2.1. Geometry and Fire Model

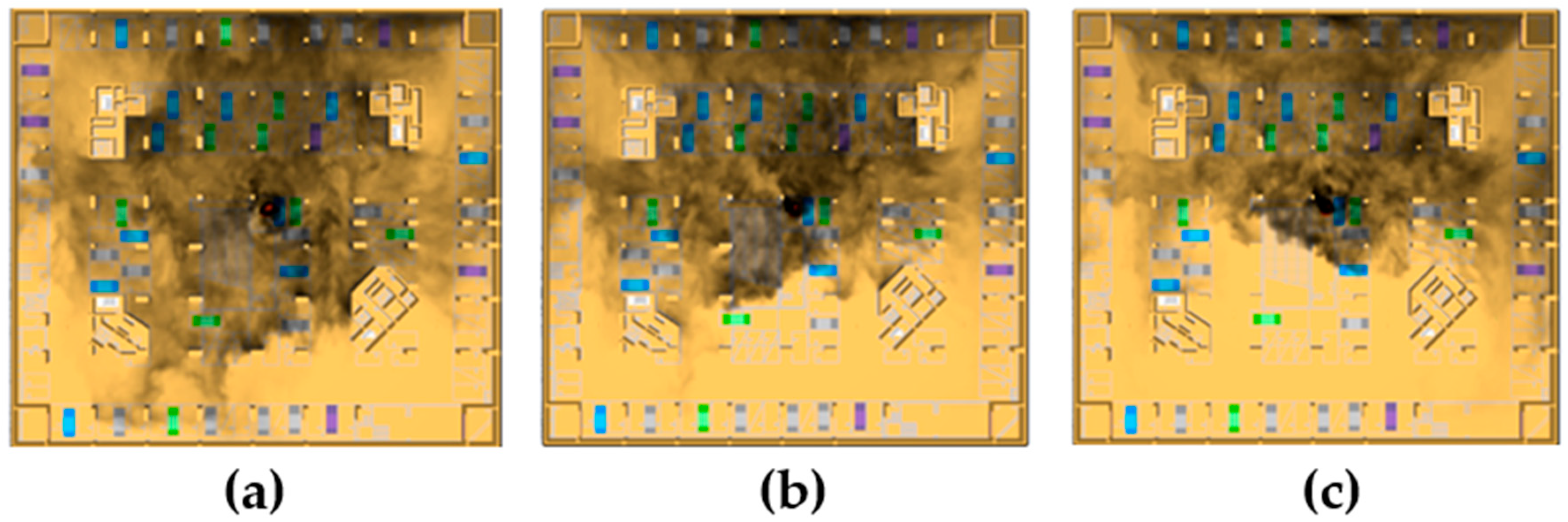

The movement of smoke from vehicle fires is calculated based on the Fire Dynamics Simulator (FDS), developed by the Building and Fire Research Laboratory (BFRL) under the U.S. National Institute of Standards and Technology. FDS provides detailed insights into how smoke flows during fire events through the finite element method. As a result, it is one of the most widely used fire simulation programs. For better understanding of the visibility of occupants, PyroSim, which integrates FDS with Smokeview—a program specifically developed for visualizing simulation outputs—was also employed to analyze smoke flow in underground parking lots.

To describe the smoke flow during a fire with in an underground parking lot with a ventilation system, we used the following equations. Equation (1) represents an empirical correlation for the thickness of the smoke layer (

lT) due to a ceiling jet, which describes the horizontal flow of hot combustion products that rise in the fire plume, impinge on the ceiling, and subsequently spread outward as a thin buoyancy-driven layer immediately beneath the ceiling surface. According to the Society of Fire Protection Engineers (SFPE)

Handbook of Fire Protection Engineering,

lT is defined as the ceiling height (

H) where the gap between smoke temperature (

T) and ambient temperature (

T∞) decreases to 1/

e (approximately 37%) of its maximum value. Based on this definition,

lT is generally reported to be about 10–12% of

H [

25]. The correlations of

lT,

H, and radial distance to detector (

r) are widely employed as empirical formulas in CFD simulations to predict smoke movement.

Through Equations (2) and (3), simplified correlations for predicting

T and velocity of the smoke (

U) were achieved. These correlations are widely applied in fire hazard analysis for a ceiling jet flow with an HRR of

Q [

25]. Furthermore, the correlations distinguish between the plume impingement region—where the vertical fire plume strikes the ceiling—and the radial region beneath the ceiling where the flow subsequently spreads outward. Thus, they enable the prediction of both the reduction in

T with

r and the corresponding variation in

U. We continuously monitored the distribution of smoke controlled by

T,

U, and

lT under different Q for 1000 s as shown in

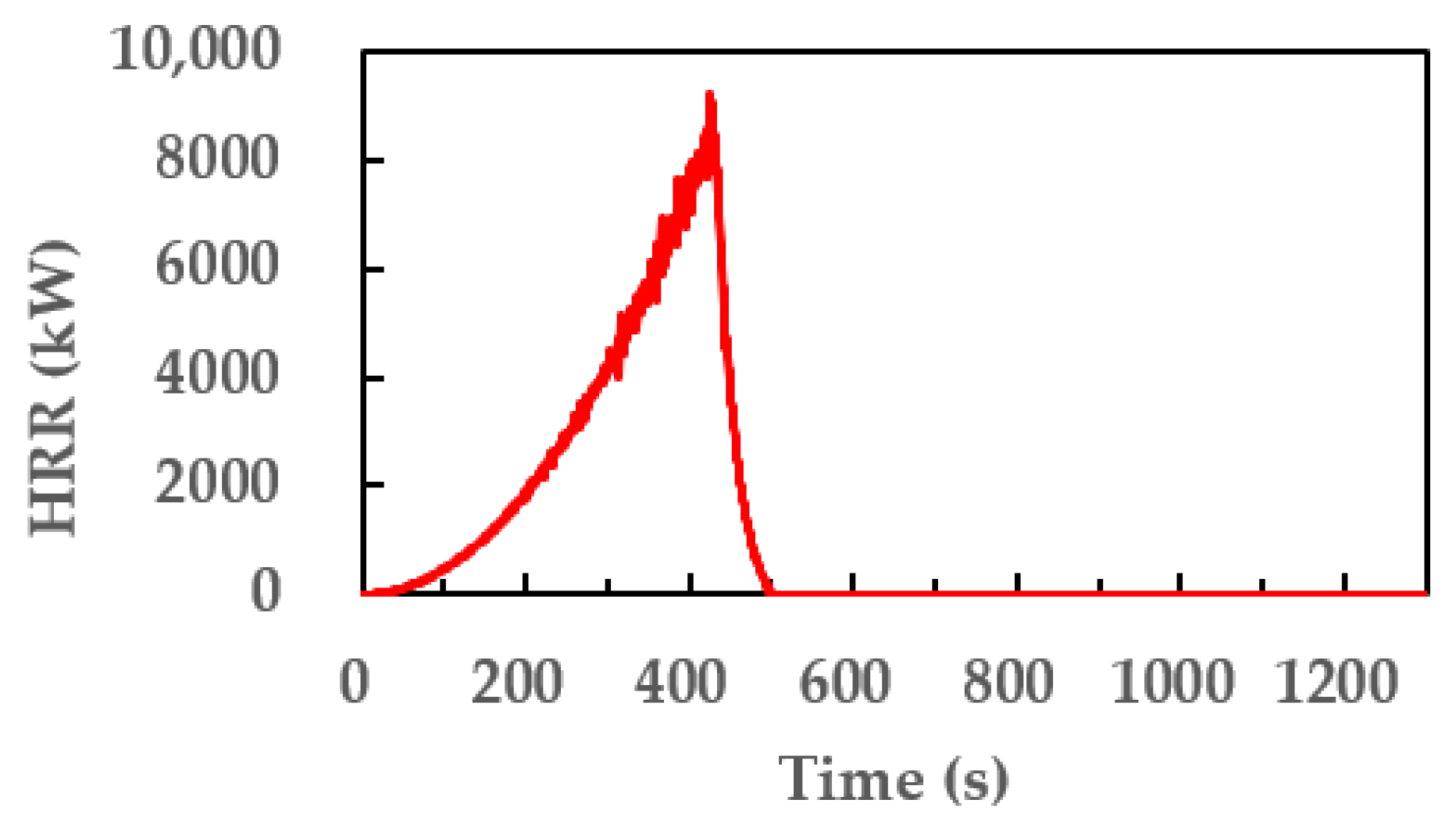

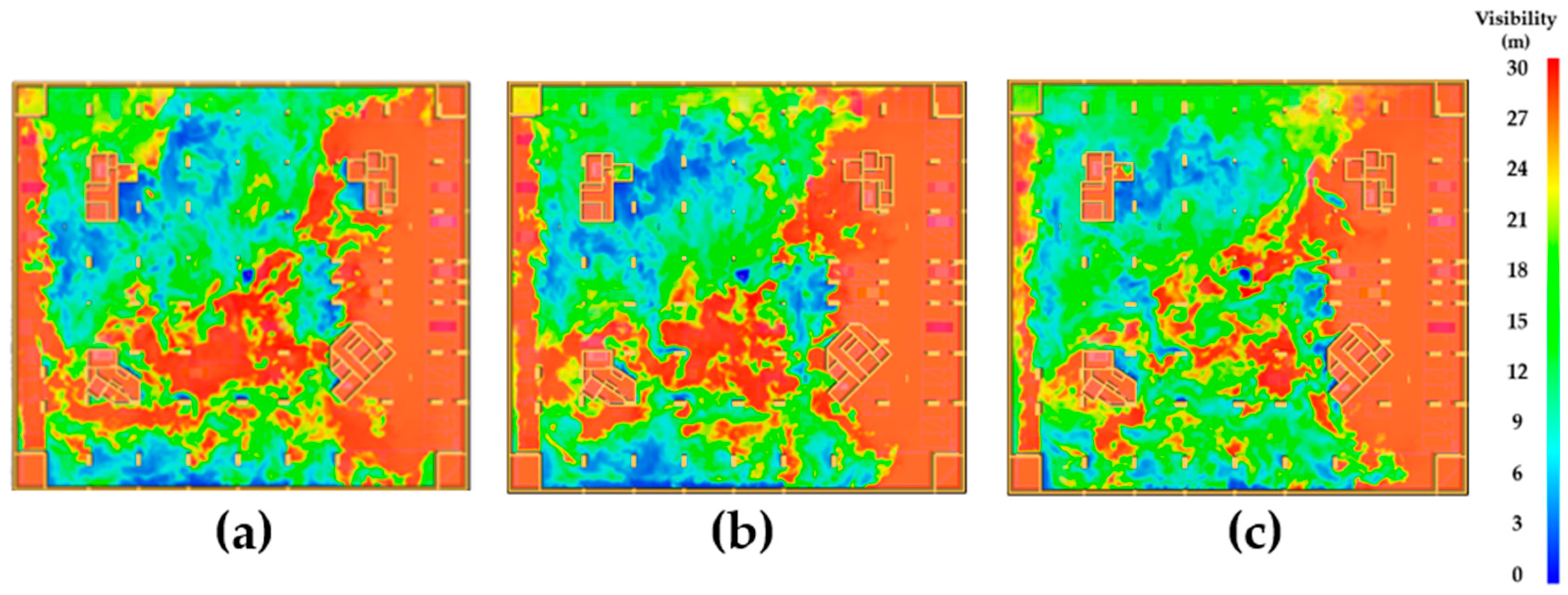

Figure 1, where the ventilation and inducer fans were operating.

Meanwhile,

D*, serving as the basis for grid sensitivity analyses and mesh resolution decisions in the FDS simulation, can be expressed as an Equation (4) [

26].

D* provides a more representative measure of the fire size than the physical diameter and is derived from

Q and the thermophysical properties of the surrounding fluid (density (

ρ), specific heat (

Cp), gravitational acceleration (

g), and

T).

For FDS simulation, we set the grid size as 0.3 m × 0.3 m × 0.3 m, an appropriate resolution for examining airflow at the ventilation fan intakes and exhausts and for evaluating smoke movement. A smaller size of grid might achieve more accurate analysis, but the grid size used in this work was sufficiently small to precisely analyze the smoke distribution with small errors [

27]. According to the FDS guidelines (NIST Special Publication 1019-5,

Fire Dynamics Simulator (Version 5) User’s Guide, page 30) [

28] and

Verification and Validation of Selected Fire Models for Nuclear Power Plant Applications (NUREG-1824) [

26], the recommended size of grid (dx) is determined by the characteristic fire diameter (

D*). The desirable ratio between

D* and dx (

D*/dx) is 4–16 in the case of isotropic fire. Since we used a grid size of 0.3 m in the calculation,

D*/dx was 7.5, within the desirable range, and the size of space we considered was sufficiently large to use a 0.3 m grid size [

29]. Moreover, the result with a small grid size (0.15 m × 0.15 m × 0.15 m, not shown here) was similar to that with a 0.3 m × 0.3 m × 0.3 m grid, so we conducted all simulations with a 0.3 m × 0.3 m × 0.3 m grid considering the accuracy and calculation time.

Regarding the materials of conventional combustion engine-based vehicles, it was assumed that two vehicles were burning simultaneously during the fire scenario, with polyurethane—commonly used as an interior material in vehicles—considered the primary combustible source of smoke [

20]. Furthermore, we assumed that the amount of smoke from the two vehicles was mainly attributed to the polyurethane, similarly to the previous report [

20]. The HRR of the vehicles during the simulation was determined by comparing values presented in the

SFPE Handbook [

9,

25], as shown in

Table 2 and

Figure 1. While the HRR of electric vehicle fires tends to be slightly higher than that of gasoline vehicles, with a longer burning duration, no significant difference was observed in terms of peak HRR [

30]. Therefore, in this study, an HRR of 8500 kW—corresponding to the simultaneous burning of two vehicles, as specified in the

SFPE Handbook [

25]—was adopted, and the grid sensitivity was set as 7.53 following previous studies [

20,

26,

28,

29]. The fire scenario was modeled under conditions similar to experimental data, with combustion rapidly being extinguished after the fire reached its target HRR. This assumption was made to enable comparison of the time required for smoke to be exhausted following fire suppression, which would be difficult to assess under continuous burning conditions. As shown in

Figure 1, the HRR rose to 8500 kW and then quickly decayed after reaching the peak value. The fire location was assumed to be at the center of the parking lot, representing the most disadvantageous position for ventilation. In this study, the fire scenario did not account for fire spread to adjacent vehicles after approximately five minutes [

31].

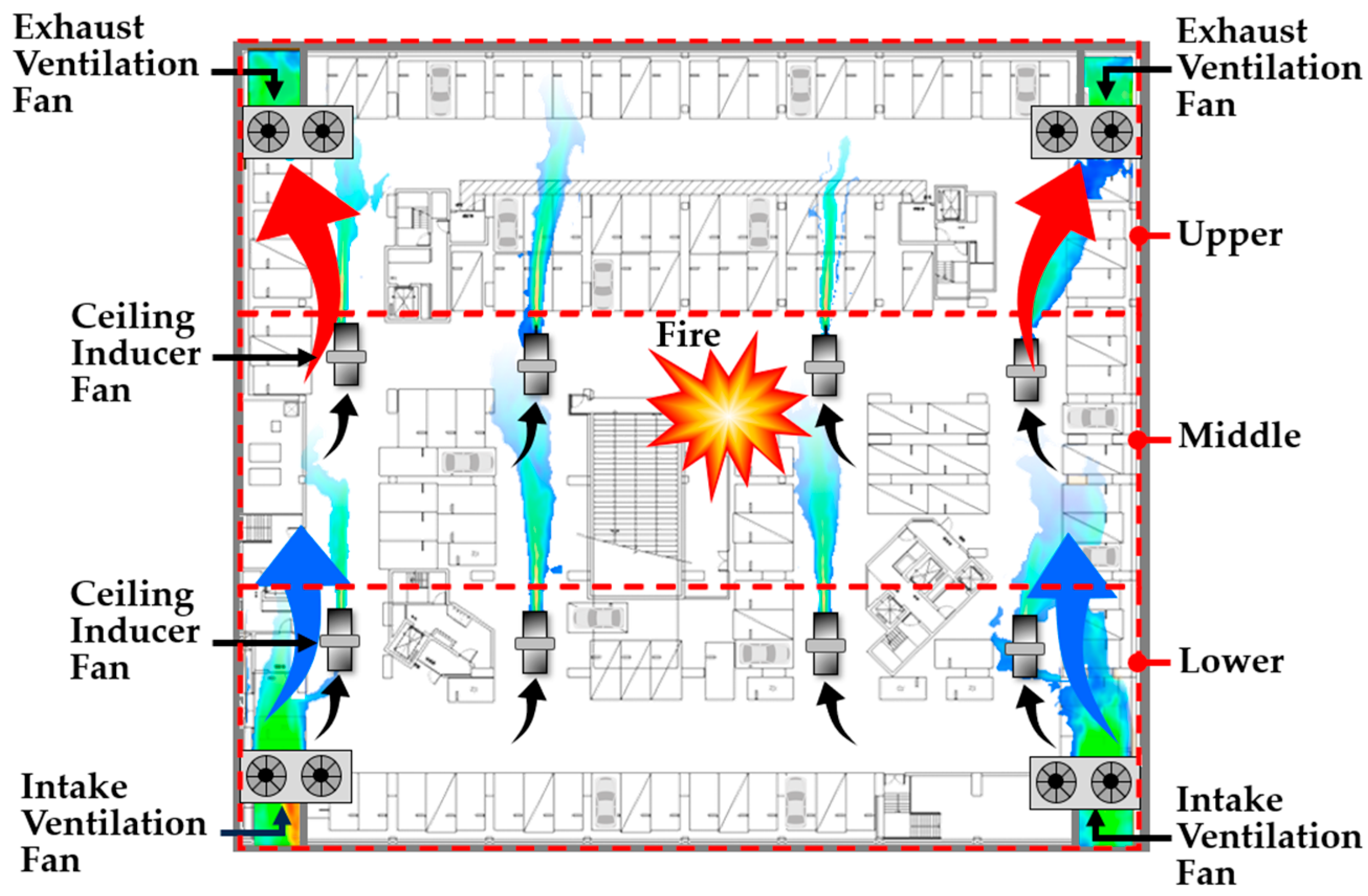

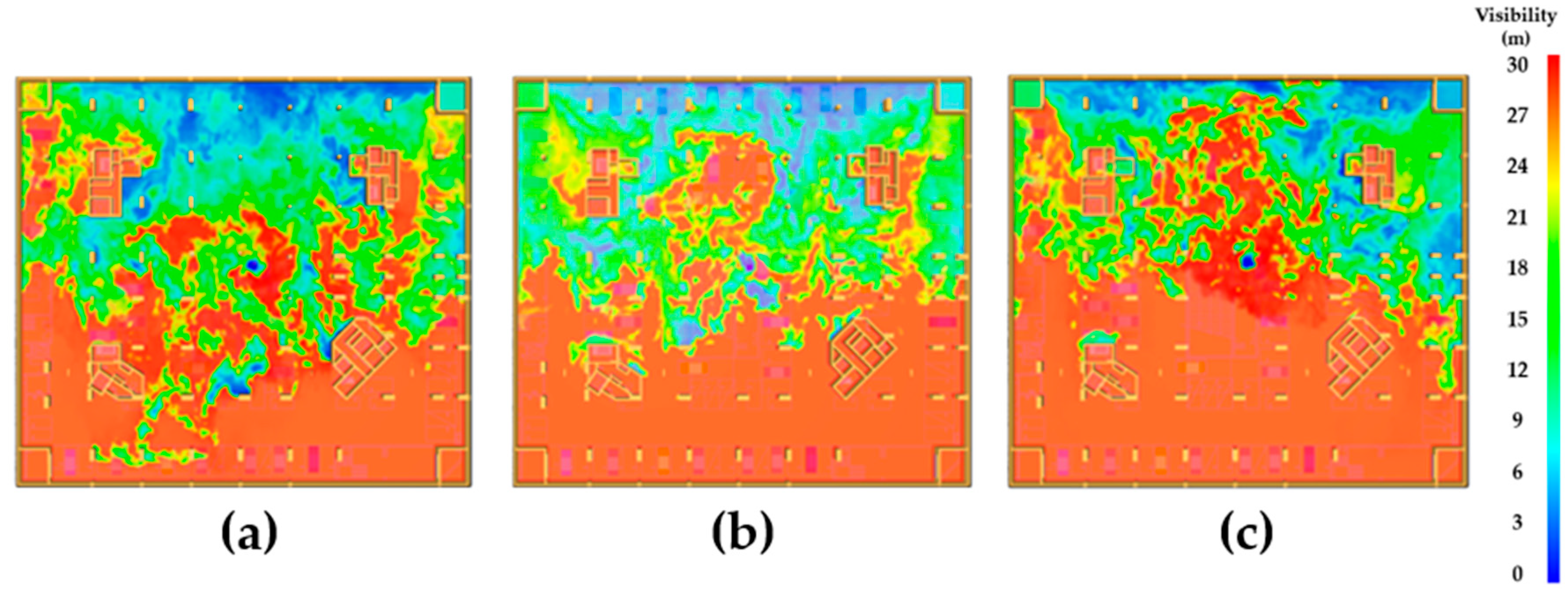

The simulation was conducted in a widely used model of a deep underground parking lot, as summarized in

Table 2. The parking lot had a total floor area of 4700 m

2 and a floor-to-ceiling height of 3.5 m, yielding a total volume of 16,450 m

3. As illustrated in

Figure 2, the parking lot included vertical connections to the ground at the left, right, upper, and lower central areas. Elevators and staircases were located at the center, enabling people to move to the ground level.

2.2. Ventilation Fan Configuration

For smoke extraction in the simulations, the ventilation capacity of the parking lot fans was determined according to the strictest regulatory standard among various national codes [

32,

33], namely the UK British Standards Institution (BSI), which prescribes 10 air changes per hour [

34]. This criterion was selected with reference to comparative data on smoke exhaust ventilation rates and practical design guidelines [

14]. The intake and exhaust flow rates of the inducer fans were fixed at 1 m

3/s, reflecting the most commonly applied value in current practice. This constraint was necessary because excessive inducer airflow may contribute to reverse smoke spread due to the increased flow rate [

35]. The inducer fans were positioned between the intake and exhaust fans to facilitate airflow during a fire event. The ventilation fan intakes and exhausts were assumed to be installed at opposite ends of the underground parking lot, as illustrated in

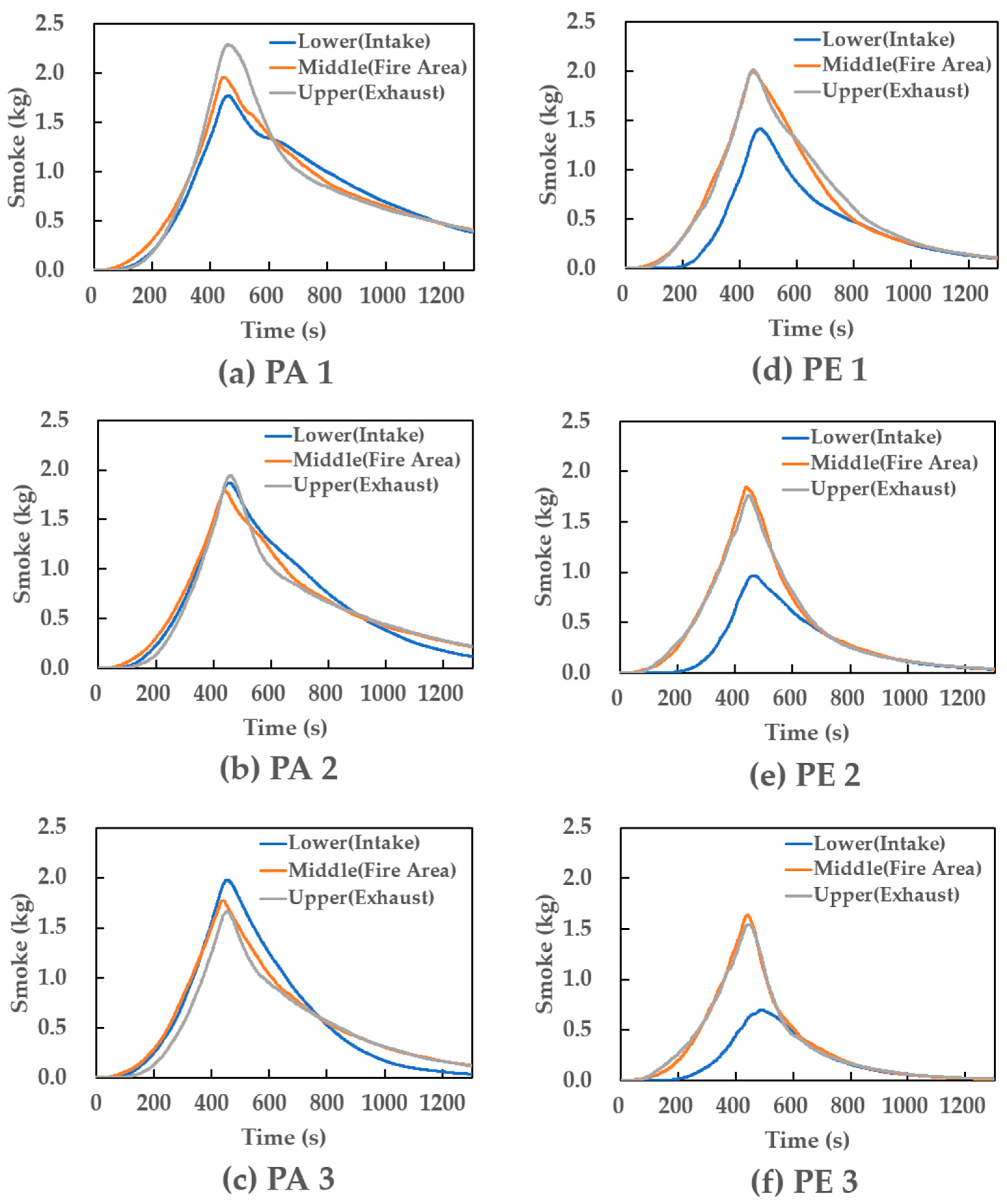

Figure 2, with smoke measurement areas defined as upper (near exhaust fan), middle (fire source area), and lower (near intake fan), in accordance with commonly applied design rules.

As summarized in

Table 3, two configurations of ventilation fans were analyzed: parallel (PA) and perpendicular (PE). In cases PA1 through PA3, the intakes and exhausts of ventilation fans were installed in parallel with the same horizontal direction to facilitate smoke flow, as shown in

Figure 2. On the other hand, in cases PE1 through PE3, the intakes and exhausts of ventilation fans were installed in perpendicular directions, as shown in

Figure 3 In addition, for each configuration, the ventilation capacity was increased incrementally to determine the optimal smoke exhaust conditions in the presence of inducer fans, depending on the orientation of the ventilation fan intakes and exhausts. The fan airflow rates were set to exhaust conditions of 10 air changes per hour (23 m

3/s), 15 air changes per hour (34 m

3/s, 1.5 times the regulation amount according to the BSI), and 20 air changes per hour (46 m

3/s, twice the regulation amount according to the BSI). Under these conditions, the intake and exhaust capacities were gradually increased to evaluate the resulting smoke flow and the extent to which visibility could be maintained. To measure the smoke-covered areas and visibility of occupants accurately, quantitative analysis based on simulation results was performed using image analysis software (ImageJ version 1.54, National Institutes of Health, Bethesda, Maryland).