Abstract

Thermal Energy Storage (TES) plays a pivotal role in the fire protection of Li-ion batteries, especially for the high-voltage (HV) battery systems in Electrical Vehicles (EVs). This study covers the application of TES in mitigating thermal runaway risks during different battery charging/discharging conditions known as Vehicle-to-grid (V2G) and Grid-to-vehicle (G2V). Through controlled simulations in Simulink, this research models real-world scenarios to analyze the effectiveness of TES in controlling battery conditions under various environmental conditions. This study also integrates Machine Learning (ML) techniques to utilize the produced data by the simulation model and to predict any probable thermal spikes and enhance the system reliability, focusing on crucial factors like battery temperature, current, or State of charge (SoC). Feature engineering is also employed to identify the key parameters among all features that are considered for this study. For a broad comparison among different models, three different ML techniques, logistic regression, support vector machine (SVM), and Naïve Bayes, have been used alongside their hybrid combination to determine the most accurate one for the related topic. This study concludes that SoC is the most significant factor affecting thermal management while grid power consumption has the least impact. Additionally, the findings demonstrate that logistic regression outperforms other methods, with the improving feature to be used in the hybrid models as it can increase their efficiency due to its linearity capture capability.

1. Introduction

EVs are rapidly revolutionizing the automotive and transportation industry, by providing a much cleaner and more sustainable alternative to traditional internal combustion engine vehicles. Their Li-ion batteries are the most common among all of the models in the market and are the main source of the necessary energy storage. However, the critical challenge related to these batteries is the risk of thermal runaway, a condition where an instance of an uncontrolled increase in temperature (spike) can lead to a self-sustaining exothermic reaction, potentially resulting in fires or explosions. This matter absorbs lots of safety concerns, particularly as the adoption of EVs continues to rise.

TES has emerged as a promising solution for enhancing fire protection and managing thermal spikes in Li-ion batteries. They can absorb, store, and release thermal energy, to control temperature fluctuations and mitigate the risks associated with thermal runaway. By integration of TES and EV battery systems, enhancement in battery thermal management and overall safety for these vehicles is possible.

In addition to TES, advancements in ML offer powerful tools for utilization in predicting and preventing thermal runaway incidents. By analyzing the vast amount of stored and real-time data, ML algorithms can identify patterns and predict potential thermal spikes, leading to proactive measures to be taken before a dangerous situation arises. By the combination of ML and TES, optimization of deployment in thermal management strategies in real life can be used to enhance the reliability and effectiveness of the system.

These two are complementary while TES provides physical solutions to thermal management, and ML offers the predictive capabilities to address any potential thermal issues. Also, in order to narrow down the scope of this study, a modified model was developed specifically for this study, using different EVs (V2G or G2V mode) and environmental conditions to make this paper a unique piece of research.

Due to the continuously growing market of the automotive industry, the inherent dangers of thermal runaway, especially in Li-ion batteries pose a significant barrier to the widespread adoption of EVs. This study is driven by the need to consider the safety and reliability of these cars, especially since the integration of these cars is increasing day by day.

Furthermore, the complex interplay among V2G and G2V operations introduces additional challenges in maintaining the safety of the batteries. These power transmissions among EVs and grids can exacerbate thermal management issues due to varying loads and environmental conditions. The usage of TES and ML offers a novel way to overcome this challenge by the usage of real-life Simulink models and physical thermal regulation.

The aim of this paper is to explore the integration of TES and ML for fire protection enhancement in EV batteries by using simulation models in Simulink to resemble various scenarios and gather the data for the application of various ML techniques. The study focuses on high-voltage (HV) battery systems, particularly in the context of V2G and G2V applications, where the interaction between the vehicle and the electrical grid introduces additional complexities in thermal management.

2. Literature Review

The integration of TES and ML for enhancing fire protection in EV batteries represents a multidisciplinary research area that leverages advances in energy storage, thermal management, and artificial intelligence. The aim of this section is to explore existing research related to the area and technological advancements in these fields to provide a solid foundation for the proposed study.

2.1. Thermal Runaway in Lithium-Ion Batteries

Li-ion batteries are central to the operation of EVs, offering key advantages like high-energy density, long life cycles, and remarkable efficiency. Considering these characteristics, they are a perfect candidate for energy storage in EVs. The inherent benefits of Li-ion batteries have played a pivotal role in the widespread adoption of EVs across the globe. Despite all of the perks that this type of battery has, there is a significant risk associated with them. Thermal runaway is a highly dangerous condition where a rapid and uncontrolled increase in the temperature within the battery causes a self-destructive exothermic reaction. It can cause the release of excessive heat, leading to further battery temperature escalation and creating a vicious cycle. As the heat inside the battery increases, the electrolyte inside the battery decomposes, leading to the release of flammable gases. In severe cases, it can cause a fire in the batteries or even explosions.

Moreover, the thermal runaway process also generates particulate matter, which includes tiny metal particles and other debris. When these particles are ejected from the battery they can cause further harm by damaging nearby components, creating short circuits, or even spreading the fire hazard beyond the near components. This secondary risk adds another layer of complexity to the challenges posed by the thermal runaway in Li-ion batteries, enhancing the necessity of comprehensive safety measures and advanced thermal management systems to overcome the mentioned challenges effectively. These factors also can be seen in Figure 1 [1,2,3,4].

2.2. Overview of Thermal Energy Storage (TES) Systems and Their Application in Battery Thermal Management

TES systems emerged as a promising solution for managing heat generation and dissipation in different applications, including Li-ion battery systems. They can absorb, store, and release thermal energy which leads to temperature stabilization and risk mitigation with thermal runaway. This paper considers three types of TES systems. Phase Change Materials (PCMs), which can absorb and release large amounts of heat during phase transitions, making them effective for managing thermal spikes [5]. Sensible heat storage systems, which involve storing thermal energy by changing the temperature of a storage medium, such as water or molten salts. And lastly, latent heat storage, which uses materials that undergo phase changes (solid-liquid, liquid-gas) so that they can store and release energy offering high-energy density and efficient thermal management [6].

For further elaboration on the role of TES systems in battery thermal management, it is essential to discuss the dynamic interaction between TES and the operational battery environment. The integration of TES and Battery Management Systems (BMS) introduces another layer of thermal control that goes beyond passive heat dissipation. By using predicting algorithms within the BMS, TES systems can actively regulate temperature fluctuations that can anticipate probable thermal spikes, especially during critical phases like rapid charging/discharging (V2G and G2V) [7,8].

Moreover, the choice of TES materials and related configurations can be tailored to specific EV batteries profile usage. For instance, during high-demand conditions, where various EVs act as V2G/G2V and their batteries could be subjected to frequent charging/discharging, materials with higher thermal conductivity and phase change efficiency, like, PCMs or hybrid systems may be more effective. Considering that these systems not only could be beneficial for the batteries as they can reduce thermal degradation over time but also they could enhance the life span and efficiency of the batteries [9].

Considering fundamental thermal properties is crucial for evaluating the thermal management capabilities of TES systems for Li-ion batteries. Thermal resistance, measured as 0.6411 degrees Celsius per watt, and thermal time, the duration of the battery temperature reaching 63.2% of its final value, are two important characteristics in this matter. A lower thermal resistance is indicative of a more effective thermal management system, as it suggests that the cell can transfer excess heat away from itself at a faster rate. This factor stabilizes the temperature during V2G and G2V cycles [10].

Figure 1.

Thermal runaway [11].

2.3. Review of Machine Learning Techniques for Thermal Management and Prediction in Battery Systems

ML techniques have gained significant attention for their potential to enhance thermal management and predict thermal runaway incidents in battery systems. By utilizing large datasets and various inputs, ML algorithms can identify patterns and make accurate predictions, enabling proactive thermal management strategies crucial for Li-ion batteries’ safety and reliability in EVs. The following section will discuss various techniques and their case studies in papers.

- Logistic Regression: This method is commonly favored for its ability to provide probability estimates for binary classification tasks, like this study, for predicting the dangerous environment of the EV battery. It can model the probability of the default class as a function of the input features. Other advantages of this model are its simplicity, interpretability, and robustness in terms of statistical significance. In this paper [12], this method had a comprehensive review of its characteristics.

- SVMs: These kinds of methods are effective for classification tasks and are common in identifying high-risk conditions that could cause thermal runaway. They work by finding the optimal hyperplane parameters that separate different classes in data. Related to this matter, this paper [13] demonstrates the usage of SVM in the accurate classification methods related to EVs.

- Naïve Bayes: These kinds of classifiers are efficient and widely used for probabilistic classification tasks in various domains. They operate under a default assumption of independence among features in the dataset. This simplification allows for quick and effective classification, even in a complex dataset [14].

In addition to each technique, the combination of these models through hybrid approaches has been considered in enhancing the predictive performance. By utilizing the strengths of multiple algorithms, hybrid models can provide a more comprehensive and accurate prediction. The combination of logistic regression and SVM, logistic regression and Naïve Bayes, and a combination of logistic regression and Naïve Bayes, have been explored in this study.

The integration of ML techniques for predictive thermal management in EV batteries has gained traction. Recent research highlights the usage of ML algorithms for the real-time monitoring and prediction of thermal events [15,16]. These kinds of studies emphasize the role of ML in optimizing thermal management strategies. By building on these recent developments, this study aims to further explore the synergic application of these techniques in TES matter.

2.4. Novality of the Study

The main novelty of this study is the integration of TES systems with ML techniques in a Simulink simulation to enhance fire protection in Li-ion batteries used in EVS. This uniqueness is explained in several key aspects that differentiate it from previous studies.

- Integration of TES in High-Voltage (HV) Battery Systems for V2G and G2V Applications: Previous studies have explored TES in stationary applications or generic battery systems [17]. However, this study shifts its focus to the application of TES in high-voltage batteries of EVs within the context of V2G and G2V operations. The importance of this concept is crucial due to the bidirectional energy flow between the grid and the vehicle, which has not been specifically addressed in previous studies.

- Identification and Definition of Thermal Spikes Using Simulink: Having a simulated model in Simulink provides this flexibility to explore various conditions of EV battery operations in V2G and G2V. This accessibility allows the precise identification and definition of thermal spikes, which as mentioned in the introduction, are considered critical events leading to thermal runaway. While previous studies mentioned this matter, their focus was on experimental data, which limits the area of study, and used a simpler model. This study relies on leveraging the advanced capabilities of Simulink to simulate real-world conditions accurately and also capture the dynamics in thermal spikes.

- Feature Engineering for Enhanced ML Model Performance: All of the features that are considered for a simulation like this one are not always going to have major impacts on the final prediction. Therefore, this study emphasizes determining the important factors to reduce any useless data or features that could put the prediction at risk of uncertainty and also increase the computational time. Feature engineering as one of the pre-processing methods in ML, provides this capability for the system.

- Comparison of Multiple ML Techniques: While ML has been used in previous studies, this paper conducts a comprehensive comparison of various ML techniques, like logistic regression, support vector regression (SVR), and hybrid models to identify the most effective method among all the mentioned ones by the use of evaluation metrics like R-Squared (R2) or Mean Square Error (MSE). This assessment under different scenarios aids the evaluation to determine the most robust model for the current or future usage.

- Real-World Simulation and Data Collection: Using a powerful software like MATLAB/Simulink (R2024a) provides this situation to not only consider different scenarios with the least amount of expenses or computational time but also allows for the generation of meaningful data that closely represents actual operations of EVs in V2G or G2V modes. Previous studies are mostly limited to theoretical models or real-world data, whereas this study bridges the gap by providing a robust simulation-based data collection methodology.

3. Methodology

This section outlines the simulation model in Simulink that was used for enhancing fire protection in HV Li-ion battery systems used in EVs. It involved various system components to capture the critical battery parameters in order to distinguish dangerous conditions for the HV batteries. Considering either environmental or physical scenarios, a vast amount of data is produced that can be used for ML techniques.

3.1. Simulation Setup

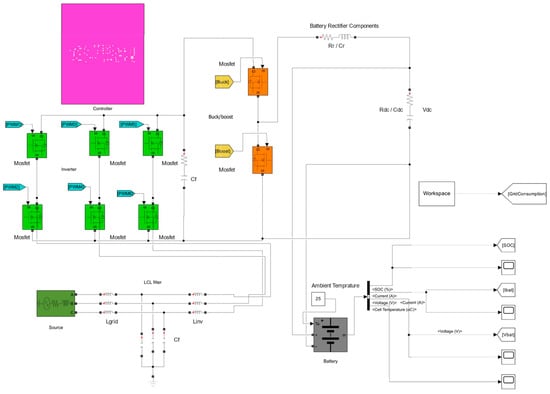

Figure 2 depicts the simulation model for a real-world simulation using Simulink. This model is modified based on models from these papers [18,19]. Key components of the model include a controller to manage battery operations, an inverter for bidirectional energy conversion (V2G or G2V mode), and buck/boost converters for voltage regulation. Additionally, the model features an LCL filter to reduce harmonics and a detailed battery pack representation. Since the model is supposed to resemble the thermal characteristics of the battery, the ambient temperature was also considered to depict the different outputs of the battery towards the injection of current and voltage to detect irregularity. To be more specific, Table 1 contains numbers related to the components that have been used in this simulation.

Figure 2.

EV bidirectional simulation.

Table 1.

Used components in the model and their values.

3.2. Selection of Initial Conditions

The selection of initial conditions is critical for having accurate and representative simulations. For this study, different parameters like nominal voltage or ambient temperature were carefully selected based on industry needs validated in previous studies. These conditions were chosen to ensure the relevancy of simulation outcomes and their applicability to real-world applications.

Nominal voltage and capacity values were obtained from the technical specifications provided by leading EV manufacturers, including Tesla and Nissan, as documented. The initial SoC values were set to represent typical charging conditions that were observed in the daily use of EVs which are crucial for assessing their battery performance. For the ambient temperature, the goal was to choose values based on different weather situations to assess performance under varying conditions.

3.3. Data Collection

To train an ML model efficiently, it is necessary to consider various conditions for the system. Therefore, this study contemplated four different HV batteries with nominal voltages of 300 V, 400 V, 600 V, and 800 V. Data was collected under a variety of environmental conditions and operational scenarios to ensure a comprehensive dataset. Most specifically, the following data points were recorded in Table 1.

The simulations were designed in a way to reflect real-world scenarios where EV batteries interact with an external load in V2G and G2V modes. A household dataset from this source [20] covered 12 different days across the four seasons. In each day, four different batteries have been used to provide a rich and varied dataset for ML training. For the simplification of the simulation, two main operational situations were considered where one was only the V2G mode of a battery in 24 h, and another one was for battery function as a load. The SoC of the battery was allowed to fluctuate between 0% and 100%, with operations halting once these limits were reached. Figure 3 shows the input and output of the ML model.

Figure 3.

Inputs and output of the ML model.

3.4. Feature Engineering/Selection

In the context of HV Li-ion batteries used in EVs, a thermal spike refers to an instance increase in the battery’s internal temperature that is the early indicator of thermal runaway, leading to potential fire explosions. To determine whether the battery is at this risk or not, some analytical measures should be defined to assess the situation.

- Battery Temperature: the temperature of the battery has a direct impact on the battery’s condition and indicates the risk of thermal runaway.

- Rate of Temperature Change (ΔT/Δt): This measurement illustrates the battery temperature changes over time. A high rate of this increase suggests a potential thermal spike.

- Current: High current flows during charging or discharging can lead to increased internal resistance and heat generation, contributing to thermal spikes.

- SoC: The SoC of batteries is usually an indicator of the stability level of thermal behavior. Having batteries at high or low SoC levels may be more susceptible to thermal runaways.

- Voltage: As another impactful unit that has a high impression on the thermal behavior of battery cells, sudden changes in voltage can be associated with thermal spikes.

By using previous indicators and designing a default function for the battery, a classification can be defined to have two various instances of battery operation.

- 0 (No Risk): At this condition, the battery is operating within safe thermal limits with no immediate risk of thermal spike, at least in the short term.

- 1 (At Risk): On the other hand, this situation indicates a warning where the battery is highly capable of thermal runaway.

Using historical data and simulated scenarios to train the ML model, patterns and thresholds that typically precede thermal spikes can be learned. For instance, a combination of a rapidly rising battery temperature, high current, and high SoC might be a solid predictor of a thermal spike.

The feature selection process is a critical component of developing robust and effective ML models. In this study, various features were gathered due to their relevance to the target variable. By applying the SelectKBest method and determining the proper ones by using their correlation with the target variable, they could be ranked and prioritized based on their importance. This method is widely used in these matters and allows the top ‘k’ features based on the univariable statistical test. For this paper, the f_classif function was used to compute the ANOVA F_value for each feature. It could measure the degree of linearity between each feature and the target value. By selecting features with the higher F_values, the model could shift its focus onto only important variables which simplified the model, reduced overfitting, and improved the model performance.

Feature importance scores played a significant role in this selection by providing a quantitative measure of each feature, a prioritizing process can be done. The feature selection process is iterative and data-driven, balancing the need for a comprehensive model with the risk of overfitting [21].

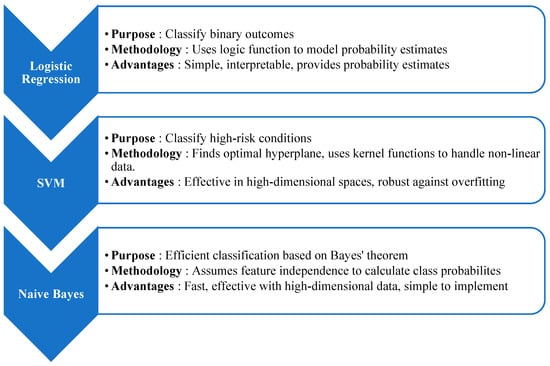

3.5. Machine Learning Model Development

In this study, three different classification methods for the risk assessment of thermal runaway in HV batteries were employed. Logistic regression, SVM, and Naïve Bayes. Logistic regression was chosen due to its simplicity and ability to provide probability estimates. SVM was selected because of its effectiveness in high-dimensional spaces and robustness against overfitting. The Naïve Bayes technique was also utilized for the capability of handling large datasets and complex interactions among features while considering their impact individually. Figure 4 illustrates different aspects of each method.

Figure 4.

Classification methods for thermal runaway risk assessment.

3.6. Evaluation

After doing the simulation based on various scenarios of V2G and G2V alongside gathering enough information and training the ML models, to determine the best one, some evaluations had to be made. For assessing the performance of the classification several key metrics were considered in this study. These metrics provided a comprehensive assessment of how well the models can predict the risk of thermal runaway in high-voltage Li-ion batteries [22].

- Accuracy: This metric measures the proportion of correct predictions (true positives and true negatives) out of total predictions to provide an overall indication of the model’s performance.

- Precision: It indicates the proportion of true positive predictions out of all positive predictions made by the model. It reflects the model’s ability to correctly identify instances of thermal runaway without the possibility of generating false alarms.

- Recall or True Positive Rate (TPR): It assesses the proportion of true positive predictions out of all actual positive instances.

- F1-Score: It is a harmonic mean of precision and recall. It provides a balanced measure of the model’s performance, useful for the times that class distributions are imbalanced.

- False Positive Rate (FPR): FPR is a metric that asses the proportion of negative instances that are incorrectly classified as positive by the model. It is calculated as the formula below.

- Receiver Operating Characteristic (ROC) and Area Under the ROC (AUC): The ROC curve is a graphical representation of a classification model performance across different threshold values. It depicts the TPR against FPR, that shows the tradeoff between sensitivity and specificity as decision threshold varies. The AUC is a scaler value that quantifies the overall ability of the model to discriminate between positive and negative classes.

To determine the practical applications and benefits of integrating TES with ML in HV battery systems, various scenarios were conducted. These different conditions were applied in the Simulink model and the performance of the integrated system also was assessed.

- V2G Operations: The reason for choosing this situation for discharging the batteries is to help the system shave the peak load that stabilizes the grid and assess the thermal risk under high load conditions. Also, it could be used for the evaluation of the battery’s response to grid frequency fluctuations and its impact on thermal behavior.

- G2V Operations: Charging the battery during off-peak hours to analyze thermal risks at different charging rates, and by considering the specific ambient temperature, to study the effects of fluctuating energy inputs.

- Environmental Conditions: To better assess the battery system, different seasonal conditions have been explored to understand the impact of ambient temperature on the battery status changes. Also, by investigating different times of the day, diurnal temperature variations and their effects on the battery performance can be captured.

- Operational Extremes: Putting batteries under heavy load conditions, in V2G mode specifically, aids the thermal stability assessment of the battery to ensure their performance in any load condition.

4. Results

As mentioned, the primary objective of this study is to have an accurate prediction of batteries which are at risk of thermal runaway in HV batteries of EVs. Several inputs were considered for this simulation, as seen in Figure 3, that are crucial for making predictions. The ambient temperature represents the external temperature surrounding the EV battery and directly impacts the battery condition. For a better exploration of batteries, twelve different days, that have various ambient temperatures, are used in this simulation. Another input that is vital for this matter is the battery temperature, which is a direct indicator of thermal runaway risk. The rapid increase in internal temperature can signal a dangerous condition for the battery and necessitate immediate intervention. The SoC is another pivotal characteristic of the battery; a high percentage of it could lead to higher energy densities, making the battery susceptible to thermal runaway.

Battery current, which flows in or out of the battery at V2G/G2V conditions, is significant as the charging/discharging currents can cause heating within the battery, potentially leading to thermal instability and runaway. Battery voltage is another essential factor of thermal runaway and is also important since variation in battery voltage could change the internal state of the battery and affect its stability and safety. Grid power consumption is another factor which impacts the battery’s V2G/G2V condition and has been used in this simulation. Time, denoted by the timestamp of each recorded data point, is essential for analyzing temporal patterns and trends in battery behavior and aides the prediction of thermal runaway events.

This paper considers four different EV models, the Tesla Model S, Nissan Leaf, Chevrolet Bolt EV, and BMW i3 [17,18,19,20], each with distinct specifications, to ensure comprehensive model training and validation. Their specified conditions have been mentioned in Table 2 [23].

Table 2.

Specification of EV batteries used in the study.

In this study, various scenarios were modeled in Simulink to elevate the performance of TES systems in the management of EV batteries under different operating conditions. The following key configurations, some of which are mentioned in Table 2, were applied across all simulated scenarios. The table signifies the selected EV models due to their popularity and representation of a broad range of HV battery systems currently in use.

The nominal voltage and capacity of each model were chosen based on the real-world specifications of the manufacturers. For instance, Tesla with its 375 V nominal voltage and 100 kWh capacity offers a high-capacity battery design, while Nissan Leaf, has a more compact battery which is suitable for urban computing. The other two models represent a balance between range and energy storage, further diversifying the study’s scope.

The initial SoC and ambient temperature conditions were selected considering typical operating environments. The SoC varies from 30% to 60%, reflecting different battery usage scenarios, such as partial charging or discharging cycles. The varied ambient temperature from 12 °C to 22 °C represents moderate climate conditions under each operational EV functionality. These conditions were critical to assessing the efficacy of TES systems in managing battery temperatures, as they have a high impact on the thermal behavior and risk of thermal runaway.

By incorporating these parameters, the study did its best to provide a comprehensive analysis of the TES system’s effectiveness across different EV models and operating conditions. By these various conditions, the system could be adapted for a broad range of applications and offer valuable insights into battery safety performance.

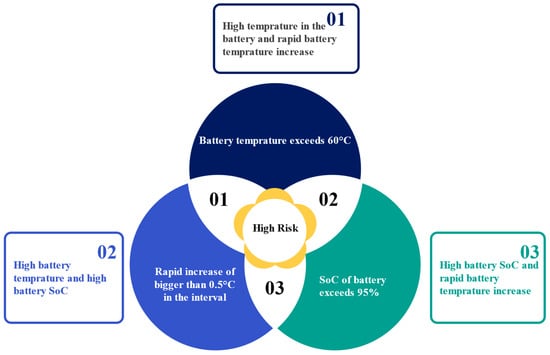

The ML model outputs the predicted risk of thermal runaway, which is classified as either True (high risk) or False (low risk). This risk was determined based on specific conditions of the batteries, most specifically, the rate of temperature change, the temperature itself, and SoC, as seen in Figure 5. If the battery temperature exceeds 60 °C, the rate of the temperature change exceeds 0.5 °C per 30 s, and SoC exceeds 95%, the battery is at high risk of thermal runaway, thereby aiding in the proactive management of battery safety. Various scenarios (e.g., different EVs) were included in this simulation to implement a robust approach to ensure that the ML model could effectively identify and address any potential thermal runaway risk across HV batteries.

Figure 5.

High-risk battery.

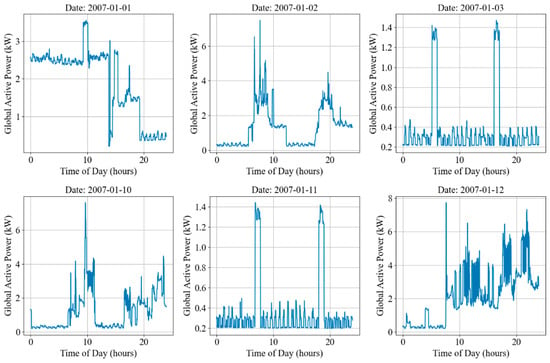

Figure 6 shows the grid power consumption pattern over 24 h. This data displays the fluctuating nature of grid consumption, with values varying significantly throughout each day. These variations are likely the result of multiple factors, including EV charging events, household energy use, and interactions with the grid through V2G applications. The power consumption experienced different peak hours, due to different seasons, emphasizing the significant energy demands of integrating EVs into the grid. This visualization highlights the importance of efficient energy management strategies to handle the variability and ensure the stability of the power grid in dealing with large-scale EV adoption.

Figure 6.

Grid power consumption over time for 6 days.

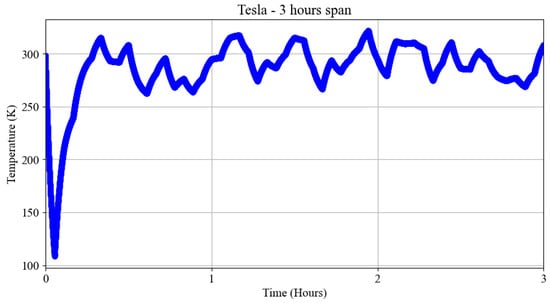

Figure 7 illustrates the profile of one of the EVs, Tesla, during the discharging phase over a span of three hours, demonstrating the dynamic thermal behavior of the battery under operational conditions. Initially, there was a significant drop in temperature, which can be attributed to the initial condition of the battery to the ambient conditions or the activation of the initial heat dissipation mechanism that was used inside the car itself. This phase is vital as it highlights the battery’s adjustability in the immediate operational environment.

Figure 7.

Battery and ambient temperature over time for 4 EVs.

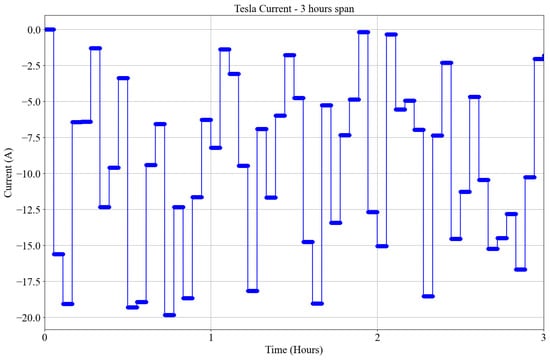

In the next section, Figure 8 shows the battery current over time which reveals significant fluctuations in the current, ranging from −20 to 0 A, indicating dynamic load conditions and a bidirectional current flow characteristic of V2G application. This frequent change in the current profile suggests that the battery was subjected to varying operational requirements, with a stair-step pattern reflecting discrete operational modes or changes in the battery management systems control strategy.

Figure 8.

Battery current over time for 4 EVs.

Figure 9 is the plotted voltage discharge curves for four various EV batteries, illustrating the voltage decay over time under a constant current discharge of 20 A. Initially, they start with a high voltage that is close to their nominal voltage and experience a steep voltage drop within 30 min, which indicates a rapid depletion of charge when the battery is near full capacity. After a couple of hours, the voltage drops gradually and stabilizes around 400 V. These plots highlight the inherent differences in discharge characteristics of each battery type, which are affected by various features like chemistries, capacities, and initial state of charge.

Figure 9.

Battery voltage over time for 4 EVs.

The next phase of this study involved applying the gathered information to ML techniques for predicting the risk of thermal runaway in EV batteries. Several critical factors, as shown in Figure 4, have been considered. These parameters are fed to the ML model, which could process the data to output the probability of thermal risk. By the usage of various advanced techniques (logistic regression, SVM, and Naïve Bayes), the model can analyze complex interactions among these variables, finding different patterns that might be indicative of imminent thermal runaway events.

For this event, various methods have been used. Logistic regression was chosen for its simplicity and interpretability, which offered a clear understanding of the contribution of each feature to the likelihood of thermal runaway. SVM was employed due to its robustness in handling high-dimensional data and its effectiveness in classification tasks, mostly dealing with non-linear datasets. Lastly, Naïve Bayes was included for its computational efficiency and ability to handle large datasets, despite its assumption of feature independence. In the end, various metrics were used to assess the models and determine the best one among all of them.

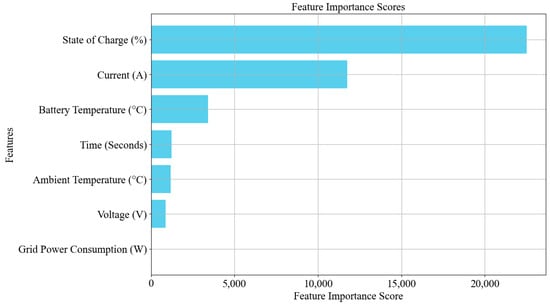

The feature importance diagram, in Figure 10, is the crucial outcome of the feature engineering phase in this study. This visualization illustrates the relative significance of various input parameters in the risk prediction in EV batteries. From the diagram, it is evident that the SoC and current are the most influential factors, with the highest importance scores. Moreover, battery temperature, like the previous two factors, has a positive impact on this prediction. Another important aspect of this diagram is about the grid power consumption; this figure shows that it doesn’t have any impact on the final prediction and it can be eliminated from the features. After this experiment, only four features (SoC, current, battery temperature, and time) were considered for use in the ML training. This approach not only reduces the computational process but also ignores less important features leading to high precision and stability in the model.

Figure 10.

Feature importance scores.

The feature importance diagram in Figure 10 illustrates the relative significance of various input parameters, that are important in predicting the thermal runaway risk in EV batteries. These scores do not have any specific units of measurement because of the fact that they are derived from the internal ML models like the coefficients in linear models. While consideration of all of these parameters is useful for the systems, due to limited computational power for bigger datasets, some of them had to be eliminated. This diagram shows the importance of each parameter and indicates how they should be prioritized. In the end, only the first four features were used for the ML operations.

- SoC: It is the most significant feature as it directly influences the battery’s operational limits. Having high or low SoC levels can lead to overcharging or deep discharging, both of which are known to increase the likelihood of thermal runaway due to the increasing internal resistance and heat generation.

- Current: Another important feature of batteries is the current as its high rate, especially during rapid charging or discharging, can lead to significant heat generation due to internal resistance. This feature’s importance highlights the need for current-level monitoring during battery operation.

- Battery Temperature: It is crucial as it is a direct indicator of the thermal state of the battery. High temperature can lead the inertial components of the battery to reduce the electrolyte’s stability and accelerate undesirable chemical reactions which can culminate in thermal runaway. The importance of this feature underscores its impact on the thermal management systems in EV batteries.

- Time and Ambient Temperature: While these features indicate a less significant role than SoC and Current, they can still play a vital role in influencing the overall thermal behavior of the battery. Time correlates with the duration of exposure to thermal stress, while ambient temperature affects the initial and boundary conditions of the battery’s thermal environment.

- Voltage and Gird Power Consumption: These features have relatively lower importance among others, still they have some contributions to the model itself. Voltage is indirectly related to SoC and internal resistance of batteries and grid power consumption is a broader measure of energy exchange during V2G and G2V operations.

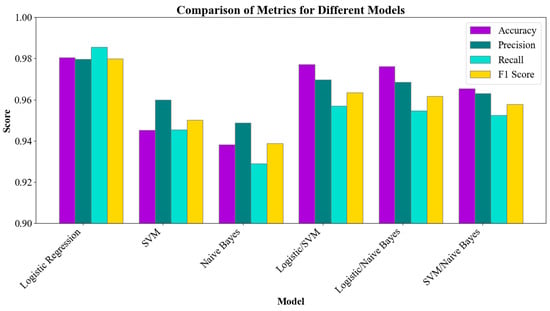

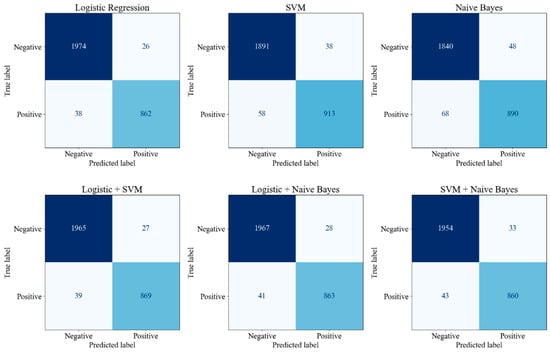

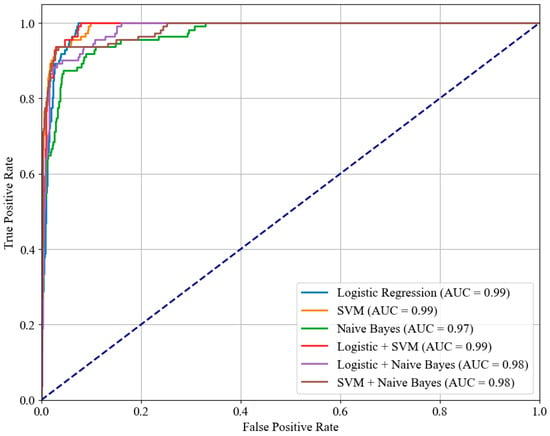

Table 3 and the bar chart, in Figure 11, provide a detailed comparison of the performance metrics for the three classification methods. Logistic regression demonstrates the highest overall performance among the three models. With an accuracy of 0.9805, precision of 0.9797, recall of 0.9856, and F1 score of 0.9798, it reflects a strong balance between all metrics that proves the model’s robustness for the classification tasks. The SVM model, while also performing well, depicts a slight decline in some metrics compared to logistic regression. It has an accuracy of 0.9453, precision of 0.9600, recall of 0.9453, and F1 score of 0.9501. While the previous model represents a significant functionality, this one also has a decent balance among its metrics. Lastly, Naïve Bayes represents a mixed performance. It has the lowest accuracy among the three models at 0.9382, while the precision is surprisingly high, with a rate of 0.9488, a recall of 0.9290, and an F1 score of 0.9388. Confusion matrices and ROC curves have been used to provide a better perspective on this comparison. While the numbers are close, logistic regression could act better in all of them. Figure 12 shows the confusion matrices for different techniques used in this study. Figure 13 shows the Receiver Operating Characteristic (ROC) curves.

Table 3.

Evaluation metrics.

Figure 11.

Comparison of classification methods.

Figure 12.

Confusion matrices comparison of methods.

Figure 13.

Receiver Operating Characteristic (ROC) curves.

Also, after using the hybrid model, the numbers are high enough to suggest that one of them could be the best one. However, logistic regression still acts as the best. One important factor that can be witnessed in this evaluation is the impact of logistic regression over other methods in the hybrid model. Using this technique helped the SVM to increase its accuracy by 4%, and naïve Bayes by 3%. This shows the strength of logistic regression which not only can have high evaluation metrics by itself but also can leverage other models by its combination.

In this study, the focus was on individual methods and their combination to find the best prediction. In the end, the final results depict the privilege of logistic regression over other methods, even when considering the hybrid models. This result will be explored further.

- Combination of Logistic Regression with SVM: Logistic regression is known for its simplicity and effectiveness in binary classification issues, while SVM excels in finding optimal hyperplanes for separating classes in non-linear cases. The hybrid model was expected to benefit from logistic regression’s probabilistic interpretation and SVM’s ability to handle non-linear separations. However, the performance did not surpass the sole method as the dataset did not have enough non-linearities to be captured by SVM, making the logistic regression linear approach sufficiently robust.

- Combination of Logistic Regression with Naïve Bayes: Naïve Bayes is considered a probabilistic method, that assumes all the features are independent of each other, which could be advantageous in certain ways, but not in the models that are enriched with complexities. The hybrid model aimed to handle the categorical data using logistic regression and gain help from Naïve Bayes’ efficiency. However, since the features were not significantly independent in this existing dataset, it diminished the potential benefits of this combination, leading to a slightly lower performance in comparison to the logistic regression alone.

- Overall Observations: Other aspects can impact the implementation, tuning, and data characteristics that could prohibit hybrid models from operating better in certain ways. The results indicate that while these types of models can offer marginal improvements, the logistic regression alone could handle this dataset perfectly. Also, it was found that the linear nature of the problem was well addressed by only using this method alongside the fact that it could also help other combinations, Naïve Bayes and SVM, to increase their performance. Yet, the difference is slight and, in other scenarios, it could be changed.

5. Limitations and Challenges

While this study demonstrated the potential of integrating TES with ML techniques for enhancing thermal management in EV batteries, several limitations need to be acknowledged to clarify the scope of this study while providing context for interpreting the results and highlighting areas for future improvement.

5.1. Simplified Assumptions in Modeling

The primary limitation of this study was the assumption of a simplified model in thermal and electrical modeling for the battery systems. For instance, in the Shepherd model [24], that was used for the battery voltage simulation, it was assumed that there were some limitations related to current distribution and temperature across the temperature of the battery (ambient) while in real life, the thermal and electrical behavior of the batteries are highly non-linear and can be varied based on different factors. These simplifications may put some obstacles and discrepancies between the simulated one and the real-world scenarios, especially under extreme conditions.

5.2. Limited Scope of TES Materials and Configurations

This study only focused on three types of TES systems: PCMs, sensible heat storage, and latent heat storage. However, the performance of these TES systems is evaluated using a generic set of thermal properties without exploring the wide range of material compositions or configurations. Other materials could offer better performance. Also, this study did not consider interactions among different TES, like hybrid TES setups, which restricts the generalizability of the findings that could not apply to other TES configurations.

5.3. Lack of Real-Time Experimental Validation

Although the study put its focus on employing advanced simulation techniques in the Simulink to model the various real-world scenarios, it still can’t capture some of the complexities of real-world thermal management and environmental influences in simulated environments. Without considering the mentioned factors, while the study’s findings could be used in real-world applications, the results could not be guaranteed.

5.4. Constraints in Machine Learning Application

In continuation of previous limitations, the lack of access to high-quality data that could resemble real-world scenarios provides restricted and less accurate situations for ML methods. Also, the models that have been used for this study were selected due to their simplicity, but other methods, like Deep Neural Networks (DNNs) [25] and ensemble methods, could potentially capture complicated relationships among features, making them more useful in real-world conditions.

5.5. Consideration of a Single Battery Type

This study primarily focused on HV battery systems, which are very common in EVs. However, these results could not be directly applicable to other battery chemistries, such as solid-state or alternative chemistry. The thermal characteristics of these batteries could differ significantly from those of Li-ion ones, thus putting some limitations on the scope of this study’s conclusions.

6. Conclusions and Future Research

The primary motivation of this paper was to address the critical safety concerns associated with thermal runaway in HV Li-ion batteries used in EVs. The study explored the integration of TES and ML techniques to enhance the overall safety of EV batteries. The key novelties of this research were to observe the TES capability in HV battery systems for V2G and G2V applications.

The Simulink model in this study was specified for this study to simulate real-world scenarios to explore the EV batteries in various sections of V2G/G2V modes. This model was the representation of battery dynamics, such as thermal characteristics and interactions with the grid. By considering different environmental conditions, various days of the year, and their ambient temperature, the Simulink model provided a proper dataset that closely resembled real-world operations.

Another aspect of this study was utilizing feature selection to determine impactful features on the ML model which also played a crucial role in optimizing the performance of the ML accuracy. From various features, four of them were chosen: SoC, current, battery temperature, and time. This careful selection not only improved the accuracy and robustness of ML models but also reduced computational complexity, ensuring the reliability of the models in dealing with further big datasets.

The evaluation of different ML models highlighted the effectiveness of logistic regression among other methods in the prediction of battery thermal risk, based on the defined assumption. This model demonstrates the highest accuracy (0.9805), precision (0.9797), recall (0.9856), and F1 score (0.9798). SVM and Naïve Bayes also showed promising results, with SVM performing well in handling high-dimensional data and Naïve Bayes offering computational efficiency. These findings could validate the integration of TES and ML techniques in enhancing battery safety and provide a foundation for further research.

Several directions for further research will be mentioned here:

- Real-world Implementation: Future studies should elevate their focus over broader data, by considering various types of energy consumptions or renewable energies to enrich the validation of ML and TES usage. Also, by deploying more days and EVs, there is a high probability of facing new challenges and finding innovative ways to overcome them.

- Advanced ML Techniques and Hybrid Models: Considering more advanced techniques for ML, such as deep learning and ensemble learning or their combination with other methods, could further enhance predictive accuracy and robustness. Also, for doing research over time-series data related to the batteries, long short-term memory (LSTM) could be useful [26].

- Context-Based Evaluation Metrics: While in this study, a broad range of metrics (accuracy, precision, recall, and F1-score) were considered to provide a proper resolution of different models comparison, for future studies, where the focus is regression rather than classification, it would be better to consider context-based evaluation methods that align with the nature of those studies. Metrics like mean squared error (MSE), root mean squared error (RMSE), mean absolute error (MAE), and R-squared (R2) would be more appropriate for assessing the performance of those models [27].

- Broader Range of Scenarios: Expanding the range of scenarios considered in simulations, including various environmental conditions, various types of EVs, and diverse operational modes, would provide a more comprehensive understanding of the system’s performance and adaptability.

- Economic and Environmental Impact Analysis: Conducting economic and environmental impact analyses of TES and ML could help the users and stakeholders to have a better understanding of the cost-benefit ratio and potential ways for reducing the environmental risks associated with thermal runaway.

- Collaboration with Industry: Collaborating with industry partners, including EV manufacturers and energy storage solution providers, gives the chance to facilitate the translation of research findings into practical applications and enhance the adoption of advanced safety measures in the market.

- Simulation and Testing Under Varying Environmental Conditions: Collaborating with industry partners, including EV manufacturers and energy storage solution providers, gives this chance to facilitate the translation of research findings into practical applications and enhance the adoption of advanced safety measures in the market.

Author Contributions

M.M.K.: conceptualization, data curation, formal analysis, investigation, methodology, resources, software, validation, visualization, writing the original draft. H.H.A.: conceptualization, data curation, formal analysis, funding acquisition, investigation, methodology, project administration, resources, software, supervision, validation, visualization, writing review & editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Natural Sciences and Engineering Research Council of Canada (NSERC).

Data Availability Statement

The data that has been used is confidential.

Acknowledgments

The author would like to acknowledge the support of the Natural Sciences and Engineering Research Council of Canada (NSERC) to financially support this work.

Conflicts of Interest

The author declares no conflict of interest.

References

- Tran, M.-K.; Mevawalla, A.; Aziz, A.; Panchal, S.; Xie, Y.; Fowler, M. A Review of Lithium-Ion Battery Thermal Runaway Modeling and Diagnosis Approaches. Processes 2022, 10, 1192. [Google Scholar] [CrossRef]

- Ren, D.; Feng, X.; Liu, L.; Hsu, H.; Lu, L.; Wang, L.; He, X.; Ouyang, M. Investigating the relationship between internal short circuit and thermal runaway of lithium-ion batteries under thermal abuse condition. Energy Storage Mater. 2021, 34, 563–573. [Google Scholar] [CrossRef]

- Kong, D.; Wang, G.; Ping, P.; Wen, J. Numerical investigation of thermal runaway behavior of lithium-ion batteries with different battery materials and heating conditions. Appl. Therm. Eng. 2021, 189, 116661. [Google Scholar] [CrossRef]

- Li, W.; Xue, Y.; Feng, X.; Rao, S.; Zhang, T.; Gao, Z.; Guo, Y.; Zhou, H.; Zhao, H.; Song, Z.; et al. Characteristics of particle emissions from lithium-ion batteries during thermal runaway: A review. J. Energy Storage 2024, 78, 109980. [Google Scholar] [CrossRef]

- Mehling, H.; Brütting, M.; Haussmann, T. PCM products and their fields of application—An overview of the state in 2020/2021. J. Energy Storage 2022, 51, 104354. [Google Scholar] [CrossRef]

- Ushak, S.; Fernández, A.G.; Grageda, M. Using molten salts and other liquid sensible storage media in thermal energy storage (TES) systems. In Advances in Thermal Energy Storage Systems; Elsevier: Amsterdam, The Netherlands, 2015; pp. 49–63. [Google Scholar] [CrossRef]

- Al Miaari, A.; Ali, H.M. Batteries temperature prediction and thermal management using machine learning: An overview. Energy Rep. 2023, 10, 2277–2305. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Chen, W.; Wang, L.; Lin, P.; Qu, C. Online accurate state of health estimation for battery systems on real-world electric vehicles with variable driving conditions considered. J. Clean. Prod. 2021, 294, 125814. [Google Scholar] [CrossRef]

- Mojumder, M.R.H.; Ahmed Antara, F.; Hasanuzzaman, M.; Alamri, B.; Alsharef, M. Electric Vehicle-to-Grid (V2G) Technologies: Impact on the Power Grid and Battery. Sustainability 2022, 14, 13856. [Google Scholar] [CrossRef]

- Olabi, A.G.; Maghrabie, H.M.; Adhari, O.H.K.; Sayed, E.T.; Yousef, B.A.A.; Salameh, T.; Kamil, M.; Abdelkareem, M.A. Battery thermal management systems: Recent progress and challenges. Int. J. Thermofluids 2022, 15, 100171. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium-ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Maresch, K.; Marchesan, G.; Cardoso, G. A logistic regression approach for improved safety of the under-frequency load shedding scheme owing to feeder machine inertia. Electr. Power Syst. Res. 2023, 218, 109189. [Google Scholar] [CrossRef]

- Manoharan, A.; Begam, K.M.; Aparow, V.R.; Sooriamoorthy, D. Artificial Neural Networks, Gradient Boosting and Support Vector Machines for electric vehicle battery state estimation: A review. J. Energy Storage 2022, 55, 105384. [Google Scholar] [CrossRef]

- Carli, F.; Leonelli, M.; Varando, G. A new class of generative classifiers based on staged tree models. Knowl.-Based Syst. 2023, 268, 110488. [Google Scholar] [CrossRef]

- Ali, Z.M.; Jurado, F.; Gandoman, F.H.; Ćalasan, M. Advancements in battery thermal management for electric vehicles: Types, technologies, and control strategies including deep learning methods. Ain Shams Eng. J. 2024, 15, 102908. [Google Scholar] [CrossRef]

- Kiasari, M.; Ghaffari, M.; Aly, H.H. A Comprehensive Review of the Current Status of Smart Grid Technologies for Renewable Energies Integration and Future Trends: The Role of Machine Learning and Energy Storage Systems. Energies 2024, 17, 4128. [Google Scholar] [CrossRef]

- Schimpe, M.; Naumann, M.; Truong, N.; Hesse, H.C.; Santhanagopalan, S.; Saxon, A.; Jossen, A. Energy efficiency evaluation of a stationary lithium-ion battery container storage system via electro-thermal modeling and detailed component analysis. Appl. Energy 2018, 210, 211–229. [Google Scholar] [CrossRef]

- Arancibia, A.; Strunz, K. Modeling of an electric vehicle charging station for fast DC charging. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012; IEEE: New York, NY, USA, 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Kiasari, M.M.; Aly, H.H. A proposed controller for real-time management of electrical vehicle battery fleet with MATLAB/SIMULINK. J. Energy Storage 2024, 99, 113235. [Google Scholar] [CrossRef]

- Kaggle, K. Household Electric Power Consumption. Available online: https://www.kaggle.com/datasets/uciml/electric-power-consumption-data-set?resource=download (accessed on 1 August 2022).

- Cai, J.; Luo, J.; Wang, S.; Yang, S. Feature selection in machine learning: A new perspective. Neurocomputing 2018, 300, 70–79. [Google Scholar] [CrossRef]

- Hossin, M.; Sulaiman, M.N. A Review on Evaluation Metrics for Data Classification Evaluations. Int. J. Data Min. Knowl. Manag. Process 2015, 5, 1–11. [Google Scholar] [CrossRef]

- Ntombela, M.; Musasa, K.; Moloi, K. A Comprehensive Review for Battery Electric Vehicles (BEV) Drive Circuits Technology, Operations, and Challenges. World Electr. Veh. J. 2023, 14, 195. [Google Scholar] [CrossRef]

- Campagna, N.; Castiglia, V.; Miceli, R.; Mastromauro, R.A.; Spataro, C.; Trapanese, M.; Viola, F. Battery Models for Battery Powered Applications: A Comparative Study. Energies 2020, 13, 4085. [Google Scholar] [CrossRef]

- Samek, W.; Montavon, G.; Lapuschkin, S.; Anders, C.J.; Muller, K.-R. Explaining Deep Neural Networks and Beyond: A Review of Methods and Applications. Proc. IEEE 2021, 109, 247–278. [Google Scholar] [CrossRef]

- Shanmuganathan, J.; Victoire, A.A.; Balraj, G.; Victoire, A. Deep Learning LSTM Recurrent Neural Network Model for Prediction of Electric Vehicle Charging Demand. Sustainability 2022, 14, 10207. [Google Scholar] [CrossRef]

- Zhou, J.; Gandomi, A.H.; Chen, F.; Holzinger, A. Evaluating the Quality of Machine Learning Explanations: A Survey on Methods and Metrics. Electronics 2021, 10, 593. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).