1. Introduction

Owing to the increased demand for contactless services following COVID-19, the logistics industry, including refrigerated and frozen foods, has witnessed a significant growth. This has resulted in an increase in large warehouses for storing goods. These logistics warehouses inherently require a large area to accommodate many items and cause significant human and property damage in the event of a fire. Traditional logistics warehouses have been highlighted for their high fire load owing to vertically intensive storage methods and the fire risk of insulation materials required to maintain constant temperature and humidity conditions in the warehouse.

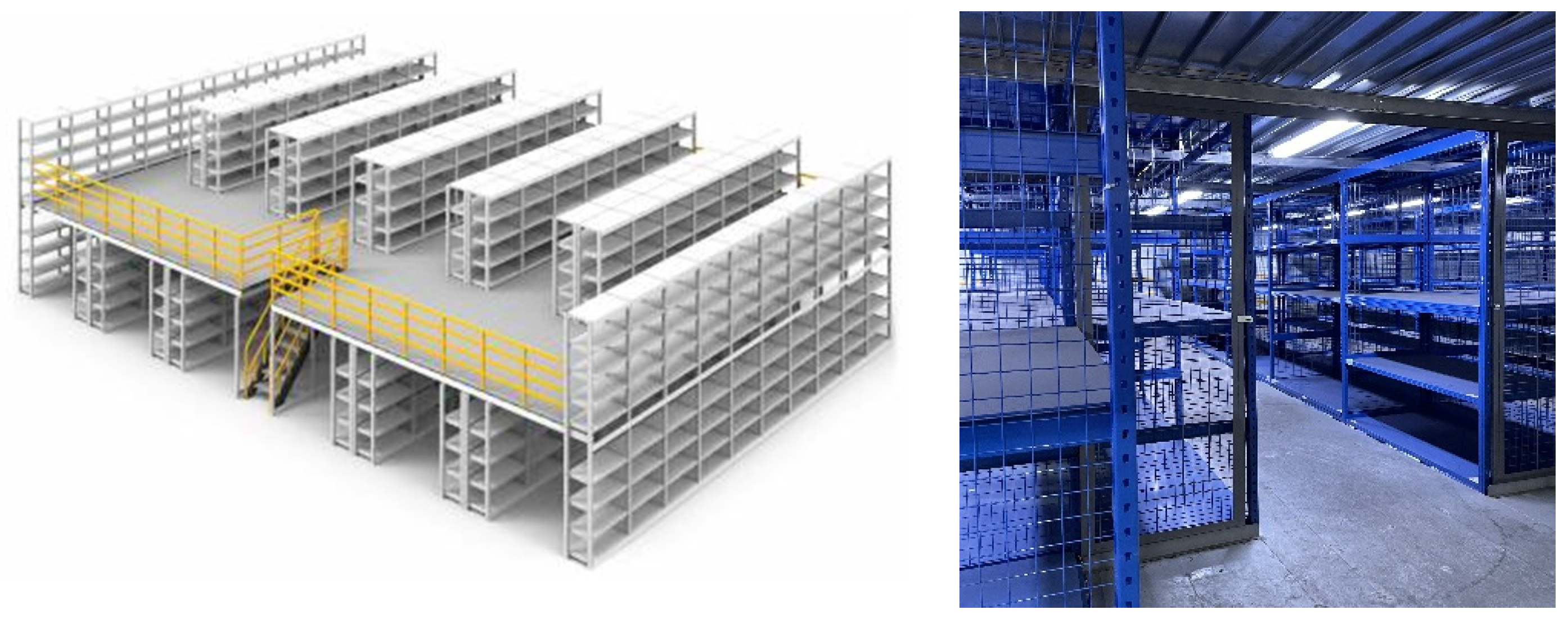

However, the recent rise of heavily automated facilities in logistics warehouses has facilitated a rapid increase in the use of mezzanine floor racking systems (hereafter called “mezzanine racks”) to use space efficiently. A mezzanine rack is a facility designed to maximize storage efficiency from floor to ceiling in single-story warehouses with high ceilings, as shown in

Figure 1. Owing to their high storage efficiency and space utilization, the installation rate of mezzanine racks in logistics warehouses that prioritize economic efficiency has been continuously increasing. In the case of mezzanine racks, low-height and small-sized shelf racks are installed owing to the low ceiling height. In addition, items stored on these shelf racks are often wrapped in extensive plastic packaging and cardboard boxes to protect lightweight or fragile items [

1].

Therefore, it is speculated that in the event of a fire in the shelf racks installed in mezzanine racks, the fire would spread rapidly owing to flames and radiative heat reaching the ceiling, similar to typical compartment fires. However, in contrast to other building uses, mezzanine racks exhibit a very high fire load and a structure that facilitates oxygen supply from all sides. This renders initial fire response challenging and the growth of fire rapid. Despite this, the installation and fire safety measures for mezzanine racks remain inadequate.

In addition, the recent emergence of automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), which are typically operated with built-in lithium batteries in automated logistics systems, also poses a fire safety threat.

These automated facilities are used to transport goods within the warehouse [

2,

3]. Therefore, in many logistics facilities using automated systems, the distance between racks is greatly reduced to increase the storage efficiency of mezzanine racks. This is because small robots like AGVs and AMRs transport items internally, excluding human entry. Owing to the heightened fire risk because of the use of lithium batteries, there have been increasing concerns regarding the risk of large fires owing to the reduction in the spacing of mezzanine racks.

However, there is a lack of appropriate data from full-scale experiments related to the intensity of fires and radiative heat flux based on spacing distances in mezzanine racks. Therefore, full-scale fire experiments are necessary to prevent large warehouse fires in the continuously increasing number of logistics facilities.

In particular, in warehouse facilities, full-scale fire experiments are rare owing to the high fire load from vertically intensive item storage. Choi and Yeo conducted fire experiments based on on-site investigations of six rack warehouses, targeting pallet unit items [

4]. However, owing to the variety of stored items, it was difficult to select standard items; thus, combustibles were selected based on the classification criteria provided by FM Global. In contrast to the experimental results of single-layer pallets, it was predicted that the fire characteristics would differ with an increase in the number of layers, highlighting the need for further experiments. Furthermore, no specific performance standards exist for fire protection systems for mezzanine racks employed in logistics facilities in Korea. The fire safety performance standards for warehouse facilities (NFPC 609), which are implemented as countermeasures against fire risks in such facilities, contain only regulation concerning stacked racks and the inclusion of each level’s floor area in the protected area. Therefore, despite various factors indicating the high risk associated with mezzanine racks, the current guidelines involve installing fire protection systems at the same level as those for standard buildings. Considering this, a risk assessment should be conducted in advance to establish at least the minimum performance standards necessary to implement appropriate countermeasures in these facilities.

Ren derived four risk assessment criteria based on fire cases to evaluate fire risks in logistics warehouses. Consequently, they designed a fire risk assessment model by reviewing expert surveys and the Analytic Hierarchy Process (AHP), which is a comprehensive evaluation method [

5]. In addition, a method to quantitatively assess the risk level of the evaluation model by composing weights for the risks was proposed.

Trapp and Rangwala simulated warehouse fires and modeled the placement and number of sprinklers inside the rack and on the ceiling. Consequently, they evaluated appropriate fire control for the optimization of a sprinkler system for mitigating damage in industrial facilities [

6].

Goran et al. developed a method based on the COPRAS multi-criteria decision-making method to determine potential hazards for the identification of fire risk zones in warehouses. Consequently, they proposed a method to display risks in a three-dimensional (3D) model during the warehouse layout planning stage [

7].

FM Global classifies combustible grades of logistics facilities, which are difficult to standardize, into five classes for standardization. Combustibles are classified according to their type. Class I includes non-combustible materials, items packaged in corrugated fiberboard boxes, and wooden pallets or flame-retardant pallets. Class II includes non-combustible materials, slatted wood or wooden boxes, and wooden pallets or flame-retardant pallets. Class III includes cellulose materials such as wood and paper, with part or all of the stored items being light plastics, and medium or high-grade plastic forming 5% or less of the stored items’ weight or volume. Class IV includes stored items where 5% or more of the total weight or volume is medium-grade plastic or 5–40% is high-grade plastic. Finally, Class V includes stored items where 40% or more of the total weight or volume is high-grade plastic. To reduce risks in such warehouse facilities, FM Global recommends designing fire protection for rack warehouses based on the most hazardous items owing to the variety of items mixed in storage [

8].

Lönnermark and Ingason conducted scaled fire experiments with four rack storage systems arranged side by side across six scenarios. The racks were spaced 0.48 m apart, and the impact of fire spread concerning ceiling presence and ignition points without the initial suppression system was examined. Consequently, they verified that the ceiling height affected fire spread. As the rack height decreased, the combustion conditions varied, thereby reducing the combustion efficiency [

9].

Thus, most existing studies have been limited to experimental research on reduced or unit pallets, classification based on combustible arrangement, or risk grading at the design stage. Therefore, this study aimed to conduct a full-scale fire experiment by implementing a mezzanine rack formed inside logistics facilities to verify the fire spread risk by considering the shape of the mezzanine rack. In this study, based on field surveys of actual sites and a comparison of mezzanine racks, the types of stored combustibles and separation distances between racks were identified. Subsequently, full-scale fire experiments were conducted to determine the ignition potential based on the spacing of the mezzanine racks. The necessity of establishing fire safety standards for mezzanine racks was also reviewed.

2. Selection of Shelf Rack Size through On-Site Investigation

This investigation was conducted on five rack warehouses located in Korea and was limited to those using shelf racks or with mezzanine racks installed. On-site investigations were conducted based on the following survey items; however, owing to internal security issues, photography was restricted:

- -

The structure type and detector installation of the mezzanine;

- -

The cushioning materials used for item storage;

- -

The size of shelf racks used internally;

- -

The aisle width inside the mezzanine.

First, the results of the structure type and detector installation of the mezzanine are presented in

Table 1. Except for facility E, which only operated shelf racks without installing mezzanine racks, all logistics facilities used steel-structured mezzanine racks. Regarding detectors, heat and smoke detectors were the most common, and one facility used an air suction type. However, in facility C, the mezzanine was installed prior to the enactment of the fire safety regulations for mezzanines; thus, a retroactive application of the relevant regulations did not occur, and neither detectors nor sprinklers were installed. Regarding sprinklers, two facilities used pre-action types, and one used a wet type. For the purpose of preventing damage to items stored on shelf racks, four facilities used expandable polystyrene (EPS) as cushioning material which was placed at the bottom inside cardboard boxes with items placed on top, and one facility used plastic sheets inside cardboard boxes.

In addition, based on on-site observations, while not universally applied across all shelf racks, certain facilities utilized corrugated fiberboard to partition the interiors of shelves to facilitate the efficient usage of space. This is believed to be because of the characteristics of mezzanine racks, which aim to maximize space efficiency by placing numerous small items and thus partition shelves to facilitate item organization.

The results summarizing the sizes and aisle widths of the shelf racks are presented in

Table 2. They were categorized according to the types of shelf racks used internally (types 1–5). The names of the parts of the shelf rack are shown in

Figure 2. The width varied from 0.15 to 1 m; however, the most common range was 0.45–0.6 m. The depth varied in the range of 0.9–1.85 m, with the most common range being 1.2–1.55 m. Furthermore, the height of a single unit of the shelf rack varied in the range of 0.4–2 m, but the most common range was 0.42–0.6 m. However, due to the variety of sizes according to the survey results and stored items, it was deemed most appropriate to estimate the height of the shelf rack based on the average size of a single unit. Thus, the dimensions of (width) 0.57 m × (depth) 1.31 m × (height) 0.63 m were selected. Although the rows were arranged in various ways, considering the size of the full-scale experiment, it was deemed most appropriate to arrange them into two rows; otherwise, conducting a comparison with the on-site survey results would be difficult.

The aisle width, which refers to the spacing distance between shelf racks, is in the range of 0.8–3.46 m. However, only three types were spaced more than 3 m, with most of them being within the range of 1.0–1.5 m. Furthermore, four types had spacing of less than 1 m among all samples. The heights of the shelf racks were in the range of 1.29–3.0 m, with most being within 1.6–1.9 m.

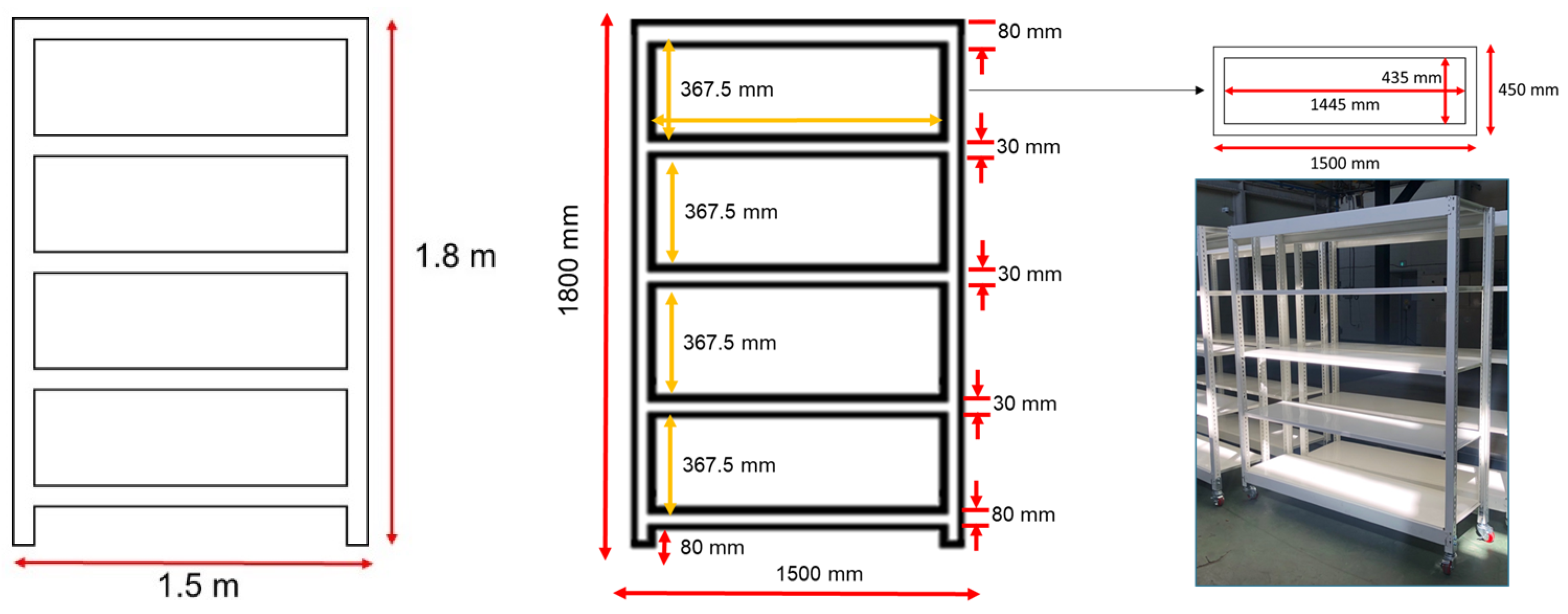

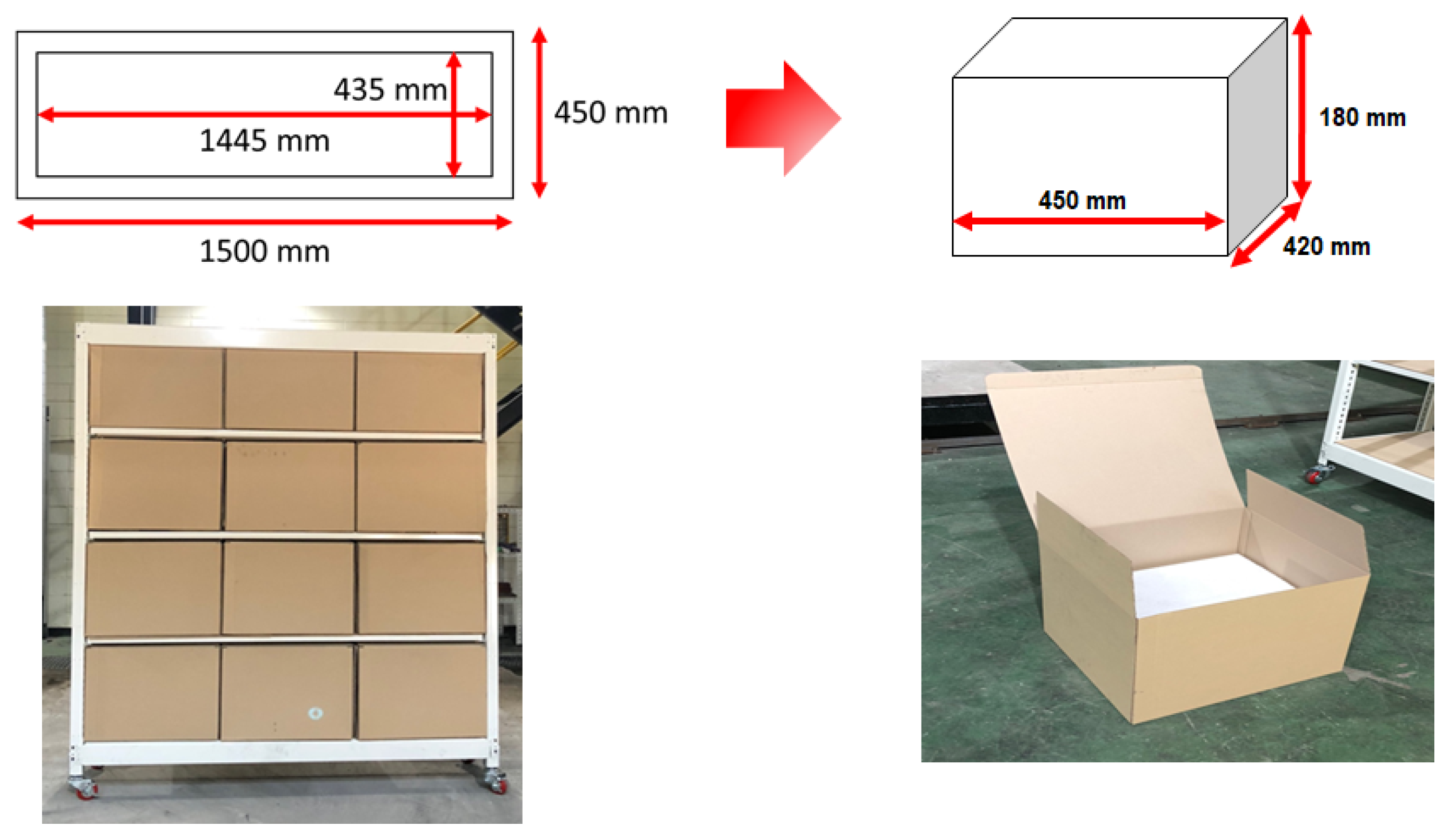

Shelf racks over 2 m in height were found to be in mezzanines that were sufficiently large to facilitate the AGVs in moving the racks themselves or using small forklifts to enter. Based on the measurements obtained from the on-site investigation, a shelf rack of the most similar size among commercial products was found, with dimensions of (width) 1.5 m × (depth) 0.45 m × (height) 1.8 m, comprising four tiers in total. Details of the size of the shelf rack are shown in

Figure 3.

3. Shelf Rack Fire Experiment for Fire Behavior Analysis

3.1. Preliminary Experiment

The on-site investigation for the fire experiment revealed that the variety of combustibles stored inside was very diverse to facilitate standardization. In particular, the characteristics of combustibles varied according to each material’s properties [

10], rendering it difficult to quantitatively assess the risk [

11]. However, considering the complex mixture of various combustibles in logistics facilities, it was deemed appropriate to conduct evaluations based on the most hazardous combustibles [

8,

12]. Therefore, the fire experiment was conducted using high-risk combustible grades suggested in Class V by FM Global [

8].

The on-site investigation also confirmed the use of corrugated fiberboard to partition the insides of shelves for the convenience of item placement. As this is a separate condition from the characteristics of stored combustibles, the corrugated fiberboard used to partition shelves must be considered as a risk variable for combustibles.

Before conducting the experiment, preliminary tests were performed on unit combustibles to review their complete combustion and characteristics to select the combustibles for the full-scale experiment. As items stored on shelf racks were often cushioned with EPS to prevent damage and facilitate storage, the preliminary experiments were divided into four categories (

Table 3) to consider the fire risk owing to cushioning materials. The experimental conditions are presented in

Table 3. Corrugated fiberboard with a length of 121 cm was used; it was bent into a U-shape to partition all exposed parts.

To facilitate a more accurate identification of the combustion characteristics of individual combustibles, ignition was induced using minimal ignition energy by applying 10 mL of heptane to cotton wool as the ignition source [

13].

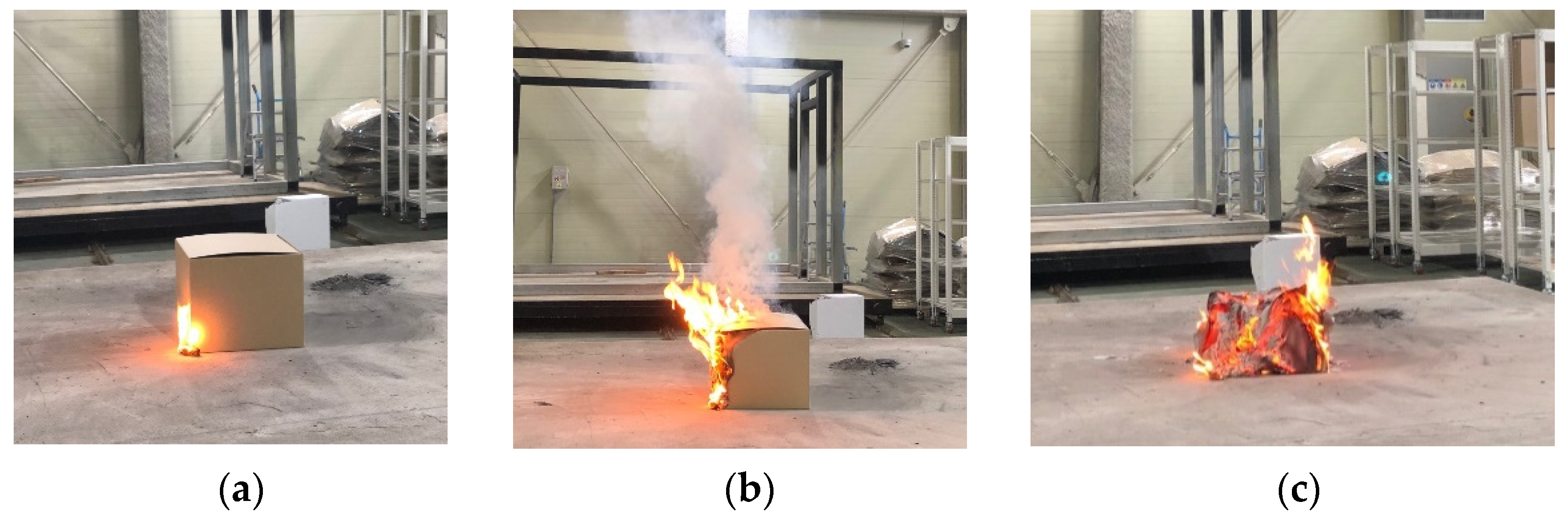

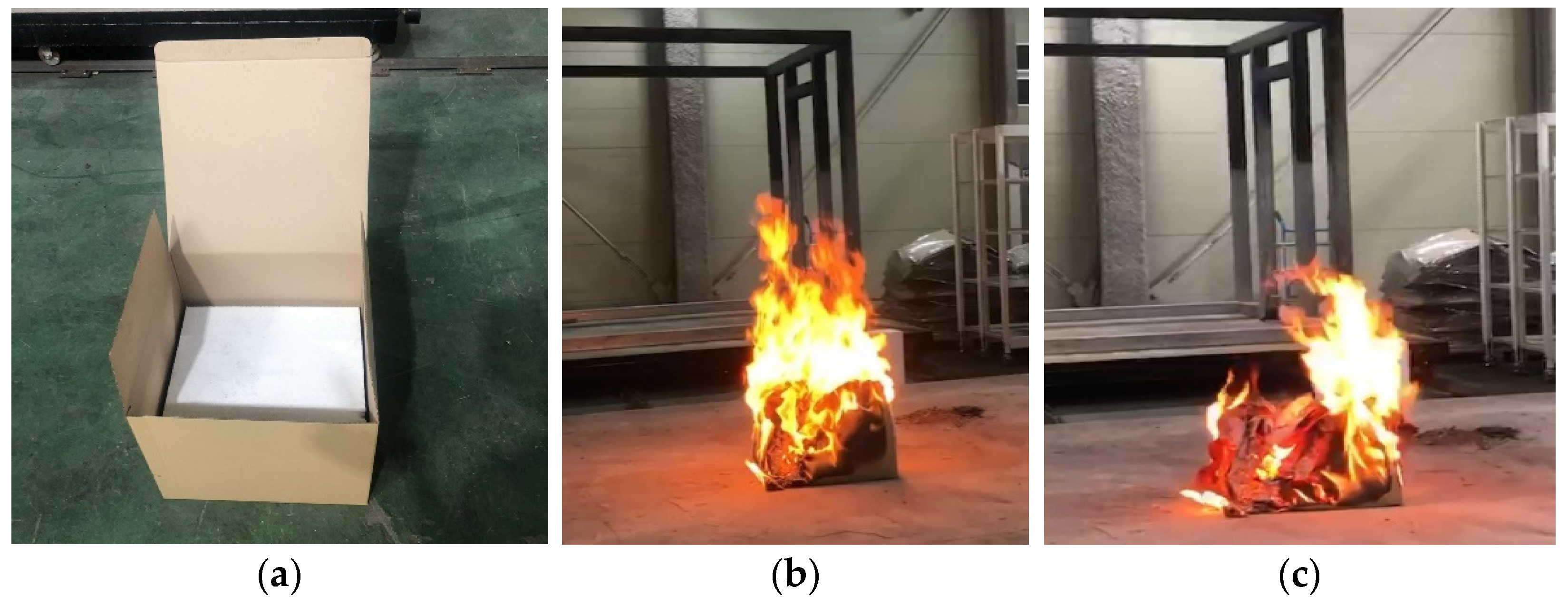

The experimental results are as follows: P-Case 1 involved a single cardboard box, as shown in

Figure 4. It burned smoothly and completely combusted in approximately 13 min.

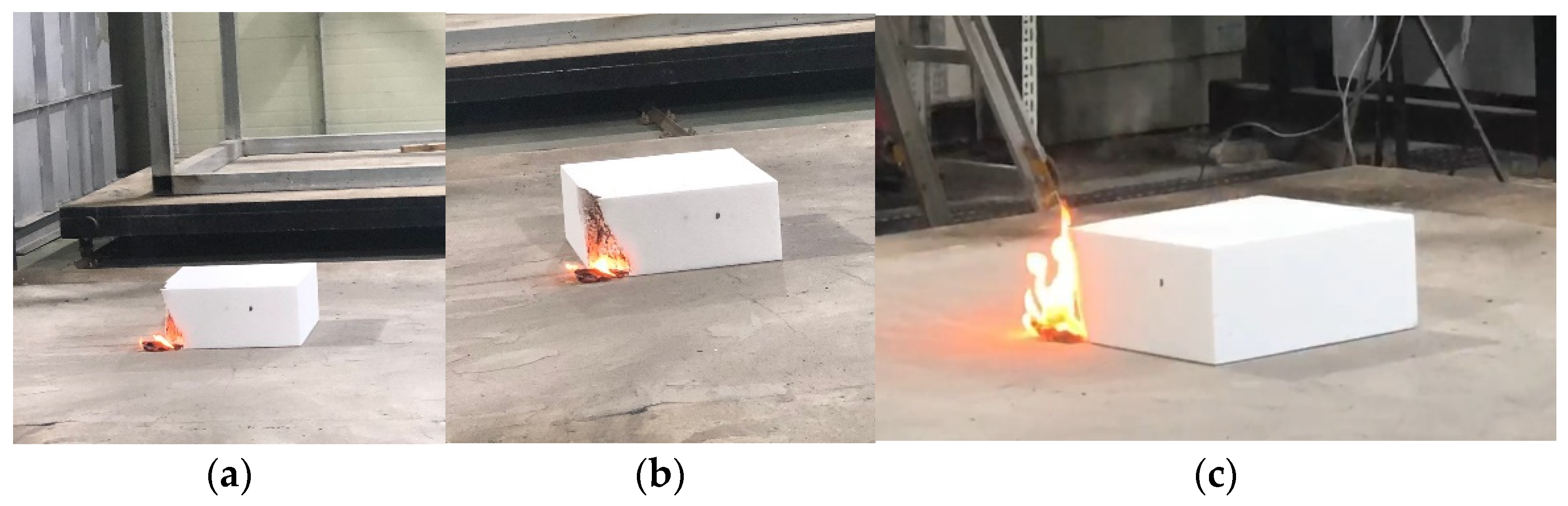

P-Case 2 involved a single piece of EPS. As shown in

Figure 5, it did not burn smoothly from the initial ignition. After approximately 5 min, the melting EPS caused the flames to drop to the ground, which stopped the fire from growing further. Thereafter, the flames began to diminish and eventually extinguished. P-Case 3, which involved a box and EPS, burned for the longest time, as shown in

Figure 6. Notably, although EPS did not cause the growth of fire when it melted as a single combustible, it caused rapid fire growth after a certain time when inside a cardboard box.

P-Case 4 involved a box, EPS, and corrugated fiberboard configuration, with the box and EPS placed on the shelf rack and the shelf interior partitioned via corrugated fiberboard, following the form observed during the on-site investigation. The size of the combustibles placed inside is shown in

Figure 7.

As shown in

Figure 8, approximately 7 min and 30 s after ignition, flames spread to all of the boxes. Initially, the fire spread vertically when ignition occurred at the bottom; however, a gradually horizontal spread was observed. Once the fire reached the combustibles located at the far right of the bottom, extinguishing activities were conducted for safety reasons.

The investigation of the combustion characteristics of the combustibles revealed that single combustibles, such as cardboard boxes and EPS, had short combustion times or did not burn smoothly owing to melting and other reasons. However, when EPS was used as a cushioning material inside a cardboard box, the combustion time increased, and the EPS, which did not burn smoothly alone, fully combusted. This suggests that owing to the characteristics of mezzanine racks, where items are stored with cushioning materials to prevent damage, these materials should be considered high-grade combustibles and reflected in the design. However, to investigate the effect of partitioning of the shelf interior by corrugated fiberboard on the combustion growth of the internal combustibles, additional fire experiments were conducted on shelf racks based on the type of combustibles.

3.2. Examination of Combustion Behavior of Shelf Racks by Type of Combustible

The types of combustibles involved were composed of corrugated fiberboard + EPS, corrugated fiberboard + cardboard box, and corrugated fiberboard + cardboard box + EPS. The fire growth and complete combustion times were measured to select the most hazardous type of item.

Corrugated fiberboard was frequently observed being used to partition shelves. Thus, to examine its impact on fire spread in shelf racks and, consequently, select the most hazardous level of combustible, the conditions inside shelf racks were set as shown in

Table 4.

In addition, to visually represent the fire temperature at the maximum growth point through combustibles, thermal imaging was performed using a thermal imaging camera. The camera model used for thermal imaging was the FLIR T560 from TELEDYNE FLIR (Wilsonville, OR, USA). Although the equipment had a mode for high-temperature measurement, as the high-temperature shooting mode was only measured in the range of 300–1500 °C, accurately tracking the initial fire spread was difficult. Therefore, in this experiment, the temperature characteristics from the initial fire growth were observed with a maximum temperature range of 0–650 °C. Therefore, the maximum temperature, considering an error margin of ±2%, was recorded as 660 °C.

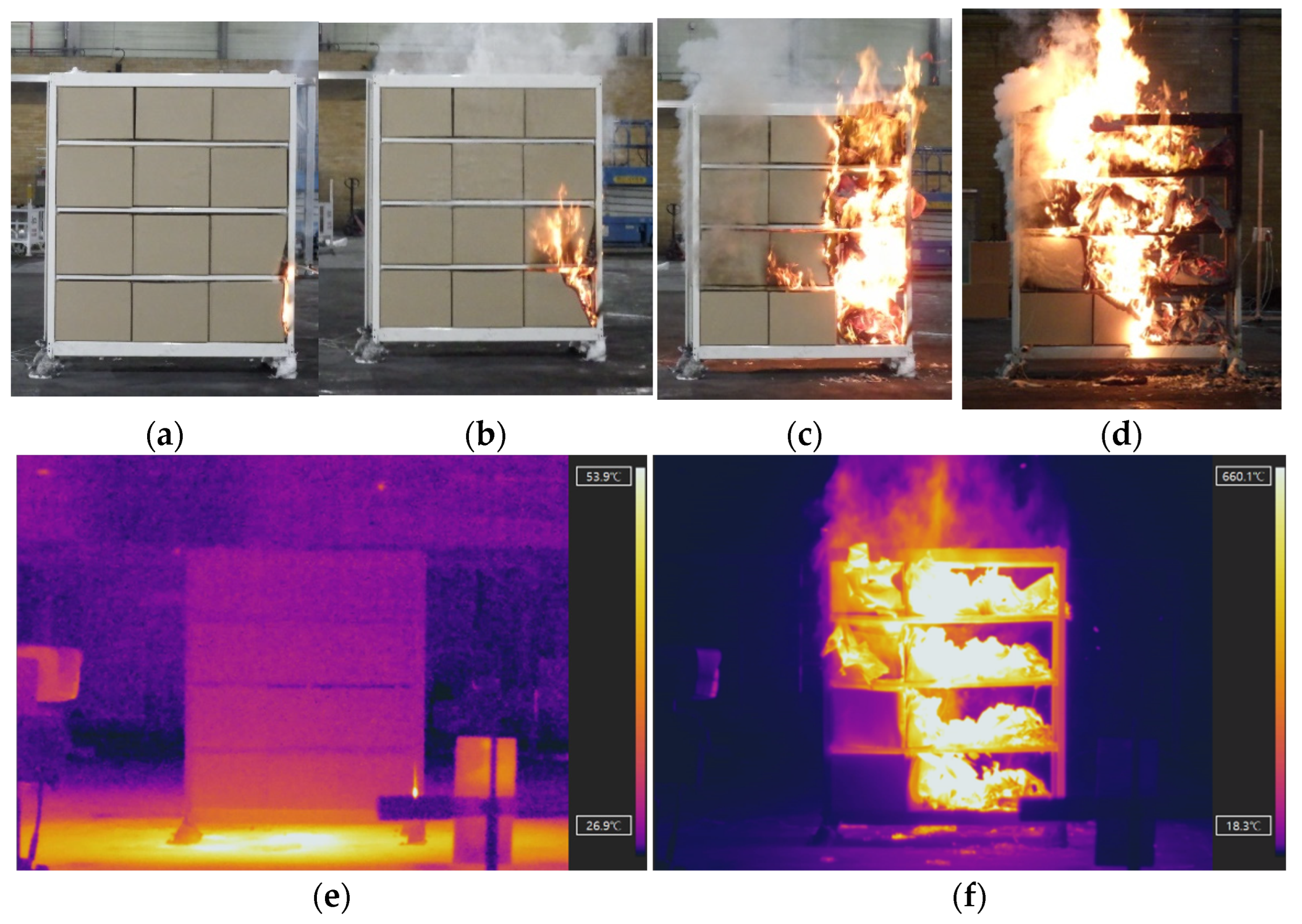

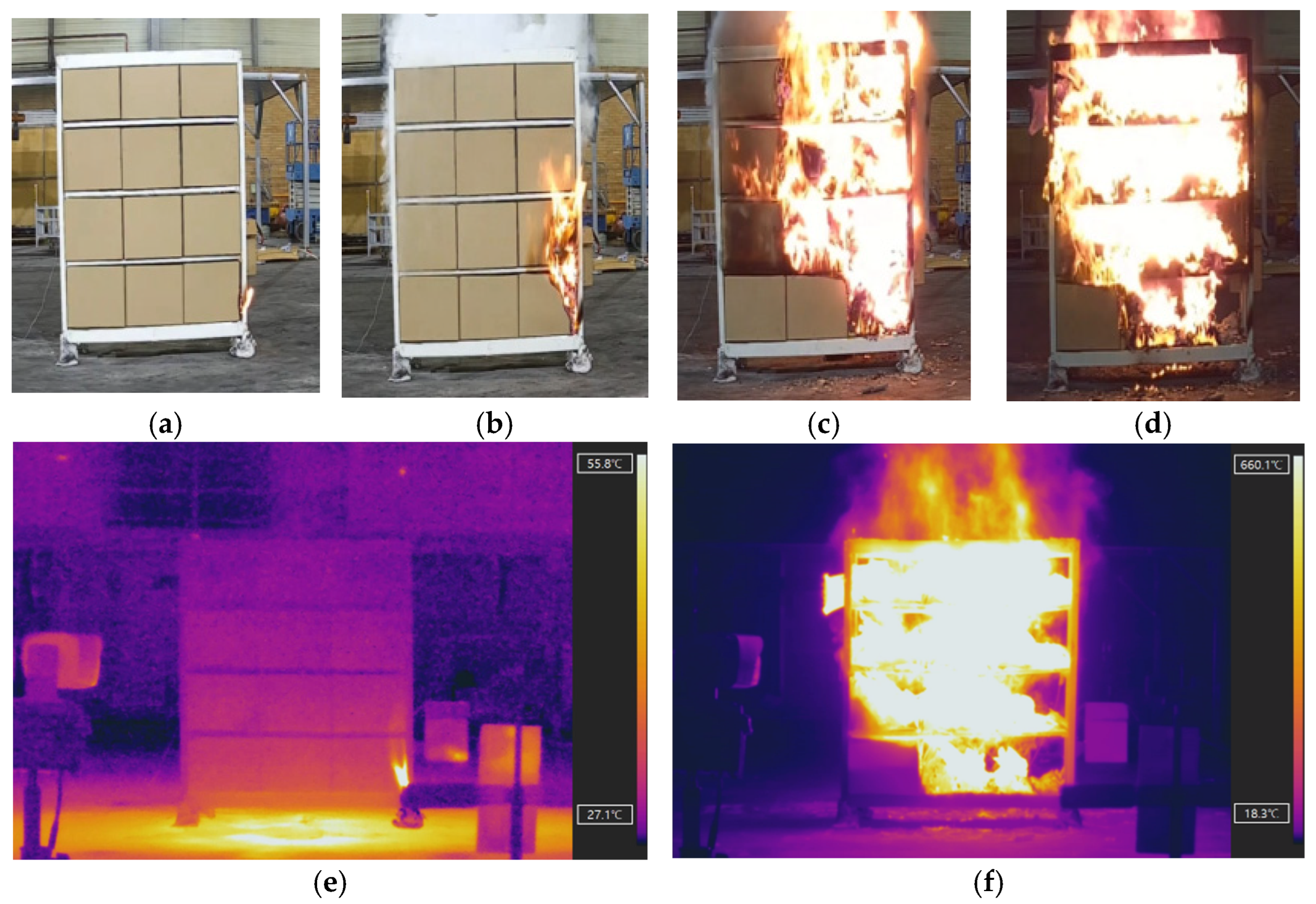

The experimental results for Case 1 are shown in

Figure 9. The fire, which began at the lower right corner, exhibited a delay in combustion within the partitioned area for approximately 5 min without spreading further. However, approximately 6 min after ignition, the fire spread to the corrugated fiberboard and the flames began to grow rapidly, expanding beyond the corrugated fiberboard partition at approximately 7 min. Approximately 8 min after ignition, the fire spread to the entire rack, and the maximum temperature recorded inside the shelf rack at the peak of the fire was 660 °C. The initial combustion behavior was almost identical to the experiment conducted with a single piece of EPS. However, once the fire ignited the corrugated fiberboard, it spread throughout the rack. Most combustibles were completely burned approximately 13 min after ignition, and the maximum temperature lasted for approximately 5 min.

The experimental results for Case 2 are shown in

Figure 10. The fire, which began at the edge of the box approximately 30 s after ignition, began to spread vertically approximately 2 min after ignition. Furthermore, approximately 3 min after ignition, vertical fire spread was observed, followed by horizontal fire spread. Approximately 6 min after ignition, the fire spread to the entire rack. The maximum temperature recorded inside the shelf rack at the peak of the fire was 660 °C. Most combustibles were completely burned approximately 11 min after ignition, and the maximum temperature lasted for approximately 5 min.

The experimental results for Case 3 are shown in

Figure 11. The fire began to spread vertically approximately 1 min 30 s after ignition. Approximately 3 min after ignition, vertical fire spread was observed, followed by horizontal fire spread. Furthermore, approximately 6 min after ignition, the fire spread to the entire rack. Most combustibles were completely burned approximately 18 min after ignition. The maximum temperature recorded inside the shelf rack at the peak of the fire for Case 3 was 660 °C, and the maximum temperature lasted for approximately 12 min.

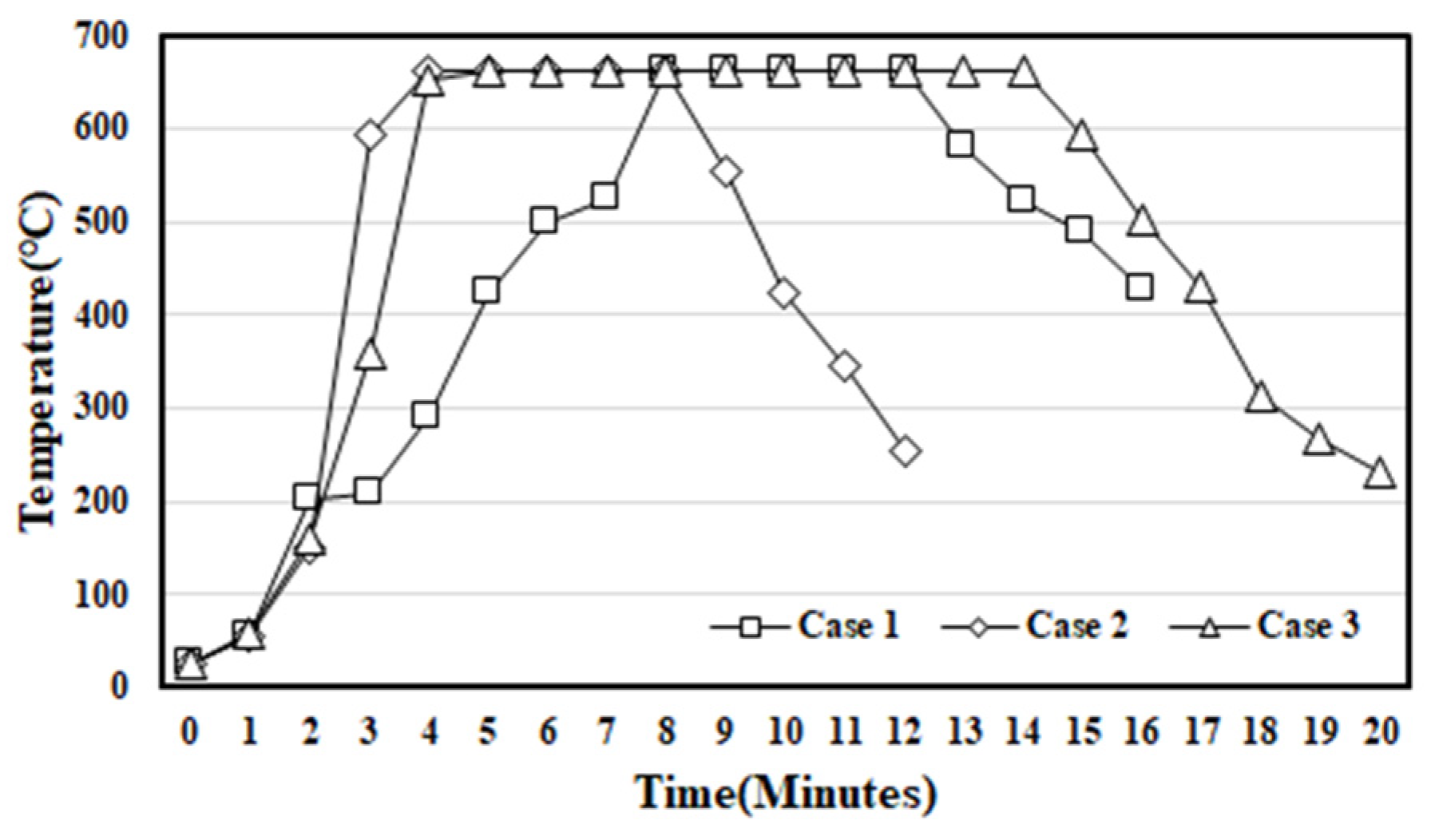

The time from the peak of the fire to complete combustion is shown in

Figure 12. Considering the fire duration, Case 3 had the longest fire duration among the combustible conditions.

Therefore, the more complex the combustibles inside the shelf rack, the higher the fire risk, and the longer and more intense the actual fire duration. The preliminary experiment showed that EPS, which did not cause fire growth when used alone, exhibited explosive fire growth and prolonged combustion when combined with corrugated fiberboard and a cardboard box. Thus, corrugated fiberboard acted as a catalyst for smooth fire growth inside the shelf rack. Therefore, the combination of corrugated fiberboard, a cardboard box, and EPS was the most hazardous condition for combustibles inside the shelf rack. Thus, the full-scale fire experiment was conducted based on this condition.

4. Full-Scale Fire Experiment on Mezzanine Racks

4.1. Experiment Overview and Method

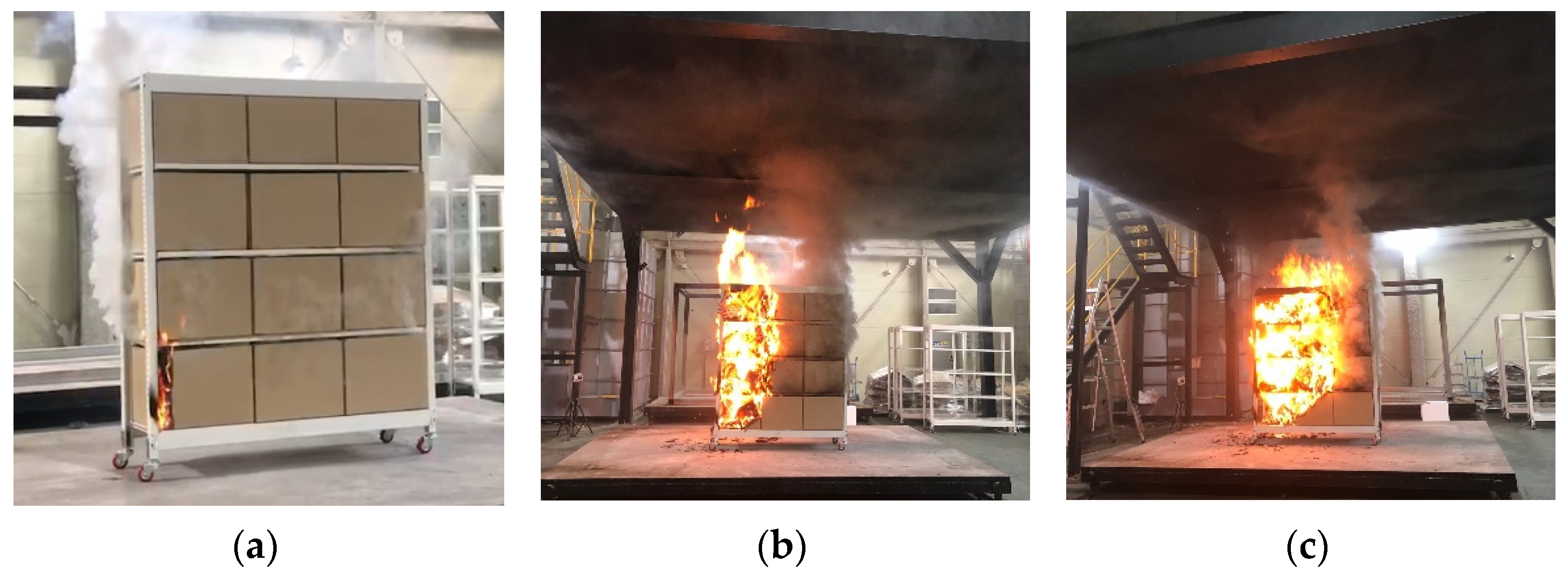

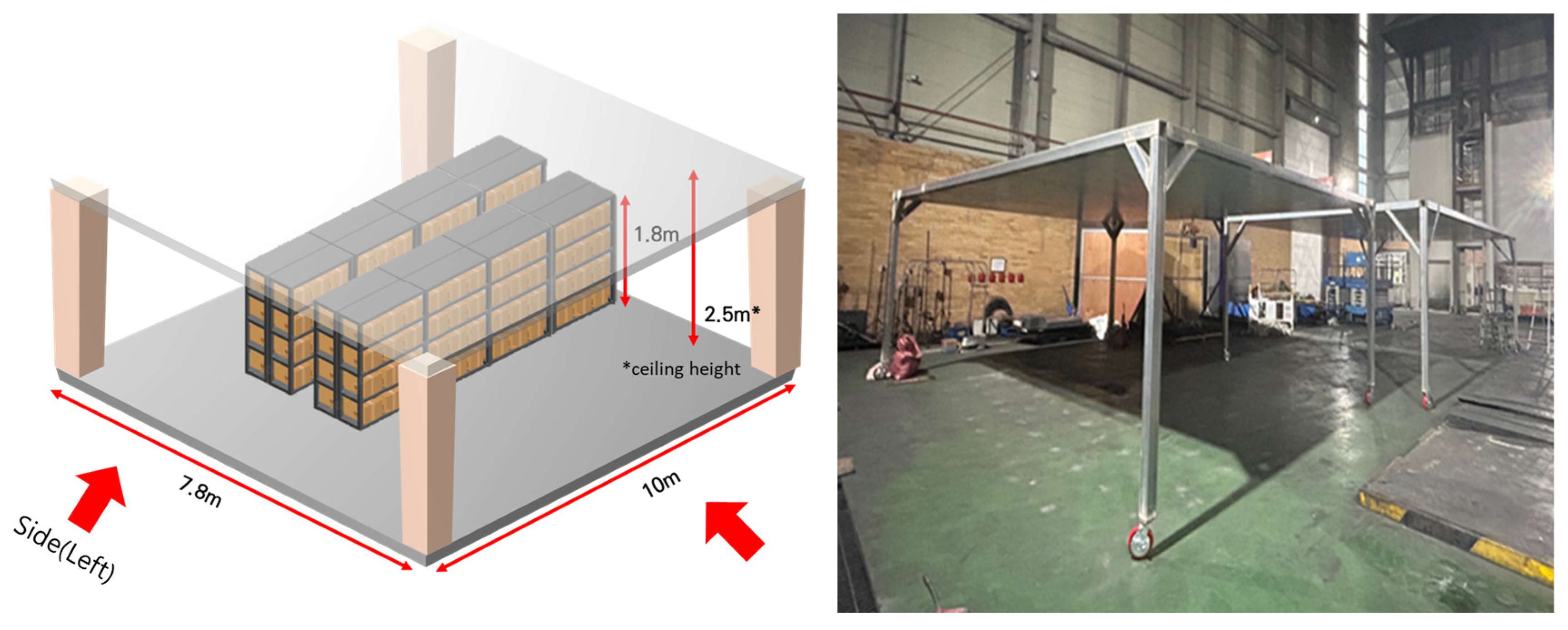

This experiment was conducted to examine the spacing distance according to fires occurring in mezzanine racks by constructing the following test setup. The overview of the test setup simulating the form of mezzanine racks is shown in

Figure 13. The test setup measured 5, 7.8, and 2.6 m in width, depth, and height, respectively. Two such setups were created and combined to form an environment similar to a mezzanine rack.

The conditions of the shelf racks inside the test setup were the same as those used in the single shelf rack fire experiment. The most hazardous condition was determined to be the combination of corrugated fiberboard, a cardboard box, and EPS, which was used for the full-scale fire experiment.

The experiment involved igniting the central lower part of the eight shelf racks arranged in two rows to examine whether flames spread according to the difference in aisle width. However, owing to the nature of the full-scale experiments, there was a limit to the number of experiments. Therefore, radiative heat flux caused by the combustibles inside was examined first using the eight shelf racks to measure the radiative heat flux according to the spacing distance.

4.2. Measurement of Radiative Heat Flux by Spacing Distance

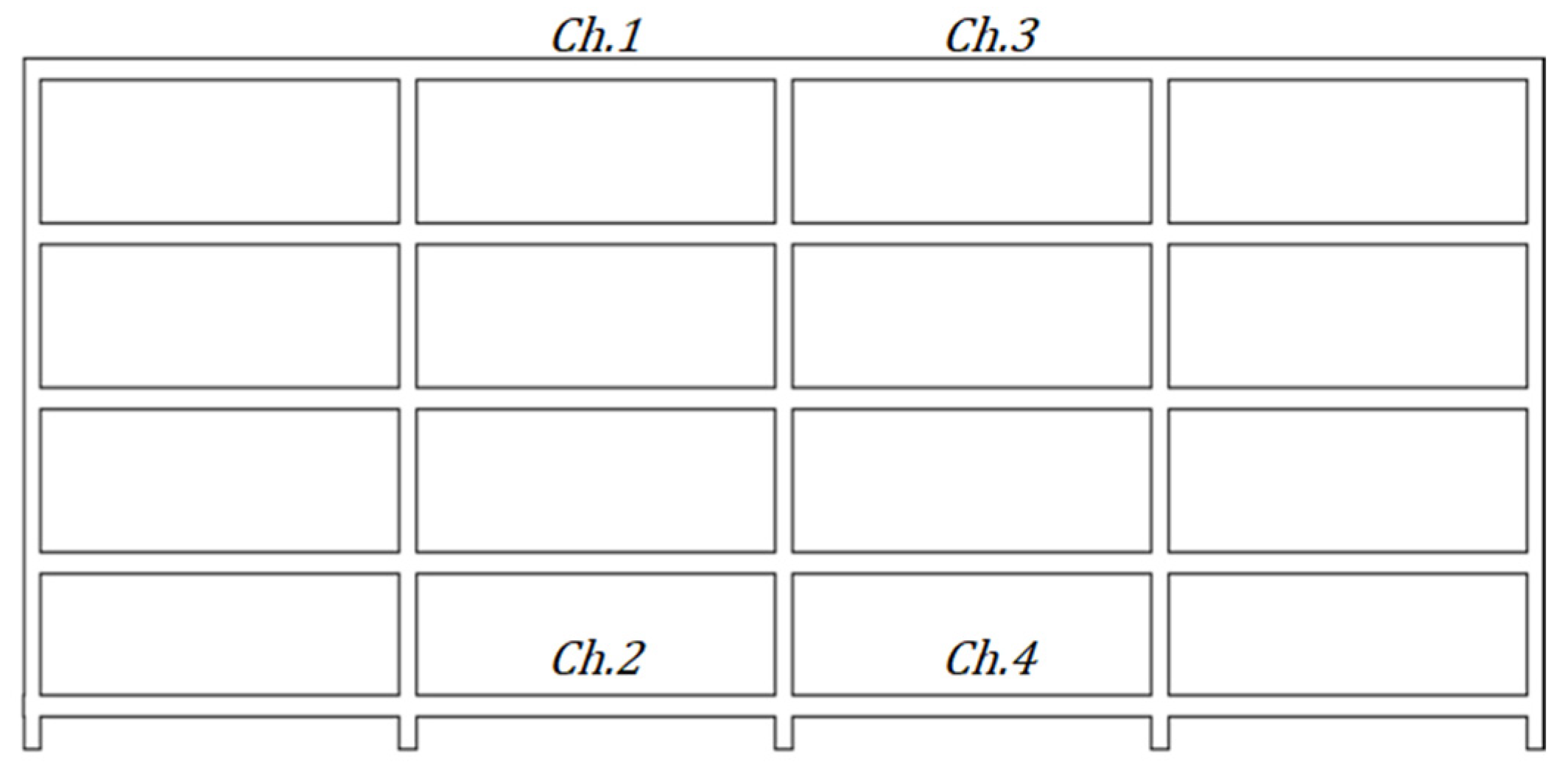

The spacing distance for measuring radiative heat flux was based on data obtained from on-site investigations. The results from the on-site investigations indicate that the most common spacing distance between racks was in the range of 1.0–1.5 m; thus, the distance conditions were set to 1.0, 1.2, and 1.5 m. The arrangement of the test setup is shown in

Figure 14.

Eight shelf racks were arranged in two rows, and heat flux sensors were installed according to the distances. The heat flux sensor used was the SBG01 water-cooled heat flux sensor (Hukseflux/Delft, The Netherlands) that can measure radiative heat up to 200 kW/m2.

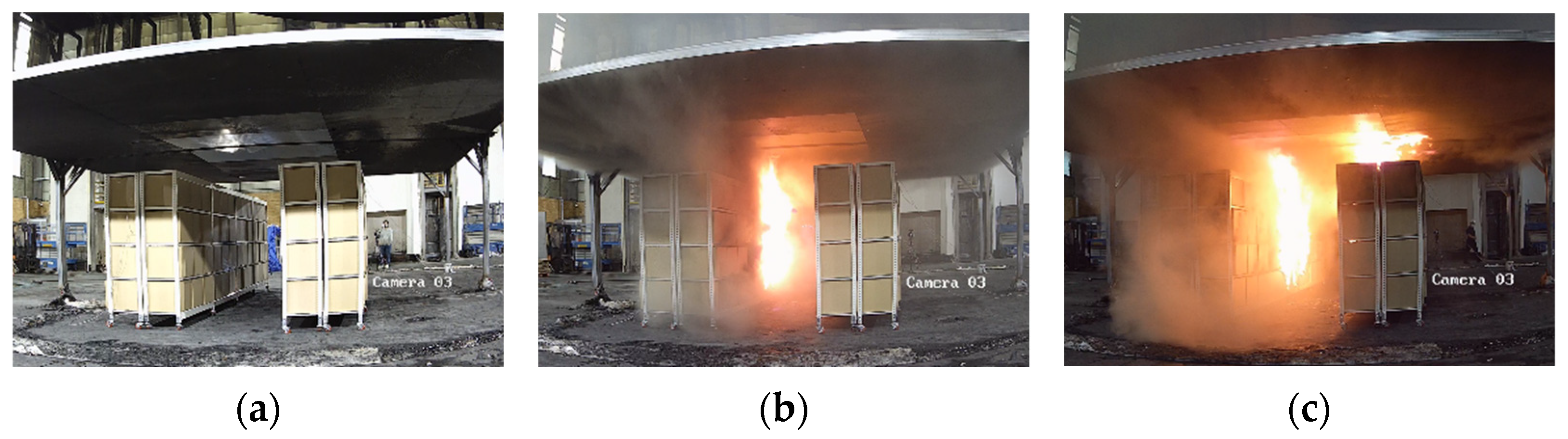

The experimental process is shown in

Figure 15. It was assumed that the initial fire occurred at the center lower part of the rack, and ignition was performed. Immediately after ignition, white smoke began to appear from areas where the corrugated fiberboard was not tightly partitioned. Approximately 2 min and 30 s after ignition, vertical fire spread began. Approximately 4 min after ignition, vertical spread was complete, and horizontal fire spread occurred. At this point, the amount of black smoke increased, and flames began to be observed from the back of the rack. Approximately 6 min after ignition, flames and heat reached the ceiling, causing fire spread at the top of the rack. Then, approximately 7 min 50 s after ignition, extinguishing was conducted owing to concerns regarding fire spreading beyond the test setup. However, during the extinguishing process, the parts ignited with EPS did not extinguish smoothly, thereby requiring considerable time for extinguishing using water.

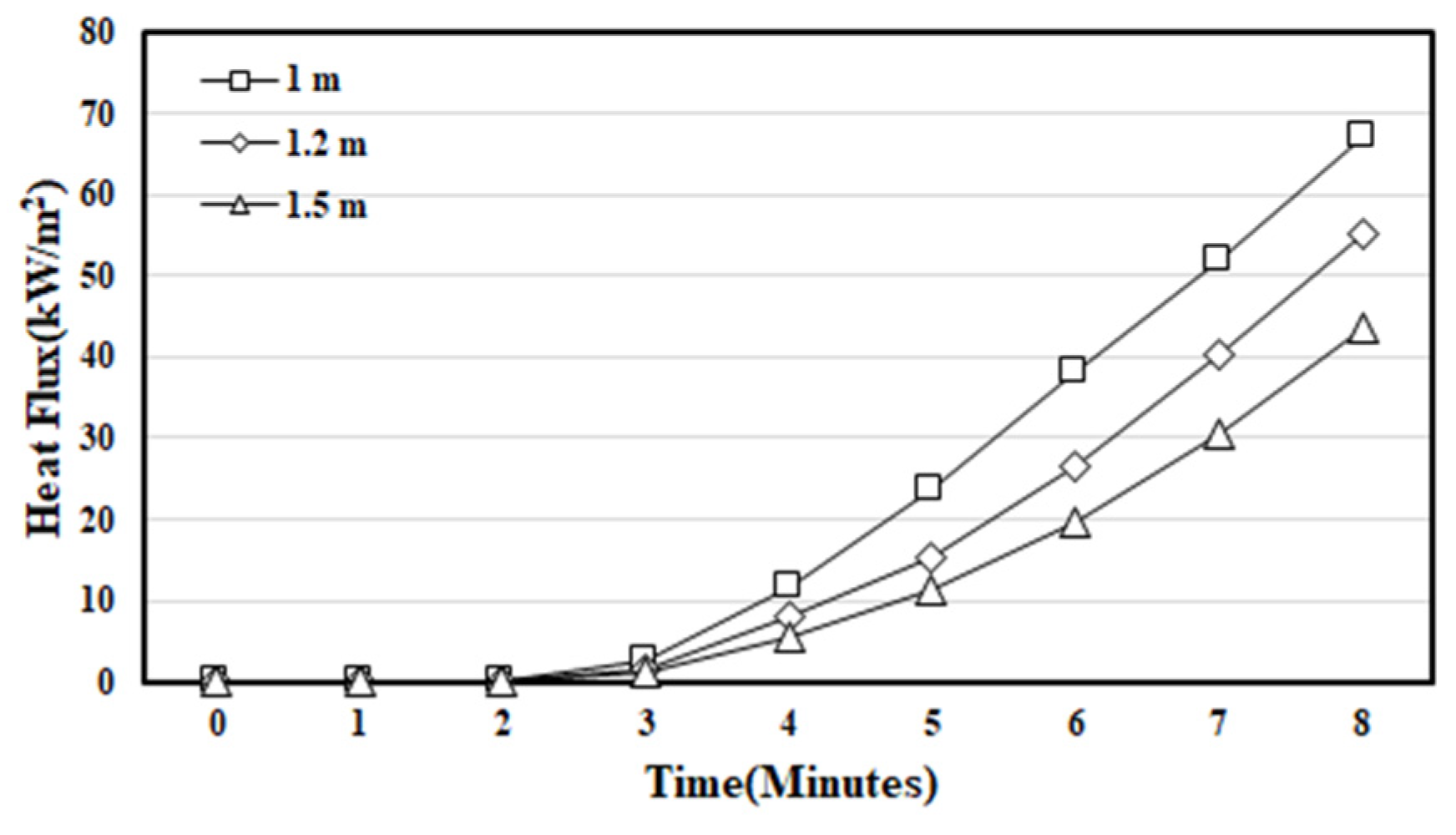

The radiative heat measurements are shown in

Figure 16. The maximum radiative heat flux at each point was 67.3, 55.3, and 43.7 kW/m

2 at 1.0, 1.2, and 1.5 m, respectively. Considering that flashover in indoor settings is judged to occur when the radiative heat flux reaching the floor exceeds 20 kW/m

2 [

14,

15,

16,

17,

18], it was estimated that there was a high risk of fire spreading to adjacent areas and beyond the mezzanine rack.

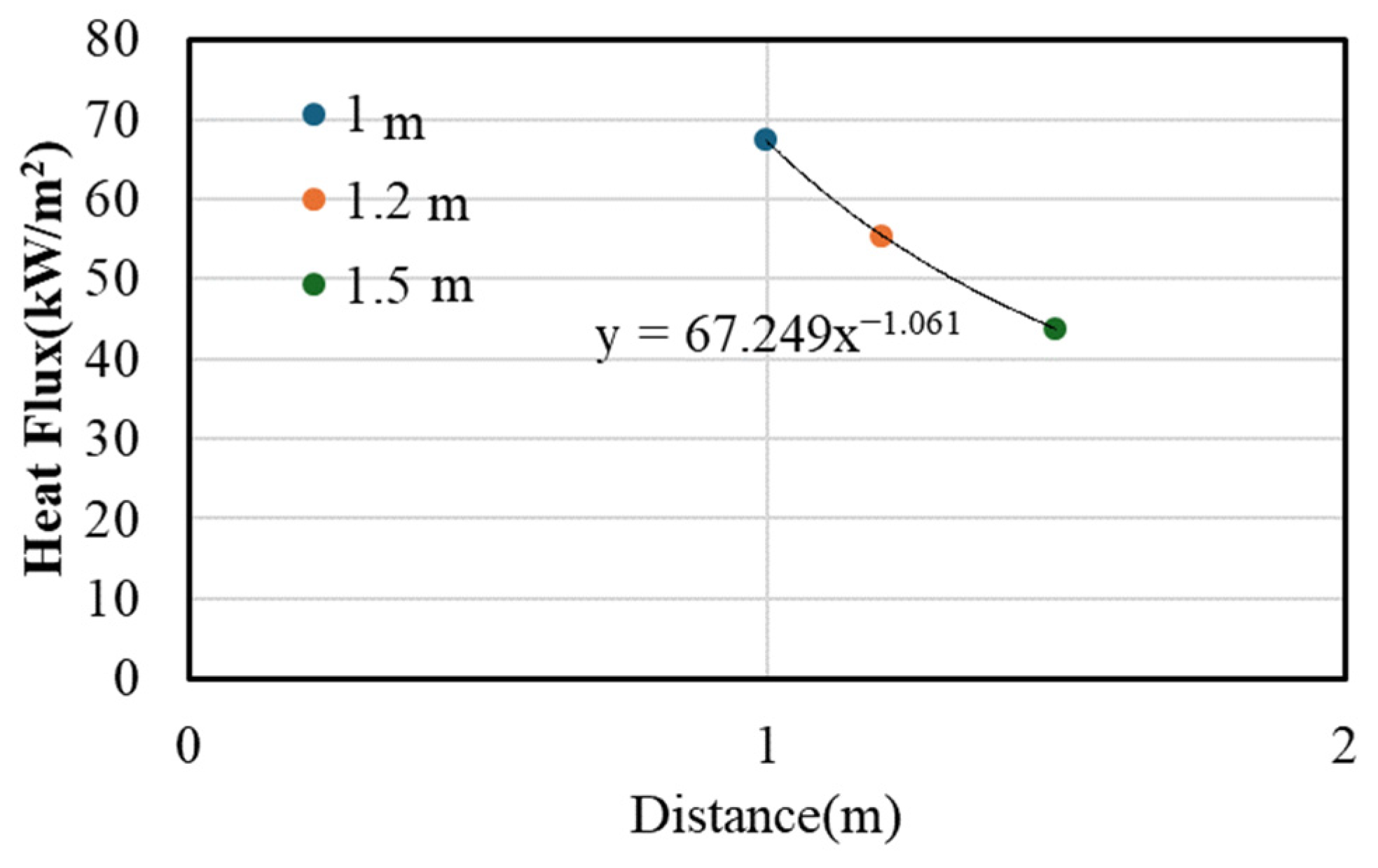

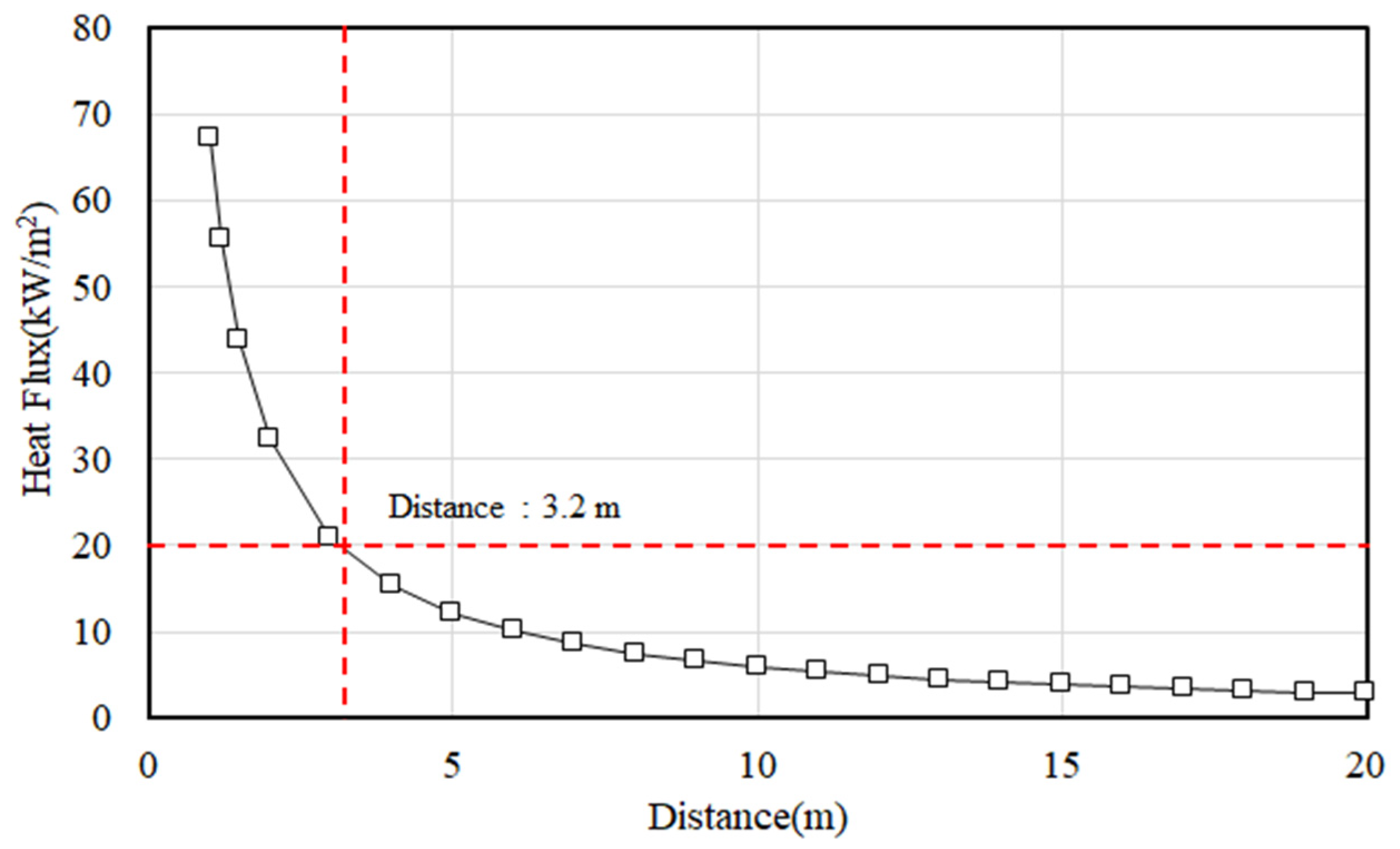

Figure 17 shows the results of the regression analysis based on the maximum heat flux, and Equation (1) is the resulting formula. Here,

q″ represents the radiative heat flux (kW/m

2), and d represents the distance (m) from the edge of the fire source.

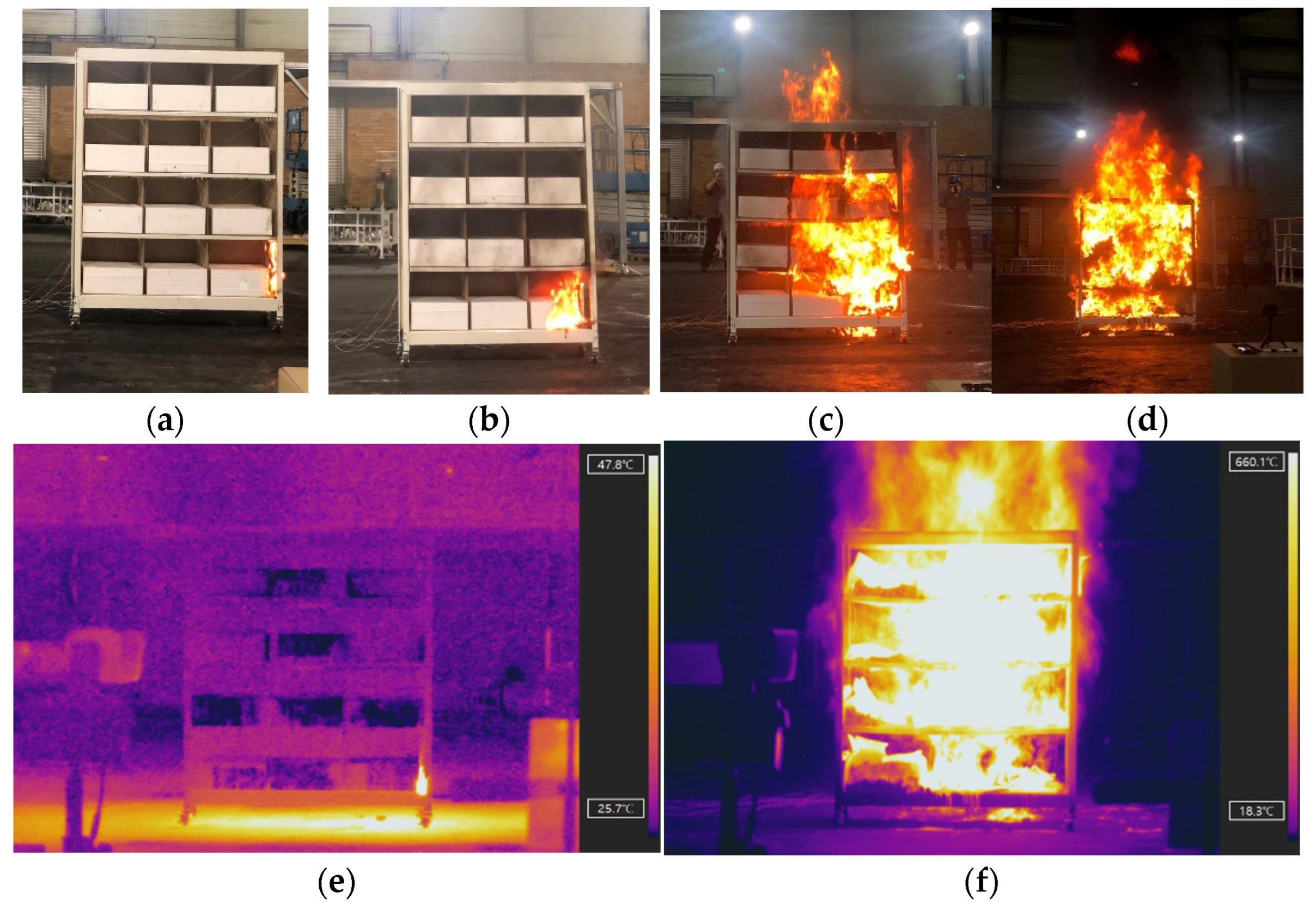

4.3. Fire Experiment and Results

A full-scale fire experiment was conducted to determine the minimum spacing distance required to prevent ignition between shelf racks. Based on the previous radiative heat flux measurement experiment, it was assessed that the radiative heat flux at 1.0 m was that high; thus, the 1.0 m condition was excluded, and the 1.2 and 1.5 m conditions were measured. An additional spacing distance of 2.0 m was included in the fire experiment.

The experimental conditions were the same as those in the previous experiment, with eight shelf racks facing each other and ignited at the center lower part using cotton wool soaked in 10 mL of heptane.

The time at which ignition occurred on the opposite shelf rack was measured. In this experiment, four K-type thermocouples capable of measuring up to 1300 °C were installed on the opposite side to measure the temperature of the facing shelf rack. The positions are shown in

Figure 18.

The ignition criterion was based on the visual observation of flames on the opposite shelf rack and the point where the temperature difference exceeded 500 °C compared to room temperature [

16]. The ignition time was recorded when either of the two criteria was satisfied first. The conditions and sequence of the experiment are presented in

Table 5.

The temperature measurement results for each condition are shown in

Figure 19, and the flame behavior over time is shown in

Figure 20,

Figure 21 and

Figure 22. The experimental results show that ignition occurred on the opposite shelf rack at 5 min 10 s, 4 min 37 s, and 5 min 15 s for 1.2, 1.5, and 2.0 m, respectively. The experiment confirmed that fire spread owing to radiative heat occurred in all three cases regardless of the distance.

As shown in the fire experiment results, even if the flames from the initially ignited shelf rack did not directly reach the opposite shelf rack, fire spread owing to radiative heat was confirmed. Based on the radiative heat flux measurements, it is estimated that there is a high risk of fire spreading to a distance for cases where more than 20 kW/m2 of radiative heat has occurred.

Furthermore, as the experimental conditions were set based on the aisle widths used in the on-site investigation, it is considered that in similar environments, there is a higher risk of rapid fire spread if a fire occurs in the shelf racks of a mezzanine.

5. Consideration of Experimental Results

In contrast to the high ceilings and vertically intensive combustible storage characteristic of logistics facilities, mezzanine racks in logistics facilities are divided into multiple layers with low ceilings. This suggests significantly different fire behavior from what has been proposed in existing research on fires in logistics facilities.

The actual experimental results verify that fire spread occurred owing to radiative heat from the fire source rather than direct flame contact. Therefore, to prevent fire spread based on radiative heat, the minimum spacing distance between shelf racks must be estimated. Using Equation (1) derived from the experiment, the calculation results of the radiative heat flux reaching the opposite shelf rack based on the spacing distance are shown in

Figure 23. Consequently, the calculation of the minimum spacing distance to generate radiative heat flux of 20 kW/m

2 or less resulted in a required minimum spacing distance of 3.2 m between shelf racks.

6. Discussions

Full-scale fire experiments were conducted using various distances to evaluate their ability to prevent fire spreading between shelving racks within mezzanine racks. However, as indicated by the results, relying solely on shelf spacing to prevent fire spread is challenging. Particularly in logistics facilities, a fire originating at a specific point can potentially cause substantially more property damage compared with standard buildings, making it essential to establish effective countermeasures for such facilities.

In Korea, new regulations have been introduced to ensure good fire safety performance in logistics facilities; however, performance standards for fire protection systems, specifically for mezzanine racks, are lacking, which likely increases the associated risks. The results of our experiment indicate that it is necessary to not only ensure sufficient physical separation between shelving racks but also to establish standards for installing flame detectors or pre-action sprinklers that can detect fires in their early stages. Additionally, installing barriers between shelving racks to actively respond to fires from the outset is recommended.

However, this experiment was conducted in the absence of references for full-scale tests on mezzanine racks, leading to difficulties in selecting the initial fire source. Additionally, it was challenging to accurately measure the radiant heat transmitted to surrounding areas. Therefore, follow-up studies should focus on enhancing these findings by considering the radiant heat-blocking performance of barriers to prevent fire spread as well as optimizing the placement and discharge capacities of sprinklers.

7. Conclusions

This study conducted a full-scale experiment on mezzanine racks used in logistics facilities and derived the following conclusions.

An on-site investigation was conducted at five logistics facilities in Korea to assess the sizes and conditions of the shelf racks. The overall size of the shelf racks placed inside the mezzanine racks was determined to be 1.8 m × 0.45 m × 1.5 m with four tiers. Based on this, the combustible arrangement for the full-scale experiment was divided into three types. The experiment conducted through unit shelf rack tests selected the combination of corrugated fiberboard, a cardboard box, and EPS, which had the longest fire duration.

Prior to conducting the full-scale fire experiment, an experiment was conducted using eight shelf racks based on the aisle widths obtained from the on-site investigation, yielding a heat flux range of 43.7–67.3 kW/m2. The experimental results show that the maximum heat flux measured at a separation distance of 1.2 m was 55 kW/m2, under which the fire spread to the opposite rack within a maximum of 5 min and 10 s.

A formula was derived based on the experimental results. A full-scale fire experiment was conducted by simulating a mezzanine rack using 16 shelf racks. The results confirm that fire spread occurred at nearly the same time even with spacing distances of 1.2–2.0 m and that the fire spread in low-ceiling mezzanine racks occurred due to radiative heat flux.

In addition, using the formula derived from the radiative heat flux measurements, it was calculated that a minimum spacing distance of 3.2 m was required to prevent fire spread between shelf racks.