Hydrogen Jet Flame Simulation and Thermal Radiation Damage Estimation for Leakage Accidents in a Hydrogen Refueling Station

Abstract

1. Introduction

2. Numerical Model and Boundary condition setting

2.1. Numerical Modeling of Hydrogen Jet Flames

2.1.1. Governing Equations

2.1.2. Turbulence Model

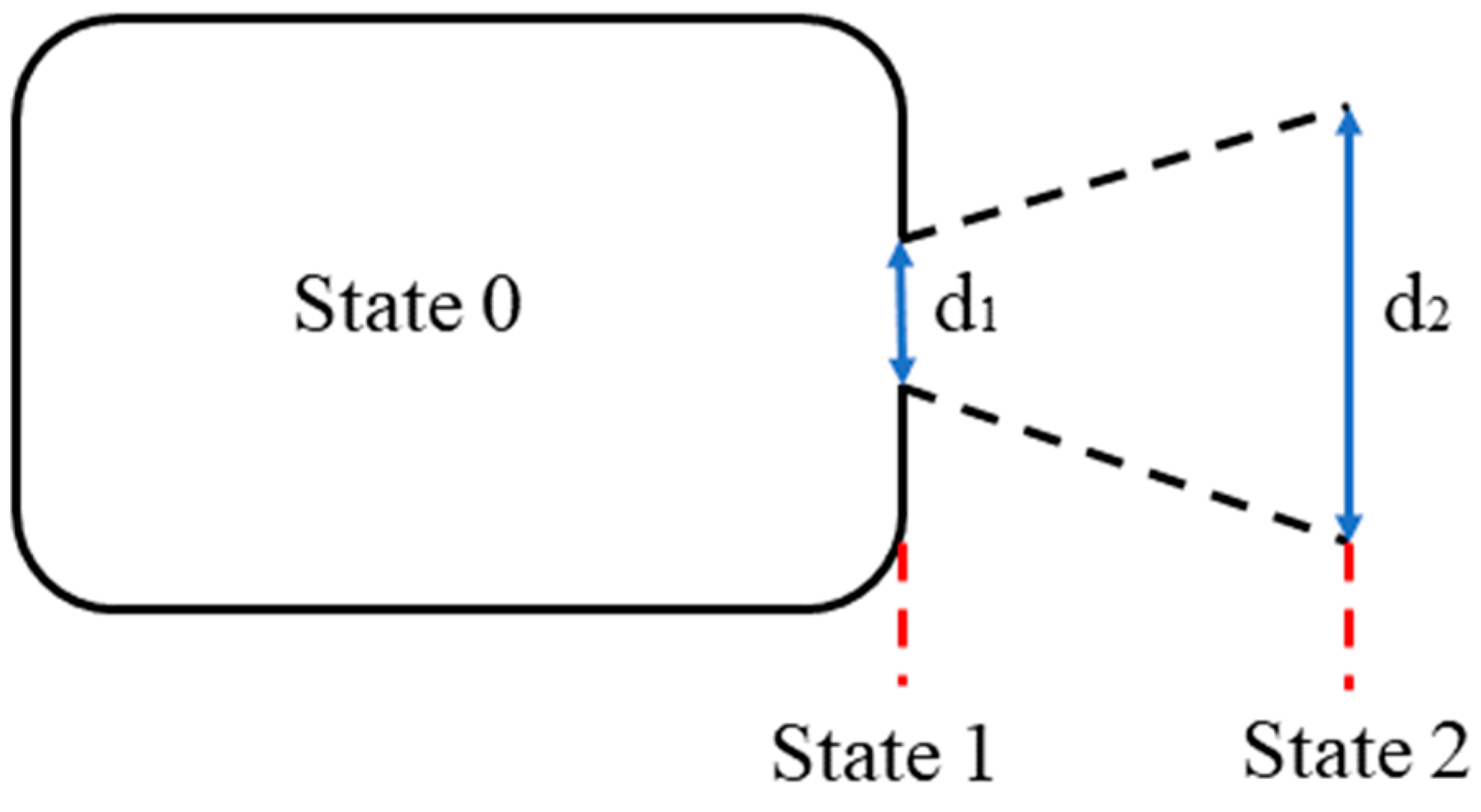

2.1.3. Virtual Nozzle Model

2.1.4. Combustion Reaction Modeling

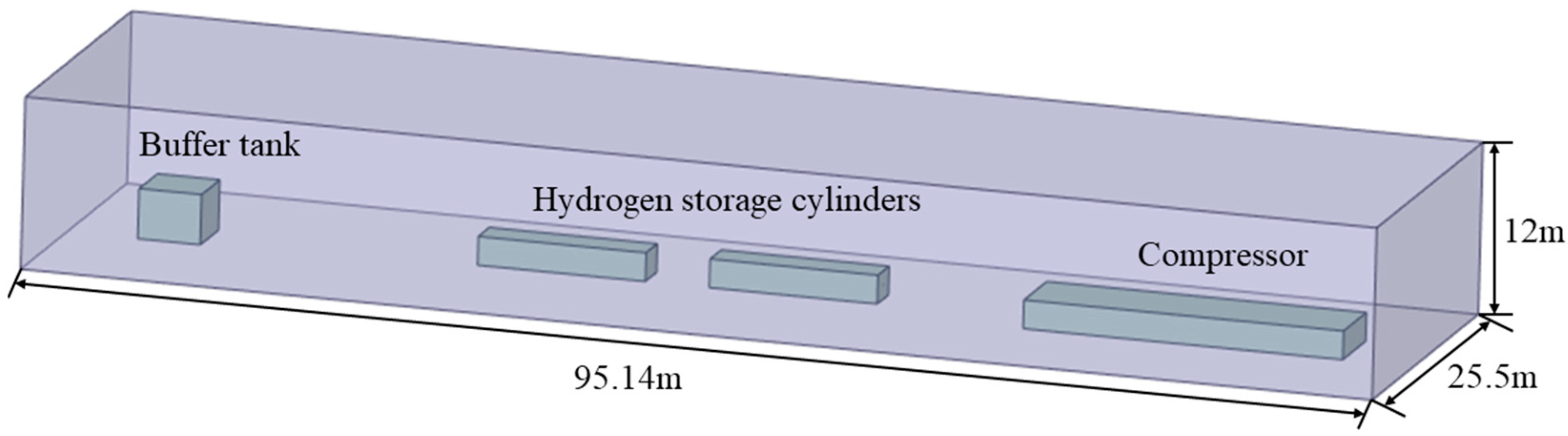

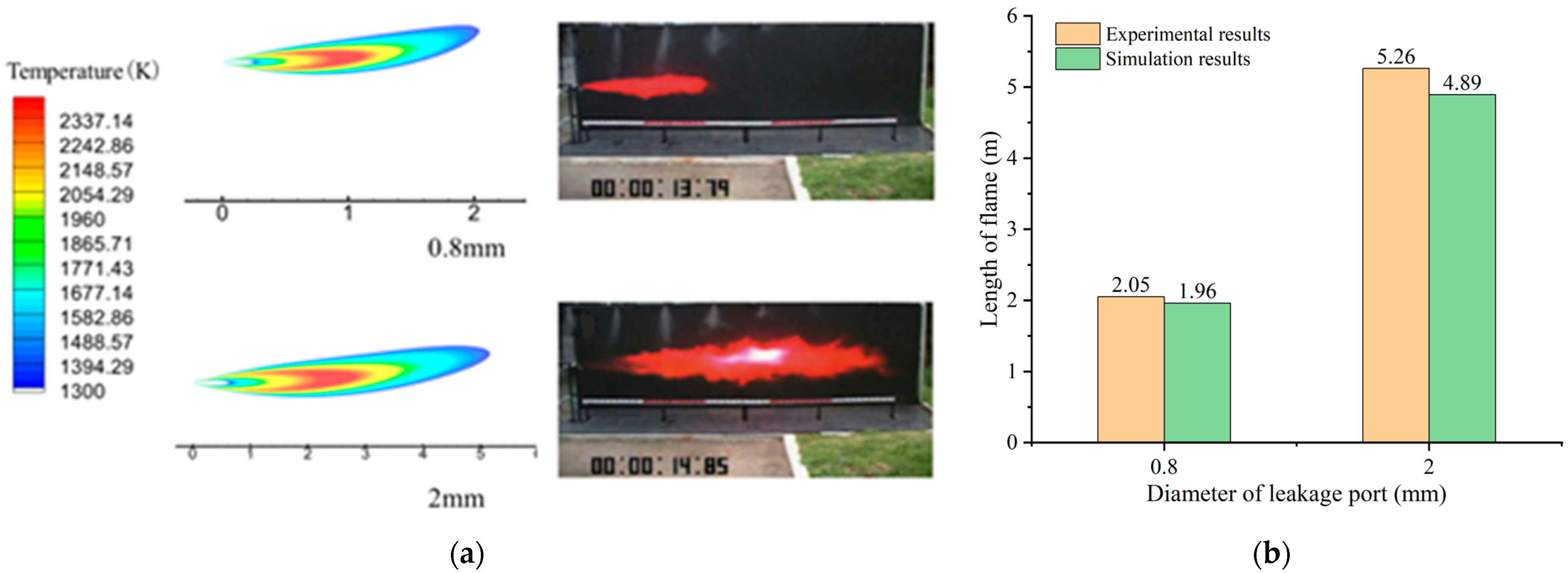

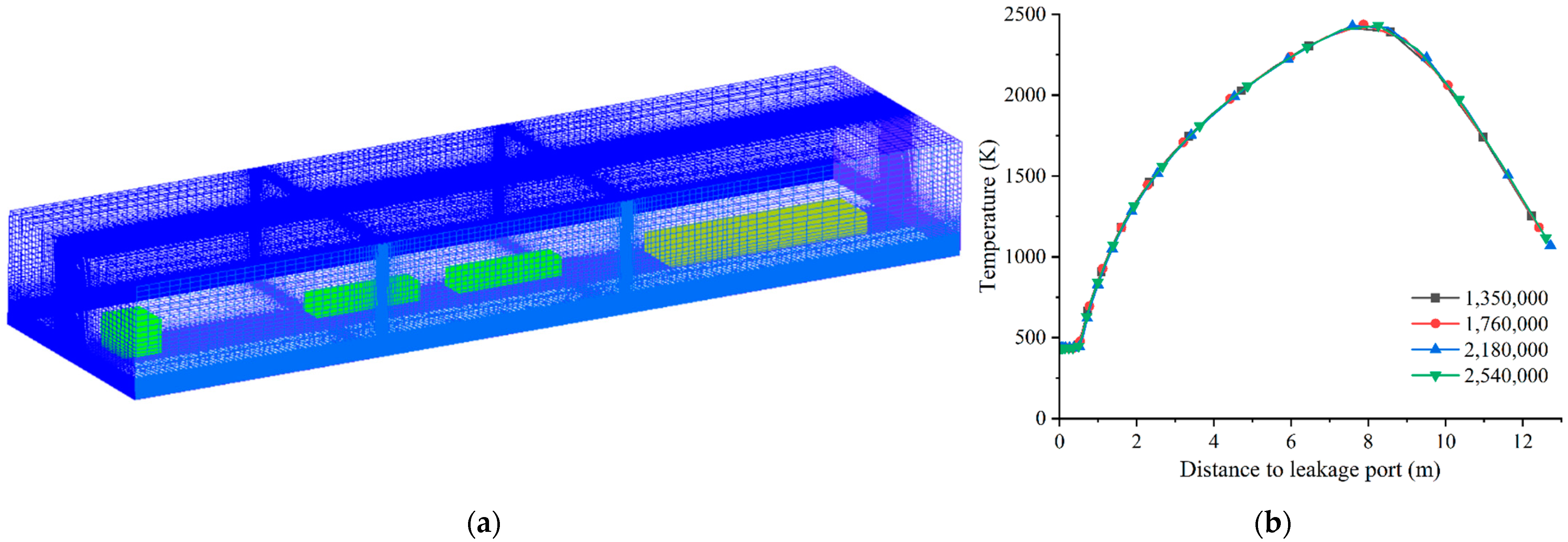

2.2. Boundary Condition Setting and Grid Verification

3. Results and Discussion

3.1. Simulation of Hydrogen Jet Flame Accidents in Hydrogen Storage Areas

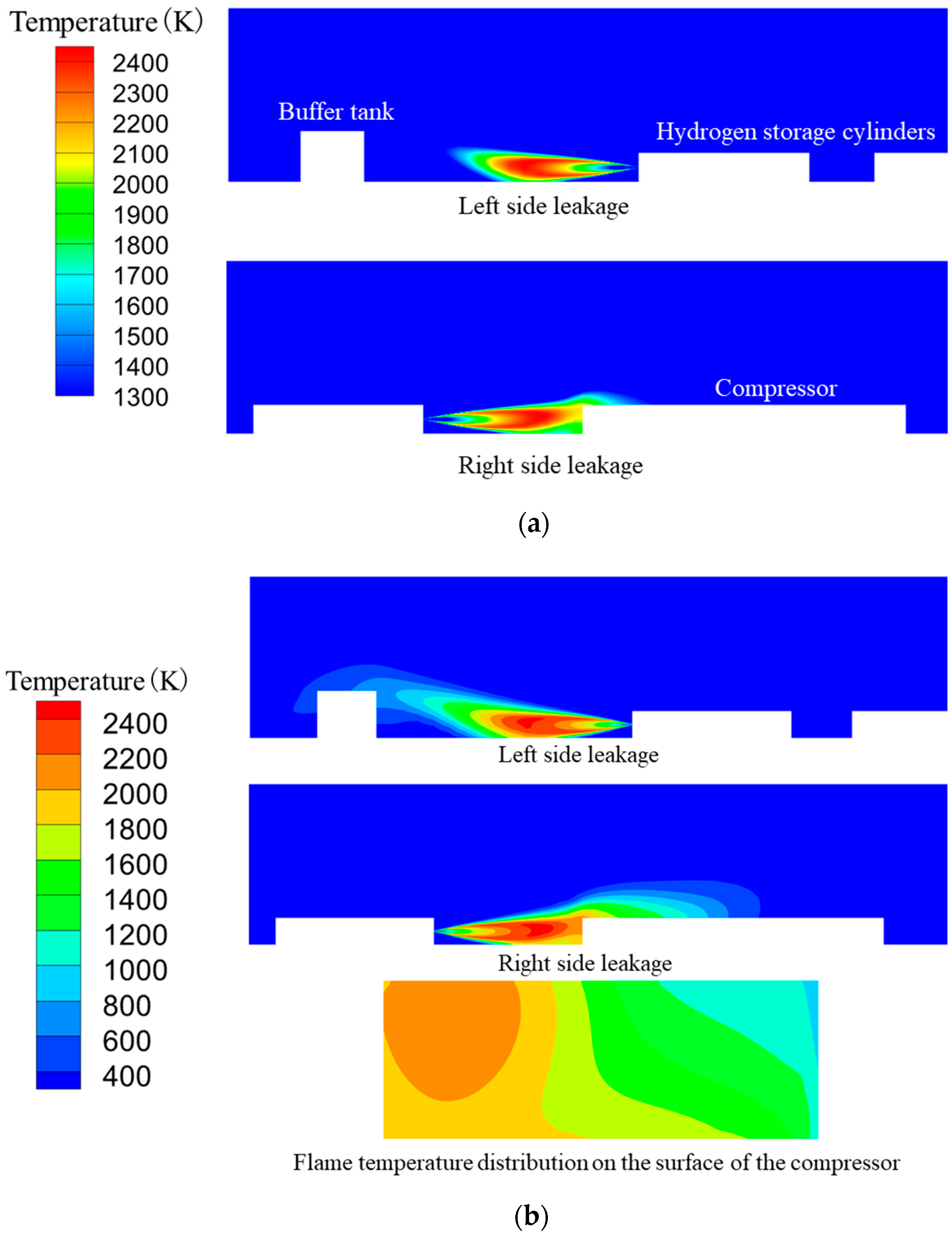

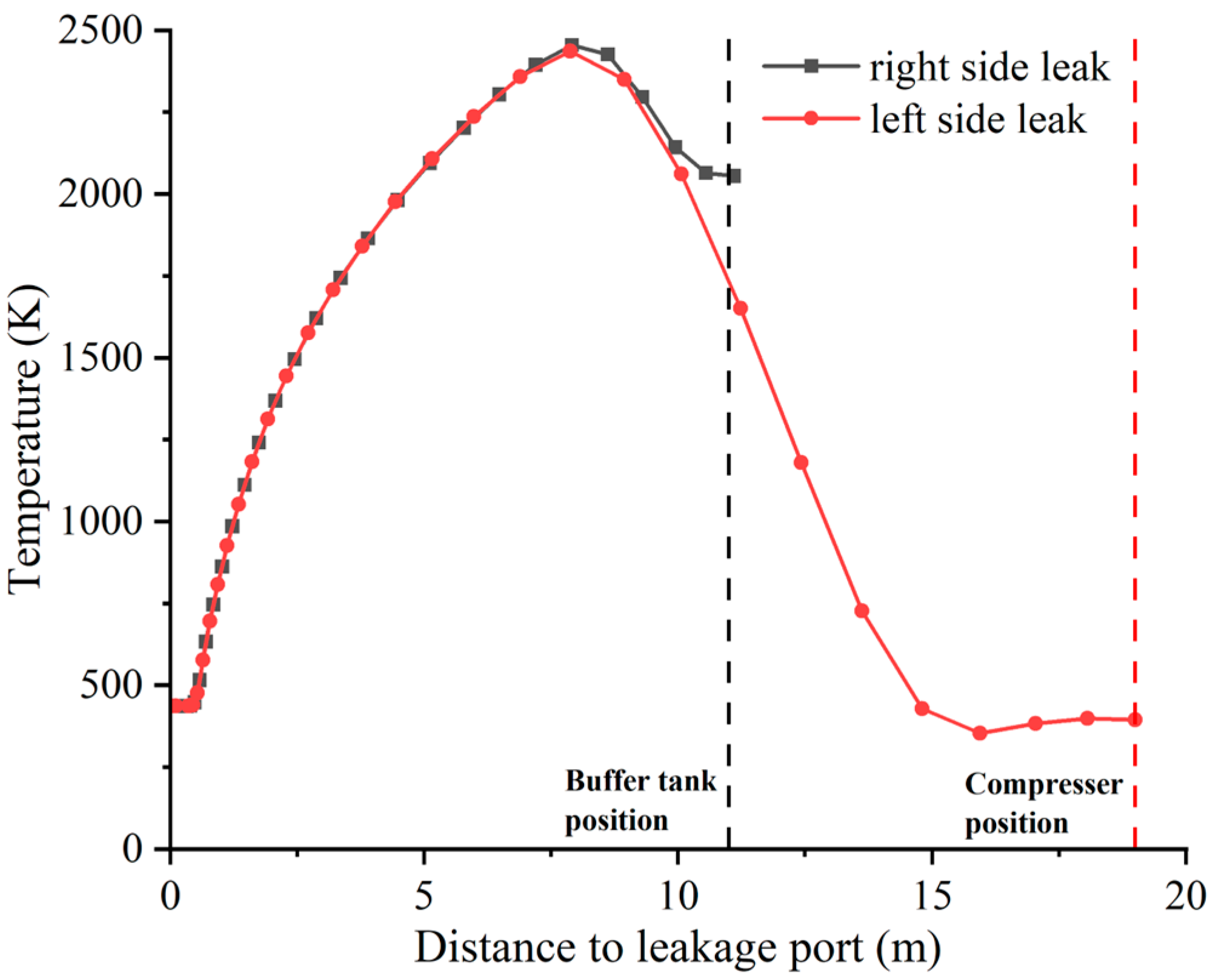

3.1.1. Effect of Leakage Locations on Equipment

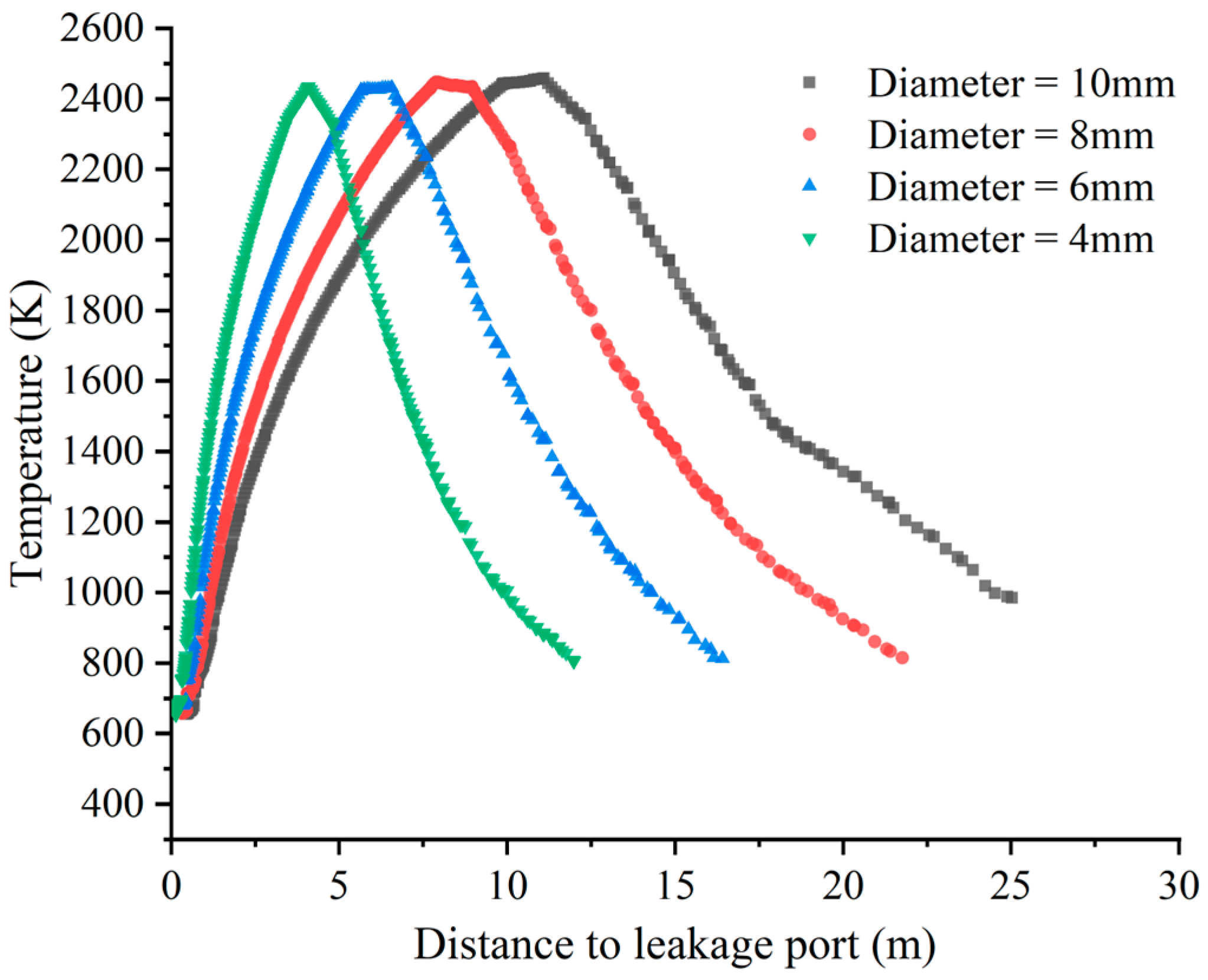

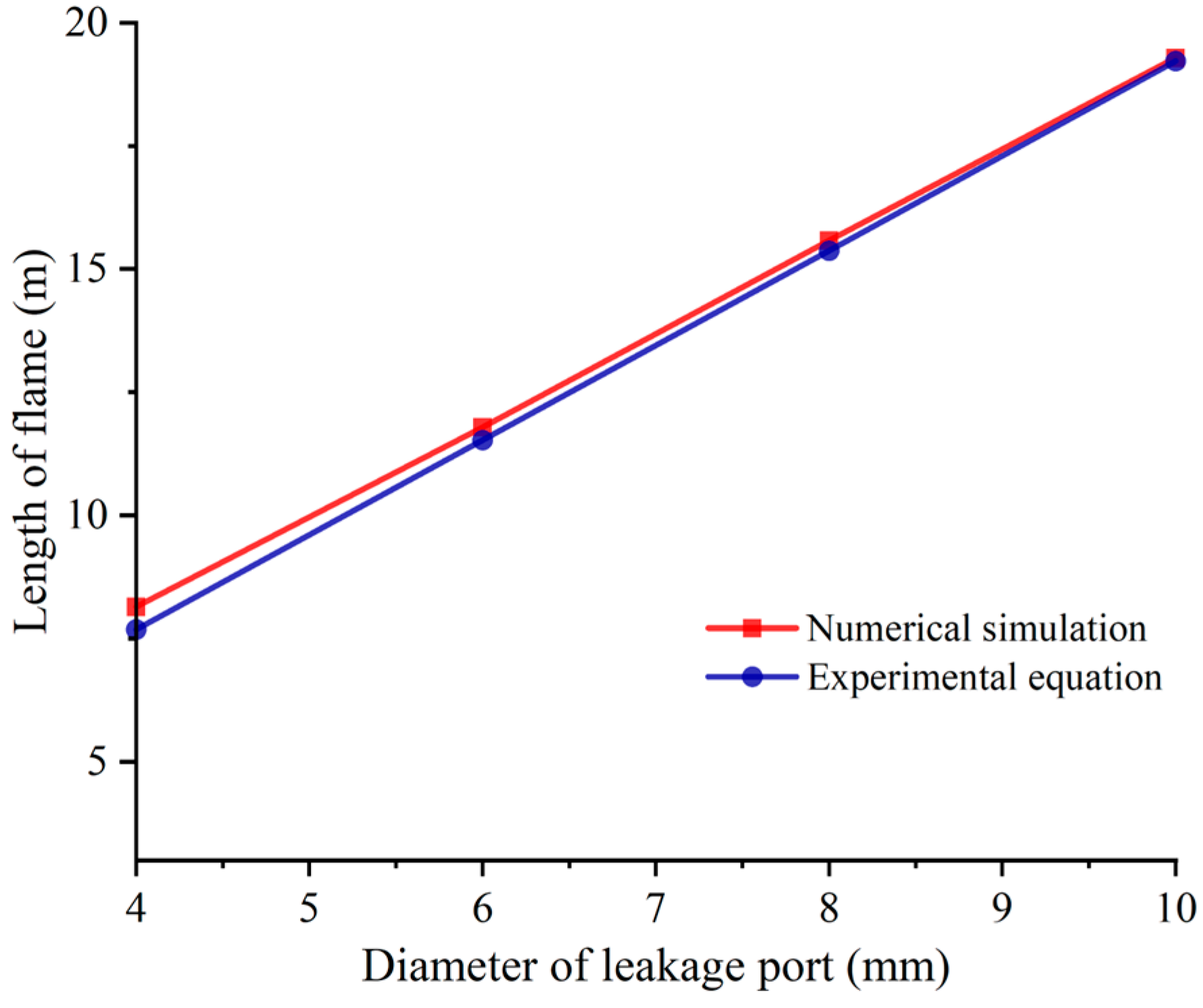

3.1.2. Effect of Different Leakage Port Diameters on Flame Characteristics

3.2. Risk Assessment of Jet Flame Accident

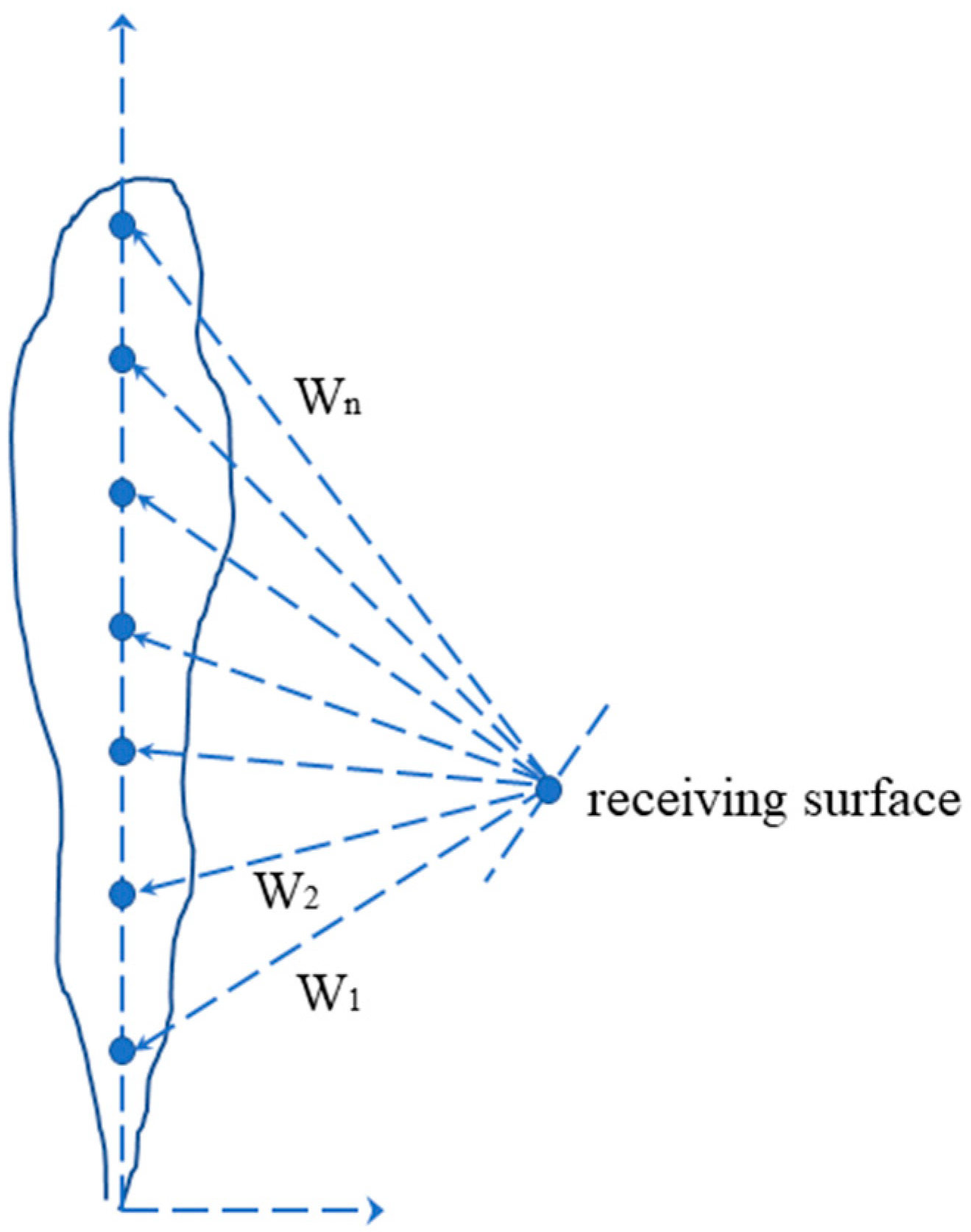

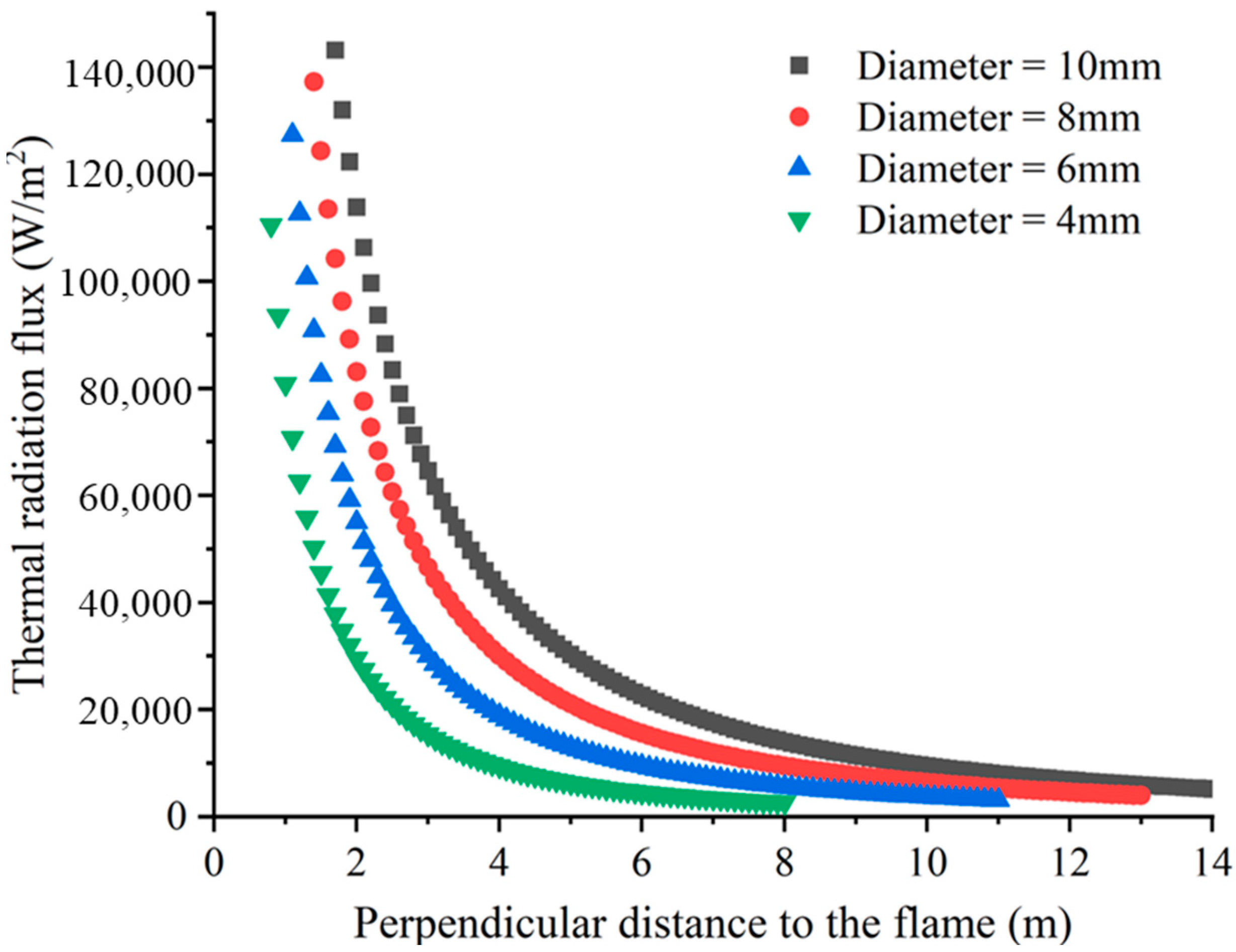

3.2.1. Calculation of Thermal Radiation Flux in Jet Flame Accidents

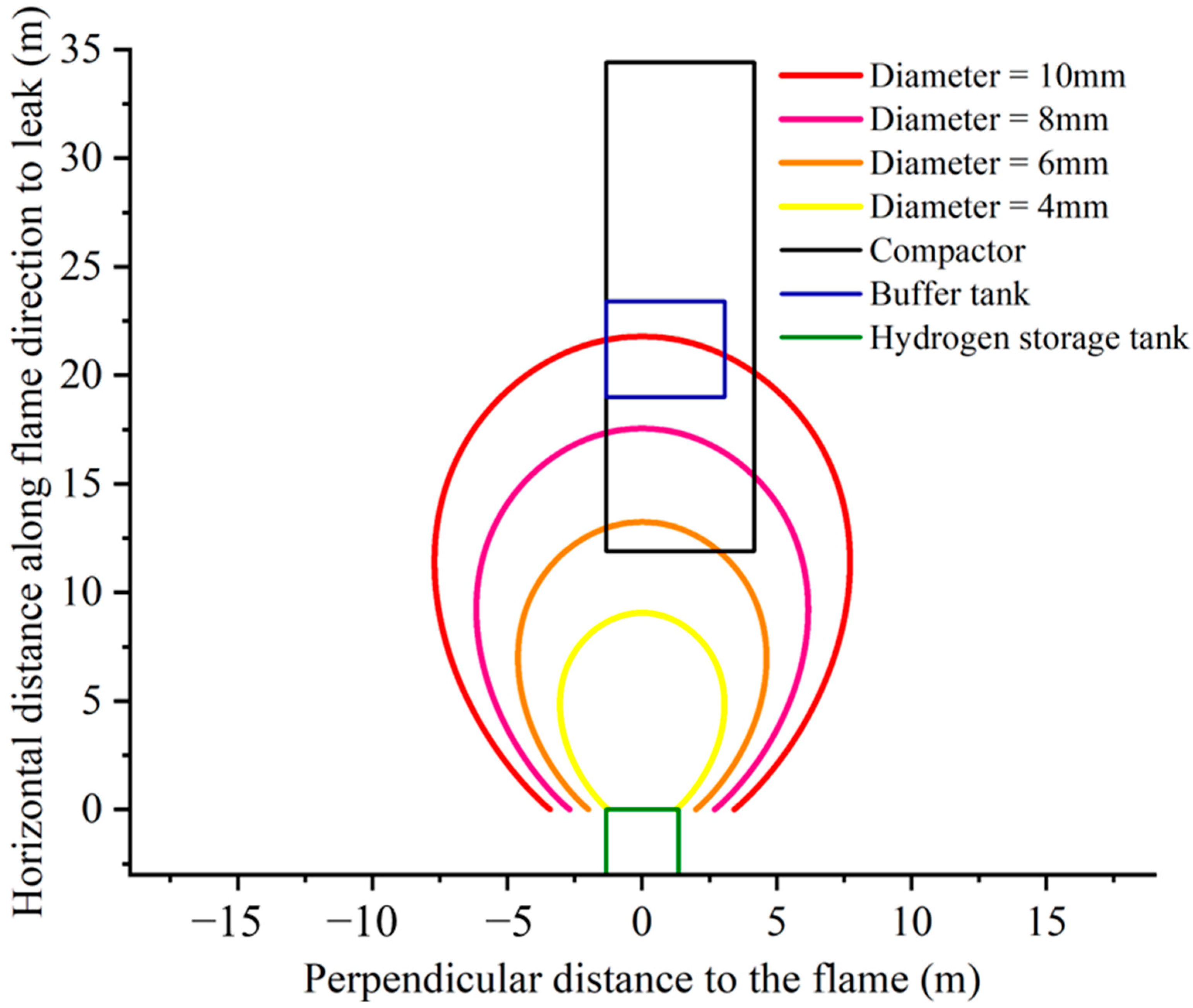

3.2.2. Consequence Assessment of Jet Flame Accidents

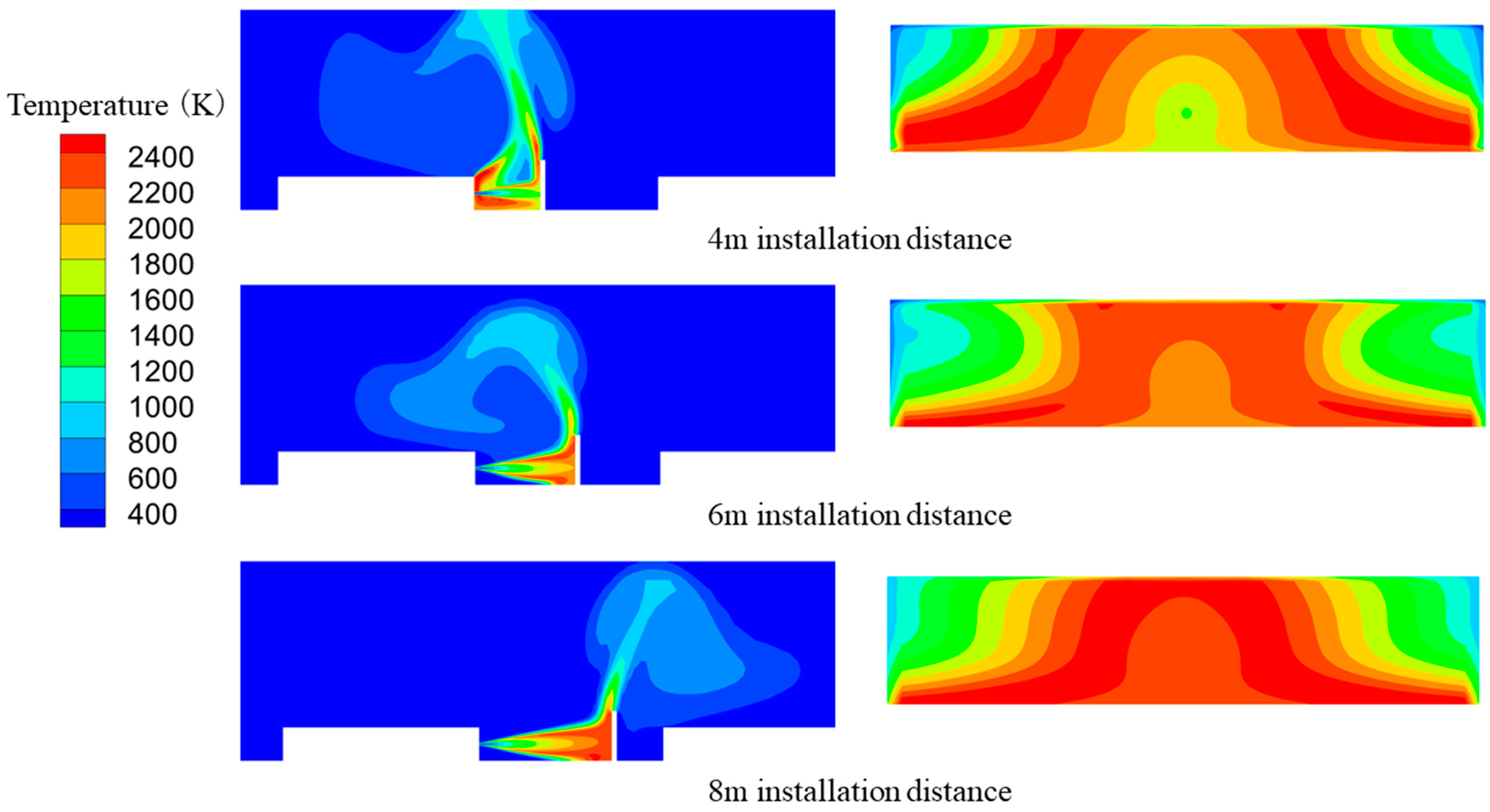

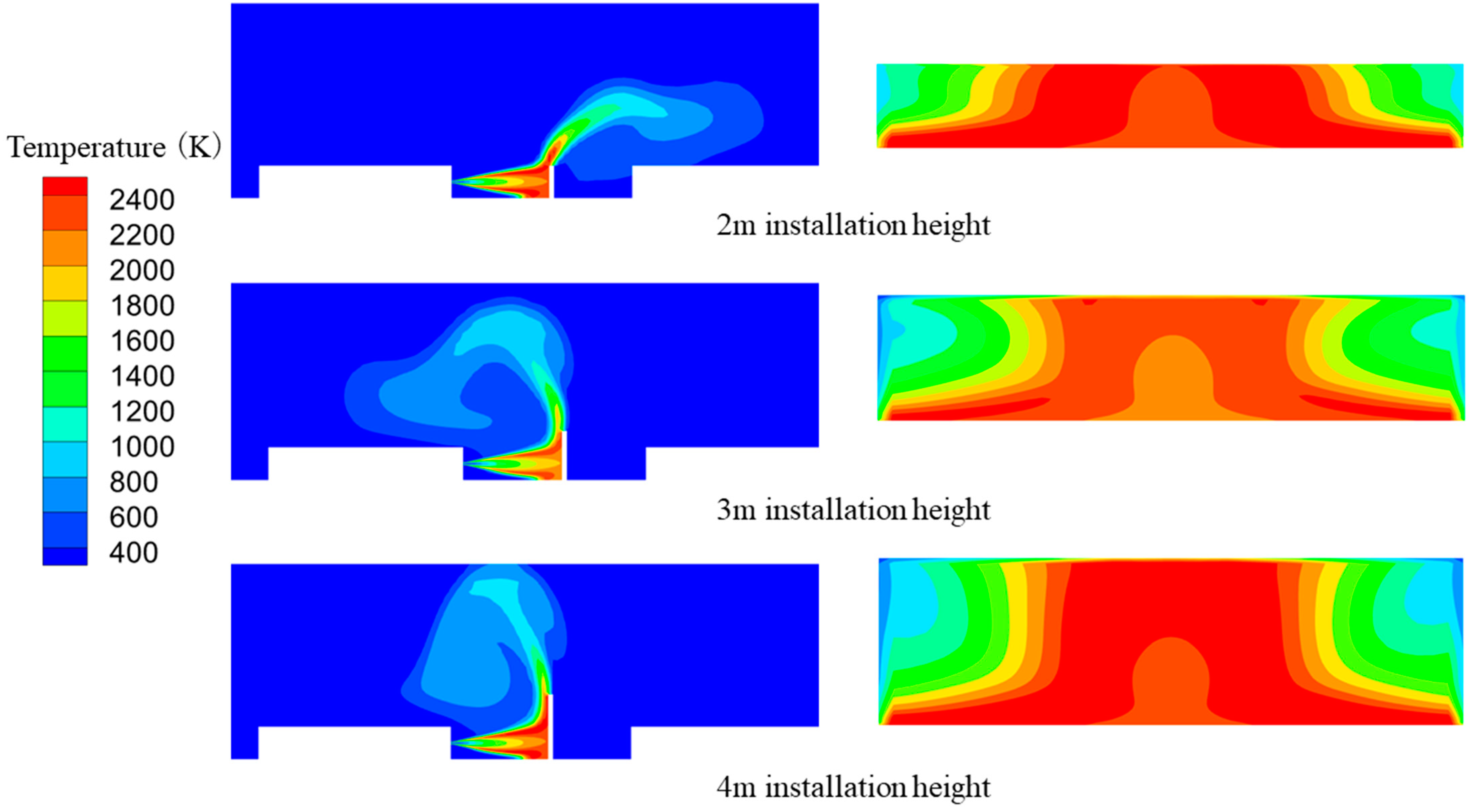

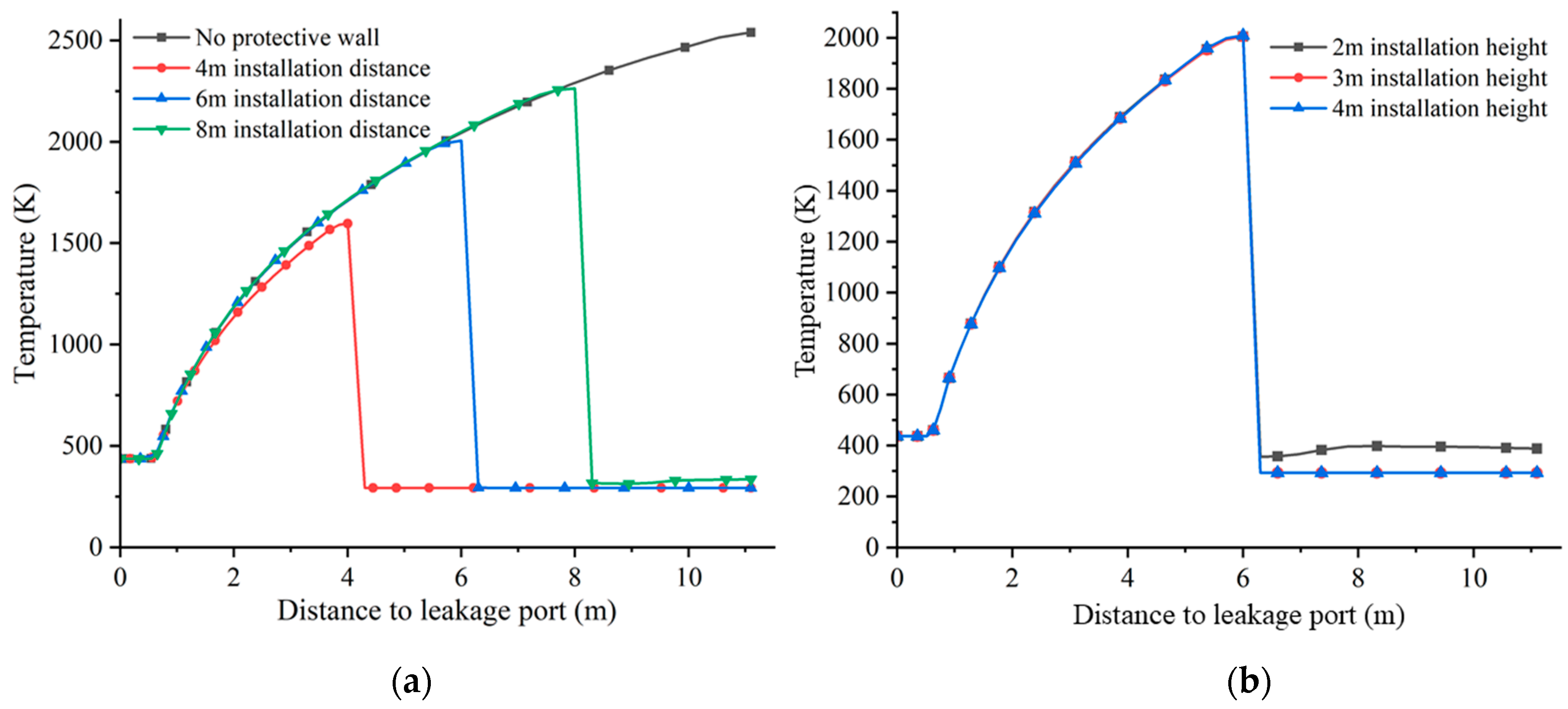

3.3. Protective Measure

4. Conclusions

- (1)

- This study takes an actual integrated hydrogen production and refueling station as the research object, combining the accident analysis with the actual scene, which is more realistic. In the current station, when a jet flame incident occurs in the hydrogen storage area, the temperature around the compressor is higher and more dangerous than in the buffer tank;

- (2)

- The temperature distribution on the flame trajectory line first increases and then decreases. The larger the diameter of the leakage port, the longer the flame length. When the diameter increases from 4 mm to 10 mm, the flame length increases by 11.145 m. The larger the diameter of the leakage port, the wider the distribution of the temperature field generated by the flame. The flame will no longer generate direct high temperatures on the surface of the buffer tank and compressor when the diameters are smaller than 6 mm and 4 mm, respectively;

- (3)

- Safety distances for jet flame accidents increased with increasing leakage ports, and more so in the perpendicular flame direction. For the three injury ranges, the range of minor injuries increased the most with increasing diameter. The rate of decrease in the probability of death of a person slows down with the increase in the distance from the flame. In the current station, the compressor and the buffer tank are in the equipment hazardous area for diameters greater than 6 mm and 10 mm, respectively. Therefore, the safety distance between the equipment should be increased, or a protective wall should be installed. The distance between the protective wall and the hydrogen storage cylinders is 6 m. The height of the protective wall is 3 m, which is reasonable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mehr, A.S.; Phillips, A.D.; Brandon, M.P.; Pryce, M.T.; Carton, J.G. Recent challenges and development of technical and technoeconomic aspects for hydrogen storage, insights at different scales; A state of art review. Int. J. Hydrogen Energy 2024, 70, 786–815. [Google Scholar] [CrossRef]

- Boddula, R.; Lee, Y.-Y.; Masimukku, S.; Chang-Chien, G.-P.; Pothu, R.; Srivastava, R.K.; Sarangi, P.K.; Selvaraj, M.; Basumatary, S.; Al-Qahtani, N. Sustainable hydrogen production: Solar-powered biomass conversion explored through (Photo)electrochemical advancements. Process Saf. Environ. Prot. 2024, 186, 1149–1168. [Google Scholar] [CrossRef]

- Yang, F.; Wang, T.; Deng, X.; Dang, J.; Huang, Z.; Hu, S.; Li, Y.; Ouyang, M. Review on hydrogen safety issues: Incident statistics, hydrogen diffusion, and detonation process. Int. J. Hydrogen Energy 2021, 46, 31467–31488. [Google Scholar] [CrossRef]

- Delichatsios, M.A. Transition from momentum to buoyancy-controlled turbulent jet diffusion flames and flame height relationships. Combust. Flame 1993, 92, 349–364. [Google Scholar] [CrossRef]

- Schefer, R.; Houf, W.; Bourne, B.; Colton, J. Spatial and radiative properties of an open-flame hydrogen plume. Int. J. Hydrogen Energy 2006, 31, 1332–1340. [Google Scholar] [CrossRef]

- Schefer, R.W.; Houf, W.G.; Williams, T.C.; Bourne, B.; Colton, J. Characterization of high-pressure, underexpanded hydrogen-jet flames. Int. J. Hydrogen Energy 2007, 32, 2081–2093. [Google Scholar] [CrossRef]

- Mogi, T.; Horiguchi, S. Experimental study on the hazards of high-pressure hydrogen jet diffusion flames. J. Loss Prev. Process Ind. 2009, 22, 45–51. [Google Scholar] [CrossRef]

- Imamura, T.; Hamada, S.; Mogi, T.; Wada, Y.; Horiguchi, S.; Miyake, A.; Ogawa, T. Experimental investigation on the thermal properties of hydrogen jet flame and hot currents in the downstream region. Int. J. Hydrogen Energy 2008, 33, 3426–3435. [Google Scholar] [CrossRef]

- Fan, R.; Pan, Y.; Xiao, Y.; Wang, Z. Investigation on flame propagation characteristics and critical ignition criteria of hydrogen jet. Int. J. Hydrogen Energy 2024, 57, 1437–1445. [Google Scholar] [CrossRef]

- Zhang, A.; Zou, X.; Shen, J.; Li, Y.; Gao, W. Experimental investigation on hydrogen jet flame behavior and temperature distribution with different shapes of outlet. Int. J. Hydrogen Energy 2024, 63, 844–856. [Google Scholar] [CrossRef]

- Brennan, S.L.; Makarov, D.V.; Molkov, V. LES of high pressure hydrogen jet fire. J. Loss Prev. Process Ind. 2009, 22, 353–359. [Google Scholar] [CrossRef]

- Cirrone, D.M.C.; Makarov, D.; Molkov, V. Simulation of thermal hazards from hydrogen under-expanded jet fire. Int. J. Hydrogen Energy 2019, 44, 8886–8892. [Google Scholar] [CrossRef]

- Ba, Q.X.; Zhao, M.B.; Zhao, Z.Y.; Huang, T.; Wang, J.Q.; Li, X.F.; Xiao, G.P. Modeling of high pressure hydrogen jet fires. J. Tsinghua Univ. (Sci. Technol.) 2022, 62, 303–311. [Google Scholar]

- Tian, Y.; Zhang, X.Y.; Shan, M.M.; Qi, M.; Shu, C.M.; Li, B.; Liu, Y. Methodology for optimally designing firewalls in hydrogen refueling stations. Int. J. Hydrogen Energy 2024, 49, 1196–1209. [Google Scholar] [CrossRef]

- Kim, H.; Kang, S. Analysis of Damage Range and Impact of On-Site Hydrogen Fueling Station Using Quantitative Risk Assessment Program (Hy-KoRAM). Trans. Korean Hydrog. New Energy Soc. 2020, 31, 459–466. [Google Scholar] [CrossRef]

- Park, B.; Kim, Y.; Paik, S.; Kang, C. Numerical and experimental analysis of jet release and jet flame length for qualitative risk analysis at hydrogen refueling station. Process Saf. Environ. Prot. 2021, 155, 145–154. [Google Scholar] [CrossRef]

- Birch, A.D.; Hughes, D.J.; Swaffield, F. Velocity decay of high pressure jets. Combust. Sci. Technol. 1987, 52, 161–171. [Google Scholar] [CrossRef]

- Magnussen, B.F.; Hjertager, B.H. On mathematical modeling of turbulent combustion with special emphasis on soot formation and combustion. Symp. Combust. 1977, 16, 719–729. [Google Scholar] [CrossRef]

- Ba, Q.; Zhao, Z.; Zhang, Y.; Liu, Y.; Christopher, D.M.; Ge, P.; Li, X. Modeling of cryogenic compressed hydrogen jet flames. Int. J. Hydrogen Energy 2024, 51, 917–927. [Google Scholar] [CrossRef]

- Zheng, J.; Bie, H.; Xu, P.; Liu, P.; Zhao, Y.; Chen, H.; Liu, X.; Zhao, L. Numerical simulation of high-pressure hydrogen jet flames during bonfire test. Int. J. Hydrogen Energy 2012, 37, 783–790. [Google Scholar] [CrossRef]

- Makarov, D.; Molfeou, V. Plane hydrogen jets. Int. J. Hydrogen Energy 2013, 37, 18563–18574. [Google Scholar] [CrossRef]

- GB/T 37243-2019; Determination Method of External Safety Distance for Hazardous Chemicals Production Units and Storage Installations. Ministry of Emergency Management of the People’s Republic of China: Beijing, China, 2019; p. 52.

- Tsao, C.K.; Perry, W.W. Modifications to the Vulnerability Model: A Simulation System for Assessing Damage Resulting from Marine Spills; Final Report; Defense Technical Information Center: Fort Belvoir, VA, USA, 1979.

- GB 50183-2004; Code for Fire Protection Design of Petroleum and Natural Gas Engineering. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2004; p. 63.

| Leakage Port Diameter d1 | Airflow Status at the Location of the Leakage Port |

|---|---|

| 4 mm | = 2035.4 m/s; = 34.1 mm |

| 6 mm | = 2035.4 m/s; = 51.2 mm |

| 8 mm | = 2035.4 m/s; = 68.2 mm |

| 10 mm | = 2035.4 m/s; = 85.3 mm |

| Thermal Radiation Fluxes (kW/m2) | Damage to the Human Body |

|---|---|

| ≥37.5 | 100% dead |

| 25 | Major burns, 100% dead (60 s exposure) |

| 6.3 | Pain in exposed skin |

| 1.58 | Prolonged exposure without discomfort |

| Thermal Radiation Fluxes (kW/m2) | Building Layout Standards |

|---|---|

| ≥4.73 kW/m2 | No office buildings shall be constructed. |

| ≥9 kW/m2 | Buildings such as centralized control rooms, maintenance workshops, etc., shall not be accommodated. |

| ≥15 kW/m2 | Pressure vessels and metal-walled storage tanks shall not be located. |

| ≥32 kW/m2 | Concrete-walled tanks shall not be arranged. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, X.; Yan, X.; Chen, S.; Song, C.; Xiao, Z.; Luo, H.; Wan, J.; Yang, T.; Xu, N.; Xiao, J. Hydrogen Jet Flame Simulation and Thermal Radiation Damage Estimation for Leakage Accidents in a Hydrogen Refueling Station. Fire 2024, 7, 210. https://doi.org/10.3390/fire7070210

Fu X, Yan X, Chen S, Song C, Xiao Z, Luo H, Wan J, Yang T, Xu N, Xiao J. Hydrogen Jet Flame Simulation and Thermal Radiation Damage Estimation for Leakage Accidents in a Hydrogen Refueling Station. Fire. 2024; 7(7):210. https://doi.org/10.3390/fire7070210

Chicago/Turabian StyleFu, Xiang, Xianglin Yan, Shiyu Chen, Chunyan Song, Zhili Xiao, Hao Luo, Jiaqi Wan, Tianqi Yang, Nianfeng Xu, and Jinsheng Xiao. 2024. "Hydrogen Jet Flame Simulation and Thermal Radiation Damage Estimation for Leakage Accidents in a Hydrogen Refueling Station" Fire 7, no. 7: 210. https://doi.org/10.3390/fire7070210

APA StyleFu, X., Yan, X., Chen, S., Song, C., Xiao, Z., Luo, H., Wan, J., Yang, T., Xu, N., & Xiao, J. (2024). Hydrogen Jet Flame Simulation and Thermal Radiation Damage Estimation for Leakage Accidents in a Hydrogen Refueling Station. Fire, 7(7), 210. https://doi.org/10.3390/fire7070210