Numerical Investigation of the Combustion Characteristics of a Hydrogen-Fueled Engine with Water Injection

Abstract

1. Introduction

2. System Modelling

2.1. Numerical Model

2.2. Boundary Conditions

2.3. IMEP Calculation

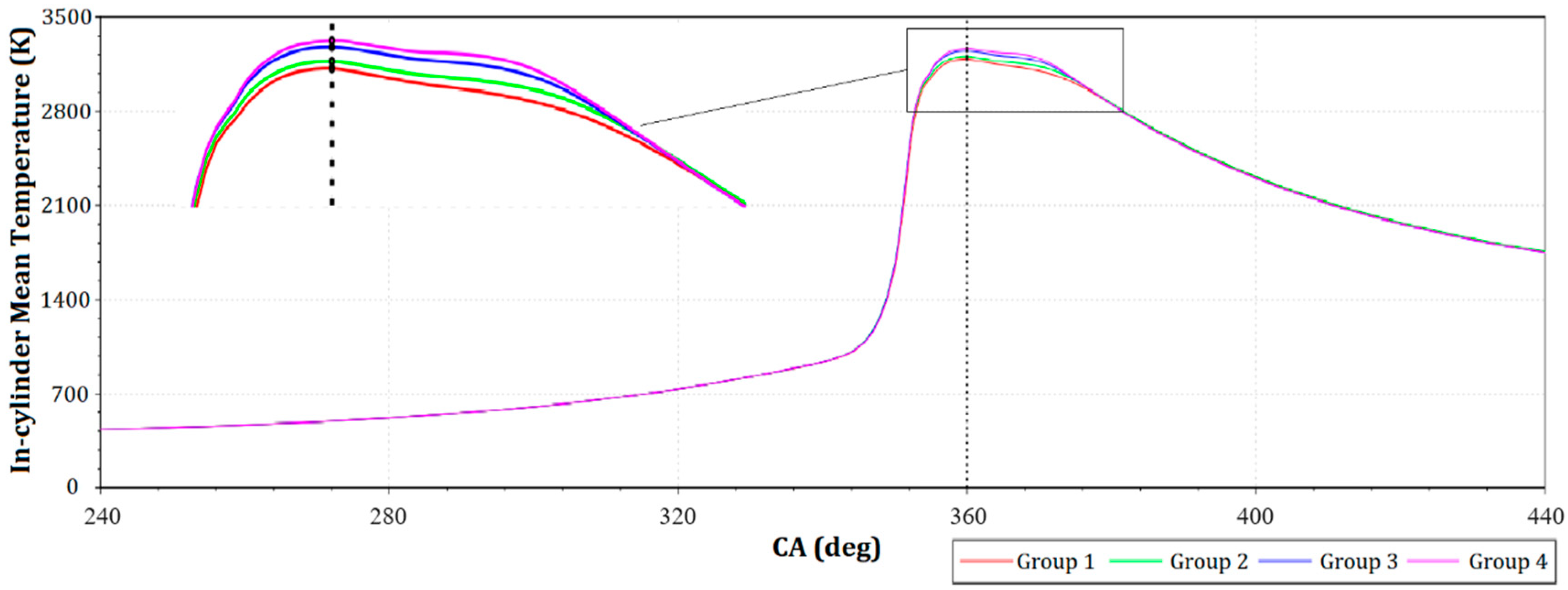

2.4. Validation and Mesh Independence

3. Simulation Results

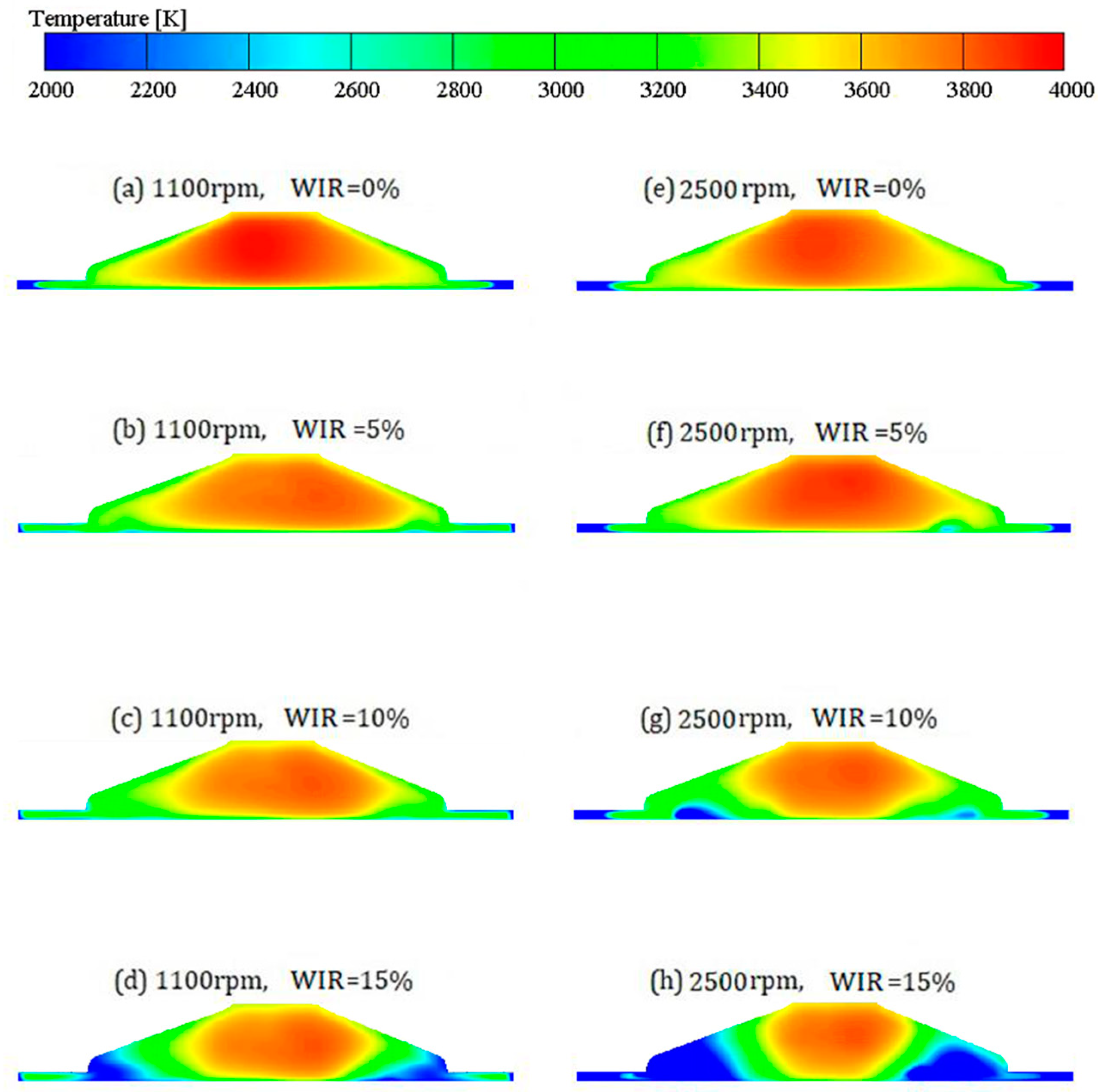

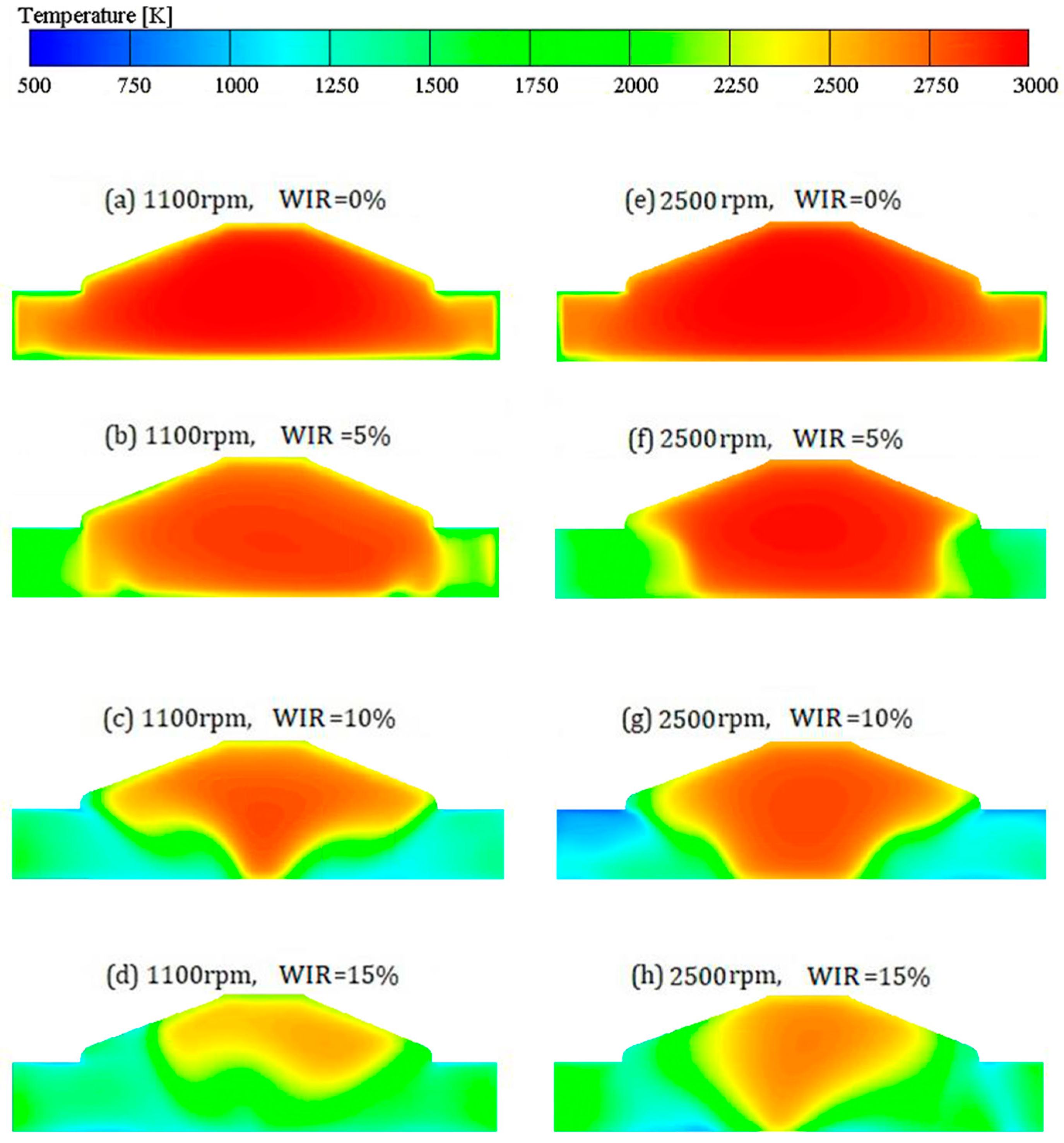

3.1. Temperature Profiles

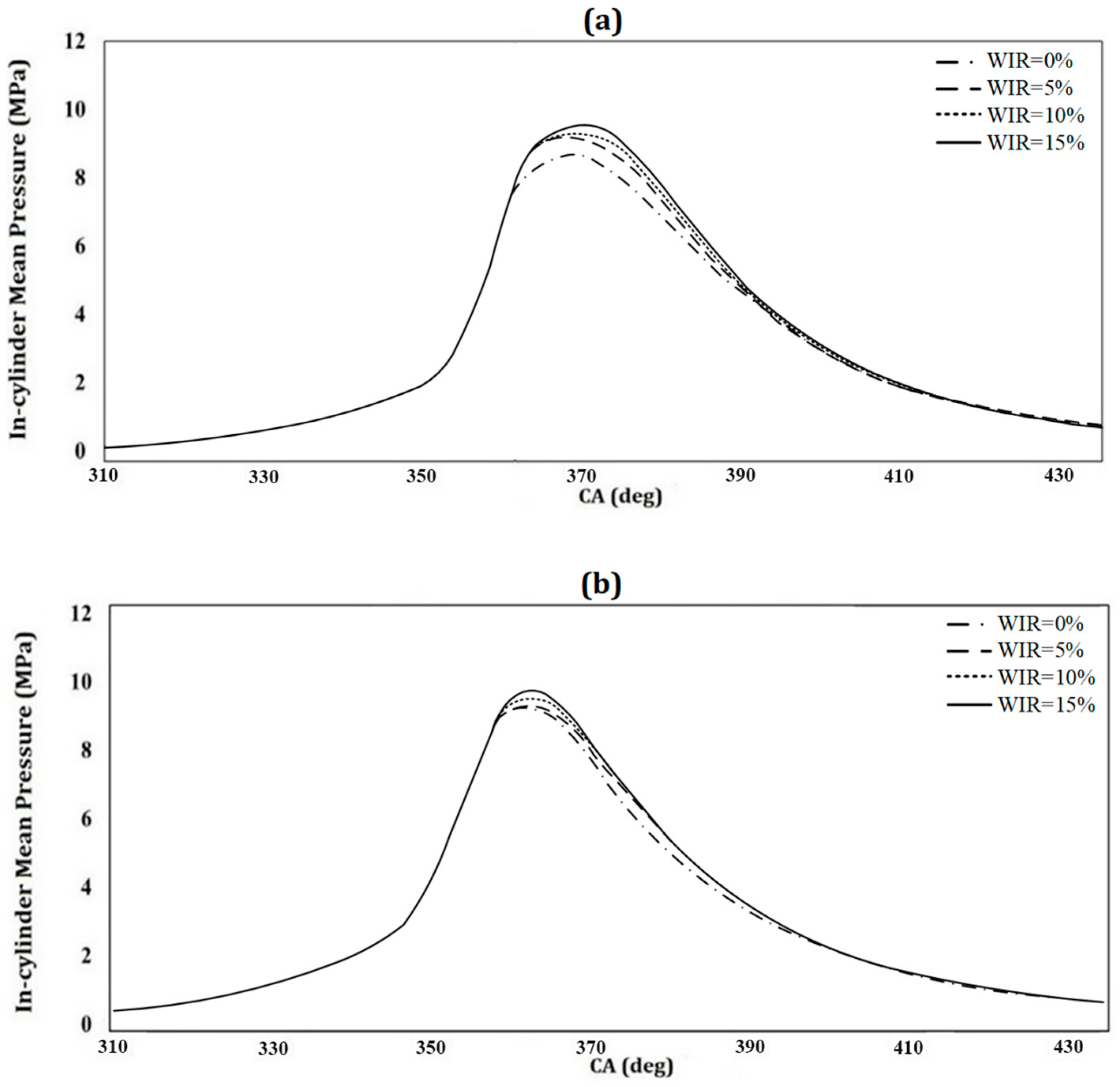

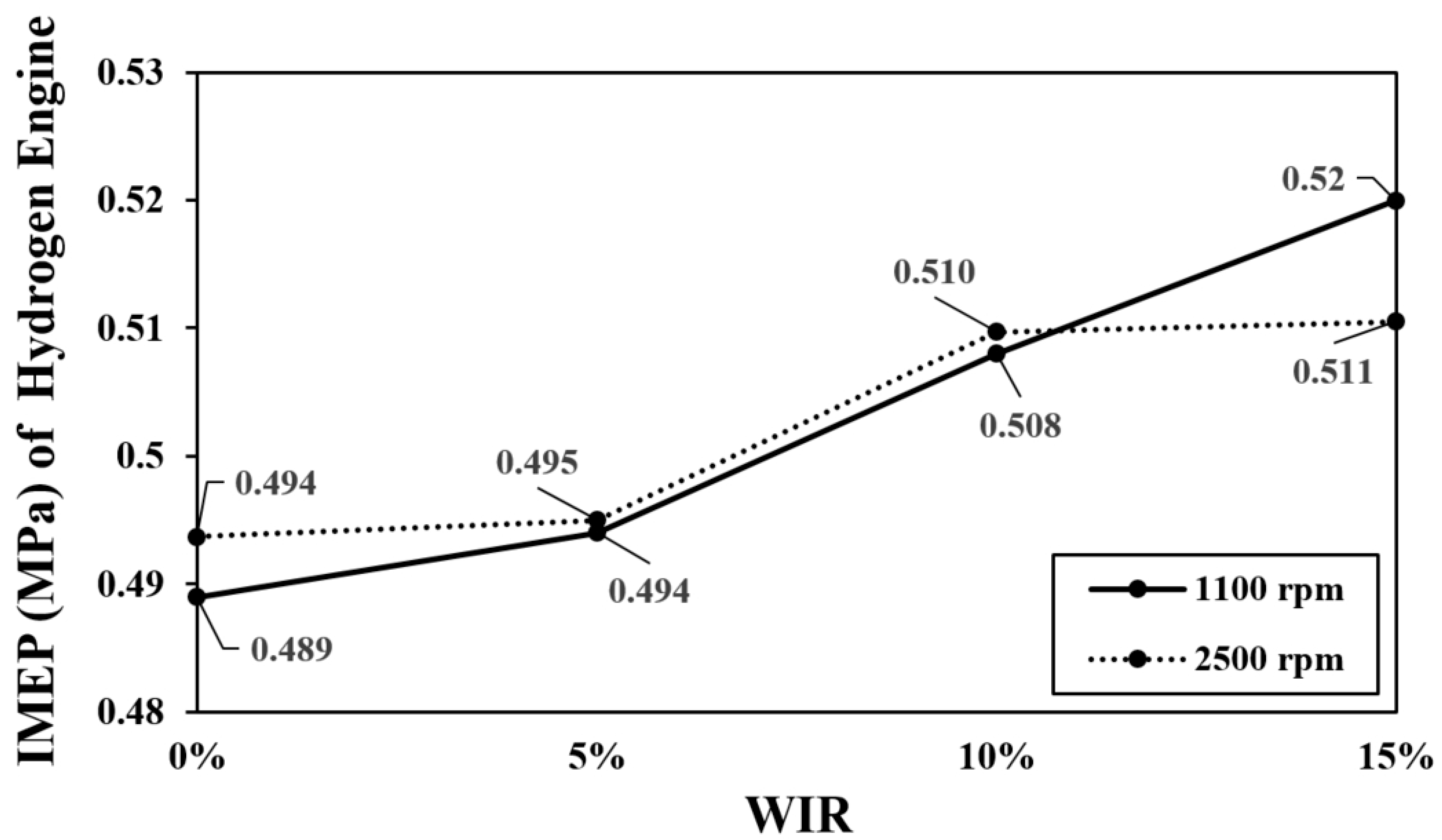

3.2. Pressure and IMEP Profiles

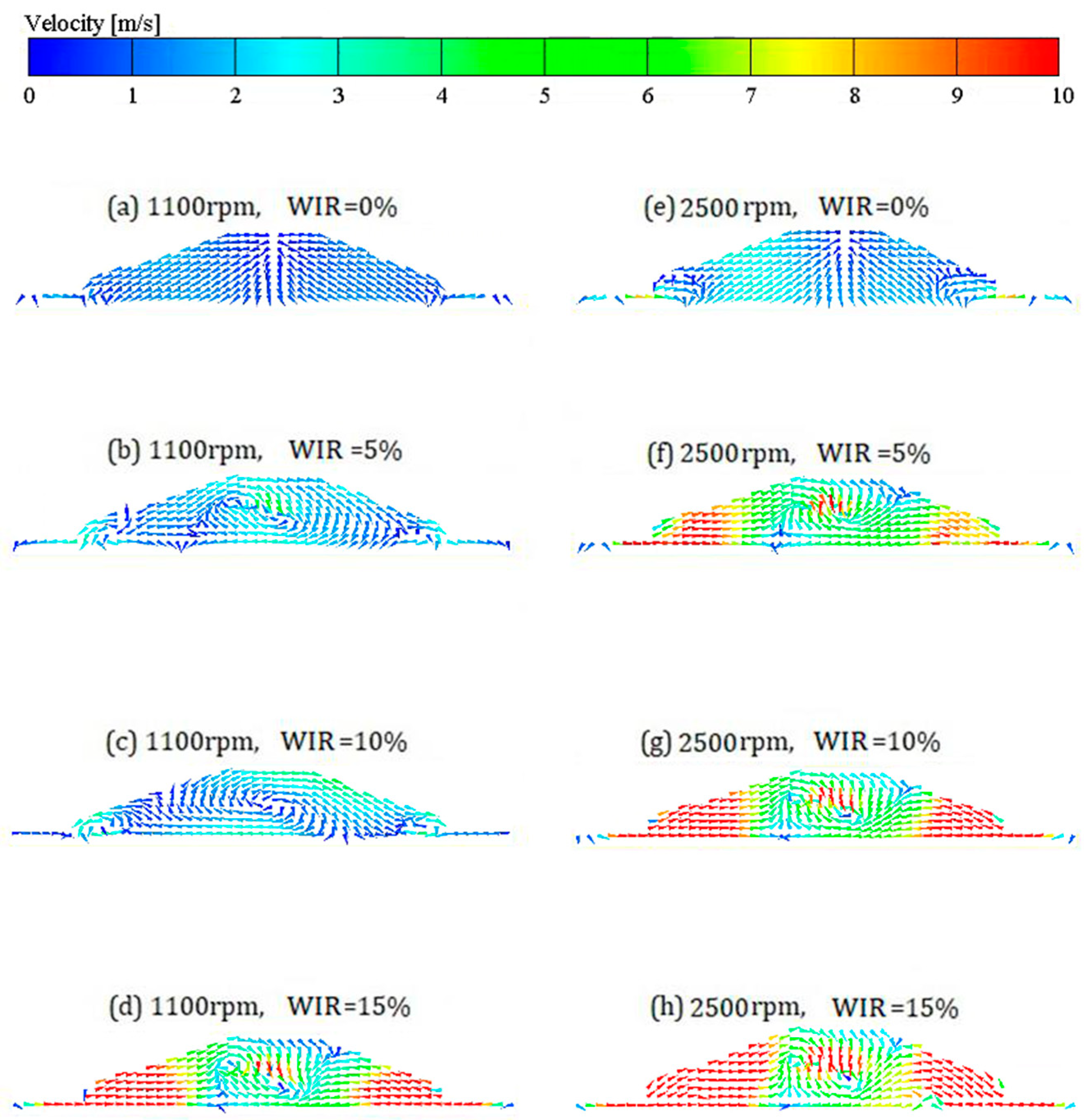

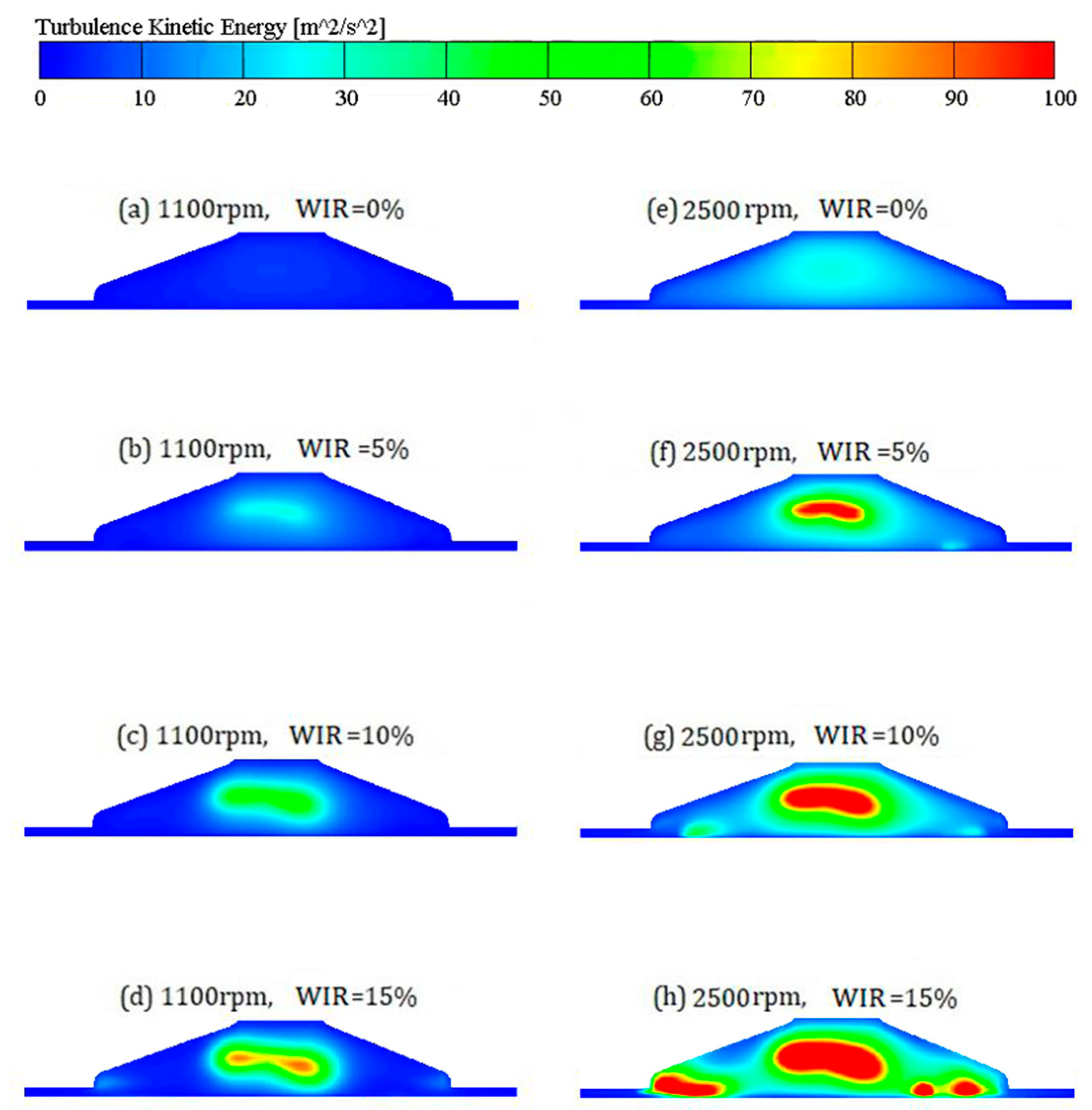

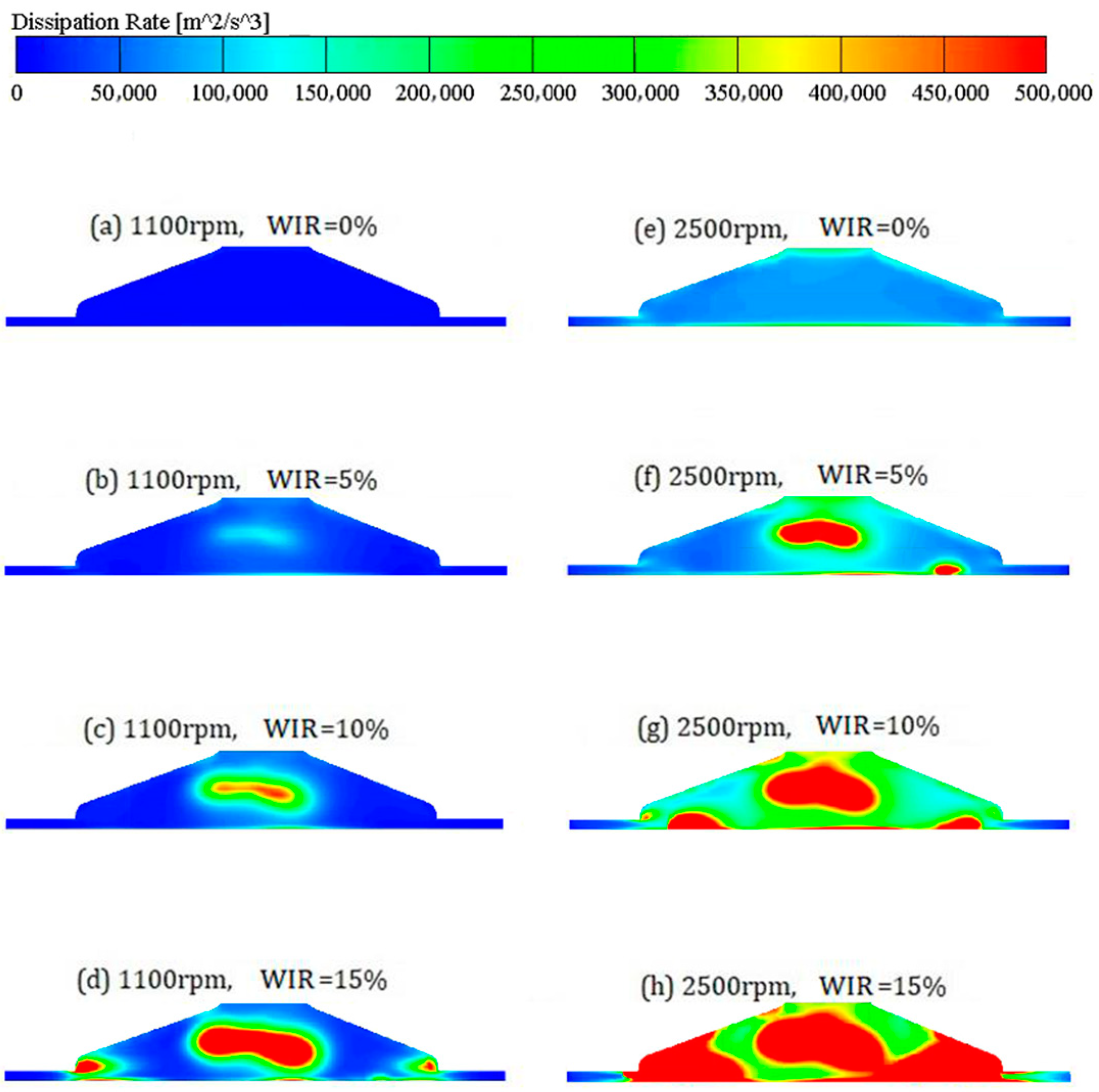

3.3. Internal Flow Characteristics

4. Conclusions

- (1)

- From the perspective of engine health, water injection offers a satisfactory cooling effect during the power stroke, which is conducive to the constant and healthy operation of the engine. However, a WIR exceeding 10% can lead to uneven in-cylinder temperature distribution and high-temperature concentration, generating a large temperature difference on the surfaces of the cylinder head and cylinder wall. This results in excessive thermal stress on the cylinder, potentially affecting the service life of engine components.

- (2)

- From the perspective of engine performance, a higher WIR will increase the engine’s in-cylinder mean pressure and IMEP, which means the engine can provide more power without changing other conditions. However, once the WIR reaches 10%, the optimization effect of water injection is dramatically reduced, especially at 2500 rpm. This indicates that the beneficial effects of water injection are not limitless as the WIR increases.

- (3)

- From the perspective of in-cylinder flow characteristics, the flow velocity and TKE increase with the WIR. Consequently, the combustible gas mixture can be sufficiently mixed, and the speed of the flame propagation can be accelerated within the cylinder by increasing the WIR, which improves the combustion quality. The dissipation rate also increases with the WIR, resulting in greater energy loss and a decline in energy efficiency and engine economy. The most drastic change in the dissipation rate occurs during the phase in which the WIR increases from 10% to 15%.

- (4)

- Comparing all the numerical results in this study, the case of WIR = 15% maximizes the performance of the hydrogen engine; however, such a high WIR is detrimental to engine health and fuel economy. Alternatively, at WIR = 10%, engine performance is close to that at WIR = 15%, but the negative impact on engine health and fuel economy due to water injection is sharply reduced. In summary, the optimum WIR to maintain a hydrogen engine running well is 10%, based on the simulations in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| VS | Swept Volume Per Cylinder (m3) |

| V | Volume of the Combustion Chamber (m3) |

| P | In-cylinder Pressure (Pascal) |

| Abbreviations | |

| CA | Crank Angle |

| CFM | Coupled Flame Model |

| CFD | Computational Fluid Dynamics |

| CI | Compression Ignition |

| GDI | Gasoline Direct Injection |

| IMEP | Indicated Mean Effective Pressure |

| PFI | Port Fuel Injection |

| SI | Spark Ignition |

| TKE | Turbulent Kinetic Energy |

| WIR | Water Injection Ratio |

References

- Gökalp, Ç.; Çınarer, G.; Yeşilyurt, M.K.; Ağbulut, Ü.; Yılbaşı, Z.; Kılıç, K. Application of various machine learning algorithms in view of predicting the CO2 emissions in the transportation sector. Sci. Technol. Energy Transit. 2024, 79, 15. [Google Scholar]

- Amiri, S.S.; Mostafavi, N.; Lee, E.R.; Hoque, S. Machine learning approaches for predicting household transportation energy use. City Environ. Interact. 2022, 7, 100044. [Google Scholar] [CrossRef]

- Yazilitaş, C.; Yilbaşi, Z.; Yeşilyurt, M. Biodiesel production from hempseed (Cannabis sativa L.) oil: Providing optimum conditions by response surface methodology. Sci. Technol. Energy Transit. (STET) 2024, 79, 11. [Google Scholar] [CrossRef]

- Yilbaşi, Z.; Yesilyurt, M.K.; Arslan, M.; Yaman, H. Energy, exergy and exergoeconomic assessment of a compres-sion-ignition engine powered by 1-pentanol, 1-hexanol or 1-heptanol/hempseed oil biodiesel/diesel. Interna-Tional J. Exergy 2023, 42, 410–432. [Google Scholar] [CrossRef]

- Yilbaşi, Z.; Yeşilyurt, M.K.; Arslan, M.; Yaman, H. Understanding the performance, emis-sions, and combustion behaviors of a DI diesel engine using alcohol/hemp seed oil biodiesel/diesel fuel ternary blends: Influence of long-chain alcohol type and concentration. Sci. Technol. Energy Transit. 2023, 78, 5. [Google Scholar] [CrossRef]

- Yilbaşi, Z.; Yesilyurt, M.K.; Yaman, H.; Arslan, M. The industrial-grade hemp (Cannabis sativa L.) seed oil biodiesel application in a diesel engine: Combustion, harmful pollutants, and performance characteristics. Sci. Technol. Energy Transit. 2022, 77, 15. [Google Scholar] [CrossRef]

- Escobar-Jiménez, R.F.; Cervantes-Bobadilla, M.; García-Morales, J.; Aguilar, J.G.; Pérez, J.H.; Alvarez-Gallegos, A. Short communication: The effects of not controlling the hydrogen supplied to an internal combustion engine. Int. J. Hydrogen Energy 2020, 45, 14991–14996. [Google Scholar] [CrossRef]

- Verhelst, S.; Wallner, T. Hydrogen-fueled internal combustion engines. Prog. Energy Combust. Sci. 2009, 35, 490–527. [Google Scholar] [CrossRef]

- Lamas, M.I.; Rodriguez, C.G. Numerical model to analyze Nox reduction by ammonia injection in diesel-hydrogen engines. Int. J. Hydrog. Energy 2017, 4, 26132–26141. [Google Scholar] [CrossRef]

- Castro, N.; Toledo, M.; Amador, G. An experimental investigation of the performance and emissions of a hydrogen-diesel dual fuel compression ignition internal combustion engine. Appl. Therm. Eng. 2019, 156, 660–667. [Google Scholar] [CrossRef]

- White, C.M.; Steeper, R.R.; Lutz, A.E. The hydrogen-fueled internal combustion engine: A technical review. Int. J. Hydrog. Energy 2005, 31, 1292–1305. [Google Scholar] [CrossRef]

- Taghavifar, H.; Khalilarya, S.; Mirhasani, S.; Jafarmadar, S. Numerical energetic and exergetic analysis of CI diesel engine performance for different fuels of hydrogen, dimethyl ether, and diesel under various engine speeds. Int. J. Hydrog. Energy 2014, 39, 9515–9526. [Google Scholar] [CrossRef]

- Hames, Y.; Kaya, K.; Baltacioglu, E.; Turksoy, A. Analysis of the control strategies for fuel saving in the hydrogen fuel cell vehicles. Int. J. Hydrog. Energy 2018, 43, 10810–10821. [Google Scholar] [CrossRef]

- Blum, L.; Deja, R.; Peters, R.; Stolten, D. Comparison of efficiencies of low, mean and high temperature fuel cell Systems. Int. J. Hydrog. Energy 2011, 36, 11056–11067. [Google Scholar] [CrossRef]

- Krishnanunni, J.; Bhatia, D.; Das, L.M. Experimental and modelling investigations on the performance and emission characteristics of a single cylinder hydrogen engine. Int. J. Hydrog. Energy 2017, 42, 29574–29584. [Google Scholar] [CrossRef]

- Ghazal, O.H. Performance and combustion characteristic of CI engine fueled with hydrogen enriched diesel. Int. J. Hydrog. Energy 2013, 38, 15469–15476. [Google Scholar] [CrossRef]

- Boretti, A. Advances in hydrogen compression ignition internal combustion engines. Int. J. Hydrog. Energy 2011, 36, 12601–12606. [Google Scholar] [CrossRef]

- Antunes, J.M.G.; Mikalsen, R.; Roskilly, A.P. An experimental study of a direct injection compression ignition hydrogen engine. Int. J. Hydrog. Energy 2009, 34, 6516–6522. [Google Scholar] [CrossRef]

- Barilo, N.F.; Weiner, S.C.; James, C.W. Overview of the DOE hydrogen safety, codes and standards program part 2: Hydrogen and fuel cells: Emphasizing safety to enable commercialization. Int. J. Hydrog. Energy 2016, 42, 7625–7632. [Google Scholar] [CrossRef]

- Xing, L.; Xiang, W.; Zhu, R.; Tu, Z. Modeling and thermal management of proton exchange membrane fuel cell for fuel cell/battery hybrid automotive vehicle. Int. J. Hydrog. Energy 2022, 47, 1888–1900. [Google Scholar] [CrossRef]

- Stockhausen, W.F.; Natkin, R.J.; Kabat, D.M.; Reams, L.; Tang, X.; Hashemi, S.; Szwabowski, S.J.; Zanardelli, V.P. Ford P2000 Hydrogen Engine Design and Vehicle Development Program; SAE Technical Paper: Warrendale, PA, USA, 2002. [Google Scholar]

- Tang, X.; Kabat, D.M.; Natkin, R.J.; Stockhausen, W.F.; Heffel, J. Ford P2000 Hydrogen Engine Dynamometer Development; SAE Transactions: Warrendale, PA, USA, 2002; pp. 631–642. [Google Scholar]

- Wallner, T.; Lohse-Busch, H.; Gurski, S.; Duoba, M.; Thiel, W.; Martin, D.; Korn, T. Fuel economy and emissions evaluation of BMW Hydrogen 7 Mono-Fuel demonstration vehicles. Int. J. Hydrog. Energy 2008, 33, 7607–7618. [Google Scholar] [CrossRef]

- Pan, H.; Pournazeri, S.; Princevac, M.; Miller, J.W.; Mahalingam, S.; Khan, M.Y.; Jayaram, V.; Welch, W.A. Effect of hydrogen addition on criteria and greenhouse gas emissions for a marine diesel engine. Int. J. Hydrog. Energy 2014, 39, 11336–11345. [Google Scholar] [CrossRef]

- Sun, Z.-Y.; Liu, F.-S.; Liu, X.-H.; Sun, B.-G.; Sun, D.-W. Research and development of hydrogen fuelled engines in China. Int. J. Hydrog. Energy 2012, 37, 664–681. [Google Scholar] [CrossRef]

- Becherif, M.; Ramadan, H.; Cabaret, K.; Picard, F.; Simoncini, N.; Béthoux, O. Hydrogen energy storage: New techno-economic emergence solution analysis. Energy Procedia 2015, 74, 371–380. [Google Scholar] [CrossRef]

- Abe, J.O.; Popoola, A.; Ajenifuja, E.; Popoola, O. Hydrogen energy, economy and storage: Review and recommendation. Int. J. Hydrog. Energy 2019, 44, 15072–15086. [Google Scholar] [CrossRef]

- Chen, Y.; Lou, D.; Zhang, Y.; Fang, L.; Yang, D.; Ren, D.; Song, G. An investigation on the H2O, unburned H2 and NO emission characteristics from a direct injection hydrogen engine. Int. J. Hydrog. Energy 2024, 81, 1181–1191. [Google Scholar] [CrossRef]

- Mingrui, W.; Sa, N.T.; Turkson, R.F.; Jinping, L.; Guanlun, G. Water injection for higher engine performance and lower emissions. J. Energy Inst. 2017, 90, 285–299. [Google Scholar] [CrossRef]

- Chintala, V.; Subramanian, K. Experimental investigation of hydrogen energy share improvement in a compression ignition engine using water injection and compression ratio reduction. Energy Convers. Manag. 2016, 108, 106–119. [Google Scholar] [CrossRef]

- Fu, L.; Wu, Z.; Yu, X.; Deng, J.; Hu, Z.; Li, L. Experimental investigation of combustion and emission characteristics for internal combustion rankine cycle engine under different water injection laws. Energy Procedia 2015, 66, 89–92. [Google Scholar] [CrossRef][Green Version]

- Arabaci, E.; İçingür, Y. Thermodynamic investigation of experimental performance parameters of a water injection with exhaust heat recovery six-stroke engine. J. Energy Inst. 2016, 89, 569–577. [Google Scholar] [CrossRef]

- Nour, M.; Kosaka, H.; Abdel-Rahman, A.K.; Bady, M. Effect of water injection into exhaust manifold on diesel engine combustion and emissions. Energy Procedia 2016, 100 (Suppl. C), 178–187. [Google Scholar] [CrossRef]

- Berni, F.; Breda, S.; Lugli, M.; Cantore, G. A numerical investigation on the potentials of water injection to increase knock resistance and reduce fuel consumption in highly downsized GDI engines. Energy Procedia 2015, 81, 826–835. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, F.; Han, K.; Zhu, Z.; Liu, Y. Effects of intake manifold water injection on combustion and emissions of diesel engine. Energy Procedia 2014, 61, 777–781. [Google Scholar] [CrossRef]

- Arabaci, E.; İçingür, Y.; Solmaz, H.; Uyumaz, A.; Yilmaz, E. Experimental investigation of the effects of direct water injection parameters on engine performance in a six-stroke engine. Energy Convers. Manag. 2015, 98, 89–97. [Google Scholar] [CrossRef]

- Bozza, F.; De Bellis, V.; Teodosio, L. Potentials of cooled EGR and water injection for knock resistance and fuel consumption improvements of gasoline engines. Appl. Energy 2016, 169, 112–125. [Google Scholar] [CrossRef]

- Yu, H.; Su, Y.; Shen, B.; Zhang, Y.; Wang, B.; Xie, F. Experimental study on knock suppression by direct water injection and direct ammonia-water injection based on low-flow injector under high load. Appl. Therm. Eng. 2024, 255, 124055. [Google Scholar] [CrossRef]

- Ianniello, R.; Pipicelli, M.; Di Luca, G.; Beatrice, C.; Di Blasio, G. A study on supercritical water injection as waste heat recovery system in in-ternal combustion engines. Appl. Therm. Eng. 2024, 248, 123084. [Google Scholar] [CrossRef]

- Taghavifar, H.; Anvari, S.; Parvishi, A. Benchmarking of water injection in a hydrogen-fueled diesel engine to reduce emissions. Int. J. Hydrog. Energy 2017, 42, 11962–11975. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhong, X.; Zhao, X.; Wang, Y.; Zheng, Z.; Yao, M.; Wang, H. Numerical investigation on combustion system optimization of stoichiometric operation natural gas engine based on knocking boundary extension. Fuel 2021, 290, 120092. [Google Scholar] [CrossRef]

- Sun, Y.; Yu, X.; Dong, W.; Tang, Y. Effects of hydrogen direct injection on engine stability and optimization of control parameters for a combined injection engine. Int. J. Hydrog. Energy 2018, 43, 6723–6733. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Z.; Huang, Y.; Liu, D.; Duan, J.; Guo, S.; Qin, Z. The effect of hydrogen injection parameters on the quality of hydrogen–air mixture formation for a PFI hydrogen internal combustion engine. Int. J. Hydrog. Energy 2017, 42, 23832–23845. [Google Scholar] [CrossRef]

- Brunt, M.F.; Emtage, A.L. Evaluation of IMEP Routines and Analysis Errors; SAE Transactions: Warrendale, PA, USA, 1996; pp. 749–763. [Google Scholar]

- Wang, S.; Ji, C. Cyclic variation in a hydrogen-enriched spark-ignition gasoline engine under various operating conditions. Int. J. Hydrog. Energy 2012, 37, 1112–1119. [Google Scholar] [CrossRef]

- Yang, G.; Yang, Z.Z. Analysis of the Hydrogen Engine’s Combustion Process Based on the AVL-FIRE. Mach. Des. Manuf. 2013, 4, 30. [Google Scholar]

- Mansoury, M.; Jafarmadar, S.; Talei, M.; Lashkarpour, S. Optimization of HCCI (Homogeneous Charge Compression Ignition) engine combustion chamber walls temperature to achieve optimum IMEP using LHS and Nelder Mead algorithm. Energy 2017, 119, 938–949. [Google Scholar] [CrossRef]

- Wu, C.; Deng, K.; Wang, Z. The effect of combustion chamber shape on cylinder flow and lean combustion process in a large bore spark-ignition CNG engine, Evaluation of the turbulent hot jet flame characteristics for achieving high thermal efficiency of hybrid engine. J. Energy Inst. 2016, 89, 240–247. [Google Scholar] [CrossRef]

- Schröder, M.; Bätge, T.; Bodenschatz, E.; Wilczek, M.; Bagheri, G. Estimating the turbulent kinetic energy dissipation rate from one-dimensional velocity measurements in time. Atmos. Meas. Tech. 2024, 17, 627–657. [Google Scholar] [CrossRef]

- Wang, G.; Yang, F.; Wu, K.; Ma, Y.; Peng, C.; Liu, T.; Wang, L.-P. Estimation of the dissipation rate of turbulent kinetic energy: A review. Chem. Eng. Sci. 2020, 299, 116133. [Google Scholar] [CrossRef]

| Parameters | Indexes |

|---|---|

| Length of Connecting Rod/mm | 160 |

| Stroke/mm | 85 |

| Bore/mm | 94 |

| Compression Ratio | 9.7:1 |

| Maximum Power/kW | 30 |

| Maximum power speed/r·min−1 | 6000 |

| Maximum Torque/Nm | 51 |

| Parameters | Temperature/K |

|---|---|

| Liner | 425 |

| Cylinder head surface | 450 |

| Piston | 500 |

| Exhaust valves | 550 |

| Intake valves | 450 |

| Initial Conditions | Water Injection Parameters | ||

|---|---|---|---|

| Crank Position | 220°CA | Starting time | 361°CA |

| Pressure | 0.1 MPa | End Time | 365°CA |

| Temperature | 400 K | Temperature | 60 °C |

| A: F ratio | 36.25 | WIRs | 0%, 5%, 10%, 15% |

| Swirl ratio | 1.64 | Ignition Time | 337°CA |

| Intake Stroke | 0~180°CA | ||

| Compression Stroke | 180~360°CA | ||

| Power Stroke | 360~540°CA | ||

| Exhaust Stroke | 540~720°CA | ||

| Test Groups | Avg Cell Size | Number of Cells | Max In-Cylinder Mean Temperature | Time Cost |

|---|---|---|---|---|

| Group 1 | 0.8 mm | 57,912 | 3186.71 K | 71 min |

| Group 2 | 1.0 mm | 42,780 | 3207.17 K | 50 min |

| Group 3 | 1.2 mm | 35,364 | 3246.06 K | 42 min |

| Group 4 | 1.4 mm | 29,660 | 3262.01 K | 34 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, Q.; Lu, H.; Chen, J.; Kwan, T.H. Numerical Investigation of the Combustion Characteristics of a Hydrogen-Fueled Engine with Water Injection. Fire 2024, 7, 289. https://doi.org/10.3390/fire7080289

Yao Q, Lu H, Chen J, Kwan TH. Numerical Investigation of the Combustion Characteristics of a Hydrogen-Fueled Engine with Water Injection. Fire. 2024; 7(8):289. https://doi.org/10.3390/fire7080289

Chicago/Turabian StyleYao, Qinghe, Hongbo Lu, Junyi Chen, and Trevor Hocksun Kwan. 2024. "Numerical Investigation of the Combustion Characteristics of a Hydrogen-Fueled Engine with Water Injection" Fire 7, no. 8: 289. https://doi.org/10.3390/fire7080289

APA StyleYao, Q., Lu, H., Chen, J., & Kwan, T. H. (2024). Numerical Investigation of the Combustion Characteristics of a Hydrogen-Fueled Engine with Water Injection. Fire, 7(8), 289. https://doi.org/10.3390/fire7080289