A Review of Safety Measures in Battery Electric Buses

Abstract

1. Introduction

2. Safety Tests

- crash tests: frontal collision, side collision, and rear collision tests

- fire tests

- vibration tests

- safety tests for REESS (rechargeable energy storage systems) and battery packs

- rollover tests

2.1. Safety Tests for REESS and Battery Pack

- Mechanical stress: crash tests, impact tests, drop tests, nail penetration tests, and others [37].

- Thermal stress: high-temperature hazard battery test, thermal stability test, thermal shock cycling, and others [33].

- Electrical stresses: overcharge, over discharge, external short-circuit, forced discharge, and others [38].

2.2. Roll-Over Simulation

2.3. Frontal Collision Test

2.4. Side Collision Test

2.5. Fire Tests

2.6. Vibration Tests

2.7. Standards and Regulation

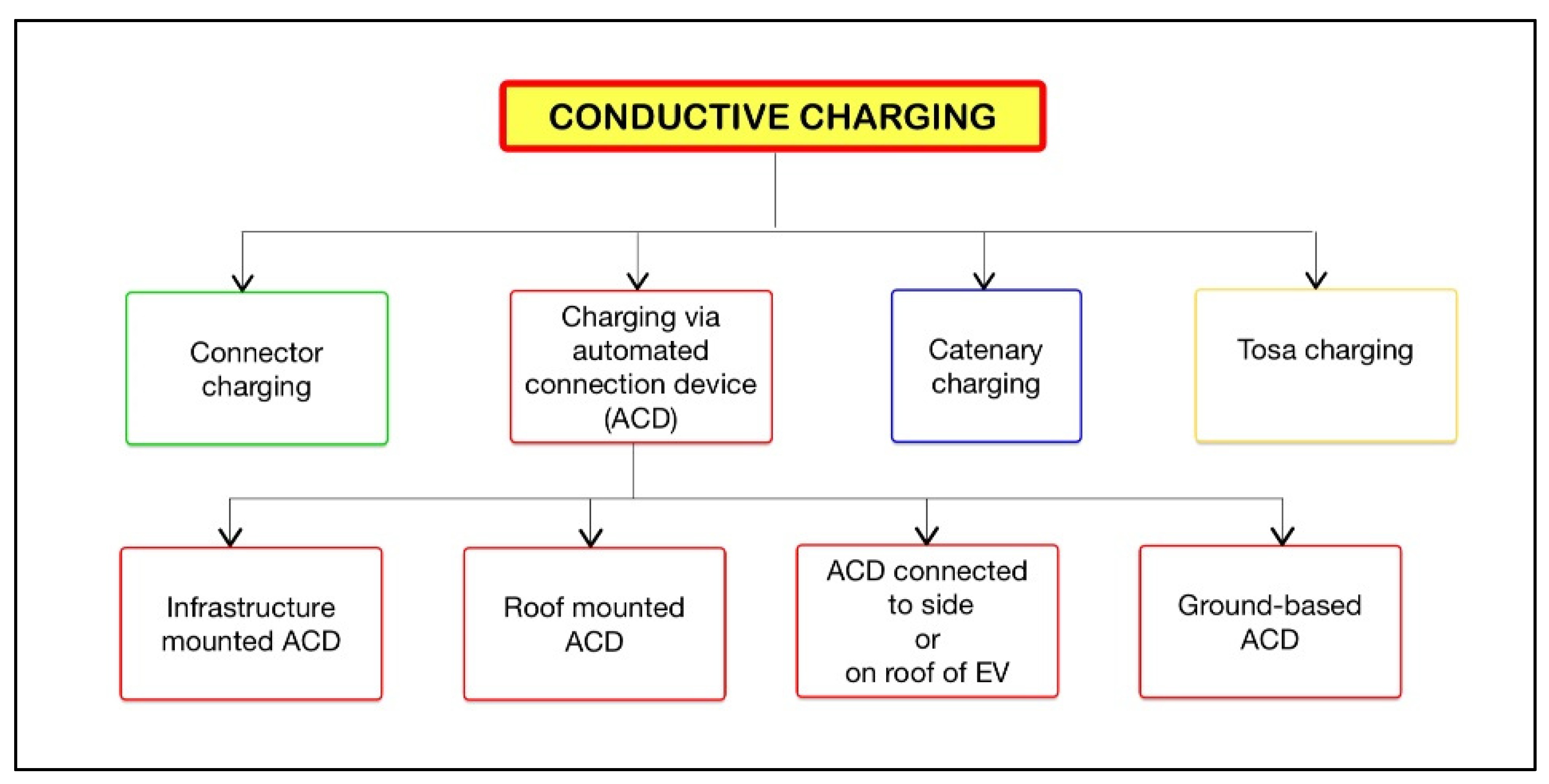

3. Charging Safety of E-Bus

Fast Charging Stations

- There is no comprehensive assessment of the potential negative impacts of high-power BEB charging on the electricity distribution network.

- There is no consolidated view by European DSOs on mitigation measures [103].

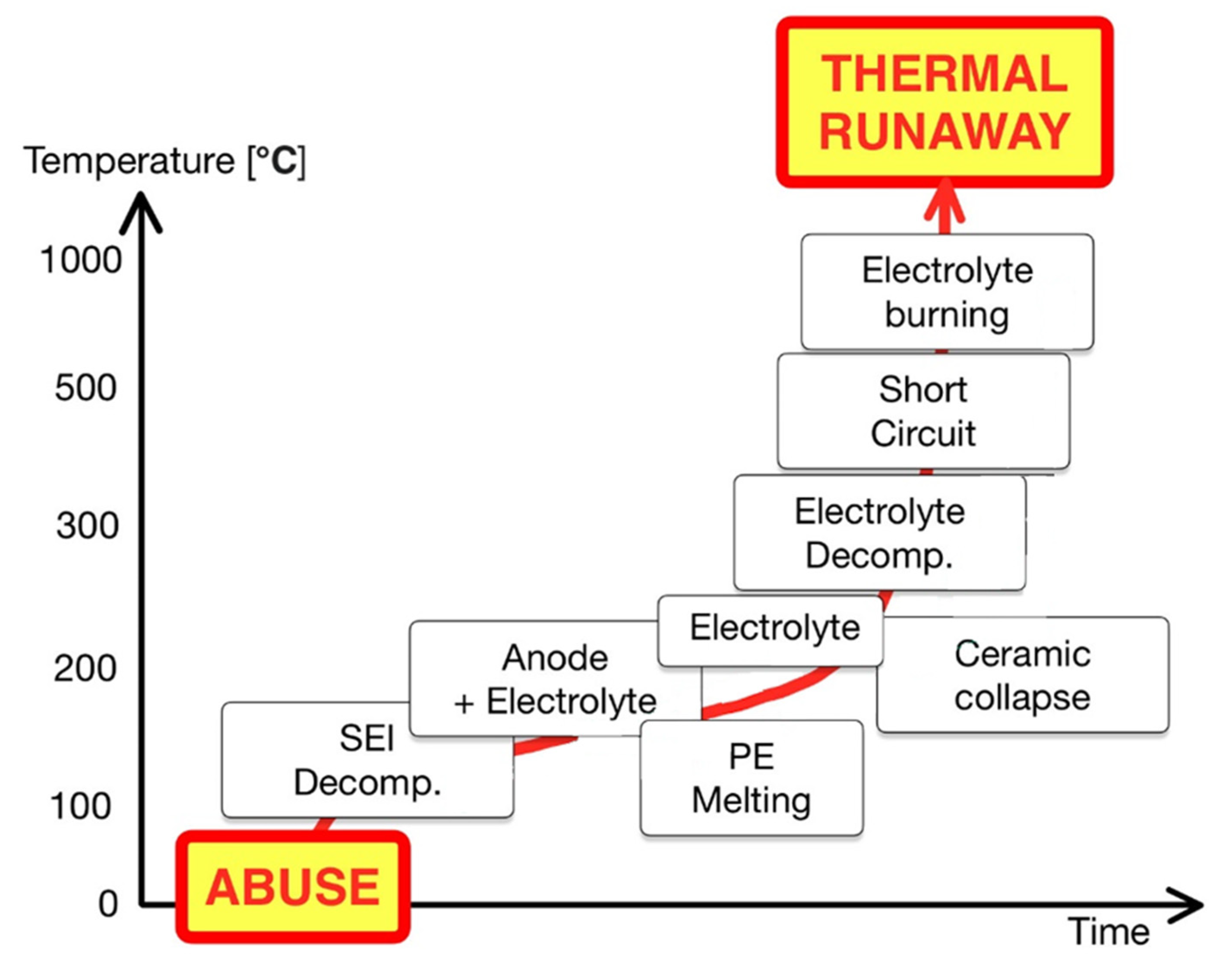

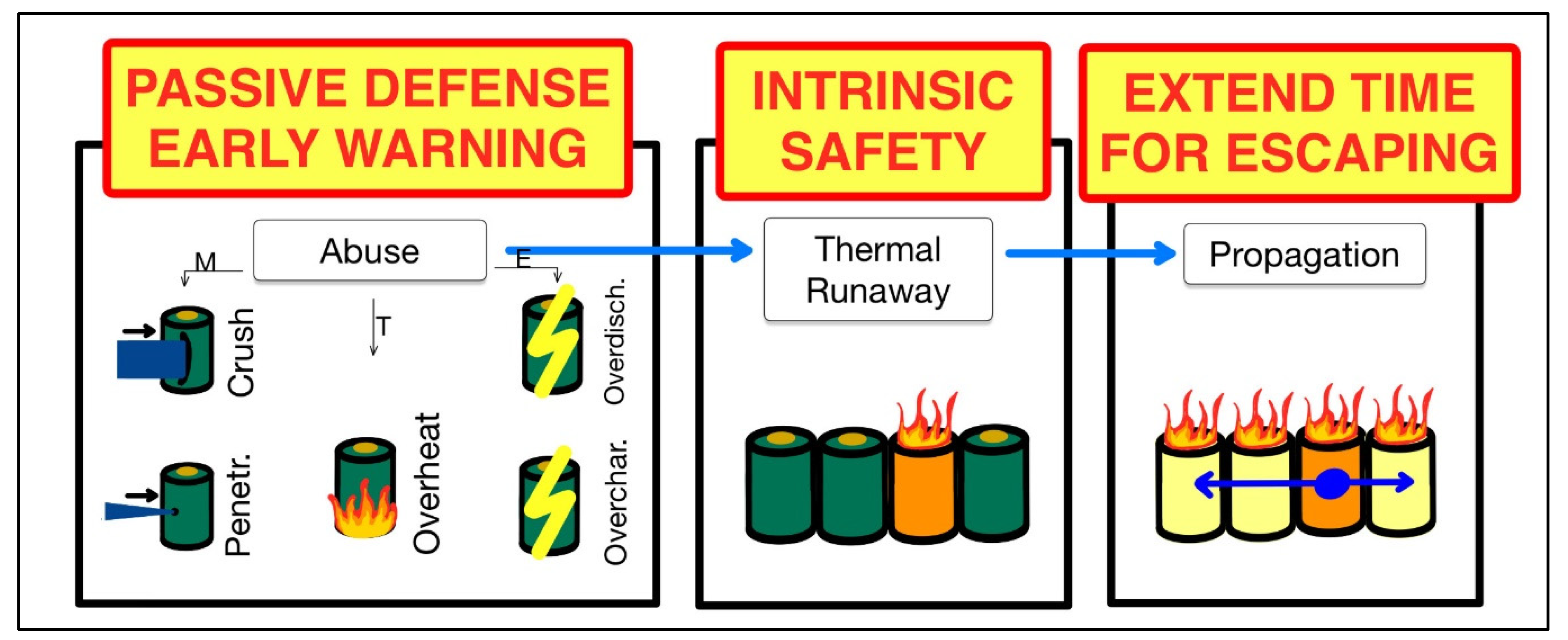

4. Thermal Runaway and Prevention

- State of charge (SOC) (0–100%)

- Electrodes material (LCO, NCA, LFP, NMC, …)

- Battery capacity (0.5–80 Ah)

- State of health (SOH)

- Type of configuration (coin cells, prismatic cells, pouch cells …)

- Lithium Iron Phosphate (LFP): This chemistry is known for its thermal and chemical stability, reducing the risk of fires and explosions.

- Lithium Nickel Manganese Cobalt Oxide (NMC): Although this chemistry has a high energy density, it is generally considered safe and stable.

- Lithium Nickel Cobalt Aluminum Oxide (NCA): Mainly used by Tesla, this chemistry offers a good balance between energy density and stability.

- Lithium Manganese Oxide (LMO): This chemistry is known for its stability at high temperatures [117].

- Battery cooling system designed to maintain BEV batteries at a safe and optimal temperature during both operation and charging.

- Battery Management System (BMS), which has the function of constantly keeping track of the temperature, charge level, and other factors of the battery. The purpose of the BMS is to prevent the battery from overcharging, over-discharging, or overheating, all of which can trigger fires [125]. Specifically, the BMS constantly monitors the individual cells and shuts them down if they are not operating within the aspired range of parameters. The cells operate within strings; if an anomaly occurs, each string can be switched off, but the vehicle can continue to run to a safe location [126].

- Thermal management system, to keep the battery at a safe temperature and avoid thermal runaway reactions that can cause fires, this system uses cooling and heating.

- Fire walls, which prevent flames from spreading to other interior compartments. They are usually constructed of heat-resistant materials. Fire walls can tolerate extreme temperatures.

- Fuses and circuit breakers are designed to protect the electrical system of electric vehicles from overloads and short circuits, both of which can lead to fires. Fuses are strategically placed along the circuit and are designed to melt and interrupt the flow of current in the event of an overload or short circuit, avoiding more serious damage to the system [127]. Circuit breakers, on the other hand, are used to regulate the current flow within the module pack [128].

- Emergency shutdown is a crucial function of battery management systems (BMS) to prevent future damage or fire; this mechanism shuts down the electrical system and disconnects the battery.

- The incorporation of a pressure release valve is a common practice in the lower section of the battery pack. When the pressure within the battery pack exceeds a specified threshold, the valve opens, resets, and then closes again after the thermal runaway of individual cells and subsequent pressure release. This mechanism prevents external air from entering the battery pack, thereby slowing down the propagation of thermal leakage risk within the pack [124].

5. Safety of E-Buses in Tunnels and Enclosed Spaces

Mechanical Ventilation System

6. E-Buses in E-Bus Depots

6.1. The Netherlands—The Westraven E-Bus Depot

6.2. High-Pressure Water Mist Systems

6.3. Li-ionFire Project: An Innovative Fire Suppression System

- -

- Early detection and action:

- -

- Integrated fire protection system:

6.4. Fire Guidelines for E-Bus Depots

7. Cybersecurity in E-Bus

- 1. Reliability of bus mechatronic systems;

- 2. Battery and power system reliability;

- 3. Monitoring energy levels and battery charging;

- 4. Reliability of the individual technical elements of the charging system;

- 5. Security and reliability of the public transport IT system [173].

- Past Cyber threats

- AI

- and Cybersecurity

Moving-Target Defense (MTD) and Blockchain in Charging Stations

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ACD | Automated Connection Device |

| AMT | Automated Mechanical Transmission |

| BEB | Battery Electric Bus |

| BEM | Boundary-Element Method |

| BEV | Battery Electric Vehicles |

| BMS | Battery Management Systems |

| CAN | Controller Area Network |

| DCA | Delayed Charging Attack |

| DDoS | Distributed Denial of Service |

| DSOs | Distribution System Operators |

| EESS | Electrical Energy Storage System |

| EV | Electric Vehicles |

| FEM | Finite Element Method |

| FMEA | Failure Mode and Effects Analysis |

| FMVSS | Federal Motor Vehicle Safety Standards |

| FTA | Fault Tree Analysis |

| GWP | Global Warming Potential |

| HEV | Hybrid Electric Vehicle |

| HMA | Hazard Mitigation Analysis |

| HRR | Heat Release Rate |

| ICEB | Internal Combustion Engine Bus |

| ICV | Internal Combustion Vehicle |

| IDS | Intrusion Detection Systems |

| IT | Information Technology |

| LFP | Lithium Iron Phosphate |

| LSR | Least-Squares Regression |

| MTD | Moving Target Defense |

| NCA | Lithium Nickel Cobalt Aluminum Oxide |

| NHTSA | National Highway Traffic Safety Administration |

| NMC | Lithium Nickel Manganese Cobalt Oxide |

| PCM | Phase Change Material |

| RBFNN | Radial-Based Neural Network |

| REESS | Rechargeable Energy Storage System |

| TR | Thermal Runaway |

| V2C | Vehicle-to-Cloud |

| WM | Water Mist |

| ZEB | Zero Emission Bus |

References

- International Association of Public Transport (UITP). EBRD UITP GIZ Going Electric A Pathway to Zero Emission Buses; UITP Publication: Brussels, Belgium, 2021. [Google Scholar]

- Chapman, L. Transport and climate change: A review. J. Transp. Geogr. 2007, 15, 354–367. [Google Scholar] [CrossRef]

- Doulgeris, S.; Zafeiriadis, A.; Athanasopoulos, N.; Tzivelou, Ν.; Michali, M.; Papagianni, S.; Samaras, Z. Evaluation of energy consumption and electric range of battery electric busses for application to public transportation. Transp. Eng. 2024, 15, 100223. [Google Scholar] [CrossRef]

- Leone, E. Fire Safety Analysis of Alternative Vehicles in Confined Spaces: A Study of Road Tunnels and Underground Parking Facilities. Master’s Thesis, Politecnico di Torino, Torino, Italy, 2023. [Google Scholar]

- El Houssami, M.; Försth, M.; Fredriksson, H.; Drean, V.; Guillaume, E.; Hofmann-Böllinghaus, A.; Sandinge, A. Fire safety of interior materials of buses. Fire Mater. 2023, 47, 910–924. [Google Scholar] [CrossRef]

- Tohir, M.Z.M.; Martín-Gómez, C.; Electric Vehicle Fire Risk Assessment Framework Using Fault Tree Analysis. Open Research Europe. Available online: https://open-research-europe.ec.europa.eu/articles/3-178/v1 (accessed on 14 June 2024).

- Weiss, M.; Dekker, P.; Moro, A.; Scholz, H.; Patel, M.K. On the electrification of road transportation—A review of the environmental, economic, and social performance of electric two-wheelers. Transp. Res. Part D Transp. Environ. 2015, 41, 348–366. [Google Scholar] [CrossRef]

- Hodges, T. Public Transportation’s Role in Responding to Climate Change; Federal Transit Administration: Darby, PA, USA, 2010. [Google Scholar]

- Kapatsila, B.; Grisé, E.; Crumley, M.; El-Geneidy, A. Empirical analysis of battery-electric bus transit operations in Portland, OR, USA. Transp. Res. Transp. Environ. 2024, 128, 104120. [Google Scholar] [CrossRef]

- Rodrigues, L.P. Battery-electric buses and their implementation barriers: Analysis and prospects for sustainability. Sustain. Energy Technol. Assess. 2022, 51, 101896. [Google Scholar] [CrossRef]

- U.S. Department of Transportation. Transitioning to Zero-Emission Bus Operations; U.S. Department of Transportation: Washington, DC, USA, 2023. [Google Scholar]

- Mathes, M.; Schmidt, M.; Käsgen, J.; Fievet, B.; Van Tichelen, P.; Berecibar, M.; Al-Saadi, M. Heavy-Duty Battery Electric Buses’ Integration in Cities Based on Superfast Charging Technologies: Impact on the Urban Life. Sustainability 2022, 14, 4777. [Google Scholar] [CrossRef]

- Ntombela, M.; Musasa, K.; Moloi, K. A Comprehensive Review for Battery Electric Vehicles (BEV) Drive Circuits Technology, Operations, and Challenges. World Electr. Veh. J. 2023, 14, 195. [Google Scholar] [CrossRef]

- Vengatesan, S.; Jayakumar, A.; Sadasivuni, K.K. FCEV vs. BEV—A short overview on identifying the key contributors to affordable & clean energy (SDG-7). Energy Strat. Rev. 2024, 53, 101380. [Google Scholar] [CrossRef]

- Pramuanjaroenkij, A.; Kakaç, S. The fuel cell electric vehicles: The highlight review. Int. J. Hydrogen Energy 2023, 48, 9401–9425. [Google Scholar] [CrossRef]

- Foorginezhad, S.; Mohseni-Dargah, M.; Falahati, Z.; Abbassi, R.; Razmjou, A.; Asadnia, M. Sensing advancement towards safety assessment of hydrogen fuel cell vehicles. J. Power Sources 2021, 489, 229450. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Li, B.; Mo, T.; Li, Y.; Feng, S.-P.; Qu, J.; Chu, P.K. Development and application of fuel cells in the automobile industry. J. Energy Storage 2021, 42, 103124. [Google Scholar] [CrossRef]

- Togun, H.; Aljibori, H.S.S.; Abed, A.M.; Biswas, N.; Alshamkhani, M.T.; Niyas, H.; Mohammed, H.I.; Rashid, F.L.; Dhabab, J.M.; Paul, D. A review on recent advances on improving fuel economy and performance of a fuel cell hybrid electric vehicle. Int. J. Hydrogen Energy 2024, 89, 22–47. [Google Scholar] [CrossRef]

- Chiara, B.D.; Pede, G.; Deflorio, F.; Zanini, M. Electrifying Buses for Public Transport: Boundaries with a Performance Analysis Based on Method and Experience. Sustainability 2023, 15, 14082. [Google Scholar] [CrossRef]

- Duelli, S. Analysis of Economic Impacts on the Austrian Economy: The Path to a CO2-Neutral Freight Transport Sector by 2040. Available online: http://unipub.uni-graz.at/obvugrhs/6134381 (accessed on 22 January 2025).

- Topal, O. Sustainable urban mobility in Istanbul: A financial assessment of fuel cell hybrid-electric buses in the metrobus system. CTF Cienc. Tecnol. Futur. 2023, 13, 15–30. [Google Scholar] [CrossRef]

- EV Fire Safe. Why Do E-Buses Catch Fire? Available online: https://www.evfiresafe.com/post/why-do-e-buses-catch-fire (accessed on 22 January 2025).

- Sustainable Bus. Final Report on RATP Buses on Fire in 2022 Is Out. Cause? Thermal Runaway. “Mylar Insulation Had Been Incorrectly Positioned”. Available online: https://www.sustainable-bus.com/news/report-bea-tt-fire-ratp-buses-bluebus-cause (accessed on 22 January 2025).

- Sturm, P.; Fößleitner, P.; Fruhwirt, D.; Heindl, S.F.; Heger, O.; Galler, R.; Wenighofer, R.; Krausbar, S. “BRAFA”—Brandauswirkungen von Fahrzeugen mit alternativen Fahrzeugantrieben, Teil 1; Graz University of Technology: Styria, Austria, 2021. [Google Scholar] [CrossRef]

- Yao, H.; Xing, M.; Song, H.; Zhang, Y.; Luo, S.; Bai, Z. The Impact of Different Ventilation Conditions on Electric Bus Fires. Fire 2024, 7, 182. [Google Scholar] [CrossRef]

- Caliendo, C.; Russo, I.; Genovese, G. A Numerical Evaluation for Estimating the Consequences on Users and Rescue Teams Due to the Fire of an Electric Bus in a Road Tunnel. Appl. Sci. 2024, 14, 9191. [Google Scholar] [CrossRef]

- UITP. ZeEUS eBus Report #2 An Updated Overview of Electric Buses in Europe; UITP: Brussels, Belgium, 2017. [Google Scholar]

- Mellert, L.D.; Welte, U.; Tuchschmid, M.; Held, M.; Hermann, M.; Kompatscher, M.; Tesson, M.; Nachef, L. Risikominimierung von Elektrofahrzeugbränden in Unterirdischen Verkehrsinfrastrukturen; Schweizerischer Verband der Strassen- und Verkehrsfachleute (VSS): Zürich, Switzerland, 2020. [Google Scholar]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; van den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Andersson, P.; Willstrand, O. Proceedings of the 5th International Conference on Fires in Vehicles—FIVE 2018, Borås, Sweden, 3–4 October 2018; RISE Research Institutes of Sweden: Borås, Sweden, 2018. [Google Scholar]

- Doughty, D.H.; Crafts, C.C. FreedomCAR: Electrical Energy Storage System Abuse Test Manual for Electric and Hybrid Electric Vehicle Applications; Sandia National Laboratories (SNL): Albuquerque, NM, USA, 2006. [Google Scholar] [CrossRef]

- Torres-Castro, L.; Lamb, J. United States Advanced Battery Consortium Battery Abuse Testing Manual for Electric and Hybrid Vehicle Applications; Sandia National Lab (SNL-NM): Albuquerque, NM, USA, 2022. [Google Scholar] [CrossRef]

- SAE International Recommended Practice. Electric and Hybrid Electric Vehicle Rechargeable Energy Storage System (RESS) Safety and Abuse Testing J2464_200911; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Lambert, H.E. Use of Fault Tree Analysis for Automotive Reliability and Safety Analysis. In The SAE 2004 World Congress & Exhibition; SAE International: Warrendale, PA, USA, 2004; pp. 690–696. [Google Scholar] [CrossRef]

- G-41 Reliability. Recommended Failure Modes and Effects Analysis (FMEA) Practices for Non-Automobile Applications; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Sinz, W.; Breitfuß, C.; Tomasch, E.; Gugler, J.; Feist, F.; Lacher, H.; Conte, F.V.; Kutsenits, S.; Kieninger, E. Integration of a crashworthy battery in a fully electric city bus. Int. J. Crashworthiness 2012, 17, 105–118. [Google Scholar] [CrossRef]

- Sinz, W.; Feist, F.; Gstrein, G.; Gugler, J.; Tomasch, E.; Breitfuss, C.; Luttenberger, P.; Steffan, H.; Gollob, P.; Hennige, V. Concepts for Mechanical Abuse Testing of High-Voltage Batteries. In Proceedings of the SAE 2012 World Congress & Exhibition, Detroit, MI, USA, 24–26 April 2012; p. 20. [Google Scholar] [CrossRef]

- Biensan, P.; Simon, B.; Pérès, J.; de Guibert, A.; Broussely, M.; Bodet, J.; Perton, F. On safety of lithium-ion cells. J. Power Sources 1999, 81–82, 906–912. [Google Scholar] [CrossRef]

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- EUCAR. Battery Requirements for Future Automotive Applications; European Council for Automotive R&D: Brussels, Belgium, 2019. [Google Scholar]

- Spirk, S.; Kepka, M. Tests and Simulations for Assessment of Electric Buses Passive Safety. Procedia Eng. 2015, 114, 338–345. [Google Scholar] [CrossRef][Green Version]

- Shuyan, L.; Yan, C.; Fachao, J.; Jianzhu, Z.; Guoye, W. Guoye. Research on the Finite Element Analysis and Failure Strengthening Test of Electric Bus Quick-Change Battery Box. In Proceedings of the 2015 8th International Conference on Intelligent Computation Technology and Automation (ICICTA), Nanchang, China, 4–5 June 2015; pp. 771–775. [Google Scholar] [CrossRef]

- Spirk, S.; Kepka, M. Effects of Dynamic Forces and Strain Rate During Battery-Electric Bus Impact. In Proceedings of the 26th International DAAAM Symposium on Intelligent Manufacturing and Automation, Zadar, Croatia, 19–22 October 2015; Katalinic, B., Ed.; DAAAM International Vienna: Vienna, Austria, 2016; pp. 920–925. [Google Scholar] [CrossRef]

- Yu, D.; Li, Y.; Zhang, S.; Dong, H.; Han, G.; Xian, X. Fire Extinguishing Test of Lithium-Ion Battery Case in Electric Bus. In Proceedings of the 9th International Conference on Fire Science and Fire Protection Engineering (ICFSFPE), Chengdu, China, 20–23 October 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Un, C.; Aydın, K. Thermal Runaway and Fire Suppression Applications for Different Types of Lithium Ion Batteries. Vehicles 2021, 3, 480–497. [Google Scholar] [CrossRef]

- Andersson, P.; Brandt, J.; Willstrand, O. Full Scale Fire-Test of an Electric Hybrid Bus. 2016. Available online: https://www.semanticscholar.org/paper/Full-scale-fire-test-of-an-electric-hybrid-bus-Andersson-Brandt/b832eade1cf39f70564256d6a59aeb1793787581 (accessed on 23 January 2025).

- Bisschop, R.; Willstrand, O.; Rosengren, M. Handling Lithium-Ion Batteries in Electric Vehicles: Preventing and Recovering from Hazardous Events. Fire Technol. 2020, 56, 2671–2694. [Google Scholar] [CrossRef]

- Bhatambarekar, M.; Sharma, S. Electric vehicle Traction Batteries Installation Guidelines for Bus Application. Int. J. Eng. Tech. Res. 2023, 13, 23–27. [Google Scholar]

- UNECE. Review and Revision of UN-ECE Regulation No. 66. Consolidated Document Presenting the Work to Date of the Adhoc Expert Group; UNECE: Geneva, Switzerland, 2002. [Google Scholar]

- Kunakron-ong, P.; Ruangjirakit, K.; Jongpradist, P. Design and analysis of electric bus structure in compliance with ECE safety regulations. In Proceedings of the 2017 2nd IEEE International Conference on Intelligent Transportation Engineering (ICITE), Singapore, 14–16 September 2017; pp. 25–29. [Google Scholar] [CrossRef]

- National Highway Traffic Safety Administration (NHTSA). Federal Motor Vehicle Safety Standards; Bus Rollover Structural Integrity; National Highway Traffic Safety Administration (NHTSA): Washington, DC, USA, 2021. [Google Scholar]

- Wang, D.; Xie, C.; Liu, Y.; Xu, W.; Chen, Q. Multi-objective Collaborative Optimization for the Lightweight Design of an Electric Bus Body Frame. Automot. Innov. 2020, 3, 250–259. [Google Scholar] [CrossRef]

- Mihradi, S.; Dhaniswara, A.; Wicaksono, S.; Mahyuddin, A.I. Bus Superstructure Reinforcement for Safety Improvement Against Rollover Accidents. J. Eng. Technol. Sci. 2022, 54, 220206. [Google Scholar] [CrossRef]

- Satrijo, D.; Kurdi, O.; Haryanto, I.; Yob, M.S.; Riyantiarno, N.; Taufiqurrahman, I. Rollover performance analysis of electric bus superstructure frame with alternative material using finite element method. In Proceedings of the the 5th International Conference on Industrial, Mechanical, Electrical, and Chemical Engineering 2019 (ICIMECE 2019), Surakarta, Indonesia, 16–17 October 2019; p. 030153. [Google Scholar] [CrossRef]

- Alpar, M.; Savran, E.; Karpat, F. Anti-Roll Bar Optimization of an Urban Electric Bus. Arch. Adv. Eng. Sci. 2024, 1–8. [Google Scholar] [CrossRef]

- Nguyen, T.-T.; Nguyen, C.-T.; Nguyen, V.-S.; Nguyen, D.-N. Optimal Design for Body Structure of Coach Bus to Satisfy Rollover Collision Safety Based on ECER66 Standard. In Proceedings of the International Conference on Advanced Mechanical Engineering, Automation, and Sustainable Development 2021 (AMAS2021), Ho Chi Minh, Vietnam, 26–27 November 2021; Long, B.T., Kim, H.S., Ishizaki, K., Toan, N.D., Parinov, I.A., Kim, Y.-H., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 76–85. [Google Scholar]

- Jongpradist, P.; Saingam, N.; Tangthamsathit, P.; Chanpaibool, P.; Sirichantra, J.; Aimmanee, S. Crashworthiness analysis and design of a sandwich composite electric bus structure under full frontal impact. Heliyon 2022, 8, e11999. [Google Scholar] [CrossRef]

- Jongpradist, P.; Saingam, N.; Tangthamsathit, P.; Chanpaibool, P.; Sirichantra, J.; Aimmanee, S. Crash analysis of sandwich composite electric microbus. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1137, 012048. [Google Scholar] [CrossRef]

- Yang, X.; Fan, D.; Zhou, P.; Zhang, S. Six-sigma robust design optimisation of an electric bus considering crashworthiness and lightweight. Veh. Perform. 2023, 9, 109–133. [Google Scholar] [CrossRef]

- Menino, B.G.; Spengler, F.; Biondo, F. Design and Analysis of an Impact Absorber for Battery Pack Protection in Electric Buses Using Numerical Simulation; SAE International: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Wen-wei, W.; Cheng-jun, Z.; Jiao-yang, C. Pure Electric Bus Crashworthiness Analysis. In Proceedings of the 1st International Conference on Mechanical Engineering and Material Science; Atlantis Press: Beijing, China, 2012. [Google Scholar] [CrossRef]

- UNECE. UN Regulation No. 95-Rev.2-Amend.5; UNECE: Geneva, Switzerland, 2021. [Google Scholar]

- National Highway Traffic Safety Administration (NHTSA). Federal Motor Vehicle Safety Standards; Side Impact Protection, Ejection Mitigation; Technical Corrections; National Highway Traffic Safety Administration (NHTSA): Washington, DC, USA, 2020. [Google Scholar]

- Dai, R.; Yang, X.; Shi, S.; Wu, X. Electric Bus Frame Optimization for Side-Impact Safety and Mass Reduction Based on the Surrogate Model Method; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, J.; Li, H.; Zhang, L. Impact Safety Control Strategy for the Battery System of an Example Electric Bus. Math. Probl. Eng. 2015, 2015, 123626. [Google Scholar] [CrossRef]

- Kurdi, I.; Haryanto, I.; Yulianti, I.; Satrijo, D.; Suprihanto, A.; Taufiqurrahman, I. Side Collision Dynamic Analysis of Electric Bus Frame Using Finite Element Method. In Proceedings of the 2019 6th International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 5–7 November 2019; pp. 100–104. [Google Scholar] [CrossRef]

- Wang, Z.P.; Wang, Y. Finite Element Modeling and Simulation Analysis on Side Impact of Electric Bus. Trans. Beijing Inst. Technol. 2013, 33, 266–270. [Google Scholar]

- Wang, Z.; Cui, J.; Luo, J. Analysis of collision safety of power battery system of electric bus with simulation. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Willstrand, J.; Gehandler, J.; Andersson, P. Proceedings of the Seventh International Conference on Fires in Vehicles, Stavanger, Norway, 24–25 April 2023; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2023. [Google Scholar]

- Digges, K.H.; Gann, R.; Grayson, S.; Hirschler, M.; Lyon, R.; Purser, D.; Quintiere, J.; Stephenson, R.; Tewarson, A. Improving Survivability in Motor Vehicle Fires. Int. J. Web Serv. Res. 2007, 7, 135–143. [Google Scholar]

- Hammarström, R.; Axelsson, J.; Försth, M.; Johansson, P.; Sundström, B. Fire Safety in Buses; SP Technical Research Institute of Sweden: Borås, Sweden, 2007. [Google Scholar]

- Försth, M.; Modin, H.; Sundström, B. A comparative study of test methods for assessment of fire safety performance of bus interior materials. Fire Mater. 2013, 37, 350–357. [Google Scholar] [CrossRef]

- Krishna, K.; Mahesha, G.T.; Hegde, S.; Shenoy, B.S. A Review on Vibrations in Electric and Hybrid Electric Vehicles. J. Inst. Eng. Ser. C 2023, 104, 423–438. [Google Scholar] [CrossRef]

- Ghosh, A.; Chatterjee, S. An overview on various sources of vibration in electric vehicle and their identification techniques. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 401. [Google Scholar] [CrossRef]

- Ministry of Road Transport and Highways. AIS 153: Additional Requirements for Bus Construction; Ministry of Road Transport and Highways: New Delhi, India, 2019. [Google Scholar]

- Bijwe, V.B.; Mahajan, R.; Vaidya, R.; Patel, K.; Hiwale, D.; Walke, A.A. Simulation Methodology Development for Vibration Test of Bus Body Structure Code AIS-153:2018; SAE International: Warrendale, PA, USA, 2024. [Google Scholar] [CrossRef]

- Patwardhan, M.; Jawale, P.; Nirmal, P. Aluminium for Curbing GHG Emissions in Indian Public Transport Buses; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Lei, Y.; Hu, J.; Fu, Y.; Liu, Z.; Yan, B. Simulation and Experimental Study of Vibration and Noise of Pure Electric Bus Transmission based on Finite Element and Boundary Element Methods. Int. J. Eng. 2019, 32, 1023–1030. [Google Scholar] [CrossRef]

- Tajanowskij, G.; Kruglenya, C.; Tanaś, W.; Szymanek, M. A methodical approach to the evaluation of vibrations of passengers of electric bus 6K2 in the task of selecting a general layout and suspension. Mech. Agric. Conserv. Resour. 2022, 66, 45–49. [Google Scholar]

- Zeng, M.; Tan, B.; Ding, F.; Zhang, B.; Zhou, H.; Chen, Y. An experimental investigation of resonance sources and vibration transmission for a pure electric bus. Proc. Inst. Mech. Eng. Automob. Eng. 2020, 234, 950–962. [Google Scholar] [CrossRef]

- Tucci, J.; Dougherty, J.; Cachecho, A.; Kaufman, L.; Leachman, D.; Perez, W.; Staes, L. Safety and Security Certification of Electric Bus Fleets—Industry Best Practices; SAE International: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Codes and Standards—NFPA. Available online: https://www.nfpa.org/for-professionals/codes-and-standards (accessed on 27 February 2025).

- NFPA 750; Standard on Water Mist Fire Protection Systems. National Fire Protection Association (NFPA): Quincy, MA, USA, 2023.

- Publications Office of the EU. Regulation No 100 of the Economic Commission for Europe of the United Nations (UNECE)—Uniform Provisions Concerning the Approval of Vehicles with Regard to Specific Requirements for the Electric Power Train [2015/505], CELEX1. Available online: https://op.europa.eu/en/publication-detail/-/publication/fd8e6b47-d767-11e4-9de8-01aa75ed71a1 (accessed on 27 February 2025).

- National Standardization Administration—China. Available online: https://www.sac.gov.cn (accessed on 27 February 2025).

- AS 1170.4-2007 Amd 2:2018; Structural Design Actions, Part 4: Earthquake Actions in Australia. Standards Australia: Sydney, Australia, 2018. Available online: https://store.standards.org.au/product/as-1170-4-2007-amd-2-2018 (accessed on 23 October 2023).

- JISC-Japanese Industrial Standards Committee. JISC-Japanese Industrial Standards Committee: Topics. Available online: https://www.jisc.go.jp/eng/ (accessed on 27 February 2025).

- CEN-CENELEC. User Centric Charging Infrastructure for Electric Vehicles—Guidelines for Operators to Implement Advanced Smart Charging and Management Strategies; CEN-CENELEC: Brussels, Belgium, 2023. [Google Scholar]

- Borbujo, C.; Pereirinha, P.G.; Del Valle, J.A.; Vega, M.G.; Gonzalez, D.A.; Perez, J.C.V. International and European Legislation and Standards for Battery Electric Buses. In Proceedings of the 2020 IEEE Vehicle Power and Propulsion Conference (VPPC), Gijon, Spain, 18–20 November 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Cremers, P.A. Standardisation of E-Bus Charging: Overview & Project Activities, ASSURED Interoperability Workshop. Available online: https://assured-project.eu/storage/files/2-asr-interop-workshop-standardisation-activities-peter-cremers_1.pdf (accessed on 27 February 2025).

- Willstrand, J.; Gehandler, J.; Andersson, P. Fire Safety of Zero Emission Buses Depots: Fire Prevention and Incident Response; RISE Research Institutes of Sweden: Borås, Sweden, 2023. [Google Scholar]

- ZeEUS. Establish a Common European Standard for e-Bus Systems. Available online: https://zeeus.eu/news/establish-a-common-european-standard-for-e-bus-systems (accessed on 31 March 2025).

- Volvo Buses. Group of European Electric Bus Manufacturers Agrees on an Open Interface for Charging. Available online: https://www.volvobuses.com/en/news/2016/mar/grp-eu-elec-bus-manuf-open-charging.html (accessed on 14 March 2025).

- He, Y.; Song, Z.; Liu, Z. Fast-charging station deployment for battery electric bus systems considering electricity demand charges. Sustain. Cities Soc. 2019, 48, 101530. [Google Scholar] [CrossRef]

- He, Y.; Liu, Z.; Song, Z. Optimal charging scheduling and management for a fast-charging battery electric bus system. Transp. Res. Part E Logist. Transp. Rev. 2020, 142, 102056. [Google Scholar] [CrossRef]

- Kunith, A.; Mendelevitch, R.; Kuschmierz, A.; Goehlich, D. Optimization of fast charging infrastructure for electric bus transportation–Electrification of a city bus network. In Proceedings of the EVS29 International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Montreal, QC, Canada, 19–22 June 2016. [Google Scholar]

- Ranabhat, P. Secure design and development of IoT enabled charging infrastructure for electric vehicle: Using CCS standards for DC fast charging. Bachelor’s Thesis, Metropolia University of Applied Sciences, Helsinki, Finland, 2018. [Google Scholar]

- Dixon, I.; Elders, I.; Bell, K. Characterization of Electric Vehicle Fast Charging Forecourt Demand. In Proceedings of the 2018 IEEE PES Innovative Smart Grid Technologies Conference Europe (ISGT-Europe), Sarajevo, Bosnia and Herzegovina, 21–25 October 2018; IEEE: New York, NY, USA, 2018; pp. 1–9. [Google Scholar] [CrossRef]

- Dias, F.G.; Mohanpurkar, M.; Medam, A.; Scoffield, D.; Hovsapian, R. Impact of controlled and uncontrolled charging of electrical vehicles on a residential distribution grid. In Proceedings of the 2018 IEEE International Conference on Probabilistic Methods Applied to Power Systems (PMAPS), Boise, ID, USA, 24–28 June 2018; IEEE: New York, NY, USA, 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Sun, X.; Qiu, J. A Customized Voltage Control Strategy for Electric Vehicles in Distribution Networks with Reinforcement Learning Method. IEEE Trans. Ind. Inform. 2021, 17, 6852–6863. [Google Scholar] [CrossRef]

- ASSURED. Clean Bus Report an Overview of Clean Buses in Europe; ASSURED: Brussels, Belgium, 2022. [Google Scholar]

- Oualmakran, Y.; De Vroey, L.; Novak-Zdravkovi, A.; Lehfuss, F.; Hegazy, O. Mitigating the impact of high power charging of electric buses: Perspective of European distribution grid operators. In Proceedings of the 33rd Electric Vehicle Symposium (EVS33), Lyon, France, 14–17 June 2020. [Google Scholar]

- Sturm, P.; Fößleitner, P.; Fruhwirt, D.; Galler, R.; Wenighofer, R.; Heindl, S.F.; Krausbar, S.; Heger, O. Fire tests with lithium-ion battery electric vehicles in road tunnels. Fire Saf. J. 2022, 134, 103695. [Google Scholar] [CrossRef]

- Li, T.; Jiao, Y. Revealing the Thermal Runaway Behavior of Lithium Iron Phosphate Power Batteries at Different States of Charge and Operating Environment. Int. J. Electrochem. Sci. 2022, 17, 221030. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles—A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Feng, X.; Fang, M.; He, X.; Ouyang, M.; Lu, L.; Wang, H.; Zhang, M. Thermal runaway features of large format prismatic lithium ion battery using extended volume accelerating rate calorimetry. J. Power Sources 2014, 255, 294–301. [Google Scholar] [CrossRef]

- Raza, H.; Li, S. The impact of battery electric bus fire on road tunnel. In Expanding Underground—Knowledge and Passion to Make a Positive Impact on the World, 1st ed.; CRC Press: London, UK, 2023; pp. 3280–3288. [Google Scholar] [CrossRef]

- Li, Y.Z. Study of fire and explosion hazards of alternative fuel vehicles in tunnels. Fire Saf. J. 2019, 110, 102871. [Google Scholar] [CrossRef]

- Bugryniec, P.J.; Resendiz, E.G.; Nwophoke, S.M.; Khanna, S.; James, C.; Brown, S.F. Review of gas emissions from lithium-ion battery thermal runaway failure—Considering toxic and flammable compounds. J. Energy Storage 2024, 87, 111288. [Google Scholar] [CrossRef]

- Golubkov, A.W.; Fuchs, D.; Wagner, J.; Wiltsche, H.; Stangl, C.; Fauler, G.; Voitic, G.; Thaler, A.; Hacker, V. Thermal-runaway experiments on consumer Li-ion batteries with metal-oxide and olivin-type cathodes. RSC Adv. 2014, 4, 3633–3642. [Google Scholar] [CrossRef]

- Lecocq, M.; Bertana, B.; Truchot, B.; Marlair, G. Comparison of the fire consequences of an electric vehicle and an internal combustion engine vehicle. In Proceedings of the 2nd International Conference on Fires in Vehicles—FIVE 2012, Chicago, IL, USA, September 2012; SP Technical Research Institute of Sweden: Borås, Sweden, 2012; pp. 183–194. Available online: https://hal-ineris.archives-ouvertes.fr/ineris-00973680 (accessed on 16 March 2022).

- Lecocq, G.G.; Eshetu, G.; Grugeon, S.; Martin, N.; Laruelle, S.; Marlair, G. Scenario-based prediction of Li-ion batteries fire-induced toxicity. J. Power Sources 2016, 316, 197–206. [Google Scholar] [CrossRef]

- Truchot, B.; Fouillen, F.; Collet, S. An experimental evaluation of toxic gas emissions from vehicle fires. Fire Saf. J. 2018, 97, 111–118. [Google Scholar] [CrossRef]

- Lecocq, M.; Bertana, B.; Truchot, B.; Marlair, G. Comparison of the Fire Consequences of an Electric Vehicle and an Internal Combustion Engine Vehicle; SP Technical Research Institute of Sweden: Borås, Sweden, 2012. [Google Scholar]

- Liu, W.; Placke, T.; Chau, K.T. Overview of batteries and battery management for electric vehicles. Energy Rep. 2022, 8, 4058–4084. [Google Scholar] [CrossRef]

- Houache, M.; Yim, C.-H.; Karkar, Z.; Abu-Lebdeh, Y. On the Current and Future Outlook of Battery Chemistries for Electric Vehicles—Mini Review. Batteries 2022, 8, 70. [Google Scholar] [CrossRef]

- Kim, A.; Mallarapu, A.; Finegan, D.P.; Santhanagopalan, S. Modeling cell venting and gas-phase reactions in 18650 lithium ion batteries during thermal runaway. J. Power Sources 2021, 489, 229496. [Google Scholar] [CrossRef]

- Ai, X.P.; Cao, Y.-L.; Yang, H.-X. Self-activating Safety Mechanisms for Li-ion Batteries. J. Electrochem. 2010, 16, 1–5. [Google Scholar] [CrossRef]

- Vu, T.T.; Cheon, H.J.; Shin, S.Y.; Jeong, G.; Wi, E.; Chang, M. Hybrid electrolytes for solid-state lithium batteries: Challenges, progress, and prospects. Energy Storage Mater. 2023, 61, 102876. [Google Scholar] [CrossRef]

- Cho, W.; Kim, S.-M.; Lee, K.-W.; Song, J.H.; Jo, Y.N.; Yim, T.; Kim, H.; Kim, J.-S.; Kim, Y.-J. Investigation of new manganese orthophosphate Mn3(PO4)2 coating for nickel-rich LiNi0.6Co0.2Mn0.2O2 cathode and improvement of its thermal properties. Electrochim. Acta 2016, 198, 77–83. [Google Scholar] [CrossRef]

- Chen, M.; Yu, Y.; Ouyang, D.; Weng, J.; Zhao, L.; Wang, J.; Chen, Y. Research progress of enhancing battery safety with phase change materials. Renew. Sustain. Energy Rev. 2024, 189, 113921. [Google Scholar] [CrossRef]

- Paciolla, P.; Papurello, D. Improved Thermal Management of Li-Ion Batteries with Phase-Change Materials and Metal Fins. Batteries 2024, 10, 190. [Google Scholar] [CrossRef]

- He, H.; Sun, F.; Wang, Z.; Lin, C.; Zhang, C.; Xiong, R.; Deng, J.; Zhu, X.; Xie, P.; Zhang, S.; et al. China’s battery electric vehicles lead the world: Achievements in technology system architecture and technological breakthroughs. Green Energy Intell. Transp. 2022, 1, 100020. [Google Scholar] [CrossRef]

- Tang, Q.; Shu, X.; Zhu, G.; Wang, J.; Yang, H. Reliability Study of BEV Powertrain System and Its Components—A Case Study. Processes 2021, 9, 762. [Google Scholar] [CrossRef]

- White, P. Together in Electric Reality: Fire Prevention in the Bus and Coach Sector; Gallagher: Glasgow, UK, 2023. [Google Scholar]

- Nurse, N.; Wright, A.; Newbery, P.G. Electric Fuses: Fundamentals and New Applications, 4th ed.; The Institution of Engineering and Technology: Stevenage, UK, 2022. [Google Scholar]

- Ollé, P. Project of the conversion from an ICE (internal combustion engine) vehicle to a BEV (battery electric vehicle) vehicle applied to GLAB 30. Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2018. [Google Scholar]

- Qiu, Y.; Jiang, F. A review on passive and active strategies of enhancing the safety of lithium-ion batteries. Int. J. Heat Mass Transf. 2022, 184, 122288. [Google Scholar] [CrossRef]

- Xue, Q.; Li, G.; Zhang, Y.; Shen, S.; Chen, Z.; Liu, Y. Fault diagnosis and abnormality detection of lithium-ion battery packs based on statistical distribution. J. Power Sources 2020, 471, 228964. [Google Scholar] [CrossRef]

- Larsson, F.; Andersson, P.; Mellander, B.-E. Lithium-Ion Battery Aspects on Fires in Electrified Vehicles on the Basis of Experimental Abuse Tests 2279; SP Technical Research Institute of Sweden: Borås, Sweden, 2016. [Google Scholar]

- Wu, C. Safety of Lithium Battery for New Energy Vehicles: A Literature Review. Int. J. Energy 2022, 1, 14–17. [Google Scholar] [CrossRef]

- Yang, K.; Miao, H.; Ji, H.; Chen, S.; Xing, Z.; Jiang, J.; Zheng, K.; Liu, G. Experimental study on the coupling effect of heptafluoropropane and different arrangement of obstacles on methane-air explosion. Fuel 2024, 358, 130204. [Google Scholar] [CrossRef]

- Li, G.; Wang, X.; Xu, H.; Liu, Y.; Zhang, H. Experimental study on explosion characteristics of ethanol gasoline–air mixture and its mitigation using heptafluoropropane. J. Hazard. Mater. 2019, 378, 120711. [Google Scholar] [CrossRef]

- Li, T.; Jiao, Y. Research on optimal thermal runaway suppression parameters of heptafluoropropane fire extinguishing devices for electric buses. Energy Storage Sci. Technol. 2022, 11, 3239. [Google Scholar]

- Li, S.; Zhang, X.; Li, X.; Yu, R.; Chang, Z.; Yang, Z.; Wang, H.; Guo, X.; Li, J. Theoretical and experimental studies on the thermal decomposition and fire-extinguishing performance of 1,1,2,3,3,3-hexafluoro-1-propene (R1216). Int. J. Quantum Chem. 2023, 123, e27217. [Google Scholar] [CrossRef]

- Lv, Z.; Yang, Z.; Zhang, Y.; Chen, Y.; Li, J. A comparative investigation on the flame inhibition characteristics and mechanism of 1,1,2,3,3,3-hexafluoro-1-propene (R1216). Fuel 2022, 324, 124652. [Google Scholar] [CrossRef]

- UNECE. Regulation No. 100 Rev.3; UNECE: Geneva, Switzerland, 2024. [Google Scholar]

- Mao, B.; Liu, C.; Yang, K.; Li, S.; Liu, P.; Zhang, M.; Meng, X.; Gao, F.; Duan, Q.; Wang, Q.; et al. Thermal runaway and fire behaviors of a 300 Ah lithium ion battery with LiFePO4 as cathode. Renew. Sustain. Energy Rev. 2021, 139, 110717. [Google Scholar] [CrossRef]

- Meng, N.; Liu, X.; Li, X.; Liu, B. Effect of blockage ratio on backlayering length of thermal smoke flow in a longitudinally ventilated tunnel. Appl. Therm. Eng. 2018, 132, 1–7. [Google Scholar] [CrossRef]

- Liu, W.; Liu, M.; Chang, R.; Yang, B.; Cui, H.; Li, C.; Zhang, H. Study on moving fire smoke characteristics and mechanical ventilation system of tunnel. Fire Saf. J. 2023, 141, 103932. [Google Scholar] [CrossRef]

- Tang, W.; Hu, L.; Chen, L. Effect of blockage-fire distance on buoyancy driven back-layering length and critical velocity in a tunnel: An experimental investigation and global correlations. Appl. Therm. Eng. 2013, 60, 7–14. [Google Scholar] [CrossRef]

- Kunikane, Y.; Kawabata, N.; Yamada, T.; Shimoda, A. Influence of Stationary Vehicles on Backlayering Characteristics of Fire Plume in a Large Cross Section Tunnel. JSME Int. J. Ser. B 2006, 49, 594–600. [Google Scholar] [CrossRef]

- Meng, N.; Yang, W.; Xin, L.; Li, X.; Liu, B.; Jin, X. Experimental study on backlayering length of thermal smoke flow in a longitudinally ventilated tunnel with blockage at upstream of fire source. Tunn. Undergr. Space Technol. 2018, 82, 315–324. [Google Scholar] [CrossRef]

- Ho, Y.-T.; Kawabata, N.; Seike, M.; Hasegawa, M.; Chien, S.-W.; Shen, T.-S. Scale Model Experiments and Simulations to Investigate the Effect of Vehicular Blockage on Backlayering Length in Tunnel Fire. Buildings 2022, 12, 1006. [Google Scholar] [CrossRef]

- Gannouni, S.; Ben Maad, R. Numerical study of the effect of blockage on critical velocity and backlayering length in longitudinally ventilated tunnel fires. Tunn. Undergr. Space Technol. 2015, 48, 147–155. [Google Scholar] [CrossRef]

- Impact-of-New-Propulsion-Technologies-on-Road-Tunnel-Operations-and-Safety-A-PIARC-Technical-Report. [Online]. Available online: https://www.piarc.org/ressources/publications/source/2/10603dba-43385-2023R34EN-Impact-of-New-Propulsion-Technologies-on-Road-Tunnel-Operations-and-Safety-A-PIARC-Technical-Report.pdf (accessed on 22 March 2024).

- Pálmai, Z.; Ikonen, M.; Bal, F.; Dirksen, R.; Golstein, J. Fire Safety in e-Bus Depots—Risk, Prevention and Handling. Available online: https://projects2014-2020.interregeurope.eu/fileadmin/user_upload/tx_tevprojects/library/file_1649674339.pdf (accessed on 27 February 2025).

- C40 Cities Finance Facility. Zero-Emission Bus Systems: Depot Electrification for Zero-Emission Bus Systems; C40 Cities Finance Facility: Monterrey, Mexico, 2021. [Google Scholar]

- Williams, F.A. Mechanisms of fire spread. Symp. Int. Combust. 1977, 16, 1281–1294. [Google Scholar] [CrossRef]

- Stewart, C. Battery Electric Vehicles Fires. In Proceedings of the Ventism User Conference VUC Montreal 2023, Montreal, QC, Canada, 26–27 September 2023. [Google Scholar]

- Interreg Europe. Technological Requirements in e-Bus Deployment; Interreg Europe: Berlin, Germany, 2021. [Google Scholar]

- VDA; VDIK. Technische Quarantäneflächen für Beschädigte Fahrzeuge mit Lithium-Ionen-Batterien; VDA: Berlin, Germany/VDIK: Berlin, Germany, 2022. [Google Scholar]

- Cui, Y.; Liu, J. Research progress of water mist fire extinguishing technology and its application in battery fires. Process Saf. Environ. Prot. 2021, 149, 559–574. [Google Scholar] [CrossRef]

- Abrahamsen, H. The European Watermist Standard Implementation Date 30 June 2020. Available online: https://prevent-systems.com/new-european-standard-for-water-mist-systems/ (accessed on 27 February 2025).

- ISO 6182-1:2021; Fire Protection—Automatic Sprinkler Systems. ISO: Geneva, Switzerland, 2021.

- AS 4587-1999; Water Mist Fire Protection Systems—System Design, Installation and Commissioning. Australian Standard: Sydney, NSW, Australia, 1999.

- Zhao, C.; Hu, W.; Meng, D.; Mi, W.; Wang, X.; Wang, J. Full-scale experimental study of the characteristics of electric vehicle fires process and response measures. Case Stud. Therm. Eng. 2024, 53, 103889. [Google Scholar] [CrossRef]

- Back, G.G.; Beyler, C.L.; DiNenno, P.J.; Hansen, R.; Zalosh, R. Full-Scale Testing of Water Mist Fire Suppression Systems in Machinery Spaces; US Department of Transportation United States Coast Guard Systems (G-S) and Marine Safety and Environmental Protection (G-M): Washington, DC, USA, 1998. [Google Scholar]

- Hu, J.; Tang, X.; Zhu, X.; Liu, T.; Wang, X. Suppression of thermal runaway induced by thermal abuse in large-capacity lithium-ion batteries with water mist. Energy 2024, 286, 129669. [Google Scholar] [CrossRef]

- Santangelo, P.E.; Tarozzi, L.; Tartarini, P. Full-Scale Experiments of Fire Control and Suppression in Enclosed Car Parks: A Comparison Between Sprinkler and Water-Mist Systems. Fire Technol. 2016, 52, 1369–1407. [Google Scholar] [CrossRef]

- Tang, X.; Hu, J.; Liu, T.; Hu, S.; Zhu, P.; Wang, X. Experimental investigation on the cooling effect of fully submerged fine water mist on lithium-ion batteries in confined space. Appl. Therm. Eng. 2024, 239, 122166. [Google Scholar] [CrossRef]

- Alenezi, M.H.; Sadek, H. Fire-suppression performance of high-pressure water mist system inside scaled-down road tunnel section. J. Eng. Res. 2023, 11, 100024. [Google Scholar] [CrossRef]

- Lu, J.; Liang, P.; Chen, B.; Wu, C.; Zhou, T. Investigation of the Fire-Extinguishing Performance of Water Mist with Various Additives on Typical Pool Fires. Combust. Sci. Technol. 2020, 192, 592–609. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Gong, J.; Zhang, X.; Fan, C.; Wang, X. Assessment of a clean and efficient fire-extinguishing technique: Continuous and cycling discharge water mist system. J. Clean. Prod. 2018, 182, 682–693. [Google Scholar] [CrossRef]

- LiionFire Project. Automated e-buses Lithium Ion Battery Early Warning and Fire Suppression System|LiionFire Project|Fact Sheet|H2020’, CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/806842 (accessed on 22 January 2025).

- Open Access to Scientific Publications and Related Research Data|H2020’, CORDIS|European Commission. [Online]. Available online: https://cordis.europa.eu/project/id/806842/reporting (accessed on 21 June 2024).

- Safety First: Comprehensive Solution Provides Fire Protection in Electric Vehicles. CORDIS-EU. [Online]. Available online: https://cordis.europa.eu/article/id/421783-safety-first-comprehensivesolution-provides-fire-protection-in-electric-vehicles (accessed on 14 March 2025).

- Nolan, D.P. Handbook of Fire and Explosion Protection Engineering Principles for Oil, Gas, Chemical, and Related Facilities; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Hutchison, V. Lithium-Ion Battery Transit Bus Fire Prevention and Risk Management; NFPA: Washington, DC, USA, 2023. [Google Scholar]

- CROW. Ontwerprichtlijnen Brandveiligheid Voor Stallingen Zero-Emissiebussen; CROW: Utrecht, The Netherlands, 2022. [Google Scholar]

- ISGF. ISGF Report on Electrical Safety Hazard Mitigation at Bus Depots for Electric Vehicle Supply Equipment (EVSE); ISGF: New Dehli, India, 2023. [Google Scholar]

- Krawiec, K.; Markusik, S.; Sierpiński, G. (Eds.) Electric Mobility in Public Transport—Driving Towards Cleaner Air; Lecture Notes in Intelligent Transportation and Infrastructure. Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Sahu, A.; Mao, Z.; Wlazlo, P.; Huang, H.; Davis, K.; Goulart, A.; Zonouz, S. Multi-Source Multi-Domain Data Fusion for Cyberattack Detection in Power Systems. IEEE Access 2021, 9, 119118–119138. [Google Scholar] [CrossRef]

- Shi, J.; Wu, J.; Xu, B.; Song, Z. Cybersecurity of Hybrid Electric City Bus with V2C Connectivity. IEEE Trans. Intell. Veh. 2024, 9, 4070–4084. [Google Scholar] [CrossRef]

- Köhler, S.; Baker, R.; Strohmeier, M.; Martinovic, I. Brokenwire: Wireless Disruption of CCS Electric Vehicle Charging. In Proceedings of the 2023 Network and Distributed System Security Symposium, San Diego, CA, USA, 27 February–3 March 2023. [Google Scholar] [CrossRef]

- Guo, S.; Chen, H.; Rahman, M.; Qian, X. DCA: Delayed Charging Attack on the Electric Shared Mobility System. IEEE Trans. Intell. Transp. Syst. 2023, 24, 12793–12805. [Google Scholar] [CrossRef]

- Abreu, R.; Simão, E.; Serôdio, C.; Branco, F.; Valente, A. Enhancing IoT Security in Vehicles: A Comprehensive Review of AI-Driven Solutions for Cyber-Threat Detection. AI 2024, 5, 2279–2299. [Google Scholar] [CrossRef]

- Din, S. Collaborative Approaches to Enhancing Smart Vehicle Cybersecurity by AI-Driven Threat Detection. arXiv 2024, arXiv:arXiv:2501.00261. [Google Scholar] [CrossRef]

- Pandian, A.P.D. AI and ML Cybersecurity solutions for V2V communication. In Proceedings of the 2022 IEEE International Conference on Advanced Networks and Telecommunications Systems (ANTS), Gandhinagar, Gujarat, India, 18–21 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Namburi, V.L.; Adapa, S.R.; Chamala, S.S.K.; Yerram, M.; Gupta, P.; Upreti, K. Integrating AI and Cybersecurity: Advancing Autonomous Vehicle Security and Response Mechanisms. In Proceedings of the 2024 International Conference on Emerging Trends in Networks and Computer Communications (ETNCC), Windhoek, Namibia, 23–25 July 2024; pp. 253–258. [Google Scholar] [CrossRef]

- Far, M.F.; Pihlatie, M.; Paakkinen, M.; Antila, M.; Abdulah, A. Pre-Normative Charging Technology Roadmap for Heavy-Duty Electric Vehicles in Europe. Energies 2022, 15, 2312. [Google Scholar] [CrossRef]

- Encs, A. Security Architecture for EV Charging Infrastructure. Available online: https://encs.eu/resource/ev-201-2019-security-architecture-for-ev-charging-infrastructure/ (accessed on 25 February 2025).

- Sanghvi, A.; Markel, T. Cybersecurity for Electric Vehicle Fast-Charging Infrastructure. In Proceedings of the 2021 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 21–25 June 2021; pp. 573–576. [Google Scholar] [CrossRef]

- Bogosyan, S.; Gokasan, M. Novel Strategies for Security-hardened BMS for Extremely Fast Charging of BEVs. In Proceedings of the 2020 IEEE 23rd International Conference on Intelligent Transportation Systems (ITSC), Rhodes, Greece, 20–23 September 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Potteiger, B.; Zhang, Z.; Cheng, L.; Koutsoukos, X. A Tutorial on Moving Target Defense Approaches Within Automotive Cyber-Physical Systems. Front. Future Transp. 2022, 2, 792573. [Google Scholar] [CrossRef]

- Bogosyan, S.; Akgul, T.; Gokasan, M. MTD Based Novel Scheme for BMS Security against CAN Bus Attacks during BEV Charging. In Proceedings of the 2020 9th Mediterranean Conference on Embedded Computing (MECO), Budva, Montenegro, 8–11 June 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Dorokhova, M.; Vianin, J.; Alder, J.-M.; Ballif, C.; Wyrsch, N.; Wannier, D. A Blockchain-Supported Framework for Charging Management of Electric Vehicles. Energies 2021, 14, 7144. [Google Scholar] [CrossRef]

- Lazaroiu, G.C.; Roscia, M.; Dumbrava, V.; Kayisli, K. Blockchain and Smart Charging Infrastructure of Electric Vehicles. In Holistic Approach for Decision Making Towards Designing Smart Cities; Lazaroiu, G.C., Roscia, M., Dancu, V.S., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 175–198. [Google Scholar] [CrossRef]

- Sidiq, M.F.; Basuki, A.I.; Ramdhani, T.I.; Setiawan, I.; Haris, A.I.; Rosiyadi, D.; Susanto, H.; Salim, T.I. BC-MTD: Blockchain-driven Moving Target Defense for Secure Vehicle Access. In Proceedings of the 2023 International Conference on Radar, Antenna, Microwave, Electronics, and Telecommunications (ICRAMET), Bandung, Indonesia, 15–16 November 2023; pp. 300–306. [Google Scholar] [CrossRef]

- Jalowski, Ł.; Zmuda, M.; Rawski, M. A Survey on Moving Target Defense for Networks: A Practical View. Electronics 2022, 11, 2886. [Google Scholar] [CrossRef]

| Reference | Researcher/Research Organization | Publication Date | Investigation Method | Summary |

|---|---|---|---|---|

| [41] | Spirka, Kepkaa | 2015 | Finite element analysis | A simulation was conducted to evaluate a REESS as part of the development of an electric ŠKODA bus. The impact of load dynamics was assessed by comparing calculation results based on UN/ECE 100.2 [41]. |

| [42] | Kunakron-ong, Ruangjirakit, Jongpradist | 2017 | Finite element analysis | Mechanical analysis, modal constraint analysis, and frequency response analysis were conducted using finite element model simulations and vibration testing under various conditions for the battery compartment. This research serves as a foundation and reference for the structural design of the battery compartment in the REESS quick-change electric bus, aiming to enhance the safety and reliability of BEBs [42]. |

| [43] | Spirk, Kepka | 2016 | Finite element analysis | The study simulates the behavior of the front REESS during impact involving a battery electric bus. The effects of dynamic impact on the load are analyzed, taking into account the material behavior at higher strain rates [43]. |

| Reference | Researcher/Research Organization | Publication Date | Investigation Method | Summary |

|---|---|---|---|---|

| [44] | Yu, Li, Zhang, Dong, Han, Xian | 2019 | Experiments | A fire test model for the lithium-ion battery of an electric bus was developed. A test was conducted to extinguish a lithium-ion battery using a perfluorohexanone-based extinguishing agent, verifying its effectiveness [44]. |

| [45] | Un, Aydin | 2021 | Experiments | This study focuses on the thermal escape mechanism and fire-fighting applications of LIB batteries. Ten experiments were carried out. In the first, a manual water-based fire extinguishing system was used, while in the second, an automatic boron-based fire extinguishing system was used. The LIB cells used in the experiments were selected from models currently used in BEBs and the electric vehicle industry [45]. |

| [46] | P. Andersson, J. Brandt, O. Willstrand | 2016 | Experiments | A full-scale fire test was conducted on an electric–diesel hybrid bus at the rescue-service training facility Guttasjön outside of Borås. The fire was started in the engine compartment and allowed to spread and grow until the entire bus was consumed in the fire. |

| Reference | Researcher/Research Organization | Publication Date | Investigation Method | Summary |

|---|---|---|---|---|

| [52] | China SAE | 2020 | Finite element analysis | A simulation based on the GB 17578-2013 standard was conducted to analyze rollover safety, leading to improvements in the electric bus chassis to reduce weight [52]. |

| [53] | Mihradi, Dhaniswara, Wicaksono, Mahyuddin | 2022 | Finite element analysis | A numerical simulation of the rollover of an Indonesian-manufactured electric bus was conducted, identifying structural improvements based on deformation and stress analysis results [53]. |

| [54] | Satrijo, Kurdi, Haryanto, Yob, Riyantiarno, Taufiqurrahman | 2020 | Finite element analysis | The rollover performance of an electric bus chassis made from three different materials was simulated. Simulation results were compared to identify the material with the best structural performance. Based on the comparison results, aluminum 6061 T6 was proposed as the material for the electric bus chassis [54]. |

| [55] | Alpar, Savran, Karpat | 2024 | Finite element analysis | A numerical optimization study was conducted on an anti-roll bar for a BEB, defining its diameter and comparing different materials to identify the best solution in terms of weight and stability [55]. |

| [56] | Nguyen, TT., Nguyen, CT., Nguyen, VS., Nguyen, DN. | 2022 | Finite element analysis | This study optimized the BEB’s structural design to comply with the ECE R66 standard. The simulation process examined different steel-tube thicknesses to reduce weight while ensuring compliance with ECE R66 [56]. |

| Reference | Researcher/ Research Organization | Publication Date | Investigation Method | Summary |

|---|---|---|---|---|

| [57] | Jongpradist, Saingam, Tangthamsathit, Jariyavadee, Aimmanee | 2022 | Finite element analysis | A LS-DYNA simulation was conducted on a BEB. This study concerns the analysis and design of the impact resistance of a sandwich composite microbus, especially to improve the efficient transfer of energy from the point of impact to the other structural elements [57]. |

| [58] | Jongpradist, Limpanawisut, Siritana, Saardying, Saingam, Tangthamsathit, Chanpaibool | 2021 | Finite element analysis | The optimized design of a lightweight composite microbus with a one-piece sandwich structure was analyzed. There are constraints on torsional and bending stiffness and natural frequency under frontal impact conditions [58]. |

| [59] | Yang, Fan, Zhou, Zhang | 2023 | Finite element analysis | The frontal structure of a BEB was optimized for weight reduction and impact resistance [59]. |

| Reference | Researcher/Research Organization | Publication Date | Investigation Method | Summary |

|---|---|---|---|---|

| [64] | SAE | 2021 | Finite element analysis | To optimize the electric bus chassis for reduced weight and improved side-impact resistance, the surrogate model method based on Least Squares Regression (LSR) and Radial Basis Function Neural Network (RBFNN) was used [64]. |

| [65] | Wang, Liu, Li, Zhang | 2015 | Finite element analysis | The BK612EV electric bus was used in the simulation study. A side-impact safety control strategy was developed for a BEB to mitigate risks associated with battery system failures, including high-voltage hazards [65]. |

| [66] | Kurdi, Haryanto, Yulianti, Satrijo, Suprihanto, Taufiqurrahman | 2019 | Finite element analysis | An analysis of side collision effects on an electric bus chassis conducted based on ECE R95 was presented. A side collision simulation was performed on a medium-sized electric bus chassis with a 48-passenger capacity [66]. |

| [67] | Wang Z., Wang Y. | 2013 | Finite element analysis | A side collision simulation was conducted on the BK6122EV electric bus. The model includes the frame, body panels, power battery, and moving barrier. The side collision test was conducted at the rear hull section in accordance with collision regulations [67]. |

| [68] | Wang, Cui, Luo | 2014 | Finite element analysis | To enhance collision safety, finite element models of the entire BK6122EV electric bus, its power battery system, and the movable deformable barrier were developed. The study included equivalent stress analysis of the battery module and deformation analysis of the battery pack and rear panel of the battery box [68]. |

| Reference | Researcher/Research Organization | Publication Date | Investigation Method | Summary |

|---|---|---|---|---|

| [77] | SAE | 2024 | Finite element analysis | Numerical simulation—vibration test of a complete bus (normna AIS-153:2018, clause 2.3.1)—assessment of the minimum natural frequency of the bus. This simulation framework helps the bus industry assess the natural frequency of the entire vehicle body [77]. |

| [78] | SAE | 2020 | Finite element analysis | The use of eco-friendly materials like aluminum in bus manufacturing is under evaluation. Lightweight aluminum bus prototypes meet Indian regulatory standards, including AIS:052, AIS:153, and city bus strength requirements. The added weight of battery packs can be offset by lightweight aluminum technology [78]. |

| [79] | Lei, Hu, Fu, Liu, Yana | 2019 | Finite element analysis/experiments | Modal and acoustic analyses using FEM and BEM methods were conducted on a three-axle, four-speed automated mechanical transmission (AMT) model for all-electric buses [79]. |

| [80] | Tajanowskij, Kruglenya, Tanaś, Szymanek | 2022 | Mathematical model, two-mass and four-mass models of the human body according to ISO | Passenger vibration levels in a mobile machine were assessed according to ISO standards. A computational experiment was conducted for parametric optimization of the 6K2 electric bus suspension. These considerations enable structural optimization of the electric bus layout [80]. |

| [81] | Zeng, Tan, Ding, Zhang, Zhou, Chen | 2019 | Finite element analysis | The proposed approach effectively addresses vibration problems, offering an efficient strategy to identify resonance sources and vibration transmission in all-electric buses [81]. |

| Inductive Charging | |

| IEC 61980 | This is a set of standards and specifications for equipment required for the wireless transfer of electrical energy from the power grid to electric road vehicles (IEC-2020b, IEC-2019b, IEC-2019c) |

| ISO 19363 | Safety and interoperability requirements for on-board equipment enabling wireless transfer of magnetic field energy for charging electric vehicles (ISO-2020c) |

| SAE J1773 | Recommended practices on electric-vehicle inductively coupled charging (SAE international, 2009b) |

| SAE J2954 | Safety, interoperability, and electromagnetic compatibility with wireless energy specifications for plug-in light electric vehicles (SAE international, 2020b) |

| Battery Swapping | |

| IEC 62840 | Set of standards for battery exchange systems for electric vehicles (IEC-2016A, IEC-2019a) |

| Type of Gas | NMC 18650 Cells [111] | LCO/NMC 18650 Cell [111] | LFP 18650 Cell [111] | Li-ion Batteries—Review Article [110] |

|---|---|---|---|---|

| % | % | % | % | |

| H2 | 2.4 | 2.6 | 2.2 | 2–50 |

| CO | 14.1 | 33.3 | 4.8 | 27–29 |

| CO2 | 70.4 | 47.3 | 83.4 | 35–37 |

| CH4 | 4.2 | 5.9 | 2.3 | 4–5 |

| C2H4 | 8.9 | 9.3 | 6.8 | - |

| C2H6 | - | 1.6 | 0.3 | 0.5–1 |

| C3H6 | - | - | - | 0–0.5 |

| HF | - | - | - | 0.003 |

| Focus Area | Description | Implemented Solutions (Westraven E-Bus Depot) |

|---|---|---|

| Fire risk from thermal runaway | A fire can start inside the battery pack and quickly spread to other buses. | Depot compartmentalization with fire-resistant walls between groups of max 40 buses. |

| Minimizing impact on operational buses | A fire can compromise the fleet and disrupt public transportation services. | The 40-bus-per-compartment limit allows for quick replacement in case of damage. |

| Fire propagation | Fire can rapidly spread between nearby buses, causing chain fires. | Fire barriers between compartments and a 4 m-wide space between them for firefighter access. |

| Challenges in rapid intervention | Thermal runaway becomes visible only after battery rupture, making timely action difficult. | Installation of an innovative radar-based thermal detection system to identify overheating early. |

| Management of suspect buses | Buses involved in minor accidents may pose a latent fire risk. | Creation of a separate quarantine area to isolate potentially hazardous buses. |

| Study | Experiment | Key Findings |

|---|---|---|

| Santangelo et al. (2016) [160] | Comparison of high-pressure water mist (C1WM2.0, C2WM2.0) vs. traditional sprinklers (C1SPK, C2SPK) in an enclosed car park. | -Suppression was achieved only by water mist at higher discharge density, while re-ignition occurred at lower discharge densities in both water mist and sprinkler experiments.-Water mist used significantly less water than sprinklers but provided comparable or superior suppression efficiency. -The lower water usage of mist systems reduces runoff and potential water damage, making them environmentally favorable. |

| X. Tang et al. (2024) [161] | Effectiveness of FWM cooling on thermal runaway (TR) hazard control in confined space. | -Confined space accelerated TR triggering, reducing TR triggering time by 8.3%. -LIB mass loss in confined space increased by 14.6% compared to open space. |

| M. H. Alenezi et al. (2023) [162] | Effect of mechanical ventilation on water mist performance in fire suppression. | -More water was needed for suppression with ventilation due to increased oxygen supply. -Ventilation fans shifted the fire center toward the air-inlet end of the tunnel due to more oxygen being introduced. -Designers must consider ventilation effects when determining fire-suppression zones, water storage volumes, and the delay they might cause in suppressing the fire, which can increase losses. |

| Lu et al. (2020) [163] | Water mist performance in extinguishing alkane pool fire under roof ventilation. | -Fire extinguishing time increased by 54 s at 50 m3/min and by 202 s at 75 m3/min ventilation rates. -Fire could not be extinguished at 120 m3/min ventilation rate. -Excessive ventilation reduced extinguishing efficiency, while moderate ventilation slightly enhanced fire combustion and further strengthened the cooling effect of water mist. |

| Zhou et al. (2018) [164] | Water mist with cycling vs. continuous discharge mode in a test room with smoke vents. | -Water mist failed to extinguish a gasoline pool fire, whose volume was 0.3 m × 0.3 m × 0.05 m, when the exhaust rate exceeded 0.6 m3/s. -At 0.15 m3/s exhaust rate, fire extinguishing time was 10 s shorter than without ventilation. -Cycling discharge mode was more effective than continuous discharge mode when tested in a room with smoke vents. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Liberto, E.; Borchiellini, R.; Fruhwirt, D.; Papurello, D. A Review of Safety Measures in Battery Electric Buses. Fire 2025, 8, 159. https://doi.org/10.3390/fire8040159

Di Liberto E, Borchiellini R, Fruhwirt D, Papurello D. A Review of Safety Measures in Battery Electric Buses. Fire. 2025; 8(4):159. https://doi.org/10.3390/fire8040159

Chicago/Turabian StyleDi Liberto, Edoardo, Romano Borchiellini, Daniel Fruhwirt, and Davide Papurello. 2025. "A Review of Safety Measures in Battery Electric Buses" Fire 8, no. 4: 159. https://doi.org/10.3390/fire8040159

APA StyleDi Liberto, E., Borchiellini, R., Fruhwirt, D., & Papurello, D. (2025). A Review of Safety Measures in Battery Electric Buses. Fire, 8(4), 159. https://doi.org/10.3390/fire8040159