Degradation Pathways of Electrical Cable Insulation: A Review of Aging Mechanisms and Fire Hazards

Abstract

1. Introduction

1.1. Degradation Mechanisms

1.1.1. Thermal Degradation

1.1.2. Electrical Degradation

1.1.3. Mechanical Degradation

1.1.4. Environmental Degradation

1.2. Literature Search and Selection

1.3. Possible Research Gaps and Trend Implications

2. Fire Initiation and Propagation Due to Insulation Failure

2.1. Ignition Mechanisms in Degraded Insulation

2.2. Fire Spread Dynamics in Cable Systems

3. Influence of Aging on the Combustion Characteristics

3.1. Heat Release Rate and Smoke Generation of Aged Cables

3.2. Ignition Behavior and Flame Spread in Aged Cables

3.3. Aging-Induced Thermal Conductivity Degradation in Cable Insulation

3.3.1. Mechanisms Leading to Increased Thermal Conductivity with Cable Aging

Thermal Crosslinking and Crystallinity Enhancement

Polymer Densification

Conductive Filler Rearrangement

Carbonaceous Char Formation

- A.

- Inner boundary (conductor–insulation interface, Neumann-type boundary condition):

- B.

- Outer boundary (insulation–air interface; Robin boundary condition)

3.4. Degradation of Dielectric Properties in Aged Electrical Insulation

3.4.1. Dielectric Strength Reduction

Thermal-Oxidative Degradation

3.4.2. Aging-Induced Increase in Dielectric Loss and tan(δ)

3.4.3. Aging Mechanisms: Natural Versus Artificial Aging

4. Flame Retardants for Polymeric Materials and Aging

- Mineral fillers such as aluminum trihydrate (ATH) generate a protective residual layer on the polymer surface during combustion, which not only shields the underlying material from fire exposure but also limits moisture ingress into the degraded matrix. As a result, ATH-containing systems can retain or even enhance their flame-retardant performance after prolonged aging.

- Organically modified montmorillonite (OMMT) nanocomposites exhibit limited thermal stability and contain metal ions that deactivate stabilizers, leading to a reduction in the flame-retardant efficiency of APP-based intumescent polypropylene composites following aging. By contrast, in glass fiber-reinforced polyamide systems combined with brominated epoxy/antimony trioxide, OMMT, were found to slow degradation by promoting crosslinking of the polymer matrix.

- Red phosphorus maintains flame retardancy under thermo-oxidative aging by migrating to the material surface, where it decomposes and forms a charred, intertwined network of P–O and P–C complexes that reinforce the protective barrier.

- Phosphinate salts, such as diethyl aluminum phosphinate, show high resistance to aging and hydrolysis, combined with elevated thermal stability. Consequently, they effectively preserve the fire performance of polyamides over extended aging.

- Brominated flame retardants, although capable of initiating adverse interactions with the host polymer and stabilizers, benefit from high thermal and hydrolytic stability, allowing them to maintain flame-retardant functionality after aging.

- (1)

- Additional cross-linking within the polymer reduces conduction current and lowers the imaginary part of the complex permittivity.

- (2)

- Oxidative degradation dominates, producing an increase in conduction current together with higher real and imaginary permittivity values.

- (3)

- The conduction current stabilizes while the complex permittivity continues to rise, reflecting sustained structural and chemical transformations.

5. The Service Lifetime of Cable Insulation

6. Conclusions

- (i)

- The development of more realistic artificial aging protocols that better replicate field conditions;

- (ii)

- Advanced diagnostic and monitoring techniques capable of detecting degradation-induced precursors to ignition;

- (iii)

- Multi-scale fire modeling frameworks that incorporate evolving material properties.

Author Contributions

Funding

Conflicts of Interest

References

- Available online: https://www.usfa.fema.gov/ (accessed on 9 July 2025).

- Available online: https://www.nfpa.org/ (accessed on 19 July 2025).

- Li, G.; Guo, J.; Kang, Y.; Huang, Q.; Zhao, J.; Liu, C. Classification and Prevention of Electrical Fires: A Comprehensive Review. Fire 2025, 8, 154. [Google Scholar] [CrossRef]

- Yu, F.; Wang, S.; Tang, K.; Lin, Y.; Wang, S.; Zhang, Y. Research Progress on the Fire Characteristics of Electric Cables and Wires. Fire 2024, 7, 186. [Google Scholar] [CrossRef]

- French, R.H.; Podgornik, R.; Peshek, T.J.; Bruckman, L.S.; Xu, Y.; Wheeler, N.R.; Gok, A.; Hu, Y.; Hossain, M.A.; Gordon, D.A.; et al. Degradation science: Mesoscopic evolution and temporal analytic of photovoltaic energy materials. Curr. Opin. Solid State Mater. Sci. 2015, 19, 212–226. [Google Scholar] [CrossRef]

- Salvi, A.; Marzullo, F.; Ostrowska, M.; Dotelli, G. Thermal Degradation of Glass Fibre-Reinforced Polyamide 6,6 Composites: Investigation by Accelerated Thermal Ageing. Polymers 2025, 17, 509. [Google Scholar] [CrossRef]

- Li, L.; Bowler, N.; Hondred, P.R.; Kessler, M.R. Influence of thermal degradation and saline exposure on dielectric permittivity of polyimide. J. Phys. Chem. Solids 2011, 72, 875–881. [Google Scholar] [CrossRef]

- Wanasekara, N.; Chalivendra, V.; Calvert, P. Sub-micron scale mechanical properties of polypropylene fibers exposed to ultraviolet and thermal degradation. Polym. Degrad. Stab. 2011, 96, 432–437. [Google Scholar] [CrossRef]

- Celina, M.; Linde, E.; Brunson, D.; Quintana, A.; Giron, N. Overview of accelerated aging and polymer degradation kinetics for combined radiation-thermal environments. Polym. Degrad. Stab. 2019, 166, 353–378. [Google Scholar] [CrossRef]

- Liu, S.; Fifield, L.S.; Bowler, N. Aging mechanisms of filled cross-linked polyethylene (XLPE) cable insulation material exposed to simultaneous thermal and gamma radiation. Radiat. Phys. Chem. 2021, 185, 109486. [Google Scholar] [CrossRef]

- Wu, G.; Li, J.; Luo, Y. Flame retardancy and thermal degradation mechanism of a novel post-chain extension flame retardant waterborne polyurethane. Polym. Degrad. Stab. 2016, 123, 36–46. [Google Scholar] [CrossRef]

- Ren, P.; Li, T.; Feng, L.; Gu, X.; Jiang, M.; Duan, J.; Zhang, C. Thermal degradation of polyamide 6: Mechanisms, mitigation strategies and challenges. Chem. Eng. Sci. 2025, 316, 121985. [Google Scholar] [CrossRef]

- Choudhary, M.; Taklaja, P.; Palu, I. A comprehensive study of partial discharge based extrinsic aging in nomex insulation films: Modeling, simulation and measurement. Electr. Power Syst. Res. 2025, 245, 111663. [Google Scholar] [CrossRef]

- Wang, Q.; Deng, Y.; Yap, M.; Yang, Y.; Ma, J.; Chern, W.K.; Li, J.; Chen, Z. Electrical tree modelling in dielectric polymers using a phase-field regularized cohesive zone model. Mater. Des. 2023, 235, 112409. [Google Scholar] [CrossRef]

- Chen, G.; Tham, C.H. Electrical treeing characteristics in XLPE power cable insulation in frequency range between 20 and 500 Hz. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 179–188. [Google Scholar] [CrossRef]

- Su, J.; Wei, L.; Zheng, J.; Liu, J.; Zhang, P.; Pang, X.; Xing, Y. Effects of Mechanical Stress on Insulation Structure and Performance of HV Cable. Polymers 2022, 14, 2927. [Google Scholar] [CrossRef]

- Shah, S.; Niasar, M.G. The effect of bending fatigue on the breakdown strength of polymer-insulated conductors. In Proceedings of the 11th International Conference on Insulated Power Cables, Jicable’23, Lyon, France, 18–22 June 2023. [Google Scholar]

- Ringsberg, J.W.; Dieng, L.; Li, Z.; Hagman, I. Characterization of the Mechanical Properties of Low Stiffness Marine Power Cables through Tension, Bending, Torsion, and Fatigue Testing. J. Mar. Sci. Eng. 2023, 11, 1791. [Google Scholar] [CrossRef]

- Plaček, V.; Kohout, T.; Kábrt, J.; Jiran, J. The influence of mechanical stress on cable service life-time. Polym. Test. 2011, 30, 709–715. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Pattanayak, A. Effect of Environmental Aging on the Electrical and Mechanical Properties of Polymeric Cable Insulation: A Review. Polymers 2021, 13, 2091. [Google Scholar] [CrossRef]

- Venkataraman, S.; Gorur, R.S.; Bass, R.; Rhodes, C. Tracking and erosion resistance of polymeric materials in oxygen deficient conditions. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 595–600. [Google Scholar] [CrossRef]

- Wang, R.Y.; Dou, Z.-F.; Li, H.-S.; Li, N.; Liu, X.-R.; Zhang, W.-F. Degradation behavior and aging mechanisms of silicone rubber under Ultraviolet–Thermal–Humidity Coupling in simulated tropical marine atmospheric environment. Polymer 2025, 328, 128398. [Google Scholar] [CrossRef]

- Tayefi, M.; Eesaee, M.; Hassanipour, M.; Elkoun, S.; David, E.; Nguyen-Tri, P. Recent progress in the accelerated aging and lifetime prediction of elastomers: A review. Polym. Degrad. Stab. 2023, 214, 110379. [Google Scholar] [CrossRef]

- Bensalem, K.; Eesaee, M.; Hassanipour, M.; Elkoun, S.; David, E.; Agbossou, K.; Nguyen-Tri, P. Lifetime estimation models and degradation mechanisms of elastomeric materials: A critical review. Polym. Degrad. Stab. 2024, 220, 110644. [Google Scholar] [CrossRef]

- Liu, H.; Wang, W.; Yan, L.; Xu, Z. Fire-resistant degradation mechanism of polyvinyl chloride cable sheaths exposed to different accelerated ageing conditions. Thermochim. Acta 2025, 748, 179983. [Google Scholar] [CrossRef]

- Zhang, Z.; Liang, T.; Li, C.; Jiang, X.; Wu, J.; Wu, B. Electrical Strength and Physicochemical Performances of HTV Silicone Rubber under Salt-Fog Environment with DC Energized. Polymers 2020, 12, 324. [Google Scholar] [CrossRef]

- Fernando, M.A.R.M.; Gubanski, S.M. Ageing of silicone rubber insulators in coastal and inland tropical environment. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 326–333. [Google Scholar] [CrossRef]

- Rajini, V.; Udayakumar, K. Degradation of Silicone Rubber under AC or DC Voltages in Radiation Environment. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 834–841. [Google Scholar] [CrossRef]

- Fahmi, D.; Asfani, D.A.; Hernanda, G.N.S.; Septiano, B.; Negara, M.Y.; Illias, H.A. Partial discharge characteristics from polymer insulator under various contaminant. Electr. Power Syst. Res. 2024, 236, 110978. [Google Scholar] [CrossRef]

- Hassan, W.; Shafiq, M.; Hussain, G.; Choudhary, M.; Palu, I. Investigating the progression of insulation degradation in power cable based on partial discharge measurements. Electr. Power Syst. Res. 2023, 221, 109452. [Google Scholar] [CrossRef]

- Güneș, I. Examination of Surface Tracking on Polyurethane Foam Insulators. Procedia—Soc. Behav. Sci. 2015, 195, 2629–2633. [Google Scholar] [CrossRef]

- Krirapee, S.; Potivejkul, S.; Pattanadech, N. Comparison of Voltage-Time to Surface Failure of Various Insulation Material for Space Aerial Cables. Procedia Comput. Sci. 2016, 86, 413–416. [Google Scholar] [CrossRef][Green Version]

- Bao, M.; Yin, X.; He, J. Analysis of electrical tree propagation in XLPE power cable insulation. Phys. B Condens. Matter 2011, 406, 1556–1560. [Google Scholar] [CrossRef]

- Qin, R.; Zhang, X.; Li, Y.; Wei, J.; Ding, C.; Jiao, Y. Influence of Cable Spacing on Flame Interaction and Combustion Characteristics of Parallel Thermoplastic Cables. Fire 2025, 8, 258. [Google Scholar] [CrossRef]

- McGrattan, K.B.; Lock, A.J.; Marsh, N.D.; Nyden, M.R. (Eds.) Cable Heat Release, Ignition, and Spread in Tray Installations During Fire (CHRISTIFIRE): Phase 1—Horizontal Trays; NUREG/CR-7010; Contractor Report; Office of Nuclear Regulatory Research: Rockville, MD, USA, 2012.

- McGrattan, K.; Bareham, S. (Eds.) Cable Heat Release, Ignition, and Spread in Tray Installations During Fire (CHRISTIFIRE) Phase 2: Vertical Shafts and Corridors; NUREG/CR-7010; Office of Nuclear Regulatory Research: Rockville, MD, USA, 2013; Volume 2.

- Zhang, Z.; Chen, P.; Lin, Z.; Sun, S. Combustion characteristics and heat transfer mechanisms analysis of cable fire over ladder-type tray. Int. J. Therm. Sci. 2025, 215, 109935. [Google Scholar] [CrossRef]

- Xu, T.; Chen, C.; Du, W.; Gao, F.; Wang, Z.; Yi, T. Experimental study on fire spread behavior of single 110 kV cable under different layout conditions. Fire Saf. J. 2023, 141, 103957. [Google Scholar] [CrossRef]

- Magalie, C.; Anne-Sophie, C.; Rodolphe, S.; Laurent, F.; Emmanuelle, G.; Christian, L. Fire behaviour of electrical cables in cone calorimeter: Influence of cables structure and layout. Fire Saf. J. 2018, 99, 12–21. [Google Scholar] [CrossRef]

- Lu, K.; Miao, R.; Zhu, Z.; Xu, H.; Wang, J.; Li, B. An experimental investigation of the dual wire fire spread behavior and its heat transfer process. Int. J. Heat Mass Transf. 2025, 242, 126883. [Google Scholar] [CrossRef]

- Zhu, H.; Ji, J.; Nie, J. Early fire evolution and alarm characteristics of cable fires in long and narrow spaces. Fire Saf. J. 2022, 131, 103627. [Google Scholar] [CrossRef]

- Wan, H.; Zhang, G.; Xu, F.; Ding, Y.; Li, M. Experimental investigation and numerical analysis on fire response of parallel-wire cable exposed to open-air fire. Eng. Struct. 2025, 338, 120546. [Google Scholar] [CrossRef]

- Xie, Q.; Zhang, H.; Tong, L. Experimental study on the fire protection properties of PVC sheath for old and new cables. J. Hazard. Mater. 2010, 179, 373–381. [Google Scholar] [CrossRef]

- Kim, M.H.; Seo, H.J.; Lee, S.K.; Lee, M.C. Influence of Thermal Aging on the Combustion Characteristics of Cables in Nuclear Power Plants. Energies 2021, 14, 2003. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J. An experimental study on the fire characteristics of new and aged building wires using a cone calorimeter. J. Therm. Anal. Calorim. 2019, 135, 3115–3122. [Google Scholar] [CrossRef]

- Bai, Z. Burning characteristics of power cables with cone calorimeter. Heliyon 2024, 10, e25103. [Google Scholar] [CrossRef] [PubMed]

- Tang, K.; Wang, S.; Fu, M.; Tian, F.; Chen, X.; Zhang, Y. Comprehensive assessment of the thermal aging effects on fire risks of PVC cable. J. Therm. Anal. Calorim. 2024, 149, 3785–3793. [Google Scholar] [CrossRef]

- Shi, B.; Yang, C.; Long, H. Research on the Fire Hazard of Different Cables Based on Cone Calorimetry. Fire 2023, 6, 431. [Google Scholar] [CrossRef]

- Liu, H.; Wang, W.; Yan, L.; Xu, Z. Flammability degradation behavior and ageing mechanism of flame-retardant cable sheath under different ageing conditions. Polym. Degrad. Stab. 2024, 230, 111019. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, J.; Li, Q.; Wang, L.; Xie, H.; Fan, M. Effects of Insulating Material Aging on Ignition Time and Heat Release Rate of the Flame Retardant Cables. Procedia Eng. 2018, 211, 972–978. [Google Scholar] [CrossRef]

- Choudhary, M.; Shafiq, M.; Kiitam, I.; Hussain, A.; Palu, I.; Taklaja, P. A Review of Aging Models for Electrical Insulation in Power Cables. Energies 2022, 15, 3408. [Google Scholar] [CrossRef]

- Huang, P.; Yu, W.; Lu, C.; He, X.; Zhang, Y.; Liu, Y.; Zhou, J.; Liang, Y. Quantitative Evaluation of Thermal Ageing State of Cross-Linked Polyethylene Insulation Based on Polarization and Depolarization Current. Polymers 2023, 15, 1272. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhang, H.; Du, B. Thermal Aging Evaluation of XLPE Power Cable by Using Multidimensional Characteristic Analysis of Leakage Current. Polymers 2022, 14, 3147. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Guo, Y.; Jian, Z.; Huang, M.; Zhao, T. Experimental Study on the Thermal Conductivity of Improved Graphite Composite Insulation Boards. Crystals 2023, 13, 102. [Google Scholar] [CrossRef]

- Pleşa, I.; Noţingher, P.V.; Schlögl, S.; Sumereder, C.; Muhr, M. Properties of Polymer Composites Used in High-Voltage Applications. Polymers 2016, 8, 173. [Google Scholar] [CrossRef]

- Wang, X.; Weinell, C.; Ring, L.; Kiil, S. Thermal insulation performance and char formation and degradation mechanisms of boron-containing hydrocarbon intumescent coatings. Fire Saf. J. 2021, 123, 103369. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Y.; Man, P. Kinetic Analysis of Thermal Decomposition of Polyvinyl Chloride at Various Oxygen Concentrations. Fire 2023, 6, 404. [Google Scholar] [CrossRef]

- Lv, H.; Lu, T.; Xiong, L.; Zheng, X.; Huang, Y.; Ying, M.; Cai, J.; Li, Z. Assessment of thermally aged XLPE insulation material under extreme operating temperatures. Polym. Test. 2020, 88, 106569. [Google Scholar] [CrossRef]

- Blivet, C.; Larché, J.; Israëli, Y.; Bussière, P.; Gardette, J. Thermal oxidation of cross-linked PE and EPR used as insulation materials: Multi-scale correlation over a wide range of temperatures. Polym. Test. 2021, 93, 106913. [Google Scholar] [CrossRef]

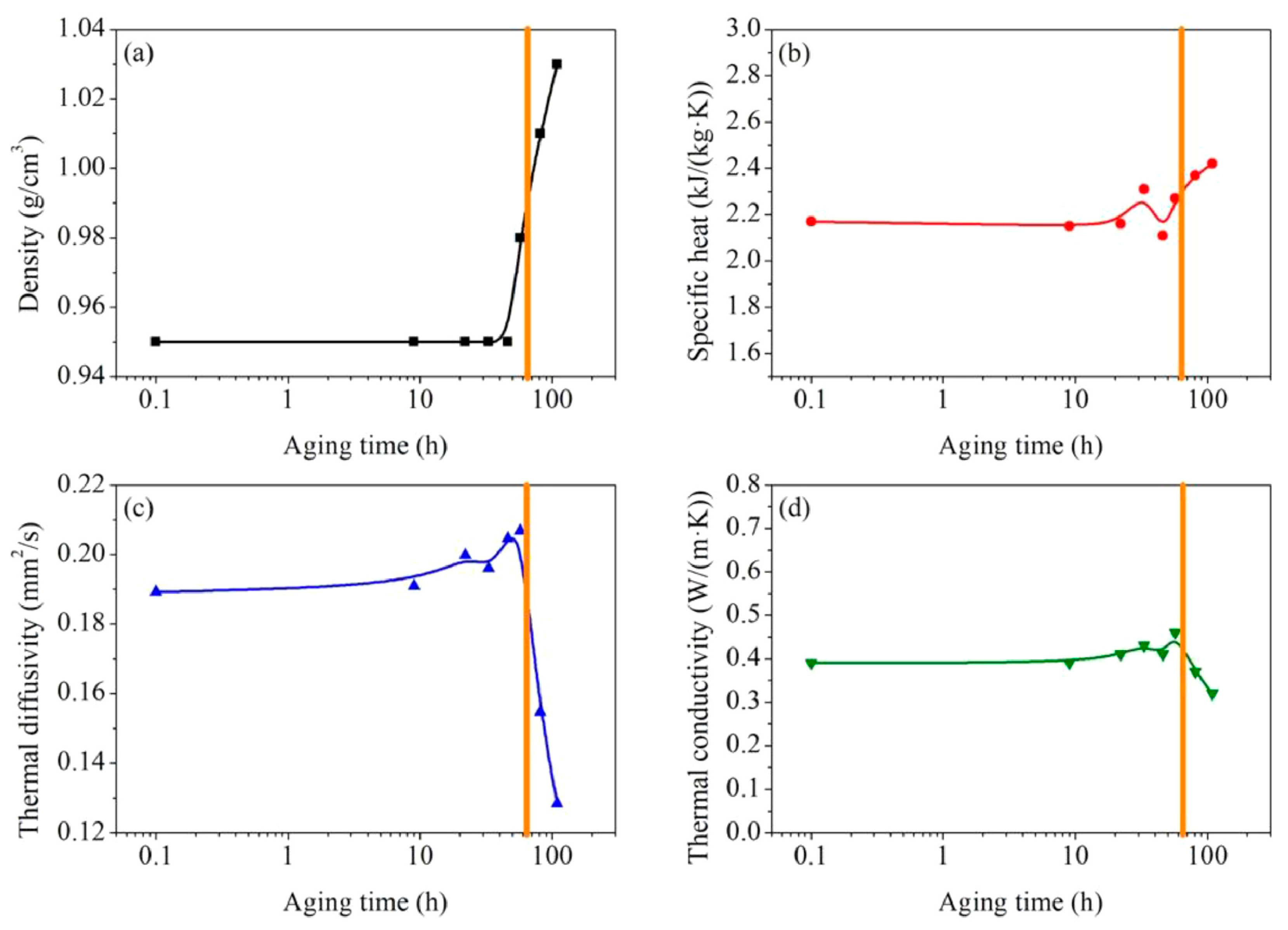

- Liu, Y.; Sun, J.; Chen, S.; Sha, J.; Yang, J. Thermophysical properties of cross-linked polyethylene during thermal aging. Thermochim. Acta 2022, 713, 179231. [Google Scholar] [CrossRef]

- Zhang, M.; He, M.; Gu, H.; Huang, A.; Xiang, W. Influence of pore distribution on the equivalent thermal conductivity of low porosity ceramic closed-cell foams. Ceram. Int. 2018, 44, 19319–19329. [Google Scholar] [CrossRef]

- Venkataraman, M.; Sözcü, S.; Militký, J. Radiative Heat Transfer Properties of Fiber–Aerogel Composites for Thermal Insulation. Gels 2025, 11, 538. [Google Scholar] [CrossRef] [PubMed]

- Blazejczyk, A.; Jastrzebski, C.; Wierzbicki, M. Change in Conductive–Radiative Heat Transfer Mechanism Forced by Graphite Microfiller in Expanded Polystyrene Thermal Insulation—Experimental and Simulated Investigations. Materials 2020, 13, 2626. [Google Scholar] [CrossRef]

- Rantuch, P.; Štefko, T.; Martinka, J. Critical Heat Flux Determination of Electric Cable Insulation. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2018, 26, 11–20. [Google Scholar] [CrossRef]

- Diban, B.; Mazzanti, G. The Effect of Insulation Characteristics on Thermal Instability in HVDC Extruded Cables. Energies 2021, 14, 550. [Google Scholar] [CrossRef]

- Omastová, M.; Podhradská, S.; Prokeš, J.; Janigová, I.; Stejskal, J. Thermal ageing of conducting polymeric composites. Polym. Degrad. Stab. 2003, 82, 251–256. [Google Scholar] [CrossRef]

- Torres-Regalado, P.; Santiago-Calvo, M.; Gimeno, J.; Rodríguez-Pérez, M.A. Thermal conductivity aging and mechanical properties of polyisocyanurate (PIR) foams produced with different contents of HFO. J. Appl. Polym. Sci. 2023, 140, 1–14. [Google Scholar] [CrossRef]

- Berardi, U. The impact of aging and environmental conditions on the effective thermal conductivity of several foam materials. Energy 2019, 182, 777–794. [Google Scholar] [CrossRef]

- Boggs, S.A. Mechanisms for Degradation of TR-XLPE Impulse Strength during Service Aging. IEEE Power Eng. Rev. 2002, 22, 57. [Google Scholar] [CrossRef]

- Han, T.; Li, W.; Zheng, Z.; Li, Y.; Chu, J.; Hao, C. Insulation Aging Evaluation Method of High Voltage Cable Based on Dielectric Loss Characteristics. Energies 2025, 18, 1267. [Google Scholar] [CrossRef]

- Liu, D.; Tong, X.; Liu, L.; Chen, T.; Tang, J.; Tang, W.; Wang, L.; Cao, B.; Luo, Z. Research on the Thermal Aging Characteristics of Cured Epoxy Resin Insulating Materials for DC Bushings. Polymers 2025, 17, 1064. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, C.; Du, H.S.; Miyake, H.; Tanaka, Y.; Du, B. Effects of Thermo-Oxidative Aging on the Dielectric Property and Electrical Breakdown of Epoxy Resin Using in High-Voltage Equipment. IEEE Trans. Dielectr. Electr. Insul. 2025, 32, 254–262. [Google Scholar] [CrossRef]

- He, G.; Zhang, W.; Sun, K.; Qi, J.; Zhao, J.; Han, J.; Zhu, X. The impact of XLPE surface defects on electric field and breakdown voltage. Front. Energy Res. 2024, 12, 1476046. [Google Scholar] [CrossRef]

- Kim, C.; Jin, Z.; Huang, X.; Jiang, P.; Ke, Q. Investigation on water treeing behaviors of thermally aged XLPE cable insulation. Polym. Degrad. Stab. 2007, 92, 537–544. [Google Scholar] [CrossRef]

- Smaida, A.; Mecheri, Y.; Boukezzi, L.; Bouazabia, S. Mechanical behavior of 60 kV HV XLPE insulation under thermal aging and cross-correlation assessment of degradation mechanisms. J. Mech. Sci. Technol. 2025, 39, 611–625. [Google Scholar] [CrossRef]

- Ji, M.; Colin, X.; Liu, W.; Chi, X.; Chatenet, S.; Wei, W. Comparison of the performances and aging mechanisms of XLPE and EVA insulation during their thermal oxidative aging. Polym. Degrad. Stab. 2024, 222, 110699. [Google Scholar] [CrossRef]

- Li, C.; Tan, X.; Liu, L.; Zhang, W.; Yang, Q.; Cao, J.; Zhou, E.; Li, M.; Song, Z. Investigation of Near-Infrared Spectroscopy for Assessing the Macroscopic Mechanical Properties of Cross-Linked Polyethylene During Thermal Aging. Materials 2025, 18, 504. [Google Scholar] [CrossRef] [PubMed]

- Hedir, A.; Rondot, S.; Jbara, O.; Durmus, A.; Moudoud, M.; Lamrous, O.; Haddad, A.M. Assessment of UV-Aging of Crosslinked Polyethylene Cable Insulation by Electrical Measurements, FTIR and DSC Analyses. ECS J. Solid State Sci. Technol. 2025, 14, 013008. [Google Scholar] [CrossRef]

- Barra, G.; Guadagno, L.; Raimondo, M.; Santonicola, M.G.; Toto, E.; Vecchio Ciprioti, S. A Comprehensive Review on the Thermal Stability Assessment of Polymers and Composites for Aeronautics and Space Applications. Polymers 2023, 15, 3786. [Google Scholar] [CrossRef]

- Gao, C.; Yu, Y.; Wang, Z.; Wang, W.; Zheng, L.; Du, J. Study on the Relationship between Electrical Tree Developmentand Partial Discharge of XLPE Cables. J. Nanomater. 2019, 2019, 8932312. [Google Scholar] [CrossRef]

- Chandrasekar, S.; Purushotham, S.; Montanari, G.C. Investigation of electrical tree growth characteristics in XLPE nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 558–564. [Google Scholar] [CrossRef]

- Su, J.; Zhang, P.; Liu, Z.; Huang, X.; Pang, X.; Zheng, Z.; Han, T. Electrical Tree and Partial Discharge Characteristics of Silicone Rubber Under Mechanical Pressure. Energies 2024, 17, 5645. [Google Scholar] [CrossRef]

- Camalov, M.; Akin, F.; Hashimov, A.; Arikan, O.; Orucov, A.; Guliyev, M. The Degradation Analysis of XLPE Materials Under Thermal Aging: A Comprehensive Study Through Partial Discharge Measurements and Structural Characterization Techniques. Trans. Electr. Electron. Mater. 2024, 25, 494–506. [Google Scholar] [CrossRef]

- Domingos, A.C.; Duarte, L.; Pinheiro, A.P.; Moura, F.A.M.; Vasconcelos, L.; de Carvalho, D.P.; Fadel, F.E.d.F.; Sakai, P.N. Comparative Analysis of Insulation Aging in Cross-Linked Polyethylene and Ethylene–Propylene Rubber Cables Through the Progression Rate of Partial Discharge. Energies 2025, 18, 2653. [Google Scholar] [CrossRef]

- Han, T.; Yao, Y.; Li, Q.; Huang, Y.; Zheng, Z.; Gao, Y. Locating Method for Electrical Tree Degradation in XLPE Cable Insulation Based on Broadband Impedance Spectrum. Polymers 2022, 14, 3785. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, X.; Qiao, J.; Xiao, Y.; Zhang, J.; Li, Y.; Cao, H.; Yang, L.; Liao, R. Structural Changes and Very-Low-Frequency Nonlinear Dielectric Response of XLPE Cable Insulation under Thermal Aging. Materials 2023, 16, 4388. [Google Scholar] [CrossRef] [PubMed]

- IEC 60216-6; Electrical Insulating Materials—Thermal Endurance Properties—Part 6: Determination of Thermal Endurance Indices (TI and RTI) of an Insulating Material Using the Fixed Time Frame Method. IEC: Geneva, Switzerland, 2022; ISBN 978-2-8322-6173-6.

- Li, K.; Zhou, K.; Zhang, H.; Jin, H.; Li, X. Understanding the Crystalline Region Damage Mechanism of XLPE in Water Tree Propagation by Erosion Method. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 2074–2082. [Google Scholar] [CrossRef]

- Afia, R.S.A.; Mustafa, E.; Adam, T.Z. Evaluation of thermally aged nuclear power plant power cables based on electrical condition monitoring and regression analysis. In Proceedings of the 2019 International IEEE Conference and Workshop in Óbuda on Electrical and Power Engineering (CANDO-EPE), Budapest, Hungary, 20–21 November 2019; pp. 203–206. [Google Scholar]

- Afia, R.S.A.; Mustafa, E.; Tamus, Z.A. Dielectric Spectroscopy of Low Voltage Nuclear Power Cables Under Simultaneous Thermal and Mechanical Stresses. Energy Rep. 2020, 6, 662–667. [Google Scholar] [CrossRef]

- IEEE 383-2023; IEEE Standard for Qualifying Electric Cables and Splices for Nuclear Facilities. IEEE: Piscataway, NJ, USA, 2023.

- Frigione, M.; Rodríguez-Prieto, A. Can Accelerated Aging Procedures Predict the Long Term Behavior of Polymers Exposed to Different Environments? Polymers 2021, 13, 2688. [Google Scholar] [CrossRef]

- Colom, X.; Canavate, J.J.; Sunol, P.; Pages, J.; Saurina, J.; Carrasco, F. Natural and artificial aging of polypropylene–polyethylene copolymers. J. Appl. Polym. Sci. 2003, 87, 1685–1692. [Google Scholar] [CrossRef]

- Qiao, X.; Ming, Y.; Xu, K.; Yi, N.; Sundararajan, R. Aging of Polymeric Insulators under Various Conditions and Environments: Another Look. Energies 2022, 15, 8809. [Google Scholar] [CrossRef]

- Ullah, I.; Akbar, M.; Ahmad Khan, H. Degradation analysis of RTV-SiR based composites under both polarities DC voltage for insulators coating. Mater. Today Commun. 2021, 29, 102890. [Google Scholar] [CrossRef]

- Qiao, X.; Zhang, Z.; Jiang, X.; Sundarajan, R.; Ma, X.; Li, X. AC failure voltage of iced and contaminated composite insulators in different natural environments. Int. J. Electr. Power Energy Syst. 2020, 120, 105993. [Google Scholar] [CrossRef]

- Wang, W.; Shang, X.; Huo, Y.; Yi, H.; Li, Z.; Wu, J.; Guo, Y.; Shu, C. Thermal decomposition characteristics of polyvinyl chloride sheathing in MYJV-type mining cables. J. Therm. Anal. Calorim. 2025, 150, 6201–6210. [Google Scholar] [CrossRef]

- Jiang, Y.; He, W.; Huo, X.; Lu, X.; Li, K.; Xiao, F. Unveiling Thermal Degradation and Fire Behavior of 110 kV Ultra-High-Voltage Flame-Retardant Cable Sheath After Thermal Aging. Polymers 2025, 17, 1273. [Google Scholar] [CrossRef]

- Zhang, C.; An, X.; Li, Q.; Wu, J.; Xu, Z.; Khaled, U.; He, D.; Zhu, L. Research on the Electrical Tree Deterioration Characteristics of Silicone Gel and Silicone Rubber Under Pulsed Electric Field. Gels 2025, 11, 253. [Google Scholar] [CrossRef]

- Fard, M.A.; Farrag, M.E.; McMeekin, S.; Reid, A. Electrical Treeing in Cable Insulation under Different HVDC Operational Conditions. Energies 2018, 11, 2406. [Google Scholar] [CrossRef]

- Xing, Z.; Zhang, C.; Hu, X.; Guo, P.; Zhang, J.; Wang, Z.; Wu, K.; Li, J. Surface Tracking of MgO/Epoxy Nanocomposites: Effect of Surface Hydrophobicity. Appl. Sci. 2019, 9, 413. [Google Scholar] [CrossRef]

- Tariq Nazir, M.; Khalid, A.; Akram, S.; Mishra, P.; Kabir, I.I.; Yeoh, G.H.; Toan Phung, B.; Wong, K.L. Electrical tracking, erosion and flammability resistance of high voltage outdoor composite insulation: Research, innovation and future outlook. Mater. Sci. Eng. R Rep. 2023, 156, 100757. [Google Scholar] [CrossRef]

- Li, Z.; Ohki, Y.; Chen, G.; Li, S. Surface flashover in 50 years: II. Material modification, structure optimisation, and characteristics enhancement. High Volt. 2025, 10, 243–278. [Google Scholar] [CrossRef]

- Riba, J.-R.; Moreno-Eguilaz, M.; Bogarra, S. Tracking Resistance in Polymeric Insulation Materials for High-Voltage Electrical Mobility Applications Evaluated by Existing Test Methods: Identified Research Needs. Polymers 2023, 15, 3717. [Google Scholar] [CrossRef] [PubMed]

- Maraveas, C.; Kyrtopoulos, I.V.; Arvanitis, K.G.; Bartzanas, T. The Aging of Polymers under Electromagnetic Radiation. Polymers 2024, 16, 689. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Yang, H.; Xu, Q.; Lin, H.; Yang, Y.; Jadoon, A. Research on the impact of water-ingression defects on the electromagnetic-thermal fluctuation and heat distribution characteristics of high voltage cable terminals. Case Stud. Therm. Eng. 2023, 51, 103567. [Google Scholar] [CrossRef]

- Friškovec, N.; Obreza, M.; Pirc, M.; Sredenšek, K.; Praunseis, Z. Analysis of aged cables insulation with X Ray fluorescence spectrometry. J. Energy Technol. 2024, 17, 32–46. [Google Scholar] [CrossRef]

- Ahmad, J.; Niasar, M.G. Aging Behavior of PEEK, PTFE, and PI Insulation Materials Under Thermal Oxidative and Humid Conditions for Aerospace Applications. J. Appl. Polym. Sci. 2025, 142, e56858. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, S.-M.; Kim, J.-T. Comparison of Thermal Conductivity and Long-Term Change of Building Insulation Materials According to Accelerated Laboratory Test Methods of ISO 11561 and EN 13166 Standard. Energies 2024, 17, 6105. [Google Scholar] [CrossRef]

- Gunnarshaug, A.; Metallinou, M.-M.; Log, T. Industrial Thermal Insulation Properties above Sintering Temperatures. Materials 2021, 14, 4721. [Google Scholar] [CrossRef]

- Troitzsch, J.H. Fire performance durability of flame retardants in polymers and coatings. Adv. Ind. Eng. Polym. Res. 2024, 7, 263–272. [Google Scholar] [CrossRef]

- Yang, Z.; Hirai, N.; Ohki, Y. Evaluation of Aging Status of Flame-retardant Cross-linked Polyethylene by Measuring Indenter Modulus. In Proceedings of the 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7–10 April 2019; pp. 57–60. [Google Scholar] [CrossRef]

- Zhou, D.; He, W.; Wang, N.; Chen, X.; Guo, J.; Ci, S. Effect of thermo-oxidative aging on the mechanical and flame retardant properties of long glass fiber-reinforced polypropylene composites filled with red phosphorus. Polym. Compos. 2018, 39, 2634–2642. [Google Scholar] [CrossRef]

- Zhou, Y.; He, W.; Wu, Y.; Xu, D.; Chen, X.; He, M.; Guo, J. Influence of thermo-oxidative aging on flame retardancy, thermal stability, and mechanical properties of long glass fiber–reinforced polypropylene composites filled with organic montmorillonite and intumescent flame retardant. J. Fire Sci. 2019, 37, 176–189. [Google Scholar] [CrossRef]

- Guo, J.; Wang, M.; Li, L.; Wang, J.; He, W.; Chen, X. Effects of thermal-oxidative aging on the flammability, thermal degradation kinetics and mechanical properties of DBDPE flame retardant long glass fiber reinforced polypropylene composites. Polym. Compos. 2018, 39 (Suppl. S3), E1733–E1741. [Google Scholar] [CrossRef]

- Zuo, X.; Shao, H.; Zhang, D.; Hao, Z.; Guo, J. Effects of thermal-oxidative aging on the flammability and thermal-oxidative degradation kinetics of tris(tribromophenyl) cyanurate flame retardant PA6/LGF composites. Polym. Degrad. Stab. 2013, 98, 2774–2783. [Google Scholar] [CrossRef]

- Zuo, X.; Song, H.; Shao, H.; Wei, T.; Guo, J. Aging of OMMT/halogen-antimony-filled LGFPA6 composite: Effect on static and dynamic mechanical properties and fire behaviors. Polym. Compos. 2019, 40, 2208–2218. [Google Scholar] [CrossRef]

- Alghamdi, A.S.; Desuqi, R.K. A study of expected lifetime of XLPE insulation cables working at elevated temperatures by applying accelerated thermal ageing. Heliyon 2020, 6, e03120. [Google Scholar] [CrossRef]

- IAEA Nuclear Energy Series No. NP-T-3.6, International Atomic Energy Agency, Vienna. 2012. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1554_web.pdf (accessed on 18 September 2025).

| Cable/Insulation Type | Layout/Configuration | Main Findings/Results | Ref |

|---|---|---|---|

| 110 kV cable Flame-retardant cross-linked PE insulation corrugated aluminum sheath and armored polyethylene sheath. | Horizontal cable above horizontal floor structure. Inclined Cable Above Horizontal Floor Structure Inclined Cable Above Inclined Floor Structure | Flame spread is sustained only within an optimal cable-to-floor distance (0.75 d–2 d). Spread rates were highest for inclined layouts with lower ignition; cable geometry significantly influenced fire behavior. | Xu et al. [38] |

| Thermoplastic insulation PVC or generic cable insulation 10 kV cable with large-section (ZC-YJLW03-Z) Halogen-free telecom cables Polyurethane foam insulation XLPE, LDPE, MDPE, HDPE | Parallel, horizontal cables with varying spacing Horizontal cable above horizontal floor, inclined cable above horizontal floor, inclined cable above inclined floor Grouped halogen-free telecom cables under varying spacing and cable density Inclined plane setup with 4 kV applied voltage under ASTM D2303 conditions Dip setup using Nichrome wire electrode and 0.1% ammonium chloride solution, tested under ICEA S-66-524 | Max flame spread at 2.5 mm spacing due to strong flame interaction. Vertical layouts favor spread; horizontal trays limit it unless heat radiates from upper layers. Stable spread at optimal spacing; too close or distant spread reduces combustion. Heat flux controls ignition; sheath thickness delays peak burning; layout influences HRR. Tracking on PU foam shows abrupt failure after roughening and arc-induced loss of hydrophobicity. HDPE and XLPE resist tracking best; aging has little effect; composition is a key factor. | Magalie et al. [39] |

| Copper-core polyethylene-coated (Cu-PE) wires | Dual parallel wires with variable spacing and inclination angle | Flame spread rate shows a rise-then-drop trend with increasing wire spacing; oxygen depletion at narrow spacing limits flame. Inclination affects molten PE droplet behavior—downward spread is enhanced by a sliding effect, and upward spread by thermal buoyancy. | Lu et al. [40] |

| Generic cable types in interlayer setups; focus on smoldering and initial fire stages. | Full-scale interlayer platform simulating tunnel-like, narrow and long cable installations. | Temperature decays exponentially in early fires. CO spreads steadily in smoldering but slows in flaming. Cable-contact detectors had the fastest response (up to 82% faster). Point-temp detector failed. High alarm thresholds delayed detection by 10–20%. | Zhu et al. [41] |

| HDPE-sheathed parallel-wire cable under mechanical load. | Horizontal cable under tension, exposed to open-air pool fire; combined FDS-FEA numerical and full-scale experimental study. | Surface and pool fire interacted, raising cable surface temps to 400 °C. Sheath first insulates, then supports combustion post-ablation. Distinct radial and axial temp gradients appear after HDPE burnout. Cable deformation has 3 stages; failure occurs at 0.055 mm/s deformation rate. Fire resistance is influenced by cable diameter, sheath, and prestress. The FDS-FEA model effectively simulates fire response and deformation. | Wan et al. [42] |

| Property | New Cable | Aged Cable | Ref |

|---|---|---|---|

| Ignition time | Longer (due to intact insulation and flame retardants) | Shorter (due to surface cracks, oxidation, and degradation) | Kim et al. [44] Wang and Wang [45] |

| HRR | Lower peak HRR | Higher peak HRR | Bai [46] Wang and Wang [45] Tang et al. [47] |

| Smoke generation | Reduced, often within regulatory limits | Increased, due to incomplete combustion and altered chemistry | Shi et al. [48] Liu et al. [49] |

| Flame spread rate | Slower, more predictable | Faster, enhanced by microcracks and polymer breakdown | Wang and Wang [45] |

| Combustion efficiency | Slower | More complete | Xie et al. [43] |

| Cable | Aging Method | Ignition Delay | Flame Spread Rate | Main Findings | Ref |

|---|---|---|---|---|---|

| XLPE | Thermal aging | Decreased by 30% | Accelerated by 20% | Aging reduced ignition resistance; lower decomposition temperature led to earlier ignition | Kim et al. [44] |

| PVC XLPE | Thermal Xenon arc Ozone Hydrothermal | Increased to values depending on the aging method | Not provided | XLPE showed a reduced fire hazard compared to PVC-insulated cables from the ignition time point of view | Zhang et al. [50] |

| PVC | Naturally aged cables (>10 years) | Slightly decreased ignition temperature. Aged sheath ignites earlier under MCC and TG conditions | Increased combustion rate (faster heat release and prolonged flame behavior) | Aged PVC sheaths show reduced fire protection; higher peak heat release; earlier and longer HCl evolution; and stronger overall combustion intensity | Xie et al. [43] |

| Material | Ref | |

|---|---|---|

| XLPE | ~160 (thermo-oxidative aging) | Lv et al. [58] |

| EPR | ~100 (thermo-oxidative aging) | Blivet et al. [59] |

| PVC | Three stages of the thermal degradation process were observed under the oxygenated atmosphere: 130–175 stage 1 145–510 stage 2 75–190—stage 2 | Yang et al. [57] |

| Aging Mechanism | Test Conditions and Results | Ref |

|---|---|---|

| Thermal aging of XLPE cables | 220 kV XLPE cable slices aged at 135 °C for 70 days; tracked AC breakdown field vs. crystallinity and carbonyl index | Han et al. [70] |

| Thermal-oxidative aging of epoxy resin | DC bushings epoxy resin, 10 cycles at 250 °C → breakdown strength dropped by 9.9%; volume resistivity dropped by 53.8% | Liu et al. [71] |

| Thermo-oxidative aging of epoxy resin (HV aging) | Aging for 1440 h; breakdown strength dropped by 18.1%, conductivity increased by 59.6% | Kong et al. [72] |

| Defects in XLPE (scratches, moisture, particles) | Sheet simulations and lab tests show defect-induced breakdown voltage drop from ~129.6 kV → 59–70 kV (≈45–55% loss) | He et al. [73] |

| Partial discharges/electrical treeing | Electrical tree propagation creates weakened regions → reduced breakdown strength (~50%, depending on tree size) | Kim et al. [74] |

| Material, Aging Protocol | Key Findings | Ref |

|---|---|---|

| Epoxy resin (DGEBA/anhydride), 10 cycles at 250 °C | DC breakdown dropped by 9.9%; volume resistivity dropped by 53.8%; carbonyl index (FTIR) increased | Liu et al. [71] |

| High-voltage epoxy, thermo-oxidative aging (1440 h) | Breakdown strength dropped by ~18.1%; conductivity increased by 59.6% | Kong et al. [72] |

| XLPE cable, thermal aging at 110–135 °C (2000 h) | Carbonyl index increased significantly; tensile/AC breakdown strength declined; | Smaida et al. [75] |

| XLPE/EVA sheets at 165 °C | FTIR shows diffusion-limited oxidation; carbonyl index rise matches dielectric constant and elongation loss | Ji et al. [76] |

| XLPE cables, multi-temperature aging, NIR and FTIR | Carbonyl index, tensile strength, elongation at break, and dielectric loss increased with aging | Li et al. [77] |

| Bio-PE (LDPE), long-term thermal oxidation | FTIR confirms carbonyl growth and chain scission; dielectric deterioration expected | Hedir et al. [78] |

| PEEK, PI, PTFE, aged at 250 °C in humid air | FTIR shows oxidative degradation, which implies a reduction in dielectric performance (breakdown not reported) | Barra et al. [79] |

| Material and Conditions | Key Findings | Ref |

|---|---|---|

| 35 kV and 110 kV XLPE slices, AC stress causing electrical tree growth | PD characteristics evolve with tree development; distinct time–frequency patterns at each growth stage; early detection possible | Gao et al. [80] |

| XLPE specimens underwent cyclic AC voltage | PD emissions recorded over 500 cycles; electrical tree growth monitored and correlated with PD evolution | Chandrasekar et al. [81] |

| Silicone rubber (SIR) under varied mechanical pressure | Electrical tree inception voltage increases under mechanical pressure; tree morphology and PD vary significantly | Su et al. [82] |

| XLPE cables aged thermally and PD-tracked | Dielectric breakdown accelerated by PD; treeing behavior dependent on thermal aging profile | Camalov et al. [83] |

| XLPE and EPR cables, PD progression under thermal cycling | Rate of PD increase strongly correlates with insulation degradation; PD progression metric proposed | Domingos et al. [84] |

| XLPE cable trunk impedance tracking (BIS) | Broadband impedance changes track tree growth; location errors < 3%; capacitance drop indicates degradation | Han et al. [85] |

| Environment | Material/Test Conditions | Main Findings | Reference |

|---|---|---|---|

| Salt-fog environment | Silicone rubber; Salt-fog environment, simulated by generating ultrasonic water–salt mist into the test chamber at 2.5 kg/h with salt particles 1–10 mm; The spray device was first activated, and then a predetermined voltage was applied to the sample to initiate pressure aging for 2, 4, 6, and 8 h in the salt-fog environment with different water conductivity rates (γ20) of 100, 1000, 3000, and 5000 μS/cm | and increased; Change in surface morphology (SEM images) from compact to rough and porous; FTIR spectra showed a hydroxylation and decomposition of alumina trihydrate | Zhang et al. [26] |

| Tropical environment | 33 kV insulators, silicone rubber, on-site test Koggala (KG site), on the west coast of Sri Lanka, and the other one was an inland site situated in Peradeniya (PG site) | Leakage current varied from 0.5 mA to 2 mA with a 16 mA peak | Fernando and Gubanski [27] |

| Radiation environment | Silicone rubber under gamma radiation, dose rates 0.14 and 0.47 kGy/h; Inclined plane test procedure IEC—60587 | Variation in gamma dose did not affect the performance of insulation when AC voltage was applied | Rajini and Udayakumar [28] |

| High-intensity electric fields | Polymeric insulator;Cable samples placed under a DC electric field, 2.4 kV. 10,000 h, aging was performed according to IEC1109/IEC61109-modified standard (equivalent to 15 years of normal operation) | FTIR shows that unfilled SR suffers loss in main peaks at wavenumber 1008 cm−1; of depolymerization. | Ullah et al. [95] |

| Low temperature/icing environment | Silicone rubber 500 kV insulator; Test performed according to IEEE 1783-2009 Standard. | The icing surface density causes a significant drop in the flashover voltage. The study does not examine the degradation effect of icing on the material | Qiao et al. [96] |

| Underground mining environment | PVC sheathing in MYJV-type mining cables TG-FTIR analysis | Thermal decomposition of PVC sheathing occurs in four stages Primary chain scission reaction, occurring in the second stage of PVC decomposition, released a large amount of combustible and toxic gases | Wang et al. [97] |

| Degradation Mechanism | Key Material Effects | Fire-Relevant Consequences | Fire Parameters Affected | Reference |

|---|---|---|---|---|

| Thermal aging/Oxidation | - Chain scission - Carbonyl formation - Reduced crystallinity | - Lower ignition temperature - Increased flammable volatiles - Faster decomposition | Reduced ignition time Increased HRR Increased smoke production | Kim et al. [45] Jiang et al. [98] |

| Electrical degradation (PD, treeing) | - Carbonized paths - Local heating - Surface cracking | - Local hot spots - Arc-induced ignition - Accelerated failure modes | Higher arc frequency Reduced dielectric strength Higher flame probability | Zhang et al. [99] Fard et al. [100] Han et al. [86] |

| Surface tracking | - Conductive carbon trails - Surface erosion | - Flashover risk - Ignition via arcing - Thermal runaway | Higher surface temp Higher ignition risk Higher flame spread rate | Xing et al. [101] Tariq Nazir et al. [102] Li et al. [103] Riba et al. [104] |

| UV/Radiation degradation | - Crosslink scission - Surface embrittlement | - Reduced flame retardancy - Greater crack formation - More volatiles | Lower char yield Higher HRR Higher smoke density | Hedir et al. [78] Liu et al. [25] Maraveas et al. [105] |

| Moisture ingress | - Increased conductivity - Hydrolysis | - Higher leakage currents - Tracking/PD susceptibility - Easier ignition under arc conditions | Higher dielectric loss Lower flashover voltage | Liu et al. [106] Friškovec et al. [107] Ahmad et al. [108] |

| Thermal conductivity degradation | - Reduced k - Local heat concentration Impaired dissipation | - Faster ignition - Hot spots - Enhanced flame propagation | Lower critical heat flux Higher temperature gradients Higher flame spread rate | Liu et al. [71] Kim et al. [109] Gunnarshaug et al. [110] |

| Material/FR | Aging Procedure | Flammability Test/Results | Ref |

|---|---|---|---|

| Long glass fiber-reinforced (LGF) polypropylene/red phosphorus | Thermo-oxidative exposure at 140 °C | UL94, LOI, and cone calorimeter demonstrated no significant effect on | Zhou et al. [113] |

| Long glass fiber-reinforced polypropylene/organic intumescent montmorillonite | Different exposure times at 140 °C | UL94, LOI, cone calorimeter, TGA. Aging reduces the effectiveness of the FR Aging causes ground particles and microscale cracks on the surface | Zhou et al. [114] |

| Long glass fiber reinforced polypropylene/decabromodiphenyl ethane | Thermal-oxidative exposure time (0–50 days) at 140 °C | LOI values varied within statistically insignificant limits with increasing the aging time, UL-94 level maintains a constant V-0 rating | Guo et al. [115] |

| Long glass fiber-reinforced polyamide 6 composites/tris (tribromophenyl) cyanurate | Thermal-oxidative exposure time (0–50 days) at 140 °C | LOI, UL94, cone calorimeter The surface migration effect improved the flame retardancy of the composites with better LOI values, a more protective char layer structure, and excellent UL 94 ratings | Zuo et al. [116] |

| Long glass fiber-reinforced polyamide 6 composite/organo-modified montmorillonite/brominated epoxy resins/antimony trioxide | Thermal oxidative exposure for 50 days. | LOI increased from 25% to 38% UL94 maintained class V0 Contrary to its negative effect in polypropylene composites, OMMT promotes crosslinking at the surface of the polyamide composite and improves its flame retardancy. | Zuo et al. [117] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anghelescu, L.; Handra, A.D.; Diaconu, B.M. Degradation Pathways of Electrical Cable Insulation: A Review of Aging Mechanisms and Fire Hazards. Fire 2025, 8, 397. https://doi.org/10.3390/fire8100397

Anghelescu L, Handra AD, Diaconu BM. Degradation Pathways of Electrical Cable Insulation: A Review of Aging Mechanisms and Fire Hazards. Fire. 2025; 8(10):397. https://doi.org/10.3390/fire8100397

Chicago/Turabian StyleAnghelescu, Lucica, Alina Daniela Handra, and Bogdan Marian Diaconu. 2025. "Degradation Pathways of Electrical Cable Insulation: A Review of Aging Mechanisms and Fire Hazards" Fire 8, no. 10: 397. https://doi.org/10.3390/fire8100397

APA StyleAnghelescu, L., Handra, A. D., & Diaconu, B. M. (2025). Degradation Pathways of Electrical Cable Insulation: A Review of Aging Mechanisms and Fire Hazards. Fire, 8(10), 397. https://doi.org/10.3390/fire8100397