The Impact of Different Ventilation Conditions on Electric Bus Fires

Abstract

1. Introduction

2. Materials and Methods

2.1. FDS Model Introduction and Numerical Solution Method

2.1.1. FDS Model Introduction

- (1)

- Turbulence model

- (2)

- Combustion model

- (3)

- Thermal radiation model

- (4)

- Carbon monoxide concentration control equation

2.1.2. Numerical Solution Method

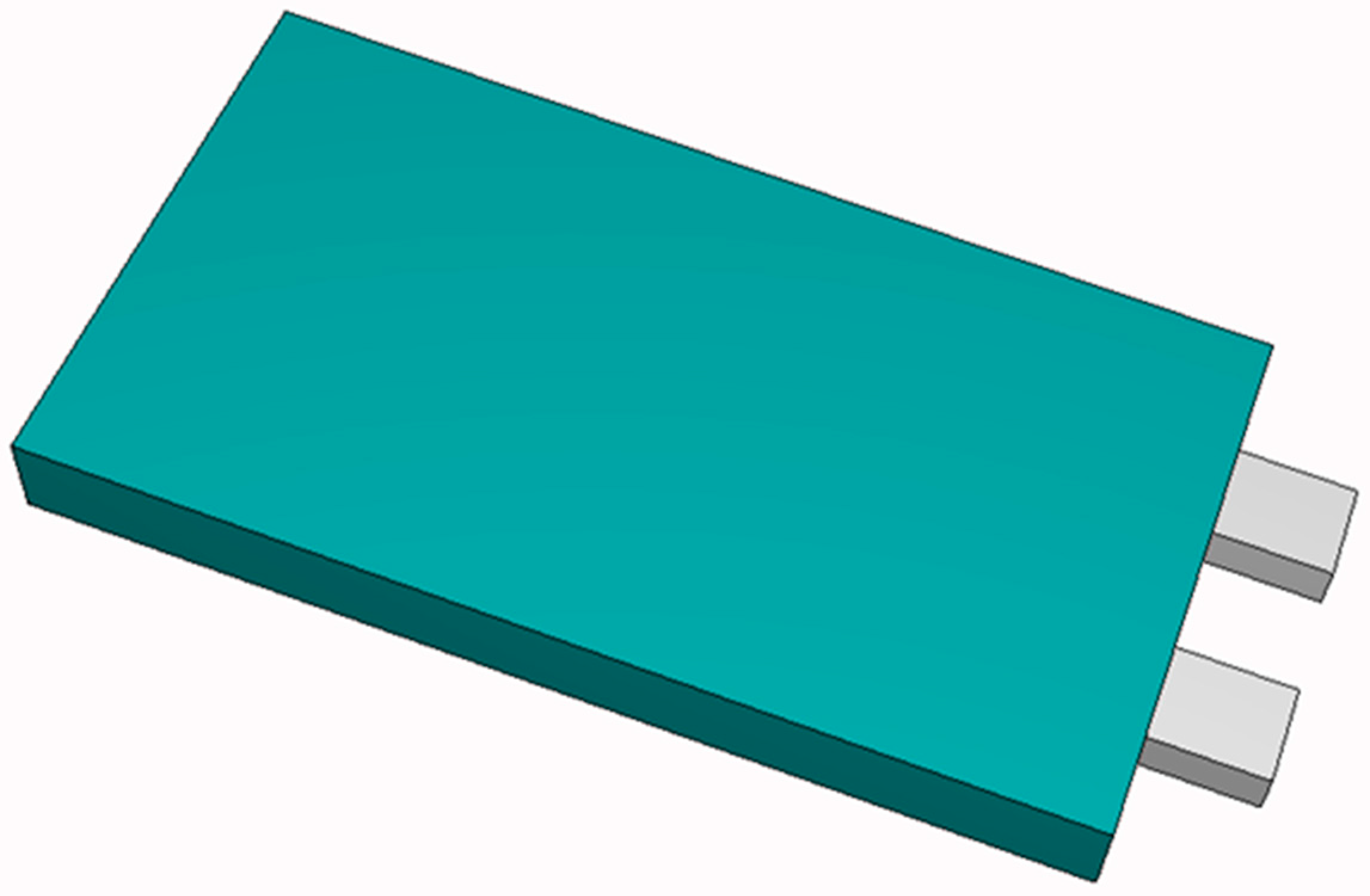

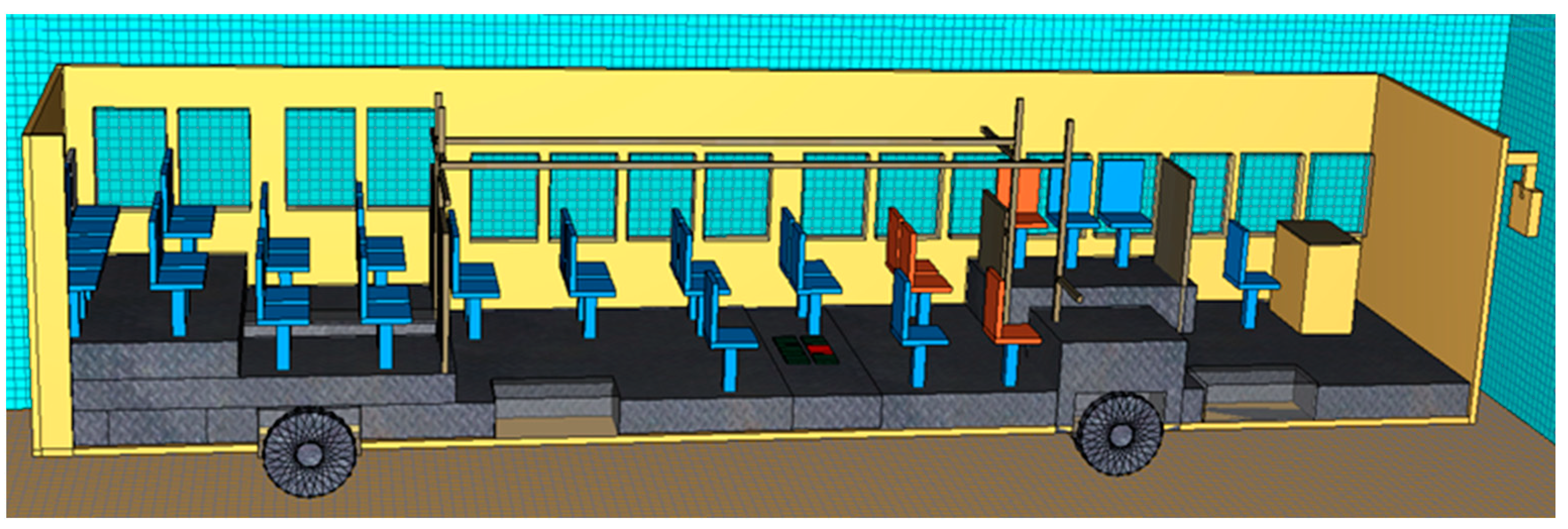

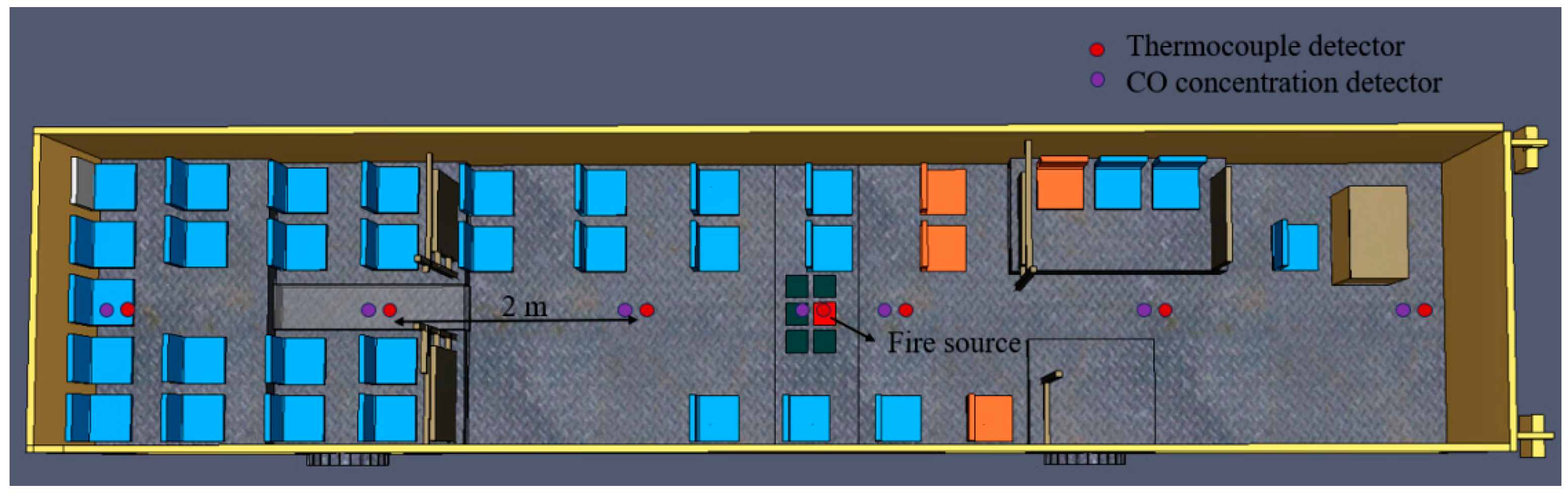

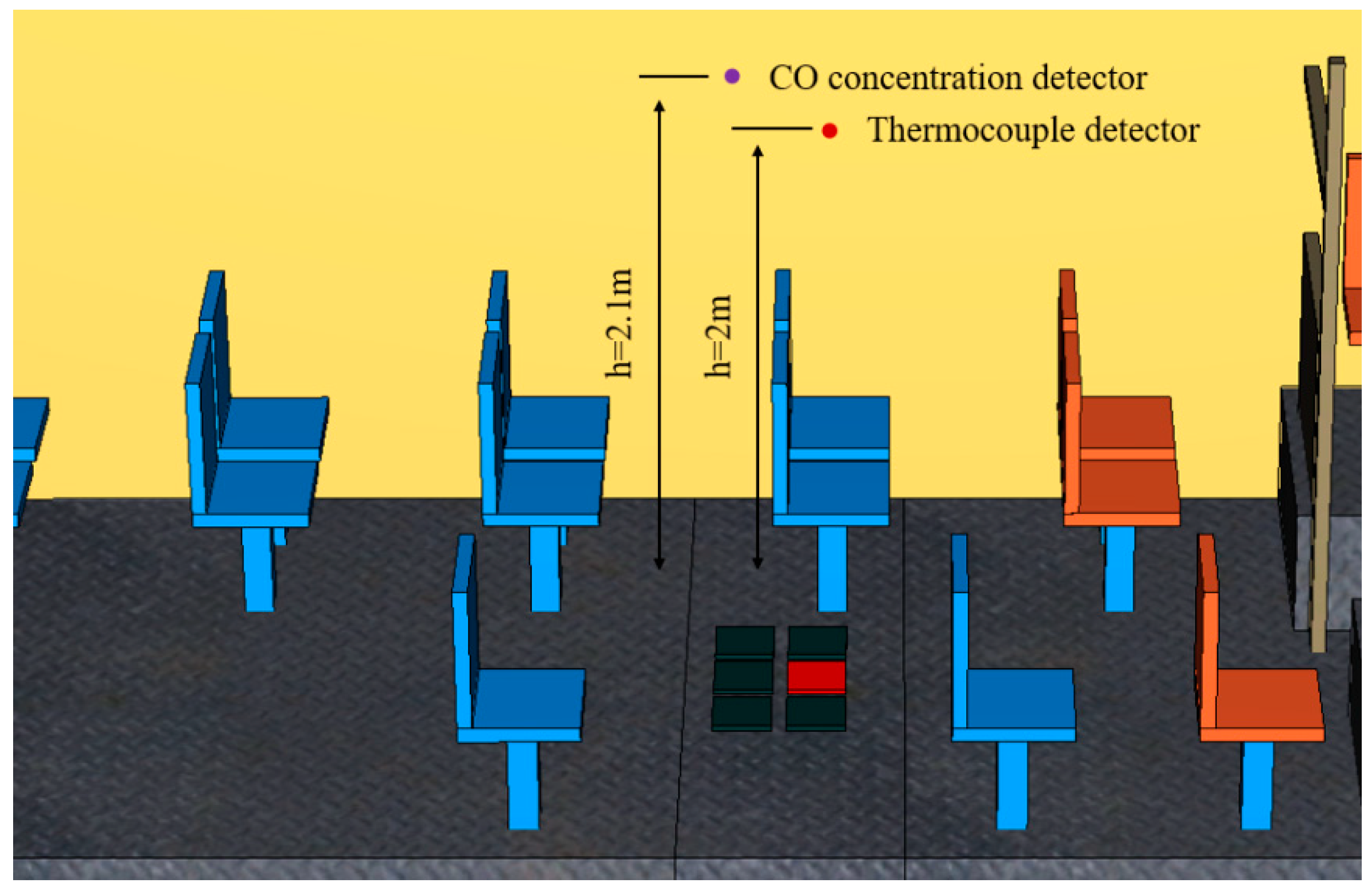

2.2. Model Settings

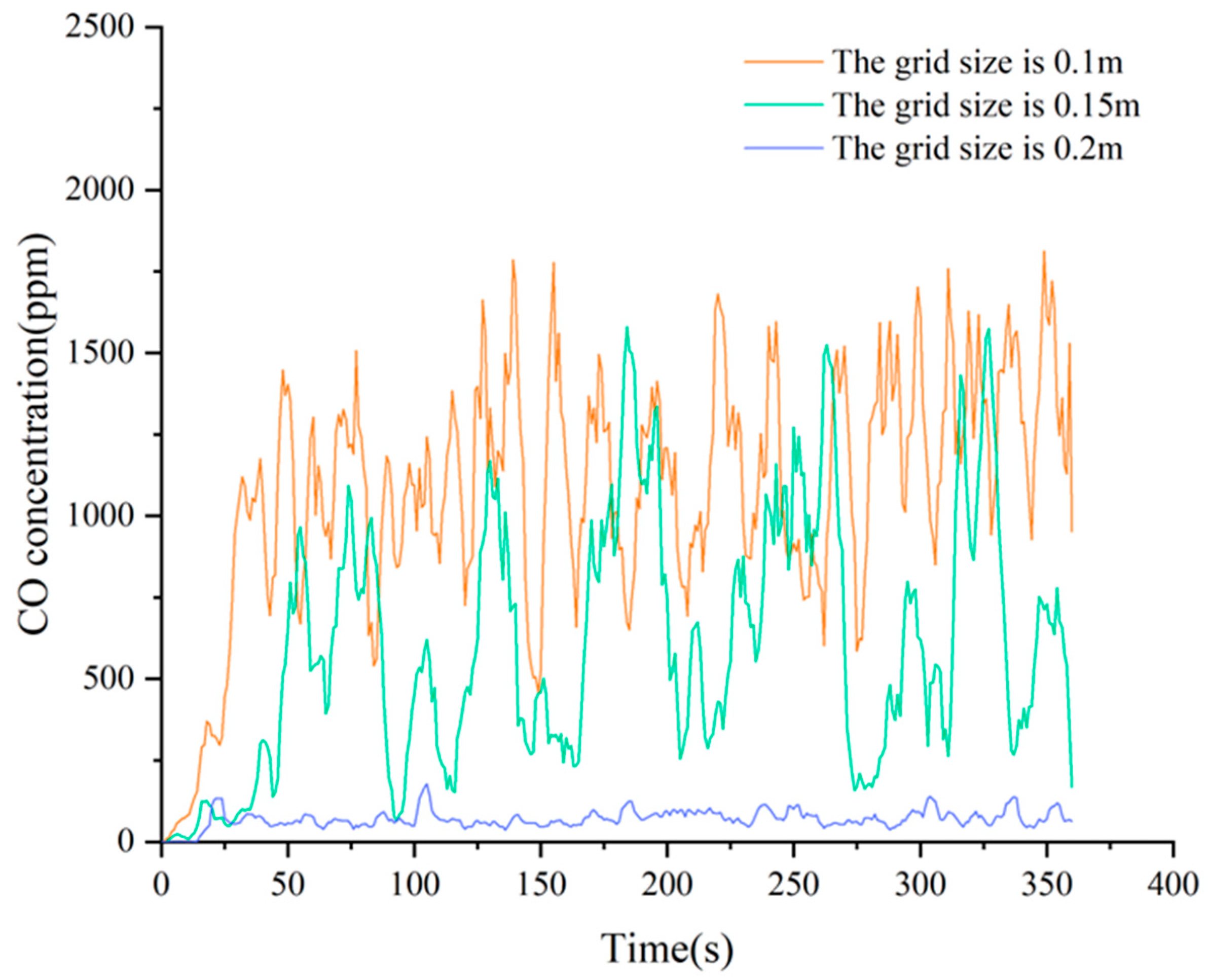

2.3. Grid Independence Verification

2.4. Fire Condition Settings

3. Analysis of Simulation Results

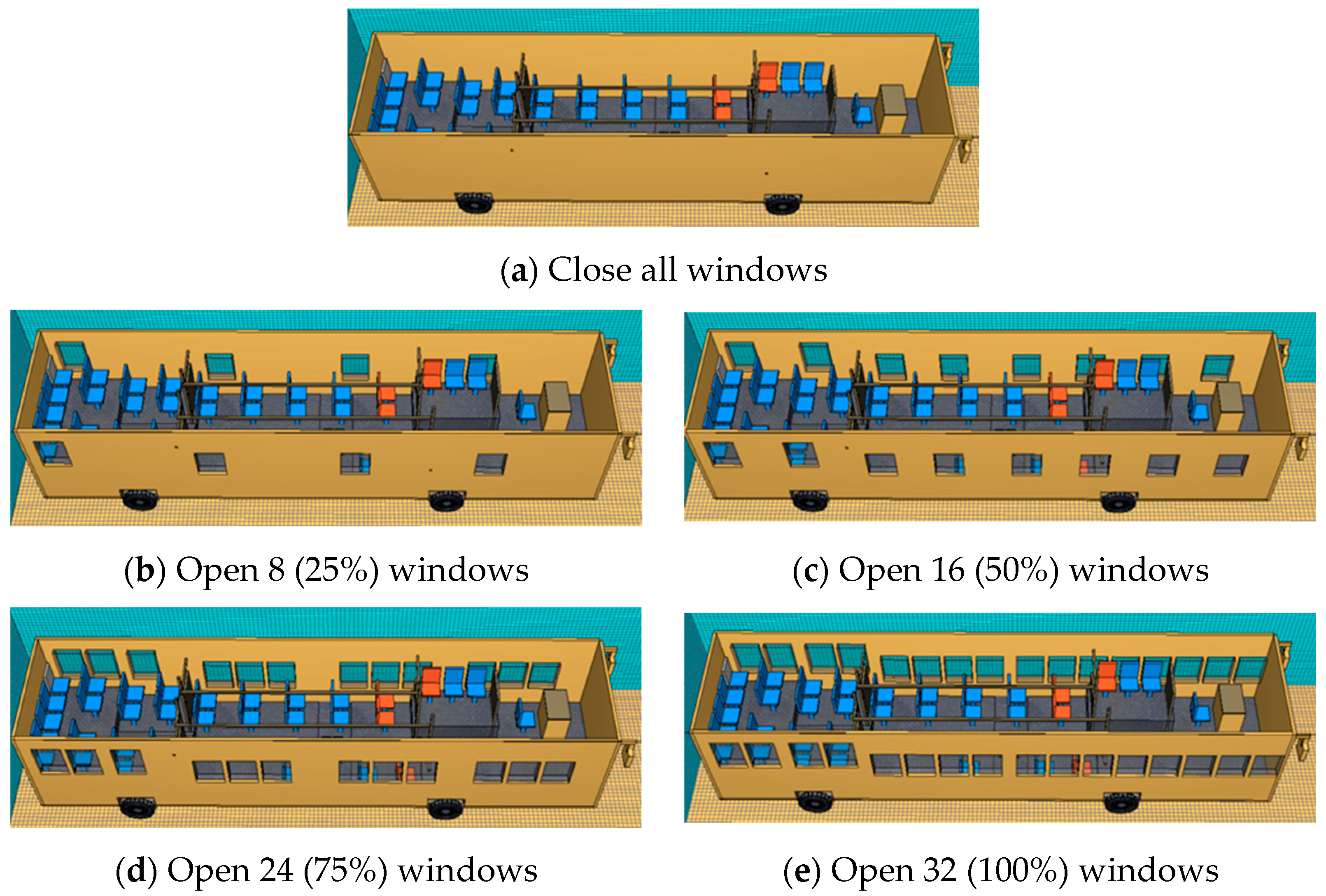

3.1. Fire Risk of Electric Buses under Different Ventilation Areas

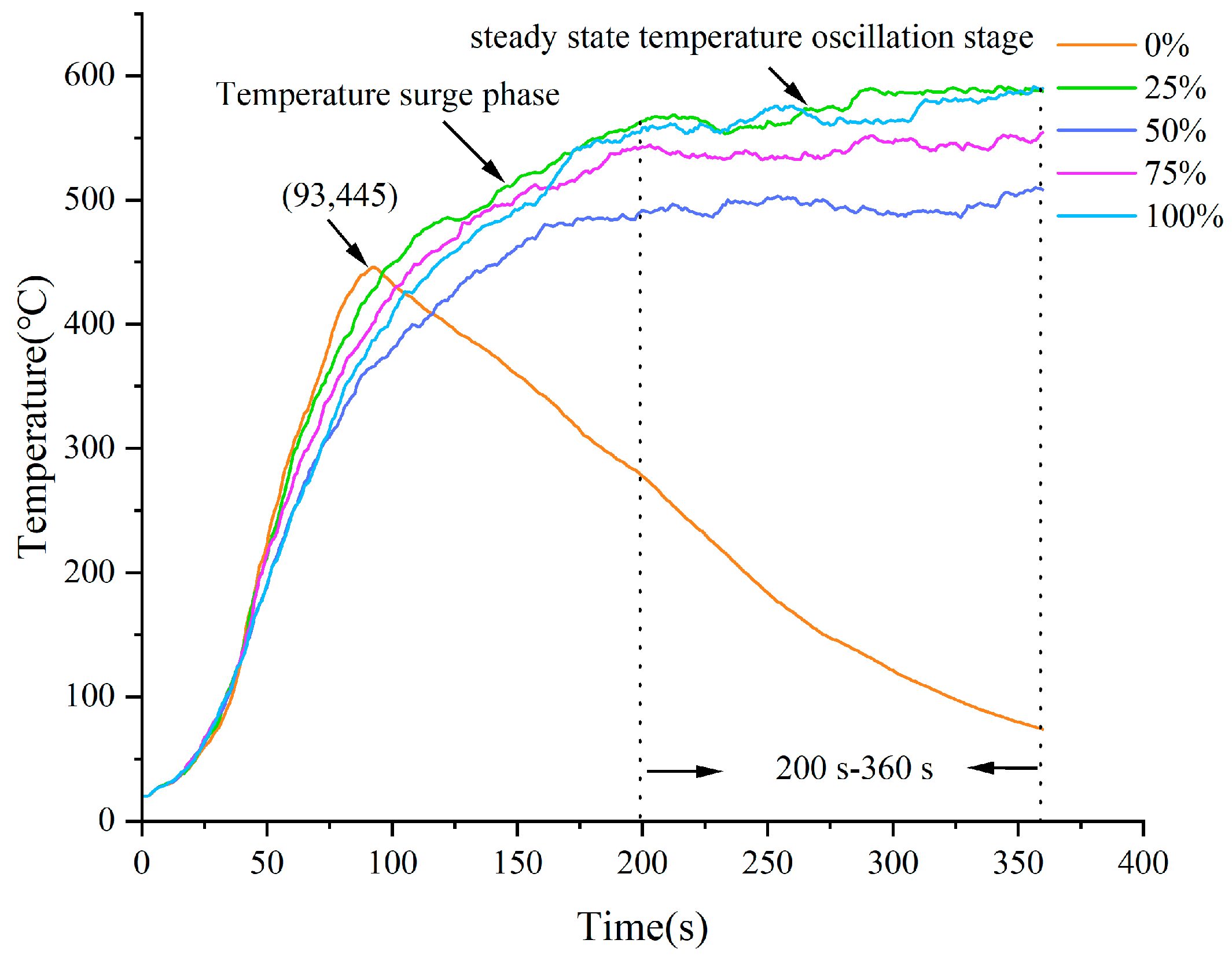

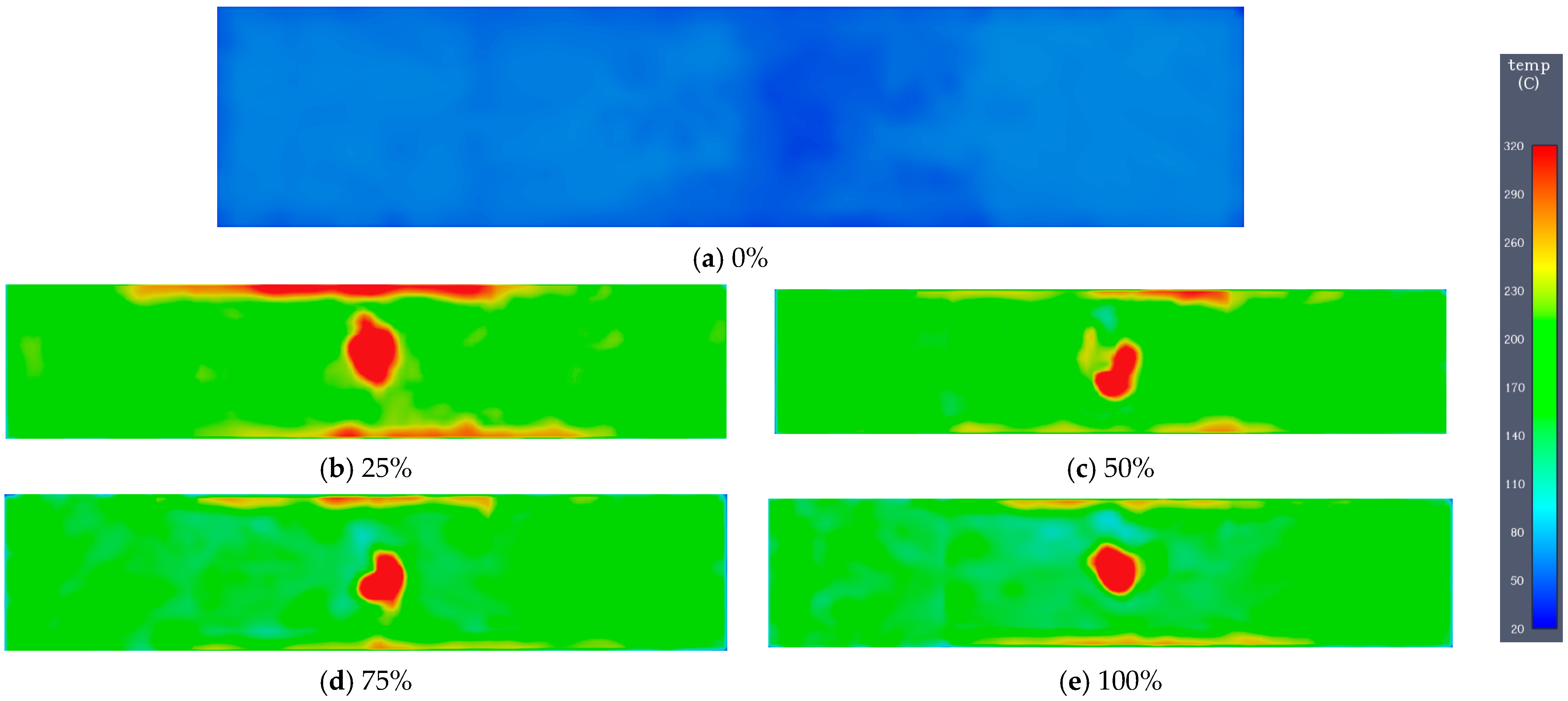

3.1.1. Temperature of Electric Bus Fire under Different Ventilation Areas

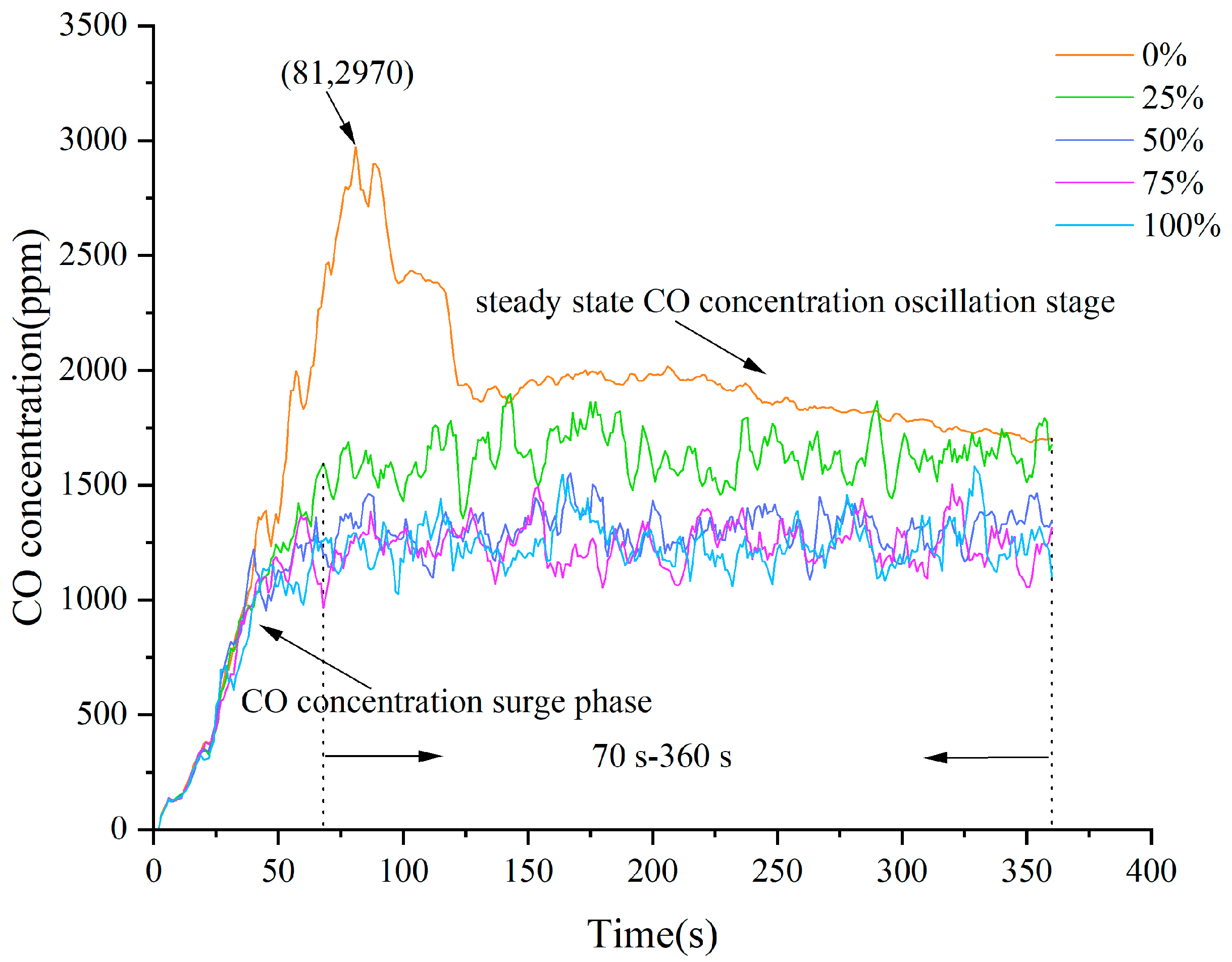

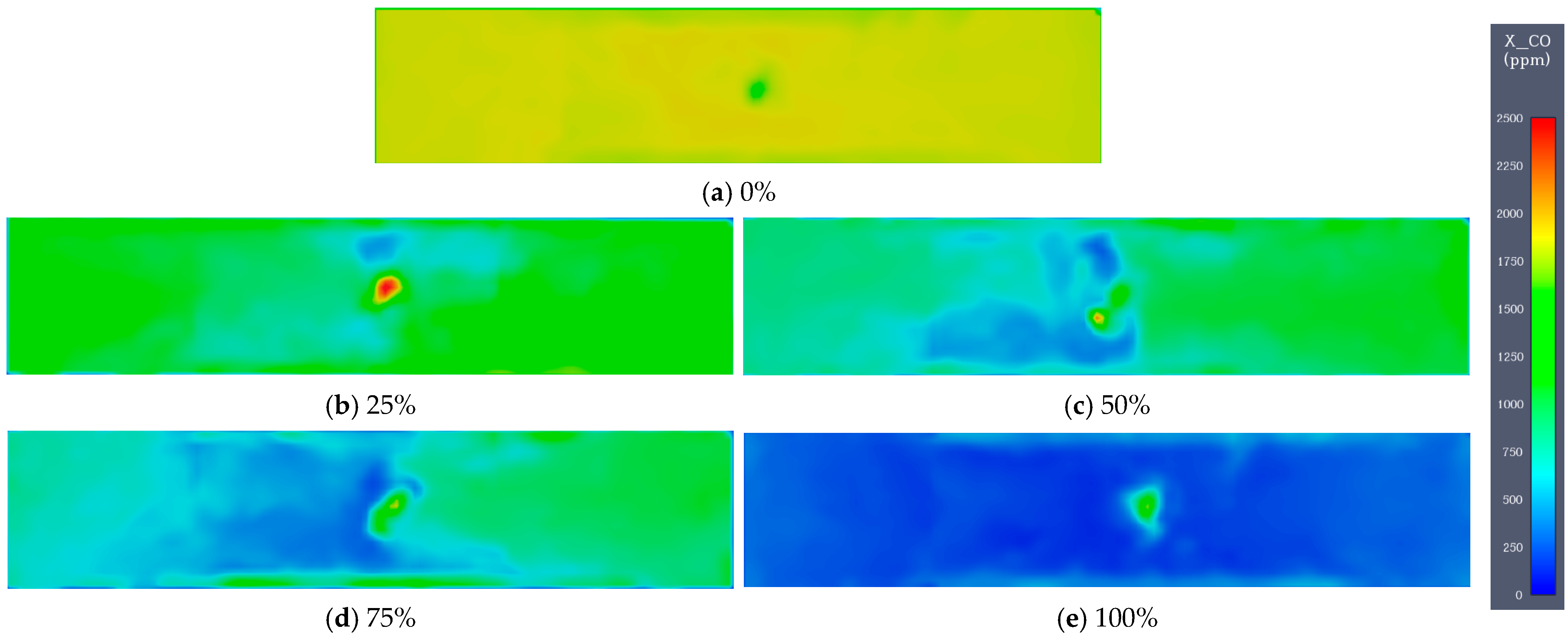

3.1.2. CO Concentration in Electric Bus Fires under Different Ventilation Areas

3.2. Fire Risk of Electric Buses under Different Wind Speeds

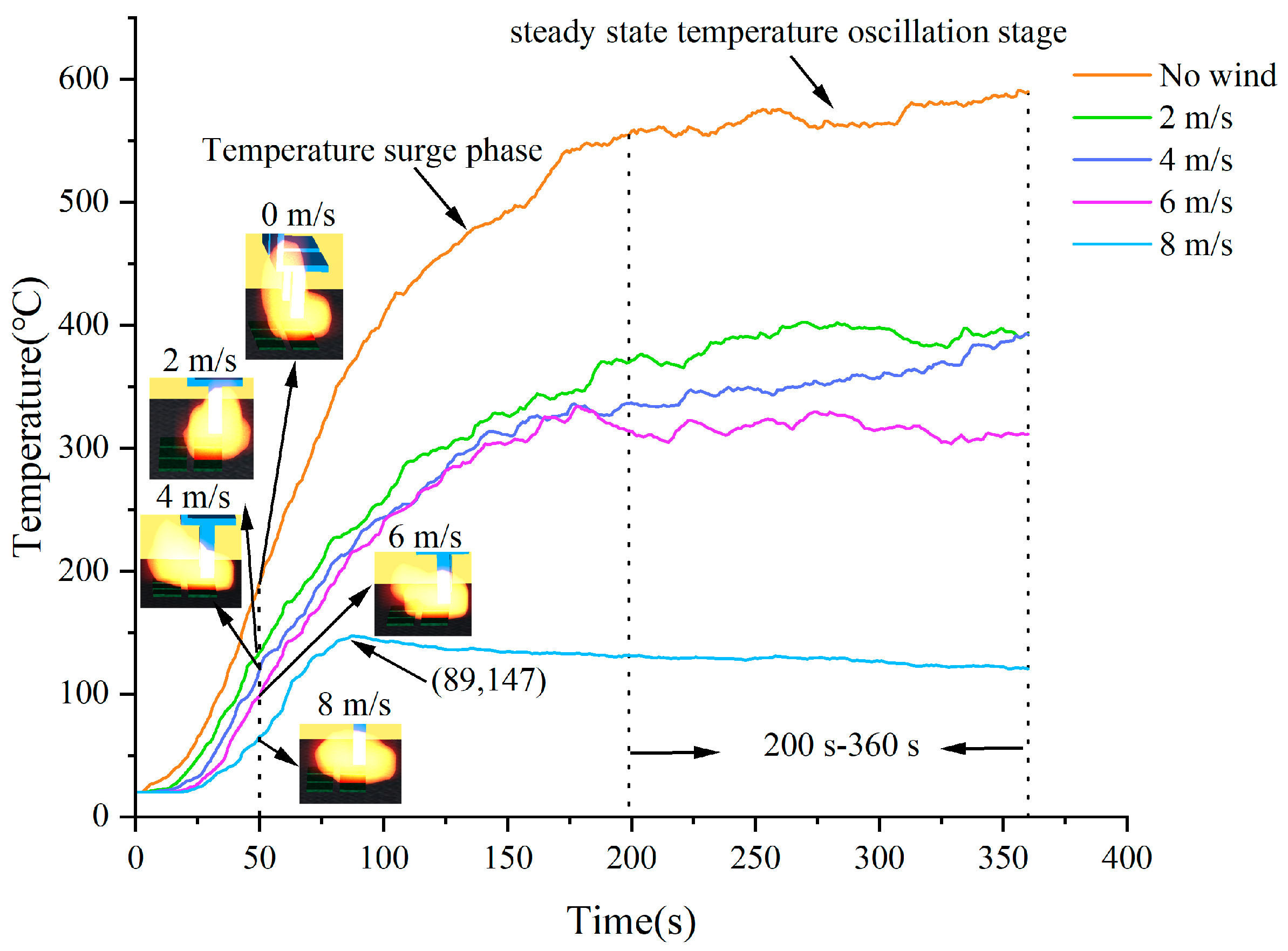

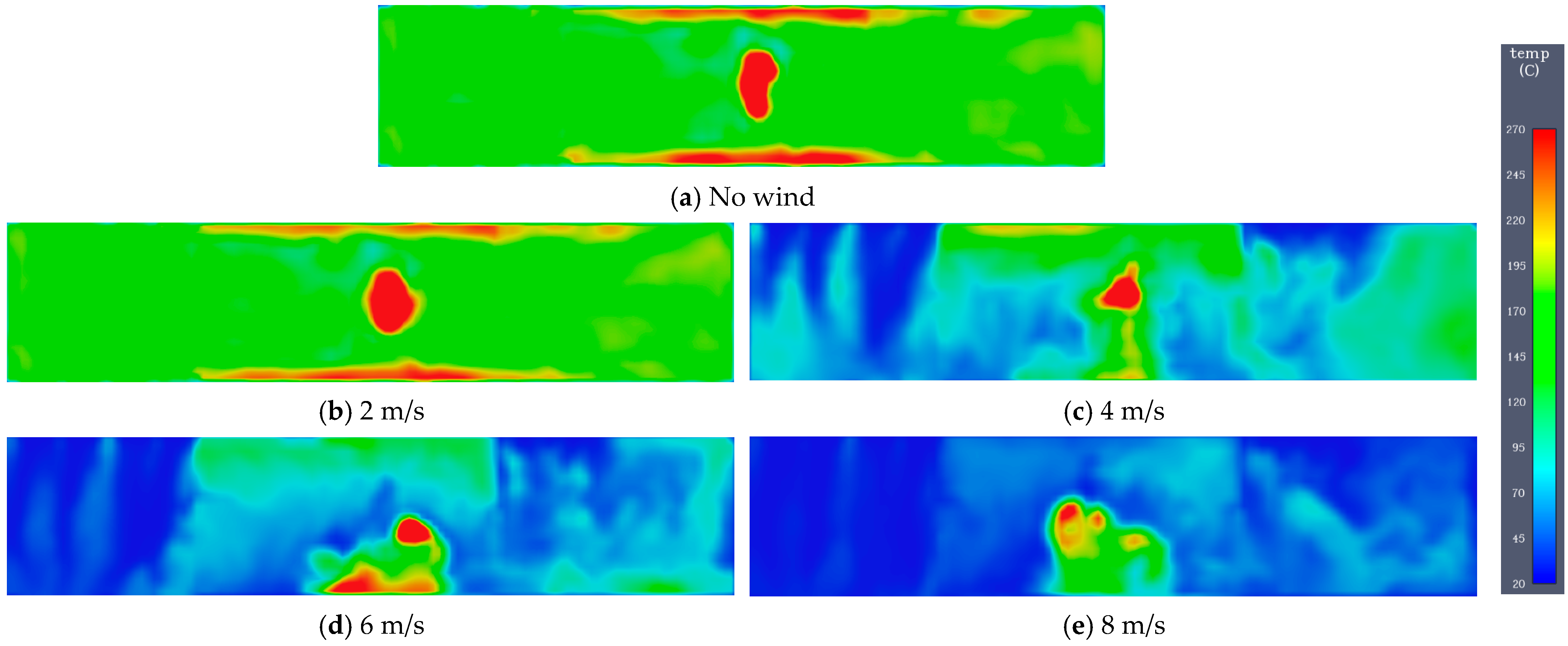

3.2.1. Temperature of Electric Bus Fire under Different Wind Speeds

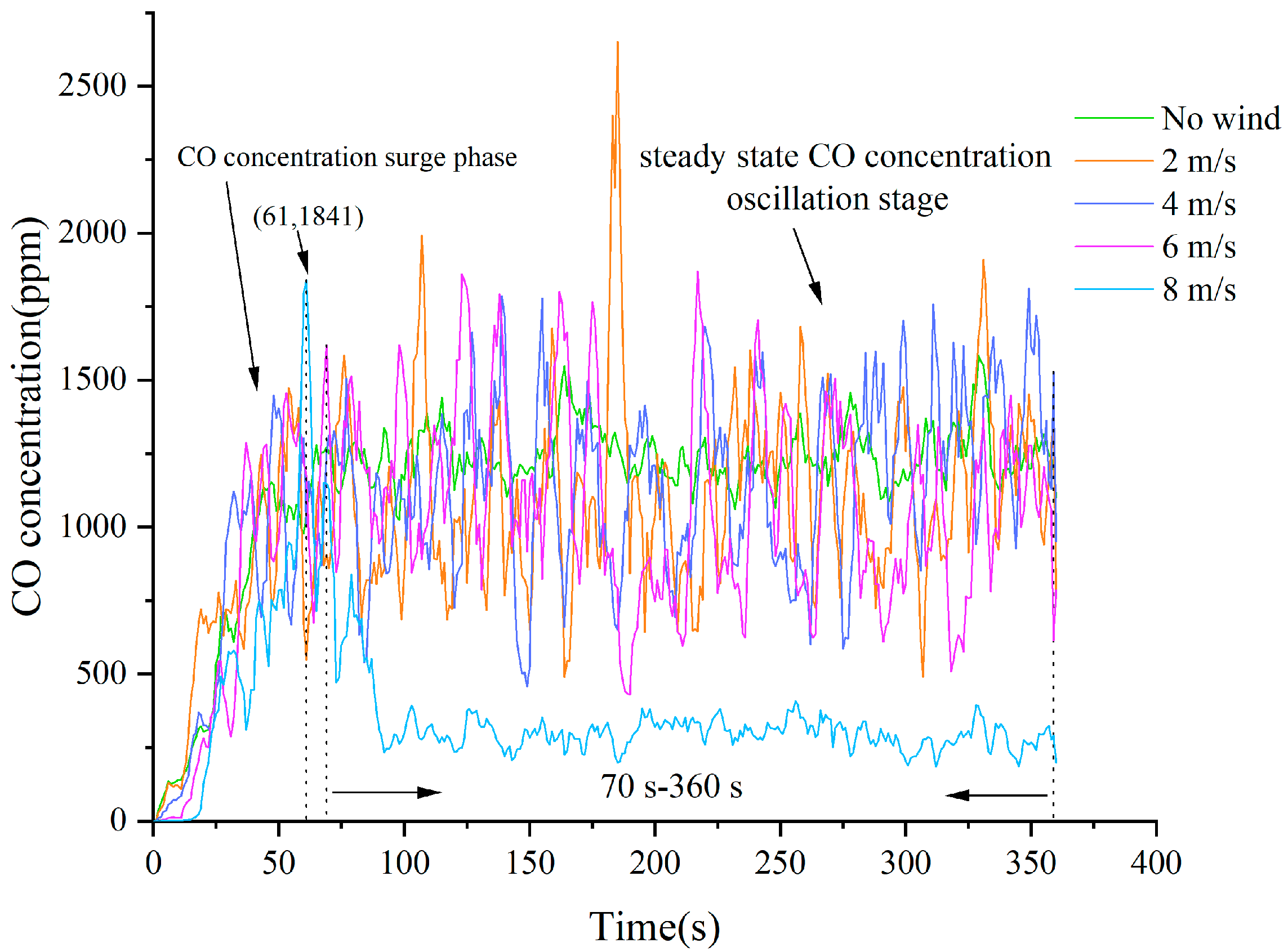

3.2.2. CO Concentration in Electric Bus Fires under Different Wind Speed Conditions

3.3. Fire Risk of Electric Buses at Different Window Opening Positions

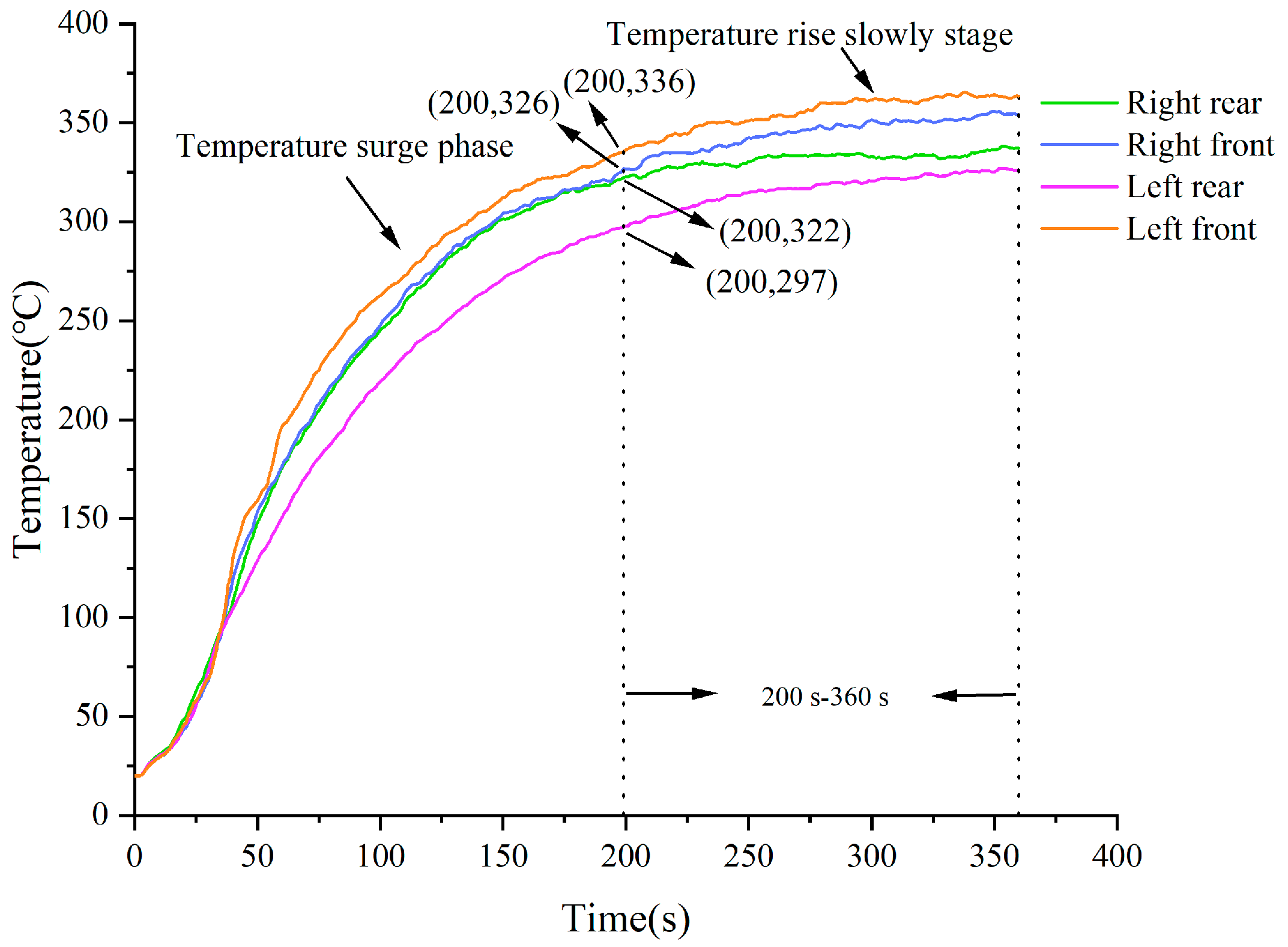

3.3.1. Temperature of Electric Bus Fire at Different Window Opening Positions

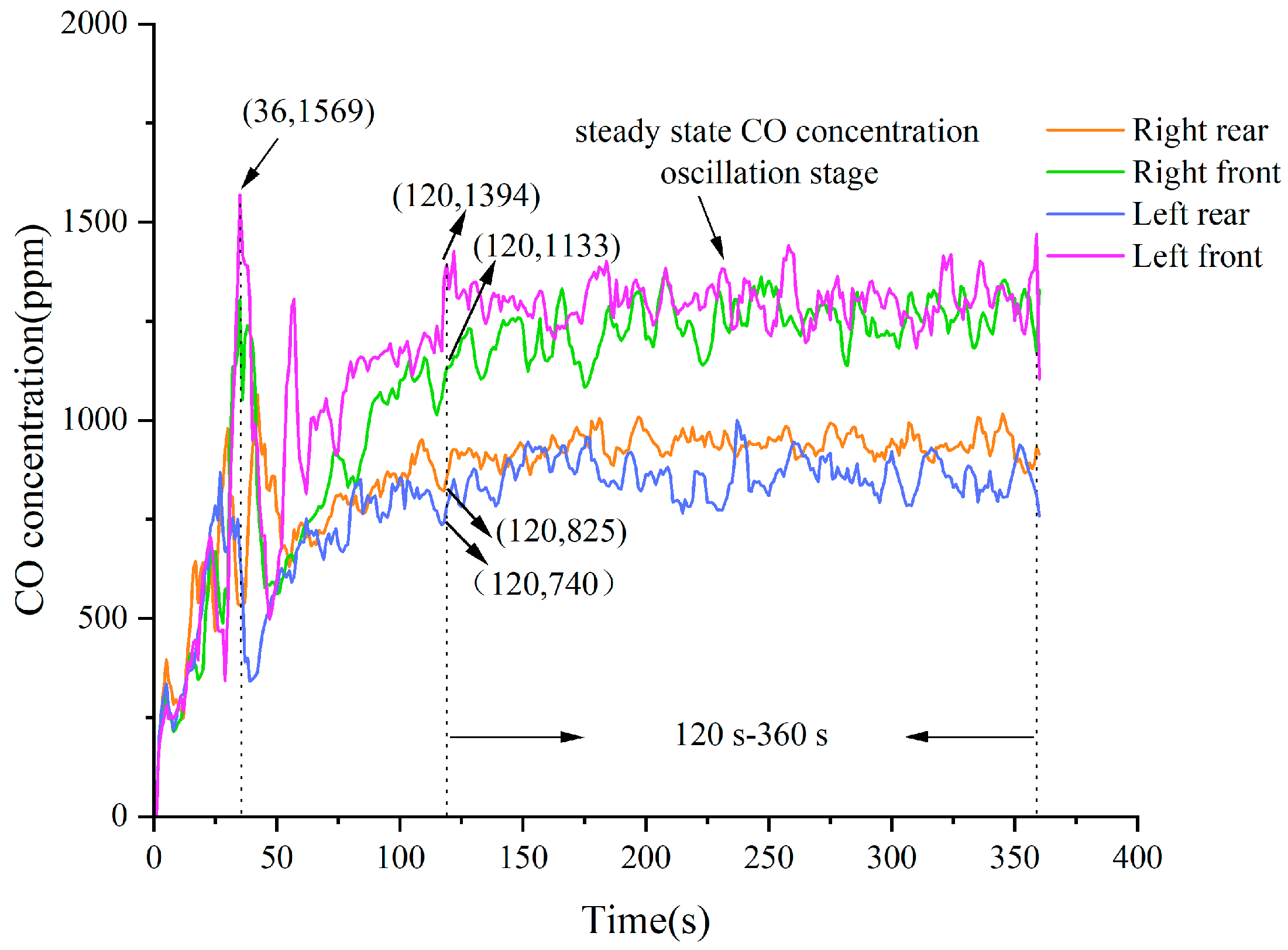

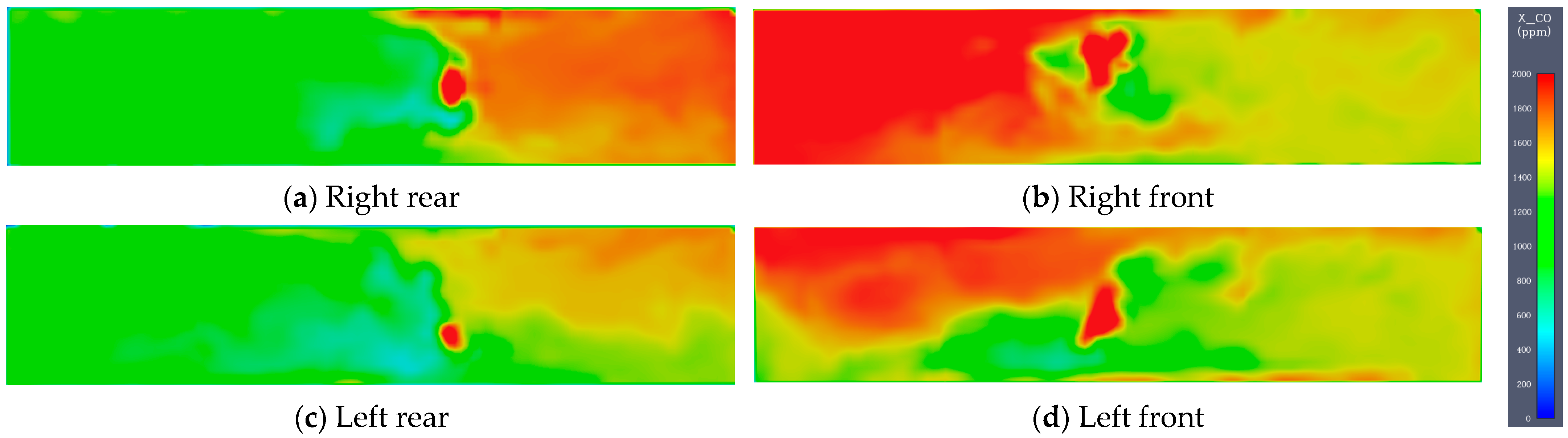

3.3.2. CO Concentration in Electric Bus Fires under Different Window Opening Positions

4. Conclusions

- (1)

- When all windows are closed, the temperature above the fire source reaches a maximum value of 445 °C at 93 s, and then the temperature begins to drop sharply; the CO concentration in the cabin reaches a maximum value of 2970 ppm at 81 s, and then the CO concentration begins to drop sharply and 125 s late and is maintained at a stable value near 1800 ppm. When the ventilation area gradually increases from 25% to 100%, the stable value of the temperature above the fire source reaches a minimum value of 508 °C; when the ventilation area is 50%, the stable value of the CO concentration in the compartment reaches a minimum value of 1200 ppm when the ventilation area is 100%. Since toxic smoke is the most harmful to people in a fire, and the temperature above the fire source is not very different under different ventilation areas, when a fire occurs in an electric bus, we should open 100% of the windows.

- (2)

- Under windless conditions, the temperature above the fire source reaches a steady state temperature oscillation stage after 200 s, and the average temperature in the steady state temperature oscillation stage is 569 °C; the CO concentration in the compartment reaches a maximum value of 1841 ppm at 61 s, and then drops rapidly and stabilizes at 250 ppm. When the wind speed gradually increases from 2 m/s to 8 m/s, the temperature above the fire source and the temperature inside the cabin decrease with the increase in wind speed. When the wind speed is 8 m/s, the stable value of the temperature is above the fire source and the CO in the cabin. The concentration stability values are the lowest, respectively, at 126 °C and 316 ppm. Therefore, when a fire occurs in an electric bus, the wind speed of 8 m/s is most conducive to personnel evacuation.

- (3)

- When opening different window opening positions, the temperature above the fire source when the rear window is opened, and the CO concentration in the cabin are significantly lower. When the rear windows (right rear, left rear) are opened for 360 s, the temperatures above the fire source are 337 °C and 326 °C, respectively; the stable values of CO concentration in the cabin with the rear windows (right rear, left rear) open are 937 ppm and 861 ppm, respectively. When a fire breaks out in an electric bus, we should choose to open the rear window first and escape from the rear door.

- (4)

- This study introduces in detail the influence of different ventilation conditions on the fire of electric buses and provides theoretical guidance for fire escape and rescue of electric buses. However, there are some limitations to this study. The paper only considers lithium-ion batteries as combustibles for fire simulation and does not consider the spread of combustibles such as seats and curtains. In the simulation process, the lithium-ion battery pack was set on the surface of the electric bus floor, while the actual lithium-ion battery pack is located inside the electric bus. At the same time, the impact of the door on the fire was not considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joshy, N.; Hajiyan, M.; Siddique, A.; Tasnim, S.; Simha, H.; Mahmud, S. Experimental investigation of the effect of vibration on phase change material (PCM) based battery thermal management system. J. Power Sources 2020, 450, 227717. [Google Scholar] [CrossRef]

- Ouyang, D.; Chen, M.; Huang, Q.; Weng, J.; Wang, Z.; Wang, J. A Review on the Thermal Hazards of the Lithium-Ion Battery and the Corresponding Countermeasures. Appl. Sci. 2019, 9, 2483. [Google Scholar] [CrossRef]

- Victor Chombo, P.; Laoonual, Y.; Wongwises, S. Lessons from the Electric Vehicle Crashworthiness Leading to Battery Fire. Energies 2021, 14, 4802. [Google Scholar] [CrossRef]

- Liu, B.; Jia, Y.; Yuan, C.; Wang, L.; Gao, X.; Yin, S.; Xu, J. Safety issues and mechanisms of lithium-ion battery cell upon mechanical abusive loading: A review. Energy Storage Mater. 2020, 24, 85–112. [Google Scholar] [CrossRef]

- Wang, K.; Ouyang, D.; Qian, X.; Yuan, S.; Chang, C.; Zhang, J.; Liu, Y. Early Warning Method and Fire Extinguishing Technology of Lithium-Ion Battery Thermal Runaway: A Review. Energies 2023, 16, 2960. [Google Scholar] [CrossRef]

- Wang, Q.; Mao, B.; Stoliarov, S.I.; Sun, J. A review of lithium-ion battery failure mechanisms and fire prevention strategies. Prog. Energy Combust. 2019, 73, 95–131. [Google Scholar] [CrossRef]

- Mallick, S.; Gayen, D. Thermal behaviour and thermal runaway propagation in lithium-ion battery systems—A critical review. J. Energy Storage 2023, 62, 106894. [Google Scholar] [CrossRef]

- Lin, C.-S.; Hsu, J.-P. Modeling and analysis of a bus fire accident for evaluation of fire safety door using the fire dynamics simulator. Clust. Comput. 2019, 22, 14973–14981. [Google Scholar] [CrossRef]

- Sandinge, A.; Fredriksson, H.; Blomqvist, P. Evaluation of smoke gas toxicity and smoke density of bus interior materials. Fire Mater. 2023, 47, 270–281. [Google Scholar] [CrossRef]

- Klippel, A.; Hofmann, A.; Gnutzmann, T.; Piechnik, K. Reaction-to-fire testing of bus interior materials: Assessing burning behaviour and smoke gas toxicity. Fire Mater. 2023, 47, 665–680. [Google Scholar] [CrossRef]

- Jiang, F.; Liu, K.; Wang, Z.; Tong, X.; Guo, L. Theoretical analysis of lithium-ion battery failure characteristics under different states of charge. Fire Mater. 2018, 42, 680–686. [Google Scholar] [CrossRef]

- He, X.; Restuccia, F.; Zhang, Y.; Hu, Z.; Huang, X.; Fang, J.; Rein, G. Experimental Study of Self-heating Ignition of Lithium-Ion Batteries During Storage: Effect of the Number of Cells. Fire Technol. 2020, 56, 2649–2669. [Google Scholar] [CrossRef]

- Park, S.-G.; Kim, S.-W.; Lee, E.-J. Experimental Study on Fire Characteristics of Lithium-ion Battery using Cone Calorimeter. Fire Sci. Eng. 2021, 35, 1–6. [Google Scholar] [CrossRef]

- Vendra, C.M.R.; Shelke, A.V.; Buston, J.E.H.; Gill, J.; Howard, D.; Read, E.; Abaza, A.; Cooper, B.; Wen, J.X. Numerical and experimental characterisation of high energy density 21700 lithium-ion battery fires. Process. Saf. Environ. Prot. 2022, 160, 153–165. [Google Scholar] [CrossRef]

- Hynynen, J.; Willstrand, O.; Blomqvist, P.; Andersson, P. Analysis of combustion gases from large-scale electric vehicle fire tests. Fire Saf. J. 2023, 139, 103829. [Google Scholar] [CrossRef]

- Sturm, P.; Fößleitner, P.; Fruhwirt, D.; Galler, R.; Wenighofer, R.; Heindl, S.F.; Krausbar, S.; Heger, O. Fire tests with lithium-ion battery electric vehicles in road tunnels. Fire Saf. J. 2022, 134, 103695. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, J.; Cong, B.; Han, X.; Yin, S. Characterization and assessment of fire evolution process of electric vehicles placed in parallel. Process. Saf. Environ. Prot. 2022, 166, 524–534. [Google Scholar] [CrossRef]

- Arvidson, M.; Westlund, Ö. Water Spray Fire Suppression Tests Comparing Gasoline-Fuelled and Battery Electric Vehicles. Fire Technol. 2023, 59, 3391–3414. [Google Scholar] [CrossRef]

- Kang, S.; Kwon, M.; Yoon Choi, J.; Choi, S. Full-scale fire testing of battery electric vehicles. Appl. Energy 2023, 332, 120497. [Google Scholar] [CrossRef]

- Li, H.; Peng, W.; Yang, X.; Chen, H.; Sun, J.; Wang, Q. Full-Scale Experimental Study on the Combustion Behavior of Lithium-Ion Battery Pack Used for Electric Vehicle. Fire Technol. 2020, 56, 2545–2564. [Google Scholar] [CrossRef]

- Xie, J.; Li, J.; Wang, J.; Jiang, J. Fire protection design of a lithium-ion battery warehouse based on numerical simulation results. J. Loss Prev. Process Ind. 2022, 80, 104885. [Google Scholar] [CrossRef]

- Wang, J.; Jia, Z.; Qin, P. Simulation of thermal runaway gas diffusion in LiFePO4 battery module. Energy Storage Sci. Technol. 2022, 11, 185–192. [Google Scholar]

- Jiang, J.; Liu, Q.; Wang, Z. Study on fire spreading law of lithium-ion battery in storage shelf. Fire Sci. Technol. 2023, 42, 471–476. [Google Scholar]

- Guo, Q.; Tao, L.; Ma, Z. Numerical simulation analysis of combustion of electric sport utility vehicles. Energy Storage Sci. Technol. 2024, 13, 1000–1008. [Google Scholar]

- Kang, Q.; Zhao, L.; Li, Z. Numerically simulated study on the characteristic features and spreading process of the bus fire. J. Saf. Environ. 2015, 15, 107–110. [Google Scholar]

- Xia, J. Discussion on fire characteristics and heat release rate of blade electric vehicles. J. Saf. Environ. 2021, 21, 1028–1032. [Google Scholar]

- Ren, C.; Zhang, G. Analysis of Growth and Spreading of Fire Started from Engine Compartment of Large Bus. In Proceedings of the 2018 International Conference on Information Systems and Computer Aided Education (ICISCAE), Changchun, China, 6–8 July 2018. [Google Scholar]

- Brzezinska, D.; Bryant, P. Performance-Based Analysis in Evaluation of Safety in Car Parks under Electric Vehicle Fire Conditions. Energies 2022, 15, 649. [Google Scholar] [CrossRef]

- Pan, H.; Ji, H.; Qiu, M. Numerical simulation study on fire of lithium-ion battery pack in electric vehicle. China Work. Saf. Sci. Technol. 2020, 16, 104–109. [Google Scholar]

- Dorsz, A.; Lewandowski, M. Analysis of Fire Hazards Associated with the Operation of Electric Vehicles in Enclosed Structures. Energies 2022, 15, 11. [Google Scholar] [CrossRef]

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Lou, Z.; Huang, J.; Wang, M.; Zhang, Y.; Lv, K.; Yao, H. Inhibition performances of lithium-ion battery pack fires by fine water mist in an energy-storage cabin: A simulation study. Phys. Fluids 2024, 36, 045141. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium-ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Kim, E.; Woycheese, J.P.; Dembsey, N.A. Fire Dynamics Simulator (Version 4.0) Simulation for Tunnel Fire Scenarios with Forced, Transient, Longitudinal Ventilation Flows. Fire Technol. 2008, 44, 137–166. [Google Scholar] [CrossRef]

- Mao, B.; Liu, C.; Yang, K.; Li, S.; Liu, P.; Zhang, M.; Meng, X.; Gao, F.; Duan, X.; Wang, Q.; et al. Thermal runaway and fire behaviors of a 300 Ah lithium-ion battery with LiFePO4 as cathode. Renew. Sustain. Energy Rev. 2021, 139, 110717. [Google Scholar] [CrossRef]

- Lee, J. Numerical analysis of how ventilation conditions impact compartment fire suppression by water mist. Ann. Nucl. Energy 2020, 136, 107021. [Google Scholar] [CrossRef]

| Time | Place | Event |

|---|---|---|

| 16 February 2023 | Shijingshan District, Beijing, China | A non-passenger-carrying bus suddenly caught fire while in transit. Due to the timely control of the fire, there were no casualties. The cause of the fire is currently unknown. |

| 12 February 2022 | Shenyang City, Liaoning Province, China | A bus traveling on the road experienced an explosion, resulting in one fatality, two severe injuries, and 40 minor injuries. According to reports, the cause of the fire was an explosion of the lithium battery used in the bus. |

| 9 January 2021 | South India | A bus caught fire suddenly while in motion, leading to at least 19 fatalities. According to reports, the cause of the fire was a short circuit resulting from an engine malfunction. |

| 11 August 2021 | Karnataka, India | A public bus caught fire, resulting in five fatalities and 27 injuries, including one child. Preliminary investigations indicate that the cause of the accident was an engine malfunction. |

| 12 September 2020 | Punjab Province, Pakistan | A bus caught fire suddenly while in transit, resulting in at least nine fatalities and 15 injuries. According to reports, the cause of the fire was an electrical malfunction. |

| 1 June 2017 | Nanning City, Guangxi Province, China | A bus caught fire suddenly while in transit, resulting in at least 35 fatalities and 19 injuries. According to reports, the cause of the fire was a fire in the vehicle’s electrical system due to a malfunction. |

| Author | Research Content | Conclusion |

|---|---|---|

| Jiang et al. | The relationship between thermal runaway characteristics of lithium-ion batteries and different charging states | The higher the lithium-ion battery capacity, the lower the starting temperature for thermal runaway [11]. |

| He et al. | Surface and core temperatures, voltages and ignition times of stacked lithium-ion cells with different numbers. | Self-heating ignition of open-circuit lithium-ion batteries is possible, and its behavior is divided into three stages: heating, self-heating and thermal runaway [12]. |

| Park et al. | Fire characteristics and heat release rates of cylindrical standard lithium-ion batteries | The fire consists of two combustion stages. The peak HRR of the second stage of combustion is higher than that of the first stage and is accompanied by a violent explosion [13]. |

| Vendra et al. | A total of 21,700 heat release rate and temperature evolution during the thermal runaway of lithium-ion batteries | Under thermal abuse conditions, the average peak values of battery heat release rate, battery surface, and internal temperature are 3.6 kW, 753 °C and 1080 °C, respectively [14]. |

| Hynynen et al. | Toxic gases produced when lithium-ion batteries burn | The biggest difference between electric vehicles and internal combustion engine vehicles is hydrogen fluoride [15]. |

| Author | Research Content | Conclusion |

|---|---|---|

| Sturm et al. | Electric vehicle fire test. | The heat release rate of electric vehicles is higher than that of traditional fuel vehicles [16]. |

| Cui et al. | Fire evolution process and characteristics of two electric vehicles placed side by side. | The precursor to a fire in an electric vehicle is white smoke coming out of the chassis, and the flames spread between electric vehicles faster than in internal combustion engine vehicles [17]. |

| Arvidson et al. | Fire extinguishing tests on water sprinkler systems for fuel vehicles and electric vehicles. | Electric vehicle fires take longer to burn, and the combustion products are more complex [18]. |

| Kang et al. | Thermal behavior of pure electric vehicle fires. | The intensive emission of jet flames from lithium-ion battery packs causes the flames to quickly spread to adjacent combustible parts, thereby accelerating the growth of the fire [19]. |

| Li et al. | Comprehensive thermal runaway testing of lithium-ion battery packs. | In the worst case, it only takes 22 s for a lithium-ion battery cell to undergo thermal runaway and turn into a flame that spreads to the entire battery pack [20]. |

| Author | Research Content | Conclusion |

|---|---|---|

| Xie et al. | Numerical simulation of lithium-ion battery warehouse under different fire scenes. | Determine the warehouse layout plan with optimal battery state of charge, shelf spacing, and fire extinguishing measures [21]. |

| Wang et al. | Gas diffusion rules during battery thermal runaway. | Among the four thermal runaway gases H2, CO, CO2, and CH4, the concentration of CO2 is about 30%, accounting for the largest proportion, the concentration of CO is about 5%, the concentration of H2 is about 18%, and the concentration of CH4 is about 14% [22]. |

| Jiang et al. | Fire spread rules in different fire locations of lithium-ion batteries. | In a four-layer lithium battery shelf, the continuous release time of CO is 54% longer when the bottom shelf catches fire than when the top shelf catches fire [23]. |

| Guo et al. | Fire combustion characteristics, flame propagation during combustion and cockpit smoke analysis of pure electric vehicles. | Smoke will enter the cabin through the gaps in the body, and the smoke concentration in the passenger compartment will reach 100% coverage within 40 s [24]. |

| Kang et al. | Effect of door opening on bus fire development and personnel escape. | The critical time for passengers to escape is within 20 s after the door is opened [25]. |

| Xia et al. | Fire characteristics and heat release rate of pure electric vehicles. | The formula is reasonable to estimate the heat release rate of pure electric vehicle [26]. |

| Ren et al. | Numerical simulation of the fire process in the bus engine compartment. | The faster the wind speed, the shorter the time it takes for a bus fire to reach the peak heat release rate [27]. |

| Brzezinska et al. | Numerical simulation of the thermal runaway process of the electric vehicle lithium-ion battery pack. | Electric car fires in garages do not pose a risk to people staying in the garage [28]. |

| Pan et al. | The diffusion process of toxic smoke after thermal runaway of lithium-ion batteries in electric buses. | After an electric bus fire, it is safer for people to escape through the back door than through the front door [29]. |

| Dorsz et al. | Comparison of fire characteristics between electric vehicles and conventional internal combustion engine passenger vehicles. | There is little difference in temperature and visibility during fires between electric vehicles and conventional combustion engine vehicles [30]. |

| Argument | Positive Electrode | Negative Electrode | Electrolyte | Diaphragm |

|---|---|---|---|---|

| Density/(kg/m3) | 2700 | 8500 | 2600 | 492 |

| Specific heat capacity/[kJ·/(kg·K)] | 900 | 385 | 1100 | 1978 |

| Thermal conductivity/[W/(m·K)] | 160 | 146 | 21 | 0.334 |

| Thermal absorption coefficient | 0.8 | 0.8 | 0.9 | 0.8 |

| Serial Number | Fire Scene Settings |

|---|---|

| 1 | Close all windows |

| 2 | Open 8 (25%) windows |

| 3 | Open 16 (50%) windows |

| 4 | Open 24 (75%) windows |

| 5 | Open 32 (100%) windows |

| 6 | Conducted under windless conditions |

| 7 | The wind speed is 2 m/s |

| 8 | The wind speed is 4 m/s |

| 9 | The wind speed is 6 m/s |

| 10 | The wind speed is 8 m/s |

| 11 | Open the right front windows |

| 12 | Open the right rear windows |

| 13 | Open the left front windows |

| 14 | Open the left rear windows |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, H.; Xing, M.; Song, H.; Zhang, Y.; Luo, S.; Bai, Z. The Impact of Different Ventilation Conditions on Electric Bus Fires. Fire 2024, 7, 182. https://doi.org/10.3390/fire7060182

Yao H, Xing M, Song H, Zhang Y, Luo S, Bai Z. The Impact of Different Ventilation Conditions on Electric Bus Fires. Fire. 2024; 7(6):182. https://doi.org/10.3390/fire7060182

Chicago/Turabian StyleYao, Haowei, Mengyang Xing, Huaitao Song, Yang Zhang, Sheng Luo, and Zhenpeng Bai. 2024. "The Impact of Different Ventilation Conditions on Electric Bus Fires" Fire 7, no. 6: 182. https://doi.org/10.3390/fire7060182

APA StyleYao, H., Xing, M., Song, H., Zhang, Y., Luo, S., & Bai, Z. (2024). The Impact of Different Ventilation Conditions on Electric Bus Fires. Fire, 7(6), 182. https://doi.org/10.3390/fire7060182