Abstract

The use of fiberglass blankets as fire suppression blankets to extinguish accidental cooking fires has been regulated and widely used, especially in homes and small firms and laboratories. Understanding the properties, which have significant effect on their performance, is essential for ensuring effective fire control and improving the quality of these blankets in fire suppression. This study examines key properties including toxicity, physical characteristics, thermal behavior, and fire suppression capabilities. Novel properties such as air permeability and spectroscopic structural analysis are explored, areas previously under-researched. The sample number S4 had Warp/weft count 21/12 with comparison to air permeability; it gave the lowest value among the selected samples. Thermal properties, including heat transfer and temperature dynamics, are also analyzed to understand how fire spreads through the material. The optimal performance of air permeability was observed to be below 650 L/m2/s. Blankets demonstrated over 45% heat blocking efficiency at low heat flux and more than 78% at high heat flux. Temperature rise within the first minute of fire exposure is a key determinant, with effective blankets maintaining temperatures below 300 °C after one minute and ensuring that the final temperature after three minutes does not exceed 390–400 °C. Additionally, a new classification system based on the toxicity of gases emitted during combustion was introduced, enhancing the safety profile of fiberglass blankets and improving their suitability for practical use. This research contributes valuable insights into both the performance and safety of fiberglass fire blankets

1. Introduction

Fire safety is a critical aspect of public and occupational safety, with various tools designed to mitigate fire hazards. Among these, fire blankets serve as an essential component, particularly for suppressing small fires and providing thermal protection. Unlike fire extinguishers, fire blankets offer a clean and efficient method for handling certain fire types, particularly in kitchen and vehicle fire scenarios. Modern fire blankets are typically made from non-flammable materials such as fiberglass, which is widely used due to its high heat resistance and durability. Coated with fire-retardant substances, fiberglass blankets are effective in smothering flames by cutting off the oxygen supply. Their application is particularly valuable in kitchen fires, where grease fires—categorized as Class K (or Class F in some regions)—require specialized suppression methods to prevent re-ignition [1,2,3].

Recently, car fire blankets were employed as a solution for extinguishing vehicles with various propulsion systems. Several researchers have dedicated their attention to this issue and have come to various conclusions. Peter Sturm et al. reached the conclusion that fire resistant blankets minimize the oxygen content in the flame area and smother the fire, which make them a useful tool in vehicle firefighting. The development of the HRR over time during test BV01 monitored. When the fire blanket was applied (at ~500 s), the fire was already fully developed and the battery was totally involved (in BV01, the fire was initiated in the battery compartment). This resulted in a strong reduction in HRR. Wijesekere et al. tested practical firefighting technologies for electric cars on ro-ro ferries. For this purpose, an experimental test setup (approx. 12 m × 7 m) was constructed using two 40 ft shipping containers, joined together and opened at both ends. The results showed that several methods could limit the spread of fire to neighboring cars (fire blanket, water mist, water curtains) [4,5,6,7,8].

Takahashi et al. have investigated the thermal response characteristics of over fifty relatively thin (0.15–3.7 mm) fire blanket materials from four different fiber groups (aramid, fiberglass, amorphous silica, and pre-oxidized carbon) and their composites. A plain or coated fabric sample was subjected to a predominantly convective or radiant heat flux (up to 84 kW/m2) using a Meeker burner and a cone heater, respectively. In addition to thermal protective performance ratings for protective clothing, two transient thermal response times (for the fabric back-side temperature to reach 300 °C and for the through-the-fabric heat flux to reach 13 kW/m2) and a steady-state heat-blocking efficiency (HBE) were introduced for both convective and radiant heat sources [9].

Another application of fire blanket with and without flame retardant to protect houses against Wild land-Urban Interface Fires was studied by Chow WK. A series of proof-of-concept experiments were conducted by placing wooden structures covered with different fire blankets in various fires in ascending order of size. First, birdhouse-sized boxes were exposed to burning wood pallets in a burn room. Second, wall-and-eave panels were exposed to prescribed fires climbing up slopes with chaparral vegetation in California. Finally, a cedar shed was placed in the passage of the prescribed head fire in the Pine Barrens in New Jersey. The experiments demonstrated both the successful performance and technical limitations of thin fire blankets [3].

Aventi studied fire blankets samples made from different fabrics coated with different kinds of chemicals, which are widely available and very easy to get on market, meaning that the general public can easily obtain the fabrics and chemicals used for the development of these fire blanket. He used ten types of fabric, three types of fire-retardant chemicals, and three types of preservative chemicals, so that fire blanket fabric, according to its function, can inhibit spread of fire/extinguish the fire and not be quickly damaged/torn/decay/eaten by insects [10].

The above research on fire blankets covered different types of application, either in small fires, car fires, or as a component in insulating construction materials. The outcomes of these research works covered some of the physical properties of different kinds of fire blankets and their effect on thermal insulating properties, in addition to their application as fire suppression tools. Despite these advancements, a critical research gap exists in evaluating the toxicity of gases released by fiberglass blankets during combustion. In addition, the mean physical properties that govern the fire suppression properties of such blankets have not yet been studied.

The primary objective of this research is to identify the key physical and thermal properties that influence the fire suppression efficiency of fiberglass blankets. Additionally, a significant gap in the literature exists regarding the evaluation of gas toxicity associated with fiberglass blankets, which this study aims to address. Novel physical properties, including air permeability and microscopic surface morphology, are analyzed to provide deeper insights into their impact on fire suppression performance. Furthermore, the toxicity assessment of gases emitted during combustion introduces a new dimension of study, enabling the classification of fiberglass blankets into categories of safe and unsafe usage based on their toxicological profiles.

2. Materials and Testing Methods

In general, the different tests were repeated five times. The standard deviation was calculated and is stated beside the results in each table.

2.1. Materials

Eleven fiberglass fire blankets were randomly chosen from the Saudi market (Figure 1). The blanket samples are each from different producers and have different thicknesses and different weights per unit area. The physical and fire suppression properties were tested according to either standard test methods or in-house methods. The heptane used is highly pure, with purity 99% determined by Lab-Scan Analytical Science, UK. Heptane is widely recognized in fire testing due to its consistent combustion characteristics and well-defined heat release rate, making it a standard surrogate fuel for assessing fire suppression efficiency. The choice of high-purity heptane ensures minimal variability in the experimental setup, providing accurate and scientifically robust data. The selection and testing of these materials aims to provide comprehensive insights into the efficacy of commercially available fire blankets under standardized conditions, contributing to a better understanding of their performance in real-world fire scenarios.

Figure 1.

Photo image of glass fiber blanket.

2.2. Physical Properties Testing Methods

2.2.1. Determination of Yarns per Unit Length

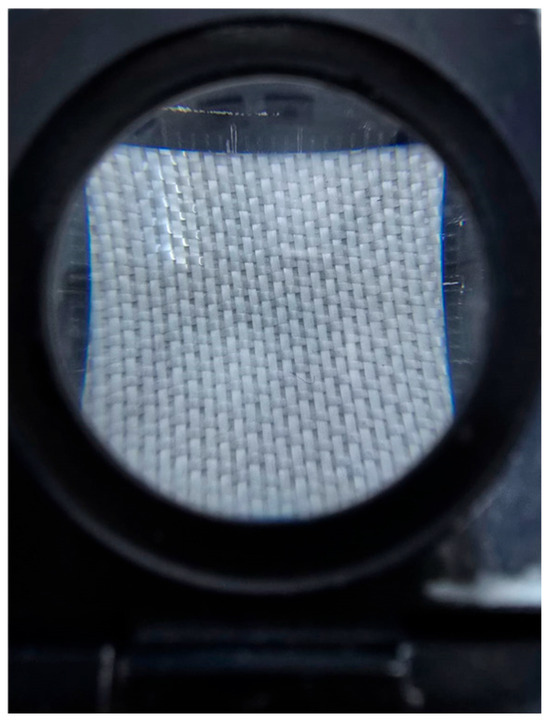

The standard ISO 7211-2 [11] was applied to measure warp and weft count. It is performed by laying the fabric flat on a horizontal surface and placing the counting glass (Figure 2) on the fiberglass fabric. The number of warp threads and the weft threads were counted.

Figure 2.

Photo of counting glass.

2.2.2. Air Permeability of Blankets

The air permeability of blankets was measured before and after fire suppression testing according to standard EN ISO 9237 [12]. The results were presented in L/m2/s, expressing the amount of air that passes through a square meter of fabric in one second. i.e., the velocity required to achieve a desired pressure drop. The test material is clamped into the air permeability device with the right side facing the air inlet. The air is sucked through the test material. The air flow is adjusted so that the agreed pressure drop is achieved. The normal test area is 20 cm2, and for garments the pressure difference is normally 100 Pa. This test was conducted using the TEXTEST FX3300 air permeability tester manufactured by TEXTEST AG, Schwerzenbach, Switzerland, as shown in Figure 3.

Figure 3.

Photos of air permeability test equipment.

2.2.3. Fabric Weight and Thickness

The weight of the blanket (weight per unit area) was measured using a calibrated balance and caliper. The thickness of the blankets was measured using a calibrated thickness gauge.

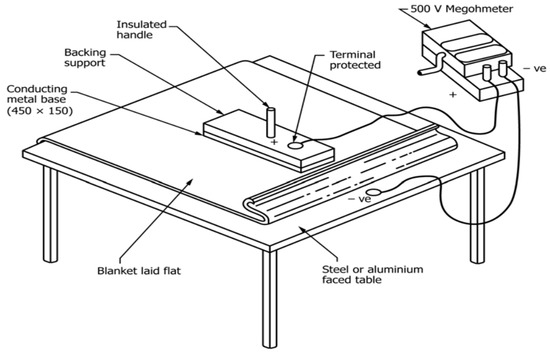

2.2.4. Electrical Resistance Test

According to ASTM F 1989-05 [13], the electrical resistance of the fire blanket was measured between a negative electrode formed by a steel or aluminum-topped table and a flat rectangular conducting positive electrode. Figure 4 shows a diagram of the equipment used to measure the electrical resistance of the blankets.

Figure 4.

Diagram of electrical resistance measuring system.

2.3. Blankets Fire Suppression Testing

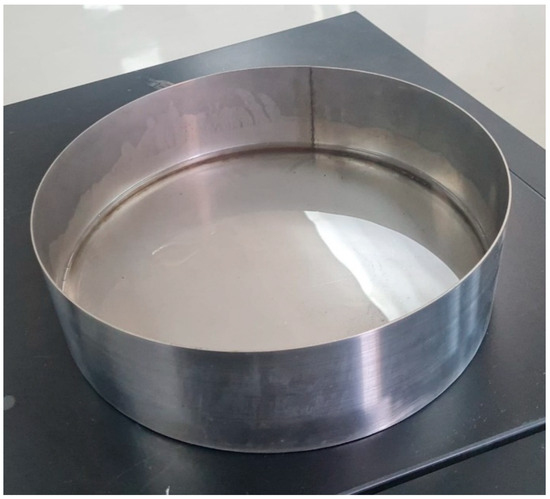

Fire Performance Tests (Volatile Liquid Test Fires)

The ASTM F 1989-05 [13] specification covers requirements for fire suppression blankets to extinguish accidental cooking fires and establishes relevant testing methods. Fire suppression was conducted using a test tray on a 0.8 m high horizontal metal table, equidistant from the two opposite sides and positioned so that the distance from one of the other two sides (Side (a)) to the far edge of the tray was 900 ± 5 mm (see Figure 5). The testing table was placed in a room free from drafts, with sufficient ventilation to allow the fire to develop freely and to remove products of combustion. The ambient temperature was between 10 and 30 °C. The tray was filled with sufficient water (half the Heptane fuel volume) to give an average depth of 15 mm. After ignition, allow the fire to burn freely for 1 min, and then apply the fire blanket as symmetrically as possible to the fire.

Figure 5.

Photo image for system used to evaluate the fire suppression of fire blankets.

2.4. Thermal Response Characteristics

2.4.1. Exposure to Heat Flux

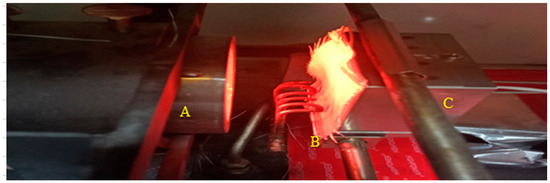

The different fiberglass blankets were subjected to heat flux from a furnace on one face and the transmitted heat flux from the opposite face was measured using a flux meter. The incident heat flux rates were 25 and 55 kW/m2. The time of exposure was three minutes. The dimension of samples was 75 × 75 mm. A photo image of the testing system is shown in Figure 6.

Figure 6.

Image of test set up for the testing effect of 25 kW/m2 heat on blanket samples. (A): Heat furnace, (B): Blanket sample, and (C): flux meter detector.

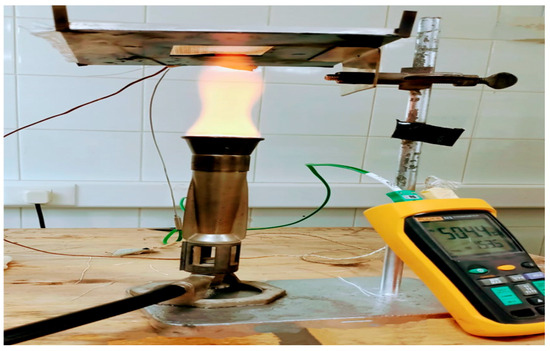

2.4.2. Temperature Profile Measurement of Blanket Samples

The blanket samples were subjected to direct flame to simulate a real-world fire and to check their temperature profiles during real fires. The flame temperature reached 680 °C and was applied to one face of the blanket for three minutes. The temperatures of both blanket faces, the exposed and opposite, were recorded by thermocouples. A photo of the measuring system is shown in Figure 7.

Figure 7.

Photo image of test setup for measuring the difference in temperature between inner and outer faces after applying a flame with a maximum temperature of 680 °C.

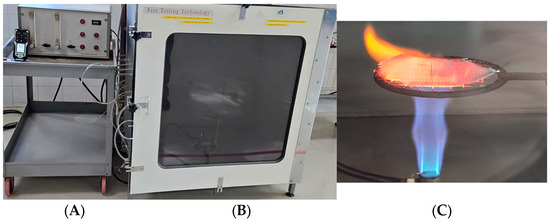

2.5. Toxicity of the Evolved Gases During Process of Fire Suppression

The characterization of toxic gases released during the suppression process using fiberglass blankets is a critical aspect of material performance evaluation, particularly in applications where fire safety and toxicity are of paramount concern. This analysis is conducted in accordance with the standardized procedure outlined in “Determination of Toxicity Index of the Product of Combustion from Specimen of Materials” (Def. Stan. 02-713, Issue 2) [14]. The experimental setup, depicted in Figure 8, involved subjecting a fiberglass blanket sample to direct flame exposure under controlled conditions. The evolved gases were quantitatively assessed using the advanced Dräger X-am 8000 gas monitoring system (Dräger, Lübeck, Germany), ensuring the precise detection of toxic species. The test was carried out over a three-minute interval, during which the peak concentrations of the emitted gases were recorded. These measurements were then normalized to the initial mass of the sample, providing critical insights into the material’s combustion toxicity profile. These data are integral to understanding the safety implications of fiberglass blankets in real-world fire scenarios.

Figure 8.

Photo of the test setup for measuring the toxicity ((A): Gas measuring equipment, (B): toxicity chamber and (C): blanket sample under fire).

The toxicity index is calculated using the following equation:

where

1, 2, 3 are the gases detected and calculated according to the following equation:

where

Ci = concentration of gas in test chamber that resulted from combustion of the test specimen (ppm);

m = mass of the test specimen (g);

V = volume of test chamber (m3);

Cf = concentration of the gas considered fatal to humans over 30 min exposure (ppm).

3. Results and Discussion

3.1. Summary of Results and Discussion

- Physical Properties

- -

- Air Permeability: The air permeability of blanket samples varied significantly, with values ranging from 317 to 745 L/m2/s before the fire test. After the fire test, some samples showed a decrease due to fiber swelling and densification, while others increased due to fiber separation. Sample S11 had the highest air permeability (745 L/m2/s) and S10 had the lowest (279 L/m2/s).

- -

- Microscopic Analysis: Microscopy images revealed varying air gap structures among samples, correlating with air permeability results.

- -

- Textile Count, Insulation, and Thickness: The samples had two thickness categories (0.3 mm and 0.4 mm), influencing their weight (0.6–0.7 kg/m2) and air permeability. The highest static insulation (370 MΩ) was observed in S10, while S2 had the lowest (70 MΩ).

- Thermal Properties

- -

- Heat Blocking Efficiency (HBE):

- ◦

- At 25 kW/m2, the HBE ranged from 36.76% (S6) to 61.08% (S7). Samples with lower air permeability generally had better thermal insulation.

- ◦

- At 55 kW/m2, efficiency increased across all samples, with S3 achieving the highest HBE (83.84%) and S7 the lowest (76.45%).

- -

- Heat Transmission:

- ◦

- The time to reach steady-state transmission varied among samples, with most reaching equilibrium within 20–60 s.

- ◦

- At higher heat flux, blankets with tighter weaves and lower air permeability exhibited better insulation.

- Direct Flame Resistance

- -

- Inner surface temperatures reached 680.9 °C for all samples, but the outer surface temperature varied significantly.

- -

- S10 exhibited the lowest outer surface temperature (255.8 °C), whereas S1 had the highest (473.9 °C), indicating differences in heat resistance.

- -

- Samples with slower heat transmission provided better thermal protection.

- Fire Suppression Performance

- -

- Out of 11 tested samples, 8 passed the ASTM F1989-5 fire suppression test, while 3 failed (S1, S6, S11) due to re-ignition or flame penetration.

- -

- Smoke emission varied, with some samples emitting heavy smoke (S1, S2, S5, S6, S11) and others emitting light/moderate smoke (S3, S4, S7, S8, S9, S10).

- Toxicity Assessment

- -

- Carbon monoxide (CO) exceeded safety limits in S2 (7293 ppm) and S4 (5752.8 ppm).

- -

- Nitric oxide (NO) was above the limit (285.9 ppm) in S6.

- -

- Volatile organic compounds (VOC) exceeded limits in S2, S7, and S9.

- -

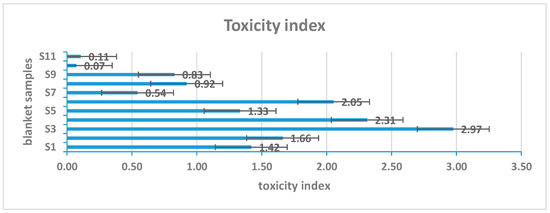

- S10 and S11 had the lowest toxicity index, while S3 had the highest (2.97).

- -

- Based on the proposed classification, S10 and S11 were the least toxic, while S3 and S4 fell into the more hazardous category.

3.2. Physical Properties

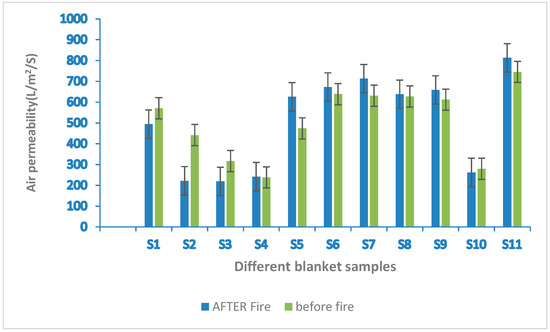

3.2.1. Air Permeability

The results for air permeability of the different blanket samples under study are tabulated in Table 1 and graphically represented as bar chart in Figure 9. There is a wide difference in air permeability values from one sample to another. Samples S2, 3, 4, and 10 have the lowest air permeability values, ranging from 317 (S3) to 279 (S10) L/m2/s. The other samples showed higher air permeability values between 441–638 L/m2/s except sample S11, which showed the highest value (745 L/m2/s). To understand the effects of fire on the air permeability of the blanket samples, we have produced a comparison between the values of air permeability before and after fire testing. In some samples, the air permeability increased, while in others it decreased. This means that the glass fibers swelled and came close to each other, thereby decreasing the air passing through the blanket (this is for samples with decreased air permeability). The opposite occurred for the samples with increased air permeability after fire testing.

Table 1.

Air permeability of fire blanket samples before and after fire suppression test.

Figure 9.

Comparison of Air permeability before and after fire suppression.

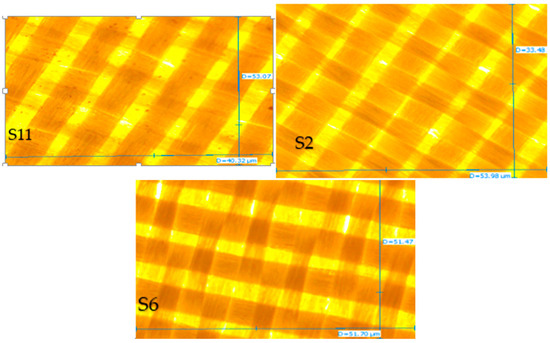

3.2.2. Optical Microscopic Scan

Figure 10 presents three images for three samples (S2, S6, and S11) obtained using a microscope with power 1X. The images show that there are air gaps through the blanket. The air gaps differ from one sample to another in shape, placement, and size. For sample S6, the air gaps are big and disrupted near each other. In sample S11, there are a lot of air gaps and with different sizes (big and small). In the case of sample S2, the air gaps are small and not close to each other. These images support the results of the air permeability tests for these samples.

Figure 10.

Optical spectroscopic images of different blanket samples.

3.2.3. Textile Count, Static Insulation, and Thickness Measurements

Four important textile physical properties of glass fiber blankets are tabulated in Table 2. The textile count, static insulation, weight per m2, and thickness were measured for the blanket samples under study. The thickness of the samples fell into two groups, one 0.3 mm (five samples) and one 0.4 mm (six samples). The weight per m2 is, like thickness, also divided into two categories: 0.7 kg/m2 for the samples with thickness 0.4 mm and 0.6 kg/m2 for the samples with thickness 0.3 mm. The count of weft played an important role in the physical properties, especially the air permeability and flexibility on use. The highest weft count is 13 for sample S10, and warp count for the same sample is 22. Sample S4 had Warp/weft count 21/12; for air permeability, it gave the lowest value between samples. The other blanket samples’ weft counts ranged between 10–12 threads per one inch. The count number of warp/weft played an important role in the increase and decrease of air permeability of blankets samples. The warp/weft count that gave the lowest air permeability was S4 (21/12).

Table 2.

Physical properties of fiberglass blanket samples.

All blankets under evaluation were good insulators against electrical static. Sample S10 showed the highest static insulation with 370 MΩ. The lowest static insulation achieved by S2 with 70 MΩ.

3.3. Thermal Properties

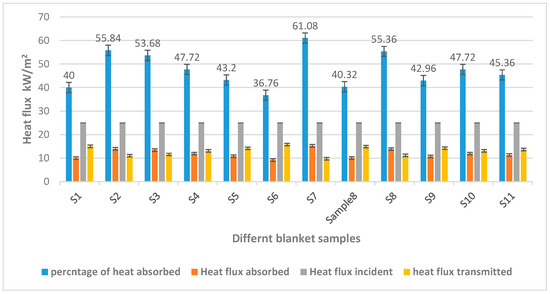

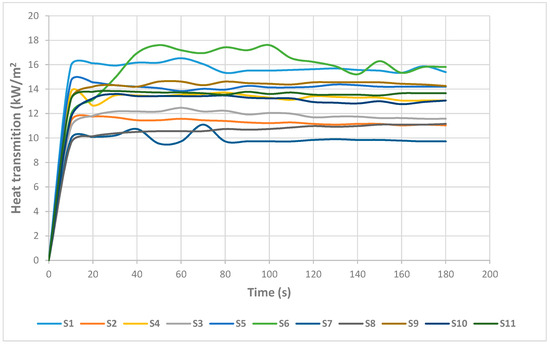

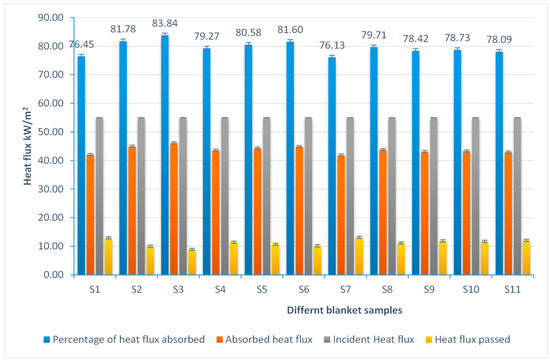

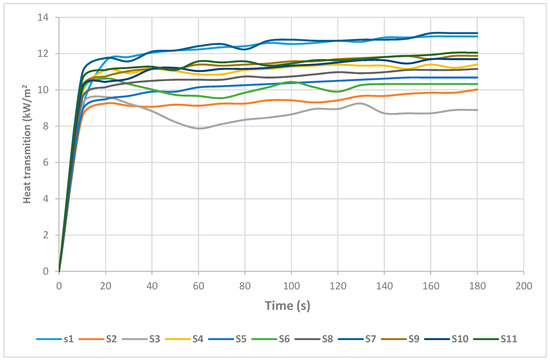

The radiative properties of blankets depend on the fiber materials (chemical composition) and the physical structure (fiber size, the volume fraction of fibers, and weaving method). To study the thermal characteristics of fiberglass blanket samples, we applied different heat flux rates on one surface (25 and 55 kW/m2) and measured the transmitted heat flux from the other surface. The results are tabulated in Table 3 and Table 4 and graphically represented in Figure 11, Figure 12, Figure 13 and Figure 14. The results in Table 3 show that the effect of heat flux at 25 kW/m2 on fiberglass blankets is similar to the fire growth stage.

Table 3.

The results of heat flux transfer through the blanket when incident heat flux is 25 kW/m2.

Table 4.

The results of heat flux transfer through the blanket when the incident heat flux is 55 kW.

Figure 11.

Comparison of the thermal behavior of blanket samples when subjected to 25 kW/m2.

Figure 12.

Heat transmitted from the blanket during application of 25 kW/m2 for three minutes.

Figure 13.

Comparison of the thermal behavior of blanket samples when subjected to 55 kW/m2.

Figure 14.

Heat transmitted from the blanket during application of 55 kW/m2 for three minutes.

The blanket samples showed different behaviors with a incident heat flux 25 kW/m2 in relation to the amount of heat absorbed and transmitted. Finally, we calculated the heat blocking efficiency (HBE) according the following equation:

The S6 blanket sample had the lowest heat blocking efficiency (36.76%), while sample S7 was characterized by the highest HBE percentage among all blanket samples (61.08%). The HBE values of the other samples are arranged in ascending order as follows:

S1 < S9 < S5 < S11 < S4 < S10 < S3 < S8

The curves in Figure 11 show that most of the blanket samples reached a steady state of heat transmission after 20 s. Four samples reached the maximum heat transmission below 12 kW/m2 (S2, S3, S7, and S8). The seven other blankets either had higher heat transmission, around 13 kW/m2 (S4 and S10), or exceed 13 kW/m2 (S5, 6, 9, and 11) to reach 15 kW/m2 (S1).

The thermal behavior of fiberglass blankets when subjected to higher heat flux (55 kW/m2) is different when compared to the 25 kW/m2 heat source. The HBE efficiency increased, and this means that heat transmitting from the blanket decreased. The highest HBE was achieved by S3 (83.84%) and the lowest by S7 (76.13%). The HBE percentage of Samples S8–S11 fell between 78.09 and 79.71%. The top HBE values, which were above 80% for samples, were in the ascending order S5, S6, S2, and S3 (80.58–83.84%).

Figure 13 gives a collective picture of the thermal behavior of different blanket samples when subjected to 55 kW/m2 for three minutes from a heat source. The deviation between the highest and the lowest results was 5% across all parameters.

The steady state of heat transmission from the blankets when applying 55 kW/m2 is shown in Figure 14. The time to reach the steady state is different from one sample to another. Two samples reached the steady state of heat transmission after 30 s (S5 and S1). The remaining samples reached the steady state between 40–60 s. The observed thermal characteristic is that the transmitted heat slightly exceeds 13 kW/m2 for the sample (S7).

3.4. Heat Effect of Direct Flame

The setup in Figure 14 shows the effect of a direct flame on the temperature of the inner face of a fiberglass blanket sample against the temperature transfer onto outer face.

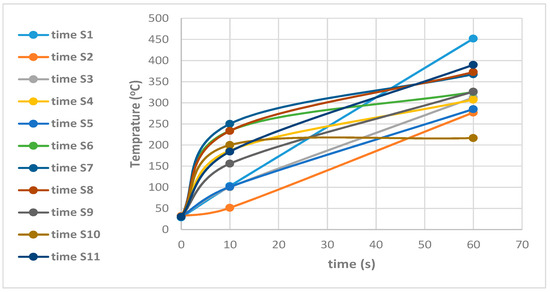

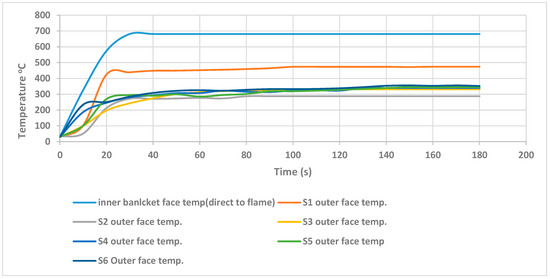

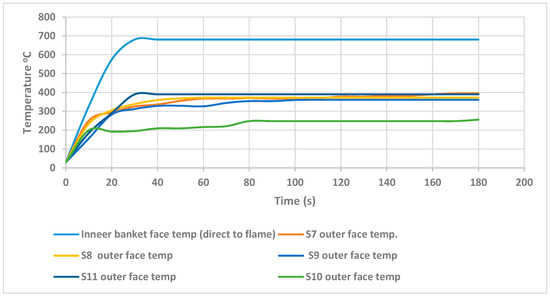

The response of the blanket surface to rising temperature from a direct flame is tabulated in Table 5 and Table 6 and graphically represented in Figure 15, Figure 16 and Figure 17.

Table 5.

Comparison between the temperature of inner and outer blanket surface samples (S1–S6) when subjected to a direct flame.

Table 6.

Comparison between the temperature of inner and outer blanket surface samples (S7–S11) when subjected to a direct flame.

Figure 15.

The temperature increase within one minute for different blanket samples.

Figure 16.

Response of blanket samples (S1–S6) to the temperature from a direct flame.

Figure 17.

Response of blanket samples (S7–S11) to the temperature from a direct flame.

The maximum temperature recorded from the inner surface facing the flame was 680.9 °C across three minutes. The maximum temperatures reached on the outer surface for different samples are different. The highest temperature was detected for blanket sample S1 (473.9 °C) and the lowest temperature was detected for the sample S10 (255.8 °C). The temperature of the rest of the blanket samples varies in value between 330 to 390 °C. The change in the temperature during the first minute is totally different from one sample to another; samples S1, S6, and S11 recorded the highest rise in temperature and mean temperature rise rate.

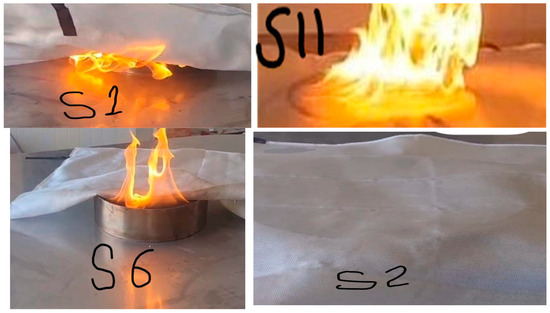

3.5. Fire Suppression Performance

The results of fire suppression performance of different fiberglass fire blankets are tabulated in Table 7 and images of the performance are shown in Figure 18. The fire suppression performance of blankets were determined according the requirement of ASTM F1989-5, using heptane as burning fuel.

Table 7.

Fire suppression performance results of different fiberglass blankets.

Figure 18.

Photos of fire suppression performance of selected blanket samples.

Eleven samples were tested for their fire suppression qualities. Eight samples passed the test and suppressed the fire with no ignition of the fuel after three minutes and removal of the blankets. Three samples failed to either suppress the fire from the first second, like sample S11, after which the flame transmitted to the surroundings, or after removing the blanket on completion of three minutes test duration, the flame was still burning (S1 and S6). One more observation was made during the suppression testing: the blanket samples produced smoke when subject to fire. In some samples, the smoke was heavy (S1, 2, 5, 6, and 11), while in others it was between moderate and light (S3, 4, 7, 8, 9, and 10).

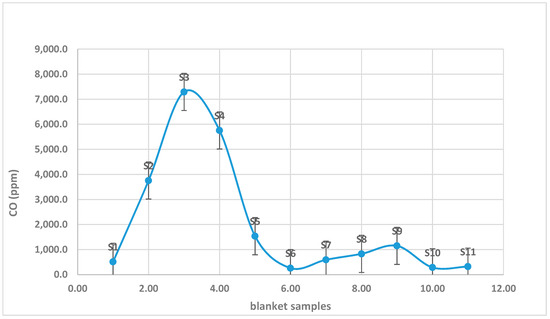

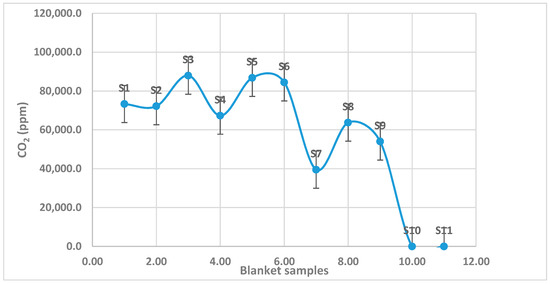

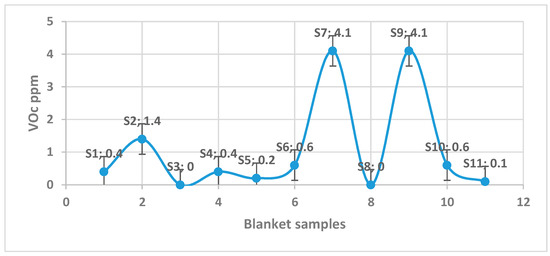

3.6. Toxicity

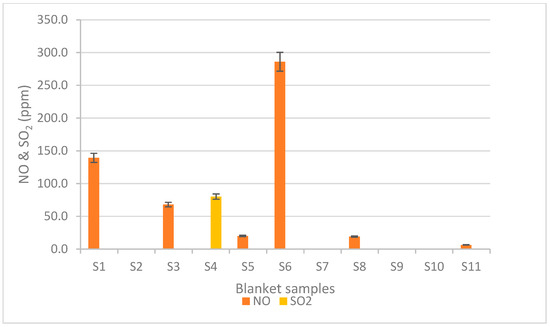

The results of toxic gases emitted during the suppression process are simulated by using small samples. We calculated the results for 100 g of blanket samples, and these are tabulated in Table 8. In addition, the toxicity index was calculated according to Equation (1) and is tabulated in same table. Figure 18, Figure 19, Figure 20, Figure 21 and Figure 22 show the change in toxic gases by changing the different fiberglass blanket samples.

Table 8.

Toxic gases emitted during the burning of fiberglass samples.

Figure 19.

Calculated CO gas emitted from 100 g of different burnt fiberglass blankets (based on the measured small samples).

Figure 20.

Calculated CO2 gas emitted from 100 g of different burnt fiberglass blankets (based on the measured small samples).

Figure 21.

Comparison of VOC emitted from different burnt fiberglass blankets.

Figure 22.

Calculated NO and SO2 gas emitted from 100 g of different burnt fiberglass blankets (based on the measured small samples).

The first toxic gas detected during the exposure of blanket samples to direct flame was carbon monoxide, with two samples exceeding the toxicity limit (S2 (7293.0 ppm) and S4 (5752.8 ppm)). The lowest value was recorded from sample S6 (259.9 ppm). The other samples varied in the amount of carbon monoxide emitted during the heating process, with the values falling in the range of 284 to 3774.5 ppm.

In general, the carbon dioxide gas emitted from different samples is below the toxic limit. The samples that achieved the lowest emissions were S10 and S11 (0.0 ppm). On the other hand, the results of carbon dioxide emissions for the rest of samples ranged between 39,499.7 to 86,840.3 ppm.

Volatile organic compounds were detected in most of the burnt blanket samples, except samples S3 and S8. The highest values, which exceeded the limit, were measured for samples S7 and S9 and S2, with values 4.1 and 1.4 ppm, respectively. On the other hand, two samples emitted VOC on the limit of 0.6 ppm (S6 and S10).

The fourth toxic gas emitted from blanket samples during the process of suppression was nitric oxide, which was emitted in different concentrations; only one sample (S6, 285.9 ppm) exceeded the toxic limit (250 ppm). Four blanket samples showed no nitric oxide gas emitted during the heating process (S2, S4, S7, and S9 and S10). In the case of samples S5 and S8, the values of NOx were nearly 20 ppm. Sulfur dioxide was only detected in sample S4 (80.16 ppm).

The toxicity index was calculated according to Equation (1), and the results are tabulated in Table 8 and graphically represented in Figure 23. Samples S10 and S11 showed the lowest toxicity index. The highest toxicity index was calculated for sample S3 (2.97). The other samples the toxicity index fell in the range 0.54–2.31.

Figure 23.

Toxicity index of different burnt fiberglass blankets (based on the measured small samples).

Classification of Blanket Toxicity

Here, we propose a method for classifying the toxicity of fiberglass blankets in relation to the toxic gases emitted during the fire suppression process, based on the results of total toxicity index and individual gas toxicity ratio.

The first class is non-toxic and shall achieve the following criteria:

- -

- The total toxicity index is lower than the number of gases detected (e.g., if the number of gases detected during the fire suppression process is three, the toxicity index shall be less than three);

- -

- The toxicity ratio of the individual gas detected shall be less than the total number of gas detected, when calculated according to following formula:Toxicity ratio =

Where the calculation is conducted according to Equation (1) in the experimental part of this paper.

The second class is designated as toxic and shall achieve one of the following criteria:

- The total toxicity index is equal to or exceeds the number of gases detected. For example, if three gases were detected during the fire suppression process, the toxicity index must be greater than or equal to three.

- Alternatively, the total toxicity index is lower than the number of gases detected, but the toxicity ratio of each individual gas must be equal to or greater than one. For instance, if three gases were detected, the total toxicity index should be less than three, but the toxicity ratio for each gas must be at least one.

4. Conclusions

Critical factors affecting the fire suppression performance of fiberglass blankets. The effectiveness of these blankets in controlling fires is intrinsically linked to their physical properties and thermal stability.

Among the most influential physical properties, air permeability is paramount. Lower air permeability is directly associated with superior fire suppression capabilities, whereas higher air permeability significantly undermines the blanket’s ability to suppress fire. Additionally, the warp/weft count and the structural configuration of the blanket play a crucial role. An increased weft count enhances the fire suppression performance of the material.

Heat blocking efficiency (HBE) at a heat flux of 25 kW/m2 is a key indicator of fire suppression performance. Blankets exhibiting HBE values exceeding 45% demonstrate high levels of fire control. Furthermore, the temperature rise during the initial minute of fire exposure is critical in assessing the suppression potential. A blanket with effective fire suppression should not exceed 300 °C after one minute, and its final temperature after three minutes should remain below 390–400 °C.

The introduction of a toxicity-based classification system further strengthens the safety profile of fiberglass blankets, ensuring their suitability for practical use. Notably, sample S2 demonstrated exceptional fire suppression performance, characterized by low air permeability, high HBE, gradual temperature increase, and excellent thermal stability, thus setting a new standard for fiberglass blanket design.

5. Practical Implications of the Study

The findings of this study have significant real-world applications in fire safety, industrial protection, and emergency response. The key practical implications include:

- Selection of Fire Blankets for Enhanced Safety

- Fire blankets with lower air permeability (e.g., S10) provide superior thermal insulation, making them ideal for high-temperature industrial applications, such as welding, foundries, and firefighting gear.

- S10 demonstrated the best fire suppression performance with minimal heat transmission and low toxicity emissions, making it a top choice for residential, commercial, and industrial fire safety applications.

- Improving Fire Suppression Efficiency

- The failure of certain samples (S1, S6, S11) in fire suppression suggests that not all fiberglass blankets are equally effective in real fire scenarios.

- Manufacturers should optimize textile weave, air permeability, and fiber composition to enhance fire resistance and eliminate flame penetration risks.

- Fire safety professionals should carefully evaluate blankets based on ASTM F1989-5 compliance rather than assuming all fiberglass blankets perform equally.

- Consideration of Toxic Gas Emissions

- Toxic gas emissions (CO, NO, VOCs) varied widely between samples, highlighting the need for stricter regulations on blanket materials to minimize health hazards during fire suppression.

- S10 and S11 had the lowest toxicity index, making them safer for indoor use, while S3 and S4 had the highest toxicity levels, which may pose respiratory risks in enclosed spaces.

- Fire departments and emergency responders should prioritize blankets with lower toxicity emissions to reduce exposure risks to occupants and first responders.

- Enhancing Industrial and Personal Protective Equipment (PPE)

- Fire-resistant blankets are widely used in hazardous workplaces, such as chemical plants, electrical insulation, and oil and gas industries.

- Thicker blankets with optimized warp/weft count provide better protection against direct flame and high heat flux, reducing the likelihood of burns and heat-related injuries.

- The study underscores the importance of thermal performance testing for PPE materials, ensuring compliance with OSHA and NFPA standards.

- Future Design and Manufacturing Innovations

- The results provide a foundation for developing next-generation fire blankets with improved heat-blocking efficiency, lower smoke generation, and reduced toxic emissions.

- Material engineers can use these data to design composite fire blankets that combine fiberglass with other heat-resistant materials (e.g., silica, aramid fibers) to enhance durability and performance.

- There is a need for further research into environmentally friendly fire suppression blankets that minimize CO and VOC emissions while maintaining high efficiency.

Author Contributions

Methodology, M.M.A. and M.R.A.; Formal analysis, A.A.Z.; Investigation, M.M.A., M.R.A., S.A.S. and N.A.A.; Writing—review & editing, M.A.H. and A.A.Z.; Supervision, M.A.H.; Project administration, M.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research work is funded by Saudi standards, metrology and quality organization (SASO).

Data Availability Statement

The information is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tewarson, A.; Wu, P.K.; Chin, W.K.; Shuford, R. Fire Blankets for Munition Protection: Flame and Heat Blocking Properties of Advanced Materials; ARL-TR-2398; Army Research Laboratory: Adelphi, MD, USA, 2001. [Google Scholar]

- Hansen, J.G.R.; Frame, B.J. Flame penetration and burn testing of fire blanket materials. Fire Mater. 2008, 32, 457–483. [Google Scholar] [CrossRef]

- Chow, W.K. Fire safety concern on open kitchen in small residential units of tall buildings. Int. J. Eng. Perform. Based Fire Codes 2011, 10, 58–62. [Google Scholar]

- Arvidson, M.; Gehandler, J.; Bleye, J. Fire Suppression and Manual Firefighting of Battery Electric Vehicle Fires on Ro-Ro Ships. In Proceedings of the Seventh International Conference on Fires in Vehicles, Stavanger, Norway, 24–25 April 2023. [Google Scholar]

- Sturm, P.; Fößleitner, P.; Fruhwirt, D.; Galler, R.; Wenighofer, R.; Heindl, S.F.; Krausbar, S.; Heger, O. Fire tests with lithium-ion battery electric vehicles in road tunnels. Fire Saf. J. 2022, 134, 103695. [Google Scholar] [CrossRef]

- Wijesekere, T.; Funk, E.; Wilkens, K.; Husted, B. Long-Scale Tests of Firefighting Technologies for Electric Vehicle Fires on Board Ro-Ro Ferries. In Proceedings of the Seventh International Conference on Fires in Vehicles, Stavanger, Norway, 24–25 April 2023. [Google Scholar]

- Kwon, J.-S.; Kim, H.-J.; Lee, S.-H.; Park, T.-H.; Kim, T.-D.; Kim, S.-Y. Application of car fire blankets to car fires. Fire Sci. Eng. 2021, 35, 143–149. [Google Scholar] [CrossRef]

- Slašťan, K.; Svetlík, J.; Konárik, M.; Boroš, M. Identifying effect of car fire blankets on chosen fire parameters using large-scale fire tests of internal combustion engine vehicle and high-voltage traction battery—Comparative Slovak case study. Appl. Sci. 2024, 14, 4902. [Google Scholar] [CrossRef]

- Takahashi, F.; Abbott, A.; Murray, T.M.; T’ien, J.S.; Olson, S.L. Thermal response characteristics of fire blanket materials. Fire Mater. 2014, 38, 609–638. [Google Scholar] [CrossRef]

- Aventi. Performance optimization of thin fire blankets by varying their radiative properties. Int. J. Sci. Technol. 2019, 5, 36–58. [Google Scholar] [CrossRef]

- ISO 7211-2:2024; Textiles—Methods for Analysis of Woven Fabrics Construction—Part 2: Determination of Number of Threads per Unit Length. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO 9237:1995; Textiles—Determination of the Permeability of Fabrics to Air. International Organization for Standardization: Geneva, Switzerland, 1995.

- ASTM F1989−05; Standard Specification for Cooking Fire Suppression Blankets. ASTM International: West Conshohocken, PA, USA, 1989; (Reapproved 2020). [CrossRef]

- Standard 02-713 Issue 3; Determination of Toxicity Index of the Product of Combustion from Small Specimen of Materials. UK Ministry of Defence: London, UK, 2006.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).