Development and Application of an Intelligent Approach to Reconstruct the Location of Fire Sources from Soot Patterns Deposited on Walls

Abstract

1. Introduction

2. Reconstruction of the Location of a Fire Source Using an ANN

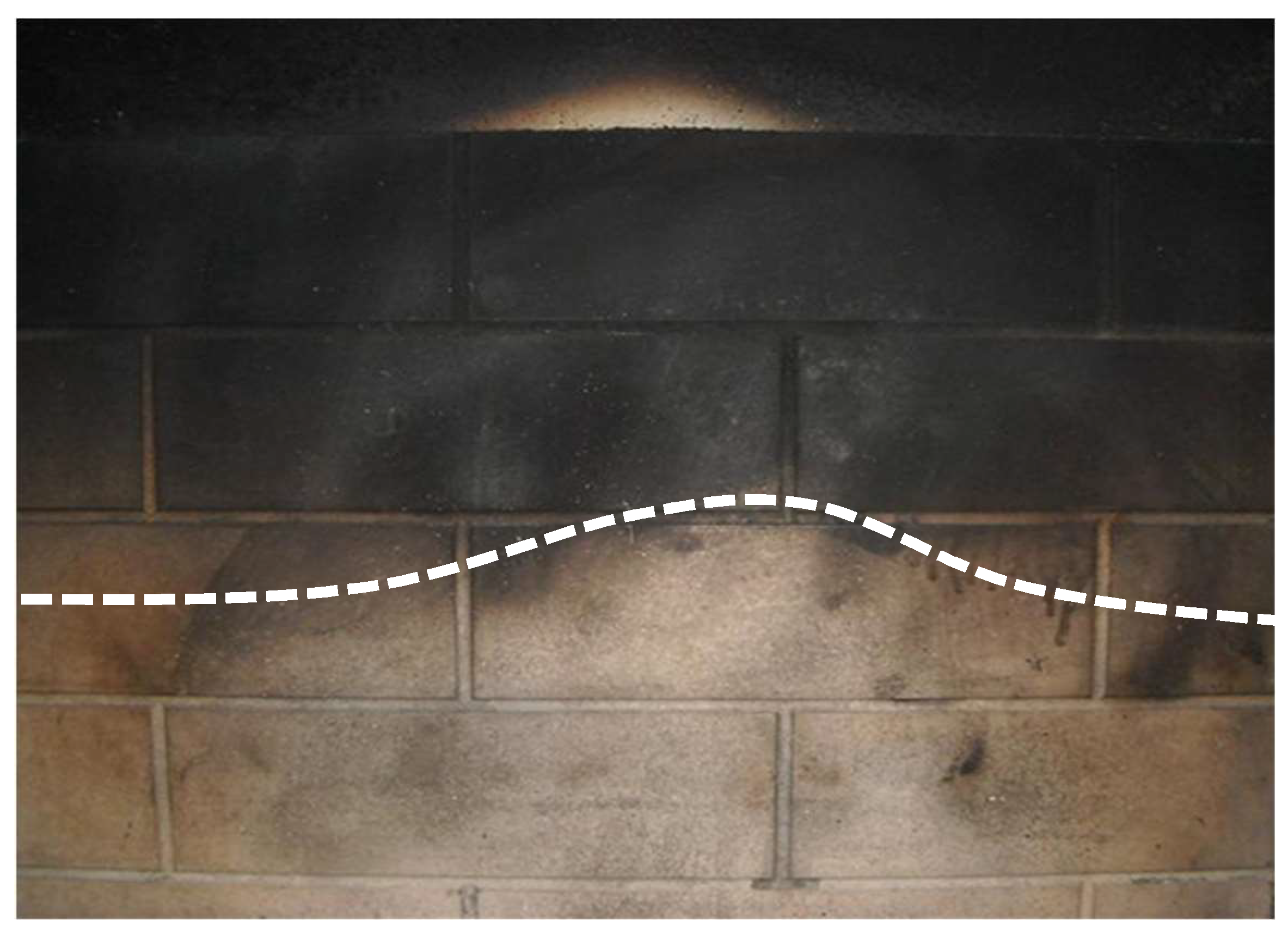

2.1. Soot Patterns Deposited on Walls

2.2. Data Collection

2.2.1. CFD Simulation

2.2.2. Data Preprocessing

- The average height of the smoke interface , which is the average value of heights of the soot interface (i.e., );

- The average gradient of the smoke interface , which is the slope of the straight line (i.e., ) that best fits heights of the soot interface;

- The average curvature of the smoke interface , which is the coefficient of the squared term (i.e., ) of the quadratic equation (i.e., ) that best fits heights of the soot interface.

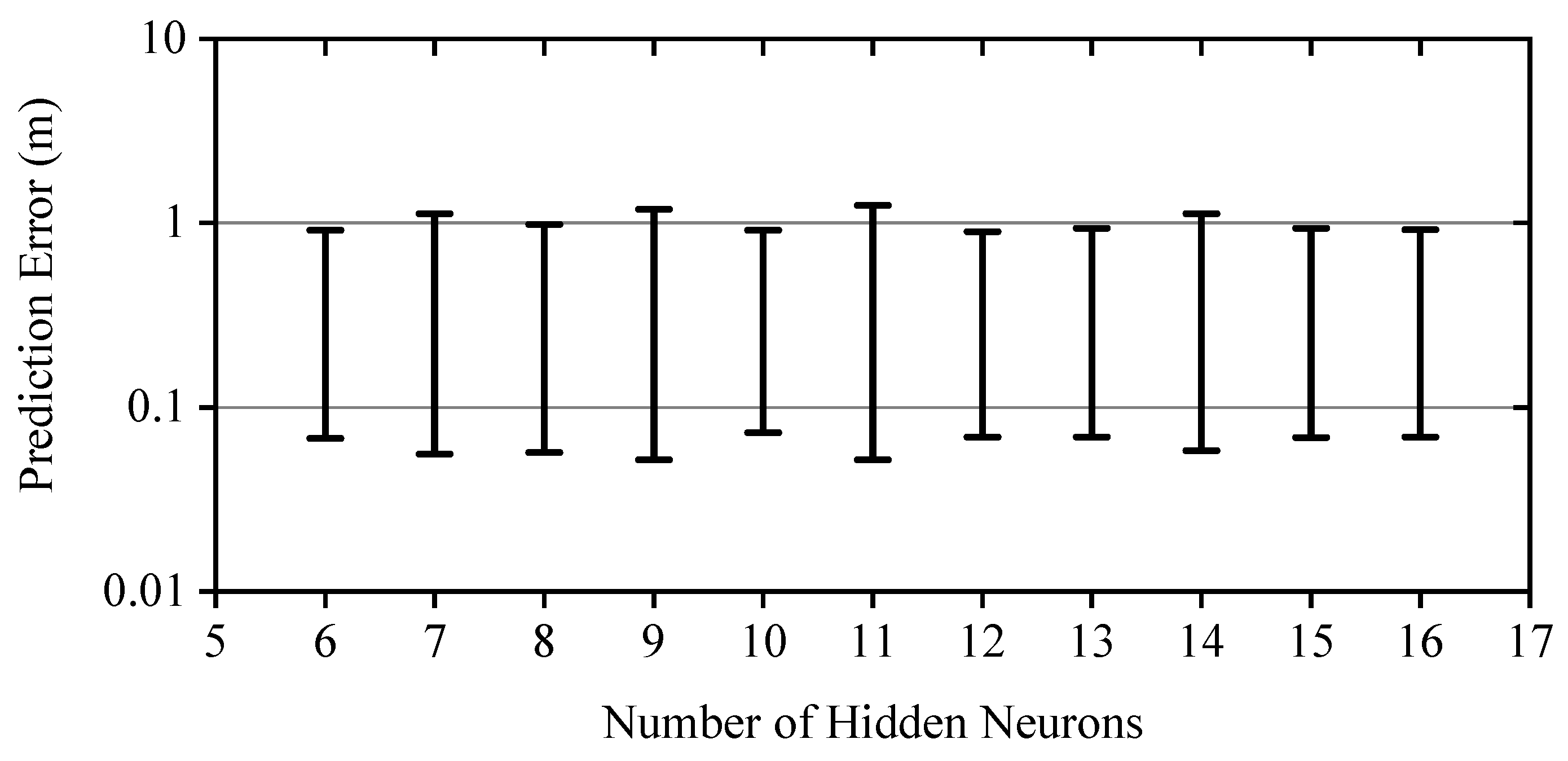

2.3. ANN Modelling

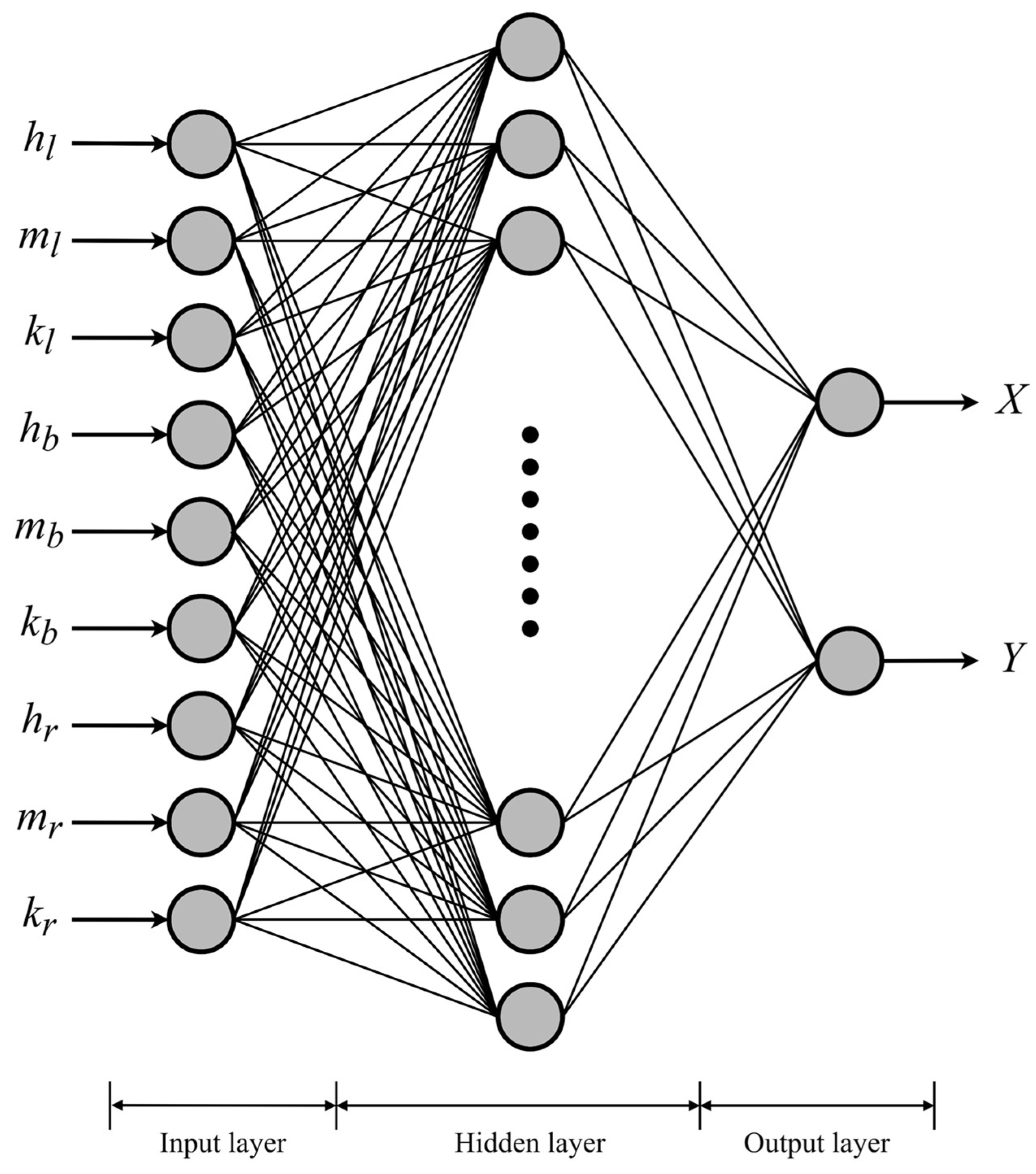

2.3.1. Model Architecture

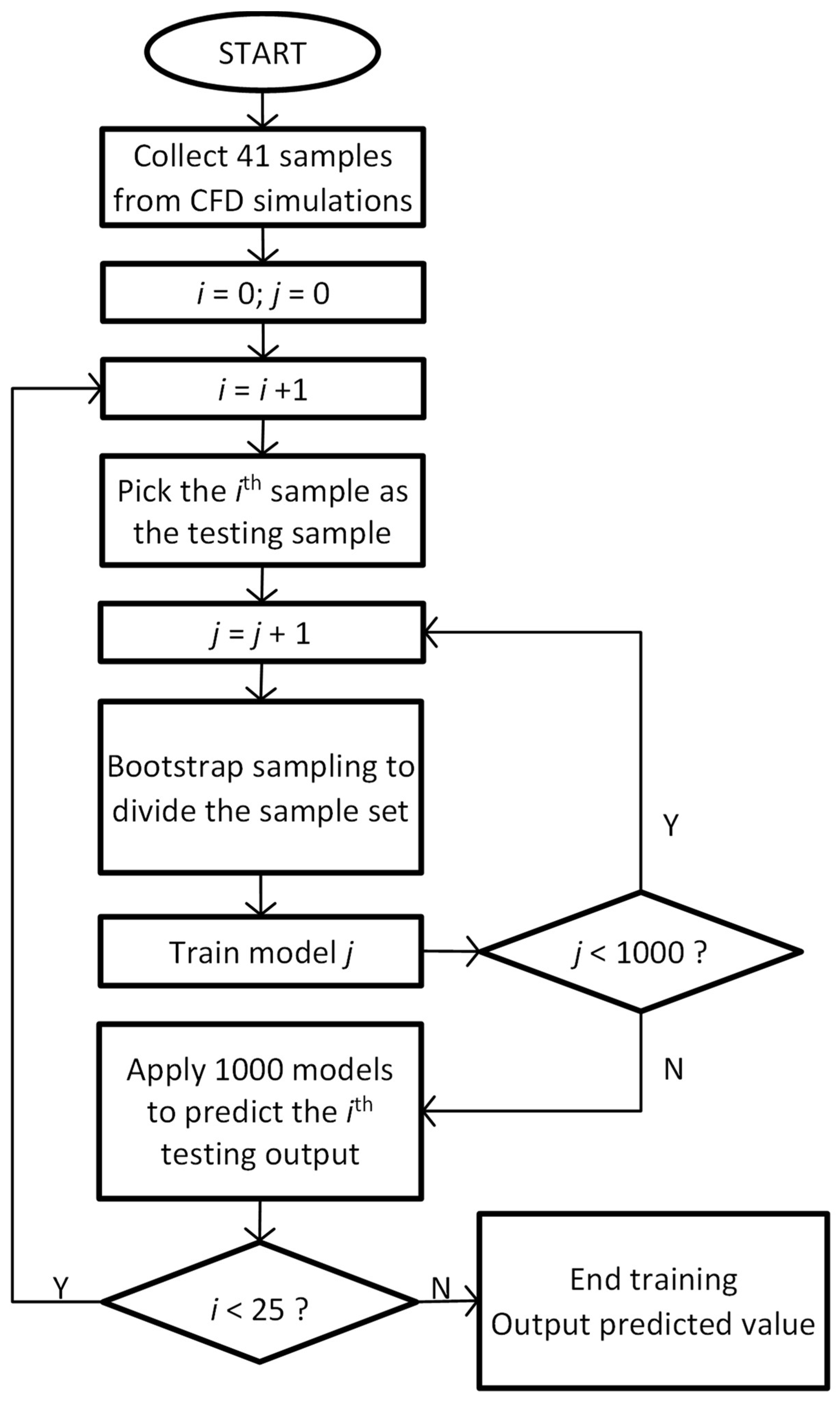

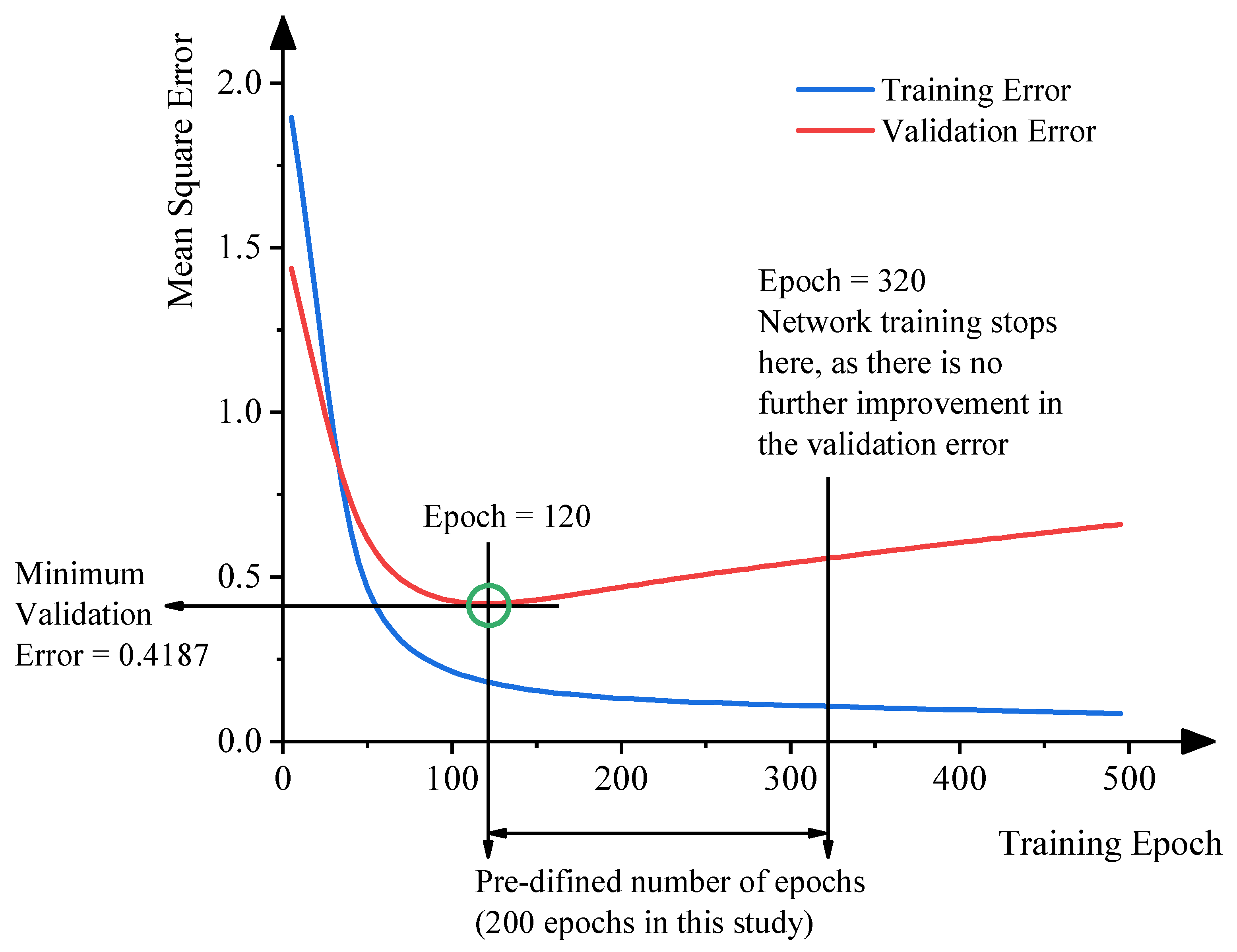

2.3.2. Model Training

3. Results and Discussion

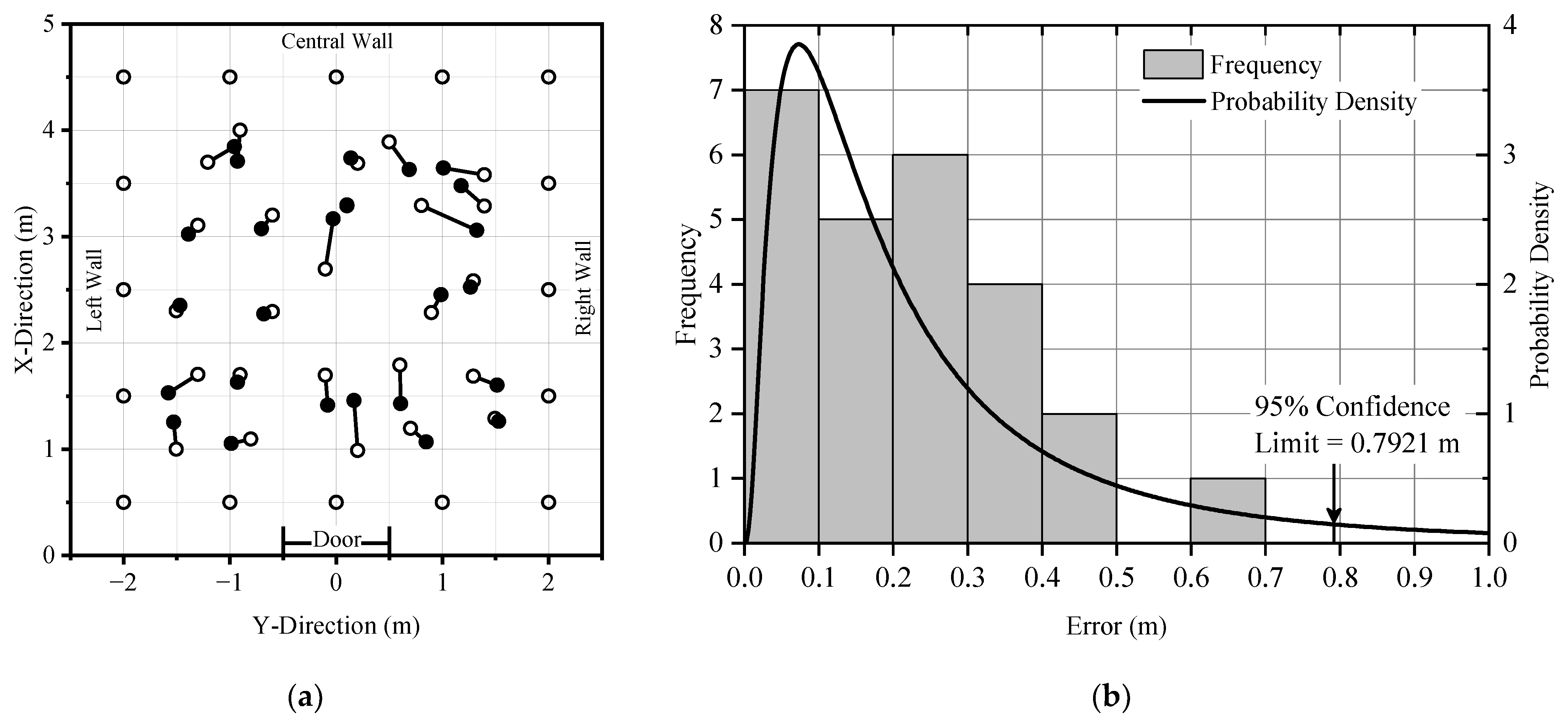

3.1. Results of the MLP Prediction

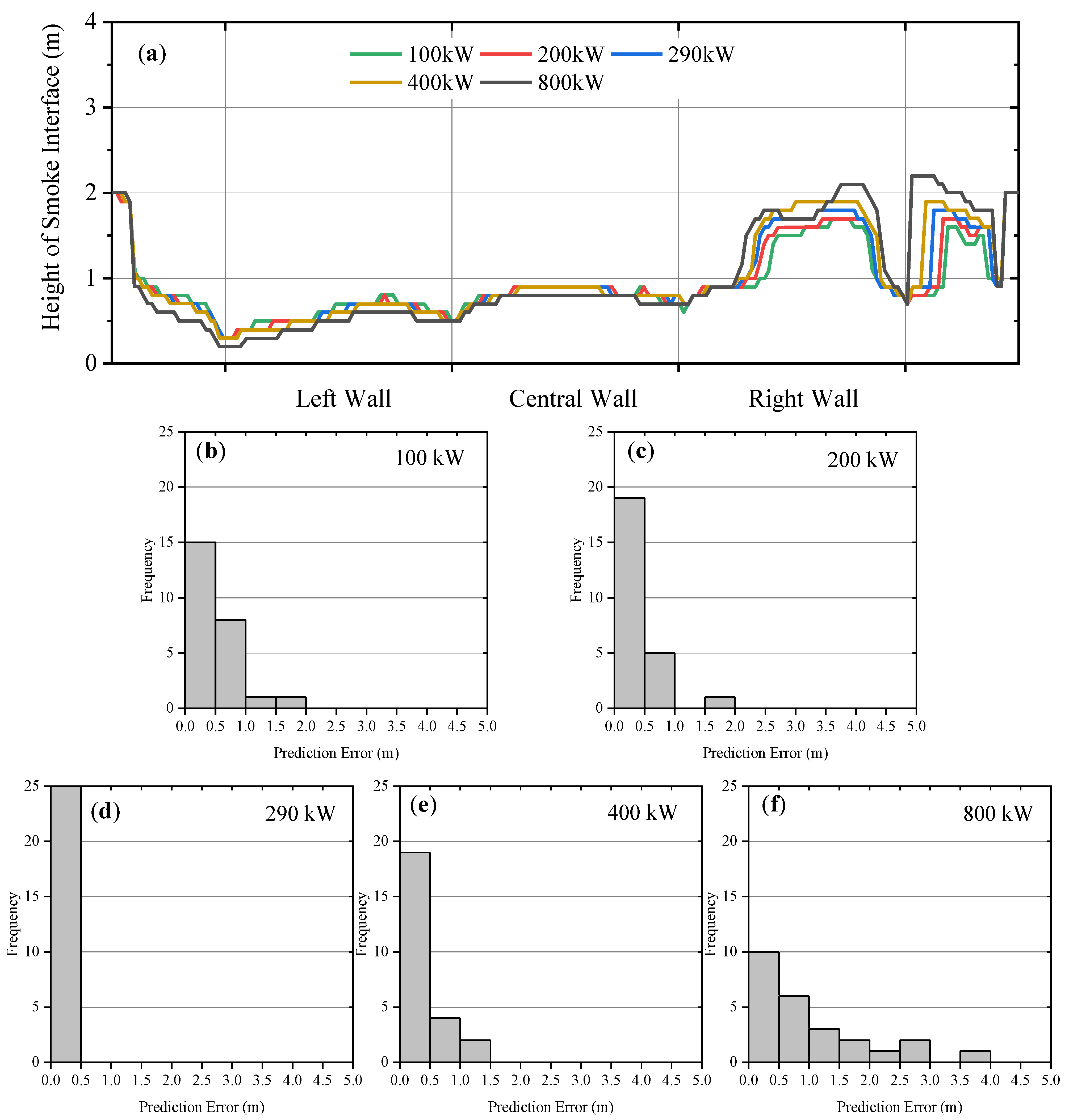

3.2. Effect of the Heat Release Rate on the Prediction Results

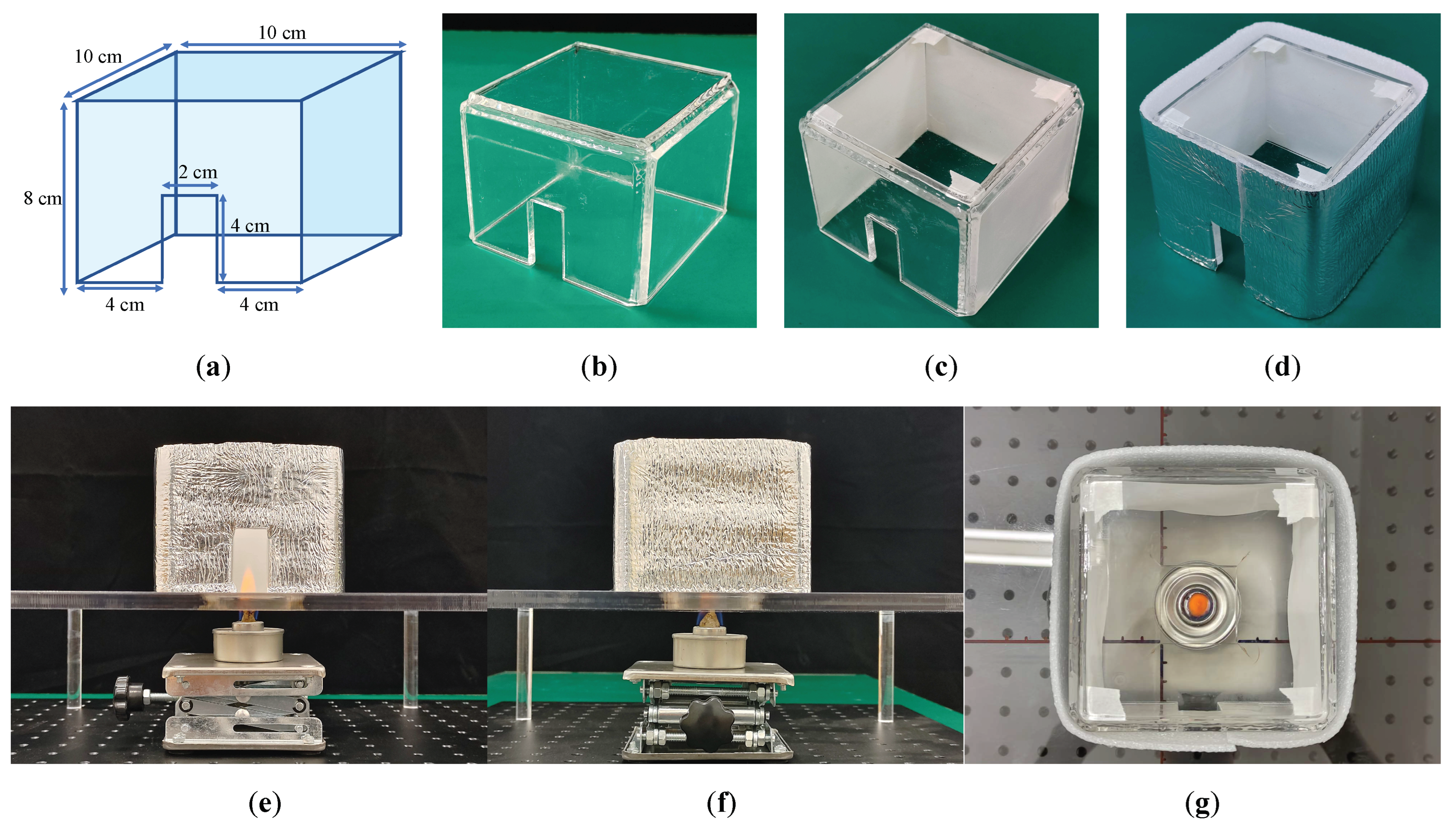

3.3. Experiments in a Scaled Space

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fire Services Department—Hong Kong Fire Services Review 2011. Available online: https://www.hkfsd.gov.hk/eng/publications/review/review_11.html (accessed on 20 October 2022).

- Milke, J.A.; McAvoy, T.J. Analysis of Signature Patterns for Discriminating Fire Detection with Multiple Sensors. Fire Technol. 1995, 31, 120–136. [Google Scholar] [CrossRef]

- Lee, W.M.; Yuen, K.K.; Lo, S.M.; Lam, K.C. Prediction of Sprinkler Actuation Time Using the Artificial Neural Networks. J. Build. Surv. 2000, 2, 10–13. [Google Scholar]

- Lee, E.; Yuen, R.; Lo, S.M.; Lam, K.C. Probabilistic Inference with Maximum Entropy for Prediction of Flashover in Single Compartment Fire. Adv. Eng. Inform. 2002, 16, 179–191. [Google Scholar] [CrossRef]

- Lee, E.W.M.; Lim, C.P.; Yuen, R.K.K.; Lo, S.M. A Hybrid Neural Network Model for Noisy Data Regression. IEEE Trans. Syst. Man Cybern. Part B 2004, 34, 951–960. [Google Scholar] [CrossRef]

- Lee, E.W.M.; Yuen, R.K.K.; Lo, S.M.; Lam, K.C.; Yeoh, G.H. A Novel Artificial Neural Network Fire Model for Prediction of Thermal Interface Location in Single Compartment Fire. Fire Saf. J. 2004, 39, 67–87. [Google Scholar] [CrossRef]

- Lee, E.W.M.; Lee, Y.Y.; Lim, C.P.; Tang, C.Y. Application of a Noisy Data Classification Technique to Determine the Occurrence of Flashover in Compartment Fires. Adv. Eng. Inform. 2006, 20, 213–222. [Google Scholar] [CrossRef]

- Yuen, R.K.; Lee, E.W.; Lo, S.; Yeoh, G. Prediction of Temperature and Velocity Profiles in a Single Compartment Fire by an Improved Neural Network Analysis. Fire Saf. J. 2006, 41, 478–485. [Google Scholar] [CrossRef]

- Asgary, A.; Sadeghi Naini, A.; Levy, J. Modeling the Risk of Structural Fire Incidents Using a Self-Organizing Map. Fire Saf. J. 2012, 49, 1–9. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, J.; Wang, W.; Liu, M. Prediction of Temperature of Tubular Truss under Fire Using Artificial Neural Networks. Fire Saf. J. 2013, 56, 74–80. [Google Scholar] [CrossRef]

- Barros-Daza, M.J.; Luxbacher, K.D.; Lattimer, B.Y.; Hodges, J.L. Real Time Mine Fire Classification to Support Firefighter Decision Making. Fire Technol. 2022, 58, 1545–1578. [Google Scholar] [CrossRef]

- Buffington, T.; Cabrera, J.-M.; Kurzawski, A.; Ezekoye, O.A. Deep-Learning Emulators of Transient Compartment Fire Simulations for Inverse Problems and Room-Scale Calorimetry. Fire Technol. 2021, 57, 2859–2885. [Google Scholar] [CrossRef]

- Lattimer, B.Y.; Hodges, J.L.; Lattimer, A.M. Using Machine Learning in Physics-Based Simulation of Fire. Fire Saf. J. 2020, 114, 102991. [Google Scholar] [CrossRef]

- Gu, W.; Bai, S.; Kong, L. A Review on 2D Instance Segmentation Based on Deep Neural Networks. Image Vis. Comput. 2022, 120, 104401. [Google Scholar] [CrossRef]

- Otter, D.W.; Medina, J.R.; Kalita, J.K. A Survey of the Usages of Deep Learning for Natural Language Processing. IEEE Trans. Neural Netw. Learn. Syst. 2021, 32, 604–624. [Google Scholar] [CrossRef]

- Zhang, F.; Shi, L.; Liu, S.; Zhang, C.; Liu, Z. CFD-Based Validation Study on the Fire Prevention Wisdom of Ancient Village Houses in Western Hunan. Fire 2023, 6, 144. [Google Scholar] [CrossRef]

- Delémont, O.; Martin, J.-C. Application of Computational Fluid Dynamics Modelling in the Process of Forensic Fire Investigation: Problems and Solutions. Forensic Sci. Int. 2007, 167, 127–135. [Google Scholar] [CrossRef]

- Hofmann, A.; Muehlnikel, R. Experimental and Numerical Investigation of Fire Development in a Real Fire in a Five-Storey Apartment Building. Fire Mater. 2011, 35, 453–462. [Google Scholar] [CrossRef]

- Manea, F.; Ghicioi, E.; Suvar, M.C.; Prodan, M.; Vlasin, N.I.; Suvar, N.S.; Vlase, T. FDS Results for Selecting the Right Scenario in the Case of a Building Fire: A Case Study. Fire 2022, 5, 198. [Google Scholar] [CrossRef]

- Yan, X.; Yang, H.; Mo, H.; Xie, Y.; Jin, Z.; Zhou, Y. Numerical Simulation on the Smoke Prevention Performance of Air Curtains in an Island-Type Subway Station. Fire 2023, 6, 177. [Google Scholar] [CrossRef]

- Li, Y.; Huang, F.; Ma, C.; Tang, K. A Simulation Study on the Smoke Control Effect with Different Smoke Exhaust Patterns and Longitudinal Air Supply for Ultra-Wide Tunnels. Fire 2022, 5, 72. [Google Scholar] [CrossRef]

- Chi, J.-H. Metallographic Analysis and Fire Dynamics Simulation for Electrical Fire Scene Reconstruction. J. Forensic Sci. 2012, 57, 246–249. [Google Scholar] [CrossRef]

- Barshick, S.-A. Analysis of Accelerants and Fire Debris Using Aroma Detection Technology. J. Forensic Sci. 1998, 43, 284–293. [Google Scholar] [CrossRef]

- Biedermann, A.; Taroni, F.; Delemont, O.; Semadeni, C.; Davison, A.C. The Evaluation of Evidence in the Forensic Investigation of Fire Incidents (Part I): An Approach Using Bayesian Networks. Forensic Sci. Int. 2005, 147, 49–57. [Google Scholar] [CrossRef]

- Lu, W.; Rankin, J.G.; Bondra, A.; Trader, C.; Heeren, A.; Harrington, P.d.B. Ignitable Liquid Identification Using Gas Chromatography/Mass Spectrometry Data by Projected Difference Resolution Mapping and Fuzzy Rule-Building Expert System Classification. Forensic Sci. Int. 2012, 220, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Zhou, X.; Zhu, G.; Yan, S. A New Accident Analysis and Investigation Model for the Complex Building Fire Using Numerical Reconstruction. Case Stud. Therm. Eng. 2019, 14, 100426. [Google Scholar] [CrossRef]

- Overholt, K.J.; Ezekoye, O.A. Quantitative Testing of Fire Scenario Hypotheses: A Bayesian Inference Approach. Fire Technol. 2015, 51, 335–367. [Google Scholar] [CrossRef]

- Freitas, R.A.; Rodrigues, J.P.C. A Fire Investigation Methodology for Buildings. Archit. Struct. Constr. 2022, 2, 269–290. [Google Scholar] [CrossRef]

- Hartman, J.R.; Beyler, A.P.; Riahi, S.; Beyler, C.L. Smoke Oxidation Kinetics for Application to Prediction of Clean Burn Patterns. Fire Mater. 2012, 36, 177–184. [Google Scholar] [CrossRef]

- Ciro, W.D.; Eddings, E.G.; Sarofim, A.F. Experimental and Numerical Investigation of Transient Soot Buildup on a Cylindrical Container Immersed in a Jet Fuel Pool Fire. Combust. Sci. Technol. 2006, 178, 2199–2218. [Google Scholar] [CrossRef]

- Cohan, B.D. Verification and Validation of a Candidate Soot Deposition Model in Fire Dynamics Simulator Version 5.5.1. Master’s Thesis, University of Maryland, College Park, MD, USA, 2010. [Google Scholar]

- Riahi, S.; Beyler, C.L.; Hartman, J. Wall Smoke Deposition from a Hot Smoke Layer. Fire Technol. 2013, 49, 395–409. [Google Scholar] [CrossRef]

- Talbot, L.; Cheng, R.K.; Schefer, R.W.; Willis, D.R. Thermophoresis of Particles in a Heated Boundary Layer. J. Fluid Mech. 1980, 101, 737–758. [Google Scholar] [CrossRef]

- Papavergos, P.G.; Hedley, A.B. Particle Deposition Behavior from Turbulent Flows. Chem. Eng. Res. Des. 1984, 62, 275–295. [Google Scholar]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Weinschenk, C.; Overholt, K. Fire Dynamics Simulator Technical Reference Guide Volume 1: Mathematical Model; NIST Special Publication: Baltimore, MD, USA, 2013. [CrossRef]

- Brock, J.R. On the Theory of Thermal Forces Acting on Aerosol Particles. J. Colloid Sci. 1962, 17, 768–780. [Google Scholar] [CrossRef]

- Floyd, J.; Overholt, K.; Ezekoye, O. Soot Deposition and Gravitational Settling Modeling and the Impact of Particle Size and Agglomeration. Fire Saf. Sci. 2014, 11, 174. [Google Scholar] [CrossRef]

- He, Y.; Fernando, A.; Luo, M. Determination of Interface Height from Measured Parameter Profile in Enclosure Fire Experiment. Fire Saf. J. 1998, 31, 19–38. [Google Scholar] [CrossRef]

- Wright, E.M. Adaptive Control Processes: A Guided Tour. Math. Gaz. 1962, 46, 160–161. [Google Scholar] [CrossRef]

- Brinson, A.; Johnson, P.; Kip, S.; Torero, J.; Lange, D.; Salomonsson, T. Fire Safety Engineering: Comparison of FSE Guidance Documents and Assessment Criteria Special Report; The Warren Centre for Advanced Engineering: Sydney, Australia, 2019; ISBN 978-0-648-50292-0. [Google Scholar]

- McGrattan, K. Verification and Validation of Selected Fire Models for Nuclear Power Plant Applications: Fire Dynamics Simulator (FDS). Available online: https://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr1824/v7/index.html (accessed on 30 July 2023).

- Rosenblatt, F. Principles of Neurodynamics: Perceptrons and the Theory of Brain Mechanisms; Spartan Books: Washington, DC, USA, 1962. [Google Scholar]

- Hornik, K.; Stinchcombe, M.; White, H. Multilayer Feedforward Networks Are Universal Approximators. Neural Netw. 1989, 2, 359–366. [Google Scholar] [CrossRef]

- Breiman, L. Bagging Predictors. Mach. Learn. 1996, 24, 123–140. [Google Scholar] [CrossRef]

| Type | No. | Description |

|---|---|---|

| Inputs | 1 | Average height of the smoke interface on the left wall |

| 2 | Average slope of the smoke interface on the left wall | |

| 3 | Average curvature of the smoke interface on the left wall | |

| 4 | Average height of the smoke interface on the central wall | |

| 5 | Average slope of the smoke interface on the central wall | |

| 6 | Average curvature of the smoke interface on the central wall | |

| 7 | Average height of smoke interface on the right wall | |

| 8 | Average slope of the smoke interface on the right wall | |

| 9 | Average curvature of the smoke interface on the right wall | |

| Outputs | 1 | X-coordinate of the fire bed centre |

| 2 | Y-coordinate of the fire bed centre |

| Experiment No. | Fire Source Location in Experiment (cm, cm) | Scaling of Fire Source Location (m, m) | Predictions Generated by the ANN Model (m, m) | Difference between the Actual and Average Predicted Locations (m) |

|---|---|---|---|---|

| 1 | (5.00, 0.00) | (2.50, 0.00) | (2.36, −0.09) | 0.17 |

| 2 | (7.00, 2.00) | (3.50, 1.00) | (3.22, 0.37) | 0.68 |

| 3 | (7.00, 0.00) | (3.50, 0.00) | (2.87, −0.18) | 0.66 |

| 4 | (3.00, 0.00) | (1.50, 0.00) | (1.73, 0.12) | 0.26 |

| 5 | (5.00, 2.00) | (2.50, 1.00) | (2.40, −0.01) | 0.99 |

| 6 | (3.00, 2.00) | (1.50, 1.00) | (1.74, 0.18) | 0.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Li, H.; Zhang, Z.; Lee, E.W.M. Development and Application of an Intelligent Approach to Reconstruct the Location of Fire Sources from Soot Patterns Deposited on Walls. Fire 2023, 6, 303. https://doi.org/10.3390/fire6080303

Shi M, Li H, Zhang Z, Lee EWM. Development and Application of an Intelligent Approach to Reconstruct the Location of Fire Sources from Soot Patterns Deposited on Walls. Fire. 2023; 6(8):303. https://doi.org/10.3390/fire6080303

Chicago/Turabian StyleShi, Meng, Hanbo Li, Zhichao Zhang, and Eric Wai Ming Lee. 2023. "Development and Application of an Intelligent Approach to Reconstruct the Location of Fire Sources from Soot Patterns Deposited on Walls" Fire 6, no. 8: 303. https://doi.org/10.3390/fire6080303

APA StyleShi, M., Li, H., Zhang, Z., & Lee, E. W. M. (2023). Development and Application of an Intelligent Approach to Reconstruct the Location of Fire Sources from Soot Patterns Deposited on Walls. Fire, 6(8), 303. https://doi.org/10.3390/fire6080303