Evaluation of the Fire Safety Performance of Fire-Resistant Coatings in BIPV Modules

Abstract

1. Introduction

2. Materials and Experimental Details

2.1. PV Module Specimens and FR Coating

2.2. Physicochemical Properties and Combustion Tests

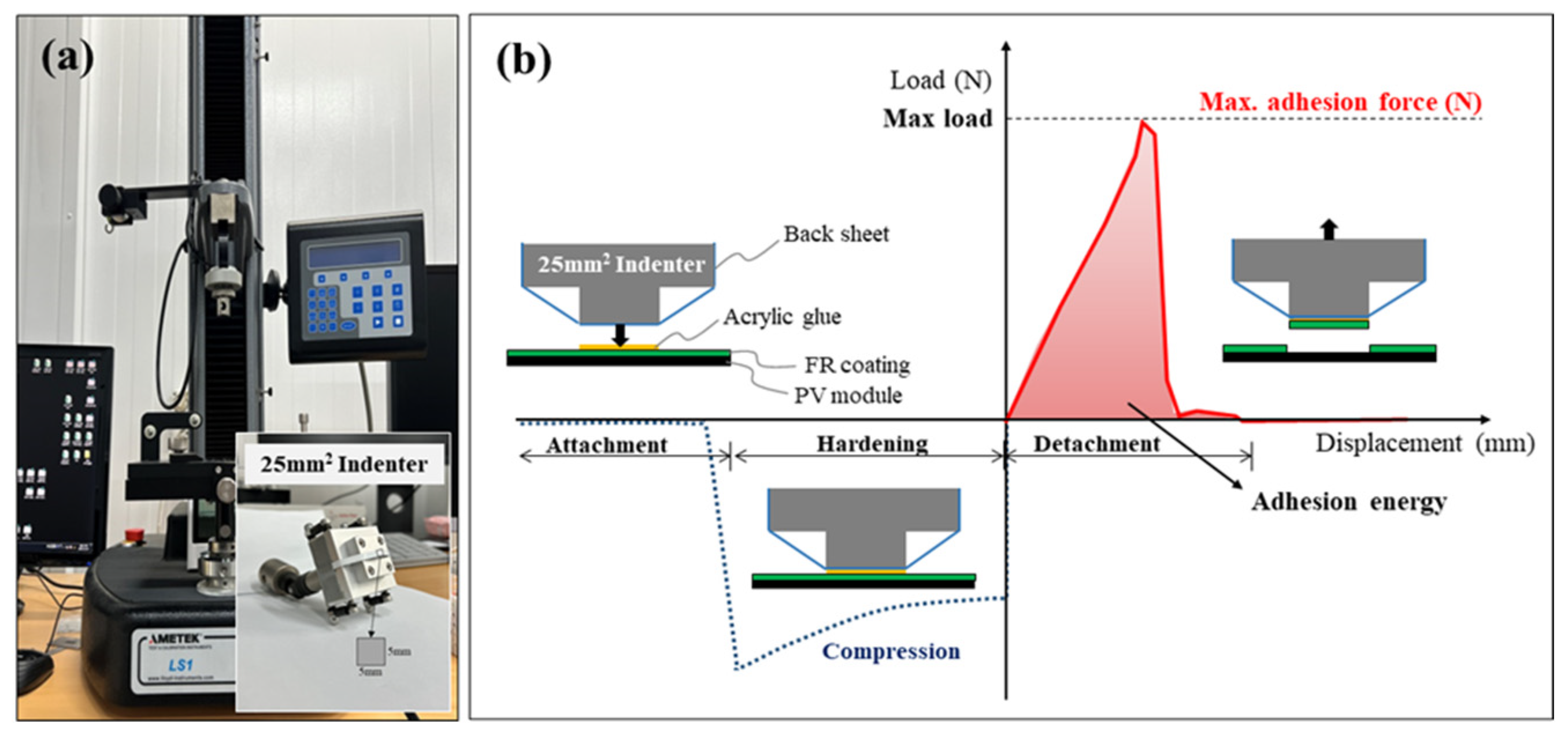

2.3. Tack Test

3. Results and Discussion

3.1. Evaluation of Physical Properties and Durability

3.2. Flame Propagation and Heat Release Properties

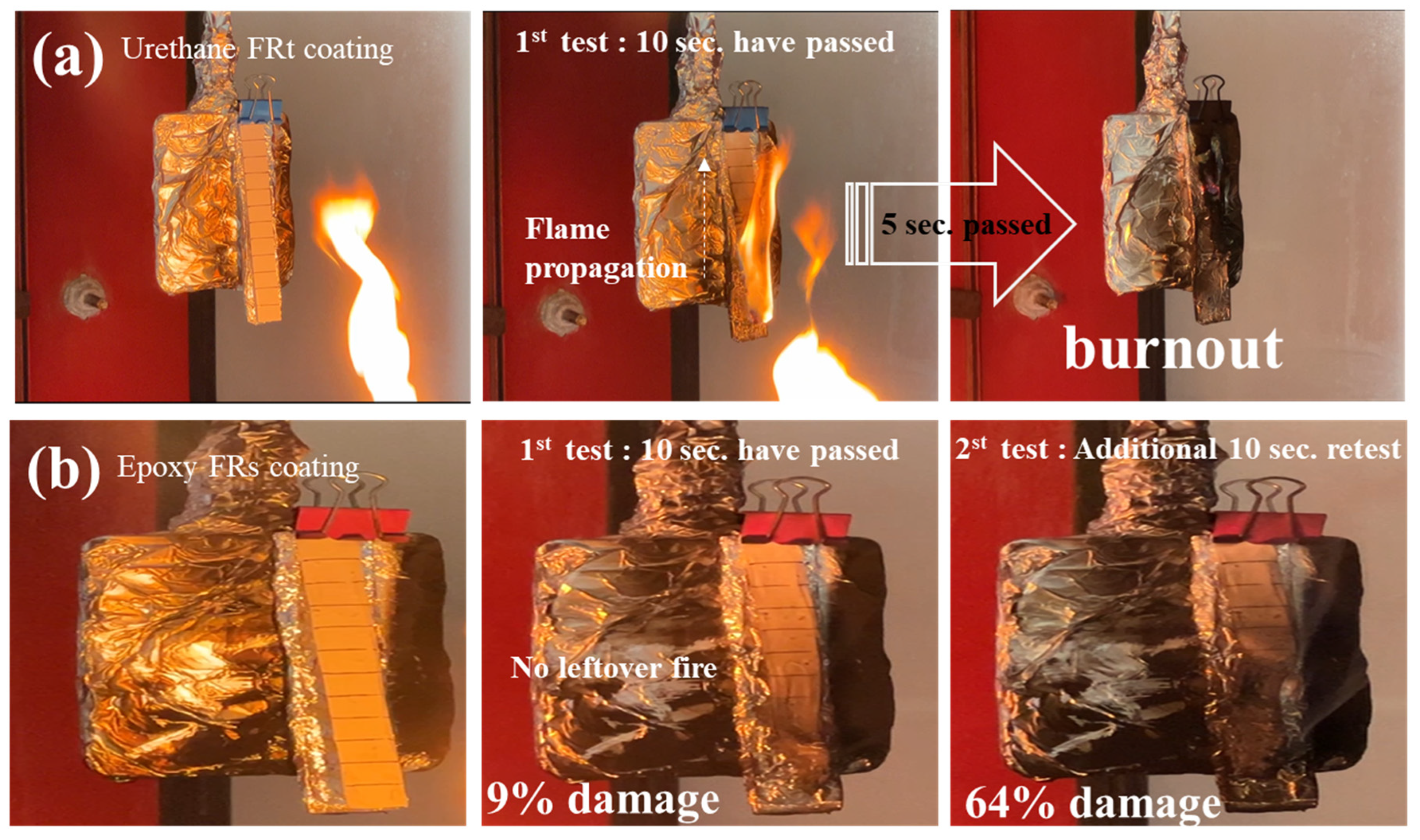

3.2.1. UL-94 Test Results

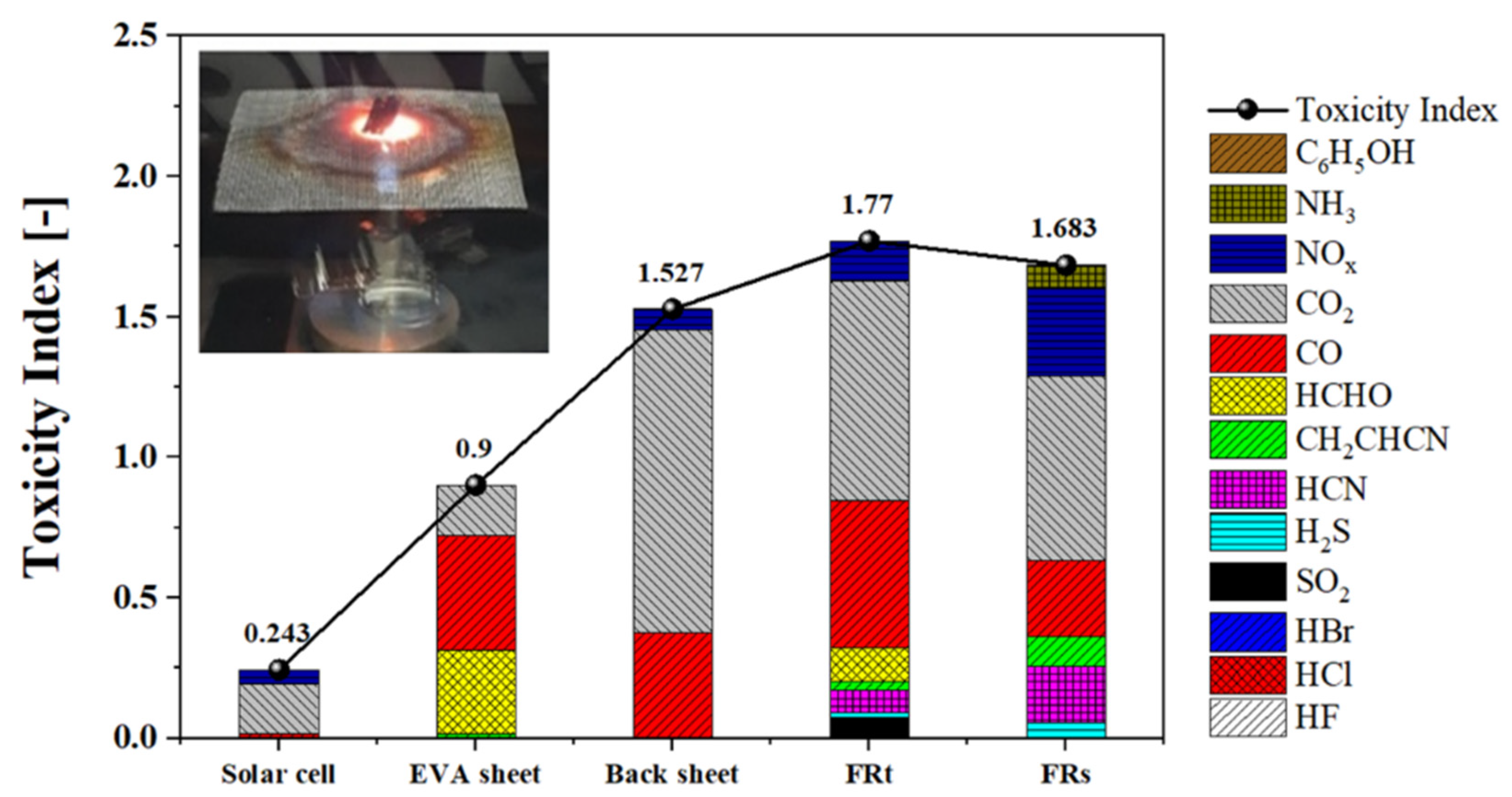

3.2.2. Cone-Calorimeter and NES 713 Test Results

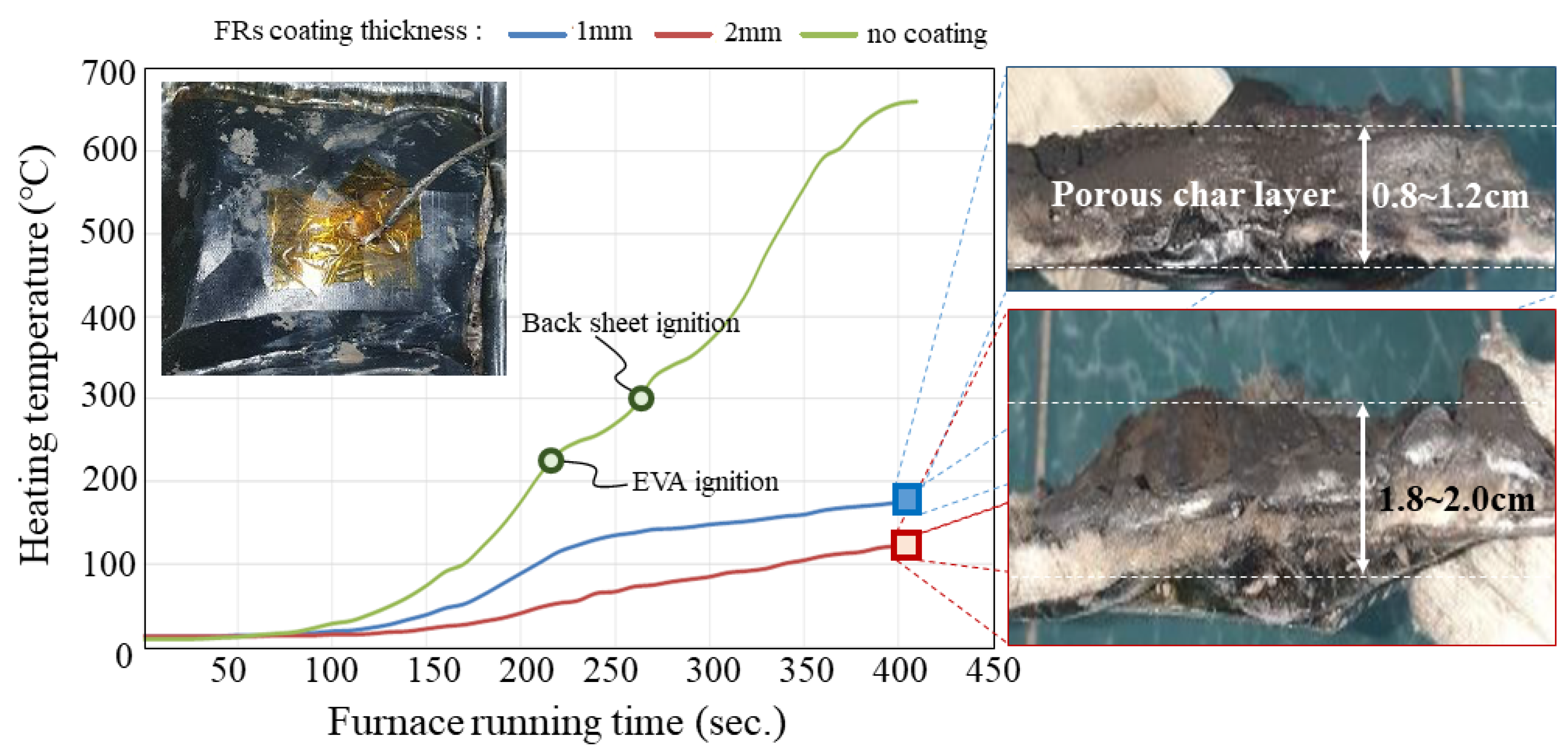

3.2.3. ISO 834 Test Results

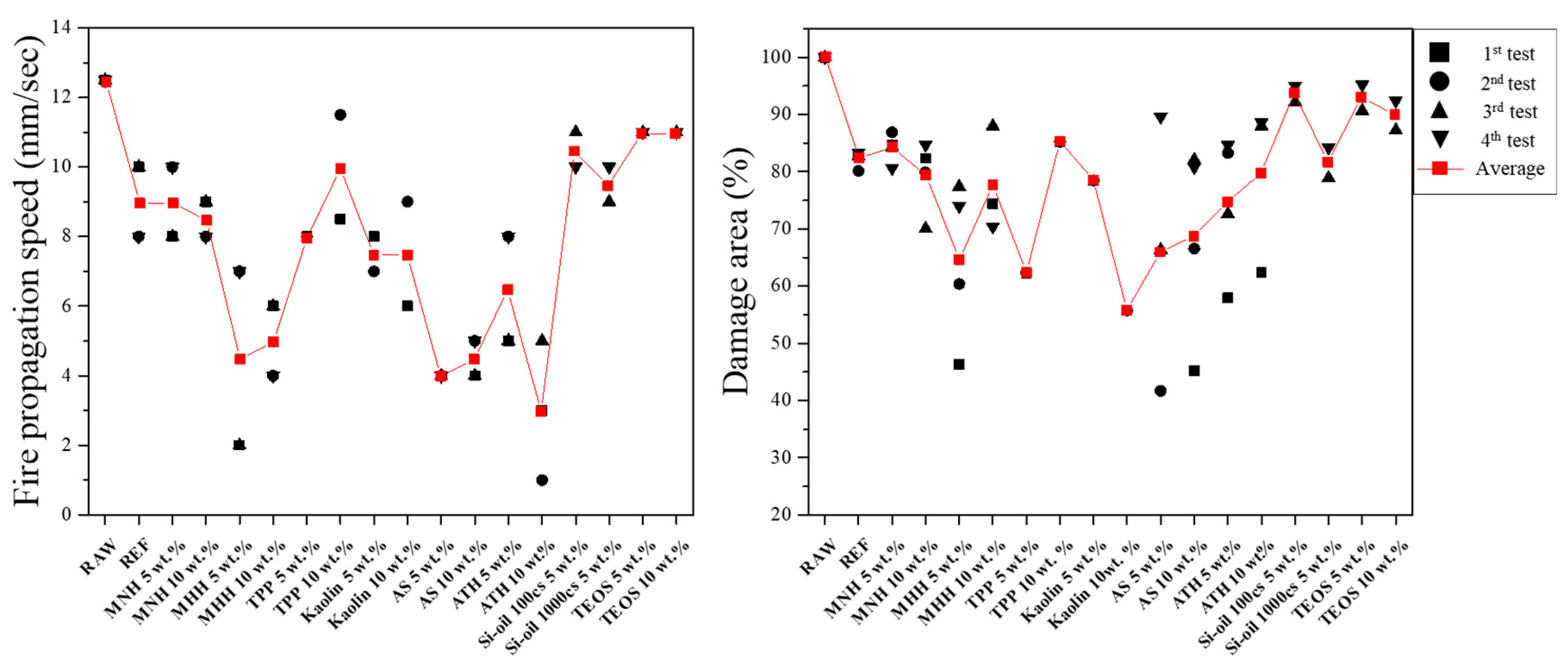

3.2.4. Additives’ Effect on Fire Resistance

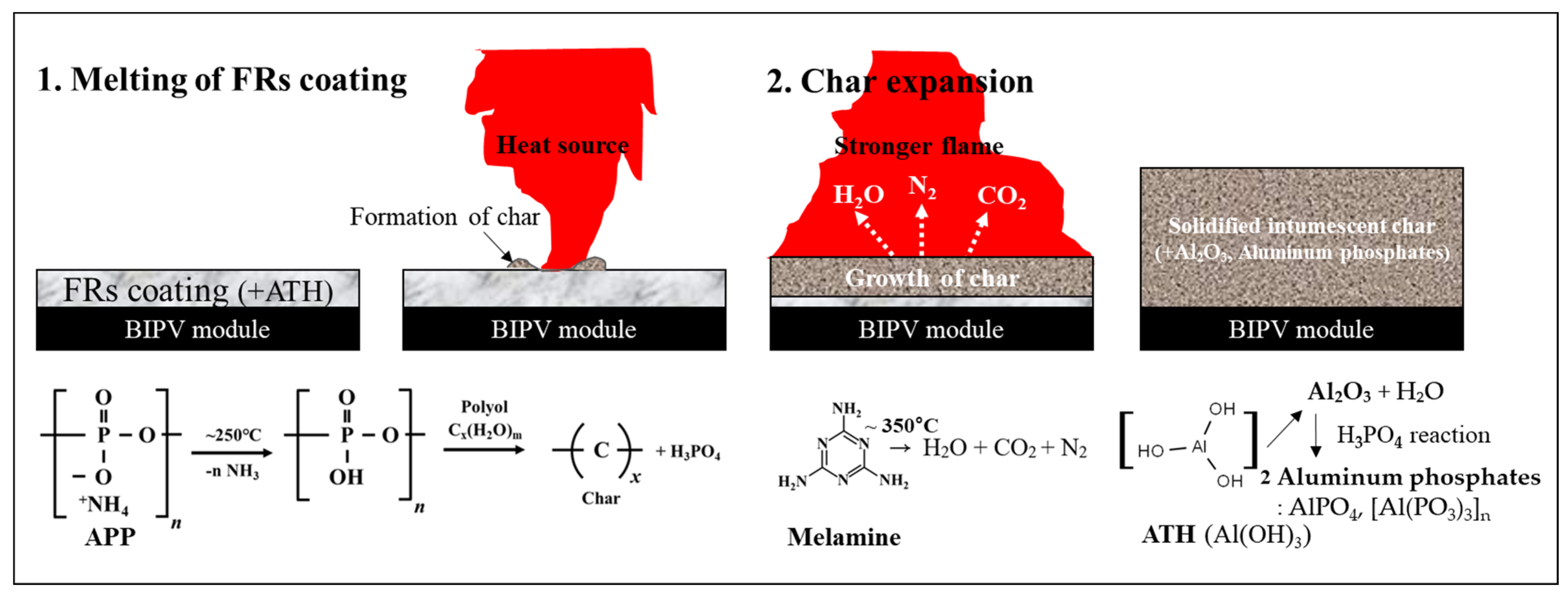

3.3. Mechanism for FRt Coating Modes of Action with ATH

- -

- Step 1: When the FR-coated solar module is exposed to flames, the FR coating layer expands to form a porous ceramic multilayer structure, including a carbonized char layer and an oxide layer on the surface, creating a heat-shielding layer with extremely low thermal conductivity. As the temperature of the FR coating layer rises due to the flame and reaches approximately 250 °C, APP begins to decompose, initiating a gas expansion reaction driven by melamine. APP consists of polyphosphate chains formed through the condensation of ammonium ions and phosphate molecules. At around 250 °C, it decomposes to release phosphoric acid, which then combines with polyol to form a char that acts as a physical protective layer.

- -

- Step 2: The expansion of the char formed by melamine decomposition is activated. As the internal temperature of the FR coating layer reaches approximately 350 °C, melamine releases a significant amount of expandable gases (CO2, N2), promoting the expansion and foaming of the carbonized layer. The nitrogen and carbon dioxide gases released from melamine decomposition expand the char into a porous form, forming a porous heat-shielding layer that effectively protects the module from high-temperature flames.

- -

- Step 3: Aluminum hydroxide is decomposed into Al2O3 and H2O. At this stage, some Al2O3 reacts with phosphoric acid to form thermally stable aluminum phosphate compounds, such as AlPO4 and [Al(PO3)3]ₙ.

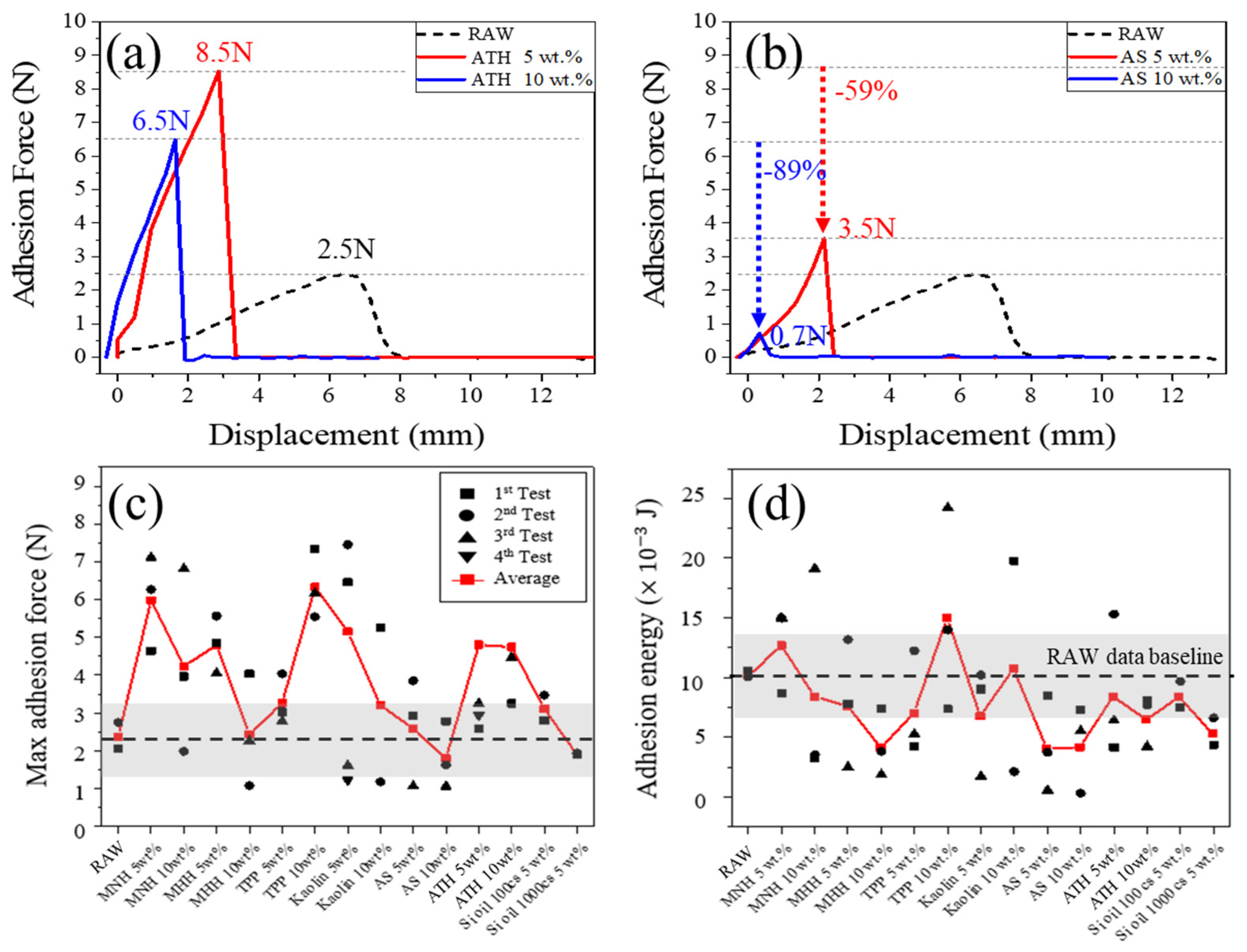

3.4. Adhesion Properties Between the Coated Layer and the Substrate

3.5. Comparison of Cost-Effectiveness Among the Additives

- ⋅

- a: flame spread (mm/s)

- ⋅

- b: the percentage of damaged area (%)

- ⋅

- c: the percentage of flame spread area on the surface (%)

- ⋅

- d: the remaining combustion duration (seconds)

- ⋅

- e: the percentage of the sample area melted (%)

- ⋅

- α, β, γ, δ, and ε: constants

4. Conclusions

- (1)

- An epoxy-based FRs coating applied to the module showed better overall performance than a urethane-based FRt coating. Surface damage, such as cracks and blisters, was observed for the FRt coating during the impact and acid resistance tests, but the FRs coating showed better durability without any defects.

- (2)

- In the UL-94 test, FRt was completely burned within 10 s in a combustion environment, whereas FRs maintained its intact condition. The damage rate of FRt was 100%, while that of FRs was only 9%.

- (3)

- In cone calorimeter tests, the maximum HRS of the three specimens, RAW, FRt, and FRs, were measured as 350 kW, 270 kW, and 74 kW, respectively. It was confirmed that the heat release was reduced solely by the FR coating. In particular, the performance of FRs was superior. FRs reduced the heat release rate to 21% of that of RAW.

- (4)

- In the ISO 834 test, the FRs-coated specimen demonstrated significantly enhanced thermal shielding performance compared to the RAW specimen. After 400 s, the temperature of the RAW specimen reached 680 °C, whereas the temperature of the FRs specimen remained below 200 °C. Even with just a 1 mm FRs coating, more than 70% of the heat can be blocked.

- (5)

- ATH manifested the most cost-effective flame-retardant characteristics among the additives. The fire propagation rate of the ATH additive was reduced by 83%, and the adhesion strength was approximately 3.4 times higher than the specimen without FR coating.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deng, Q.; Zhang, B.; Zhou, Z.; Deng, H.; Zhou, L.; Zhou, Z.; Jiang, H. Evacuation time estimation model in large buildings based on individual characteristics and real-time congestion situation of evacuation exit. Fire 2022, 5, 204. [Google Scholar] [CrossRef]

- Proulx, G. Evacuation time and movement in apartment buildings. Fire Saf. J. 1995, 24, 229–246. [Google Scholar] [CrossRef]

- National Fire Data System. Current Status of Fire in Building. Available online: https://www.nfa.go.kr/nfa/safetyinfo/residentialfire/present/ (accessed on 10 October 2024).

- Korea Fire Protection Association (KFPA). Building Fire Occurrence Trend. Available online: https://www.kfpa.or.kr/webzine/202408/disaster7.html (accessed on 10 October 2024).

- National Index. Fire Occurrence Trend. Available online: https://www.index.go.kr/unity/potal/main/EachDtlPageDetail.do?idx_cd=1632 (accessed on 10 October 2024).

- Aram, M.; Zhang, X.; Qi, D.; Ko, Y. A state-of-the-art review of fire safety of photovoltaic systems in buildings. J. Clean. Prod. 2021, 308, 127239. [Google Scholar] [CrossRef]

- Aram, M. Fire Smoke Control for Building Integrated Photovoltaic (BIPV). ASHRAE Trans. 2021, 127, 14–16. [Google Scholar]

- Meacham, B.; McNamee, M. Fire Safety Challenges of ‘Green’ Buildings and Attributes. Available online: https://www.ashb.com/wp-content/uploads/2021/03/IS-2021-68.pdf (accessed on 10 October 2024).

- Miao, L.; Chow, C.L. Investigation of burning photovoltaic panels on a double-skin facade with ejecting flame from an adjacent room fire. Indoor Built Environ. 2019, 28, 938–949. [Google Scholar] [CrossRef]

- Wu, Z.; Hu, Y.; Wen, J.X.; Zhou, F.; Ye, X. A review for solar panel fire accident prevention in large-scale PV applications. IEEE Access 2020, 8, 132466–132480. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure and Transport (MOLIT). Building Act, Article 49, Evacuation of the Building and Restrictions; Law No. 9437; Ministry of Land, Infrastructure and Transport (MOLIT): Sejong City, Republic of Korea, 2009.

- Proulx, G.; Fahy, R.F. The time delay to start evacuation: Review of five case studies. Fire Saf. Sci. 1997, 5, 783–794. [Google Scholar] [CrossRef]

- Jimenez, M.; Duquesne, S.; Bourbigot, S. Characterization of the performance of an intumescent fire protective coating. Surf. Coat. Technol. 2006, 201, 979–987. [Google Scholar] [CrossRef]

- Mariappan, T. Recent developments of intumescent fire protection coatings for structural steel: A review. J. Fire Sci. 2016, 34, 120–163. [Google Scholar] [CrossRef]

- Oktokkian. BIPV Product Description. Available online: http://oktokkiam.com/html/sub02/sub02_0203.php (accessed on 10 October 2024).

- UL 94; Tests for Flammablity of Plastic Materials for Parts in Devices and Appliances. UL Solutions: Chicago, IL, USA, 2023.

- Gao, M.; Wang, J.; Cong, C.; Ma, C.; Morshed, M.; Wang, Z. Degradation of epoxy coatings cooperated with polyaniline nanowires in the outdoor environment. Polym. Adv. Technol. 2021, 32, 988–999. [Google Scholar] [CrossRef]

- Liu, F.; Yin, M.; Xiong, B.; Zheng, F.; Mao, W.; Chen, Z.; Fang, P. Evolution of microstructure of epoxy coating during UV degradation progress studied by slow positron annihilation spectroscopy and electrochemical impedance spectroscopy. Electrochim. Acta 2014, 133, 283–293. [Google Scholar] [CrossRef]

- Maibohm, C.; Brewer, J.R.; Sturm, H.; Balzer, F.; Rubahn, H.G. Bleaching and coating of organic nanofibers. J. Appl. Phys. 2006, 100, 054307. [Google Scholar] [CrossRef]

- Gökçe, C. UV Aging of Epoxy Fiber Composite. Bachelor’s Thesis, Arcada University of Applied Sciences, Helsinki, Finland, 2020. [Google Scholar]

- Shi, X.; Croll, S.G. Thermal-induced recovery of small deformations and degradation defects on epoxy coating surface. J. Coat. Technol. Res. 2010, 7, 73–84. [Google Scholar] [CrossRef]

- Al-Dulaymi, S.A.A.; Brown, T.; Fellows, C.; Mahini, S.S. Prevention of environmental degradation of epoxy resins modified with the addition of different fillers. Ph.D. Thesis, University of New England, Biddeford, ME, USA, 2019. [Google Scholar]

- Jiang, H.; Browning, R.; Liu, P.; Chang, T.A.; Sue, H.J. Determination of epoxy coating wet-adhesive strength using a standardized ASTM/ISO scratch test. J. Coat. Technol. Res. 2011, 8, 255–263. [Google Scholar] [CrossRef]

- ISO 834-11:2014; Fire Resistance Tests—Elements of Building Construction—Part 11: Specific Requirements for the Assessment of Fire Protection to Structural Steel Elements. International Organization for Standardization: Geneva Switerland, 2014.

- ISO 4892-2:2013; Plastics—Methods of Exposure to Laboratory Light Sources—Part 2: Xenon-arc Lamps. International Organization for Standardization: Geneva Switerland, 2013.

- KS M ISO2812-1; Paints and Varnishes—Determination of Resistance to Liquids—Part 1: Immersion in Liquids Other Than Water. Korea Agency for Technology and Standards: Sejong, Republic of Korea, 2022.

- KS D 3520:2018; Prepainted Hot-Dip Zinc-Coated Steel Sheets and Coils. Korea Agency for Technology and Standards: Sejong, Republic of Korea, 2020.

- ASTM D4060-14; Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser. ASTM International: West Conshohocken, PA, USA, 2019.

- NES 713; Determination of the Toxicity Index of the Products of Combustion from Small Specimens of Materials. Ministry of Defence: London, UK, 1982.

- ASTM D 6195; Standard Test Methods for Loop Tack. ASTM International: West Conshohocken, PA, USA, 2019.

- ISO 5660-1:2015; Reaction to Fire Tests—Heat Release, Smoke Production and Mass Loss Rate. Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization: Geneva, Switzerland, 2015.

- Russell, A.T. Combustion emissions. In Air Pollution and Cancer; Springer: Berlin, Germany, 2013; Volume 161. [Google Scholar]

| Category | Number of Fires | Property Damage (USD) | Casualty (Death) | Casualty (Injuries) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2023 | 2024 | Share (%) | 2023 | 2024 | Share (%) | 2023 | 2024 | Share (%) | 2023 | 2024 | Share (%) | |

| Sum | 3400 | 3443 | 100 | 58,503,677 | 43,131,017 | 100 | 38 | 29 | 100 | 205 | 156 | 100 |

| Buildings | 2382 | 2333 | 68 | 54,316,198 | 35,661,898 | 83 | 36 | 23 | 79 | 176 | 127 | 81 |

| Other (trash fire, etc.) | 564 | 635 | 18 | 384,312 | 805,167 | 2 | 0 | 1 | 3 | 15 | 10 | 6 |

| Ships and aircraft | 5 | 13 | 0 | 48,585 | 722,778 | 2 | 0 | 0 | 0 | 0 | 1 | 1 |

| Combustible gas, etc. | 3 | 2 | 0 | 21,628 | 35,365 | 0 | 0 | 1 | 3 | 2 | 2 | 1 |

| Forests and fields | 71 | 62 | 2 | 67,194 | 71,223 | 0 | 0 | 0 | 0 | 1 | 3 | 2 |

| Car, railway, etc. | 375 | 398 | 12 | 3,665,760 | 5,834,586 | 14 | 2 | 4 | 14 | 11 | 13 | 8 |

| Category | Main Resin | Auxiliary Resin (Hardener) |

|---|---|---|

| Urethane-based flame-retardant resin (FRt) |

|

|

| Epoxy-based fire-resistant resin (FRs) |

|

|

| Category | Experimental Conditions | Standard Specifications | Note |

|---|---|---|---|

| W.O.M (Weatherometer) |

| ISO 4892-2 [25] | Visual inspection |

| Acid and alkali resistance |

| KS M ISO2812-1 [26] | Surface condition |

| Impact resistance |

| KS D 3520:2018 [27] | Cracking and peeling |

| Wear resistance |

| ASTM D4060-14 [28] | Weight change in mg |

| Heat release rate and toxicity index |

| ISO 5660-1 NES 713 [29] | ppm concentration |

| Combustion test |

| UL-94 ISO 834 | Damage Quantification |

| Name | Score Ranking | Adhesion Property | Fire resistance Property | Paint Workability | Product Price |

|---|---|---|---|---|---|

| MNH | 3 | 77 | 26 | 80 | 60 |

| MHH | 4 | 62 | 72 | 60 | 11 |

| TPP | 5 | 74 | 0 | 80 | 16 |

| AS | 2 | 48 | 54 | 80 | 68 |

| ATH | 1 | 75 | 89 | 80 | 45 |

| Si-oil 100CS | 7 | 57 | 47 | 40 | 25 |

| Si-oil 1000CS | 8 | 45 | 30 | 20 | 25 |

| TEOS | 6 | — | 37 | 100 | 33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, Y.C.; Song, M.J.; Park, H.K.; Lee, M.C.; Lee, S.Y. Evaluation of the Fire Safety Performance of Fire-Resistant Coatings in BIPV Modules. Fire 2025, 8, 428. https://doi.org/10.3390/fire8110428

Jung YC, Song MJ, Park HK, Lee MC, Lee SY. Evaluation of the Fire Safety Performance of Fire-Resistant Coatings in BIPV Modules. Fire. 2025; 8(11):428. https://doi.org/10.3390/fire8110428

Chicago/Turabian StyleJung, Yong Chan, Min Ji Song, Hee Kyung Park, Min Chul Lee, and Soo Yeol Lee. 2025. "Evaluation of the Fire Safety Performance of Fire-Resistant Coatings in BIPV Modules" Fire 8, no. 11: 428. https://doi.org/10.3390/fire8110428

APA StyleJung, Y. C., Song, M. J., Park, H. K., Lee, M. C., & Lee, S. Y. (2025). Evaluation of the Fire Safety Performance of Fire-Resistant Coatings in BIPV Modules. Fire, 8(11), 428. https://doi.org/10.3390/fire8110428