Fire Risk Reduction and Recover Energy Potential: A Disruptive Theoretical Optimization Model to the Residual Biomass Supply Chain

Abstract

1. Introduction

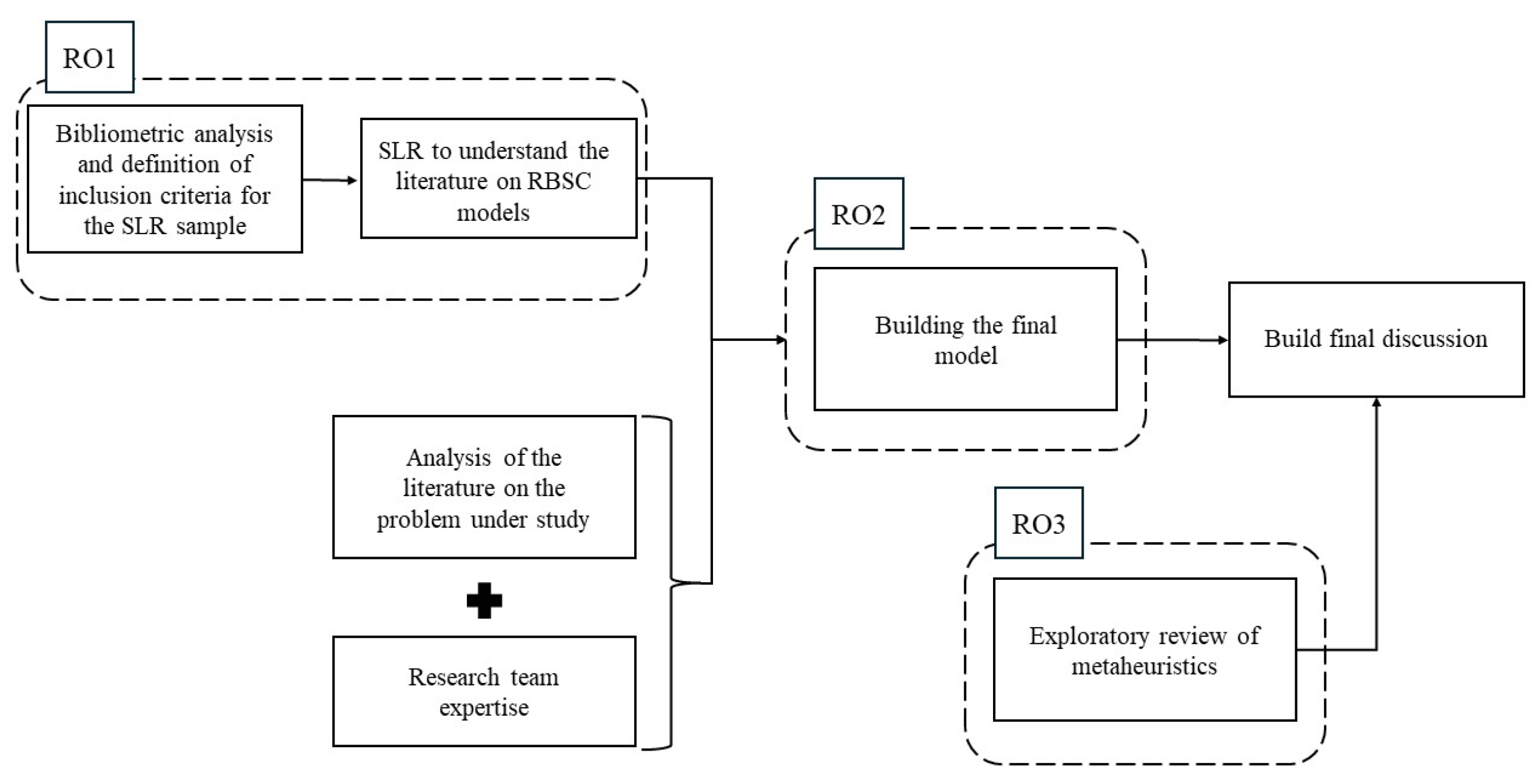

2. Methodological Approach

3. Results

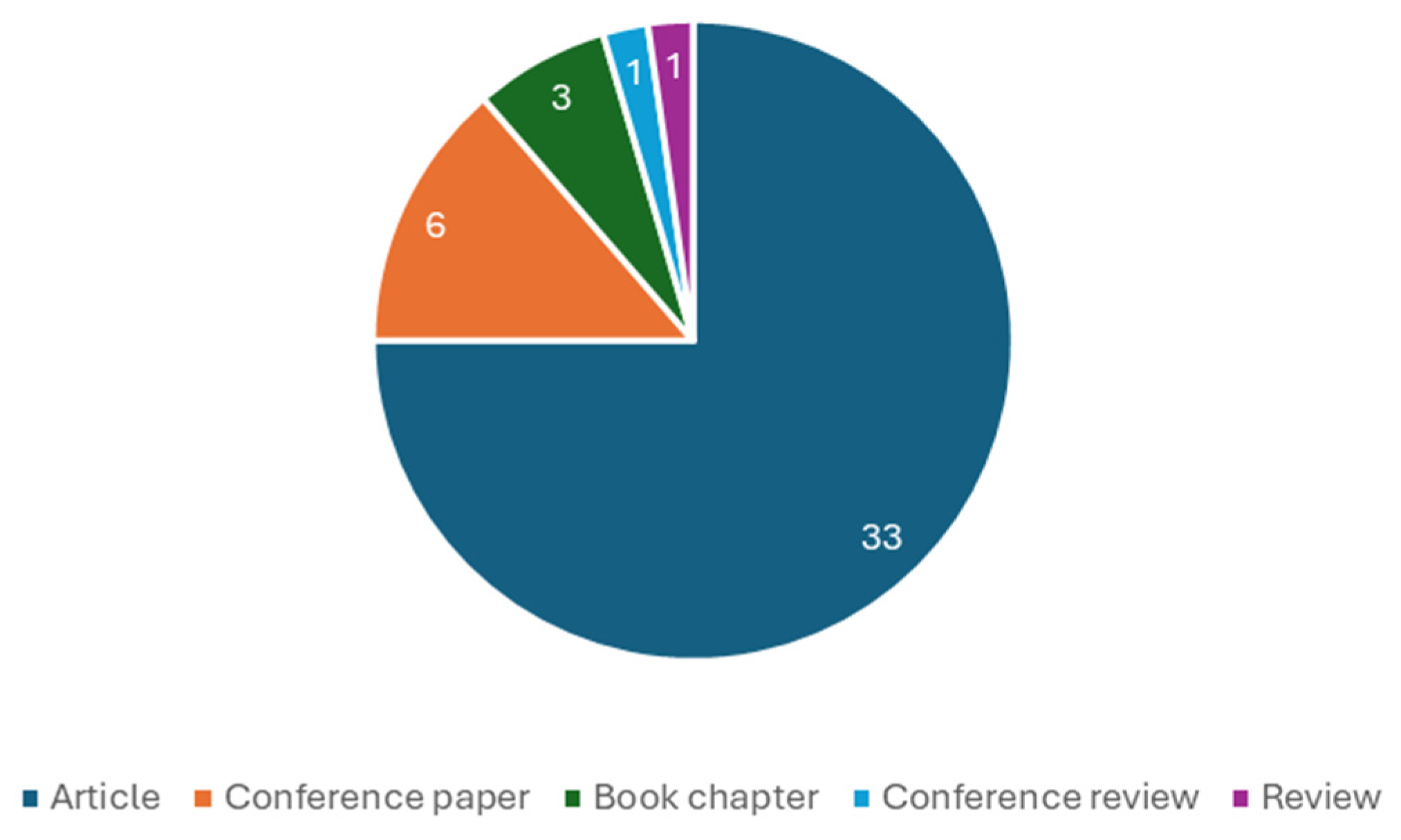

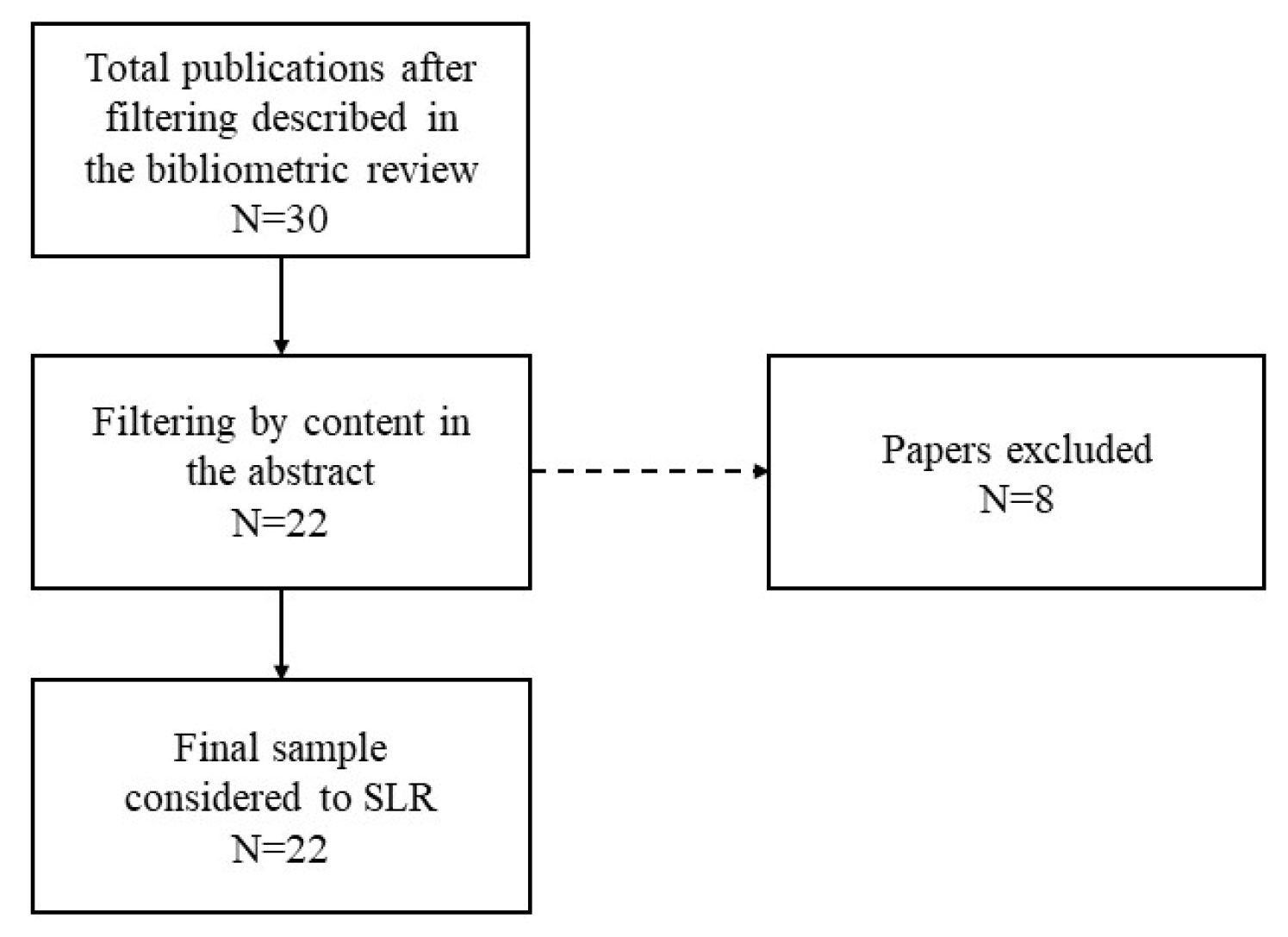

3.1. Literature Review

3.2. The Model Construction

3.2.1. Objective Functions to RBSC Model (Model I)

3.2.2. Restrictions of the Model

- Costharvestingi → Acquisition cost to biomass i, where i represents each biomass quantity;

- dj → Distance traveled on the route j, where j represents each route;

- LiterperKmh → Liter of fuel consumed per km by equipment h, where h represents each equipment;

- PriceperLiter → Price of fuel liter;

- PriceWorkerperHourz → Cost of worker z per hour, where z represents each worker;

- tTravelj → Time on the route j, where j represents each route;

- tMachiner → Time on the loading/unloading activity r, where r represents each activity;

- RentalperHourh → Cost of rent the equipment h by hour, where h represents each equipment;

- RPSs → Cost of rent the storage park s by hour, where s represents each storage park;

- as → Area of the storage park s, where s represents each storage park;

- day → Total days in storage;

- dryCost%moisture → Cost to reduce moisture by 1%;

- %dryday → Percentage of drying (moisture reduction) per day;

- CO2perLiter → CO2 produce by fuel liter consumed;

- LiterperHourh → Liter of fuel consumed per hour by equipment h, where h represents each equipment;

- Vi → Volume of individual biomass i, where i represents each biomass quantity;

- VehicleVolumeh → Maximum capacity of the vehicle h, where h represents each equipment;

- vaveragej → Average speed from route j, where j represents each route;

- tmaxWorker → Maximum working time allowed for the employee;

- IndividualAreai → Area occupied by biomass i, where i represents each biomass quantity;

- ParkAreas → Total storage park s area, where s represents each storage park.

3.2.3. The Fire Prevention Role (Model II)

- BiomassMassi → Mass of individual biomass i, where i represents each biomass quantity;

- AreaperKg → Approximation of the area needed to produce one kg of residual biomass;

- CostSavedperM2 → Costs saved per m2 not burned;

- EmissionSavedperM2 → Emissions saved per m2 not burned;

- LivesSavedperM2 → Lives saved per m2 not burned;

4. Metaheuristics Review

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ACO | Ant colony optimization |

| CHP | Combined heat and power |

| CO2 | Carbon dioxide |

| EO | Objective function |

| FSC | Forest supply chain |

| GA | Genetic algorithms |

| GIS | Geographic Information System |

| MILP | Mixed-integer linear programming |

| MINLP | Mixed-integer nonlinear programming |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| PSO | Particle swarm optimization |

| RBSC | Residual biomass supply chain |

| RO | Research objective |

| SA | Simulated annealing |

| SC | Supply chain |

| SLR | Systematic literature review |

| VRP | Vehicle routing problem |

References

- Chiang, M.C.; Yen, C.; Chen, H.L. Does Age Matter? Using Neuroscience Approaches to Understand Consumers’ Behavior towards Purchasing the Sustainable Product Online. Sustainability 2022, 14, 11352. [Google Scholar] [CrossRef]

- Marshall, E.; Elliot-Kerr, S.; McColl-Gausden, S.C.; Penman, T.D. Costs of preventing and supressing wildfires in Victoria, Australia. J. Environ. Manag. 2023, 344, 118606. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, J.V.; Nunes, R.A.O.; Alvim-Ferraz, M.C.M.; Martins, F.G.; Sousa, S.I.V. Health and economic burden of wildland fires PM2.5-related pollution in Portugal—A longitudinal study. Environ. Res. 2024, 240, 117490. [Google Scholar] [CrossRef] [PubMed]

- Scarpa, C.; Bacciu, V.; Ascoli, D.; Costa-Saura, J.M.; Salis, M.; Sirca, C.; Marchetti, M.; Spano, D. Estimating annual GHG and particulate matter emissions from rural and forest fires based on an integrated modelling approach. Sci. Total Environ. 2024, 907, 167960. [Google Scholar] [CrossRef]

- Magalhães, M.R.; Cunha, N.S.; Pena, S.B.; Müller, A. FIRELAN—An ecologically based planning model towards a fire resilient and sustainable landscape. A case study in center region of Portugal. Sustainability 2021, 13, 7055. [Google Scholar] [CrossRef]

- Méndez-López, M.; Jiménez-Morillo, N.T.; Fonseca, F.; de Figueiredo, T.; Parente-Sendín, A.; Alonso-Vega, F.; Arias-Estévez, M.; Nóvoa-Muñoz, J.C. Mercury mobilization in shrubland after a prescribed fire in NE Portugal: Insight on soil organic matter composition and different aggregate size. Sci. Total Environ. 2023, 904, 167532. [Google Scholar] [CrossRef] [PubMed]

- Tedim, F.; Samora-Arvela, A.; Coimbra, C.; Aranha, J.; Correia, F.; Pinto, D.M.; Figueiras, C.; Magalhães, C. Limitations and Opportunities of Spatial Planning to Enhance Wildfire Risk Reduction: Evidences from Portugal. Forests 2023, 14, 303. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Raposo, M.A.M.; Gomes, C.J.P. A historical perspective of landscape and human population dynamics in Guimarães (Northern Portugal): Possible implications of rural fire risk in a changing environment. Fire 2021, 4, 49. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Causer, T.P.; Ciolkosz, D. Biomass for energy: A review on supply chain management models. Renew. Sustain. Energy Rev. 2020, 120, 109658. [Google Scholar] [CrossRef]

- Casau, M.; Dias, M.F.; Teixeira, L.; Matias, J.C.O.; Nunes, L.J.R. Reducing Rural Fire Risk through the Development of a Sustainable Supply Chain Model for Residual Agroforestry Biomass Supported in a Web Platform: A Case Study in Portugal Central Region with the Project BioAgroFloRes. Fire 2022, 5, 61. [Google Scholar] [CrossRef]

- Salehi, S.; Mehrjerdi, Y.Z.; Sadegheih, A.; Hosseini-Nasab, H. Designing a resilient and sustainable biomass supply chain network through the optimization approach under uncertainty and the disruption. J. Clean. Prod. 2022, 359, 131741. [Google Scholar] [CrossRef]

- Ahmed, W.; Sarkar, B. Management of next-generation energy using a triple bottom line approach under a supply chain framework. Resour. Conserv. Recycl. 2019, 150, 104431. [Google Scholar] [CrossRef]

- Santibañez-Aguilar, J.E.; Lozano-García, D.F.; Lozano, F.J.; Flores-Tlacuahuac, A. Sequential Use of Geographic Information System and Mathematical Programming for Optimal Planning for Energy Production Systems from Residual Biomass. Ind. Eng. Chem. Res. 2019, 58, 15818–15837. [Google Scholar] [CrossRef]

- Matos-Ríos, D.M.; Martínez-Guido, S.I.; Ortega, J.M.P.; Gómez-Castro, F.I.; García-Trejo, J.F.; Gutiérrez-Antonio, C. Optimal Supply Chain Design for Renewable Aviation Fuel Production in México Considering the Full Use of Nonedible Biomass. ACS Sustain. Chem. Eng. 2022, 10, 9770–9786. [Google Scholar] [CrossRef]

- Kayikci, Y.; Kazancoglu, Y.; Gozacan-Chase, N.; Lafci, C. Analyzing the drivers of smart sustainable circular supply chain for sustainable development goals through stakeholder theory. Bus. Strateg. Environ. 2022, 31, 3335–3353. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, Y.; Liu, W.; Qiu, J.; Xie, N.; Chang, X.; Chen, J. A hybrid ACS-VTM algorithm for the vehicle routing problem with simultaneous delivery & pickup and real-time traffic condition. Comput. Ind. Eng. 2021, 162, 107747. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Mengist, W.; Soromessa, T.; Legese, G. Method for conducting systematic literature review and meta-analysis for environmental science research. MethodsX 2020, 7, 100777. [Google Scholar] [CrossRef] [PubMed]

- Nunes, L.J.R.; Silva, S. Optimization of the Residual Biomass Supply Chain: Process Characterization and Cost Analysis. Logistics 2023, 7, 48. [Google Scholar] [CrossRef]

- Sperandio, G.; Acampora, A.; Civitarese, V.; Bajocco, S.; Bascietto, M. Transport cost estimation model of the agroforestry biomass in a small-scale energy chain. Forests 2021, 12, 158. [Google Scholar] [CrossRef]

- Moretti, L.; Milani, M.; Lozza, G.G.; Manzolini, G. A detailed MILP formulation for the optimal design of advanced biofuel supply chains. Renew. Energy 2021, 171, 159–175. [Google Scholar] [CrossRef]

- Sarkar, B.; Mridha, B.; Pareek, S.; Sarkar, M.; Thangavelu, L. A flexible biofuel and bioenergy production system with transportation disruption under a sustainable supply chain network. J. Clean. Prod. 2021, 317, 128079. [Google Scholar] [CrossRef]

- Basile, F.; Pilotti, L.; Ugolini, M.; Lozza, G.; Manzolini, G. Supply chain optimization and GHG emissions in biofuel production from forestry residues in Sweden. Renew. Energy 2022, 196, 405–421. [Google Scholar] [CrossRef]

- Peter, B.; Niquidet, K. Estimates of residual fibre supply and the impacts of new bioenergy capacity from a forest sector transportation model of the Canadian Prairie Provinces. For. Policy Econ. 2016, 69, 62–72. [Google Scholar] [CrossRef]

- Santibanez-Aguilar, J.E.; Flores-Tlacuahuac, A.; Betancourt-Galvan, F.; Lozano-García, D.F.; Lozano, F.J. Facilities Location for Residual Biomass Production System Using Geographic Information System under Uncertainty. ACS Sustain. Chem. Eng. 2018, 6, 3331–3348. [Google Scholar] [CrossRef]

- Paulo, H.; Azcue, X.; Barbosa-Póvoa, A.P.; Relvas, S. Supply chain optimization of residual forestry biomass for bioenergy production: The case study of Portugal. Biomass Bioenergy 2015, 83, 245–256. [Google Scholar] [CrossRef]

- Natarajan, K.; Leduc, S.; Pelkonen, P.; Tomppo, E.; Dotzauer, E. Optimal locations for second generation Fischer Tropsch biodiesel production in Finland. Renew. Energy 2014, 62, 319–330. [Google Scholar] [CrossRef]

- De Menna, F.; Malagnino, R.A.; Vittuari, M.; Segrè, A.; Molari, G.; Deligios, P.A.; Solinas, S.; Ledda, L. Optimization of agricultural biogas supply chains using artichoke byproducts in existing plants. Agric. Syst. 2018, 165, 137–146. [Google Scholar] [CrossRef]

- Ahmed, W.; Sarkar, B. Impact of carbon emissions in a sustainable supply chain management for a second generation biofuel. J. Clean. Prod. 2018, 186, 807–820. [Google Scholar] [CrossRef]

- Piedra-Jimenez, F.; Torres, A.I.; Rodriguez, M.A. A robust disjunctive formulation for the redesign of forest biomass-based fuels supply chain under multiple factors of uncertainty. Comput. Chem. Eng. 2024, 181, 108540. [Google Scholar] [CrossRef]

- Méndez-Vázquez, M.A.; Gómez-Castro, F.I.; Ponce-Ortega, J.M.; Serafín-Muñoz, A.H.; Santibañez-Aguilar, J.E.; El-Halwagi, M.M. Mathematical optimization of a supply chain for the production of fuel pellets from residual biomass. Clean Technol. Environ. Policy 2017, 19, 721–734. [Google Scholar] [CrossRef]

- Li, Y.; Tittmann, P.; Parker, N.; Jenkins, B. Economic impact of combined torrefaction and pelletization processes on forestry biomass supply. GCB Bioenergy 2017, 9, 681–693. [Google Scholar] [CrossRef]

- Zimmer, T.; Rudi, A.; Müller, A.K.; Fröhling, M.; Schultmann, F. Modeling the impact of competing utilization paths on biomass-to-liquid (BtL) supply chains. Appl. Energy 2017, 208, 954–971. [Google Scholar] [CrossRef]

- Fernández-Puratich, H.; Rebolledo-Leiva, R.; Hernández, D.; Gómez-Lagos, J.E.; Armengot-Carbo, B.; Oliver-Villanueva, J.V. Bi-objective optimization of multiple agro-industrial wastes supply to a cogeneration system promoting local circular bioeconomy. Appl. Energy 2021, 300, 117333. [Google Scholar] [CrossRef]

- Rivera-Cadavid, L.; Manyoma-Velásquez, P.C.; Manotas-Duque, D.F. Supply chain optimization for energy cogeneration using sugarcane crop residues (SCR). Sustainability 2019, 11, 6565. [Google Scholar] [CrossRef]

- Giuliano, A.; De Bari, I.; Motola, V.; Pierro, N.; Giocoli, A.; Barletta, D. Techno-environmental assessment of two biorefinery systems to valorize the residual lignocellulosic biomass of the Basilicata Region. Math. Model. Eng. Probl. 2019, 6, 317–323. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Casau, M.; Dias, M.F.; Matias, J.C.O.; Teixeira, L.C. Agroforest woody residual biomass-to-energy supply chain analysis: Feasible and sustainable renewable resource exploitation for an alternative to fossil fuels. Results Eng. 2023, 17, 101010. [Google Scholar] [CrossRef]

- Castillo-Villar, K.K. Metaheuristic algorithms applied to bioenergy supply chain problems: Theory, review, challenges, and future. Energies 2014, 7, 7640–7672. [Google Scholar] [CrossRef]

- Chen, R.; Yue, H.H.; Yue, R.; Ai, Y.; Zheng, J.X. Numerical simulation of combustion in a biomass briquette chain boiler. Biomass Convers. Biorefinery 2021, 11, 1521–1536. [Google Scholar] [CrossRef]

- Fahmy, S.A.; Gaafar, M.L. Modelling and solving the split-delivery vehicle routing problem, considering loading constraints and spoilage of commodities. Int. J. Syst. Sci. Oper. Logist. 2023, 10, 2074566. [Google Scholar] [CrossRef]

- Sarker, B.R.; Wu, B.; Paudel, K.P. Modeling and optimization of a supply chain of renewable biomass and biogas: Processing plant location. Appl. Energy 2019, 239, 343–355. [Google Scholar] [CrossRef]

- Saghaei, M.; Ghaderi, H.; Soleimani, H. Design and optimization of biomass electricity supply chain with uncertainty in material quality, availability and market demand. Energy 2020, 197, 117165. [Google Scholar] [CrossRef]

- Abbasi, G.; Khoshalhan, F.; Hosseininezhad, S.J. Municipal solid waste management and energy production: A multi-objective optimization approach to incineration and biogas waste-to-energy supply chain. Sustain. Energy Technol. Assess. 2022, 54, 102809. [Google Scholar] [CrossRef]

- Xu, X.; Lin, Z.; Li, X.; Shang, C.; Shen, Q. Multi-objective robust optimisation model for MDVRPLS in refined oil distribution. Int. J. Prod. Res. 2022, 60, 6772–6792. [Google Scholar] [CrossRef]

- Islam, M.A.; Gajpal, Y.; ElMekkawy, T.Y. Hybrid particle swarm optimization algorithm for solving the clustered vehicle routing problem. Appl. Soft Comput. 2021, 110, 107655. [Google Scholar] [CrossRef]

- Cai, L.; Lv, W.; Xiao, L.; Xu, Z. Total carbon emissions minimization in connected and automated vehicle routing problem with speed variables. Expert. Syst. Appl. 2021, 165, 113910. [Google Scholar] [CrossRef]

- Aranguren, M.F.; Castillo-Villar, K.K. Bi-objective stochastic model for the design of large-scale carbon footprint conscious co-firing biomass supply chains. Comput. Ind. Eng. 2022, 171, 108352. [Google Scholar] [CrossRef]

- Aranguren, M.; Castillo-Villar, K.K.; Aboytes-Ojeda, M. A two-stage stochastic model for co-firing biomass supply chain networks. J. Clean. Prod. 2021, 319, 128582. [Google Scholar] [CrossRef]

- Aboytes-Ojeda, M.; Castillo-Villar, K.K.; Cardona-Valdés, Y. Bi-objective stochastic model for the design of biofuel supply chains incorporating risk. Expert. Syst. Appl. 2022, 202, 117285. [Google Scholar] [CrossRef]

| Economic | Environmental | Social |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bastos, T.; Teixeira, L.; Nunes, L.J.R. Fire Risk Reduction and Recover Energy Potential: A Disruptive Theoretical Optimization Model to the Residual Biomass Supply Chain. Fire 2024, 7, 263. https://doi.org/10.3390/fire7080263

Bastos T, Teixeira L, Nunes LJR. Fire Risk Reduction and Recover Energy Potential: A Disruptive Theoretical Optimization Model to the Residual Biomass Supply Chain. Fire. 2024; 7(8):263. https://doi.org/10.3390/fire7080263

Chicago/Turabian StyleBastos, Tiago, Leonor Teixeira, and Leonel J. R. Nunes. 2024. "Fire Risk Reduction and Recover Energy Potential: A Disruptive Theoretical Optimization Model to the Residual Biomass Supply Chain" Fire 7, no. 8: 263. https://doi.org/10.3390/fire7080263

APA StyleBastos, T., Teixeira, L., & Nunes, L. J. R. (2024). Fire Risk Reduction and Recover Energy Potential: A Disruptive Theoretical Optimization Model to the Residual Biomass Supply Chain. Fire, 7(8), 263. https://doi.org/10.3390/fire7080263