Abstract

Gas explosion accidents can easily lead to large-scale casualties and economic losses, significantly impeding the urban development. The purpose of this study was to comprehensively review and investigate a significant gas fuel explosion accident in Yinchuan City, China, and to conduct an in-depth discussion on process traceability, failure risk, hazard prevention, and urban development related to the accident. The research found that the accidental failure of double-valve liquefied petroleum gas cylinders and human error were identified as the direct causes of gas leakage. The numerical results indicated that the progression of the accident disaster was chaotic and highly destructive. The maximum explosion overpressure of 92 kPa resulted in severe shock-wave damage to personnel, leading to the complete destruction and collapse of the 0.2 m thick solid brick wall and obstructing the stairway for escape. The rapid change in temperature and oxygen levels caused by the explosion led to the risk of burns and asphyxiation for personnel at the scene. By utilizing the system safety theory, a gas leakage accident control structure system was developed. This system comprised four key levels: the local government, gas management department, gas company, and individual user. The tragedy of 31 deaths was ultimately caused by a serious lack of safety constraints on the behavior of the lower level by the higher level. The research conclusions are of great significance for preventing clean fuel explosion accidents and ensuring sustainable urban development, especially in the face of the negative impact of accidents.

1. Introduction

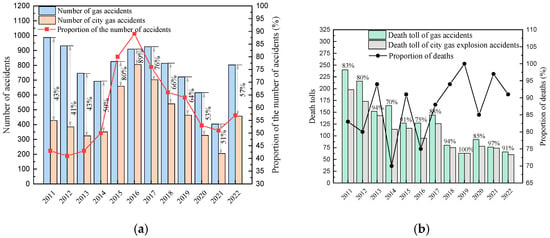

As China’s urbanization process advances and the objectives of ‘carbon neutrality’ and ‘peak carbon dioxide emissions’ are pursued, clean fuels like natural gas and liquefied petroleum gas (LPG) are increasingly prevalent in residential production and daily life [1,2]. Based on data from the National Development and Reform Commission of the People’s Republic of China, the apparent consumption of natural gas in China was projected to reach 394.53 billion cubic meters in 2023, with an average annual growth rate of 12% from 2011 to 2022. China’s demand for liquefied petroleum gas was also on the rise. In 2022, China’s demand for LPG reached 62.6473 million tons, making it the world’s largest demander and accounting for 18.10% of the total global demand. Clean and renewable fuels played a crucial role in advancing social and economic development by substantially reducing air pollution and enhancing residents’ quality of life. However, the growing incidence of gas-related accidents, including poisoning, asphyxiation, leakage, fires, and explosions, presents a significant challenge to economic progress and social stability [3]. Due to the flammable and explosive nature of gas, explosions have become the most common type of accident in gas-related incidents. According to the statistical report released by the China City Gas Association, there were hundreds of gas explosion accidents in China every year. From 2011 to 2022, explosions accounted for more than 40% of all gas accidents, with deaths accounting for more than 70%, as shown in Figure 1. Therefore, explosion accidents are considered the most dangerous type of gas accident due to their wide-ranging impact and high number of casualties [4].

In recent years, despite improvements in China’s investigation and management of hidden dangers in energy safety production, major gas leakage and explosion accidents have continued to occur frequently. These incidents pose significant obstacles to the progress of social and economic development and urban environment improvement. In June 2021, a natural gas pipeline leakage explosion accident occurred in a farmer’s market in Shiyan City, Hubei Province, resulting in a total of 26 deaths, 138 injuries, and economic losses of 53.954 million yuan [5]. In June 2023, a particularly serious accident involving an LPG leak and explosion took place in a barbecue restaurant in Yinchuan City, Ningxia Hui Autonomous Region, China, resulting in 31 deaths and seven injuries. Table 1 lists the cases of major gas fire and explosion accidents in China in recent years.

Table 1.

Major urban gas fire and explosion accidents (each causing at least 10 deaths) in China in recent years.

Figure 1.

Comparison of urban gas accidents and gas explosion accidents in China from 2011 to 2022 [6]: (a) number of accidents; (b) death toll.

In 2022, 88% of China’s gas explosion accidents occurred in residential buildings, businesses, and hotels [7]. As a result, the safety of indoor gas use has become a hot and key topic of social concern [8]. In general, gas leakage often occurs in the kitchen or gas cylinder room due to hose damage, improper maintenance, and human error. The freely diffused combustible gas can accumulate in the confined space. When the concentration reaches the explosion limit, encountering an ignition source can easily induce the risk of explosion [9]. The main disaster types of gas explosion accidents are explosion overpressure, high-temperature flame, and secondary strike of fragments. Explosion overpressure can lead to shock-wave damage to personnel in the near field and to the large-scale destruction and collapse of building components. The higher temperature of the explosion flame can cause irreparable damage to human skin and internal organs. Building fragments driven by the shock wave are prone to produce projectile strikes on personnel and facilities in the far field. The severity of the accident is related to the gas explosion effect, and factors such as obstacles, gas type, gas leakage and concentration, constraint structure, and ignition position are directly related to the derivative consequences of explosion flame and overpressure [10]. Recently, numerous scholars [11,12,13,14,15,16] have conducted extensive and in-depth research on the characteristics of gas explosions under the aforementioned influencing factors, yielding significant results in terms of explosion evolution laws, disaster assessment, and prediction. However, many studies have focused on the influence of only one or two factors on explosion characteristics, and the research scale may not fully align with real-world accident scenarios. Indoor explosion accidents typically occur in densely populated environments with numerous obstacles. The location and timing of gas leakage play a crucial role in determining the complexity of the gas distribution in such congested environments. As a result, predicting the risk of gas explosion accidents in residential areas is extremely challenging. Existing research findings may not directly translate to practical applications in accident prevention and control. Therefore, the further discussion and analysis of real urban gas explosion scenarios are necessary to enhance our understanding and preparedness for such incidents.

The primary emphasis in preventing and managing urban gas explosion incidents lies in curtailing and averting extensive fuel leakage from cylinders or pipelines during production processes. Typically, lessons learned from accidents are utilized to propose preventive measures from four key perspectives: human behavior, material conditions, production environment, and management systems. By enhancing the safety constraints of these measures, gas leakage can be effectively prevented. Currently, many scholars analyze the root causes of industrial hazardous chemical explosions and coal mine gas explosion accidents by developing intricate mathematical models. They employ methods such as fault tree analysis [17], Bayesian networks [18], the analytic hierarchy process [19], the Swiss cheese model [20], and others to identify causes and propose corresponding preventive measures. Nevertheless, the majority of studies have concentrated on assessing the risk and vulnerability of accidents, with a notable gap in the causal analysis of gas leakage incidents in intricate residential buildings.

In this paper, a serious gaseous fuel leakage explosion accident that occurred in a civil building in Yinchuan, China, in June 2023 is reviewed and investigated. Through on-site inspection and video monitoring analysis technology, the investigation details of the entire fuel leakage and ignition explosion process are comprehensively documented. By utilizing numerical simulation technology, an explosion model is developed, and the risk characteristics are assessed, providing readers with insights into the dynamic progression of the explosion and the resulting disaster damage in a complex civil building environment. Drawing from the tragic lessons of the accident, a risk control structure system aimed at preventing clean fuel leakage incidents is developed through the application of system safety theory. Recommendations for averting comparable accidents are proposed based on safety constraints. The research findings are beneficial for promoting the safe production and utilization of clean fuels, as well as for preventing and reducing losses from major accidents. They also contribute to fostering sustainable and stable societal development in the face of adverse impacts from accidents.

2. Methodology

2.1. Accident Consequences and Casualties

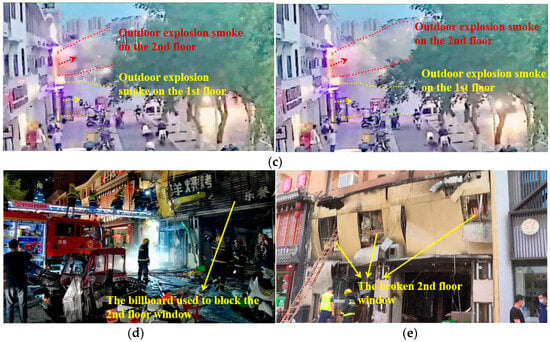

At 20:40 on 21 June 2023, an extremely serious LPG leakage explosion occurred at the ‘Fuyang’ barbecue restaurant in Minzu South Street, Xingqing District, Yinchuan City, Ningxia Hui Autonomous Region, China. Figure 2a,b shows the specific accident location. The accident resulted in a total of 38 casualties, including 31 fatalities and 7 injuries (1 critically ill, 2 with moderate burns, 2 with mild injuries, and 2 with glass scratches), with a direct economic loss of 51.145 million yuan. This disaster has garnered significant attention from people across the country due to the extremely serious casualties. The accident occurred in a two-story building. At the time of the accident, a surveillance camera outside captured the entire explosion process. The explosion shock wave, accompanied by a large amount of dust and smoke, was released into the external space at a high speed, as shown in Figure 2c. The power system of all the merchants on the entire street failed instantly, and windows up to 30 m away were shattered by high-speed fragments.

Figure 2.

Peripheral pictures of the accident building: (a) accident spot; (b) video surveillance camera; (c) local magnification of the surveillance camera; (d) accident rescue scene; (e) accident scene after rescue.

After the accident, the stairway connecting the 1st floor to the 2nd floor was fully obstructed by the collapsed wall, preventing firefighters from accessing the second floor directly for rescue operations, as shown in Figure 2d,e. Furthermore, the second-floor window was entirely obstructed by steel billboards welded to the building, significantly impeding the escape of occupants inside and prolonging the arrival time of rescuers to the second floor from the exterior. This led to the tragic loss of 28 lives on the 2nd floor.

2.1.1. Accident Damage Consequences

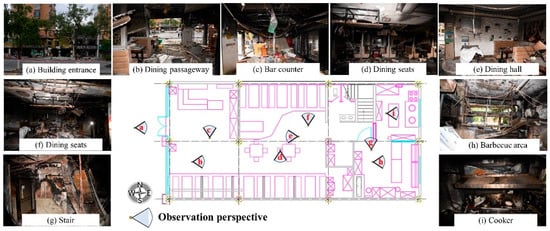

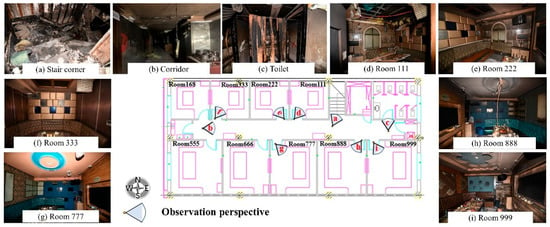

The restaurant involved in the accident was a two-story building with a total floor area of 366.56 m2. The first floor comprised a kitchen (barbecue area and cooking area), a bar, two storage rooms, a toilet, and 9 dining tables. The second floor included nine rooms equipped with karaoke facilities, a storage room, and a toilet. Following a thorough on-site examination, the specific post-destruction conditions at the location are depicted in Figure 3 and Figure 4. The severity of the damage was most evident on the 1st floor, as shown in Figure 3. All doors, windows, and glass components were shattered (Figure 3a,e); the aluminum decoration of the roof was damaged by impact (Figure 3c,f); a large section of the wall on the east side of the barbecue area collapsed outward (Figure 3h); the 0.2 m thick brick wall on the west side of the cooking area collapsed towards the west, obstructing access to the 2nd floor (Figure 3g); the self-constructed non-load-bearing walls on the east and west sides of the storage room completely collapsed; and cracks and deformations were observed on the north wall of the cooking area, with an outward displacement of approximately 0.10–0.15 m.

Figure 3.

Explosion damage on the 1st floor inside the building.

Figure 4.

Explosion damage on the 2nd floor inside the building.

The second floor exhibited significant fire and smoke damage across most areas. Near the stair corner, the ceramic tiles on the wall surface showed signs of detachment, with the decorative surface charred by fire (Figure 4a). The corridor roof had collapsed, and the floor of the storage room situated at the mezzanine level of the stairs showed localized burn damage. Room 111 on the west side of the stairs displayed cracks in the composite wall core plate, along with fire traces. The top of the door in Room 111 exhibited clear wood decoration carbonization (Figure 4d). The door of Room 999 opposite the stairs was destroyed (Figure 4i), and some decorative ceramic tiles inside Room 888 had fallen off (Figure 4h). The corridor (Figure 4b) and the majority of rooms (Figure 4e–g) remained relatively intact.

2.1.2. Statistics of the Number of Deaths at the Scene

During the rescue operation following the accident, a total of 31 bodies were discovered in the accident scene, with 3 found on the 1st floor and 28 on the 2nd floor. On the 1st floor, two bodies were located near the toilet door, and one body was found at the corner of the stairs leading to the 2nd floor. On the 2nd floor, four bodies were situated in the corridor from east to west, with two in the storage room and one in the toilet. Additionally, there were 2 bodies in Room 111, 4 in Room 222, 3 in Room 333, 4 in Room 777, 6 in Room 888, and 3 in Room 999, totaling 22 deaths across all rooms.

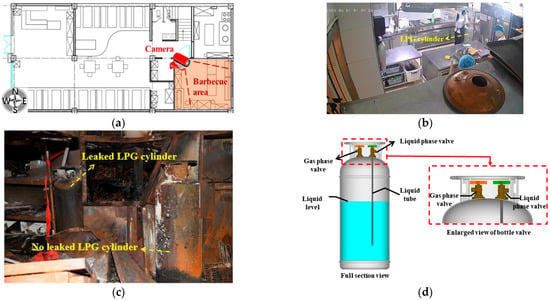

2.1.3. Fuel Leakage Caused by Human Error

Based on monitoring data and on-site investigations, it was determined that the liquefied petroleum gas cylinders located at the southeast corner of the kitchen barbecue area were the sole gas source responsible for the accident, as illustrated in Figure 5a,b. Two 50 kg LPG cylinders were identified at the explosion scene, with one cylinder found to be leaking while the valve of the other cylinder was closed, as shown in Figure 5c. Following the investigation, it was determined that the two gas cylinders left at the scene were double-valve cylinders equipped with gas phase valves and liquid phase valves. These cylinders served as LPG storage equipment for gasification devices. The liquid phase pipe within the cylinder was linked to the liquid phase valve. LPG was released from the bottom of the gas cylinder via the liquid phase pipe and the outlet of the liquid phase valve. Subsequently, after undergoing gasification by the gasification device, it was connected to gas equipment through the pressure regulator for utilization. The naturally gasified gas located above the liquid level was released from the gas phase valve and directed through the pressure regulator to the gas consumption equipment. The gas phase valve was equipped with a self-closing device, whereas the liquid phase valve did not feature a self-closing device. The structural composition of the gas–liquid double-valve LPG cylinder is depicted in Figure 5d.

Figure 5.

The double-valve LPG cylinders involved in the accident scene: (a) the area where the LPG cylinders were locatedcopyright; (b) LPG cylinder in the barbecue area before the explosion; (c) LPG cylinder in the accident scene; (d) schematic diagram of the double-valve LPG cylinder.

After conducting a thorough investigation of the accident scene, reviewing video surveillance footage, examining inquiry transcripts, and analyzing physical evidence, the accident was summarized as follows:

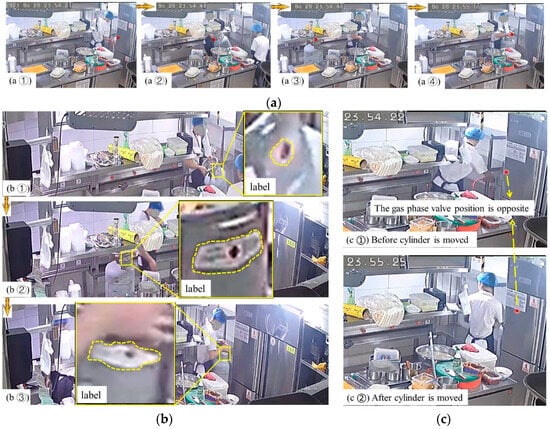

On 20 June (the day before the accident), at 23:49, while cleaning, a clerk unloaded the pressure regulator connected to the gas phase valve on the LPG cylinder (Figure 6(a①)). The clerk then proceeded to move the cylinder out and rotate it for a week, causing the orientation of the valve to change (Figure 6(a②)). Upon pushing the gas cylinder back to its original position, the position of the liquid phase valve was mistakenly facing outward (Figure 6(a③)). Subsequently, the clerk mistakenly reinstalled the disassembled pressure regulator onto the outward-facing liquid phase valve (Figure 6(a④)).

Figure 6.

Analysis of the position of the valve before and after the cylinder is moved: (a) process of the cylinder being moved; (b) comparison of the labels on the cylinder; (c) position comparison of the gas phase valve.

The red dots highlighted in Figure 6a indicate the position of the gas phase valve on the gas cylinder, enabling the tracking of the gas phase valve’s position change process before and after the cylinder was moved. By observing the size of the label on the cylinder, it can be inferred that the valve’s position indeed changed before and after the cylinder’s movement. In Figure 6(b①), the label on the cylinder appeared small before it was moved. After the cylinder was moved out, as shown in Figure 6(b②), the label became larger, indicating a shift in the direction of the two valves. Subsequently, the cylinder was translated back to its original position because the two labels in Figure 6(b②,b③) were of the same size.

In Figure 6c, a comparison is made between the position of the gas phase valve before and after the cylinder is moved. The red dot’s position in the two images differs, indicating a change in the orientation of the gas phase valve. Initially, the gas phase valve was facing outward, but after the cylinder was moved, it began to face inward. This observation suggests that the valve facing outward was the liquid phase valve. In conclusion, it could be determined that the clerk mistakenly installed the pressure regulator on the outward-facing liquid phase valve after moving the gas cylinder.

At 18:16 on 21 June (the day of the accident), the clerk opened the angle valve of the LPG cylinder and flipped the switch of the gas barbecue oven for the first time to begin the barbecue work. The observation of Figure 7a reveals that the strong light on the wall indicates the activation of the barbecue oven and the initiation of gas cylinder operation. After 80 min, the clerk noticed a gas leakage at the connection location between the angle valve and the pressure regulator. Then, the clerk disassembled and inspected the regulator attached to the liquid phase valve, discovering internal damage to the old regulator components, as shown in Figure 7b. At 20:29, the clerk purchased a new pressure regulator (later determined to be a counterfeit product) and incorrectly attached it to the liquid valve of the cylinder, as shown in Figure 7c. Despite the successful installation, multiple ignition attempts failed. At 20:36:24, the clerk rechecked the gas cylinder and removed the newly installed regulator in preparation for replacing the spare gas cylinder. At 20:36:42, a small amount of ‘white mist’ resembling LPG was emitted from the connection between the regulator and the liquid phase valve (the initial leakage), as shown in Figure 7d. The clerk promptly closed the valve, causing the ‘white mist’ to dissipate.

Figure 7.

LPG leakage process caused by human operation error: (a) turning on the barbecue oven; (b) removing the old pressure regulator; (c) installing the new pressure regulator; (d) first small-scale LPG leakage; (e) second LPG leakage; (f) large-scale LPG leakage.

At 20:36:51, the clerk inadvertently turned the liquid phase valve in the wrong direction, causing the gas cylinder to release a fan-shaped ‘white mist’ (second leakage), as shown in Figure 7e. At 20:37:19, the clerk attempted to close the valve but was unsuccessful. Instead, he mistakenly pulled the hose connected to the regulator, altering the gas injection direction. This led to a change in the leakage direction from obliquely upward to horizontally flat, creating a jet-like ‘white mist’ approximately 3 m in length, resulting in a further escalation of the leakage, as shown in Figure 7f. Subsequently, no emergency measures were implemented to mitigate the ongoing large-scale LPG leakage until the explosion occurred.

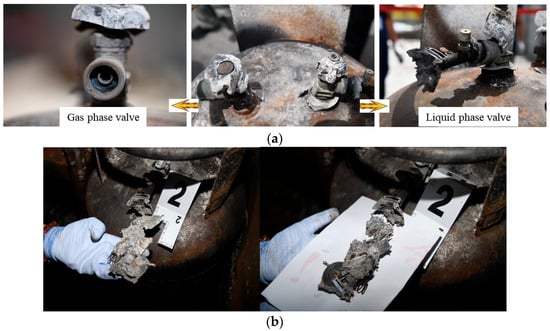

Following the accident, an examination of the damage to the two valves on the cylinder was conducted, as shown in Figure 8a. The gas phase valve exhibited nearly complete intactness. Conversely, the liquid phase valve sustained severe damage, with only a small portion of the regulator remaining connected to it, while the remainder of the regulator was completely destroyed. By reconstructing and comparing the on-site conditions, the approximate connection state between the pressure regulator and the liquid phase valve prior to the explosion was determined, as shown in Figure 8b.

Figure 8.

The double-valve LPG cylinder and the traces after explosion: (a) the damaged cylinder double valve; (b) the completely destroyed pressure regulator.

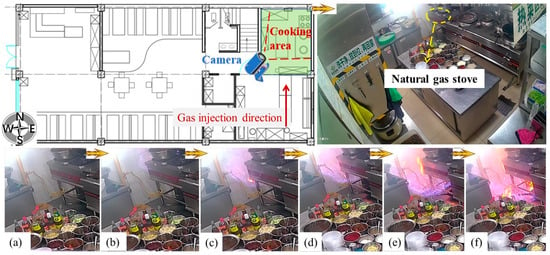

2.1.4. Accidental Ignition of Gas Stoves

The kitchen of the restaurant where the accident occurred was divided into a barbecue area on the south side and a cooking area on the north side, separated by glass with open doors, allowing for the free diffusion of leaked LPG. As per Section 2.1.3, the gas leakage direction in the barbecue area was from south to north. Consequently, the high-speed injection of the LPG mist rapidly vaporized into gas, expanding quickly and diffusing directly into the cooking area on the north side. The cooking area contained numerous closets, hanging cabinets, operating tables, various stoves, and tableware, creating a densely packed environment that facilitated the rapid accumulation of gas. This accumulation led to the gas reaching the explosion limit in a short period. At 20:37:54, one minute and three seconds after the LPG leak, the gas was ignited by a working gas stove in the northeast corner of the cooking area, a sequence captured by surveillance cameras, as shown in Figure 9.

Figure 9.

The video surveillance process of the leaked LPG ignited by a natural gas stove.

From Figure 9a–c, it is evident that when the LPG was ignited by the stove, the initial combustion flame appeared light blue, indicating a low gas concentration. Due to the heavier nature of LPG compared to air, the initial flame propagated downward first. As the flame spread, the middle and base of the flame transitioned to yellow and red, as shown in Figure 9d–f, signifying insufficient oxygen for the combustion reaction. Additionally, it indicated that the closer the proximity to the barbecue area, the higher the concentration of leaked gas. These six frames of monitoring images illustrate the development process of the initial flame, captured by a standard household camera with a low frame rate, highlighting the slow progression of the flame in the initial stages of the explosion. Influenced by numerous obstacles, the flame rapidly extended along the channel towards the barbecue area, triggering a more intense explosion effect, ultimately leading to this severe accident disaster.

2.2. Explosion Modeling

In this section, the evolution path of the accident was reproduced and quantitatively evaluated using computational fluid dynamics (CFD) techniques. Flame Acceleration Simulator (FLACS) is a CFD tool specially used to deal with industrial safety problems. It has great potential in dealing with the serious loss process of major industrial and social disasters, such as gas explosions, dust explosions, vapor cloud explosions, explosive explosions, and shock-wave propagation. FLACS uses a model that describes the development of flame to realize modeling and study the changes in parameters such as pressure, concentration, and temperature. Using the idea of a distributed porous structure, a flame smaller than the grid scale is represented by a sub-grid model to study the interaction between the flame and theobstacle. The FLACS program has been specifically tailored for gas explosion modeling, resulting in a more comprehensive explosion module. The numerical simulation results generated by this module have undergone validation through numerous experiments, affirming the software’s suitability for gas safety research. Furthermore, it has received certification from international authoritative standards bodies such as those in the United States, Norway, and Russia. As a result, FLACS is extensively utilized in high-risk industries such as petroleum, chemical, and natural gas for various applications.

Consistent with most commercial software, FLACS (V. 10.7) still relies on the turbulence model of the Navier–Stokes equations. The k-ε two-parameter turbulence equation, component transport equation, and finite rate/eddy dissipation chemical reaction model were employed to conduct a three-dimensional calculation and simulation of the explosion process of the reactive fluid involved in the accident [21,22]. By applying the principles of mass conservation, momentum conservation, energy conservation, and component conservation equations of fluid dynamics, the overpressure, temperature, and other critical disaster parameters in the numerical calculation area were solved under specific boundary and initial conditions.

2.2.1. Physical Model and Initial Condition

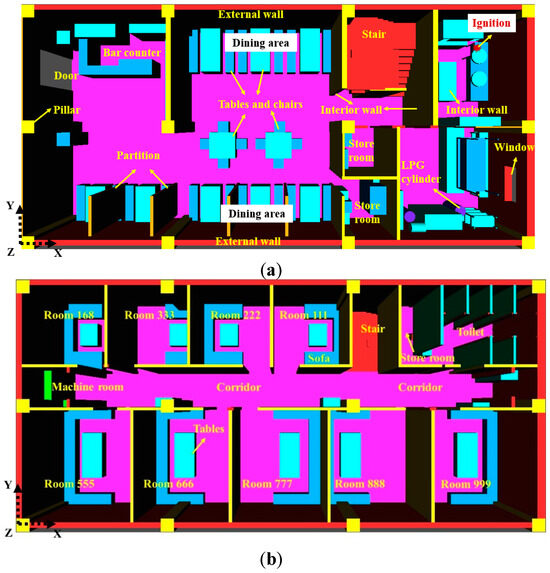

In the context of the accident building’s original structure, a detailed 1:1 full-size proportional explosion physical model was constructed, as shown in Figure 10. This physical model encompassed various components of the building, including glass elements like doors and windows, rigid structures such as internal and external walls, load-bearing pillars, and stairs. The first-floor dining hall featured items like a bar, tables and chairs, a refrigerator, and hollow decorative partitions, among others. The kitchen barbecue area retained essentials like a disinfection cabinet, freezer, locker, operational table, oven, and two gas cylinders. The cooking area included a locker, operational table, and primary stove. On the 2nd floor, there were nine rooms, a machine room, a storage room, and a toilet. Each room retained elements like partition walls, sofas, and dining tables. To streamline the modeling and simulation process, minor components such as lamps, wires, pipelines, and simple decorations that had a minimal impact on the explosion effect were omitted.

Figure 10.

Physical model of the accident building (horizontal direction): (a) the 1st floor of the building; (b) the 2nd floor of the building.

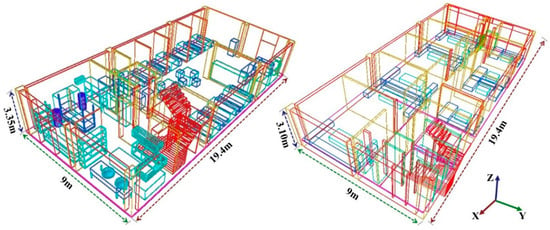

The physical model dimensions and the three-dimensional positioning of internal building components are shown in Figure 11. The overall size of the two-story building model was 19.4 m (X) × 9 m (Y) × 6.45 m (Z). The dimensions of the 1st floor and the 2nd floor were 19.4 m (X) × 9 m (Y) × 3.35 m (Z) and 19.4 m (X) × 9 m (Y) × 3.10 m (Z), respectively. For the numerical calculations, the ignition was placed near the gas stove in the northeast corner of the kitchen cooking area, with a height of approximately 0.8 m from the ground. The initial pressure in the model corresponds to the local atmospheric pressure of 9.93 × 104 Pa at the time of the incident, while the initial ambient temperature was set to 305 K. The surface roughness was 0.01, the atmospheric stability was categorized as F, and the average altitude was 1100 m. To capture critical data, multiple measuring points were positioned at key damage locations and areas where personnel were affected to gather parameters such as explosion overpressure, temperature, and oxygen content.

Figure 11.

The boundary wireframe of the physical model.

The quality of grid generation plays a crucial role in determining the accuracy of simulation results, with grid size being a key factor in capturing parameters at critical nodes accurately. In this study, a 0.1 m cube grid size was utilized based on a previous study [23], which extensively discussed and independently verified grids of various sizes. It was established that employing a 0.1 m grid size both ensured the accuracy of numerical calculations and enhanced computational efficiency. In the literature [23], Bauwens’ experimental results were used to verify the numerical results. After comparison, the relative error of explosion peak overpressure obtained by the experiment and simulation was less than 10%, which was within the acceptable error range. The above confirmed the accuracy of the selected numerical method for solving the problem of explosion transient flow field. To effectively capture the external explosion propagation process, the calculation domain was extended by 5 m along the X/-X direction, resulting in an overall calculation domain size of 29.4 m (X) × 9 m (Y) × 6.45 m (Z). The total number of grids generated amounted to 1,780,415, and the total simulation time required for the calculations was 19 h.

2.2.2. Pressure Relief Boundary

During the accident, the damage to building components such as doors, windows, and internal and external walls significantly influenced the evolution of the explosion. In the numerical model, all the collapsed structures within the accident scenario were represented as pressure relief plates to simulate the actual crushing process of building components under the impact of the explosion. This boundary could be assigned specific parameters such as fixed opening pressure, area, and quality to control the opening process of the pressure relief plate. When the pressure near the pressure relief plate reached the predetermined opening pressure, the plate would fail immediately. Table 2 outlines the parameters of the pressure relief plate used in the numerical calculations, which have been derived from extensive accident investigation experiences and relevant literature [6,23].

Table 2.

The control parameters of the pressure relief plates in the numerical simulation.

2.2.3. Fuel Filling Settings

In the numerical simulation, the characteristics of the explosion medium were crucial and involved considerations such as gas type, filling range, and volume concentration. Based on the analysis of the residual gas components found in the LPG cylinder at the accident scene, the gas medium primarily consisted of propane (78.38%), propylene (18.25%), and ethane (3.37%). The total mass of LPG leakage was determined through experimental testing conducted on the involved gas cylinders left at the scene. During a safe experiment carried out for 1 min and 3 s, the mass difference of the gas cylinders before and after the leakage test indicated a leakage mass of approximately 3.84–4.80 kg of LPG in the accident scenario. Considering factors such as the gas leakage rate, leakage time, and leakage direction observed in the surveillance videos, the diffusion cross-section of the LPG leakage before ignition was estimated to cover the barbecue area and the cooking area. The gas concentration and height from the ground were distributed in a decreasing manner from the barbecue area to the cooking area, with the highest concentration observed at the gas cylinder injection position.

Based on the information provided, it was assumed that the filling range of the LPG/air explosive mixture during ignition was 9 m (length) × 5 m (width) × 1.5 m (height). A rough estimation suggested that the total volume of obstacles (stove, console, shelf, cabinet, gas cylinder, small-scale entity, etc.) within the inflatable domain was approximately 15 m3. If the obstacle volume was subtracted, the actual combustible gas filling volume was calculated to be 52.5 m3. Considering the LPG leakage mass obtained from the test, it was inferred that the volume concentration of the explosion mixture fell within the range of 4% to 5% during ignition. To simulate the explosion accident and assess the most severe consequences, this study selected LPG with a volume concentration of 5% to employ in the explosion simulation calculations.

3. Results

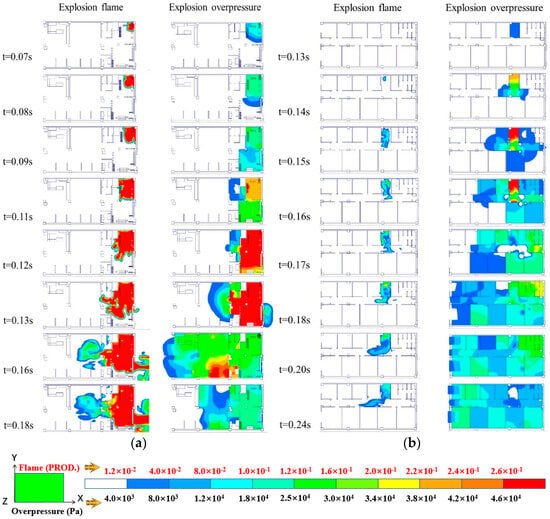

3.1. Evolution of Explosion Accident Consequences

Figure 12 illustrates the evolution of the explosion flame and overpressure observed on the horizontal plane of the first floor and the second floor over time. The volume fraction of combustion products was used to replace the observation of flame shape and propagation. In Figure 12a, it was evident that the leaked LPG was ignited by the open flame of the natural gas stove in the northeast corner of the kitchen cooking area on the first floor. The laminar flame spread and expanded, forming the initial shock wave. At a time of t = 0.07 s, the simulated flame extent effectively encompassed the area of the natural gas stove, aligning with the flame shape depicted in Figure 9f of the video. This observation indicated a degree of consistency between the numerical predictions and the actual flame development pattern. Consequently, the accuracy of the numerical results in forecasting the flame evolution was validated to a certain extent. As the flame propagated to the operating floor (t = 0.08 s), the rapidly increasing barrier blocking rate caused unburned gas in front of the impact wave to escape quickly, leading to the formation of high-intensity turbulence in the gas wake. This turbulence promoted the rapid conversion of the laminar flame into a turbulent flame, allowing the pressure wave to swiftly reach all the cooking area (t = 0.11 s) and propagate to the barbecue area.

Figure 12.

The evolution of the explosion flame (left) and explosion overpressure (right) with time: (a) the explosion propagation path of the first floor; (b) the explosion propagation path of the second floor.

When t = 0.12 s, the shock wave entered the barbecue area after destroying the glass partition wall between the cooking area and the barbecue area. It accelerated its propagation in the narrow path containing obstacles such as the operation platform and the barbecue grill, causing the pressure in the barbecue area to rise rapidly as a whole. Consequently, the pressure in the barbecue area became significantly higher than that in the cooking area due to the accelerated propagation and obstruction of the shock wave in the confined space of the barbecue area. At this point, the pressure near the wall on the west side of the cooking area adjacent to the stairs further increased, leading to the collapse of the wall in a westward direction. The explosion shock wave was rapidly released through the channel between the kitchen and the dining hall. Some of the shock waves entered the dining hall, while others propagated along the stairs to the second floor. Approximately 0.13 s later, the self-built walls on both sides of the storage room and the external wall on the east side of the barbecue area collapsed simultaneously, creating a two-way explosion-venting state in the barbecue area on the east and west sides. Around 0.03 s later, the west door and glass wall of the dining hall were damaged and thrown westward due to the force of the explosion. As the explosive medium was completely consumed and the explosion-venting action was completed, the indoor overpressure level gradually decreased when t = 0.18 s.

Approximately 0.13 s after the explosion on the first floor, the explosion shock wave reached the stairway and entered the second-floor corridor, spreading in both directions when t = 0.14 s. At t = 0.15–0.16 s, the overpressure accumulation in the narrow staircase space increased, leading to the destruction and shedding of the tile decoration near the staircase. This resulted in cracks and a small amount of displacement in the north wall due to the force of the shock wave. Subsequently, the shock wave and flame propagating along the stairs to the second floor acted on the light partition wall on the east side of Room 111, causing the core plate in the partition wall to crack and penetrate into the room when t = 0.17 s. The shock wave in the corridor entered the interior of each room through the doors when t = 0.18 s. Within the next 0.06 s, the shock wave propagated to the machine room on the westernmost side of the corridor, causing partial damage to the windows and depressurization in that area.

3.2. Explosion Consequences at Key Locations

Gas explosion disasters encompass various hazards, including shock-wave overpressure, high temperature, high-speed fragment impacts, and more. Overpressure, as a primary factor in such disasters, can lead to the rupture and collapse of building components, damage to individuals’ eardrums, injuries to vital internal organs, and even fatalities. The direct exposure to explosion flames can cause severe burns to the skin, while high-temperature gases entering the body can damage the respiratory tract, leading to conditions like pulmonary edema and irreversible harm. To accurately assess the consequences of an explosion accident, Table 3 and Table 4 summarize the peak overpressure and peak temperature of the explosion in key areas of the first floor and second floor. By analyzing these data in conjunction with the established damage criteria [24] for explosion shock-wave overpressure on individuals and buildings, a comprehensive understanding of the impact and potential outcomes of the explosion can be obtained.

Table 3.

Analysis of explosion damage consequences in key areas of the first floor.

Table 4.

Analysis of explosion damage consequences in key areas of the second floor.

In the kitchen cooking area on the first floor, the leakage of LPG led to a detonation in the northeast corner. The presence of numerous cabinets, stoves, and other obstacles in the high-congestion environment facilitated the rapid development of the explosion flame and overpressure. The maximum overpressure recorded in this area reached 80.5 kPa, resulting in complete damage at a level of 7 to the building. As a consequence, the 0.2 m thick wall collapsed entirely in a westward direction, obstructing the stairs that led to the second floor. The maximum temperature in this area exceeded 1900 K, causing severe burns to individuals present. The highest explosion overpressure of 92 kPa and temperature of 2077 K in the entire accident environment were observed in the barbecue area.

The barbecue area, being the initial location of the gas leakage, had a high concentration of LPG mist, allowing for more unburned LPG to participate in the combustion and explosion reaction during the accident. Furthermore, the explosion propagation path extended a distance of 9 m from the initial ignition position to the leakage source, leading to a more complete development of the flame and resulting in greater overpressure and temperature levels. This scenario intensified the impact of the explosion in this area. The toilet on the first floor was situated in the pressure relief channel, leading to a slight decrease in overpressure (70.8 kPa). However, at the time of the incident, two clerks near the toilet door died from shock waves and high-temperature flame burns at 1927 K. In contrast, the overpressure monitored in the dining hall outside the kitchen was significantly reduced, with a maximum overpressure of 32 kPa, causing only minor injuries to personnel and resulting in seven individuals being injured in the hall. The overpressure at the entrance of the restaurant caused level 3 damage to the building. Damage to the outdoor environment primarily stemmed from the throwing of building fragments, highlighting the secondary effects of the explosion on the surrounding area.

On the second floor, a body was discovered in the stair area where the maximum overpressure and temperature reached 78 kPa and 1766 K, respectively. These extreme conditions resulted in severe shock-wave injuries and severe burns to individuals, potentially leading to fatalities. The location of the stairway, opposite the kitchen door on the first floor, played a crucial role in the incident. As the flame from the barbecue area on the first floor extended outward, unburned LPG in front of the flame array was pushed into the confined space of the stairs and ignited, generating a high level of overpressure in the stair area. The reduced inflow of unburned gas to the second floor resulted in a maximum overpressure of 41 kPa, causing moderate overpressure damage to the four individuals in the corridor, along with burns from the high temperature of 1007 K. Room 111, being closest to the stairs, experienced the most significant impact from overpressure and high temperature, leading to structural damage, with wooden decorations falling within the room. Individuals in other rooms experienced only slight overpressure effects, with maximum explosion temperatures not exceeding 400 K. One individual in the toilet in the northeast corner of the second floor suffered moderate overpressure injuries.

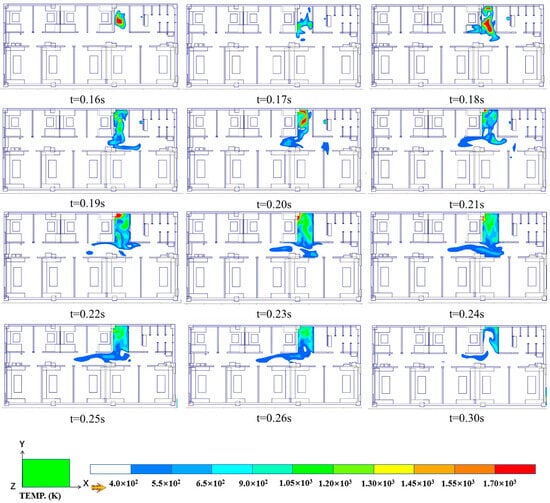

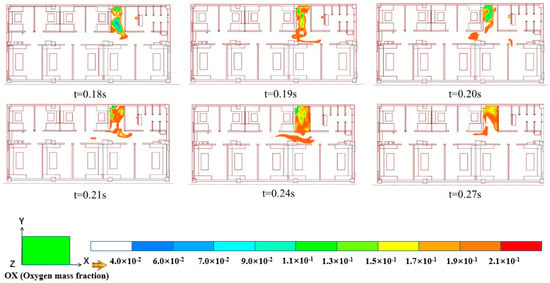

In Figure 12b, the development of explosion overpressure in the second-floor corridor was primarily concentrated in the stairway area, with the maximum overpressure occurring near the wall directly facing the stairway. The overpressure levels in the machine room and toilet exceeded 20 kPa. In Room 111, the overpressure was mainly localized in the southeast corner, where wall cracks were present. Comparatively, the toilet experienced a higher accumulation of overpressure than the corridor. To investigate the progression of the explosion flame on the second floor, Figure 13 presents a cloud map of the explosion temperature observed on the horizontal section over time. The white areas in the cloud map indicate regions on the second floor that were not significantly impacted by the explosion flame. The flame development was most pronounced in the stair area, where the explosion temperature reached its peak. The maximum explosion temperature in the corridor was near the wall opposite the stairway, aligning with the maximum overpressure distribution. The flames extended along the east and west sides of the corridor, creating a high-temperature zone of approximately 10 m with temperatures exceeding 400 K in the east–west direction. At t = 0.18 s, the fire from the stairwell breached the wall crack and entered Room 111, leading to a rise in internal temperature.

Figure 13.

The evolution of explosion temperature over time on the horizontal section of the second floor.

The analysis of the air oxygen content on the horizontal observation surface of the second floor over time provides insights into the correlation between the cause of death of individuals and the risk of explosion asphyxia, as shown in Figure 14. Following the explosion, the oxygen levels in the stairwell of the second floor experienced a significant decrease, with the minimum oxygen content dropping below 3.6% (volume fraction). Prolonged exposure to such a hypoxic environment could lead to shock, unconsciousness, heart failure, and ultimately death. In the corridor area near the staircase, the oxygen content was recorded at a minimum of 14.4% (volume fraction), with an anoxic range extending approximately 6 m in the east–west direction. Individuals within this range may remain conscious but experience reduced judgment capabilities. The oxygen content in the vicinity of Room 111 decreased to 16.2% (volume fraction), significantly impacting human muscle coordination and causing slow movement. As the accident progressed, the high-temperature toxic smoke and dust from the kitchen on the first floor were expected to rapidly spread to the second floor, leading to a substantial reduction in oxygen concentration. This severe asphyxiation scenario was likely to result in the death of most individuals on the second floor.

Figure 14.

The evolution of air oxygen content over time on the horizontal section of the second floor.

4. Discussion of the Accident Cause and Prevention Suggestions

In the exploration of the causes of liquefied petroleum gas leakage and explosion accidents, the systems theoretic accident model and processes (STAMP) framework was employed to establish four fundamental level control structures. By utilizing the STAMP, the risk control structure, safety constraints, external supervision, and grassroots operations of the accident system were comprehensively analyzed. The STAMP is a model that identifies the causes of accidents in complex systems by ensuring that control objectives align with safety constraints [25]. The STAMP diverges from the linear thought process of traditional safety analysis methods and is particularly suited for analyzing safety in complex and nonlinear systems. As a result, it finds widespread application in accident investigations, construction projects, and transportation systems, offering a robust framework for understanding and addressing the root causes of accidents in intricate systems [26,27].

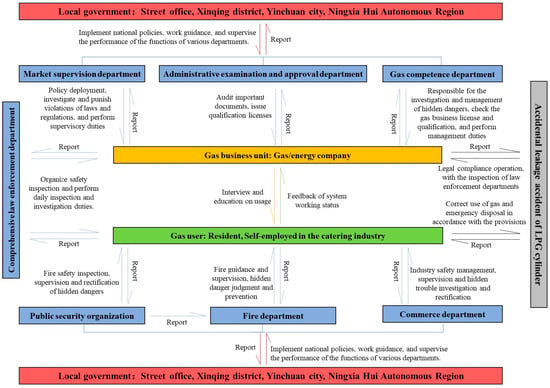

In accordance with system theory principles, the enforcement of specific levels of activity within management control behavior establishes the behavioral rules of each layer. The system is conceptualized as a hierarchical structure comprising both social and technical systems. Through the hierarchical control structure, the composition of complex systems can be elucidated, and the causes of control deficiencies in each part of the system can be analyzed. Drawing insights from the investigation report of the explosion accident in Yinchuan and the prevailing management systems in China, this study constructed a hierarchical safety control structure for LPG leakage accidents, as shown in Figure 15. The control structure incorporated four key levels: local government, gas management department, gas company, and gas users. It delineated the rights and responsibilities of each level within the system, facilitating a clear understanding of the relationships between different levels in the event of an accident. By establishing this hierarchical safety control structure, stakeholders could enhance coordination, accountability, and effectiveness in managing and preventing accidents related to LPG leakage.

Figure 15.

Layered safety control structure for preventing the leakage of LPG cylinders.

As the first control level, the local government was responsible for implementing the national energy policy, guiding the work, and supervising the gas management department to strictly perform its functions. The second control level consisted of seven departments, including the market supervision department, approval department, and law enforcement department. This level was responsible for conducting hidden danger investigations, providing education and training, overseeing rectification and investigations for gas companies and gas users, and playing a crucial role in regulating gas production and use safety. The third level, represented by the gas company, offered gas sources, operational training, and daily maintenance services for gas users. Gas users, at the fourth level, were required to promptly report any abnormal gas cylinder work conditions to the gas company and use the gas cylinder correctly. All lower levels were obligated to report to the higher level.

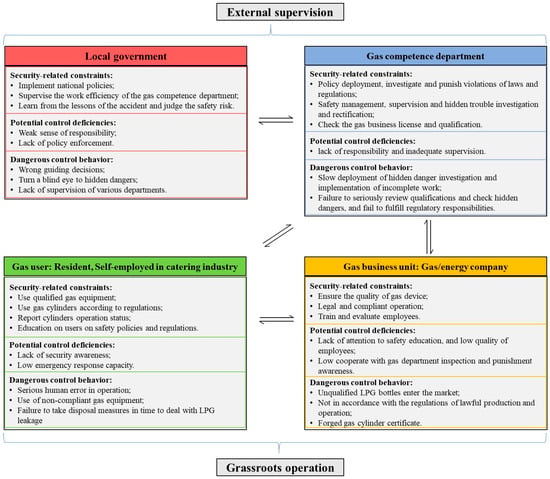

The STAMP model posits that accidents are caused by the absence of safety constraints in the control structure or inadequate control execution. According to Figure 16, the impact of safety constraints, potential control defects, and dangerous behaviors imposed by the four control levels on LPG cylinder leakage accidents is analyzed from the perspectives of external supervision and grassroots operation. External supervision was primarily carried out by the local government and gas management department, while grassroots operation involves the actions of gas companies and gas users. Based on Figure 16, the following key constraints should be implemented to prevent LPG cylinder leakage accidents: (1) supervise the function execution of the gas management department; (2) enhance safety oversight and address hidden dangers in the gas industry, as well as intensify the investigation and punishment of illegal activities; (3) ensure strict legal compliance in gas usage, including prompt and proper handling of gas leaks. In this accident, the double-valve LPG cylinders involved did not comply with national standards, yet the gas company still distributed these substandard cylinders to users, creating a significant safety risk. Despite lacking the necessary qualifications, the gas company continued its illegal gas business operations for an extended period without any oversight or inspections from the gas management department. Furthermore, when the accident transpired, the gas user improperly disassembled the pressure regulator without authorization and failed to follow the correct procedures for handling the leakage incident. These serious human errors in operation ultimately resulted in an uncontrollable leakage accident. The aforementioned unsafe behaviors significantly strayed from the safety constraints that should have been enforced at all control levels, ultimately leading to the occurrence of this major accident.

Figure 16.

The effect of external supervision and grassroots operation on LPG leakage accidents.

In light of the lessons learned from the discussed accidents, the following prevention suggestions should be considered to mitigate the risk of similar incidents in the future: (1) organize special rectification efforts to systematically eliminate the underlying causes of accidents; (2) enhance the quality of gas management personnel and reinforce their sense of responsibility towards safety; (3) implement stringent controls over gas-related businesses and gas cylinder filling licenses, ensuring a standardized approval process; (4) gas management departments should diligently fulfill their duties, focusing on safety supervision and law enforcement inspections; (5) prohibit the use of double-valve cylinders in catering enterprises, facilitate the replacement of qualified hoses and regulators, install stove flameout protection devices or switch to approved gas stoves, and enforce the installation and use of gas leakage alarm systems; (6) enforce the assessment, training, and certification system for employees rigorously, bolster daily training and educational initiatives, and enhance safety awareness and emergency response capabilities across the board.

5. Conclusions

In this paper, details of an investigation into a particularly serious accident involving a clean fuel explosion in Yinchuan, China, have been made public. By conducting a comprehensive review of the fuel leakage and explosion process, analyzing the lessons learned from tragic accidents caused by human error, and utilizing CFD technology, the explosion path and associated consequences were effectively reconstructed. Based on the STAMP, a comprehensive analysis of the accident causes was conducted. Subsequently, recommendations were proposed to mitigate and address the impact of accident consequences on urban sustainable development.

- (1)

- The causes of the accident were summarized as follows: The gas company illegally distributed double-valve liquefied petroleum gas cylinders with a gas phase valve and a liquid phase valve to the restaurant involved in the accident. A clerk mistakenly connected the gas phase valve regulator to the liquid phase valve. Upon discovering the error, the regulator was disassembled and reinstalled without proper authorization, leading to the leakage of LPG. Subsequently, the valve was mistakenly opened during disposal, resulting in a significant gas leak. The leaked gas mixed with air, reaching the explosion limit, and ignited from the open flame of the cooking area in the kitchen, causing the explosion. As the only stairway was severely blocked by the collapsed wall and the second-floor windows were also blocked, the escape of people was seriously impeded, resulting in an increase in casualties.

- (2)

- The maximum explosion overpressure in the building was observed in the barbecue area of the kitchen. The overpressure and temperature levels experienced by the three individuals on the first floor exceeded 70 kPa and 1700 K, respectively, indicating the potential for severe shock-wave injuries and burns. On the second floor, the maximum explosion overpressure in the corridor and Room 111 was measured at 41 kPa and 39.2 kPa, respectively, resulting in moderate damage to the personnel in those areas. In contrast, the overpressure in other rooms only caused slight damage to the personnel. The oxygen content (volume fraction) in a small section of the corridor decreased from 21% to 16%, posing a risk of asphyxiation due to the reduced oxygen levels.

- (3)

- Using the STAMP, the main responsibilities of the four control levels—local government, gas management department, gas companies, and users—were clearly defined. As a part of external supervision, the local government and the gas management department should monitor the department’s functions and ensure that the investigation and rectification of potential risks were carried out effectively. Gas companies and users at the grassroots level should operate and use gas in compliance with regulations, and in the event of a leak, they should promptly and correctly address the issue. The accident was a result of a series of risk control behaviors that significantly deviated from the safety constraints that should have been enforced by each control level. This deviation ultimately led to the tragic incident.

It is important to highlight that in this particular accident case, obtaining more precise gas leakage parameters such as the leakage rate and pressure can significantly enhance the accuracy of the analysis. By incorporating these detailed parameters into computational fluid dynamics (CFD) simulations, a more comprehensive understanding of the entire gas leakage, diffusion, ignition, and explosion process can be achieved, closely resembling the actual accident scenario. These concepts are poised to become pivotal research directions for utilizing numerical simulations in accident investigations in the future.

Author Contributions

Conceptualization, X.Q.; Data curation, Q.H. and M.Y.; Formal analysis, Q.H.; Funding acquisition, M.Y., X.Q., and P.L.; Investigation, Q.H. and P.L.; Methodology, R.Z.; Project administration, M.Y., X.Q., and P.L.; Resources, R.Z.; Writing—original draft, Q.H. and M.Y.; Writing—review and editing, P.L. All authors have read and agreed to the published version of the manuscript.

Funding

The research presented in this paper was supported by the National Key R&D Program of China (2023YFC3304101), the Science and Technology innovation Program of Beijing institute of technology (2022CX01025), and the Youth Fund of National Natural Science Foundation of China (12302433).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available upon request from the corresponding authors (M.Y. and P.L.).

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Meng, X.; Liu, Q.; Luo, X.; Zhou, X. Risk assessment of the unsafe behaviours of humans in fatal gas explosion accidents in China’s underground coal mines. J. Clean. Prod. 2019, 210, 970–976. [Google Scholar] [CrossRef]

- Zhou, G.; Kong, Y.; Yu, J.; Zhang, Q.; Li, R.; Wang, D.; Fan, T.; Cui, Y.; Li, Z. Experimental study on the flame-dual field overpressure coupling evolution characteristics of LPG/DME blended gas explosion venting. J. Clean. Prod. 2024, 444, 141220. [Google Scholar] [CrossRef]

- Kim, M.Y.; Lee, J.H.; Lee, C.S. Combustion characteristics and NOx emissions of a dimethyl-ether-fueled premixed charge compression ignition engine. Energy Fuels 2008, 22, 4206–4212. [Google Scholar] [CrossRef]

- Planas, E.; Pastor, E.; Casal, J.; Bonilla, J.M. Analysis of the boiling liquid expanding vapor explosion (BLEVE) of a liquefied natural gas road tanker: The Zarzalico accident. J. Loss Prevent. Proc. 2015, 34, 127–138. [Google Scholar] [CrossRef]

- Li, X.; Ma, J. Investigation of urban natural gas pipeline leak and resulting dispersion in a semi-closed space: A case of accident in Shiyan, China. Process Saf. Environ. 2024, 183, 459–475. [Google Scholar] [CrossRef]

- Pang, L.; Li, W.; Yang, K.; Meng, L.; Wu, J.; Li, J.; Ma, L.; Chen, S.; Liang, Y. Civil gas energy accidents in China from 2012–2021. J. Saf. Sci. Resil. 2023, 4, 348–357. [Google Scholar] [CrossRef]

- Tian, B.; Zhao, Z.; Cui, X.; Zhu, J. Characteristics of malignant urban gas accidents in China from 2013 to 2022. Heliyon 2024, 10, 34568. [Google Scholar] [CrossRef]

- Cen, K.; Song, B.; Jiao, W.; Yu, W.; Liu, T.; Zhang, H.; Du, J. Quantitative risk assessment of gas leakage and explosion accidents and its security measures in open kitchens. Eng. Fail. Anal. 2021, 130, 105763. [Google Scholar] [CrossRef]

- Mccann, D.P.J.; Thomas, G.O.; Edwards, D.H. Gas dynamics of vented explosions part 1: Experimental studies. Combust. Flame 1985, 59, 233–250. [Google Scholar] [CrossRef]

- Poli, M.; Grätz, R.; Schröder, V. An experimental study on safety-relevant parameters of turbulent gas explosion venting at elevated initial pressure. Procedia Eng. 2012, 42, 90–99. [Google Scholar] [CrossRef][Green Version]

- Bao, Q.; Fang, Q.; Zhang, Y.; Chen, L.; Yang, S.; Li, Z. Effects of gas concentration and venting pressure on overpressure transients during vented explosion of methane-air mixtures. Fuel 2016, 175, 40–48. [Google Scholar] [CrossRef]

- Bauwens, C.R.; Chao, J.; Dorofeev, S.B. Effect of hydrogen concentration on vented explosion overpressures from lean hydrogen-air deflagrations. Int. J. Hydrogen Energy 2012, 37, 17599–17605. [Google Scholar] [CrossRef]

- Carcassi, M.N.; Fineschi, F. Deflagrations of H2-air and CH4-air lean mixtures in a vented multi-compartment environment. Energy 2005, 30, 1439–1451. [Google Scholar] [CrossRef]

- Chow, S.K.; Cleaver, R.P.; Fairweather, M.; Walker, D.G. An experimental study of vented explosions in a 3:1 aspect ratio cylindrical vessel. Process Saf. Environ. 2000, 78, 425–433. [Google Scholar] [CrossRef]

- Di Sarli, V.; Di Benedetto, A.; Russo, G. Sub-grid scale combustion models for large eddy simulation of unsteady premixed flame propagation around obstacles. J. Hazard. Mater. 2010, 180, 71–78. [Google Scholar] [CrossRef]

- Diakow, P.A.; Thomas, J.K.; Vivanco, E. Comparison of large-scale vented deflagration tests to CFD simulations for partially congested enclosures. J. Loss Prevent. Proc. 2018, 56, 147–154. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, D. Estimation of failure probability of oil and gas transmission pipelines by fuzzy fault tree analysis. J. Loss Prevent. Proc. 2005, 18, 83–88. [Google Scholar]

- Aalirezaei, A.; Kabir, G.; Khan, M.S.A. Dynamic predictive analysis of the consequences of gas pipeline failures using a Bayesian network. Int. J. Crit. Infr. Prot. 2023, 43, 100638. [Google Scholar]

- Zhou, G.; Kong, Y.; Zhang, Q.; Li, R.; Qian, X.; Zhao, H.; Ding, J.; Li, Y.; Yang, S.; Liu, Y. Effect of dimensionless vent ratio on the flame-shock wave evolution dynamics of blended LPG/DME gas explosion venting. Fuel 2024, 358, 130205. [Google Scholar]

- Stein, J.E.; Heiss, K. The Swiss cheese model of adverse event occurrence—Closing the holes. Semin. Pediatr. Surg. 2015, 24, 278–282. [Google Scholar]

- Hansen, O.R.; Gavelli, F.; Ichard, M.; Davis, S.G. Validation of FLACS against experimental data sets from the model evaluation database for LNG vapor dispersion. J. Loss Prevent. Proc. 2010, 23, 857–877. [Google Scholar] [CrossRef]

- Hansen, O.R.; Johnson, D.M. Improved far-field blast predictions from fast deflagrations, DDTs and detonations of vapour clouds using FLACS CFD. J. Loss Prevent. Proc. 2015, 35, 293–306. [Google Scholar] [CrossRef]

- Hu, Q.; Shen, X.; Huang, Z.; Qian, X.; Jiang, J.; Yuan, M.; Pang, L. Shock wave dynamics and venting overpressure hazards induced by indoor premixed hydrogen/air explosion. Int. J. Hydrogen Energy 2014, 51, 830–847. [Google Scholar] [CrossRef]

- Zhang, Q.; Qian, X.; Li, R.; Zhou, G.; Sun, L.; Ma, Y.; Kong, Y. Explosion characteristics and chemical kinetics of blended LPG/DME clean fuel based on pyrolysis and oxidation mechanism model. Fuel 2022, 320, 123896. [Google Scholar] [CrossRef]

- Gong, Y.; Li, Y. STAMP-based causal analysis of China-Donghuang oil transportation pipeline leakage and explosion accident. J. Loss Prevent. Proc. 2018, 56, 402–413. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, C.; Guo, W.; Dai, J.; Zhao, Z. Systems theoretic accident model and process (STAMP): A literature review. Saf. Sci. 2022, 152, 105596. [Google Scholar] [CrossRef]

- Patriarca, R.; Chatzimichailidou, M.; Karanikas, N.; Di Gravio, G. The past and present of System-Theoretic Accident Model and Processes (STAMP) and its associated techniques: A scoping review. Saf. Sci. 2022, 146, 105566. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).