The Effect of Combustion Phase According to the Premixed Ethanol Ratio Based on the Same Total Lower Heating Value on the Formation and Oxidation of Exhaust Emissions in a Reactivity-Controlled Compression Ignition Engine

Abstract

1. Introduction

2. Experimental and Numerical Descriptions

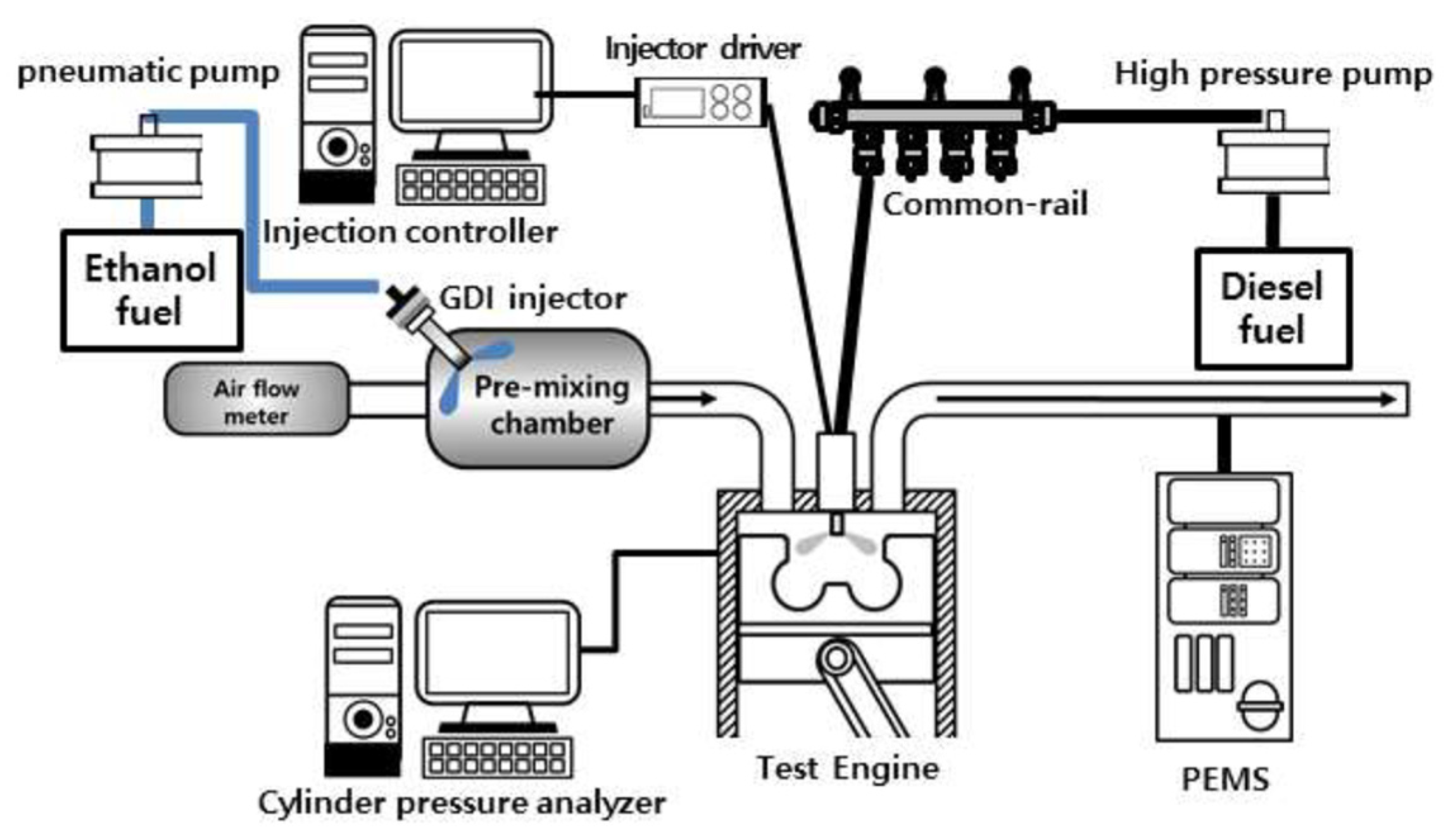

2.1. Experimental Descriptions

2.2. Numerical Descriptions

3. Results and Discussion

3.1. Validation of Numerical Models

3.2. Peak Cylinder Pressure and IMEP Characteristics

3.3. ISNO and ISCO Characteristics

3.4. Optimal Operating Conditions in RCCI Engine

4. Conclusions

- When the premixed ethanol ratio based on the same total LHV in-cylinder was increased, the amount of fuel introduced into the crevice volume when advancing the start of energizing timing was decreased, which increased the peak cylinder pressure.

- The ignition delay was longer when increasing the premixed ethanol ratio due to the low cylinder temperature due to the evaporation latent heat of ethanol, which reduced the compression loss. For this reason, the IMEP value was increased.

- When the premixed ethanol ratio based on the same total LHV in-cylinder was increased, the rich equivalence ratio was less distributed in the cylinder, which caused less increase in the cylinder temperature. So, the NO formation amount was reduced.

- The ISCO value was increased when increasing the premixed ethanol ratio based on the same total LHV in-cylinder because the flame propagation of ethanol by combustion of diesel did not work well, and the CO formed by combustion was slowly oxidized due to the low cylinder temperature due to the evaporation latent heat of ethanol.

- From these results, the optimal operating conditions for simultaneously reducing the exhaust emissions and improving the combustion performance were judged such that the start of energizing timing was BTDC 23 deg, and the premixed ethanol ratio based on the same total LHV in-cylinder was 40%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- John, B. Heywood, Internal Combustion Engine Fundamentals; McGraw-Hill Inc.: New York, NY, USA, 1988. [Google Scholar]

- Emiroğlu, A.O. Effect of fuel injection pressure on the characteristics of single cylinder diesel engine powered by butanol-diesel blend. Fuel 2019, 256, 115928. [Google Scholar] [CrossRef]

- Lee, S.; Reitz, R.D. Spray targeting to minimize soot and CO formation in premixed charge compression ignition (PCCI) combustion with a HSDI diesel engine. SAE Trans. 2006, 115, 532–541. [Google Scholar]

- Rohani, B.; Park, S.S.; Bae, C.S. Effect of injection strategy on smoothness, emissions and soot characteristics of PCCI-conventional diesel mode transition. J. Appl. Therm. Eng. 2016, 93, 1033–1042. [Google Scholar] [CrossRef]

- Pandey, S.K.; Vandana, S.; Akella, S.S.; Ravikrishna, R. Potential of Early Direct Injection (EDI) for simultaneous NOx and soot emission reduction in a heavy duty turbocharged diesel engine. Appl. Therm. Eng. 2019, 158, 113762. [Google Scholar] [CrossRef]

- Cha, J.P.; Yoon, S.J.; Lee, S.H.; Park, S.W. Effect of intake oxygen mole fraction on the near-stoichiometric combustion and emission characteristics of a CI (compression ignition) engine. J. Energy 2015, 80, 677–686. [Google Scholar] [CrossRef]

- Min, S.H.; Suh, H.K.; Cha, J.P. Effect of simulated-EGR (N2) on the distribution characteristics of equivalence ratio and the formation of exhaust emissions in a CI engine under early injection conditions. J. Energy 2020, 199, 1–12. [Google Scholar] [CrossRef]

- Kook, S.H.; Kong, J.S.; Park, S.I.; Bae, C.S.; Kim, J.H. The effect of injection angle and nozzle diameter on HCCI combustion. Trans. KSAE 2007, 15, 1–7. [Google Scholar]

- Peng, Z.; Zhao, H.; Ma, T. Characteristics of premixed homogeneous charge compression ignition (HCCI) diesel combustion and emissions. J. Combust. Sci. Technol. 2005, 177, 2113–2150. [Google Scholar] [CrossRef]

- Kim, M.Y.; Lee, C.S. Effect of a narrow fuel spray angle and a dual injection configuration on the improvement of exhaust emissions in a HCCI diesel engine. J. Fuel 2007, 86, 2871–2880. [Google Scholar]

- Kumar, K.S.; Raj, R.T.K. Effect of fuel injection timing and elevated intake air temperature on the combustion and emission characteristics of dual fuel operated diesel engine. J. Procedia Eng. 2013, 64, 1191–1198. [Google Scholar] [CrossRef]

- Pan, W.; Yao, C.D.; Han, G.P.; Wei, H.Y.; Wang, Q.G. The impact of intake air temperature on performance and exhaust emissions of a diesel methanol dual fuel engine. J. Fuel 2015, 162, 101–110. [Google Scholar] [CrossRef]

- Rocha, H.M.Z.; Pereira, R.D.S.; Nogueira, M.F.M.; Belchior, C.R.P.; Tostes, M.E.D.L. Experiment investigation of hydrogen addition in the intake air of compressed ignition engines running on biodiesel blend. Int. J. Hydrog. Energy 2017, 42, 4530–4539. [Google Scholar] [CrossRef]

- Singh, A.P.; Kumar, V.; Agarwal, A.K. Evaluation of comparative engine combustion, performance and emission charac-teristics of low temperature combustion (PCCI and RCCI) modes. J. Appl. Energy 2020, 278, 1–11. [Google Scholar] [CrossRef]

- Jo, S.I.; Park, S.H.; Kim, H.J.; Lee, J.T. Combustion improvement and emission reduction through control of ethanol ratio and intake air temperature in reactivity controlled compression ignition combustion engine. J. Appl. Energy 2019, 250, 1418–1431. [Google Scholar] [CrossRef]

- Suh, H.K.; Lee, C.S. A review on atomization and exhaust emissions of a biodiesel-fueled compression ignition engine. J. Renew. Sustain. Energy Rev. 2014, 58, 1601–1620. [Google Scholar] [CrossRef]

- AVL GmbH. Fire Version 2013 Combustion Module Manual; AVL List GMbH: Graz, Austria, 2013. [Google Scholar]

- AVL GmbH. Fire Version 2013.2 Spray Module Manual; AVL List GMbH: Graz, Austria, 2013. [Google Scholar]

- AVL List GmbH, Fire Version 2013 ESE-Diesel (Engine Simulation Environment) Module Manual; AVL List GMbH: Graz, Austria, 2013.

- Bosch, W. The Fuel Rate Indicator: A New Measuring Instrument For Display of the Characteristics of Individual Injection. In Proceedings of the National Powerplant and Transportation Meetings, Miami, FL, USA, 24–27 June 2024. [Google Scholar]

- Maes, N.; Skeen, S.A.; Bardi, M.; Fitzgerald, R.P.; Malbec, L.-M.; Bruneaux, G.; Pickett, L.M.; Yasutomi, K.; Martin, G. Spray penetration, combustion, and soot formation characteristics of the ECN Spray C and Spray D injectors in multiple combustion facilities. Appl. Therm. Eng. 2020, 172, 115136. [Google Scholar] [CrossRef]

- Aronsson, U.; Andersson, O.; Egnell, R.; Miles, P.C.; Ekoto, I.W. Influence of Spray-Target and Squish Height on Sources of CO and UHC in a HSDI Diesel Engine During PPCI Low-Temperature Combustion. In Proceedings of the SAE 2009 Powertrains Fuels and Lubricants Meeting, Florence, Italy, 15–17 June 2009. [Google Scholar]

- Dhole, A.; Yarasu, R.; Lata, D. Investigations on the combustion duration and ignition delay period of a dual fuel diesel engine with hydrogen and producer gas as secondary fuels. Appl. Therm. Eng. 2016, 107, 524–532. [Google Scholar] [CrossRef]

- Einecke, S.; Schulz, C.; Sick, V. Measurement of temperature, fuel concentration and equivalence ratio fields using tracer LIF in IC engine combustion. J. Appl. Phys. B 2000, 71, 717–723. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Boles, M.A. Thermodynamics an Engineering Approach, 17th ed.; McGraw-Hill Inc.: New York, NY, USA, 2011. [Google Scholar]

- Han, J.; Bao, L.; Somers, L.M.T. Experimental investigation of reactivity controlled compression ignition with n-butanol/n-heptane in a heavy duty diesel engine. J. Appl. Energy 2021, 282, 116164. [Google Scholar] [CrossRef]

| Item | Specification | |

|---|---|---|

| Engine | Displacement [cc] | 498 |

| Bore × Stroke [mm] | 83 × 92 | |

| Compression ratio [-] | 17.7 | |

| Injector | Number of nozzle holes [ea] | 5 |

| Hole diameter [mm] | 0.168 | |

| Inclined spray angle [deg] | 154 | |

| Emission | Method | Range | Span |

|---|---|---|---|

| NOX | CLD (CLA-150) | 0~5000 ppm | NO/N2-bal 1494 ppm |

| CO | NDIR (AIA-110) | 0~3000 ppm | CO/N2-bal 7404 ppm |

| Item | Diesel | Ethanol |

|---|---|---|

| LHV; Lower Heating Value [MJ/kg] | 42.5 | 26.8 |

| Latent heat of Evaporation [kJ/kg] | 250 | 846 |

| Density@20 °C [kg/m3] | 838.2 | 789.4 |

| Carbon Content [% mass] | 86.7 | 52.14 |

| Hydrogen content [% mass] | 12.71 | 13.13 |

| Sulfur content [% mass] | 0.041 | - |

| Oxygen content [% mass] | - | 34.73 |

| Flash point [°C] | 67 | 13 |

| Kinematic viscosity@40 °C [mm2/s] | 2.8271 | 1.056 |

| Typical formula | C14.09H24.78 | C2H6O |

| Cetane number | 42.6 | 8.5 |

| Lubricity, HFRR@60 °C [μm] | Max. 520 | Max. 605 |

| Fuel Injection Ratio [Main/Premixed] | Fuel Amount [mg] | Heating Value [J] | O2 Mass Fraction [-] | N2 Mass Fraction [-] | Ethanol Mass Fraction [-] |

|---|---|---|---|---|---|

| D100/E0 | 14/0 | 595/0 | 0.23200 | 0.76800 | 0.00000 |

| D90/E10 | 12.6/2.2 | 535.5/59.5 | 0.23081 | 0.76407 | 0.00512 |

| D80/E20 | 11.2/4.4 | 476/119 | 0.22984 | 0.76084 | 0.00932 |

| D70/E30 | 9.8/6.7 | 416.5/178.5 | 0.22876 | 0.75273 | 0.01396 |

| D60/E40 | 8.4/8.9 | 357/238 | 0.22781 | 0.75413 | 0.01806 |

| Phenomenon | Model |

|---|---|

| Turbulence | k-zeta-f |

| Break-up | Wave |

| Evaporation | Dukowicz |

| Wall interaction | Mundo Tropea Sommerfeld |

| Combustion | ECFM-3Z |

| NO | Extended Zel’dovich |

| Soot | Kennedy-Hiroyasu-Magnussen |

| Contents | Experiment and Numerical Analysis |

|---|---|

| RPM | 1800 |

| Injection pressure [MPa] | Diesel: 100, Ethanol: 10 |

| Total heating value [J] | 595 |

| Start of energizing timing [ATDC deg] | −30~−12 |

| Heating value ratio of diesel and ethanol | D100/E0, D90/E10, D80/E20, D70/E30, D60/E40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, S.-H.; Suh, H.-K. The Effect of Combustion Phase According to the Premixed Ethanol Ratio Based on the Same Total Lower Heating Value on the Formation and Oxidation of Exhaust Emissions in a Reactivity-Controlled Compression Ignition Engine. Fire 2024, 7, 258. https://doi.org/10.3390/fire7070258

Min S-H, Suh H-K. The Effect of Combustion Phase According to the Premixed Ethanol Ratio Based on the Same Total Lower Heating Value on the Formation and Oxidation of Exhaust Emissions in a Reactivity-Controlled Compression Ignition Engine. Fire. 2024; 7(7):258. https://doi.org/10.3390/fire7070258

Chicago/Turabian StyleMin, Se-Hun, and Hyun-Kyu Suh. 2024. "The Effect of Combustion Phase According to the Premixed Ethanol Ratio Based on the Same Total Lower Heating Value on the Formation and Oxidation of Exhaust Emissions in a Reactivity-Controlled Compression Ignition Engine" Fire 7, no. 7: 258. https://doi.org/10.3390/fire7070258

APA StyleMin, S.-H., & Suh, H.-K. (2024). The Effect of Combustion Phase According to the Premixed Ethanol Ratio Based on the Same Total Lower Heating Value on the Formation and Oxidation of Exhaust Emissions in a Reactivity-Controlled Compression Ignition Engine. Fire, 7(7), 258. https://doi.org/10.3390/fire7070258