Experimental Study on the Effect of Sealing Time on Combustion State of the Fuel-Ventilation Controlled Wood Crib

Abstract

1. Introduction

2. Determination of Fire Burning Type

3. Experimental Apparatus and Conditions

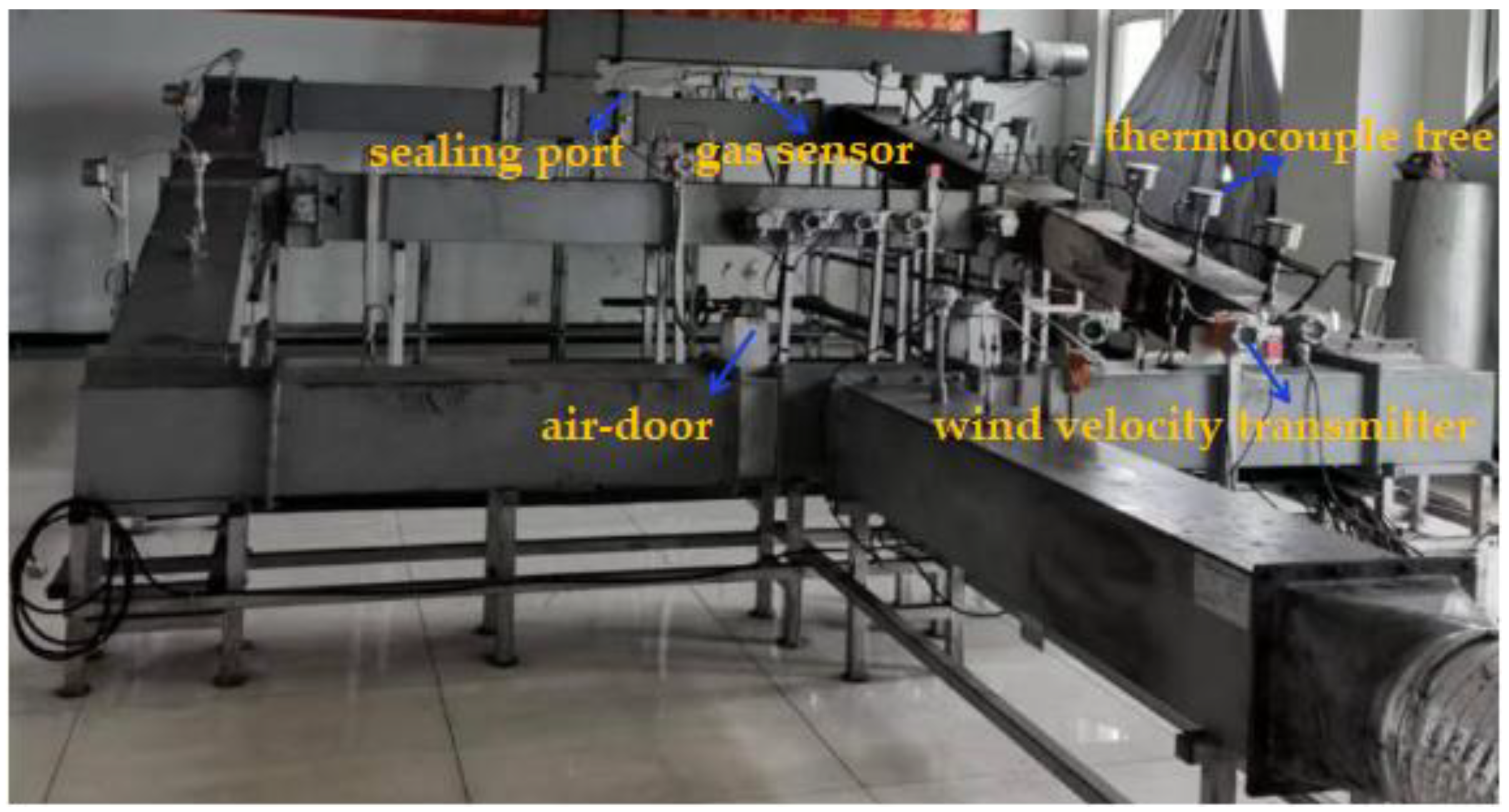

3.1. Reduced-Scale Tunnel Model

3.2. Experimental Conditions

4. Results and Discussion

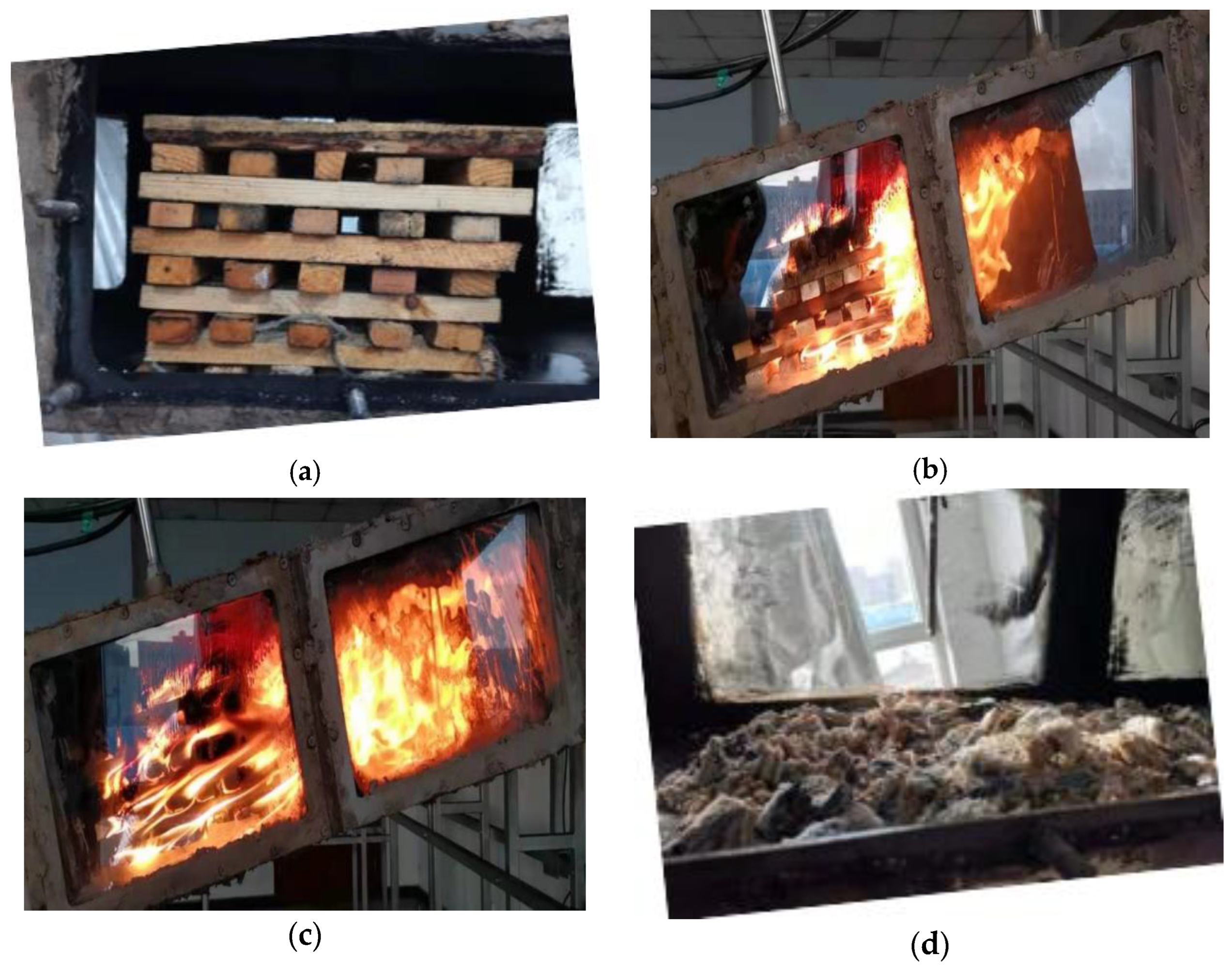

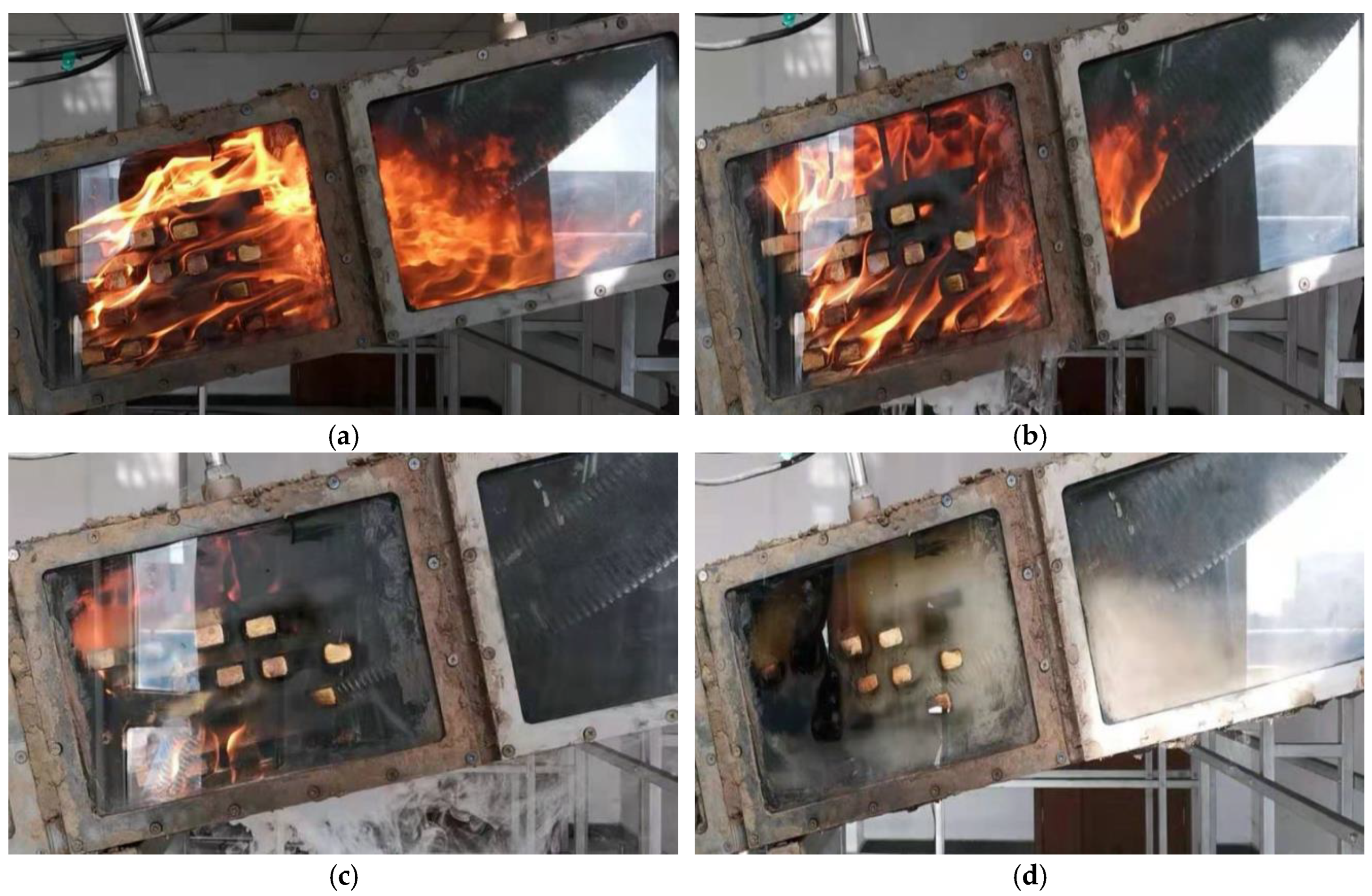

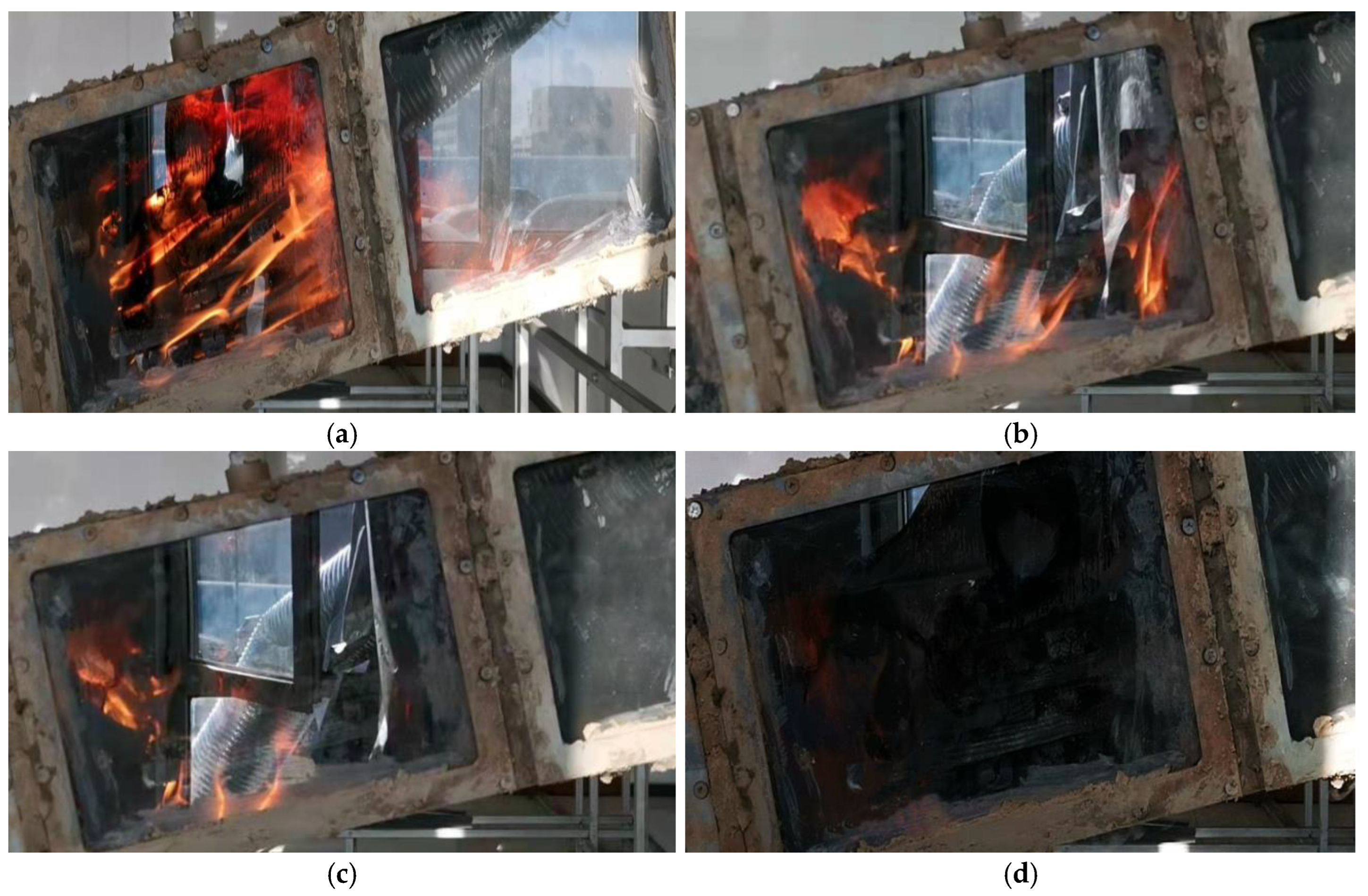

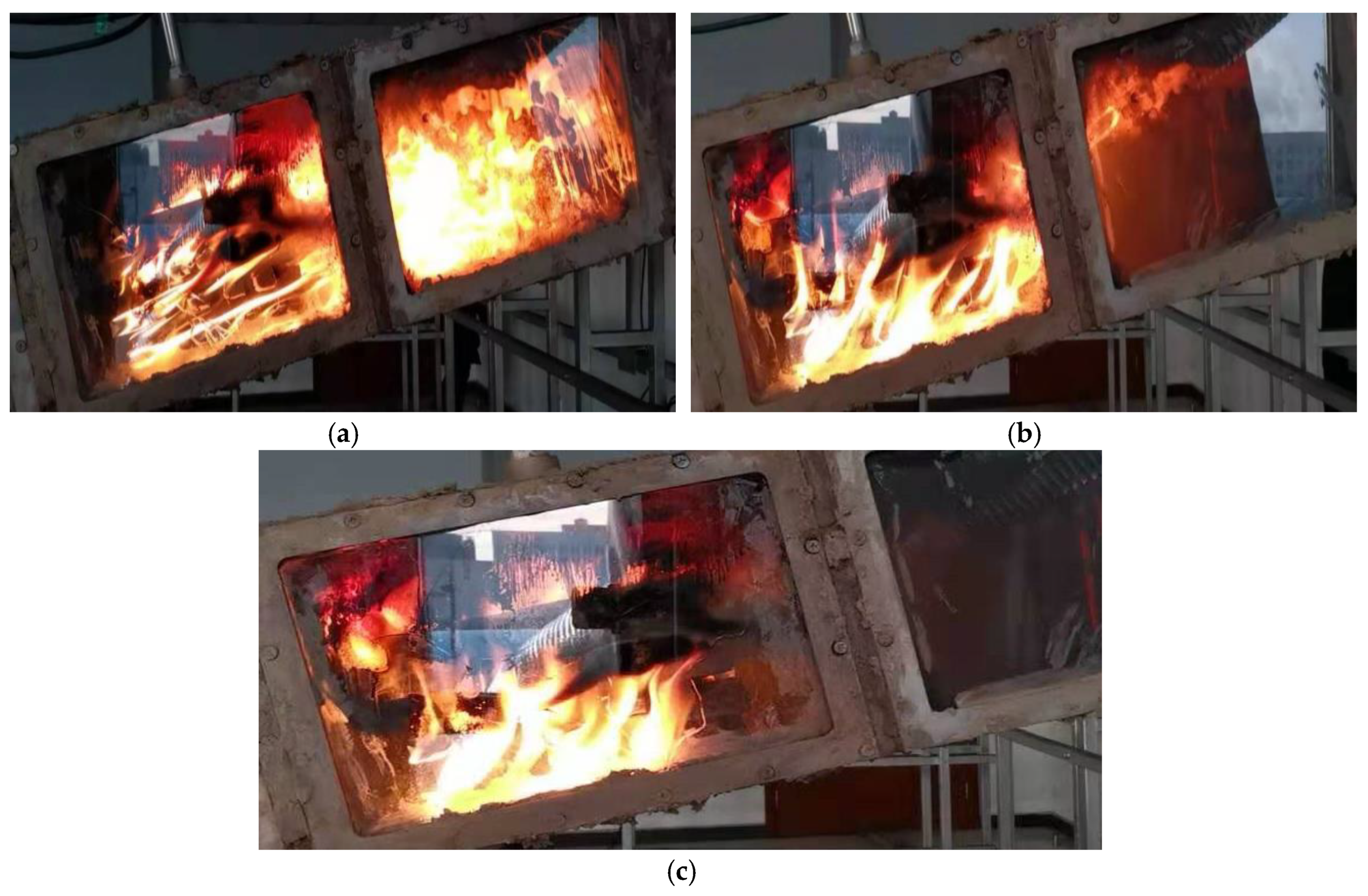

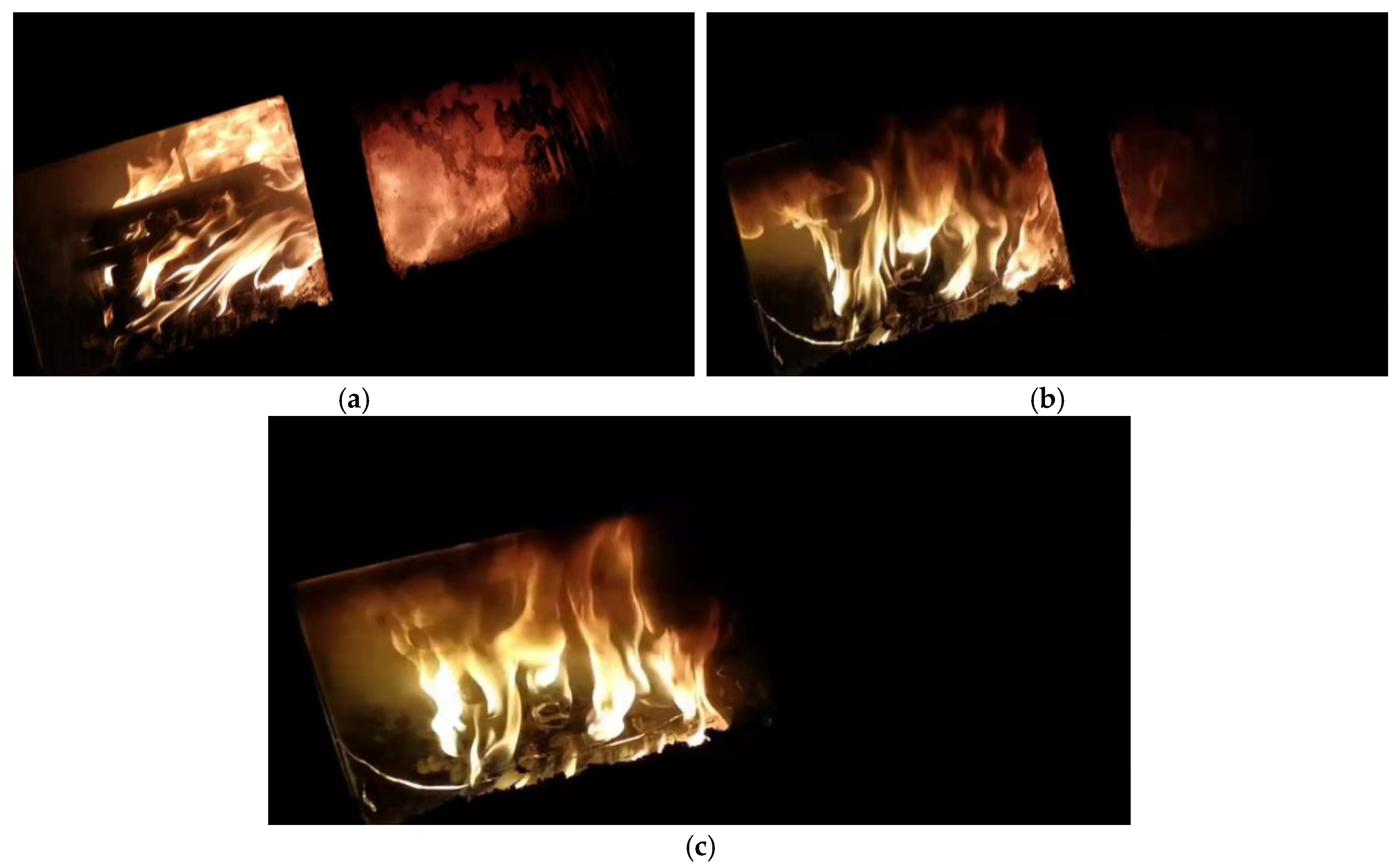

4.1. Flame Morphology

4.2. Gas Variation

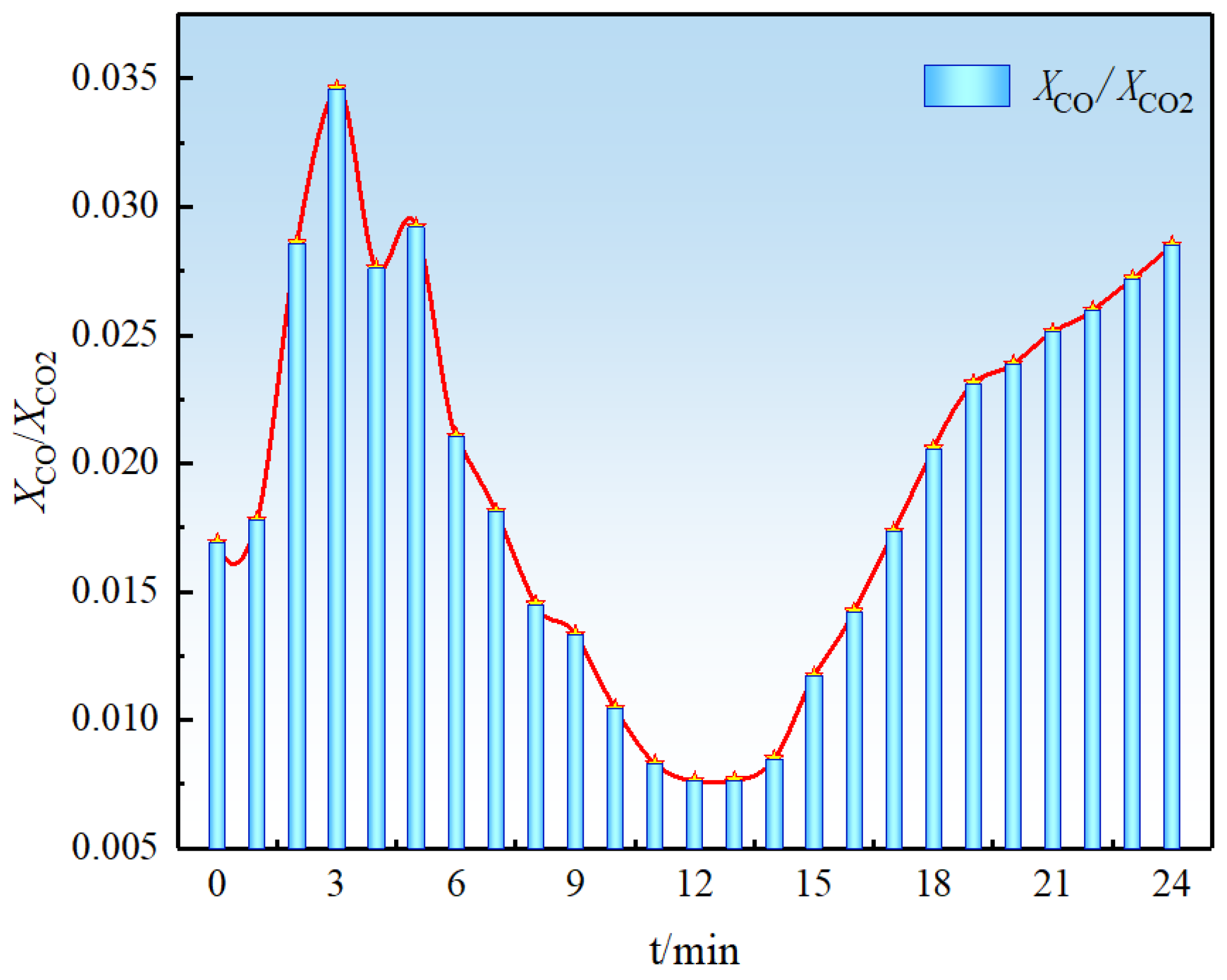

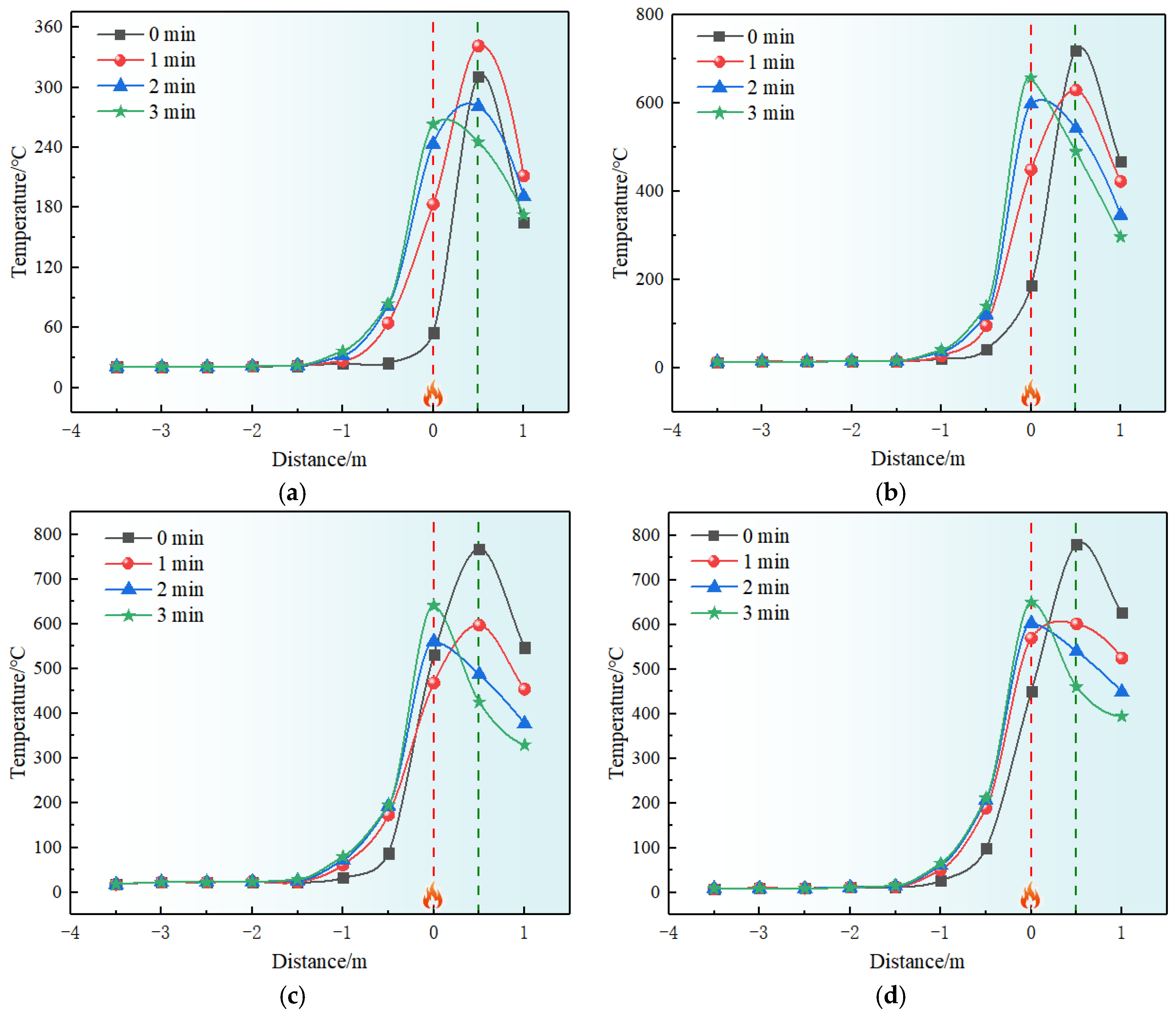

4.3. Longitudinal Temperature Distribution

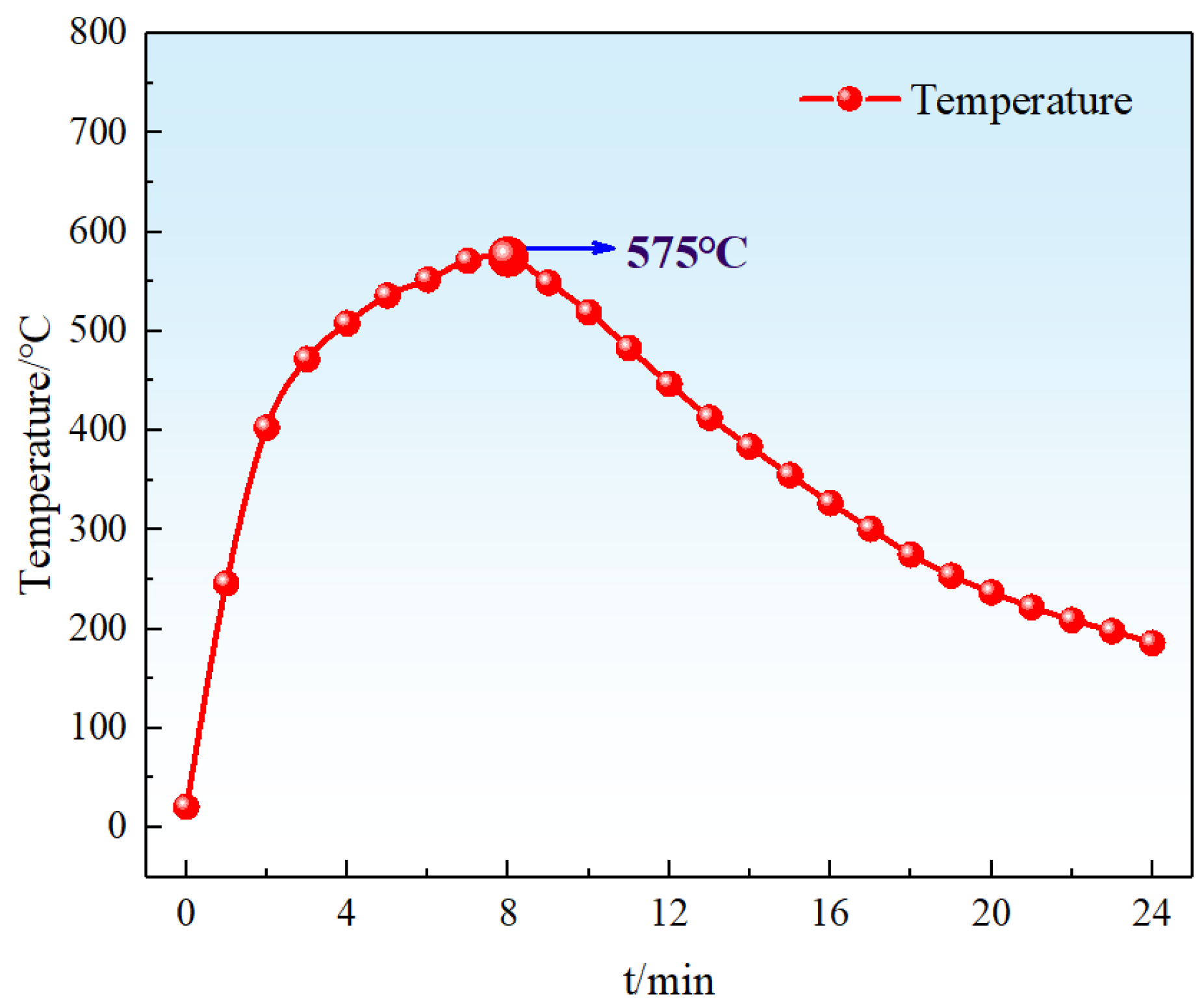

4.4. Smoke Temperature Variation

5. Conclusions

- After sealing, the flame orientation is approximately vertical, and a ceiling jet flame is formed in the tunnel. The maximum temperature of the ceiling is offset towards the fire source. The later the sealing time, the more prominent the ceiling jet flame is. When the sealing time is 1 min and 3 min, combustion can be suppressed with a relatively shorter burning duration. When the sealing time is 1 min, there are still some wood cribs that are not carbonized after combustion.

- After sealing the tunnel exit at different times, the ratio of XCO/XCO2 on the downwind side of the fire source first increases rapidly; as the sealing time increases, the XCO/XCO2 ratio increases more rapidly in a short period of time. The combustion of the wood crib is transformed from fuel-controlled to ventilation-controlled.

- The average temperature at 1 m on the downwind side of the fire source has an exponential decay relationship with time. Sealing at 3 min, 7 min, and 10 min results in a decrease in the maximum temperature of the tunnel ceiling. Sealing at 1 min demonstrates that after sealing, the flames concentrate at the source of the fire, causing the combustion rate of the wood crib to increase to a certain extent, and the temperature of the tunnel ceiling increases suddenly. In the process of tunnel sealing, certain cooling measures should be taken to improve the sealing effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, J.Q. Study on the Fire Smoke Spreading Characteristics in the Tunnel with One Closed End. Ph.D. Thesis, Chongqing University, Chongqing, China, 2022. [Google Scholar]

- Zhao, P.; Chen, T.; Yuan, Z.; Xie, Y.Y.; Yu, N.Y. Critical shaft height for complete smoke exhaustion during fire at the worst longitudinal fire location in tunnels with natural ventilation. Fire Safety J. 2020, 116, 103207. [Google Scholar] [CrossRef]

- Li, C.H. Experimental Study on Smoke Temperature and Flow Characteristics of Tunnel Fire during Sealing. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2020. [Google Scholar]

- Chen, J.F.; Cheng, H.H.; Wei, X.; Wen, Q.W.; Wu, L.; Liu, C.; Zhong, M.H. Temperature measurement errors in full scale tunnel fire experiments. Tsinghua Sci. Technol. 2022, 62, 1618–1625. [Google Scholar]

- Li, L.M.; Li, S.; Wang, X.G.; Zhang, H.P. Fire induced flow temperature along tunnels with longitudinal ventilation. Tunn. Undergr. Space Technol. 2012, 32, 44–51. [Google Scholar] [CrossRef]

- Liu, F.; Yu, L.X.; Weng, M.C.; Lu, X.L. Study on longitudinal temperature distribution of fire induced ceiling flow in tunnels with different sectional coefficients. Tunn. Undergr. Space Technol. 2016, 54, 49–60. [Google Scholar] [CrossRef]

- Kang, K. Characteristic length scale of critical ventilation velocity in tunnel smoke control. Tunn. Undergr. Space Technol. 2010, 25, 205–211. [Google Scholar] [CrossRef]

- Liu, C.; Zhong, M.H.; Tian, X.; Zhang, P.H.; Li, S.W. Study on emergency ventilation for train fire environment in metro interchange tunnel. Build Environ. 2019, 147, 267–283. [Google Scholar] [CrossRef]

- Yao, Y.Z.; Wang, Y.T.; Chen, L.; Ren, F.; Shi, C.L. Numerical study on coupled smoke control using longitudinal ventilation and naturally ventilated shafts during fires in a road tunnel. Fire 2023, 6, 126. [Google Scholar] [CrossRef]

- Liang, Q.; Li, Y.F.; Li, J.M.; Xu, H.; Li, K.Y. Numerical studies on the smoke control by water mist screens with transverse ventilation in tunnel fires. Tunn. Undergr. Space Technol. 2017, 64, 177–183. [Google Scholar] [CrossRef]

- Gong, L.Y.; Peng, Y.F.; Xu, J.; Li, W.L.; Jia, T.Y.; Ma, J.Q.; Li, H.H. Effect of Semi-Transverse Ventilation Velocity on Combustion Characteristics of Pool Fire Sources in a Scaled Tunnel. Fire 2024, 7, 18. [Google Scholar] [CrossRef]

- Chow, W.K.; Wong, K.Y.; Chung, W.Y. Longitudinal ventilation for smoke control in a tilted tunnel by scale modeling. Tunn. Undergr. Space Technol. 2010, 25, 122–128. [Google Scholar] [CrossRef]

- Li, Y.Z.; Lei, B.; Ingason, H. The maximum temperature of buoyancy-driven smoke flow beneath the ceiling in tunnel fires. Fire Safety J. 2011, 46, 204–210. [Google Scholar] [CrossRef]

- Hu, L.H.; Huo, R.; Wang, H.B.; Li, Y.Z.; Yang, R.X. Experimental studies on fire-induced buoyant smoke temperature distribution along tunnel ceiling. Build Environ. 2007, 42, 3905–3915. [Google Scholar] [CrossRef]

- Zhao, P.; Yuan, Z.; Yu, N.; Liang, C.C. Effect of heat release rate and exhaust vent settings on the occurrence of plug-holing during tunnel fires with two-point extraction ventilation. Tunn. Undergr. Space Technol. 2020, 106, 103617. [Google Scholar] [CrossRef]

- Ma, L.; Li, C.H.; Zhang, P.Y.; Qiu, X.Z.; Zhao, X. Influence of sealing ratio on ceiling temperature distribution of tunnel fire. China Safety Sci. J. 2020, 30, 79–85. [Google Scholar]

- Yao, Y.Z.; He, K.; Peng, M.; Shi, L.; Zhang, H.P. Maximum gas temperature rise beneath the ceiling in a portals sealed tunnel fire. Tunn. Undergr. Space Technol. 2018, 80, 10–15. [Google Scholar] [CrossRef]

- Chen, C.K.; Xiao, H.; Wang, N.N.; Shi, C.L.; Zhu, C.X.; Liu, X.Y. Experimental investigation of pool fire behavior to different tunnel-end ventilation opening areas by sealing. Tunn. Undergr. Space Technol. 2017, 63, 106–117. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, P.Y.; Guo, R.Z. GA-SVM model for prediction flue gas temperature of roadway fire under sealing process. J. China Univ. Min. Technol. 2021, 50, 641–648. [Google Scholar]

- Huang, Y.; Li, Y.; Dong, B.; Li, J.M.; Liang, Q. Numerical investigation on the maximum ceiling temperature and longitudinal decay in a sealing tunnel fire. Tunn. Undergr. Space Technol. 2018, 72, 120–130. [Google Scholar] [CrossRef]

- Fernanez, A.F.; Maria, C.A. Analysis of the fire propagation in a sublevel coal mine. Energies 2020, 13, 3754. [Google Scholar] [CrossRef]

- Yao, Y.Z.; Cheng, X.D.; Shi, L.; Zhang, S.G.; He, K.; Peng, M.; Zhang, H.P. Experimental study on the effects of initial sealing time on fire behaviors in channel fires. Int. J. Therm. Sci. 2018, 125, 273–282. [Google Scholar] [CrossRef]

- Yao, Y.Z. Fire Behaviors and Smoke Transportation Law of Tunnel Fires under Confined Portal Boundaries. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2019. [Google Scholar]

- Hu, L.H.; Huo, R.; Wang, H.B.; Li, Y.Z.; Lu, Q.; Yang, L.Z. Judgement on critical burning state of wood crib from ventilation to fuel controlled regime by concentration of carbon monoxide in combustion products. J. Combust. Sci. Technol. 2004, 4, 371–374. [Google Scholar]

- Zhu, W.; Liao, G.X.; Lu, P.; Li, P.D.; Hung, Y.X. Combustion Process under Longitudinal Ventilationin Tunnel Using Wood Crib Fire. J. Combust. Sci. Technol. 2006, 1, 71–75. [Google Scholar]

- Ingason, H.; Li, Y.Z.; Lönnermar, A. Tunnel Fire Dynamics, 2nd ed.; Springer: Gewerbestrasse, Switzerland, 2015; pp. 23–43. [Google Scholar]

- MA, L.; Zhang, P.Y.; Li, C.H.; Liu, S. Prediction model of roadway fire temperature field under different plugging conditions. J. Xi’an Univ. Sci. Technol. 2021, 41, 213–219. [Google Scholar]

| Test No. | Initial Sealing Time/min | The Weight of the Wood Crib/kg |

|---|---|---|

| 1 | 1 | 3.2 |

| 2 | 3 | 3.2 |

| 3 | 7 | 3.2 |

| 4 | 10 | 3.2 |

| Sealing Time/min | T(t) | R2 |

|---|---|---|

| 1 | 0.865 | |

| 3 | 0.996 | |

| 7 | 0.999 | |

| 10 | 0.999 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Wang, H.; Hu, J.; Chen, L.; Lu, S.; Tang, S. Experimental Study on the Effect of Sealing Time on Combustion State of the Fuel-Ventilation Controlled Wood Crib. Fire 2024, 7, 360. https://doi.org/10.3390/fire7100360

Xu Z, Wang H, Hu J, Chen L, Lu S, Tang S. Experimental Study on the Effect of Sealing Time on Combustion State of the Fuel-Ventilation Controlled Wood Crib. Fire. 2024; 7(10):360. https://doi.org/10.3390/fire7100360

Chicago/Turabian StyleXu, Zuohui, Haiyan Wang, Jiaying Hu, Lei Chen, Sentao Lu, and Simin Tang. 2024. "Experimental Study on the Effect of Sealing Time on Combustion State of the Fuel-Ventilation Controlled Wood Crib" Fire 7, no. 10: 360. https://doi.org/10.3390/fire7100360

APA StyleXu, Z., Wang, H., Hu, J., Chen, L., Lu, S., & Tang, S. (2024). Experimental Study on the Effect of Sealing Time on Combustion State of the Fuel-Ventilation Controlled Wood Crib. Fire, 7(10), 360. https://doi.org/10.3390/fire7100360