Abstract

Since forest fuel decomposes slowly and increases the risk of forest fires by accumulating over the years, forest fuel management to accelerate the decomposition process is essential to prevent forest fires and protect forest resources. In this study, we conducted experiments on forest fuels (Pinus sylvestris var. mongholica, Larix gmelinii, Quercus mongolica and Fraxinus mandshurica) in four typical plantation forests in northeast China by adding Trichoderma spp. to investigate the decomposition process and the changes in cellulose, hemicellulose and the water-holding capacity of the fuels. The addition of Trichoderma spp. accelerated the decomposition of cellulose, hemicellulose and lignin in the fuel. Trichoderma spp. promoted the ratio of water absorption and loss, as well as the water-holding capacity of the fuels. The ratio of water absorption and loss reached equilibrium when the decomposition time was up to 35 days, and the addition of Trichoderma spp. increased the maximal water-holding capacity of the fuel. The residual ratio of the four types of fuel degraded by the different treatments was inversely proportional to their maximal water-holding capacities and to the residual ratios of cellulose, hemicellulose and lignin. The residual ratios of degradation of the four fuels under different treatments were linearly related to their maximum water-holding capacity, cellulose, hemicellulose and lignin residual ratios. Trichoderma spp. had a positive effect on the degradation effect and water-holding capacity of fuel on the ground surface of four typical plantation forests. The study is of positive significance for the decomposition of fuel in forests, it promotes the development of biological fire prevention technology and provides a basis for the reinforcement of the management of fuel in forests and the protection of forest resources.

1. Introduction

As a natural disaster, forest fires cause serious damage to forest resources and the ecological environment. In order to effectively deal with the occurrence and spread of fires, measures mainly include the management of combustible materials in the early stage, timely fighting after the occurrence of fires and effectively stopping the spread of fires Refs. [1,2,3] Forest fuel is the material basis of forest fires and is a necessary condition for forest combustion, which can be easily regulated by humans, and reasonable management of fuel is of great significance in reducing the risk of fire and preventing forest fires [4]. The decomposition of forest surface fuels in their natural state is a continuous slow process as fuels decompose at different ratios because of significant differences in physical structure, chemical composition and their ability to be colonized by microorganisms during decomposition [5]. Therefore, accelerating their decomposition is of great significance in reducing the forest surface combustible load. Promoting the decomposition of forest surface fuel through microorganisms, reducing the accumulation of fuel and lowering the fire risk level, is a new method to change the traditional forest fire prevention mode and an important technical means of biological fire prevention [6,7,8]. Forest surface fuel has the highest content of cellulose, which is mainly composed of hemicellulose and lignin [9], and accelerating its decomposition is the key to degrading forest surface fuel and selecting suitable decomposing microbial strains is crucial. Trichoderma pers. fungi have a worldwide distribution and are mainly found in moist habitats, such as forests, slopes and ditches, agricultural fields, grasslands, etc. Soil, plant residues such as dead leaves and decaying wood, as well as the substrates of other fungi, can be used as growth substrates, and as a fungus that can secrete cellulase, xylanase and glucoamylase in forest ecosystems, Trichoderma pers. has a beneficial role in the decomposition of combustible material on the forest surface, with a facilitating effect [10]. Most of the studies on microorganisms are in the fields of energy [11], agriculture [12,13], and food [14,15], and fewer studies have been reported on the use of microorganisms in the field of forest fire prevention. Scholars at home and abroad have carried out a large number of studies on the decomposition process of fuel, and the main research methods include the mass balance method, apomictic bag method, bolting leaf method, and layered window screen method [16,17,18]. The influencing factors include temperature [19], humidity [20], geography, biodiversity [21], animals and microorganisms [22,23], but the decomposition process of fuel under the action of xylophagous fungi, as well as its water-holding capacity, is lacking, which limits the understanding of the decomposition of surface combustibles. It is of great significance to investigate the effect of Trichoderma spp. on the decomposition and water-holding capacity of surface fuel to provide a theoretical basis for strengthening the management of forest fuel and effectively preventing fires.

The maximum water-holding capacity of forest surface fuel can be up to 200.0–448.9 percent, trapping 10–20 percent of precipitation. The water-holding capacity of surface fuel is not only the key to predicting the water content of the fuel, it also plays a crucial role in soil and water conservation [24,25,26], and differences in their water-holding characteristics have been the focus of research. Most studies have focused on the differences in water-holding properties of fuel in different forest types in different regions [27] and the water-holding capacity of surface fuel is influenced by a variety of factors, including tree species composition, combustible species, combustible layer thickness, the degree of combustible decomposition [28,29,30], and local climatic conditions [31]. The water-holding properties of the fuel are related to soil porosity [32]. Currently, there are limited studies on the water-holding capacity of fuel treated with microbial agents [33], and it is not clear how to characterize the changes in the water-holding capacity of fuel after decomposition under different agents.

Northeastern China has a typical temperate monsoon climate, with a forest coverage ratio of 87.76% and a forested land area of 7.278 million hectares, with the main forest types dominated by coniferous forests, deciduous broad-leaved forests, and mixed coniferous and broad-leaved forests [34]. Restricted by the geographic location, combustible materials decompose slowly in their natural state and accumulate in large quantities in the forest understory, resulting in a high forest fire risk level and significant fire hazards. The use of microorganisms to accelerate the decomposition of combustible materials on the forest surface, thereby reducing the load of combustible materials on the forest surface and the fire risk level of the forest, is a new and effective means of forest fire management through biological fire prevention technology. This study investigates the effect of Trichoderma spp. on the degradation effect and water-holding properties of four typical plantation forests, which is of positive significance to the study of forest combustible decomposition in the northeast region of China, promotes the development of biological fire prevention technology, and provides a reference for forest fire management.

2. Materials and Methods

2.1. Degradation Experiment

The fuel samples of Pinus sylvestris var. mongholica, Larix gmelinii, Quercus mongolica and Fraxinus mandshurica were collected in October 2021 in northeast China. After collecting the test samples and bringing them back to the laboratory, the surface fuel of Pinus sylvestris var. mongholica, Larix gmelinii, Quercus mongolica and Fraxinus mandshurica were air-dried in the laboratory, and the moisture content of the four combustible samples after treatment was measured [35,36]. After the combustible samples were divided and loaded, the required sample mass was converted based on the air-dried moisture content. Then, 15.00 g of samples were accurately weighed for coniferous species and 12.00 g of samples were accurately weighed for broad-leaved species. The samples were then put into an open plastic box with specifications of 17.0 cm × 11.5 cm × 5.2 cm and loaded into a 90-mesh nylon mesh bag with a diameter of 20 cm × 15 cm to await the subsequent spraying of Trichoderma spp. and degradation tests.

The spore powder of Trichoderma spp. (Guangxi Agricultural Insurance Biotechnology Co., Ltd. in Guangxi, China) was accurately weighed using a balance and prepared as a Trichoderma spp. suspension (effective live fungal number of 1 × 108 CFU/mL). It was then put into an autoclave at 121 °C for 20 min to create Inactivated Trichoderma spp. liquid for standby. This was then prepared with the same concentration of Trichoderma spp. composite and green Trichoderma spp., respectively. The configured fungal solution was then put into a constant temperature oscillation incubator, shaken at 25 °C and 160 r·min−1 for 24 h so that the fungal solution was fully shaken.

The samples were sprayed with Trichoderma viride, Compound Trichoderma, Inactivated Trichoderma, and Ultra-pure water (Control Check) according to the groups, and the amount sprayed was 10.00 g. The spraying was as uniform as possible so that the combustible samples in the box could be in contact with the fungus. After spraying, all the samples were put into the incubation room at 25 °C and 80% air humidity for degradation. The experiment set up three kinds of treatments and a blank control, with each group having three replications. Sampling was done once a week over an experimental cycle of a total of seven weeks. For all types of samples, degradation effects, chemical component content, water-holding properties and other indicators were measured. 84 boxes of samples were set up for each type of tree species, for a total of 336 boxes of samples.

2.2. Sample Measurement

Samples were taken weekly during the degradation process, and the surface combustible samples of Pinus sylvestris var. mongholica, Larix gmelinii, Quercus mongolica and Fraxinus mandshurica were dried in a drying oven at 80 °C until a constant weight, m1, was reached. The initial mass of the combustible samples was recorded as m0, and the degradation ratio was calculated according to the weighing results [37], which were calculated using the following formula:

D (%) = (m0 − m1)/m0 × 100%

The content of cellulose, hemicellulose and lignin in the leaves was determined according to the Van Soest method, in combination with a Hainergy F800 fiber meter [38]. The residual ratio of cellulose, hemicellulose and lignin degradation in the fuel was calculated in the same way. An example for cellulose is described below, with the residual ratio of cellulose calculated as LR:

where Mt (g) is the mass of the dried sample at time t, M0 (g) is the initial air-dried sample mass, Ct (g·g−1) is the content of cellulose at time t and C0 (g·g−1) is the initial content of cellulose.

LR = (Ct × Mt)/(C0 × M0) × 100%

The degraded combustible sample was weighed at 5.00 g in a sample box, placed in an oven set at 80 °C and dried to constant weight, weighed and recorded as M0. It was then removed and placed in an artificial climate incubator at a temperature of 26 °C and a humidity of 80%. The mass of the sample was recorded every hour until the sample was saturated and its mass was recorded as M1. The water-holding capacity of the fuel was calculated [39] using the following formula:

Q = (M1 − M0)/M0

The time for the sample mass to reach water absorption saturation was recorded as t1 and the rate of water absorption of the combustible material was calculated with the following formula:

Vabsorption = (M1 − M0)/t1

The saturated sample remained in the artificial climate incubator with the temperature of the artificial climate incubator set to 26 °C and the humidity set to 15%. The mass of the sample was recorded every hour until the sample reached constant weight, with the mass recorded as M2. The time of water loss and constant weight was recorded as t2 and the data were sorted and calculated to determine the rate of water loss of the sample. The calculation formula is as follows:

where M0 is the sample mass before water absorption (g), M1 is the sample mass after water absorption and saturation (g), Q is the sample water-holding capacity (g·g−1), t1 is the water absorption and saturation time (h), Vabsorption is the sample water absorption rate (g·h−1), M2 is the sample water loss and constant weight mass (g), t2 is the water loss and constant weight time (h) and Vloss is the sample water loss rate (g·h−1).

Vloss = (M1 − M2)/t2

2.3. Data Analysis

The data were statistically analyzed using SPSS 25.0, R 4.2.3 and plotted using Origin 2023 to compare the trends of degradation ratio, water absorption rate, water loss rate, water-holding capacity, cellulose content, hemicellulose content and lignin content under different lignocellulosic fungi treatments, and analyzed using linear regression analysis to test the relationship between the mass loss and water-holding characteristics under various trichoderma fungi treatments.

3. Results and Analyses

3.1. Overall Cellulose Hemicellulose Etc. and Water-Holding Capacity after Degradation of Fuel

The study was conducted for a total of 49 days of degradation experiments and the basic statistics of the experimental results data including means, extreme and percentile values are shown in Table 1. In terms of the percentile of the key indicators, such as mass remaining rate of fuel, cellulose, hemicellulose, residual ratio of lignin, speed of water absorption, speed of water loss and maximum water-holding capacity, which are the concerns of the study, it is evident that the physicochemical properties of the fuels have been significantly altered after degradation.

Table 1.

Basic statistics of experimental data.

3.2. Residual Ratio of Combustible Degradation

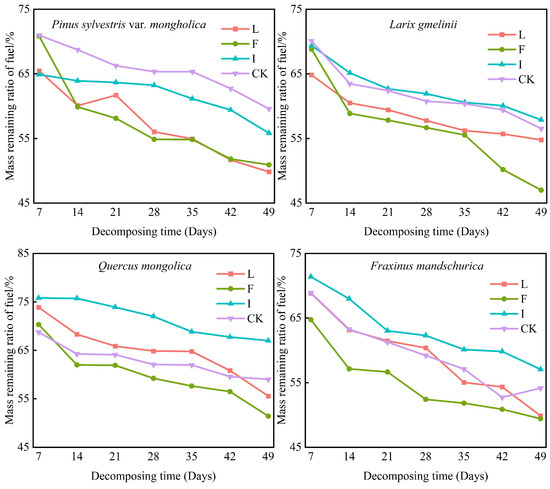

After four different treatments, the mass of four fuels decreased over time, as can be seen in Figure 1. The best degradation effect was observed in larch fuel under the action of Compound Trichoderma. After 49 days of degradation, the quality of the residual ratio was the lowest, at 47.00%. Three kinds of fuel decomposition statuses—Pinus sylvestris var. mongholica, Larix gmelinii and Fraxinus mandshurica—showed more obvious degradation by Trichoderma spp., with a faster decline in mass residual ratio compared to the other two treatements. With Quercus mongolica treated with Trichoderma spp., the decomposition ratio did not show obvious differences compared to the other treatments. The decomposition ratio of each treatment is in the following order: Compound Trichoderma > Trichoderma viride > Control Check > Inactivated Trichoderma.

Figure 1.

Mass remaining ratio of fuel degradation. Note: In the figure, L is Trichoderma viride; F is Compound Trichoderma; I is Inactivated Trichoderma; CK is Control Check. Same as below.

3.3. Decomposition of Combustible Species Cellulose, Hemicellulose and Lignin

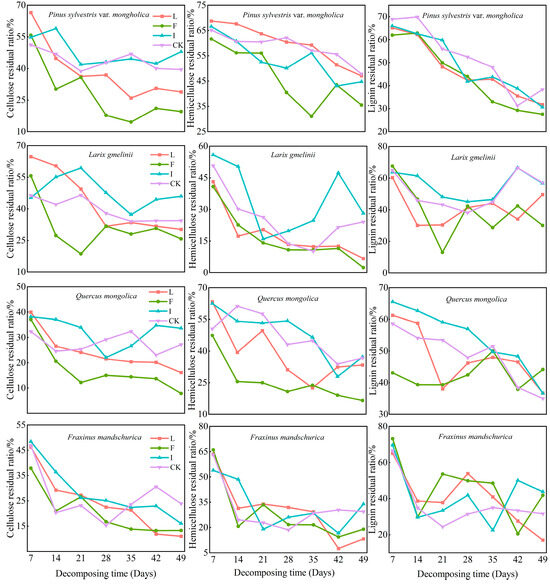

The cellulose, hemicellulose and lignin contents in the fuels of the four forest species under different treatments decreased with increasing decomposition time (Figure 2). In the Pinus sylvestris var. mongholica, Larix gmelinii and Quercus mongolica forests, the order of the combustible cellulose residual was Inactivated Trichoderma > Control Check > Trichoderma viride > Compound Trichoderma, and in the Fraxinus mandshurica forests, the order of the combustible cellulose residual was Control Check > Inactivated Trichoderma > Compound Trichoderma > Trichoderma viride. After 49 days of decomposition, the average residual ratio of cellulose of the four fuels ranged from 16.06% to 34.08%. In the Pinus sylvestris var. mongholica and Larix gmelinii forests, and also Quercus mongolica forests owing to its leathery texture, Trichoderma spp. accelerated the process of decomposition. Compound Trichoderma was superior to single green wood, whereas in Fraxinus mandshurica forests, where fuels were easy to decompose by themselves, the four treatments did not cause significant differences in the promotion of the ratio of cellulose decomposition compared to the previous period.

Figure 2.

Residual ratios of degradation of cellulose, hemicellulose and lignin in fuel.

Among the four fuels, the order of the hemicellulose residual ratio in Pinus sylvestris var. mongholica was Control Check > Trichoderma viride > Inactivated Trichoderma > Compound Trichoderma. The order of the hemicellulose residual ratio in Larix gmelinii and Quercus mongolica forests was Inactivated Trichoderma > Control Check > Trichoderma viride > Compound Trichoderma. The order of the hemicellulose residual ratio in Fraxinus mandshurica was Inactivated Trichoderma > Control Check > Compound Trichoderma > Trichoderma viride. After 49 days of decomposition, the average residual ratio of hemicellulose of the four fuels ranged from 15.32% to 43.80%. From the hemicellulose residual ratio, the degradation effect of Compound Trichoderma mold on hemicellulose was better than that of cellulose, but because cellulose degradation produces hemicellulose, the hemicellulose residual ratio had a short-lived tendency to increase in the experimental process after decomposing for a while.

The order of the lignin residual ratio of the four fuels in Pinus sylvestris var. mongholica and Larix gmelinii was Control Check > Inactivated Trichoderma > Trichoderma viride > Compound Trichoderma. The order of the lignin residual ratio in Quercus mongolica was Compound Trichoderma > Inactivated Trichoderma > Trichoderma viride > Control Check, and the order of the residual ratio of lignin in Fraxinus mandshurica was Inactivated Trichoderma > Compound Trichoderma > Control Check > Trichoderma viride. After 49 days of decomposition, the average residual ratio of lignin of the four fuels ranged from 32.07% to 48.33%.

Residual cellulose, hemicellulose and lignin residual ratios showed differences in response to Trichoderma spp. depending on the type of fuel and, taken together, the addition of Trichoderma spp. accelerated the decomposition of combustible cellulose, hemicellulose and lignin. However, this facilitation increased with the use of trichoderma fungal species due to differences in the ability of the Trichoderma spp. to colonize combustible materials from coniferous and broadleaf types.

3.4. Water-Holding Capacity: Maximum Water-Holding Capacity, Speed of Water-Absorption, Speed of Water-Loss

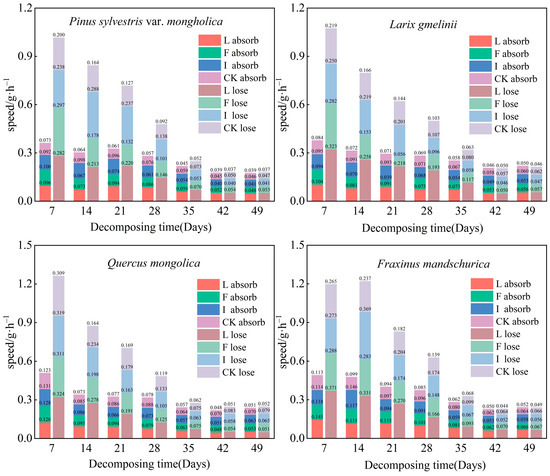

The water absorption and water loss velocities of the fuel showed a gradual decrease with the increase in decomposition time (Figure 3). After 49 days of decomposition, the average range of the water absorption rate of the Pinus sylvestris var. mongholica fuel was in the range of 0.039 to 0.048 g·h−1, and the average range of water loss rate was in the range of 0.037 to 0.053 g·h−1. The average range of the water absorption rate of Larix gmelinii was in the range of 0.049 to 0.059 g·h−1 and the average range of the water loss rate was in the range of 0.046 to 0.062 g·h−1. Quercus mongolica had an average range of water absorption rates of 0.051 to 0.070 g·h−1 and an average range of water loss rates of 0.051 to 0.079 g·h−1. Fraxinus mandshurica had an average range of water absorption rates of 0.052 to 0.066 g·h−1 and an average range of water loss rates of 0.049 to 0.067 g·h−1. Overall, the water loss rate was significantly greater than the water absorption rate and the difference between the two gradually reduced with an increase in time, and the water absorption rate between different fungicides followed the following order: Trichoderma viride (L) > Compound Trichoderma (F) > Inactivated Trichoderma (I) > Control Check (CK).

Figure 3.

Speed of water absorption and loss in fuel.

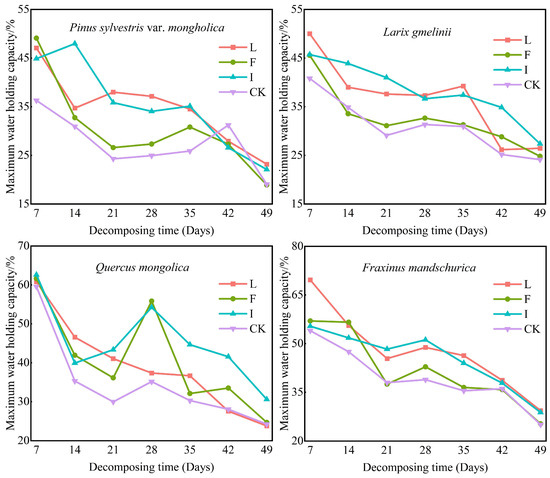

When the combustible material reached equilibrium in the constant temperature and humidity chamber, the maximum water-holding capacity showed a gently decreasing trend with time, and after 49 days of decomposition, the four average maximum water-holding capacity ranges were 18.92–23.20%, 24.14–27.38%, 23.77–30.58% and 25.04–29.35%, respectively (Figure 4). The maximum water-holding ratios of Pinus sylvestris var. mongholica, Larix gmelinii and Fraxinus mandshurica followed (I) > (L) > (F) > (CK) and the maximum water-holding ratio of Quercus mongolica followed (I) > (F) > (L) > (CK).

Figure 4.

Maximum water-holding capacity of fuel.

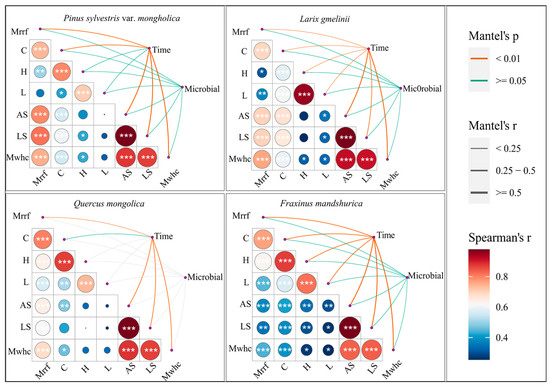

3.5. Correlation between Residual Ratio of Combustible Degradation, Cellulose, Hemicellulose, Lignin and Water-Holding Capacity

Regarding the correlation between the indicators after the degradation of fuel, it can be seen from Figure 5 that after the degradation of the four fuels, the residual ratio of combustible degradation showed a highly significant correlation with cellulose, hemicellulose, lignin, the speed of water absorption, the speed of water loss and the maximum water-holding capacity. A highly significant correlation was found between cellulose, hemicellulose, and lignin, and a highly significant correlation was found between the rate of water absorption, the rate of water loss, and the maximum water-holding capacity. The Larix gmelinii and Fraxinus mandshurica cellulose residual ratios showed a highly significant correlation with the combustible material water absorption rate, water loss rate and maximum water-holding capacity. The Quercus mongolica combustible, hemicellulose and lignin residual ratios were not significantly correlated with the water absorption rate, water loss rate and maximum water-holding capacity. From the results of Manteltest, time had a highly significant effect (p < 0.01) and a statistically significant effect on each index after degradation in Pinus sylvestris var. mongholica, Larix gmelinii and Fraxinus mandshurica, but there was no significant correlation between time and the hemicellulose and lignin residual ratio in Quercus mongolica fuel (p > 0.05). The strains showed a significant correlation (0.01 < p < 0.05) with each index of degraded Pinus sylvestris var. mongholica, Larix gmelinii and Fraxinus mandshurica fuels, but there was no significant correlation (p > 0.05) between strains and each index of degraded fuel in Quercus mongolica fuel.

Figure 5.

Correlation of combustible degradation (cellulose, hemicellulose, lignin) and water-holding properties (rate of water absorption and loss). Note: Mrrf is the mass remaining rate of fuel; C is the cellulose residual ratio; H is the hemicellulose residual ratio; L is the lignin residual ratio; AS is the speed of water absorption; LS is the speed of water absorption; and Mwhc is the maximum water-holding capacity. In the Figure, * represents correlation, ** represents significant correlation, *** represents extremely significant correlation.

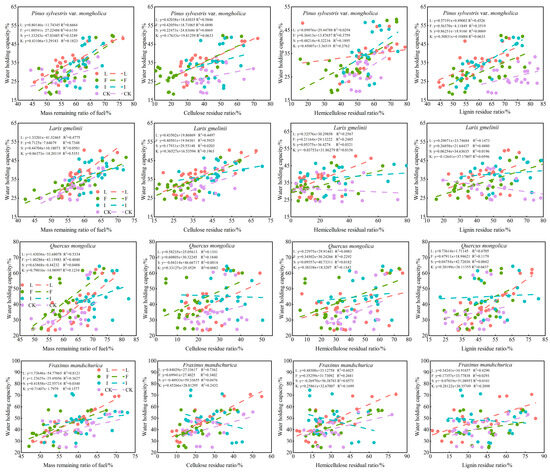

3.6. Linear Fitting of Fuels’ Water-Holding Capacity and Residual Ratio of Degradation, Cellulose, Hemicellulose, Lignin

According to the results of the fitting analysis (Figure 6), the fuel degradation residuals, cellulose residuals, hemicellulose residuals and lignin residuals of Pinus sylvestris var. mongholica were positively correlated with their respective maximum water-holding ratios. The optimal R2 correlation coefficients of the fitting results were 0.6664, 0.5846, 0.3759 and 0.4526, in that order. For Larix gmelinii, the residual ratio of combustible degradation, residual ratio of cellulose, residual ratio of hemicellulose and residual ratio of lignin were positively correlated with the maximum water-holding capacity under the three (I, L, F) treatments, but the residual ratio of hemicellulose and residual ratio of lignin were negatively correlated with the maximum water-holding capacity under the (CK) treatment. The correlation coefficients R2 of the fitted results were 0.7348, 0.5925, 0.2567 and 0.4480, respectively. For the Quercus mongolica combustible material, the cellulose residual ratio was negatively correlated with the maximum water-holding capacity under the treatment of (I), while the maximum water-holding capacity and the residual ratio of combustible degradation, cellulose residual ratio, hemicellulose residual ratio, and lignin residual ratio were positively correlated with the maximum water-holding capacity under the other treatments. The optimal R2 correlation coefficients of the fitting results were 0.5334, 0.1840, 0.2292, and 0.6705, for the combustible material of Fraxinus mandshurica. The residual ratio of cellulose, residual ratio of hemicellulose and residual ratio of lignin were negatively correlated with the maximal water-holding capacity under the treatment of (I), while a positive correlation was maintained under the remaining three (I, L, F) treatments. The optimal R2 correlation coefficients of the fitting results were 0.8121, 0.7362, 0.6025 and 0.4290, in that order.

Figure 6.

Linear fitting of water-holding capacity and residual ratio of degradation, cellulose, hemicellulose and lignin for four fuels.

4. Discussion

4.1. Degradation of Fuel by Trichoderma spp.

The results of the study showed that four different types of combustible decomposition were affected by the Trichoderma spp. agent, with different treatments and different promotion effects on combustible decomposition, and the promotion effect was significantly better than the (CK), which was in line with the expected results. The study showed that under the four treatments, the promotion effect on combustible decomposition was in the order of (F) > (L) > (CK) >(I). After inactivation, the trichoderma was completely inactivated and did not contribute to the combustible decomposition process. Time had a significant effect on combustible degradation, with an average range of 52.56–58.45% combustible residual after 49 days of degradation time. The addition of Trichoderma spp. increased the combustible decomposition effect by 5.47–19.99%.

It was found that the addition of Trichoderma spp. accelerated the decomposition of coniferous fuel significantly better than that of broadleaf species, taking into account that the decomposition process of fuel is limited by biotic factors [40,41,42,43,44], abiotic factors [45,46], and fuel’s own chemical properties [47]. The decomposition ratio is different, and it is also affected by the quantity and quality of the initial addition [48,49]. In itself, broadleaf species fuel decomposes faster than conifers [50,51], so the decomposition ratio of broadleaf surface fuel is not significantly affected by acceleration. However, the thicker cuticle or waxy layer on the surface of conifer fuel retarded the invasion of microbial mycelium and reduced the ratio of combustible decomposition [52], thus resulting in a lower final degradation ratio than that of the broadleaf species. Secondly, the limited surface area of conifer fuel in contact with microbial agents, as well as the increased presence of recalcitrant lignin compounds in fuel, led to a slower decomposition process compared to broadleaf species [53,54]. The ratio of organic matter decomposition is closely related to the quality of the decomposed material and the number of microorganisms. Due to the reduced content of decomposition-resistant fractions (mainly lignin), broadleaves are more readily taken up by microorganisms and therefore degrade more rapidly than material from conifers. Differences in the ratio of combustible decomposition may be due to differences in the physicochemical properties of apoplastic material between species, including stand composition, apoplastic type, thickness, storage, water-holding capacity, and degree of apoplastic decomposition [55,56].

4.2. Effects of Trichoderma spp. on the Degradation of Cellulose, Hemicellulose and Lignin in Fuel

It has been found that cellulose, hemicellulose and lignin tend to increase briefly in the later stages of decomposition. Cellulose, hemicellulose and lignin are large molecules and inherently degrade at a slower ratio compared to the other constituents of fuel [57,58]. During decomposition, cellulose is broken down and the products produce hemicellulose and lignin, leading to an increase in hemicellulose and lignin content [59]. In addition, substances such as cellulose and lignin may originate from the recondensation of lignin degradation products or aromatic compounds formed through microbial metabolism [58]. Secondly, byproducts of lignin degradation may form stabilized nitrogenous compounds that reduce nitrogen availability to decomposing organisms and inhibit lignin degradation [60].

He et al. [59] found that lignin degradation appeared to be a two-stage process during the latent period, consisting of a rapid decomposition phase (early) and a relatively slow decomposition phase (late). In this study, despite the relatively short time scale, significant effects of different decomposition time periods on cellulose, hemicellulose and lignin degradation could be observed. In addition, the combustible species was also an important factor controlling cellulose degradation, which is in agreement with the results of the study by Yue et al. [58] that shows that local scale environmental factors are not only very important for apoplastic mass loss, but also important for the process of cellulose degradation. Lignin and cellulose showed a consistent response to xylem agents. This is because the degradation of combustible lignin is influenced by the composition of cellulose, hemicellulose and pectin, which are shielded by hemicellulose and lignin itself, thus hindering the degradation of lignin and cellulose. In summary, Trichoderma spp., during combustible decomposition, is closely related to the dynamics of lignin and cellulose content in apoplastic material.

4.3. Effect of Trichoderma spp. on the Water-Holding Capacity of Fuel

It was found that the rate of water uptake by the fuel of coniferous species is significantly lower than that of broadleaf species, which may be due to materials covered in cuticles, with hard and difficult to wet leaves, absorb water at a slower rate [24]. Although the maximum water-holding capacity is influenced by the decomposition ratio and water-holding capacity of the combustible material, it was found that the cellulose, hemicellulose and lignin content also affect the decomposition ratio and water-holding capacity. Due to its inherent hydrophobic properties, lignin contributes to toughness and resistance to decay [61]; the rate of water loss of fuel is significantly greater than the rate of water absorption, with the fastest ratio being 210.96 percent faster than the rate of water absorption, and the differences between treatments were not significant in the process of water absorption and water loss.

The magnitude of the water-holding capacity of apoplastic litter is a key parameter in assessing its water-holding capacity, as greater water-holding capacity indicates better water-holding performance [62]. In this study, it was found that the rate of water absorption, water loss and water-holding capacity of the fuels decreased with an increase in decomposition time. Xing et al. [27] found that the water-holding capacity of fuel in both broadleaved evergreen and oak forests showed a decreasing trend corresponding to the decrease in the residual decomposition ratio, which is consistent with the results of this study. The water-holding capacity of fuel includes both the adsorption of water molecules on their surfaces and the storage of water in their internal voids. The density of fuel can reflect its degree of densification; the higher the density, the smaller the specific surface area and the smaller the structural voids. Based on the results of the fitting analysis (Figure 5), while the maximum water-holding capacity contributes to the decomposition ratio and water-holding capacity of fuel, it is important to recognize that the cellulose, hemicellulose and lignin content also influence the decomposition ratio and water-holding capacity.

4.4. Application Prospects and Challenges of Trichoderma spp. in Fire Prevention

The use of Trichoderma spp. acceleration to decompose combustibles can not only reduce the accumulation of combustibles while lowering the risk of fire, but can also promote the release of organic matter, convert degraded organic components into humus fertilizers and ensure the stability of forest ecosystems [8]. This is a new method to change the traditional forest fire prevention model. The research results can provide basic data for forest fuels management and research ideas for subsequent forest combustibles regulation, which has certain significance for preventing forest fires and reducing fire risk levels. Considering the need to maintain a certain temperature and humidity, as well as cost and expenses, in order to ensure the normal growth and survival of microbial agents during large-scale promotion and application, the time period and operation method of spraying microbial agents remain a challenge.

5. Conclusions

This study investigates the effects of Trichoderma spp. on the degradation effects and water-holding properties of combustible materials on the ground surface of four typical plantation forests, namely, Pinus sylvestris var. mongholica, Larix gmelinii, Quercus mongolica and Fraxinus mandshurica. It is of positive significance to study the decomposition of forest fuel in the northeastern region of China to promote the development of biological fire prevention technology and to provide a reference for forest fire management. The study draws the following conclusions:

(1) The addition of wood mold has a promoting effect on the decomposition of four kinds of fuel, namely, Pinus sylvestris var. mongholica, Larix gmelinii, Quercus mongolica and Fraxinus mandshurica, accelerating the decomposition process. The inactivation of wood mold does not have any significant difference compared with the control and does not play a promoting role in the decomposition. However, due to the differences in the colonization ability of wood molds on combustible materials between coniferous and broadleaf species, this promotional effect is enhanced by the type of fungicide and its combination;

(2) The four fuels’ cellulose, hemicellulose and lignin decreased gradually and smoothly with degradation, but in the late stage of decomposition, there was a temporary increase. The water-holding capacity of the four kinds of fuel changed significantly with time and decomposition state. The addition of mycorrhizal fungicides promoted water absorption and water loss rate of fuel, as well as the amount of water-holding capacity. By 35 days of decomposition, the rate of water absorption and water loss rate had basically reached equilibrium. The addition of mycorrhizal fungicides improved the maximum water-holding capacity of fuel;

(3) The residual ratios of degradation of the four fuels under different treatments showed a linear relationship with their maximum water-holding ratios, cellulose, hemicellulose and lignin residual ratios.

Author Contributions

Conceptualization, M.W. and H.Y.; methodology, G.Y. and J.N.; validation, B.L. and X.L.; formal analysis, B.L. and X.L.; investigation, L.W.; resources, G.Y.; data curation, G.Y.; writing—original draft preparation, G.Y. and B.L.; writing—review and editing, Y.Z. and F.Z.; visualization, G.Y. and B.L.; project administration, G.Y., M.W. and H.Y.; funding acquisition, G.Y. All authors have read and agreed to the published version of the manuscript.

Funding

National Forestry and Grassland Administration Project for the Open Competition Mechanism to Select the Best Candidates (202401), National Natural Science Foundation of China (32371881), Fundamental Research Funds for Chinese Academy of Forestry (CAFYBB2024ZA004), Postdoctoral Fellowship Program of China Postdoctoral Science Foundation (GZC20230398).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Plucinski, M.P.; Pastor, E. Criteria and methodology for evaluating aerial wildfire suppression. Int. J. Wildland Fire 2013, 22, 1144–1154. [Google Scholar] [CrossRef]

- Rivera, J.I.; Ebensperger, F.; Valenzuela, F.; Escandar, L.; Reszka, P.; Fuentes, A. Understanding the role of fire retardants on the discontinuous ignition of wildland fuels. Proc. Combust. Inst. 2023, 39, 3775–3783. [Google Scholar] [CrossRef]

- Hood, S.M.; Crotteau, J.S.; Cleveland, C.C. Long-term efficacy of fuel reduction and restoration treatments in N orthern R ockies dry forests. Ecol. Appl. 2024, 34, e2940. [Google Scholar] [CrossRef] [PubMed]

- Fajardo-Cantos, Á.; Peña-Molina, E.; Díaz-Montero, A.; González-Romero, J.; Moya, D.; Lucas-Borja, M.; De Las Heras, J. Short-term Macrochloa tenacissima response understory Pinus halepensis Mill forest after early prescribed burns in a semi-arid landscape. Sci. Total Environ. 2023, 902, 166268. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Xing, P.; Wu, Q.L. Interactions between bacteria and fungi in macrophyte leaf litter decomposition. Environ. Microbiol. 2021, 23, 1130–1144. [Google Scholar] [CrossRef]

- Garcia-Pausas, J.; Casals, P.; Romanyà, J. Litter decomposition and faunal activity in Mediterranean forest soils: Effects of N content and the moss layer. Soil Biol. Biochem. 2004, 36, 989–997. [Google Scholar] [CrossRef]

- Yang, Y.S.; Guo, J.F.; Chen, G.S.; Xie, J.S.; Cai, L.P.; Lin, P. Litterfall, nutrient return, and leaf-litter decomposition in four plantations compared with a natural forest in subtropical China. Ann. For. Sci. 2004, 61, 465–476. [Google Scholar] [CrossRef]

- Adams, M.A.; Neumann, M. Litter accumulation and fire risks show direct and indirect climate-dependence at continental scale. Nat. Commun. 2023, 14, 1515. [Google Scholar] [CrossRef]

- Wilhelm, R.C.; Singh, R.; Eltis, L.D.; Mohn, W.W. Bacterial contributions to delignification and lignocellulose degradation in forest soils with metagenomic and quantitative stable isotope probing. ISME J. 2018, 13, 413–429. [Google Scholar] [CrossRef]

- Rogerson, C.T. The hypocrealean fungi (ascomycetes, Hypocreales). Mycologia 1970, 62, 865–910. [Google Scholar] [CrossRef]

- Zabermawi, N.; Alsulaimany, F.A.; El-Saadony, M.; El-Tarabily, K. New eco-friendly trends to produce biofuel and bioenergy from microorganisms: An updated review. Saudi J. Biol. Sci. 2022, in press. [CrossRef]

- Ghorbani, F.; Karimi, M.; Biria, D.; Kariminia, H.; Jeihanipour, A. Enhancement of fungal delignification of rice straw by Trichoderma viride sp. to improve its saccharification. Biochem. Eng. J. 2015, 101, 77–84. [Google Scholar] [CrossRef]

- Kumaat, E.J.; Manembu, I.S.; Mambu, S.M.; Mangindaan, G.M. Small-Scale Biogas Reactors Converting Organic Waste to Energy and Ferlilizer: A Case Study of Sam Ratulangi University Green Campus Project. J. Sustain. Perspect. 2022, 2, 238–244. [Google Scholar] [CrossRef]

- Graham, A.E.; Ledesma-Amaro, R. The microbial food revolution. Nat. Commun. 2023, 14, 2231. [Google Scholar] [CrossRef] [PubMed]

- Ramírez Damián, M.; Cortes-Perez, N.G.; Quintana, E.T.; Ortiz-Moreno, A.; Noguez, C.G.; Cruceo-Casarrubias, C.E.; Pardo, M.E.S.; G.Bermúdez-Humarán, L. Functional Foods, Nutraceuticals and Probiotics: A Focus on Human Health. Microorganisms 2022, 10, 1065. [Google Scholar] [CrossRef]

- Krishna, M.P.; Mohan, M. Litter decomposition in forest ecosystems: A review. Energy Ecol. Environ. 2017, 2, 236–249. [Google Scholar] [CrossRef]

- Sun, S.; Weng, Y.; Di, X.; Liu, Z.; Yang, G. Screening of Cellulose-degrading Fungi in Forest Litter and Fungal Effects on Litter Decomposition. BioResources 2020, 15, 2937–2946. [Google Scholar] [CrossRef]

- Chakravarty, S.; Rai, P.; Pala, N.A.; Shukla, G. Litter production and decomposition in tropical forest. In Handbook of Research on the Conservation and Restoration of Tropical Dry Forests; IGI Global: Hershey, PA, USA, 2020; pp. 193–212. [Google Scholar] [CrossRef]

- Monroy, S.; Larrañaga, A.; Martínez, A.; Pérez, J.; Molinero, J.; Basaguren, A.; Pozo, J. temperature sensitivity of microbia1 1itter decomposition in freshwaters ro1e of 1eaf 1itter qua1ity and environmenta1 characteristics. Microb. Ecol. 2023, 85, 839–852. [Google Scholar] [CrossRef]

- Ullah, M.R.; Carrillo, Y.; Dijkstra, F.A. Relative contributions of fungi and bacteria to litter decomposition under low and high soil moisture in an Australian grassland. Appl. Soil Ecol. 2023, 182, 104737. [Google Scholar] [CrossRef]

- Getaneh, S.; Honnay, O.; Desie, E.; Helsen, K.; Couck, L.; Shibru, S.; Muys, B. Impact of tree litter identity, litter diversity and habitat quality on litter decomposition rates in tropical moist evergreen forest. For. Ecosyst. 2022, 9, 10. [Google Scholar] [CrossRef]

- Peng, Y.; Vesterdal, L.; Peñuelas, J.; Peguero, G.; Wu, Q.; Heděnec, P.; Yue, K.; Wu, F. Soil fauna effects on litter decomposition are better predicted by fauna communities within litterbags than by ambient soil fauna communities. Plant Soil 2023, 487, 49–59. [Google Scholar] [CrossRef]

- Peng, Y.; Holmstrup, M.; Kappel, S.I.; Ruggiero, B.L.; Schelfhout, S.; Zheng, H.; Hedenec, P.; Yue, K.; Vesterdal, L. Tree species identity is the predominant modulator of the effects of soil fauna on leaf litter decomposition. For. Ecol. Manag. 2022, 520, 120396. [Google Scholar] [CrossRef]

- Ilek, A.; Kucza, J.A.; Szostek, M.G. The effect of stand species composition on water storage capacity of the organic layers of forest soils. Eur. J. For. Res. 2015, 134, 187–197. [Google Scholar] [CrossRef]

- Xing, Z.; Yan, D.; Wang, D.; Liu, S.; Dong, G. Experimental analysis of the effect of forest litter cover on surface soil water dynamics under continuous rainless condition in north China. Kuwait J. Sci. 2018, 45, 75–83. [Google Scholar]

- Du, J.; Niu, J.; Gao, Z.; Chen, X.; Zhang, L.; Li, X.; van Doorn, N.S.; Luo, Z.; Zhu, Z. Effects of rainfall intensity and slope on interception and precipitation partitioning by forest litter layer. Catena 2019, 172, 711–718. [Google Scholar] [CrossRef]

- Xing, J.; Hu, C.; Song, C.; Wang, K.; Song, Y. Nitrogen Deposition Modulates Litter Decomposition and Enhances Water Retention in Subtropical Forests. Forests 2024, 15, 522. [Google Scholar] [CrossRef]

- Jianli, Z.; Jiaguo, W.; Weijie, L.I.; Di, W.U.; Yudong, F.U.; Zhenzhen, J. Litter Reserves and Water-holding Characteristics of Rhododendron Forest in Baili Rhododendron Nature Reserve of Guizhou. J. Soil Water Conserv. 2018, 32, 167–173. [Google Scholar] [CrossRef]

- Klamerus-Iwan, A.; Lasota, J.; Bońska, E. Interspecific Variability of Water Storage Capacity and Absorbability of Deadwood. Forests 2020, 11, 575. [Google Scholar] [CrossRef]

- Chen, B.; Yang, X.; Zhao, X.; Wang, Y.; Tian, C.; Liu, Y.; Liu, P. Hydrological Effects of Six Natural Pure Forests Litters and Soil in Northern Mountain of Hebei Province. J. Soil Water Conserv. 2012, 26, 196. [Google Scholar] [CrossRef]

- Zhou, Q.; Keith, D.M.; Zhou, X.; Cai, M.; Cui, X. Comparing the Water-holding Characteristics of Broadleaved, Coniferous, and Mixed Forest Litter Layers in a Karst Region. Mt. Res. Dev. 2018, 38, 220–229. [Google Scholar] [CrossRef]

- Su, S.; Liu, X. The water storage function of litters and soil in five typical plantations in the northern and southern mountains of Lanzhou, Northwest China. Sustainability 2022, 14, 8231. [Google Scholar] [CrossRef]

- Michaela, H.; Wymore, A.S.; Hungate, B.A.; Egbert, S.; Koch, B.J.; Marks, J.C. Microbes on decomposing litter in streams: Entering on the leaf or colonizing in the water? ISME J. 2022, 16, 717–725. [Google Scholar] [CrossRef]

- Ning, J.; Di, X.; Yu, H.; Yuan, S.; Yang, G. Spatial Distribution of Particulate Matter 2.5 Released from Surface Fuel Combustion of Pinus koraiensis—A Laboratory Simulation Study 1. Environ. Pollut. 2021, 287, 117282. [Google Scholar] [CrossRef]

- Ning, J.; Yang, G.; Zhang, Y.; Geng, D.; Wang, L.; Liu, X.; Li, Z.; Yu, H.; Zhang, J.; Di, X. Smoke exposure levels prediction following laboratory combustion of Pinus koraiensis plantation surface fuel. Sci. Total Environ. 2023, 881, 163402. [Google Scholar] [CrossRef] [PubMed]

- Ning, J.; Yang, G.; Liu, X.; Geng, D.; Wang, L.; Li, Z.; Zhang, Y.; Di, X.; Sun, L.; Yu, H. Effect of fire spread, flame characteristic, fire intensity on particulate matter 2.5 released from surface fuel combustion of Pinus koraiensis plantation–A laboratory simulation study. Environ. Int. 2022, 166, 107352. [Google Scholar] [CrossRef]

- Bai, Y.; Zhou, Y.; Du, J.; Zhang, X.; Di, N. Effects of a broadleaf-oriented transformation of coniferous plantations on the hydrological characteristics of litter layers in subtropical China. Glob. Ecol. Conserv. 2021, 25, e01400. [Google Scholar] [CrossRef]

- Truba, M.; Sosnowski, J. The Effect of Tytanit on Fibre Fraction Content in Medicago x varia T. Martyn and Trifolium pratense L. Cell Walls. Agriculture 2022, 12, 191. [Google Scholar] [CrossRef]

- Yang, Y.; Jing, L.; Li, Q.; Liang, C.; Dong, Q.; Zhao, S.; Chen, Y.; She, D.; Zhang, X.; Wang, L. Big-sized trees and higher species diversity improve water-holding capacities of forests in northeast China. Sci. Total Environ. 2023, 880, 163263. [Google Scholar] [CrossRef] [PubMed]

- Hobbie, S.E.; Reich, P.B.; Oleksyn, J.; Ogdahl, M.; Karolewski, P. Tree species effects on decomposition and forest floor dynamics in a common garden. Ecology 2006, 87, 2288–2297. [Google Scholar] [CrossRef]

- Prescott, C.E. Do rates of litter decomposition tell us anything we really need to know? For. Ecol. Manag. 2005, 220, 66–74. [Google Scholar] [CrossRef]

- Ritter, E. Litter decomposition and nitrogen mineralization in newly formed gaps in a Danish beech (Fagus sylvatica) forest. Soil Biol. Biochem. 2005, 37, 1237–1247. [Google Scholar] [CrossRef]

- Prescott, C.E. Influence of forest floor type on rates of litter decomposition in microcosms. Soil Biol. Biochem. 1996, 28, 1319–1325. [Google Scholar] [CrossRef]

- Castro, H.; Fortunel, C.; Freitas, H. Effects of land abandonment on plant litter decomposition in a Montado system: Relation to litter chemistry and community functional parameters. Plant Soil 2010, 333, 181–190. [Google Scholar] [CrossRef]

- Kurz-Besson, C.; Coûteaux, M.; Berg, B.; Remacle, J.; Ribeiro, C.; Romanyà, J.; Thiéry, J. A climate response function explaining most of the variation of the forest floor needle mass and the needle decomposition in pine forests across Europe. Plant Soil 2006, 285, 97–114. [Google Scholar] [CrossRef]

- Gholz, H.L.; Wedin, D.A.; Smitherman, S.M.; Harmon, M.E.; Parton, W.J. Long-term dynamics of pine and hardwood litter in contrasting environments: Toward a global model of decomposition. Glob. Chang. Biol. 2010, 6, 751–765. [Google Scholar] [CrossRef]

- Chomel, M.; Baldy, V.; Guittonny, M.; Greff, S.; Desrochers, A. Litter leachates have stronger impact than leaf litter on Folsomia candida fitness. Soil Biol. Biochem. 2020, 147, 107850. [Google Scholar] [CrossRef]

- Chadwick, D.R.; Ineson, P.; Woods, C.; Piearce, T.G. Decomposition of Pinus sylvestris litter in litter bags: Influence of underlying native litter layer. Soil Biol. Biochem. 1998, 30, 47–55. [Google Scholar] [CrossRef]

- Hättenschwiler, S.; Tiunov, A.V.; Scheu, S. Biodiversity and litter decomposition in terrestrial ecosystems. Annu. Rev. Ecol. Evol. Syst. 2005, 36, 191–218. [Google Scholar] [CrossRef]

- Amira, D.; Zahrah, S.F.; Anuar, M.; Adha, N. Bioconversion of empty fruit bunch (EFB) and palm oil mill effluent (POME) into compost using Trichoderma virens. Afr. J. Biotechnol. 2012, 10, 18775–18780. [Google Scholar] [CrossRef]

- Sharma, B.L.; Singh, S.P.; Sharma, M.L. Bio-degradation of Crop Residues by Trichoderma Species vis-à vis Nutrient Quality of the Prepared Compost. Sugar Tech 2012, 14, 174–180. [Google Scholar] [CrossRef]

- Gallardo, A.; Merino, J. Leaf decomposition in two Mediterranean ecosystems of southwest Spain: Influence of substrate. Ecology 1993, 74, 152. [Google Scholar] [CrossRef]

- Rowe, J.A.; Litton, C.M.; Lepczyk, C.A.; Popp, B.N. Impacts of Endangered Seabirds on Nutrient Cycling in Montane Forest Ecosystems of Hawai’i1. Pac. Sci. 2017, 71, 495–509. [Google Scholar] [CrossRef]

- Li, S.; Xu, Z.; Yu, Z.; Fu, Y.; Su, X.; Zou, B.; Wang, S.; Huang, Z.; Wan, X. Litter decomposition and nutrient release are faster under secondary forests than under Chinese fir plantations with forest development. Sci. Rep. 2023, 13, 16805. [Google Scholar] [CrossRef]

- Zhao, L.; Meng, P.; Zhang, J.S.; Zhang, J.; Sun, S.J.; He, C. Effect of slopes on rainfall interception by leaf litter under simulated rainfall conditions. Hydrol. Process. 2022, 36, e14659. [Google Scholar] [CrossRef]

- Zhu, X.; Zou, X.; Lu, E.; Deng, Y.; Luo, Y.; Chen, H.; Liu, W. Litterfall biomass and nutrient cycling in karst and nearby non-karst forests in tropical China: A 10-year comparison—ScienceDirect. Sci. Total Environ. 2021, 758, 143619. [Google Scholar] [CrossRef]

- Berg, B.; Lönn, M.; Ni, X.; Sun, T.; Dong, L.; Gaitnieks, T.; De Santo, A.V.; Johansson, M.-B. Decomposition rates in late stages of Scots pine and Norway spruce needle litter: Influence of nutrients and substrate properties over a climate gradient. For. Ecol. Manag. 2022, 522, 120452. [Google Scholar] [CrossRef]

- Yue, K.; Peng, C.; Yang, W.; Peng, Y.; Zhang, C.; Huang, C.; Wu, F. Degradation of lignin and cellulose during foliar litter decomposition in an alpine forest river. Ecosphere 2016, 7, e01523. [Google Scholar] [CrossRef]

- He, M.; Zhao, R.; Tian, Q.; Huang, L.; Liu, F. Predominant effects of litter chemistry on lignin degradation in the early stage of leaf litter decomposition. Plant Soil 2019, 442, 453–469. [Google Scholar] [CrossRef]

- Stevens, C.J. How long do ecosystems take to recover from atmospheric nitrogen deposition? Biol. Conserv. 2016, 200, 160–167. [Google Scholar] [CrossRef]

- Lisý, A.; Ház, A.; Nadányi, R.; Jablonský, M.; Šurina, I. About Hydrophobicity of lignin: A review of selected chemical methods for lignin valorisation in biopolymer production. Energies 2022, 15, 6213. [Google Scholar] [CrossRef]

- Jourgholami, M.; Sohrabi, H.; Venanzi, R.; Tavankar, F.; Picchio, R. Hydrologic responses of undecomposed litter mulch on compacted soil: Litter water-holding capacity, runoff, and sediment. Catena 2021, 210, 105875. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).