Experimental Study on the Burning Characteristics of Photovoltaic Modules with Different Inclination Angles Under the Pool Fire

Abstract

1. Introduction

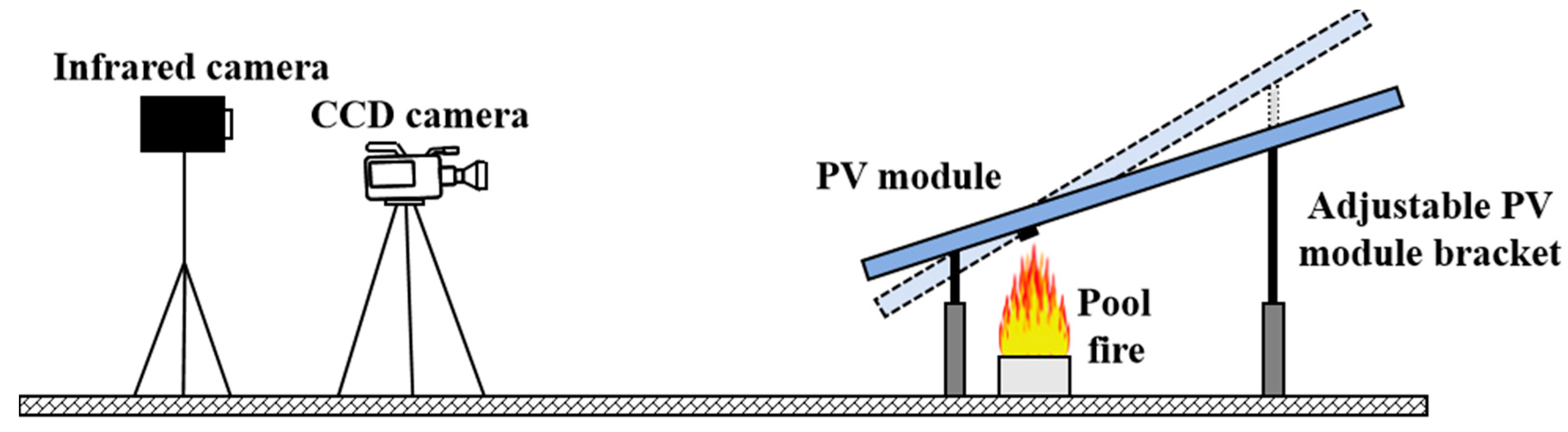

2. Experimental Setup and Conditions

3. Results and Discussion

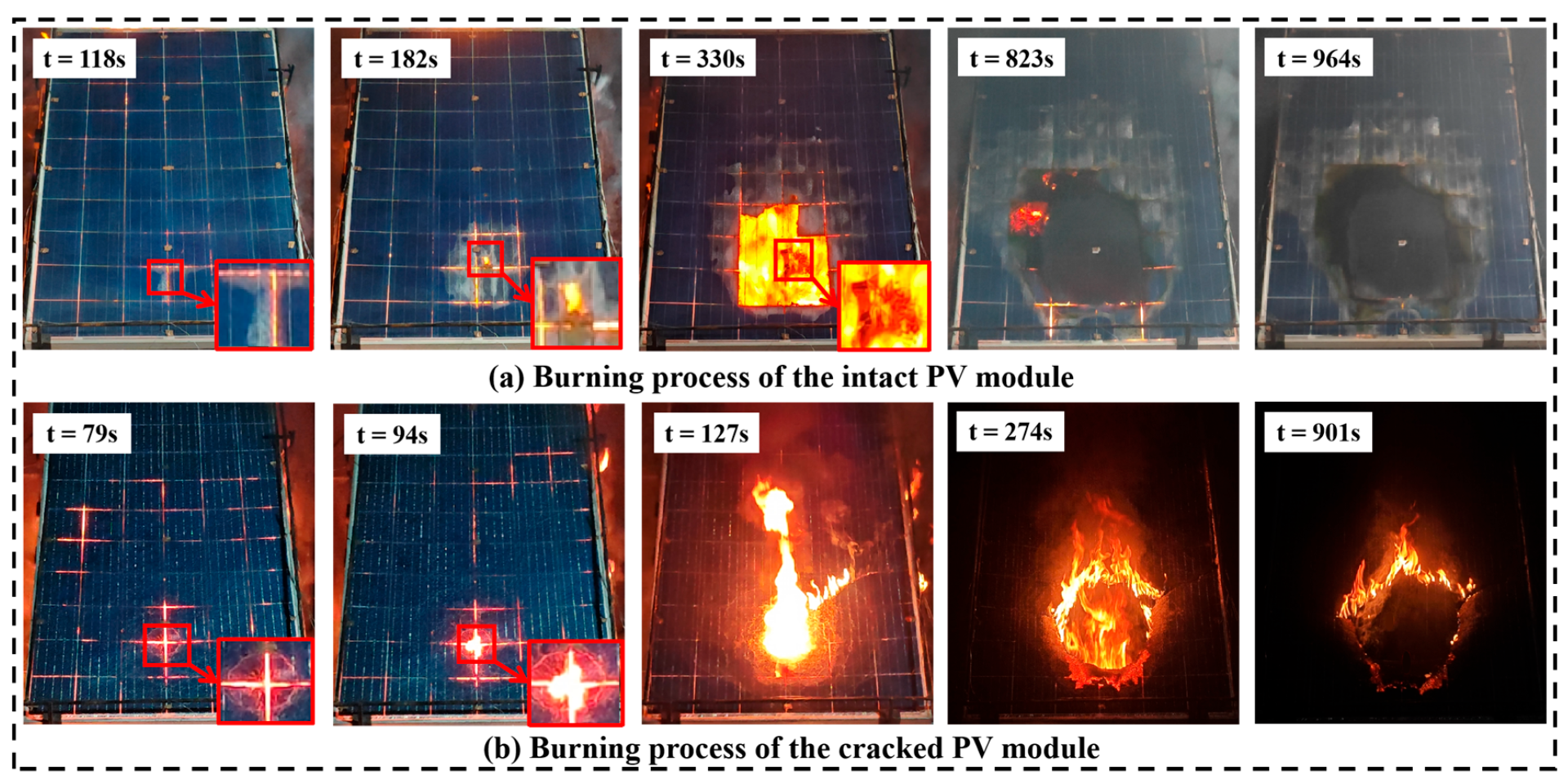

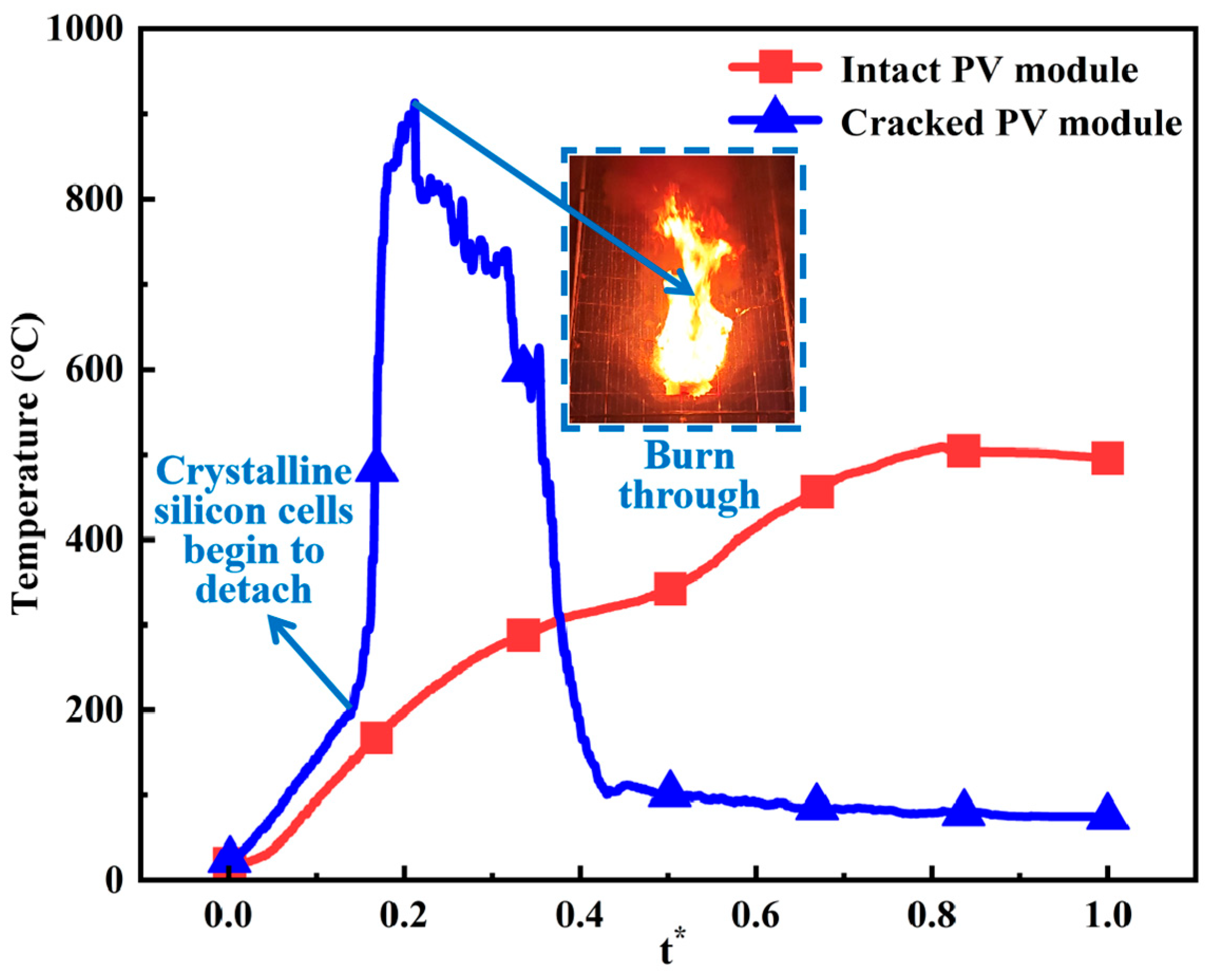

3.1. Burning Process of PV Modules

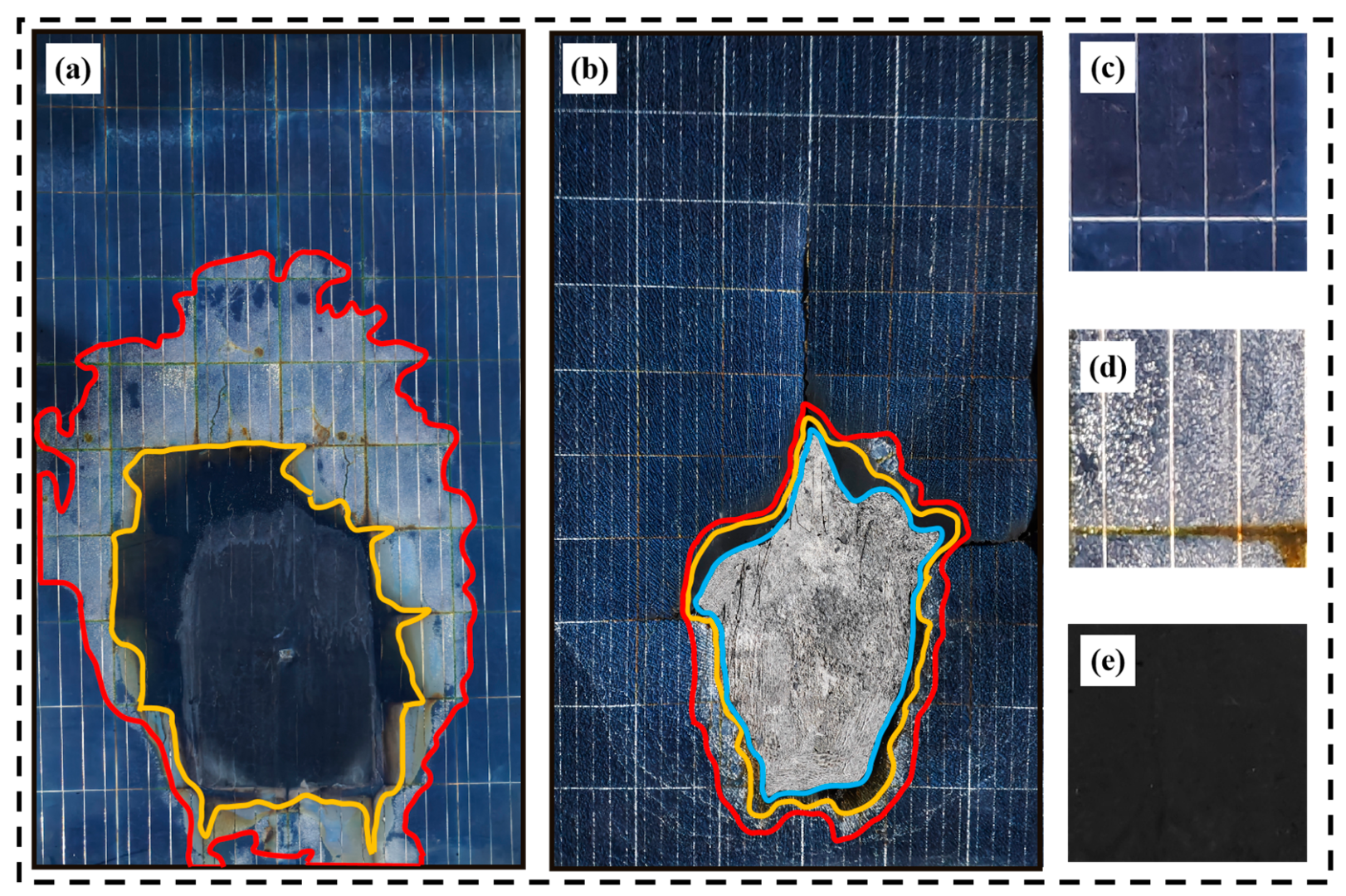

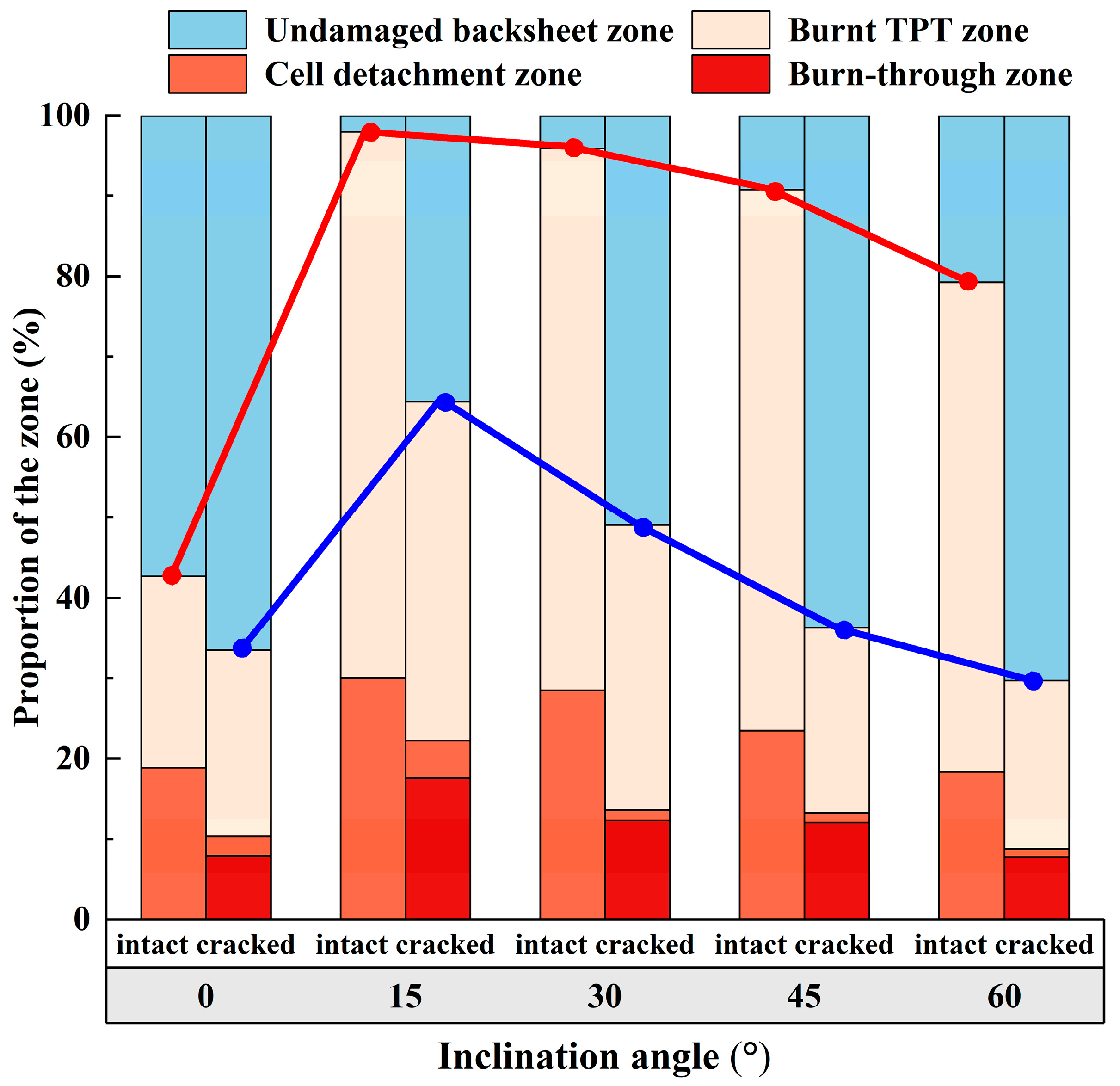

3.2. Analysis of Burning Damage Extent of PV Module

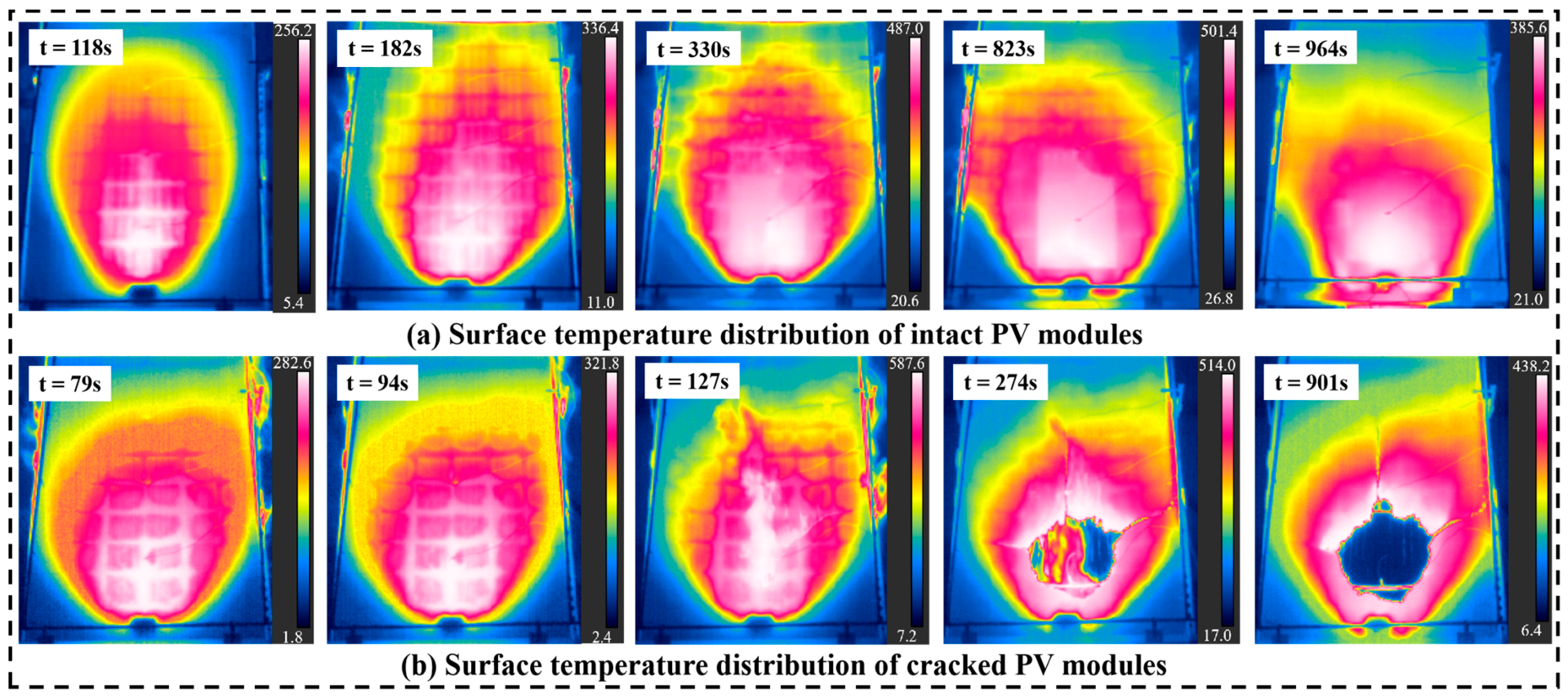

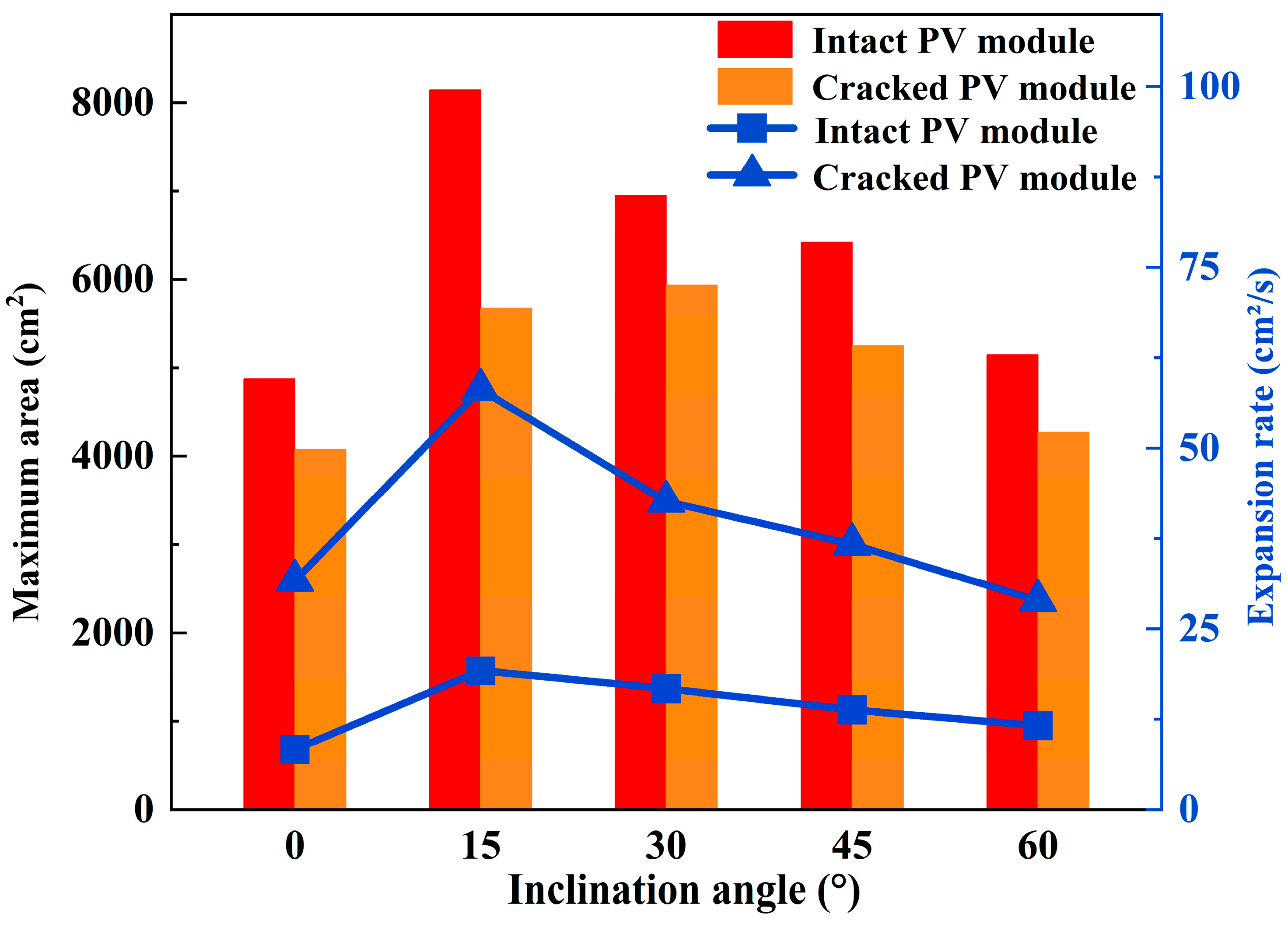

3.3. Surface Temperature Distribution of PV Modules

4. Conclusions

- (1)

- Intact PV modules exhibited a slower burning process, and the expansion rate of the high-temperature region was relatively slow. In contrast, cracked PV modules demonstrated a heightened susceptibility to being rapidly burnt through under the influence of the pool fire. The burning process of cracked PV modules was significantly faster than that of intact PV modules;

- (2)

- As the inclination angle increased from 0° to 60°, the burning damage extent and the expansion rate of the high-temperature region of both intact and cracked PV modules exhibited a trend of increasing rapidly and then decreasing. Notably, at an inclination angle of 15°, the burning damage extent and the expansion rate of the high-temperature region reached their maximum values;

- (3)

- Under the same inclination angle, intact PV modules, which were not burned through, experienced more thorough heating, resulting in a larger high-temperature region compared to cracked PV modules. However, the expansion rate of the high-temperature region was significantly higher in cracked PV modules. Additionally, stable combustion flames generated by the module were observed around the burn-through zone of cracked PV modules, indicating that the damage to the tempered glass compromised the fire resistance of the PV module;

- (4)

- PV modules exhibited distinct regional burning characteristics, with temperature distribution patterns closely corresponding to the burning damage extent. Additionally, there was a significant difference in burning damage between the front and back sides of the PV modules. Given the thermally thick characteristics of PV modules, the burning damage extent on the back side was significantly higher under the influence of the pool fire.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Reda, I.; Aram, M.; Qi, D.; Wang, L.L. Scaling method between sub-scale helium and full-scale smoke tests of smoke spread during solar roof fires. J. Build. Eng. 2023, 70, 106426. [Google Scholar]

- Yang, R.; Zang, Y.; Yang, J.; Wakefield, R.; Nguyen, K.; Shi, L.; Trigunarsyah, B.; Parolini, F.; Bonomo, P.; Frontini, F.; et al. Fire safety requirements for building integrated photovoltaics (BIPV): A cross-country comparison. Renew. Sustain. Energy Rev. 2023, 173, 113112. [Google Scholar]

- Ong, N.; Sadiq, M.A.; Said, M.S.M.; Jomaas, G.; Tohir, M.Z.M.; Kristensen, J.S. Fault tree analysis of fires on rooftops with photovoltaic systems. J. Build. Eng. 2022, 46, 103752. [Google Scholar]

- Lin, Y.; Jiang, Y.; Li, S.; Zhang, Z.; Zhang, Y. An experimental study on the morphology and behaviors of fire with nearby inclined surface during flame spread on building integrated photovoltaic (BIPV). Fuel 2025, 383, 133566. [Google Scholar] [CrossRef]

- Pandian, A.; Bansal, K.; Thiruvadigal, D.J.; Sakthivel, S. Fire hazards and overheating caused by shading faults on photo voltaic solar panel. Fire Technol. 2016, 52, 349–364. [Google Scholar]

- Despinasse, M.C.; Krueger, S. First developments of a new test to evaluate the fire behavior of photovoltaic modules on roofs. Fire Saf. J. 2015, 71, 49–57. [Google Scholar]

- Manzini, G.; Gramazio, P.; Guastella, S.; Liciotti, C.; Baffoni, G.L. The fire risk in photovoltaic installations-Test protocols for fire behavior of PV modules. Energy Procedia 2015, 82, 752–758. [Google Scholar]

- Ju, X.; Zhou, X.; Gong, J.; Zhao, K.; Peng, Y.; Zhang, C.; Yang, L.; Ren, X. Impact of flat roof–integrated solar photovoltaic installation mode on building fire safety. Fire Mater. 2019, 43, 936–948. [Google Scholar]

- Cunningham, D.W.; Solar, B.P. Analysis of hot spots in crystalline silicon modules and their impact on roof structures. In Proceedings of the Photovoltaic Module Reliability Workshop 2011 (PVMRW), Phoenix, AZ, USA, 16–17 February 2011; p. 642. [Google Scholar]

- Vedrtnam, A.; Bedon, C.; Youssef, M.A.; Wamiq, M.; Sabsabi, A.; Chaturvedi, S. Experimental and numerical structural assessment of transparent and tinted glass during fire exposure. Constr. Build. Mater. 2020, 250, 118918. [Google Scholar] [CrossRef]

- Dong, Q.; Song, Y.; Huang, L.; Song, Z.; Zhou, Y.; Zou, S.; Shi, L. Experimental study on the fire characteristics of opaque and transparent solar photovoltaic panels. Sustain. Energy Technol. Assess. 2023, 58, 103369. [Google Scholar]

- Ju, X.; Zhou, X.; Peng, F.; Wu, Z.; Lai, D.; Hu, Y.; Yang, L. Correlation analysis of heat flux and fire behaviour and hazards of polycrystalline silicon photovoltaic panels. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 201, p. 012036. [Google Scholar]

- Akram, M.W.; Li, G.; Jin, Y.; Chen, X. Failures of Photovoltaic modules and their Detection: A Review. Appl. Energy 2022, 313, 118822. [Google Scholar]

- Wang, Y.; Xiao, C.; Bedon, C. Performance of photovoltaic panels with different inclinations under uniform thermal loading. Int. J. Therm. Sci. 2025, 208, 109489. [Google Scholar]

- Kristensen, J.S.; Faudzi, F.B.M.; Jomaas, G. Experimental study of flame spread underneath photovoltaic (PV) modules. Fire Saf. J. 2021, 120, 103027. [Google Scholar] [CrossRef]

- Kristensen, J.S.; Jomaas, G. Experimental study of the fire behaviour on flat roof constructions with multiple photovoltaic (PV) panels. Fire Technol. 2018, 54, 1807–1828. [Google Scholar] [CrossRef]

- Ju, X.; Zhao, K.; Peng, F.; Yang, L. Experimental study on fire behaviors of flexible photovoltaic panels using a cone calorimeter. J. Fire Sci. 2018, 36, 63–77. [Google Scholar] [CrossRef]

- Salmerón-Manzano, E.; Muñoz-Rodríguez, D.; Perea-Moreno, A.J.; Hernandez-Escobedo, Q.; Manzano-Agugliaro, F. Worldwide scientific landscape on fires in photovoltaic. J. Clean. Prod. 2024, 461, 142614. [Google Scholar]

- Liao, B.S.; Yang, L.Z. Fire Hazard Study of Photovoltaic Modules Considering Structuralb Properties of Multilayer Non-Homogeneous Polymers. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2023. [Google Scholar]

- Yang, H.Y.; Yang, L.Z. Experimental Studies on the Fire Hazards of Photovoltaic Module. Master’s Thesis, University of Science and Technology of China, Hefei, China, 2016. [Google Scholar]

- Ju, X.Y.; Yang, L.Z. Study on Fire Characteristics of Building-integrated Flexible and Rigid Crystalline Silicon Photovoltaic Modules. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2019. [Google Scholar]

| Test No. | Inclination Angle (°) | Integrity Level of PV Modules |

|---|---|---|

| 1 | 0 | intact |

| 2 | 15 | intact |

| 3 | 30 | intact |

| 4 | 45 | intact |

| 5 | 60 | intact |

| 6 | 0 | point-like cracks directly above the ignition source |

| 7 | 15 | point-like cracks directly above the ignition source |

| 8 | 30 | point-like cracks directly above the ignition source |

| 9 | 45 | point-like cracks directly above the ignition source |

| 10 | 60 | point-like cracks directly above the ignition source |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, J.; Lin, D.; Zeng, J.; Zhang, S.; Zhao, J. Experimental Study on the Burning Characteristics of Photovoltaic Modules with Different Inclination Angles Under the Pool Fire. Fire 2025, 8, 143. https://doi.org/10.3390/fire8040143

Xiao J, Lin D, Zeng J, Zhang S, Zhao J. Experimental Study on the Burning Characteristics of Photovoltaic Modules with Different Inclination Angles Under the Pool Fire. Fire. 2025; 8(4):143. https://doi.org/10.3390/fire8040143

Chicago/Turabian StyleXiao, Jingwen, Dong Lin, Jia Zeng, Shuai Zhang, and Jinlong Zhao. 2025. "Experimental Study on the Burning Characteristics of Photovoltaic Modules with Different Inclination Angles Under the Pool Fire" Fire 8, no. 4: 143. https://doi.org/10.3390/fire8040143

APA StyleXiao, J., Lin, D., Zeng, J., Zhang, S., & Zhao, J. (2025). Experimental Study on the Burning Characteristics of Photovoltaic Modules with Different Inclination Angles Under the Pool Fire. Fire, 8(4), 143. https://doi.org/10.3390/fire8040143