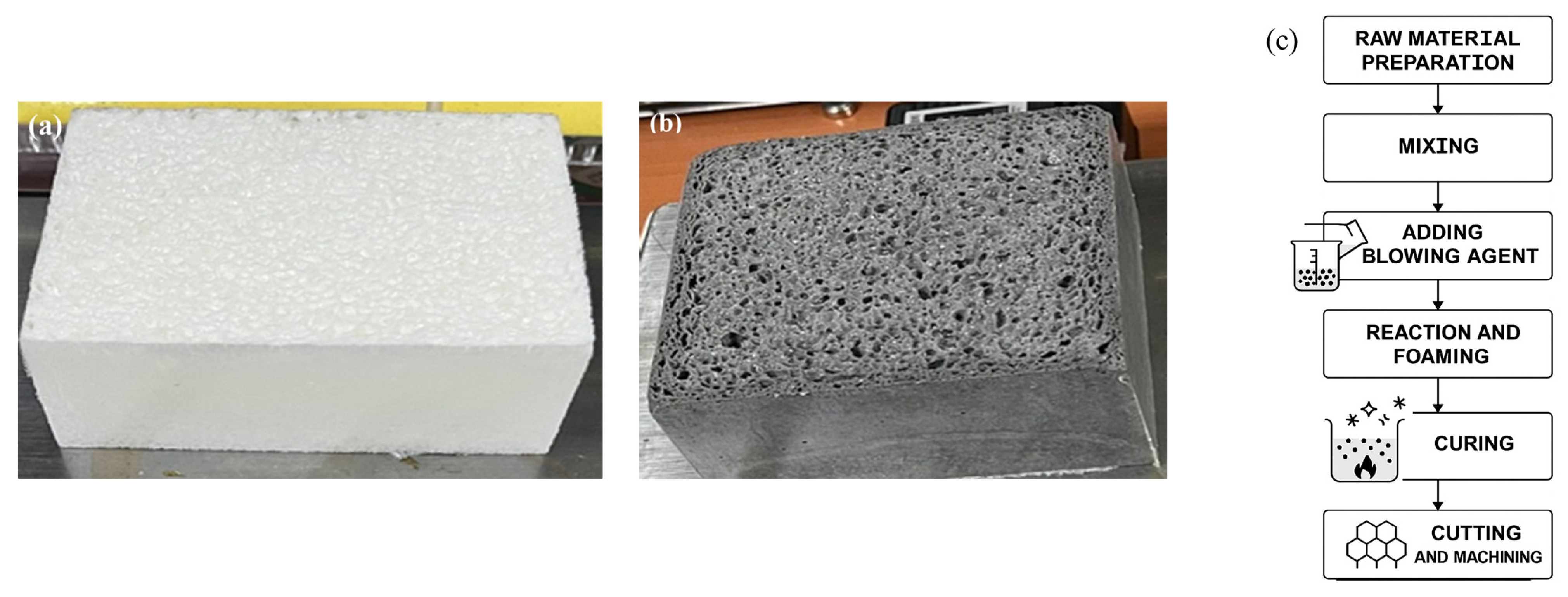

2. Materials and Methods

2.1. Materials

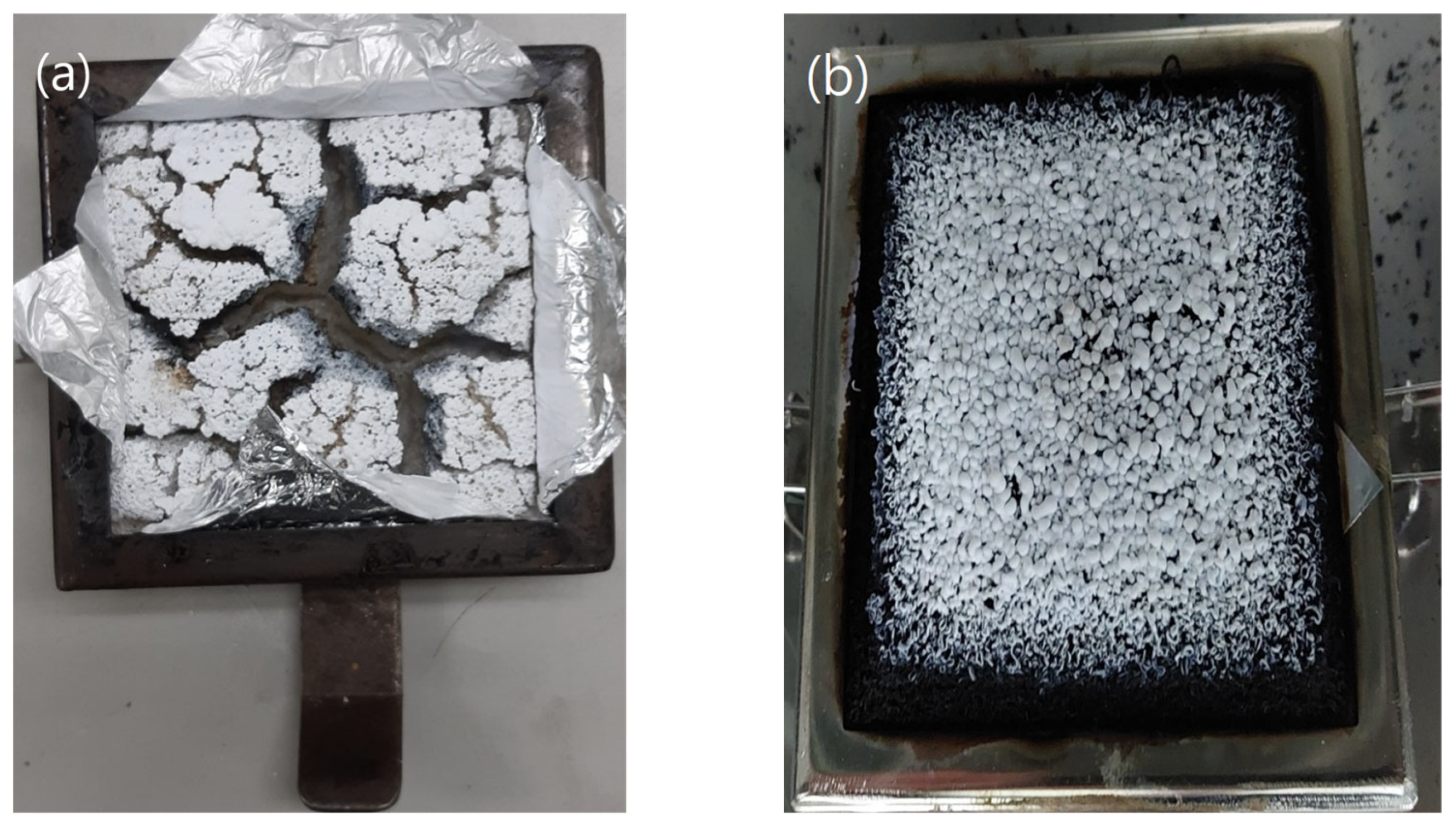

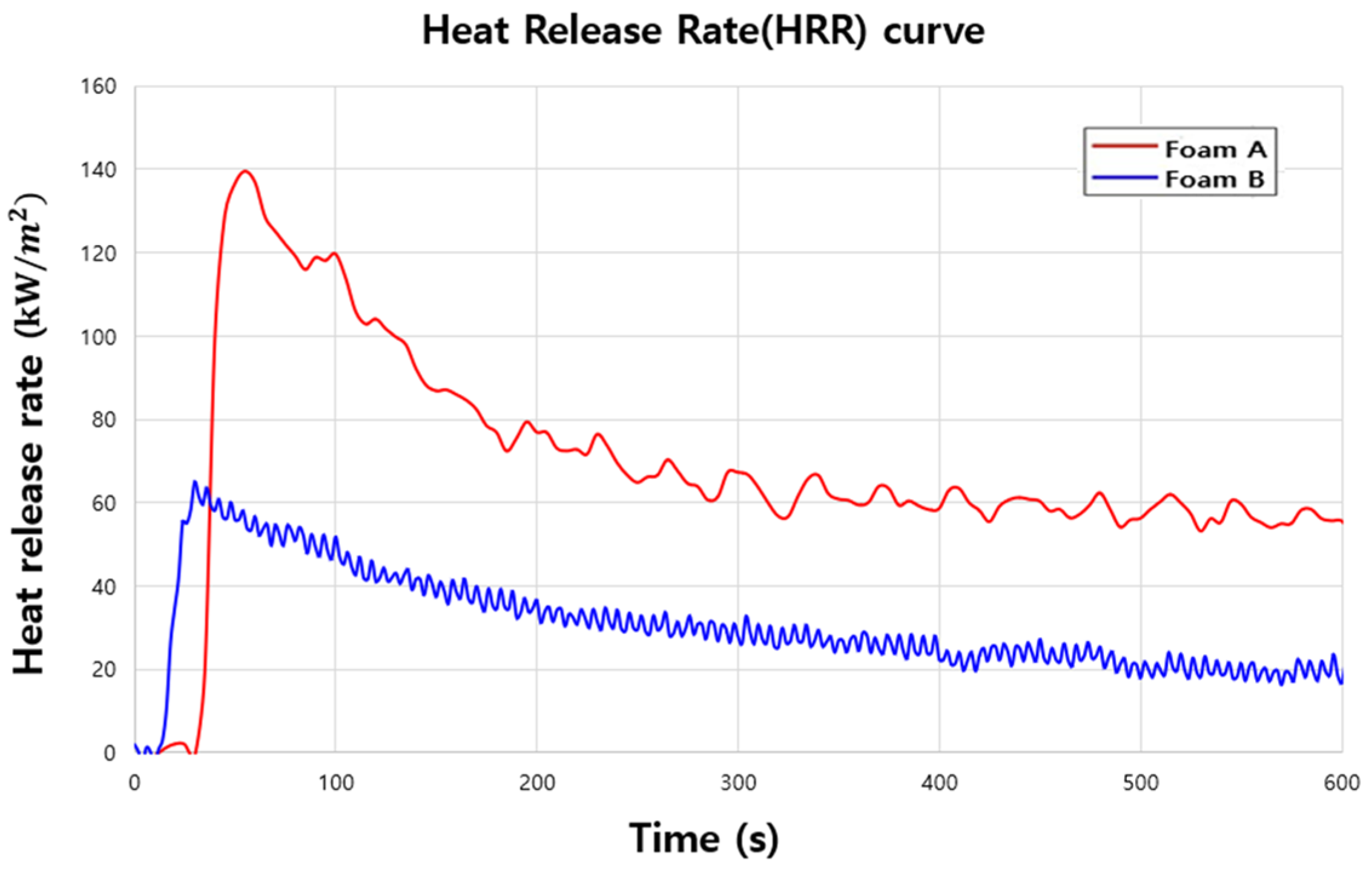

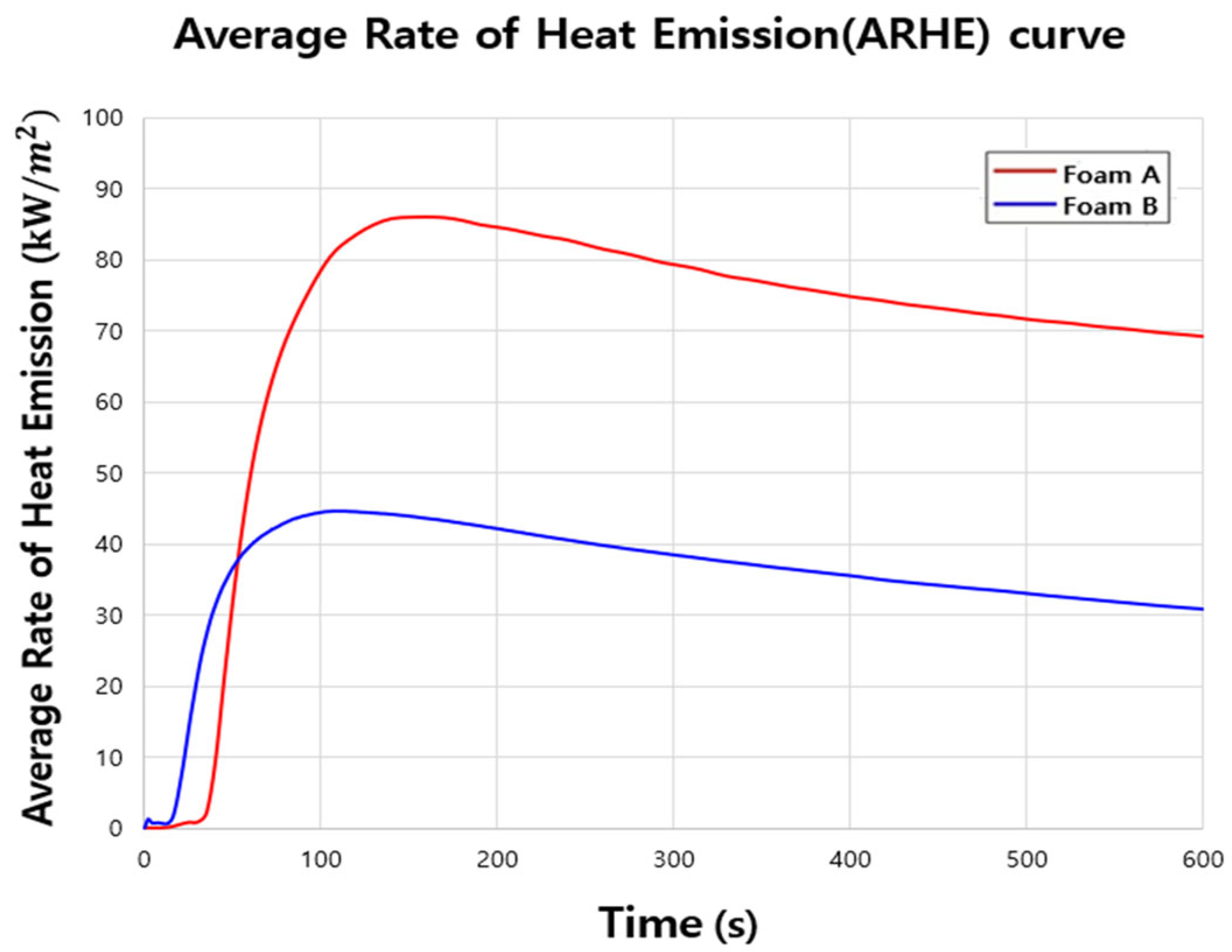

2.2. Flame-Retardant Characteristics

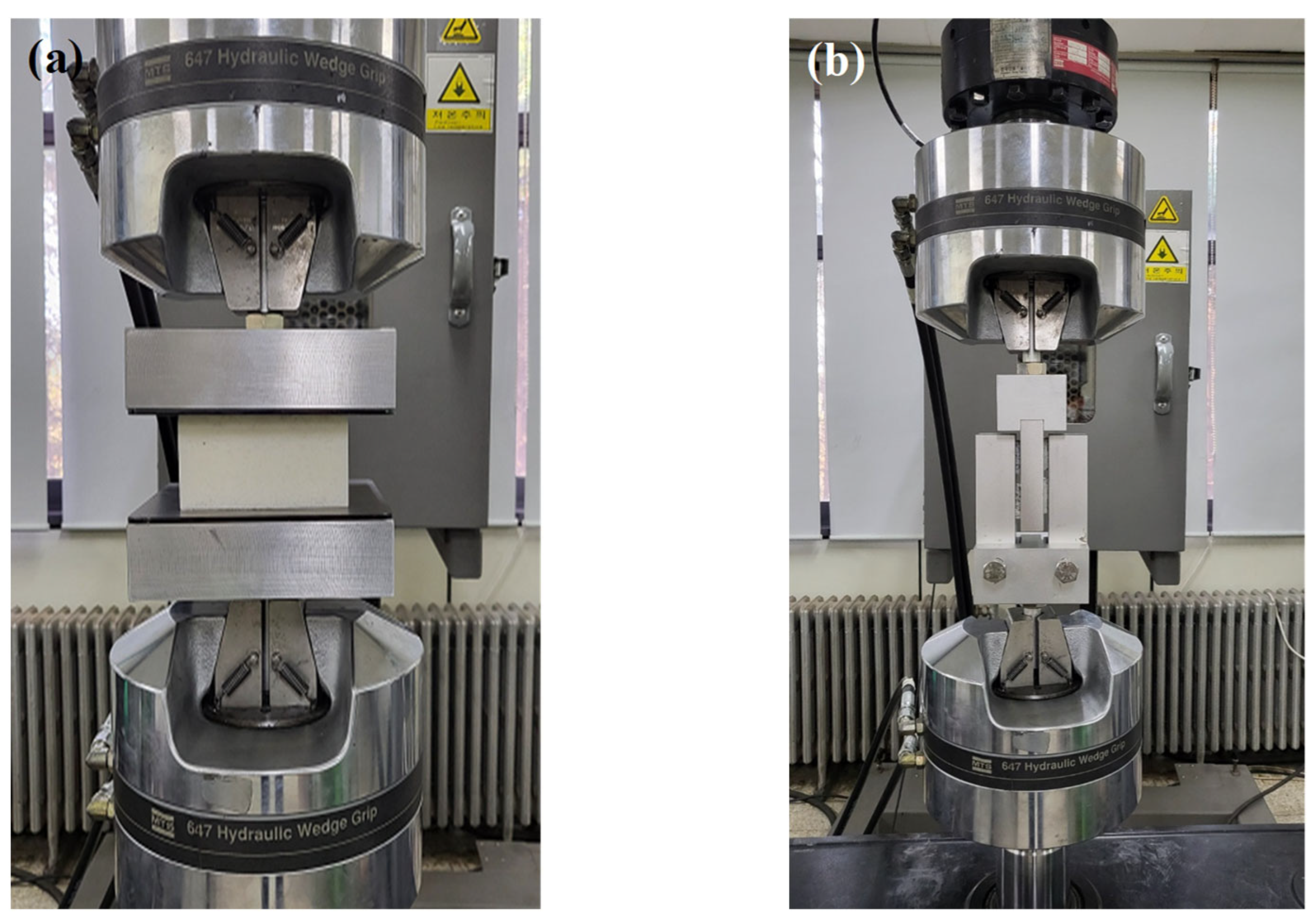

2.3. Static Characteristics

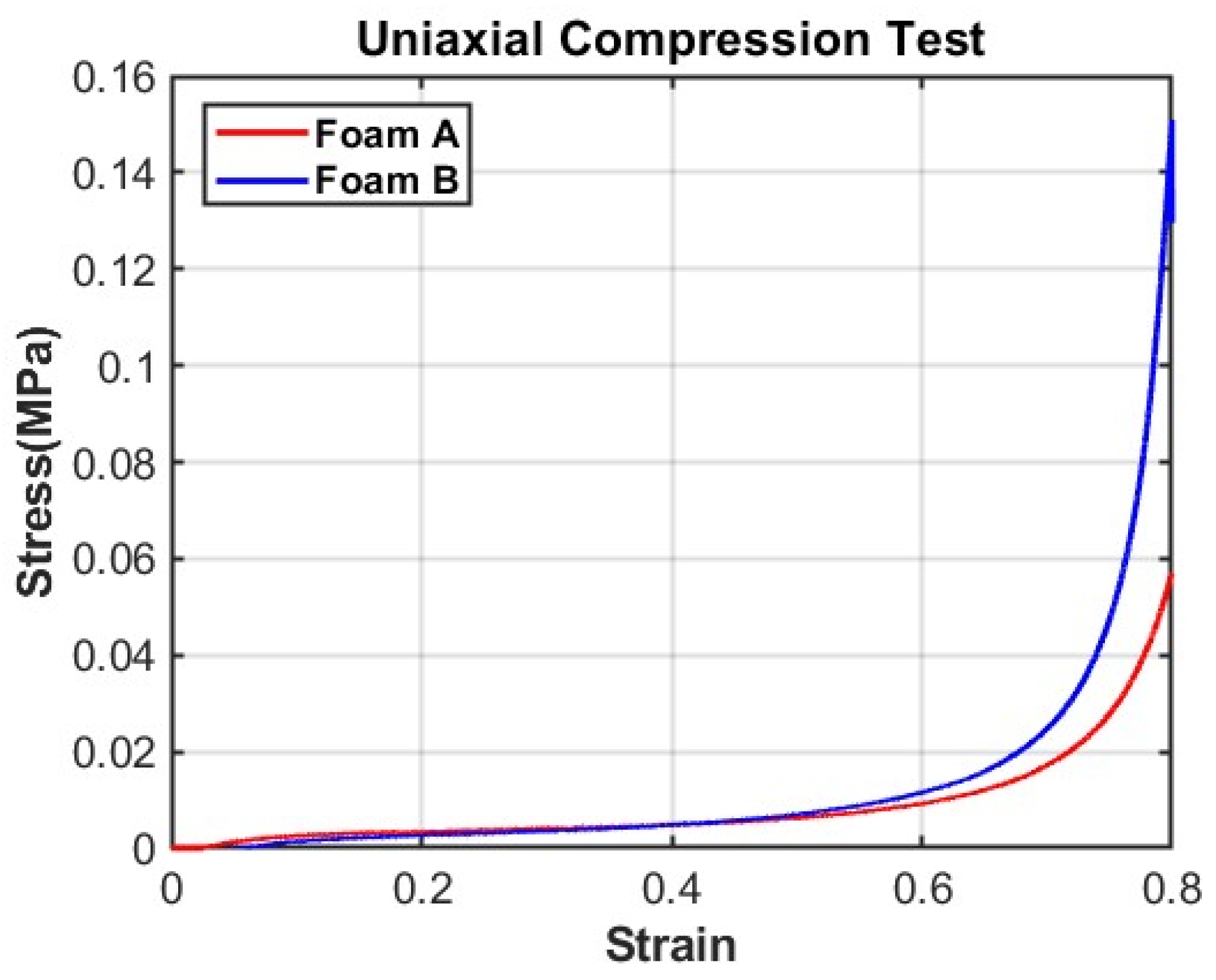

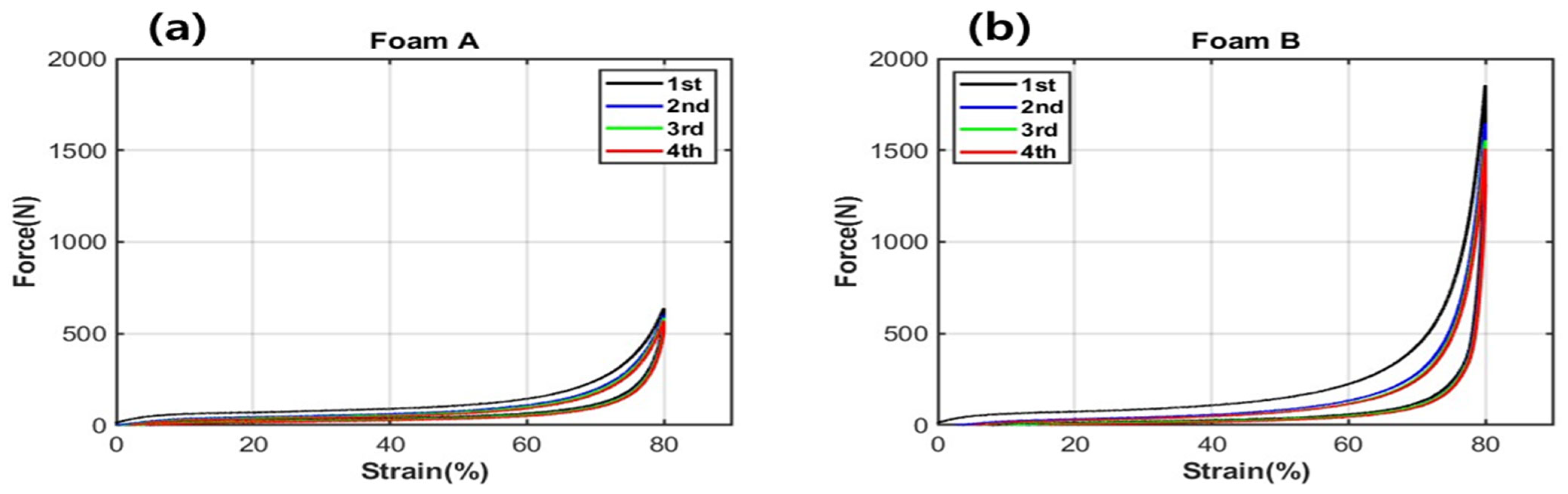

2.3.1. Uniaxial Compression Test

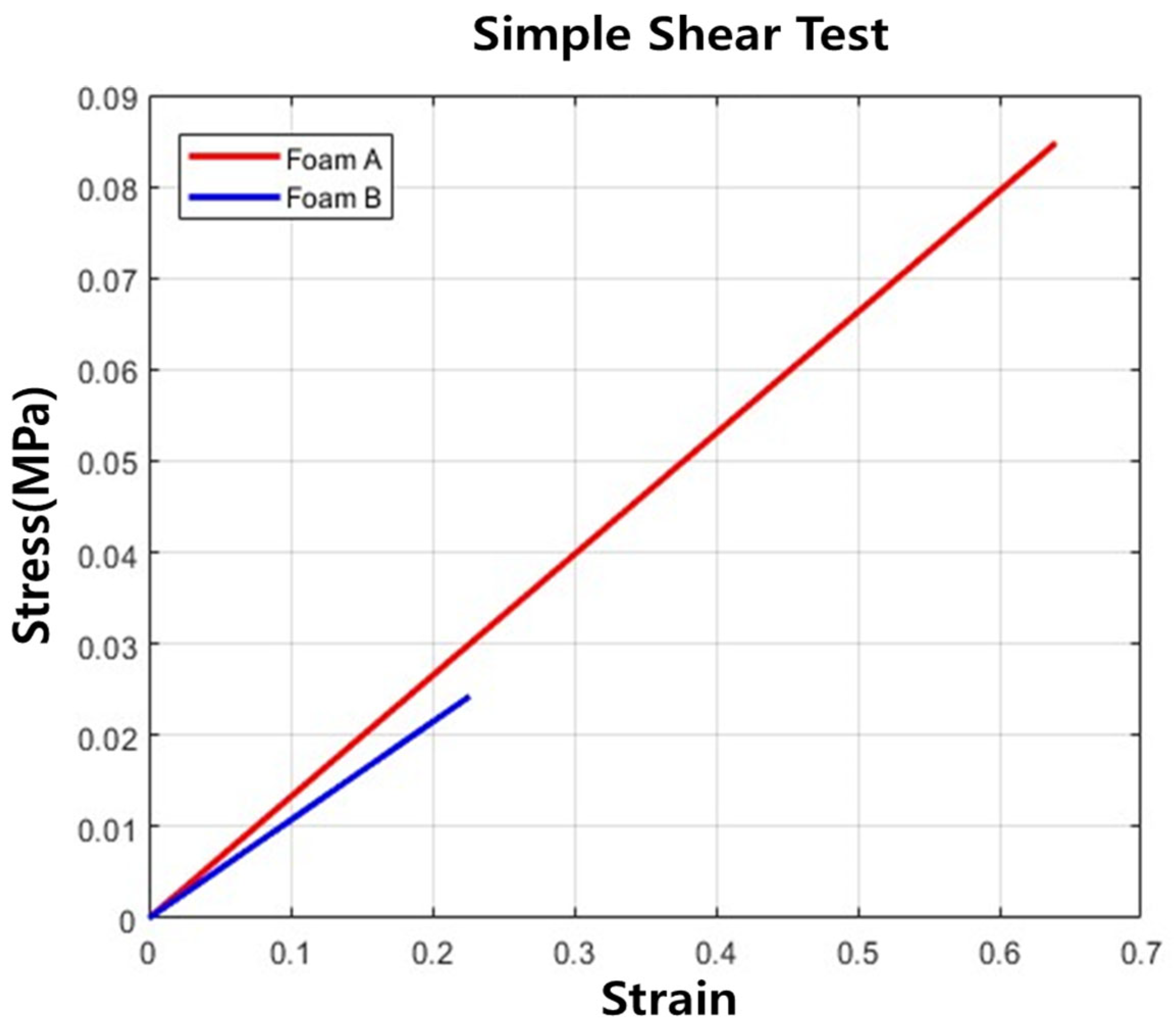

2.3.2. Simple Shear Test

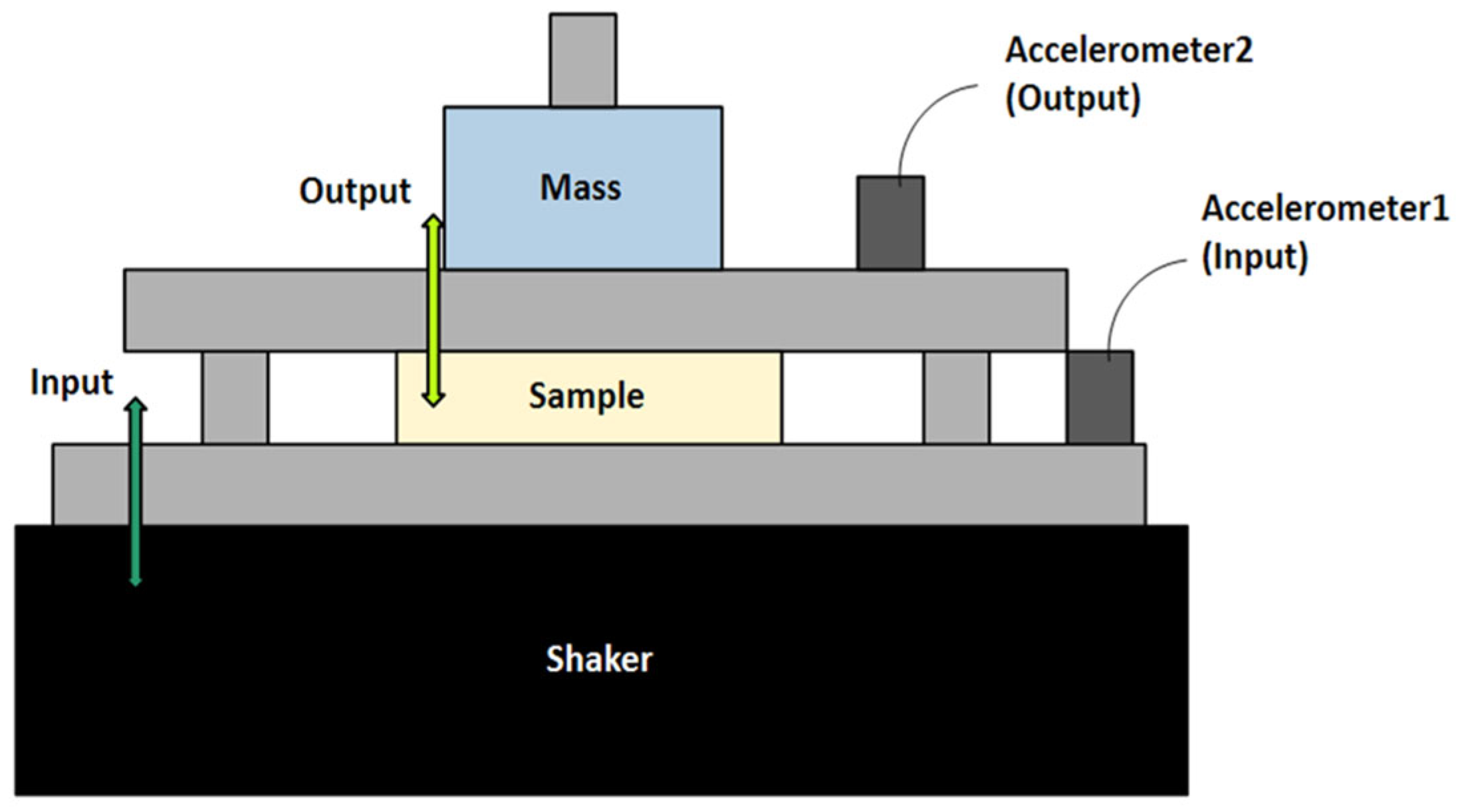

2.4. Dynamic Characteristics

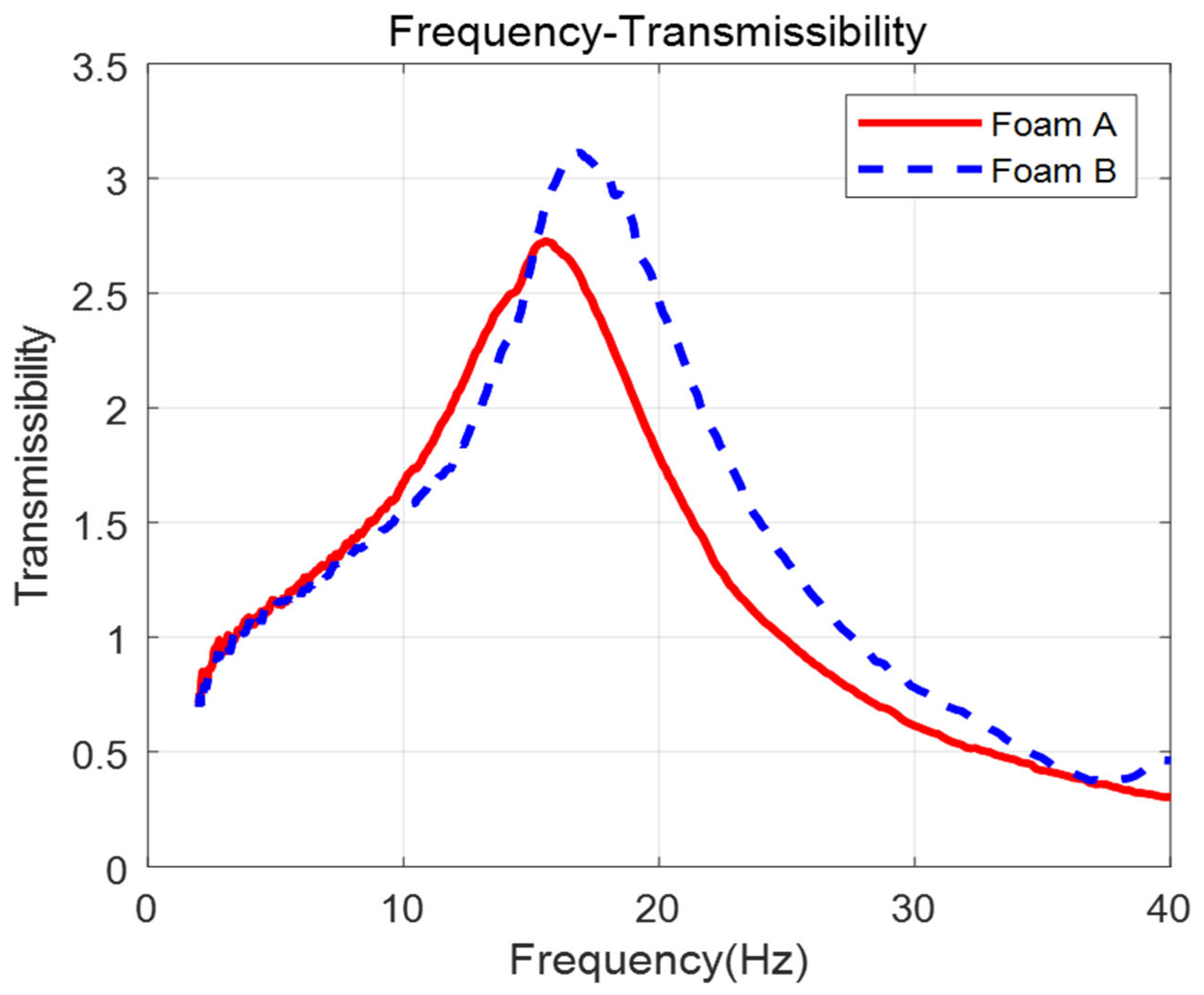

Transmissibility Test

3. Results and Discussion

3.1. Flame-Retardant Characteristics Results

3.2. Static Characteristics Results

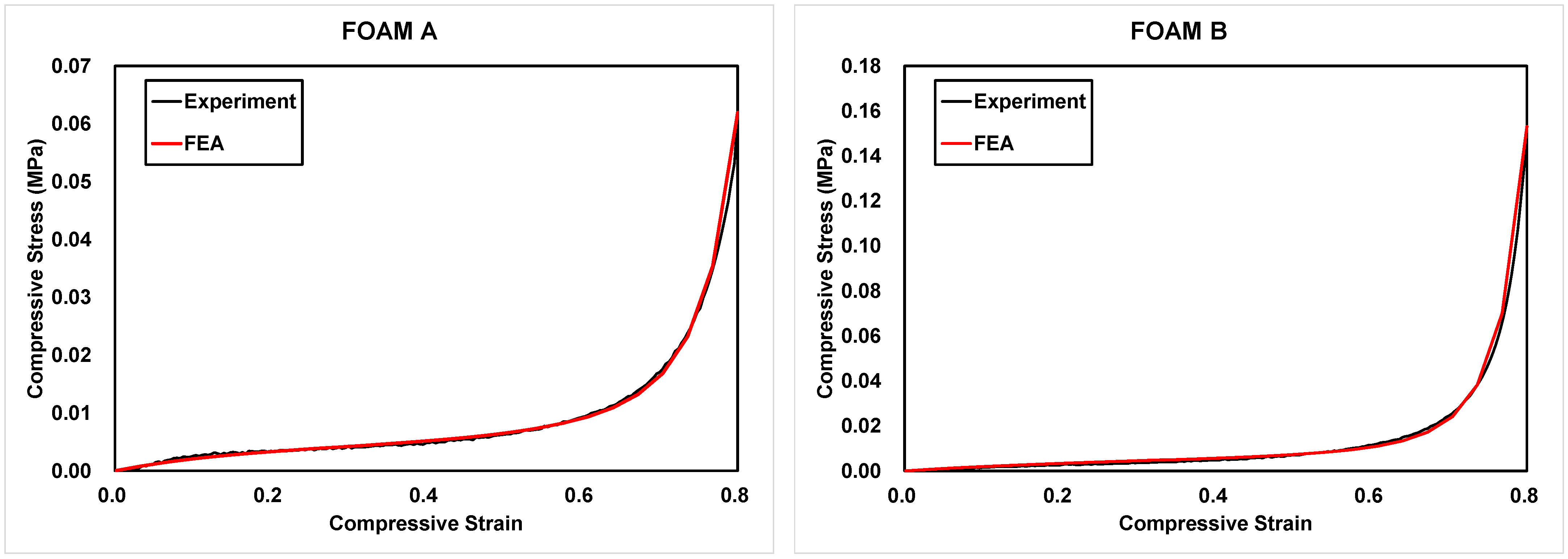

3.2.1. Uniaxial Compression Test Results

3.2.2. Static Comfort Evaluation Index

3.2.3. Simple Shear Test Results

3.2.4. Material Parameter Identification

3.3. Dynamic Characteristics Results

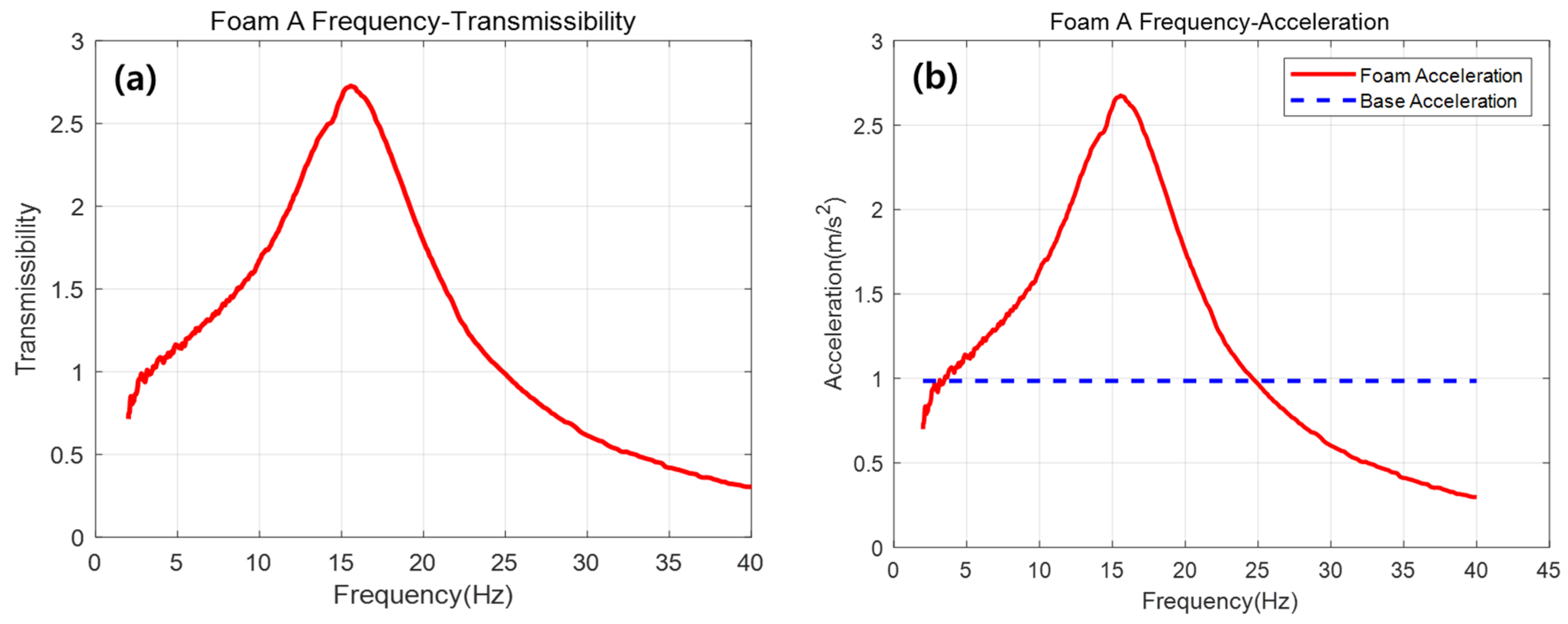

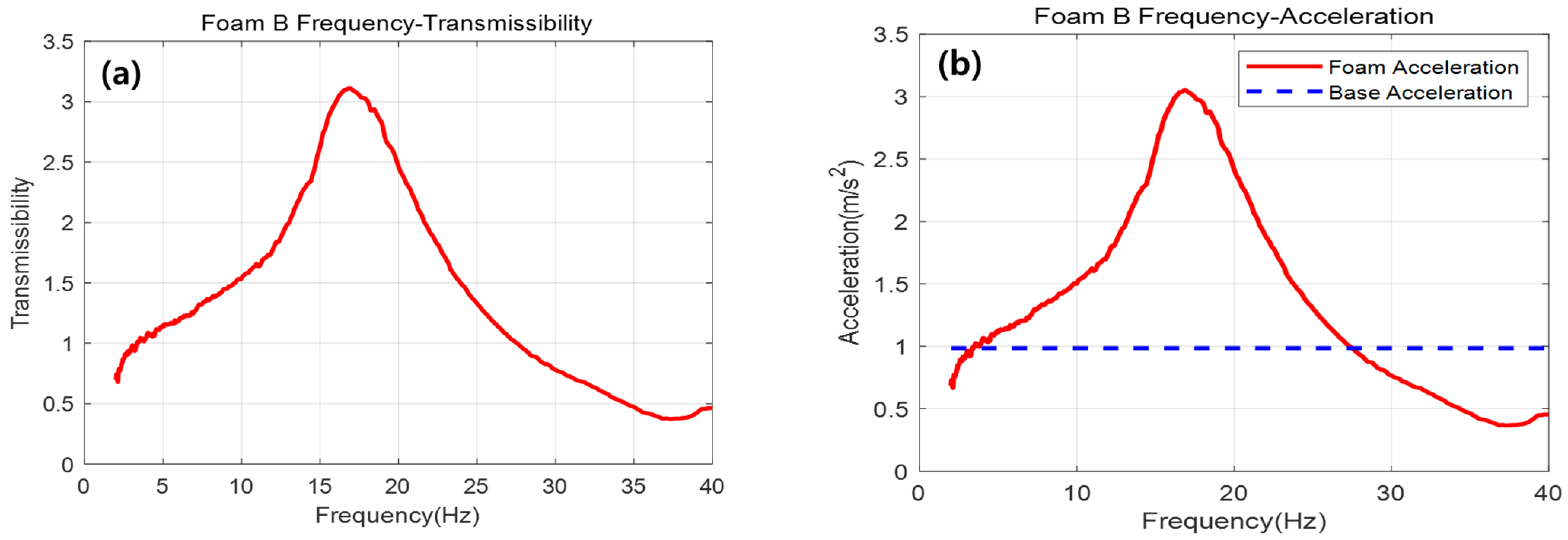

Transmissibility Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, M.J.; Chae, S.G.; Kang, M.G.; Choi, D.G.; Jang, H.L.; Choi, K.W. Mechanical Reliability Analysis of Flame Retardant Silicone Foam for Mass Transportation. Polym. Korea 2023, 47, 64–71. [Google Scholar] [CrossRef]

- Kwan, W.D.; Lee, J.C.; Seo, K.S.; Seo, C.S.; Kim, S.B. Effect of Flame Retardants on Flame Retardancy of Flexible Polyurethane Foam. Appl. Chem. Eng. 2013, 24, 208–213. [Google Scholar]

- Jang, S.Y.; Kim, S.B. Effect of Blowing Agents on Properties of Phenolic Foam. J. Korean Inst. Gas 2016, 20, 30–34. [Google Scholar] [CrossRef]

- Drysdale, D.D. Unit of Fire Safety Engineering, Fire and Cellular Polymers. Fire Saf. J. 1987, 12, 63–65. [Google Scholar]

- Park, Y.S.; Lee, J.W.; Kang, J.S. Silicorn Polymer. KISTI 2002, 1, 1–13. [Google Scholar]

- Shin, J.H. Componential Analysis of Textiles Treated by Halogen Type Flame Retardants. Korean J. Community Living Sci. 2013, 24, 460. [Google Scholar]

- Park, C.S.; Jung, W.W. Introduction and Recent Trends of Flame Retardants. Rubber Technol. 2000, 8, 114–122. [Google Scholar]

- Lee, G.W. Recent Eco-Friendly Flame Retardant Technology Trends. KISTI 2000, 1, 1–8. [Google Scholar]

- Hardy, M.L. Regulatory Status and Environmental Properties of Brominated Flame Retardants Undergoing Risk Assessment in the EU: DBDPO, OBDPO, PeBDPO and HBCD. Polym. Degrad. Stab. 1999, 64, 545–555. [Google Scholar] [CrossRef]

- Moon, S.C.; Choi, J.K.; Jo, B.W. Flame Retardancy and Foaming Properties of the NBR/Ground Tire Rubber Foams Containing Expandable Graphite. Polym. Korea 2004, 28, 412–425. [Google Scholar]

- Jang, B.N.; Choi, J.H. Research Trends in Flame Retardants and Flame Retardant Resins. Polym. Sci. Technol. 2009, 20, 8–15. [Google Scholar]

- Bae, S.J.; Go, J.W.; Lee, J.Y.; Park, J.H.; Choi, P.J.; Sur, S.H. Flame Retardancy and Physical Properties of Polyurethane Foam with Expandable Graphite. Soc. Adhes. Interface 2019, 20, 96–101. [Google Scholar]

- Kim, I.T.; Moon, J.H.; Ryu, J.H.; Yi, C.H.; Lee, W.K.; Oh, J.S. Perceptual Evaluation of Automotive Polyurethane Foams. Polym. Sci. Technol. 2019, 30, 527–531. [Google Scholar]

- Hong, C.H.; Back, H.S.; Kim, K.M.; Kim, S.Y.; Choi, S.M.; Hwang, T.W. Polyurethane Flexible Foam for Automotive Seat Cushion Having Both Superior Static and Dynamic Properties. Polym. Korea 2007, 31, 47–52. [Google Scholar]

- Lee, B.J.; Lee, S.H.; Choi, K.Y.; Kim, S.B. Effect of Change in Water Content and NCO Index on the Static Comfort of Polyurethane Seat Foam Pad for Automobiles. Appl. Chem. Eng. 2017, 28, 57–63. [Google Scholar]

- Bang, J.H.; Lee, C.A.; Kim, H.Y.; Kim, H.J.; Choi, K.Y. Optimization of the Static Properties of Seat Foam to Improve the Seating Comfort. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 231, 1945–1960. [Google Scholar] [CrossRef]

- Lee, B.J.; Kim, S.B.; Mun, J.H. Effect of Foaming Agent Productivity on Static Clamp Reduction of Flexible Polyurethane Foam for Automobile Seats. Korean Soc. Ind. Eng. Chem. 2015, 26, 272. [Google Scholar]

- ASTM D 3574-03; Standard Test Method for Flexible Cellular Materials-Slab, Bonded, and Molded Urethane Foams. Frazier Precision Instrument Company, Inc.: Hagerstown, MD, USA, 2024.

- Kim, W.D.; Kim, W.S.; Woo, C.S.; Lee, H.J. Experimental Testing of Rubber Materials for Finite Element Analysis. Proc. KSME Conf. A 2001, 29, 704–709. [Google Scholar]

- Kim, H.Y.; Choi, C.; Bang, W.J.; Kim, J.S. Large Deformation Finite Element Analysis for Automotive Rubber Components. J. Korean Soc. Automot. Eng. 1993, 15, 107–119. [Google Scholar]

- Park, W.J.; Hwang, H.H. Prediction of Failure Mode Under Static Loading in Long Span Bridge Deck Slabs by FEM. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 52–59. [Google Scholar]

- Lee, K.S.; Ki, M.S.; Park, B.J. Comparative Study on the Nonlinear Material Model of Hyperelastic Material Due to Variations in the Stretch Ratio. J. Ocean Eng. Technol. 2018, 32, 253–260. [Google Scholar] [CrossRef]

- Briody, C.; Duignan, B.; Jerrams, S. Testing, modelling and validation of numerical model capable of predicting stress fields throughout polyurethane foam. In Constitutive Models for Rubber VII; CRC Press: Boca Raton, FL, USA, 2011; p. 143. [Google Scholar]

- Briody, C.; Duignan, B.; Jerrams, S.; Tiernan, J. The implementation of a visco-hyperelastic numerical material model for simulating the behaviour of polymer foam materials. Comput. Mater. Sci. 2012, 64, 47–51. [Google Scholar] [CrossRef]

- Ju, M.L.; Jmal, H.; Dupuis, R.; Aubry, E. Visco-hyperelastic constitutive model for modeling the quasi-static behavior of polyurethane foam in large deformation. Polym. Eng. Sci. 2015, 55, 1795–1804. [Google Scholar] [CrossRef]

- Jang, H.L.; Kwon, T.S.; Park, W.H.; Lee, D.H.; Kim, S.R.; Bae, Y.H. A Study on Strength Properties of Sandwich Panels Including Flame Resisting Polyurethane Foam Cores for Application to Rolling Stocks. J. Korean Soc. Hazard Mitig. 2017, 17, 227–234. [Google Scholar] [CrossRef]

- Kim, D.M.; Min, K.W.; Park, H.K.; Park, J.H. Measurement of the Distributed Dynamic Stiffness of Seats and Analysis of Dynamic Properties of Seats. In Proceedings of the Korean Society for Noise and Vibration Engineering Conference, Daegu, Republic of Korea, 29–31 October 2014; Korean Society for Noise and Vibration Engineering: Seoul, Republic of Korea; pp. 994–995. [Google Scholar]

- Ryu, S.C.; Jun, Y.D. Hold Feeling Assessment of Vehicle Seat Cushions. Trans. Korean Soc. Automot. Eng. 2021, 29, 1025–1032. [Google Scholar] [CrossRef]

- Wang, W.; Yang, F.; Lu, Y.; Luo, Z.; Li, F.; Wu, Y.; Zhang, J.; Xiao, Z.; Li, W.; Qin, C. Application of Magnesium Hydroxide/Diphenoxy Phosphate in Silicone Rubber Flame Retardant Cable Material. Coatings 2023, 13, 934. [Google Scholar] [CrossRef]

- Hong, L.; Hu, X. Mechanical and Flame Retardant Properties and Microstructure of Expandable Graphite/Silicone Rubber Composite. J. Macromol. Sci. Part B Physics. 2016, 55, 175–187. [Google Scholar] [CrossRef]

- Sato, T.; Ikoma, S.; Ozawa, F.; Nakamura, T. Thermal Decomposition of Magnesium Hydroxide. Gypsum Lime 1982, 181, 283–289. [Google Scholar]

- ISO 5660-1:2015; Reaction-to-Fire Tests-Heat Release, Smoke Production and Mass Loss Rate-Part 1: Heat Release Rate (Con Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization: Geneva, Switzerland, 2015.

- KS M ISO 3386-2:2013; Methods for Measuring Compressive Stress-Strain Characteristics of Soft Foamed Polymer Materials—Part 2: High Load Applications. Korean Agency for Technology and Standards: Eumseong, Republic of Korea, 2013.

- KS M ISO 1827:2014; Vulcanized or Thermoplastic Rubber—Measurement of Adhesion to a Rigid Plate. Korean Agency for Technology and Standards: Eumseong, Republic of Korea, 2014.

- EN 45545-2; Fire Protection on Railway Vehicles. Technical Information. Plastic Materials and Processes (NZ) Ltd.: Auckland, New Zealand, 2020.

- Casavola, C.; Del Core, L.; Moramarco, V.; Pappalettera, G.; Patronelli, M. Full-Field Experimental Study and Numerical Modeling of Soft Polyurethane Foam Subjected to Cyclic Loading. Phys. Sci. Forum 2022, 4, 20. [Google Scholar]

- Moon, S.Y.; Lee, S.Y.; Lim, H.M. Flame Retardant Properties of Basalt Fiber Reinforced Epoxy Composite with Inorganic Fillers. Compos. Res. 2019, 32, 368–374. [Google Scholar]

- Kim, D.M.; Min, K.W.; Park, H.K.; Park, J.H. Evaluation of Vibration Comfort Using Dynamic Properties of Vehicle Seats. Korean Soc. Noise Vib. Eng. 2015, 15, 883–884. [Google Scholar]

- Ogden, R.W. Large Deformation Isotropic Elasticity–On the Correlation of Theory and Experiment for Incompressible Rubberlike Solids. Rubber Chem. Technol. 1973, 46, 102–124. [Google Scholar] [CrossRef]

- Ogden, R.W. Recent Advances in the Phenomenological Theory of Rubber Elasticity. Rubber Chem. Technol. 1986, 59, 361–383. [Google Scholar] [CrossRef]

| Foam A | Foam B | |

|---|---|---|

| H-PDMS | 2.0 | 2.0 |

| Isocyanate | 20.0 | 20.0 |

| Vinyl-PDMS | - | 12.0 |

| OH-PDMS | - | 26.0 |

| Polyol | 34.8 | 34.8 |

| Sn-Catalyst | - | 0.04 |

| MDH | - | 2.85 |

| Expandable Graphite | - | 8.55 |

| Physical Blowing Agent | - | 3.0 |

| Foam A | Foam B | |

|---|---|---|

| Hardness [N] | 40.0 | 33.4 |

| Initial Hardness Factor (IHF) | 2.3 | 8.0 |

| Modulus Irregularity Factor (MIF) [N] | 16.4 | 4.0 |

| Sag Factor | 3.0 | 4.7 |

| Hysteresis Loss [%] | 39.7 | 54.7 |

| Soft Foam | Hard Foam | |

|---|---|---|

| Hardness [N] | 85.0 | 200.0 |

| Initial Hardness Factor (IHF) | 2.3 | 2.2 |

| Modulus Irregularity Factor (MIF) [N] | 4.0 | 10.0 |

| Sag Factor | 3.0 | 3.0 |

| Hysteresis Loss [%] | 22.5 | 22.3 |

| Material Constant | Expression |

|---|---|

| Constant | |

| Material | Density ) | (MPa) | ||

|---|---|---|---|---|

| Foam A | 143.0 | 1 | 8.95 | |

| 2 | −3.98 | |||

| Foam B | 186.8 | 1 | 6.70 | |

| 2 | −5.06 |

| Material | Foam A | Foam B |

|---|---|---|

| RMSE | ||

| R2 (%) | 99.19 | 98.69 |

| Natural Frequency (Hz) | Maximum Transmissibility | |

|---|---|---|

| Foam A | 15.6 | 2.7 |

| Foam B | 17.0 | 3.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.-J.; Kwon, T.-S.; Sim, H.-J.; Seo, Y.-G.; Choi, K.; Jang, H.-L. Synergistic Enhancement of Fire Retardancy and Mechanical Performance in Silicone Foams Using Halogen-Free Fillers. Fire 2025, 8, 243. https://doi.org/10.3390/fire8070243

Park S-J, Kwon T-S, Sim H-J, Seo Y-G, Choi K, Jang H-L. Synergistic Enhancement of Fire Retardancy and Mechanical Performance in Silicone Foams Using Halogen-Free Fillers. Fire. 2025; 8(7):243. https://doi.org/10.3390/fire8070243

Chicago/Turabian StylePark, Seong-Jun, Tae-Soon Kwon, Hee-Joong Sim, Yeon-Gyo Seo, Kyungwho Choi, and Hong-Lae Jang. 2025. "Synergistic Enhancement of Fire Retardancy and Mechanical Performance in Silicone Foams Using Halogen-Free Fillers" Fire 8, no. 7: 243. https://doi.org/10.3390/fire8070243

APA StylePark, S.-J., Kwon, T.-S., Sim, H.-J., Seo, Y.-G., Choi, K., & Jang, H.-L. (2025). Synergistic Enhancement of Fire Retardancy and Mechanical Performance in Silicone Foams Using Halogen-Free Fillers. Fire, 8(7), 243. https://doi.org/10.3390/fire8070243