Case Study on Investigation of Electrical Cabinet Fire Caused by Poor Electrical Contact

Abstract

1. Introduction

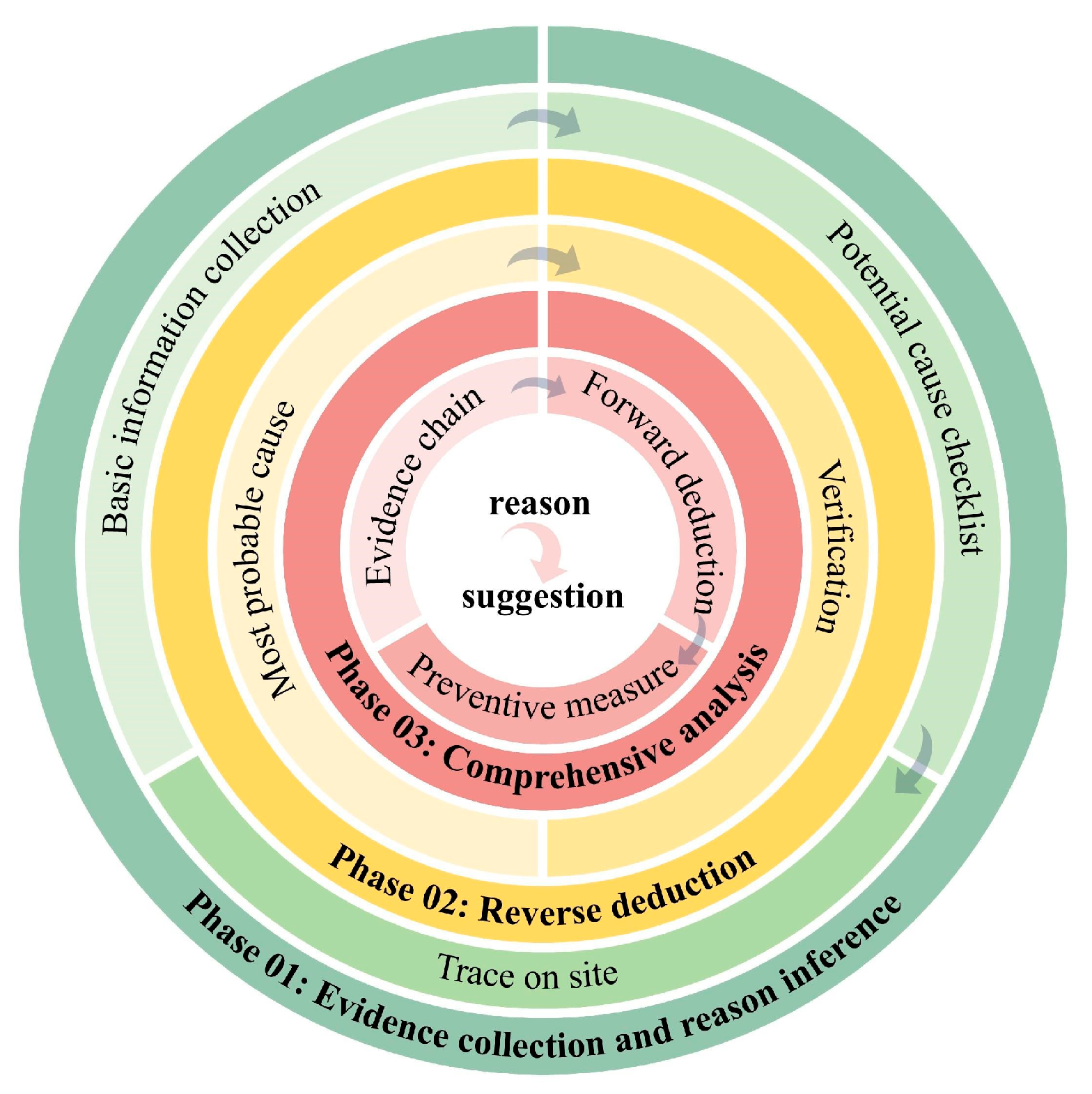

2. Investigation Methods of Electrical Cabinet Fire

2.1. Electrical Cabinet Fire Investigation Methodology

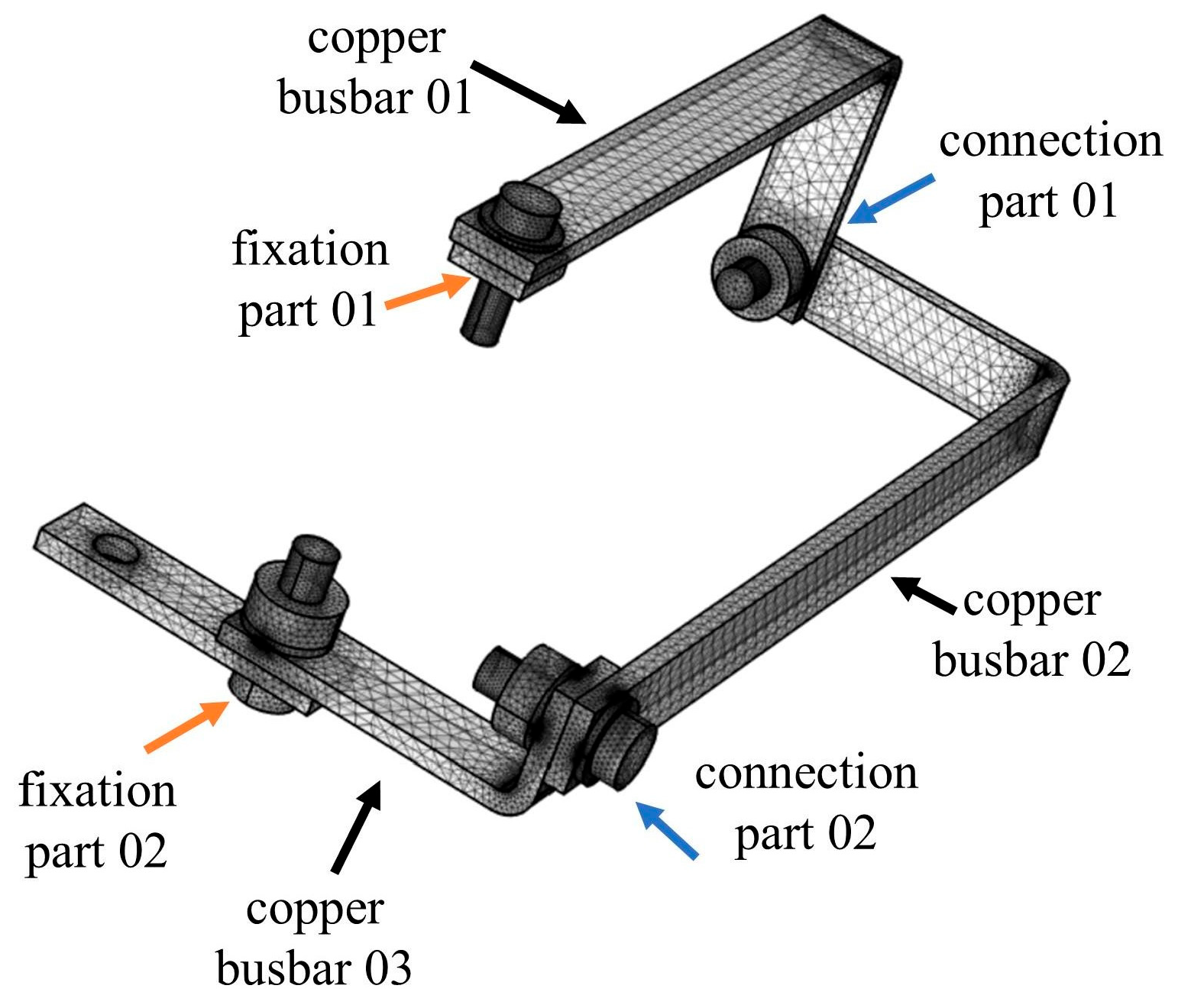

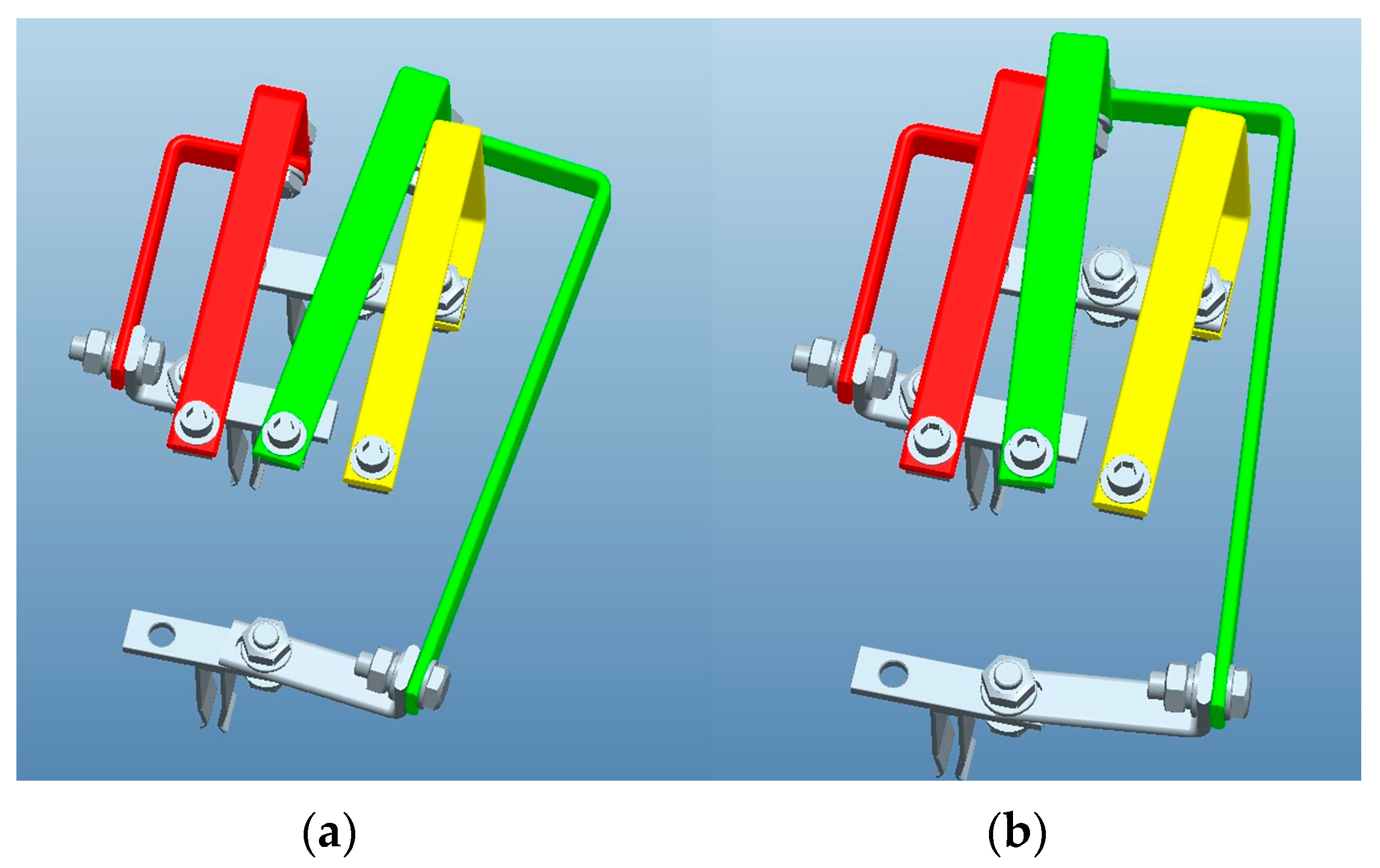

2.2. Components of Plug-In Cabinet

3. Trace Analysis

3.1. Trace Analysis Method and Apparatus

3.2. Macro Trace Analysis

- (1)

- Overall and local characteristics of the electrical cabinet after fire

- (2)

- Analysis of circuit breakers

- (3)

- Size of bolts and screw holes of busbar

3.3. Microscopic Morphology and Composition Analysis

4. Multiphysics Simulation of Poor Contact Between the Busbar and the Bolt

4.1. Theoretical Analysis and Modeling

- (1)

- Geometry model

- (2)

- Physical model

- (3)

- Meshing and consistency check

- (4)

- Parameter setup

4.2. Result Analysis

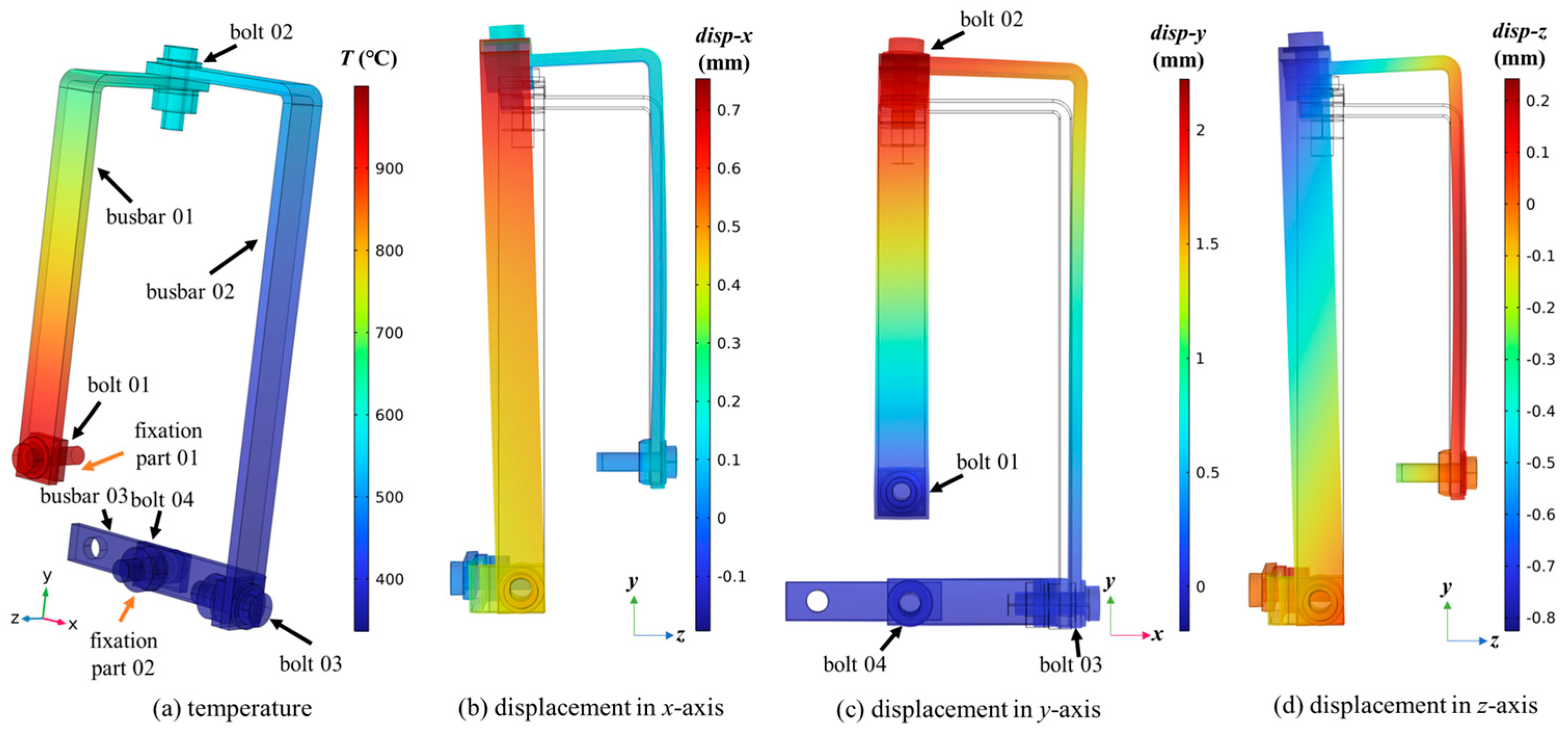

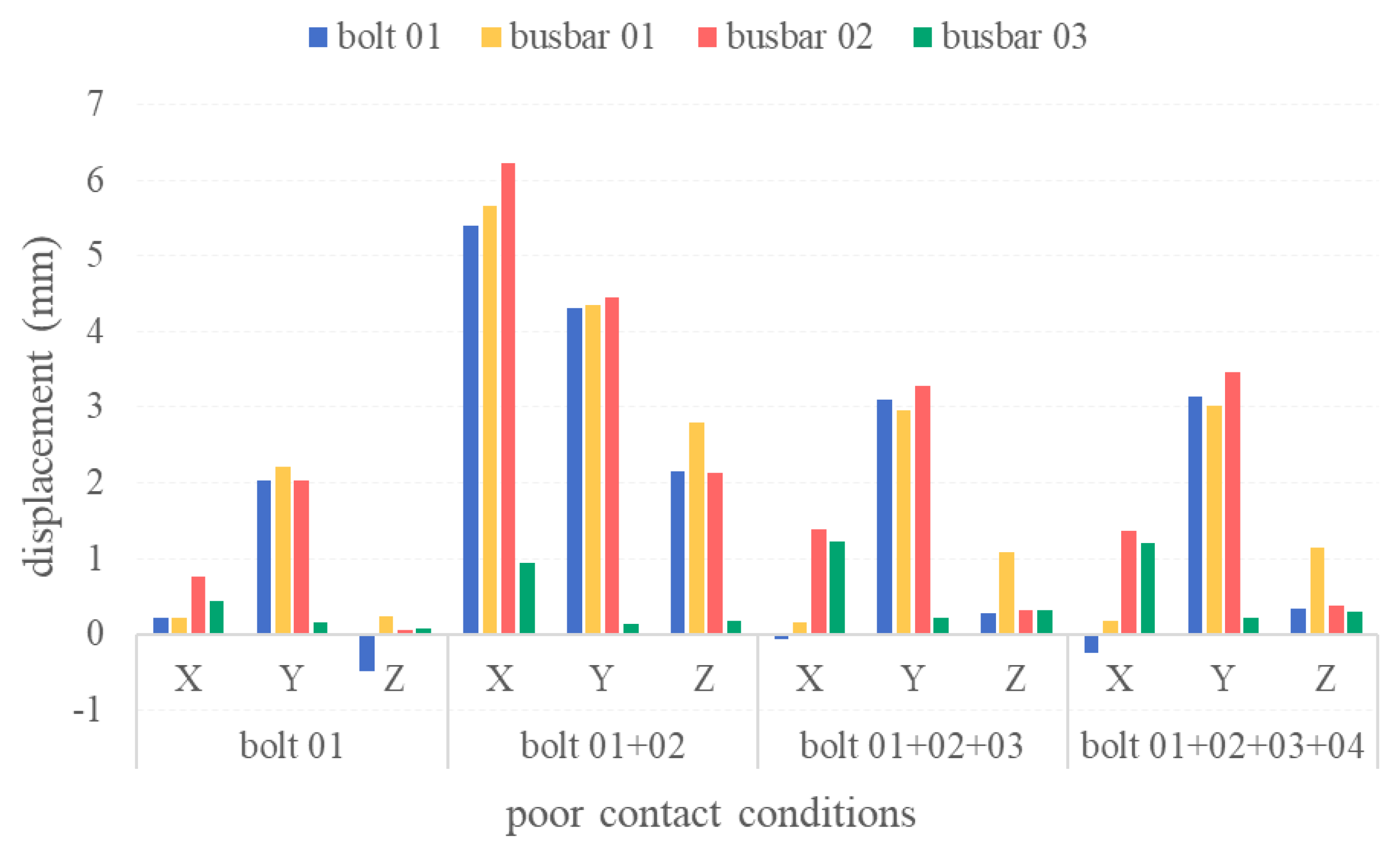

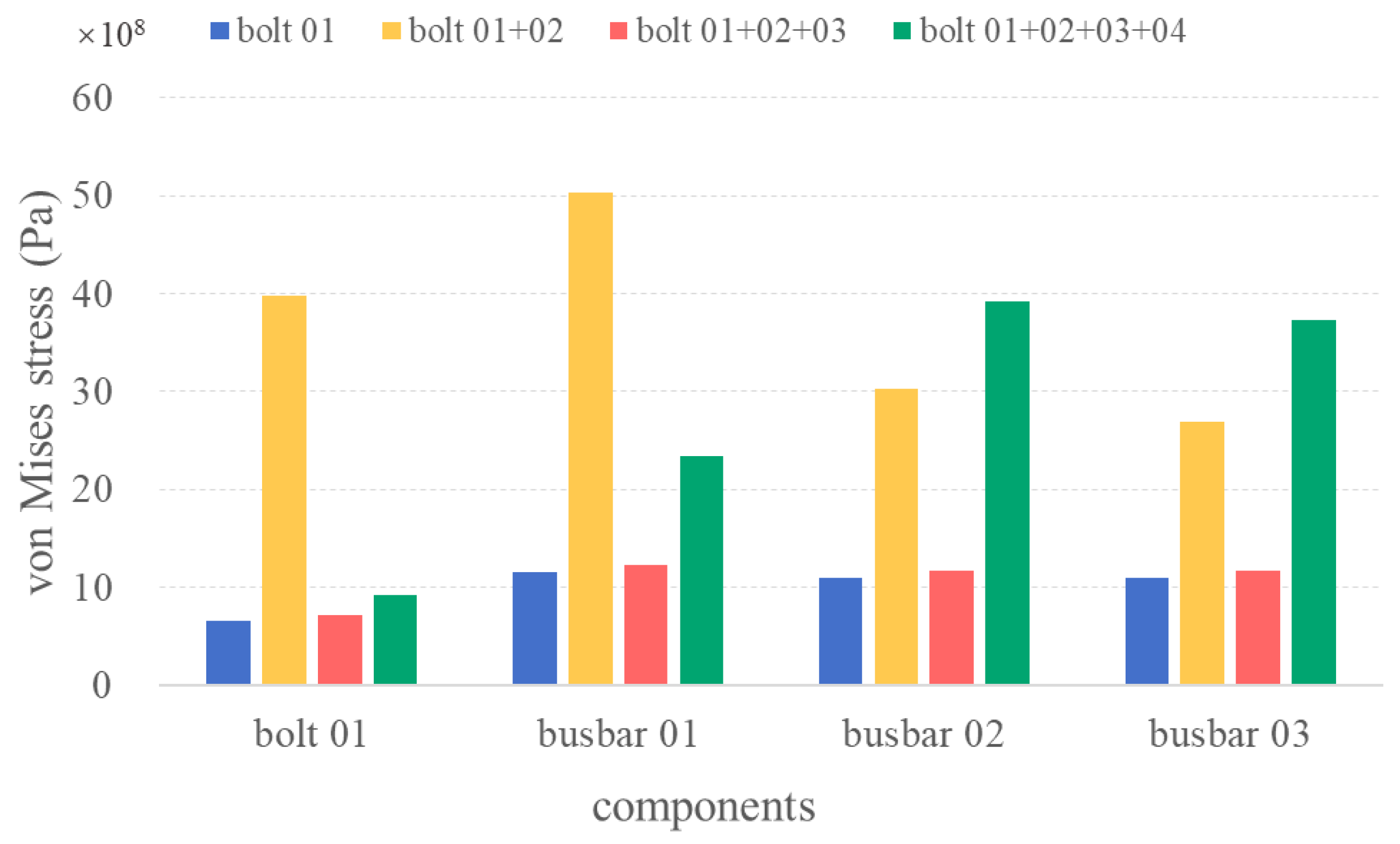

- (1)

- Bolt 01 under poor contact

- (2)

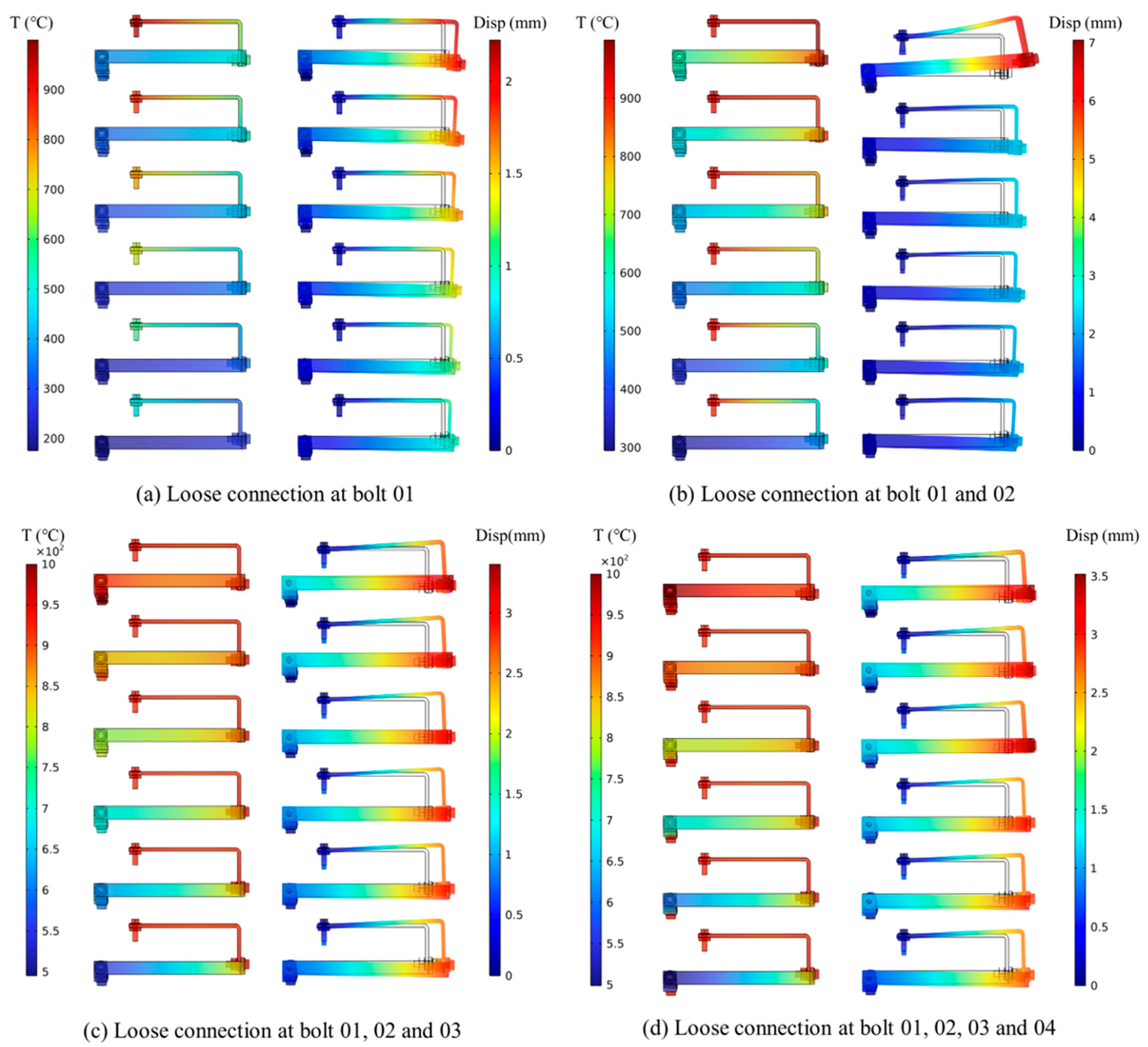

- Various bolts under poor contact

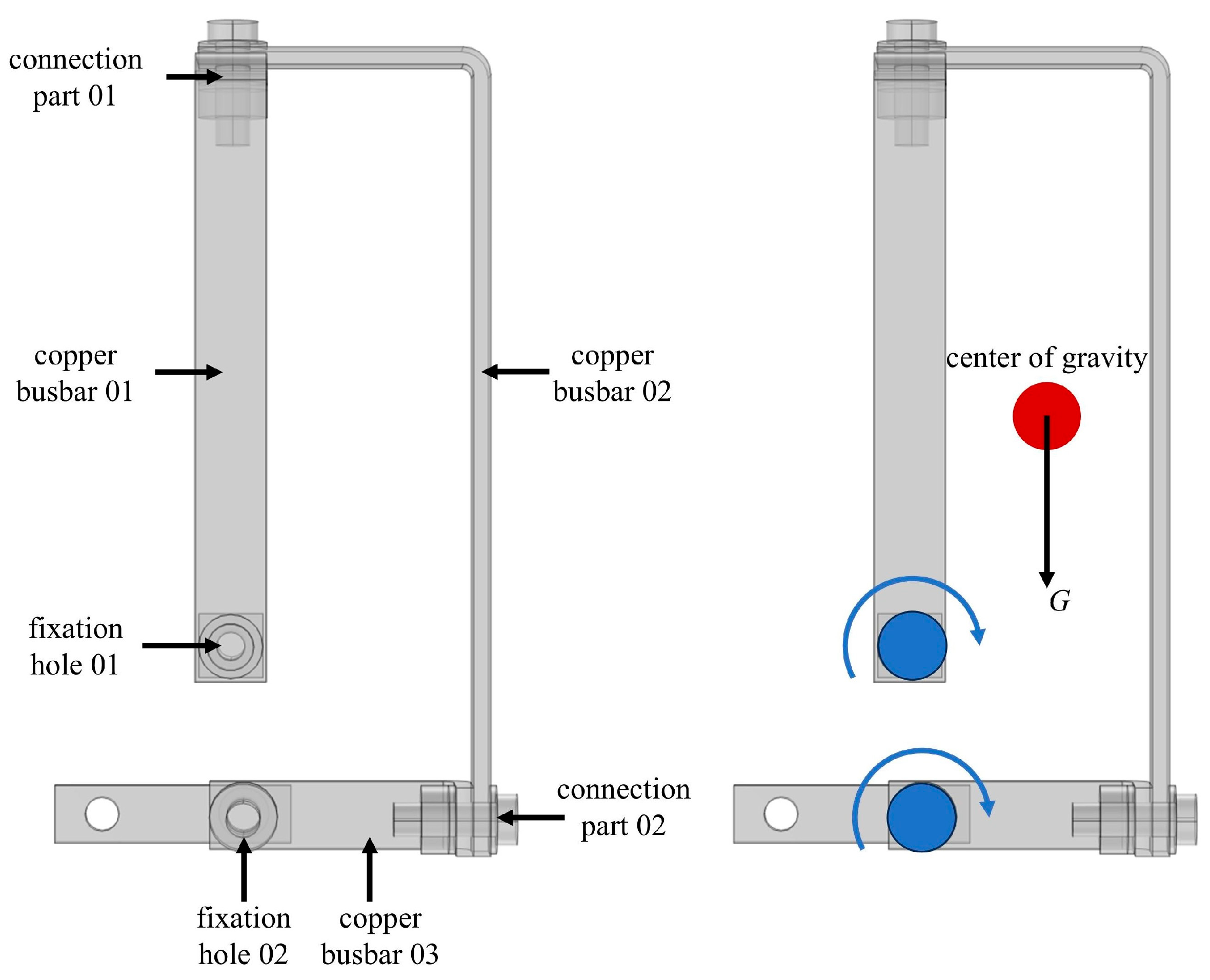

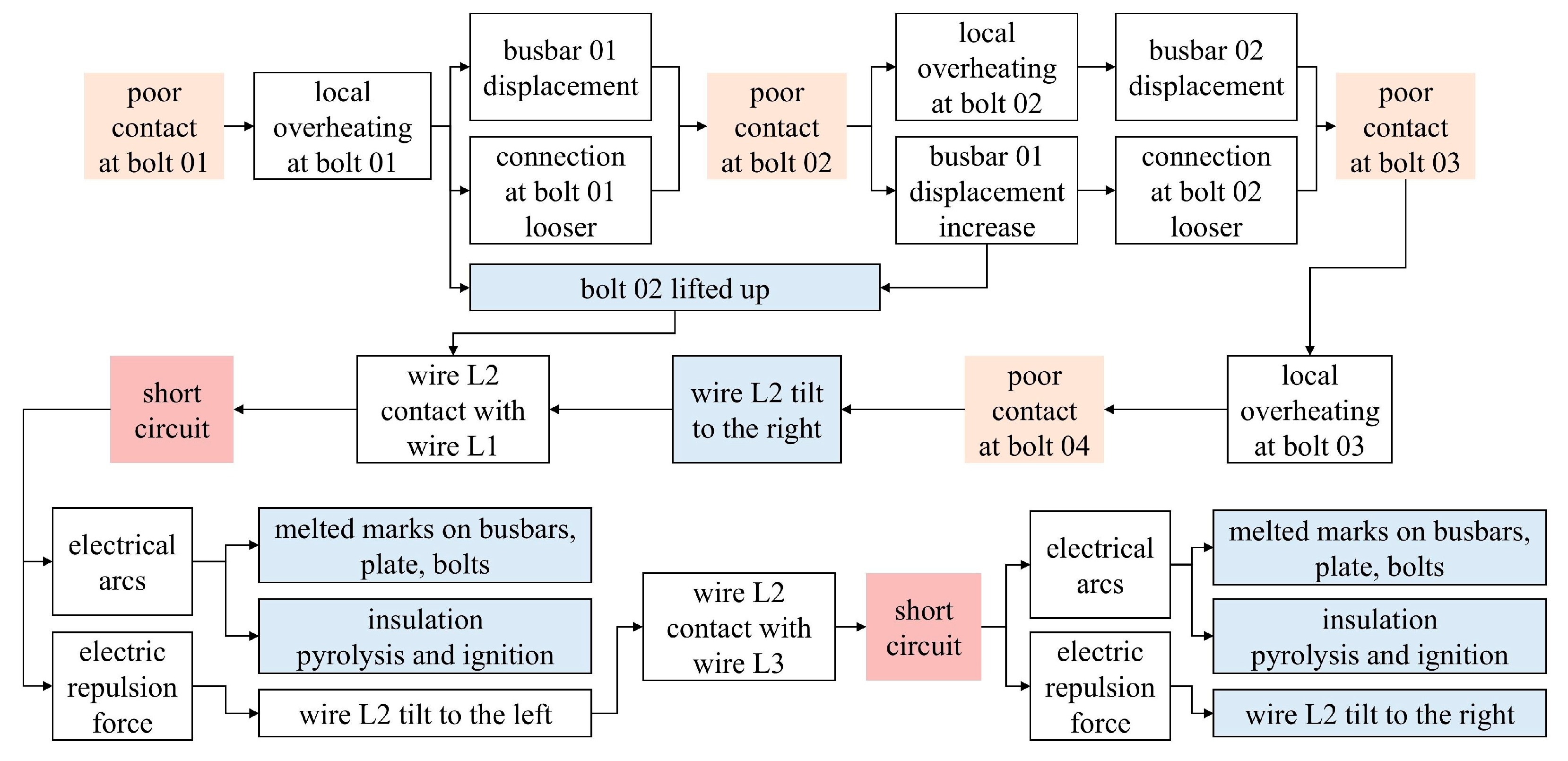

5. Force Model and Comprehensive Analysis

5.1. Force Model

5.2. Comprehensive Analysis

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meng, H.; Xiao, L.; Zhang, C.; Zhang, T.; Xia, D.; Dong, W. A Systematic Review and Bibliometric Analysis of Electrical Fires from 1993 to 2022. Fire Technol. 2024, 60, 3347–3377. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Tang, K.; Yuan, D. Coupled effects of the internal and external heat sources on flame spread behaviors over wires in a real building fire scenario. J. Build. Eng. 2025, 105, 112416. [Google Scholar] [CrossRef]

- Xinhua News Agency; Zhou, Y.; Zhang, Q. The Overall Fire Situation in China Will Remain Stable in 2024. 2025. Available online: https://www.xinhuanet.com/politics/20250124/65bd956b37f241f68399eec554fc64e8/c.html (accessed on 9 September 2025).

- U.S. Fire Administration. Fire and Fire Loss Data from NFIRS. 2023. Available online: https://www.usfa.fema.gov/statistics/data-sets/ (accessed on 9 September 2025).

- Government of Guizhou Province Accident Investigation Team. Investigation Report on the “8 · 18” Major Fire Accident at Dream Zhaoxing Inn in Liping County, Qiandongnan Autonomous Prefecture; The People’s Government of Guizhou Province. 2023. Available online: https://yjgl.guizhou.gov.cn/yjzhxxwmh/yq/sgxx_5851269/202410/P020241015615793804114.pdf (accessed on 9 September 2025).

- Li, D.; Zhong, Y.; Zhou, X.; Zhai, G. A simulated experimental system and risk prediction method for ignition caused by overhead lines short-circuit. J. Mech. Sci. Technol. 2023, 37, 6493–6501. [Google Scholar] [CrossRef]

- Huo, Y.; Xu, X.; Li, Y.; Li, R.; Yu, Z.; Wang, W. Experimental and theoretical research on the temperature evolution law of overcurrent fault wires. Fire Mater. 2024, 48, 632–641. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Gao, Y.; Sun, J.; Lyu, H.-F.; Yu, T.; Yang, S.; Wang, Y. Analysis of overload induced arc formation and beads characteristics in a residential electrical cable. Fire Saf. J. 2022, 131, 103626. [Google Scholar] [CrossRef]

- Jia, Y.; Man, P.; Guo, X.; Deng, L.; Li, Y. Effects of Overload on Thermal Decomposition Kinetics of Cross-Linked Polyethylene Copper Wires. Polymers 2023, 15, 3954. [Google Scholar] [CrossRef]

- Li, C.; Yang, Z.; Yao, W.; Zou, K.; Liu, H.; Lin, J.; Lu, S. Experimental study of ignition process caused by poor electrical contact of connecter. Process. Saf. Environ. Prot. 2024, 189, 1517–1526. [Google Scholar] [CrossRef]

- Gao, Z.; Yang, R.; Yang, W.; Yao, Y.; Wang, J. Study on arc duration and erosion characteristics of cable electrodes in AC series circuits. J. Phys. D Appl. Phys. 2023, 56, 375201. [Google Scholar] [CrossRef]

- Kang, N.; Zhao, Z.; Lin, J.; Lu, S. Ignition of silicone rubber sheaths by series arcs at different currents and durations. Fire Saf. J. 2023, 136, 103753. [Google Scholar] [CrossRef]

- Tomoyasu, I.; Michael, R.K.; Yasuaki, H.; Sugawa, O. Leakage Currents Precede Short Circuits in PVC-Insulated Cable When Exposed to External Radiant Heat. Fire Mater. 2017, 41, 339–348. [Google Scholar] [CrossRef]

- John, D.D.; David, J.I. Kirk’s Fire Investigation, 7th ed.; Pearson: Hoboken, NJ, USA, 2012. [Google Scholar]

- Ge, F.; Qiu, T.; Zhang, M.; Ji, J. Experimental research on the thermal characteristic of low-voltage alternating current (AC) arc faults. Fire Saf. J. 2022, 136, 103732. [Google Scholar] [CrossRef]

- Zhang, M.; Ge, F.; Ji, J. Experimental Research on Heat Transfer and Ignition Characteristics of Series Fault Arc Combustion in 220VAC Power System. Combust. Sci. Technol. 2023, 197, 1100–1119. [Google Scholar] [CrossRef]

- Yu, F.; Wang, S.; Tang, K.; Lin, Y.; Wang, S.; Zhang, Y. Research Progress on the Fire Characteristics of Electric Cables and Wires. Fire 2024, 7, 186. [Google Scholar] [CrossRef]

- Plumecocq, W.; Coutin, M.; Melis, S.; Rigollet, L. Characterization of closed-doors electrical cabinet fires in compartments. Fire Saf. J. 2011, 46, 243–253. [Google Scholar] [CrossRef]

- Coutin, M.; Plumecocq, W.; Zavaleta, P.; Audouin, L. Characterisation of open-door electrical cabinet fires in compartments. Nucl. Eng. Des. 2015, 286, 104–115. [Google Scholar] [CrossRef]

- Bryant, R.; Bundy, M. The NIST 20 MW Calorimetry Measurement System for Large-Fire Research, Technical Note (NIST TN) 2077. NIST; 2019. Available online: https://nvlpubs.nist.gov/nistpubs/TechnicalNotes/NIST.TN.2077.pdf (accessed on 9 September 2025).

- Pascal, Z.; Sylvain, S. Experimental Study in Open Atmosphere and Confined Conditions of Fire Spread between Adjacent Electrical Cabinets Connected by Cabe Trays. Fire Saf. J. 2023, 140, 103872. [Google Scholar] [CrossRef]

- Pascal, Z. Experimental study at reduced-scale of fire spread between electrical cabinets located opposite each other. Fire Saf. J. 2021, 122, 103319. [Google Scholar] [CrossRef]

- Ma, Q.; Chen, Z.; Chen, J.; Du, M.; Sun, Y.; Chen, N. A predictive model for centerline temperature in electrical cabinet fires. Renew. Sustain. Energy Rev. 2024, 211, 115303. [Google Scholar] [CrossRef]

- Shu, S.-B.; Chuah, Y.K.; Lin, C.-J. A study on the spread of fire caused by the stack effects of patio—A computer modeling and a reconstruction of a fire scenario. Build. Simul. 2012, 5, 169–178. [Google Scholar] [CrossRef]

- National Fire Protection Association. NFPA 921: Guide for Fire and Explosion Investigations, 2017 Edition. National Fire Protection Association. 2017. Available online: https://www.nfpa.org/product/nfpa-921-guide/p0921code (accessed on 9 September 2025).

- GB/T 16840.2-2021; Technical Determination Methods for Electrical Fire Evidence, GB. Standards Press of China: Beijing, China, 2021.

- Wang, W.; Zhao, X.; Liu, Q.; Ji, X.; Yang, Z.; Gui, X.; Li, Z.; Wang, L. Study on quantitative metallographic analysis method of copper wire melt trace under short-circuit and fire conditions. J. Therm. Anal. Calorim. 2023, 148, 12145–12158. [Google Scholar] [CrossRef]

- Park, J.; Kang, J.-H.; Lee, E.P.; Ko, Y.H.; Bang, S.B. New Approach to Distinguish Copper Molten Marks Based on Quantitative Microstructure Analysis Using Electron Backscatter Diffraction. Fire Technol. 2021, 57, 1667–1682. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, T.; Su, G.; Li, C.; Zhao, F.; Mi, W. Microstructure and component analysis of glowing contacts in electrical fire investigation. Eng. Fail. Anal. 2022, 140, 106539. [Google Scholar] [CrossRef]

- Wang, W.; Lu, C.; Shi, L.; Lyu, H.; Ji, X.; Huo, Y. Numerical simulation and experimental study on metallographic structure characteristics of melting trace caused by overcurrent fault of copper wire. J. Loss Prev. Process. Ind. 2023, 83, 105065. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, L.; Chen, T.; Su, G. Simulation based analysis of electrical fire risks caused by poor electric contact between plug and receptacle. Fire Saf. J. 2021, 126, 103434. [Google Scholar] [CrossRef]

- Incropera, F.P.; Lavine, A.S.; Bergman, T.L.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- IEC, TS 60695-1-14:2017; Fire Hazard Testing. Part 1–14: Guidance on the Different Levels of Power and Energy Related to the Probability of Ignition and Fire in Low Voltage Electrotechnical Products. Internation Electrotechnical Commission: Geneva, Switzerland, 2017.

| Mesh Scheme | Displacement Along the y-Axis (mm) | Relative Error | Temperature (°C) | Relative Error | Number of Meshes |

|---|---|---|---|---|---|

| finest | 2.2299 | / | 554.39 | / | 340,766 |

| super-fine | 2.2369 | 0.31% | 554.4 | 0.00% | 111,864 |

| finer | 2.2417 | 0.53% | 554.41 | 0.00% | 44,700 |

| fine | 2.2433 | 0.60% | 554.45 | 0.01% | 19,154 |

| regular | 2.2553 | 1.14% | 554.51 | 0.02% | 7731 |

| Parameter | Unit | Copper | Stainless Steel |

|---|---|---|---|

| Electrical conductivity | S/m | 6.00 × 107 | 4.03 × 107 |

| Coefficient of thermal expansion | 1/K | 1.70 × 10−5 | 1.23 × 10−5 |

| Constant pressure heat capacity | J/(kg·K) | 385 | 475 |

| Density | kg/m3 | 8960 | 7850 |

| Thermal conductivity | W/(m·K) | 400 | 44.5 |

| Young’s modulus | Pa | 1.10 × 1011 | 2.00 × 1011 |

| Poisson’s ratio | 1 | 0.35 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Li, C.; Su, G.; Mi, W. Case Study on Investigation of Electrical Cabinet Fire Caused by Poor Electrical Contact. Fire 2025, 8, 412. https://doi.org/10.3390/fire8110412

Zhang J, Li C, Su G, Mi W. Case Study on Investigation of Electrical Cabinet Fire Caused by Poor Electrical Contact. Fire. 2025; 8(11):412. https://doi.org/10.3390/fire8110412

Chicago/Turabian StyleZhang, Jing, Changzheng Li, Guofeng Su, and Wenzhong Mi. 2025. "Case Study on Investigation of Electrical Cabinet Fire Caused by Poor Electrical Contact" Fire 8, no. 11: 412. https://doi.org/10.3390/fire8110412

APA StyleZhang, J., Li, C., Su, G., & Mi, W. (2025). Case Study on Investigation of Electrical Cabinet Fire Caused by Poor Electrical Contact. Fire, 8(11), 412. https://doi.org/10.3390/fire8110412