Abstract

Aircraft cargo compartment fires represent a major threat to aviation safety due to their rapid development, concealment, and the challenges associated with suppression in confined spaces. This study analyzes the 2019 A330 cargo compartment fire at Beijing Capital International Airport as a representative case. Based on flight crew statements, ECAM alerts, surveillance footage, and firefighting records, the event timeline was reconstructed and the emergency response process examined. The analysis identified four defining characteristics of cargo fires: rapid escalation, interacting hazards, restricted accessibility, and prolonged suppression duration. To address these challenges, a three-stage investigation framework—comprising timeline reconstruction, evidence analysis, and experimental verification—is proposed to systematically determine the causes of fires. In addition, a portable penetrating fire-suppression device was designed and experimentally validated. Results confirm its effectiveness in achieving rapid agent delivery, enhanced structural cooling, and prevention of re-ignition. The findings demonstrate that comprehensive cargo fire investigations require the integration of multi-source data and experimental validation, while tactical and equipment innovations are critical for improving suppression efficiency in confined environments. This research provides practical insights for optimizing cargo fire investigation methodologies and emergency response strategies, thereby contributing to the advancement of aviation safety management systems.

1. Introduction

Aircraft cargo compartment fires have long been recognized as a major threat to aviation safety due to their rapid spread, strong early-stage concealment, and the difficulty of firefighting in confined spaces. Compared with cabin fires, cargo compartments are more enclosed and poorly ventilated; once ignited, heat and smoke can quickly accumulate and evolve into an uncontrollable condition. The International Civil Aviation Organization (ICAO) has repeatedly emphasized that cargo compartment fires are among the leading causes of serious aircraft accidents. To quantitatively assess the risk of such fires, this study conducted a statistical analysis of global cargo fire incidents from 2000 to 2024 based on data from the Aviation Safety Network (ASN) database (see Table 1).

Table 1.

Aviation incidents related to cargo compartment fires, 2000–2024 (Source: ASN).

As shown in Table 1, a total of six representative cargo compartment fire incidents were recorded worldwide between 2000 and 2024, among which four were directly related to lithium batteries—accounting for more than 65%—and all occurred after 2010, indicating a clear upward trend. Since the UPS Flight 6 accident in 2010, cargo fires involving lithium batteries have occurred almost every few years, suggesting that the potential risk continues to accumulate with the increasing volume of e-commerce and lithium battery shipments. Notably, most of these incidents took place on the ground or during the initial takeoff phase. Although they did not result in casualties, three of the four lithium battery–related events led to total aircraft loss, causing severe economic damage. These data indicate that lithium batteries have become the primary ignition source for cargo fires, while existing transport regulations and suppression measures remain inadequate for addressing the complex risks associated with energy-dense cargo materials.

Cargo compartment fires remain one of the most challenging safety issues in modern civil aviation. Although international regulations require fire-detection and suppression systems in Class C cargo holds, several recent incidents have shown that system malfunctions, delayed crew response, and limited ground coordination can still lead to severe consequences. The investigation of such events often relies on fragmented evidence and post-incident inference, which constrains both accuracy and timeliness. Strengthening fire-investigation capability and improving coordinated emergency response at airports are, therefore, urgent priorities for enhancing overall aviation safety management.

In recent years, studies have shown that the primary causes of aircraft cargo compartment fires are lithium battery thermal runaway and electrical system failures.

According to the UAE GCAA accident report on UPS Flight 6 [1], the smoke detectors failed to detect the early-stage pyrolysis of lithium battery pallets, as coverings such as rain shields trapped the smoke until the fire had developed into a large-scale event. Rizaldy et al. [2], based on the frameworks of the International Air Transport Association (IATA) Dangerous Goods Regulations (DGR) and the International Civil Aviation Organization (ICAO) Technical Instructions (TI), analyzed the mechanisms of lithium battery transportation and identified institutional vulnerabilities in packaging design, compliance reviews, and ground handling processes as potential contributors to such incidents. Xiong et al. [3] evaluated the safety of cargo fire suppression systems using Computational Fluid Dynamics (CFD) models, analyzing suppression performance under different fire scenarios and providing references for risk assessment in electrical failure conditions. IATA [4] summarized common violations in its Lithium Battery Guidance Document, emphasizing that strengthened declaration review and improved packaging design are key to reducing transport risks. ICAO [5] also issued the Technical Instructions for the Safe Transport of Dangerous Goods by Air, providing unified international standards to ensure transport compliance. These studies collectively indicate that compliance in hazardous goods transportation and electrical system safety management constitutes the first line of defense against cargo fires.

Regarding fire development characteristics, mainstream research focuses on fire growth, smoke behavior, and flashover mechanisms under low-ventilation, low-pressure, and confined conditions. Blake and Suo-Anttila [6] demonstrated through a three-dimensional transport model that the internal geometry and airflow distribution within cargo compartments significantly affect smoke propagation and detection delay. Zhu et al. [7] used the Fire Dynamics Simulator (FDS) to examine how nozzle arrangement, droplet size, and spray patterns influence the effectiveness of water mist suppression. Wang et al. [8] conducted full-scale combustion experiments at an altitude of 3163 m and found that low-pressure environments exacerbate radiative heat hazards and alter flame height distribution. We treat these results as qualitative references rather than quantitative evidence for aviation. Aircraft-specific validation is therefore provided in Section 4. Furthermore, Wang et al. [9] investigated pressure reduction in pressurized buildings and found that ventilation conditions strongly influence the compartment gas environment: smaller door gaps cause a rapid drop in oxygen concentration, while stronger ventilation increases corridor temperatures. These findings indicate that cargo fire evolution is closely related to ambient pressure and ventilation, suggesting that early detection and critical decision-making must account for environmental factors.

In terms of fire suppression mechanisms, current studies focus on coordination between onboard suppression systems and ground firefighting forces. Onboard suppression research primarily covers inerting, chemical inhibition, and localized cooling (e.g., water mist), which in some cases achieve performance comparable to or exceeding Halon 1301. The FAA working group [10] established the Minimum Performance Standards (MPSs) for cargo compartment suppression systems, requiring alternative agents to match Halon 1301’s performance under typical scenarios, including bulk, containerized, surface, and aerosol fires. Most researchers have adopted single-component or simplified multi-component surrogate fuels with reduced chemical reaction mechanisms [11,12,13,14]. Michail et al. [15] found that inert nitrogen effectively suppresses cargo fires when oxygen concentration drops to approximately 11%, meeting the FAA’s four-category MPS tests. Reinhardt [16] evaluated multiple dual-fluid (air/water and water/nitrogen) nozzle systems and demonstrated that optimizing spray angle and droplet size can significantly improve cooling and dilution effects.

In terms of firefighting tactics, research has focused on improving fire control efficiency and personnel safety. ICAO Doc 9137 [17] defines operational principles for airport rescue and firefighting (RFF) forces, including the “external cooling and internal attack” strategy and the use of thermal imaging cameras and skin-penetrating or telescopic piercing nozzles (HRET, SPAAT) for cargo fire suppression. Johansson et al. [18] suggested that incorporating heat release rate (HRR) evolution, smoke generation, and thermo-structural coupling parameters into decision models can improve tactical precision in complex or prolonged incidents. FAA large-scale tests validated the effectiveness of skin-penetrating nozzles in cargo fire scenarios, demonstrating that this technology allows direct water mist or foam delivery into the cargo hold without opening doors, reducing re-ignition risk and shortening suppression time. Overall, the development trend in firefighting tactics lies in transforming fire dynamics research outcomes into operational emergency procedures for more efficient and safer suppression.

Aircraft fire investigation is increasingly evolving from experience-based approaches toward scientific methods centered on fire dynamics and multi-source evidence. Wang et al. [19] proposed a “scene investigation–data recovery–simulation experiment–technical identification–reconstruction analysis” process and demonstrated the critical role of Fire Dynamics Simulation (FDS) in reconstructing evidence chains across engine, electrical, and cargo-lithium fire cases. The Federal Emergency Management Agency (FEMA) [20] emphasized that fire investigation must be based on verifiable scientific methods [21,22,23,24,25,26,27,28], integrating simulation, experimentation, and physical evidence analysis to determine ignition causes, fire spread, and accountability. Éric Stauffer [29] also highlighted the importance of trace evidence, material testing, and multimodal analysis in aviation fire source identification. These studies show that modern aircraft fire investigation has incorporated fire dynamics theory and experimental verification into its core methodology, enhancing the scientific validity and reliability of conclusions.

Despite these advances, several gaps remain. First, there is limited research on emergency response under real accident conditions, lacking a systematic evaluation of timeline reconstruction and crew–ground coordination efficiency. Second, standardized procedures for fire investigation are still underdeveloped, making it difficult to ensure reliability under conditions of evidence degradation or data loss [30,31,32]. Third, deficiencies remain in firefighting tactics and equipment—existing onboard systems are less effective for electrical fires, while large-scale penetrating devices face cost and deployment constraints. Finally, case-driven empirical studies remain scarce, with few systematic investigations linking fire causation, verification, and tactical innovation based on major incidents.

This study addresses the scientific problem of how to systematically analyze, reproduce, and validate cargo compartment fire behavior and emergency response effectiveness in confined aircraft environments through the integration of real-world investigation data and controlled experimental evidence. The writing team includes the technical investigators of the incident and the on-site commander of the firefighting operation. By retrospectively analyzing the investigation and response process of this event, we identified deficiencies in current cargo fire investigation procedures and summarized key technical elements for future regulatory manuals. The study also highlights several pain points encountered during the emergency response—such as the difficulty of rapid compartment access and localized suppression—and proposes corresponding technical improvements through the development of a portable penetrating suppression device. Existing research has primarily focused on fire-suppression efficiency or generic modeling of compartment fires, but it rarely integrates multi-source field data, operational experience, and laboratory validation. Therefore, this work develops and verifies a unified investigation framework that connects evidence, simulation, and practice, providing a reproducible and scientifically grounded methodology for aviation fire analysis and emergency decision-making.

Building on these findings, this study examines the 2019 A330 cargo compartment fire incident at Beijing Capital International Airport as a representative case. Section 2 analyzes the event timeline and emergency response; Section 3 proposes and validates an optimized fire investigation framework; Section 4 develops and tests a novel portable penetrating fire-suppression device; and Section 5 presents conclusions and future research directions.

2. Materials and Methods

Based on crew statements, ECAM warning messages, surveillance footage, and firefighting operation records, this study reconstructed the event timeline of the A330 cargo compartment fire that occurred at Beijing Capital International Airport on 27 August 2019 (see Table 2). The results indicate that the fire exhibited distinct developmental stages. Approximately 190 s elapsed between the initial ECAM alert and the complete evacuation of all occupants, demonstrating a rapid response in early detection and crew evacuation. The period from the first external water application to flame extinguishment lasted about 57 min, reflecting the strong persistence and re-ignition tendency of cargo fires under confined conditions. Even after the flames were controlled, an extended cooling and overhaul phase was required, indicating that residual heat and re-ignition risks significantly constrained the overall firefighting efficiency. This reconstructed timeline not only reveals the dynamic evolution of the fire but also provides empirical evidence for subsequent evaluation of emergency response effectiveness and tactical optimization.

Table 2.

Reconstructed timeline of the cargo compartment fire incident (Beijing time).

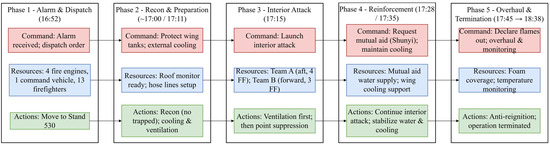

According to the firefighting operation records from Beijing Capital International Airport, the suppression process can be divided into five main phases (see Figure 1). During the alarm response and rapid deployment phase, fire engines arrived at the scene and completed setup within approximately five minutes, demonstrating a high level of response efficiency. Subsequently, the rescue team conducted initial external suppression, which effectively slowed the further spread of the fire. After confirming that no personnel remained inside the aircraft, operations transitioned to a combined “external cooling and internal attack” strategy, during which extinguishing agents were continuously discharged through the cargo door. However, the confined space and intense heat flux significantly limited operational efficiency. As the fire developed, reinforcement units arrived successively, establishing sector-based suppression zones that ensured sustained firefighting capability. Finally, during the cooling, smoke extraction, and overhaul phase, responders eliminated all re-ignition risks. Overall, the entire process followed a logical sequence of rapid response → external suppression → combined cooling and internal attack → sustained suppression → cooling and cleanup, yet it also revealed notable limitations in terms of suppression efficiency, resource consumption, and equipment adaptability.

Figure 1.

Emergency response flowchart for aircraft cargo Compartment fire.

Based on the preceding analysis, four typical characteristics of cargo compartment fires can be summarized.

- Rapid fire development: The fire progressed from the initial alarm to full-scale combustion within only a few minutes, showing a strong tendency toward re-ignition.

- Compound hazard effects: Multiple hazards acted simultaneously—cargo combustion, electrical faults, and potential fuel leakage—creating overlapping risks that increased the complexity of suppression.

- Operational limitations in confined spaces: The sealed compartment structure and low visibility severely restricted rescue efficiency, while the uneven distribution of extinguishing agents further hindered effective fire control.

- Prolonged cooling and overhaul period: Even after the flames were extinguished, long-term cooling and cleanup were required to dissipate the residual heat, extending the operational cycle and consuming significant resources.

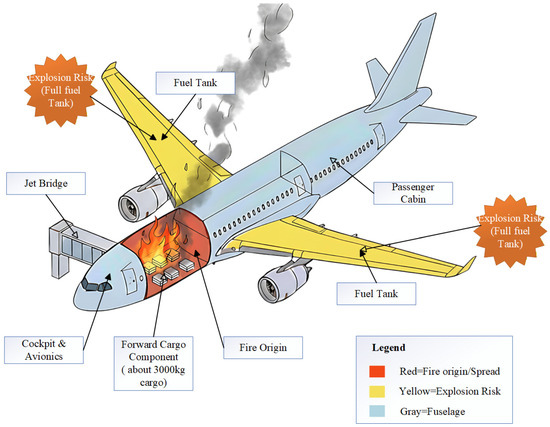

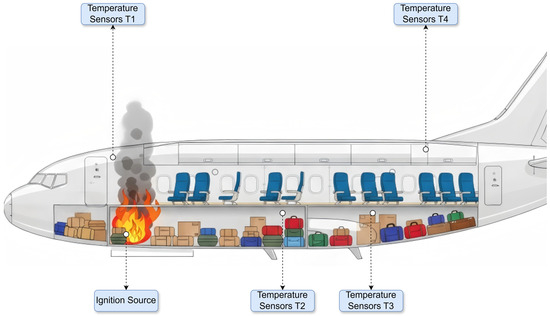

Spatially, these characteristics manifested as concentrated ignition sources, overlapping hazard zones, and restricted personnel access (see Figure 2). The spatial layout and risk distribution of this incident demonstrated significant multi-factor complexity, revealing key tactical challenges in cargo fire suppression:

Figure 2.

Schematic representation of spatial layout and risk distribution in the cargo component fire incident.

- Explosion hazard due to full fuel load: The aircraft was fully fueled at the time of the incident; if the fire had spread to the wings or fuel pipelines, an explosion could have posed a severe threat to firefighting operations.

- Exposure risk to terminal infrastructure: The aircraft was connected to a passenger boarding bridge, and any fire spread could have endangered the terminal structure and complicated passenger evacuation in the concourse area.

- Deep-seated electrical ignition source: Unlike most cargo fires—often triggered by hazardous materials located near the cargo door—the ignition source in this case was an electrical fault embedded deep within the compartment, making direct access and precision suppression extremely difficult.

These combined factors imposed substantial challenges on safety control, fire suppression efficiency, and resource coordination, highlighting the inherent limitations of current emergency response strategies and firefighting tactics. This case provides a representative and realistic scenario for advancing investigation methodology optimization and tactical innovation in aircraft cargo fire management.

The above case analysis indicates that cargo compartment fires exhibit high complexity in terms of their development process, emergency response, and risk distribution. Such incidents not only pose considerable challenges to rescue operations but also reveal the limited effectiveness of existing firefighting tactics and equipment. To fundamentally enhance prevention and control capabilities, it is essential to identify the underlying causes and evolution mechanisms of cargo fires. Therefore, Section 3 of this study proposes a systematic investigation methodology designed to elucidate the principal causes of the fire through timeline reconstruction, evidence analysis, and experimental verification, thereby providing a scientific basis for subsequent tactical improvement and system optimization.

3. Results

3.1. Overview of the Investigation Process

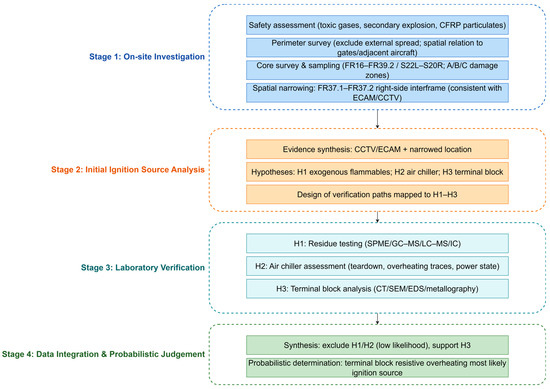

To ensure a scientific and systematic determination of the causes of this aircraft cargo compartment fire, the study followed the technical investigation process shown in Figure 3. The process consists of four core stages: on-site inspection, preliminary ignition source analysis, experimental verification, and integrated data assessment. This step-by-step approach moves from the macroscopic to the microscopic and from observed phenomena to underlying mechanisms, aiming to establish a closed-loop chain of evidence and to avoid uncertainty that may arise when conclusions rely solely on single pieces of evidence or subjective judgment.

Figure 3.

Overview of the cargo hold fire investigation process.

This investigation was organized under the leadership of the Civil Aviation Administration of China (CAAC), with the Aircraft Accident Investigation Center providing primary technical support. As the national authority for technical investigations of civil aviation accidents and incidents, the center has long been responsible for such inquiries, equipped with established investigation protocols, experimental facilities, and an interdisciplinary team of experts. Relying on this framework, the field records, experimental data, and analytical conclusions collected in the present study are characterized by a high level of scientific rigor and reliability. Consequently, the investigation presented here not only reflects a complete process for a representative aircraft cargo compartment fire but also illustrates current best practices in accident investigation within China’s civil aviation sector.

In practical implementation, the process began with an on-site inspection to collect first-hand information on structural damage and burn patterns, thereby identifying the spatial distribution of the fire and likely areas of origin. Based on these observations, a preliminary ignition source analysis was conducted, categorizing potential causes and formulating working hypotheses, which were then used to design experimental validation procedures. The experimental stage employed residue detection, physicochemical analysis of equipment, and combustion testing of electrical components to progressively exclude or confirm possible ignition sources. Finally, data analysis was used to integrate multiple lines of evidence and apply logical reasoning, leading to a scientific determination of the ignition location and mechanism.

3.2. On-Site Inspection

On-site inspection marked the starting point of the technical investigation. Its purpose was to determine the spatial distribution of the fire, patterns of structural damage, and potential points of interest, thereby laying the foundation for subsequent ignition source analysis and experimental validation. Before entering the accident site, the investigation team conducted an environmental risk assessment, focusing on hazards such as falling debris, toxic gases, and secondary explosions. In response to possible respiratory risks posed by combustion products of carbon fiber composite materials, investigators employed full respiratory and skin protection. During the peripheral survey, attention was given to confirming the spatial relationship of the fire scene with the boarding bridge, terminal building, and adjacent aircraft, as well as excluding the possibility of fire intrusion from external sources.

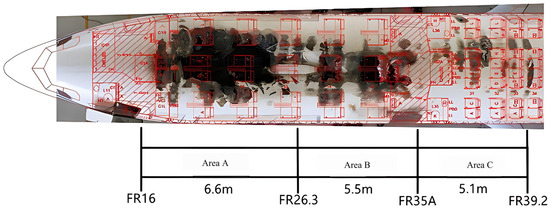

In the core inspection, the main damage was concentrated between fuselage stations FR16–FR39.2 longitudinally and S22L–S20R laterally. Burn patterns showed significant heterogeneity: Area A displayed burn-through holes, suggesting localized high-temperature penetration; Area B exhibited both burn-through and severe skin deformation, indicating the most intense fire activity; while Area C was relatively less affected, showing only surface charring (see Figure 4). Overall, the severity of fire damage varied markedly across different areas.

Figure 4.

External damage areas of the aircraft fuselage.

Inside the forward cargo compartment, the right-side section between frames FR37.1 and FR37.2 sustained the most severe damage. The air chiller casing showed significant scorching but remained structurally intact. Three electrical terminal blocks were found melted and broken, and adjacent wiring bundles exhibited signs of melting and sagging. Combined with surveillance footage showing the initial smoke location and the timing of the “Forward Cargo Compartment Smoke” alert from the cockpit ECAM system, it can be preliminarily inferred that the fire originated within the interspace of this region. Accordingly, the on-site inspection identified the right-side FR37.1–FR37.2 section of the forward cargo compartment as the likely origin area and narrowed down three potential sources of concern: external combustibles, the air chiller, and the terminal blocks. These findings provided the basis for subsequent preliminary ignition source analysis.

3.3. Preliminary Analysis of Ignition Sources

Based on the spatial localization and damage characteristics observed during the on-site inspection, preliminary hypotheses regarding the ignition source of the cargo compartment fire can be formulated. Both external surveillance footage and ECAM data indicated that abnormal smoke first appeared in the right section of the forward cargo compartment, corresponding closely to the severely burned area between frames FR37.1 and FR37.2. This section contained critical equipment, including the air chiller, terminal blocks, and wiring bundles. The burn patterns showed localized high temperatures and directional combustion, suggesting the possibility of electrical thermal failure.

From these observations, three potential ignition sources were identified:

- External combustibles—such as flammable liquids or hazardous chemical residues that may have leaked or been introduced during transport.

- Air chiller unit—as an electrical device, it could theoretically ignite due to electrical failure or refrigerant leakage.

- Terminal blocks and associated wiring—signs of melting, breakage, and sagging were observed, indicating that poor contact may have caused localized overheating.

Based on this reasoning, three hypotheses were proposed for validation:

Hypothesis 1.

Ignition was triggered by external combustibles;

Hypothesis 2.

Ignition originated from air chiller failure;

Hypothesis 3.

Ignition resulted from localized overheating due to poor contact in the terminal blocks.

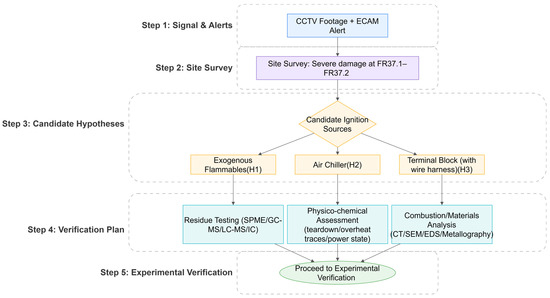

To test these hypotheses, the subsequent investigation included residue analysis, physicochemical testing of the air chiller, and combustion experiments on terminal blocks, aiming to eliminate or confirm each potential source and build a complete chain of evidence. The logic of hypothesis formulation and validation is illustrated in Figure 5.

Figure 5.

Flowchart of initial ignition source analysis.

3.4. Experimental Setup and Validation

Following the candidate ignition source hypothesis proposed in Section 3.3 (see Step 3 in Figure 5), this study designed verification experiments corresponding to Step 4 in Figure 5. The experimental and analytical pathway targeted the three potential ignition sources: residue analysis, physicochemical testing of the air chiller, and combustion and materials analysis of the terminal blocks.

Residue analysis. To test the external combustibles hypothesis (H1), surface swabs and residue samples from the cargo compartment were collected and analyzed. Headspace solid-phase microextraction (SPME) combined with gas chromatography–mass spectrometry (GC–MS), liquid chromatography–mass spectrometry (LC–MS), and ion chromatography (IC) was employed. The results revealed no detectable accelerants, organic solvents, or hazardous chemical components. These findings effectively excluded external combustibles as the fire ignition source (corresponding to the H1 validation pathway in Figure 5).

Air chiller assessment. To verify the air chiller hypothesis (H2), the unit was disassembled and subjected to detailed physicochemical examination, focusing on evidence of short circuits, arcing, or overheating in electrical components, as well as potential traces of refrigerant combustion. Results showed that although the outer casing exhibited significant scorching, the internal structure remained intact, with no signs of electrical failure or refrigerant involvement. Maintenance records further indicated that the unit was de-energized at the time of the incident. On this basis, the air chiller was ruled out as an ignition source (corresponding to the H2 validation pathway in Figure 5).

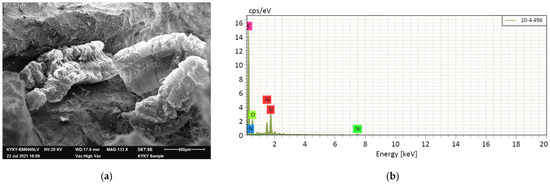

Terminal block analysis. Terminal blocks (with associated wiring) were identified as the most suspicious components during on-site inspection. To assess their potential role as an ignition source (H3), multiple analytical methods were applied, including CT scanning, scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS), and metallographic analysis. The results showed pronounced melting and charring in localized regions of terminal post No. 10, with abnormal metallurgical fusion observed at the contact surfaces (see Figure 6a). EDS results further indicated elevated levels of carbon and oxygen, consistent with high-temperature carbonization and metal oxidation/melting (see Figure 6b). Morphological and compositional evidence converged to strongly support the conclusion that abnormal contact resistance in the terminal block led to localized overheating, which served as the initial ignition source of the fire.

Figure 6.

Microscopic examination and EDS spectra of terminal block No. 10. (a) Microscopic morphology of terminal block No. 10 showing surface melting and carbonized residue. (b) EDS spectra of the same area indicate the presence of carbon (C), oxygen (O), and aluminum (Al), suggesting thermal decomposition and oxidation of polymer insulation.

Integrated judgment. Based on the synthesis of multi-dimensional evidence, the study concludes that localized overheating of terminal post No. 10 was the most likely ignition source of this cargo compartment fire. While the influence of other potential factors cannot be entirely ruled out, the overall evidence chain supports this conclusion with high confidence.

4. Discussion

4.1. Current Tactics and the Need for Innovation

In recent years, the rapid growth of air cargo transportation has led to an increasing frequency and an electrification trend of cargo compartment fires. Current suppression approaches can be broadly categorized into two types: onboard fixed fire suppression systems and ground-based airport firefighting tactics. The former typically employs halon agents that provide early suppression during flight; however, their total discharge mechanism lacks targeted intervention capability, resulting in limited effectiveness against localized electrical ignition sources and a persistent risk of re-ignition. The latter relies on fire trucks and manual operations, which allow multi-angle suppression but are significantly constrained by high temperatures, poor visibility, and equipment incompatibility within the confined cargo environment.

International studies, such as the FAA full-scale cargo fire tests, have demonstrated that directional agent injection achieves substantially higher efficiency than indirect spraying, highlighting “targeted delivery” as a key direction for improving firefighting performance. Nevertheless, large-scale penetrating equipment—such as the Aerial Skin Penetration Nozzle (ASPN) and High-Reach Extendable Turret (HRET) systems—remains expensive, complex to maintain, and difficult to deploy at most airports. In China, the majority of airports still depend on conventional fire trucks and manual hose operations, resulting in a notable response gap during the initial suppression phase.

Against this backdrop, there is an urgent need for a portable, low-cost, and rapidly deployable directional penetrating fire-suppression device to bridge the time gap between onboard suppression and ground-based intervention. After the crew evacuation is confirmed, the device enables thermal imaging–based hotspot localization, followed by mechanical penetration to deliver extinguishing agents directly into the cargo compartment, forming a rapid “arrival–localization–penetration–suppression” operational loop. The purpose of this device is not to replace large-scale firefighting systems but to serve as a tiered tactical supplement, providing a time-efficient and low-risk solution for ground rescue operations.

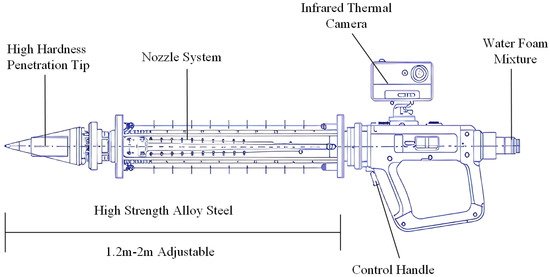

4.2. Design of a Portable Onboard Suppression Device

The device is designed to provide ground firefighters with a portable, economical, and efficient suppression tool that bridges the gap between fixed onboard systems and large-scale piercing vehicles. Its total weight is kept within the range manageable by a single operator, enabling rapid deployment once safe entry is confirmed after landing. By simplifying both structure and operation, the device aims to deliver targeted suppression within a limited time, reducing response delays and lowering the probability of re-ignition.

The system adopts a simple yet effective structure consisting of a piercing arm, piercing head, nozzle, control handle, and infrared thermal imager (see Figure 7). The piercing arm, made of high-strength alloy steel, is adjustable in length from 1.2 to 2.0 m, providing high mechanical strength and heat resistance suitable for penetrating obstacles such as unit load devices (ULDs), cargo packaging, and compartment lining. A conical, high-hardness piercing head at the front houses the nozzle system, which connects to the water–foam delivery line from a fire truck, enabling rapid application of extinguishing agents after penetration. The rear of the device is fitted with a standardized interface for coupling with airport fire truck water–foam systems, ensuring uninterrupted supply. The front end is also equipped with an infrared thermal imager and high-definition camera, allowing real-time visualization of fire conditions inside the cargo compartment. This provides firefighters with decision support for targeted suppression, minimizes operational risks, and enables effective firefighting without direct entry into the compartment.

Figure 7.

Schematic of the simplified penetrating fire suppression device.

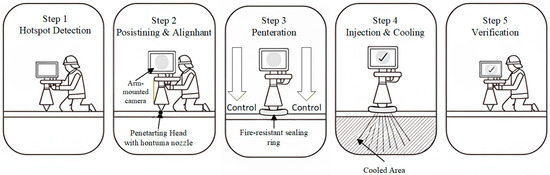

As shown in Figure 8, the operational procedure of the portable penetrating fire-suppression device consists of five sequential steps. First, an infrared thermal imager is used to scan the cabin floor and locate heat spots. Second, the penetrating device is positioned and aligned precisely with the identified source. Third, the driving mechanism is activated to perform penetration, followed by insertion of the spray pipe to achieve a sealed connection. Finally, the extinguishing agent supply system is connected, and directional discharge is initiated. The entire process can be completed by a single operator within approximately one minute. To ensure operational safety, the probe structure has been mechanically optimized to prevent damage to load-bearing components, while the sealing ring effectively prevents agent leakage and backflow of hot gases. The extinguishing agent selection follows electrical compatibility and non-corrosive principles. This device is applicable to various aircraft types and airport conditions, providing an efficient and practical tactical supplement for rapid, targeted fire suppression on the ground.

Figure 8.

Operational sequence of the portable penetrating fire-suppression device.

Compared with the High-Reach Extendable Turret (HRET) systems commonly deployed at large airports, the proposed portable device offers a compact, low-cost, and rapidly deployable alternative. While HRET systems provide long-range reach and large agent flow, their high operational costs, maintenance complexity, and limited availability often delay early intervention. The portable system, by contrast, enables immediate on-site deployment by a single operator, bridging the time gap between onboard suppression and large-scale ground operations. It thus serves as a tactical complement rather than a replacement, providing a flexible and cost-effective option for airports with varying resource capacities.

4.3. Experimental Scenario Design and Algorithmic Analysis

To verify the effectiveness of the proposed simplified penetrating fire-suppression device, a series of live-fire simulation experiments was conducted at an airport’s full-scale fire training facility. The facility is equipped with a steel-structured aircraft fire simulator capable of reproducing both cabin and cargo compartment fire scenarios. Each compartment is configured with four independent ignition points and four temperature measurement points, allowing real-time acquisition of temperature curves during the fire evolution process (see Figure 9). This experimental setup provides a controlled yet realistic environment for reproducing the thermal development of actual cargo fires, thereby offering a reliable platform for tactical efficiency comparison among different suppression methods.

Figure 9.

Experimental setup of the cargo fire test showing the fire-source location, thermocouple arrangement.

As illustrated in Figure 9, the full-scale experimental setup was arranged within the airport’s fire-training zone. The fire source was a kerosene pool placed at the center of the compartment, and thermocouples were evenly distributed along the longitudinal and vertical axes to capture temperature evolution. Each test was repeated under comparable conditions to ensure data consistency and to verify the stability of the temperature profiles obtained during the different experimental phases.

To ensure the reliability and repeatability of the results, the experiments were conducted under controlled, yet realistic conditions representative of apron environments. Ambient temperature, humidity, and airflow were maintained within stable ranges, and the compartment boundaries remained sealed throughout each trial to reproduce the confined characteristics of an aircraft cargo hold. All thermocouples were calibrated before use, and any minor fluctuations in ambient parameters were recorded and considered in the uncertainty analysis.

Two suppression methods were compared:

Method A (conventional tactics): locating hotspots via cabin or external temperature measurement, followed by opening the cargo door and removing cargo to access the fire source, or applying external piercing injection under specific conditions.

Method B (proposed device): rapidly identifying hotspots using thermal imaging of the cabin floor, then employing the piercing device to establish a direct injection channel for targeted suppression.

In each trial, the following metrics were recorded:

- (i)

- Time from ignition to first agent application ;

- (ii)

- Total suppression time ;

- (iii)

- Cooling rate within after agent discharge ;

- (iv)

- Suppression efficiency per unit mass of extinguishing agent (with being the released mass in the -th experiment).

For each metric, the mean and standard deviation were calculated:

where denotes the observation of the -th experiment, and is the total number of experiments.

To avoid bias from relying on single indicators, a composite performance evaluation function was introduced. Each metric was normalized as follows:

- (i)

- For “smaller-is-better” time-based metrics:

- (ii)

- For “larger-is-better” efficiency-based metrics:

After normalization, all values satisfy the principle that higher values indicate better performance. The composite efficiency score is then defined as follows:

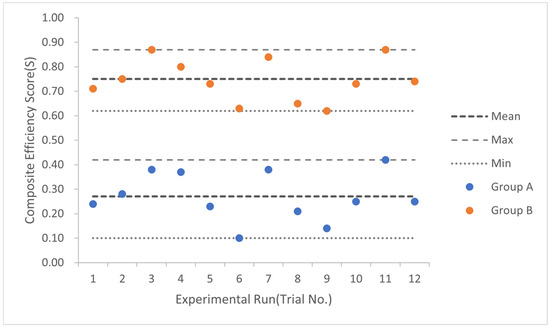

where is the composite suppression efficiency of the -th trial, and is the weight assigned to the -th metric. The composite score serves to compress multi-dimensional performance into a single dimensionless value, reflecting the overall suppression efficiency of each trial. It should be emphasized that a higher mean value of indicates superior comprehensive performance of the corresponding method. Finally, the composite score distributions for Method A and Method B, denoted as and .

The raw experimental data are presented in Table 3, which records the performance metrics from 12 trials for both the conventional method (Group A) and the proposed device (Group B). These metrics include first time (), total time (), cooling rate (), efficiency (), and score. The raw records show that both methods exhibited some variability under comparable conditions; however, the overall trend indicates that Group B consistently achieved shorter times for time-based indicators and higher values for efficiency-based indicators.

Table 3.

Experimental results for the conventional method (A) and the proposed device (B).

The statistical results showed that the ignition-to-first-attack time and the total suppression time for Method A were and , respectively, while for Method B they were and . In terms of cooling rate, the mean value for Group B was , representing an improvement of approximately 31.1% over Group A . For suppression efficiency per unit agent, Group B achieved , about 38.4% higher than Group A . Regarding the composite performance score, as shown in Figure 10, the mean for Group A was , whereas the mean for Group B reached .

Figure 10.

Performance comparison between Group A and Group B.

5. Conclusions

This study systematically investigated the 2019 A330 cargo compartment fire at Beijing Capital International Airport, integrating on-site investigation, event reconstruction, and experimental verification. The investigation revealed methodological gaps in existing cargo fire investigation practices—particularly in the traceability of evidence, quantitative verification of fire behavior, and coordination between airborne detection systems and ground response. Based on these findings, a “timeline reconstruction–evidence analysis–experimental verification” framework was established to strengthen the scientific rigor and reproducibility of cargo fire investigations. This framework provides methodological insights for refining future investigation procedures and demonstrates the value of integrating empirical data with experimental validation in aviation fire research.

Through an in-depth reconstruction of this real incident, this study also highlighted the practical challenges faced during aircraft cargo fire emergencies, including the difficulty of rapid fire-source localization and the limited accessibility for effective extinguishment. To address these issues, a portable penetrating suppression device was designed and experimentally tested as a low-cost, deployable solution. The experimental results verified its capability to achieve fast penetration, internal cooling, and re-ignition prevention under confined conditions. These findings provide both theoretical guidance for improving cargo fire investigation methodology and practical reference for enhancing on-site firefighting efficiency in airport emergency operations.

Despite these contributions, several limitations remain. First, the case data were constrained by the availability of records provided by the operating unit, which may affect the generalizability of the conclusions. Second, discrepancies still exist between the experimental conditions and actual cargo environments, necessitating further large-scale validation tests. Third, the applicability and long-term reliability of the proposed device require evaluation under diverse operational scenarios.

Building on these findings, future research will further advance this framework through both practical validation and methodological innovation. Future research should focus on the following aspects:

- (1)

- Enhancing the standardization and scientific rigor of the investigation framework through multi-case studies;

- (2)

- Optimizing tactical adaptability and equipment integration, particularly exploring coordination between ground and onboard suppression systems;

- (3)

- Incorporating numerical simulation and digital-twin technologies to predict fire evolution and assess emergency response efficiency.

By integrating these directions, an adaptive, data-driven safety framework can be developed to strengthen scientific investigation and operational decision-making for complex airport environments.

Through these efforts, it is expected that the prevention and control capacity of aircraft cargo compartment fires can be significantly improved, thereby providing both theoretical support and technical foundations for a more comprehensive aviation safety management system.

Author Contributions

Conceptualization, W.Y. and Q.S.; methodology, W.Y., N.S., H.S. and Y.G.; validation, H.S., B.Z. and L.W.; formal analysis, B.Z., H.S. and L.W.; investigation, H.S., Y.G. and L.W.; resources, N.S. and H.S.; data curation, N.S., B.Z., H.S. and W.Y.; writing—original draft preparation, W.Y., N.S. and Y.G.; writing—review and editing, B.Z., L.W. and N.S.; supervision, Q.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 52202416).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data in this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

Author Biao Zhang is affiliated with Capital Airports Holdings Co., Ltd. The rest of the authors declare no conflicts of interest.

References

- UAE General Civil Aviation Authority. Final Report: UPS Flight 6; Boeing 747-44AF, N571UP; Dubai, United Arab Emirates, 3 September 2010 [EB/OL]; UAE GCAA: Abu Dhabi, United Arab Emirates, 2013. [Google Scholar]

- Rizaldy, W.; Gultom, S.; Raffi, S.; Setiawan, A. Lithium battery handling as air cargo. In Proceedings of the 1st Green Development on Transportation (GROST 2017), Jakarta, Indonesia, 22–23 November 2017; pp. 61–66. [Google Scholar]

- Yifang, X.; Michail, D.; Akhil, D.; Sampath, S. Numerical assessment for aircraft cargo compartment fire suppression system safety. J. Fire Sci. 2021, 39, 240–261. [Google Scholar] [CrossRef]

- International Air Transport Association. Battery Guidance Document (2025 Edition) [EB/OL]; IATA: Montreal, QC, Canada, 2025. [Google Scholar]

- International Civil Aviation Organization. Technical Instructions for the Safe Transport of Dangerous Goods by Air (Doc 9284, 2023–2024 Edition); ICAO: Montreal, QC, Canada, 2022. [Google Scholar]

- Blake, D.; Suo-Anttila, J. Aircraft cargo compartment fire detection and smoke transport modeling. Fire Saf. J. 2008, 43, 576–582. [Google Scholar] [CrossRef]

- Zhu, P.; Xu, Z.; Zhang, J.; Shao, Q.; Chen, W.; Ai, H. Numerical study on fire suppression by water mist in aircraft cargo compartments: Effects of spray pattern, droplet size, and nozzle layout. Fire 2024, 7, 481. [Google Scholar] [CrossRef]

- Wang, J.; Yang, R.; Gao, Z.; Ding, S.; Qin, L. Investigation of external fuel fire hazards of full-scale aircraft fuselage under sub-atmospheric pressure. Fuel 2025, 380, 132950. [Google Scholar] [CrossRef]

- Wang, K.; Shang, Z.; Liu, W.; Wen, K.; Zhang, J.; Yao, B.; Song, W. An experimental study of fire development under varying ventilation conditions during the depressurization process in pressurized buildings. J. Saf. Sci. Resil. 2025, 6, 70–78. [Google Scholar] [CrossRef]

- Reinhardt, J.W.; Blake, D.; Marker, T. Development of a Minimum Performance Standard for Aircraft Cargo Compartment Gaseous Fire Suppression Systems; DOT/FAA/AR-00/28; Federal Aviation Administration Technical Center: Atlantic City, NJ, USA, 2000. [Google Scholar]

- Alekseev, V.A.; Soloviova-Sokolova, J.V.; Matveev, S.S.; Chechet, I.V.; Matveev, S.G.; Konnov, A.A. Laminar burning velocities of n-decane and binary kerosene surrogate mixture. Fuel 2017, 187, 429–434. [Google Scholar] [CrossRef]

- Yan, Y.W.; Liu, Y.C.; Fang, W.; Liu, Y.P.; Li, J.H. A simplified chemical reaction mechanism for two-component RP-3 kerosene surrogate fuel and its verification. Fuel 2018, 227, 127–134. [Google Scholar] [CrossRef]

- Humer, S.; Frassoldati, A.; Granata, S.; Faravelli, T.; Ranzi, E.; Seiser, R.; Seshadri, K. Experimental and kinetic modeling study of combustion of JP-8, its surrogates and reference components in laminar nonpremixed flows. Proc. Combust. Inst. 2007, 31, 393–400. [Google Scholar] [CrossRef]

- Pio, G.; Carboni, M.; Salzano, E. Realistic aviation fuel chemistry in computational fluid dynamics. Fuel 2019, 254, 115676. [Google Scholar] [CrossRef]

- Diakostefanis, M.; Sampath, S.; Dinesh, A.; Beuermann, R. Nitrogen as an environmentally friendly suppression agent for aircraft cargo fire safety. J. Fire Sci. 2021, 39, 400–424. [Google Scholar] [CrossRef]

- Reinhardt, J.W. The Evaluation of Water Mist With and Without Nitrogen as an Aircraft Cargo Compartment Fire Suppression System; DOT/FAA/AR-01/121; Federal Aviation Administration, William J. Hughes Technical Center: Atlantic City, NJ, USA, 2002. [Google Scholar]

- International Civil Aviation Organization. Airport Services Manual, Part I: Rescue and Firefighting (Doc 9137 Part I, 2023 Edition); ICAO: Montreal, QC, Canada, 2023. [Google Scholar]

- Johansson, N.; Svensson, S. Review of the use of fire dynamics theory in fire service activities. Fire Technol. 2019, 55, 81–103. [Google Scholar] [CrossRef]

- Wang, J.; Tao, Z.; Yang, R.; Gao, Z. A review of aircraft fire accident investigation techniques: Research, process, and cases. Eng. Fail. Anal. 2023, 153, 107461. [Google Scholar] [CrossRef]

- Federal Emergency Management, Agency; US Fire Administration; National Fire Academy. Fire Investigation: First Responders—Student Manual, 1st ed.; 7th printing (January 2025); FEMA/USFA/NFA: Emmitsburg, MD, USA, 2025. [Google Scholar]

- Shrigondekar, H.; Chowdhury, A.; Prabhu, S.V. Characterization of a simplex water mist nozzle and its performance in extinguishing liquid pool fire. Exp. Therm. Fluid Sci. 2018, 93, 441–455. [Google Scholar] [CrossRef]

- Kraus-Namrozy, N.; Brzezińska, D. Effectiveness of swirl water mist nozzles for fire suppression. Int. J. Environ. Res. Public Health 2022, 19, 16328. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Wang, X.; Wang, Z.; Cong, H.; Ni, X. Experimental and numerical study on attenuation of thermal radiation from large-scale pool fires by water mist curtain. J. Fire Sci. 2015, 33, 269–289. [Google Scholar] [CrossRef]

- Jenft, A.; Collin, A.; Boulet, P.; Pianet, G.; Breton, A.; Muller, A. Experimental and numerical study of pool fire suppression using water mist. Fire Saf. J. 2014, 67, 1–12. [Google Scholar] [CrossRef]

- Beji, T.; Ebrahim Zadeh, S.; Maragkos, G.; Merci, B. Influence of the particle injection rate, droplet size distribution and volume flux angular distribution on the results and computational time of water spray CFD simulations. Fire Saf. J. 2017, 91, 586–595. [Google Scholar] [CrossRef]

- Liu, H.R.; Wang, C.; De Cachinho Cordeiro, I.M.; Yuen, A.C.Y.; Chen, Q.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Critical assessment on operating water droplet sizes for fire sprinkler and water mist systems. J. Build. Eng. 2020, 28, 100999. [Google Scholar] [CrossRef]

- Lee, J. Numerical analysis of how ventilation conditions impact compartment fire suppression by water mist. Ann. Nucl. Energy 2020, 136, 107021. [Google Scholar] [CrossRef]

- Dasgotra, A.; Rangarajan, G.; Tauseef, S.M. CFD-based study and analysis on the effectiveness of water mist in interacting pool fire suppression. Process Saf. Environ. Prot. 2021, 152, 614–629. [Google Scholar] [CrossRef]

- Stauffer, É. Interpol review of fire investigation 2016–2019. Forensic Sci. Int. Synerg. 2020, 2, 368–381. [Google Scholar] [CrossRef] [PubMed]

- Pasman, H.J.; Rogers, W.J.; Mannan, M.S. How can we improve process hazard identification? What can accident investigation methods contribute and what other recent developments? A brief historical survey and a sketch of how to advance. J. Loss Prev. Process Ind. 2018, 55, 80–106. [Google Scholar] [CrossRef]

- Righi, H.; Madabhushi, A.; Ouidadi, H.; Boushab, D.; Lacy, T.E.; Kundu, S.; Pittman, C.U.; Priddy, W. Post-Crash Fire Forensic Analysis Federal Aviation Administration on Aerospace Composites; DOT/FAA/TC-20/21; U.S. Department of Transportation: Washington, DC, USA, 2020. [Google Scholar]

- Infante, V.; Silva, J.; Silvestre, M.; Baptista, R. Failure of a crankshaft of an aeroengine: A contribution for an accident investigation. Eng. Fail. Anal. 2013, 35, 286–293. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).