Analysis of a Novel Proposal Using Temperature and Efficiency to Prevent Fires in Photovoltaic Energy Systems

Abstract

1. Introduction

- A novel methodology for the detection of hotspots in PVMs that can generate fires based on the relationship between thermal analysis and the variations in the magnitude of the measured VOC and ISC.

- An electrical security methodology proposal for the design of a PV system to prevent hotspot fires.

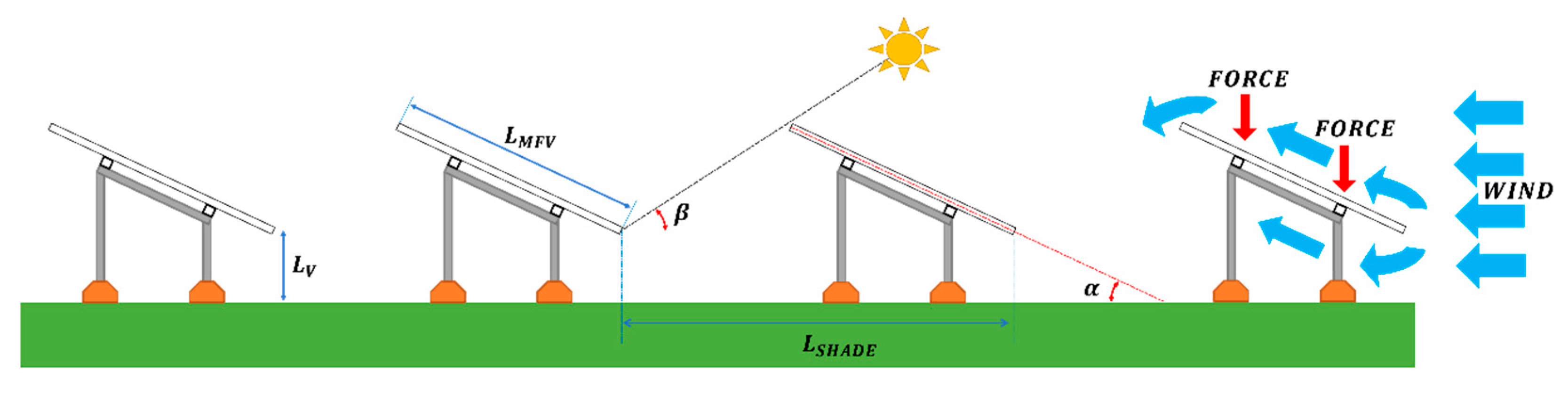

2. Materials and Methods

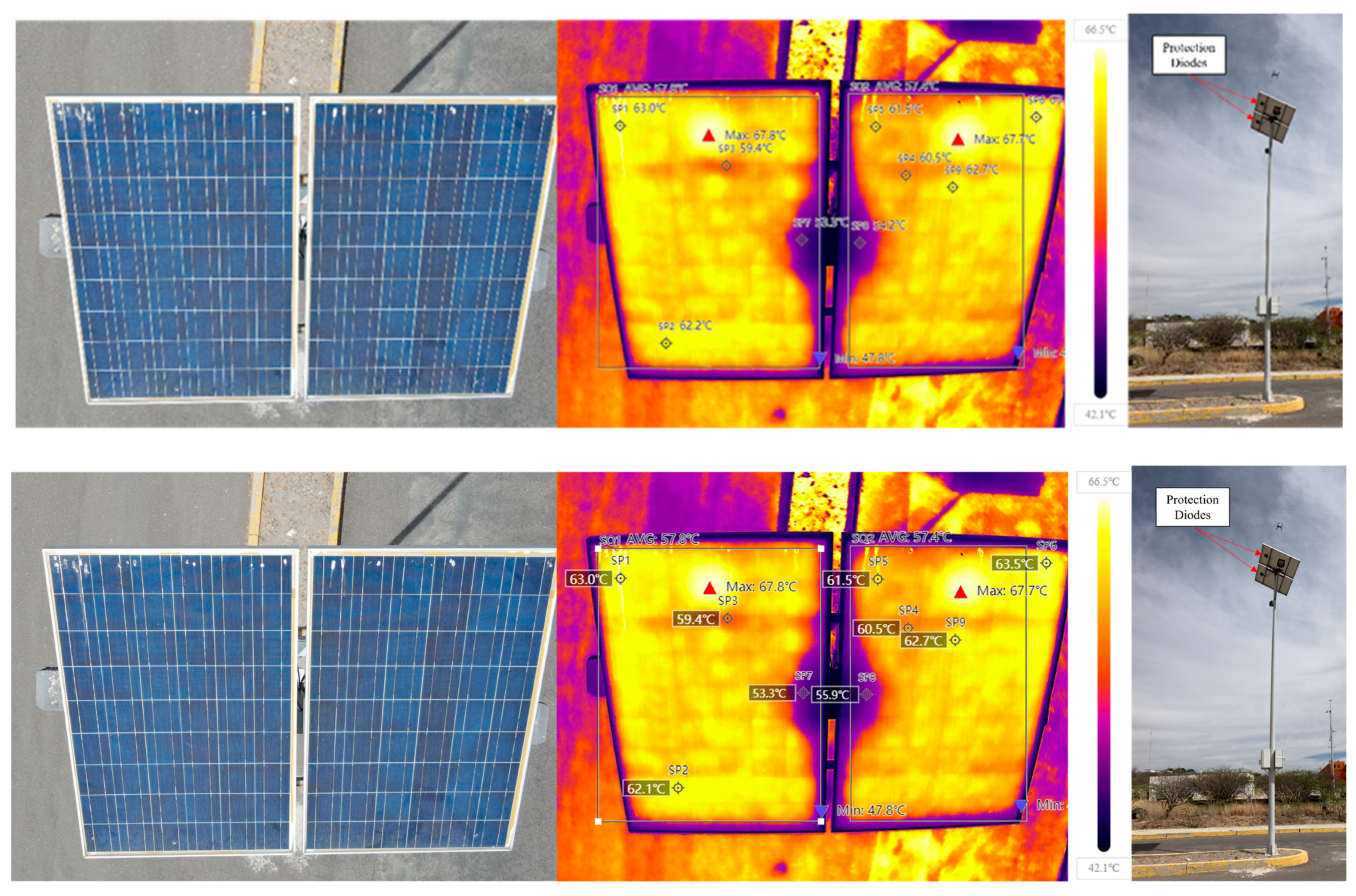

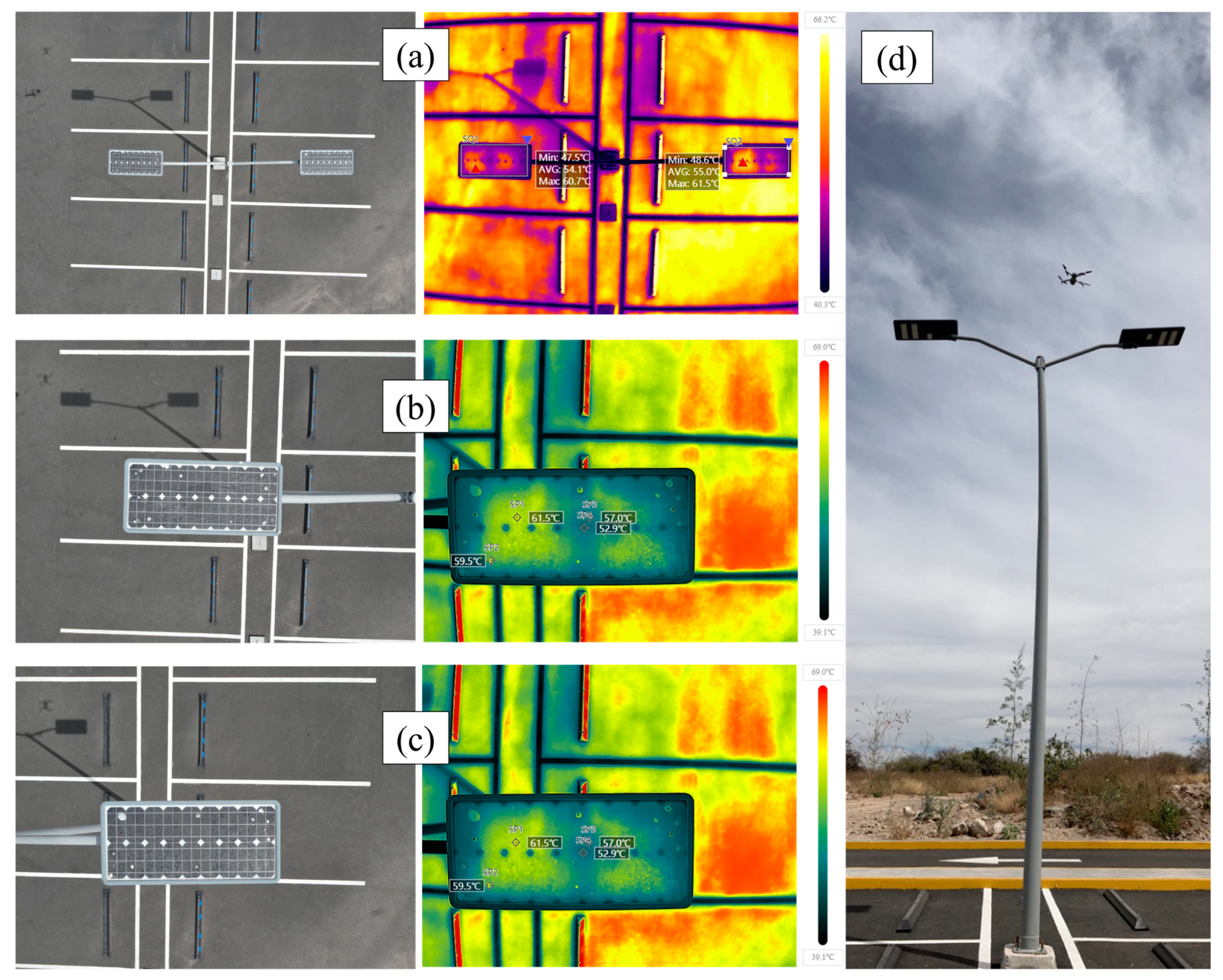

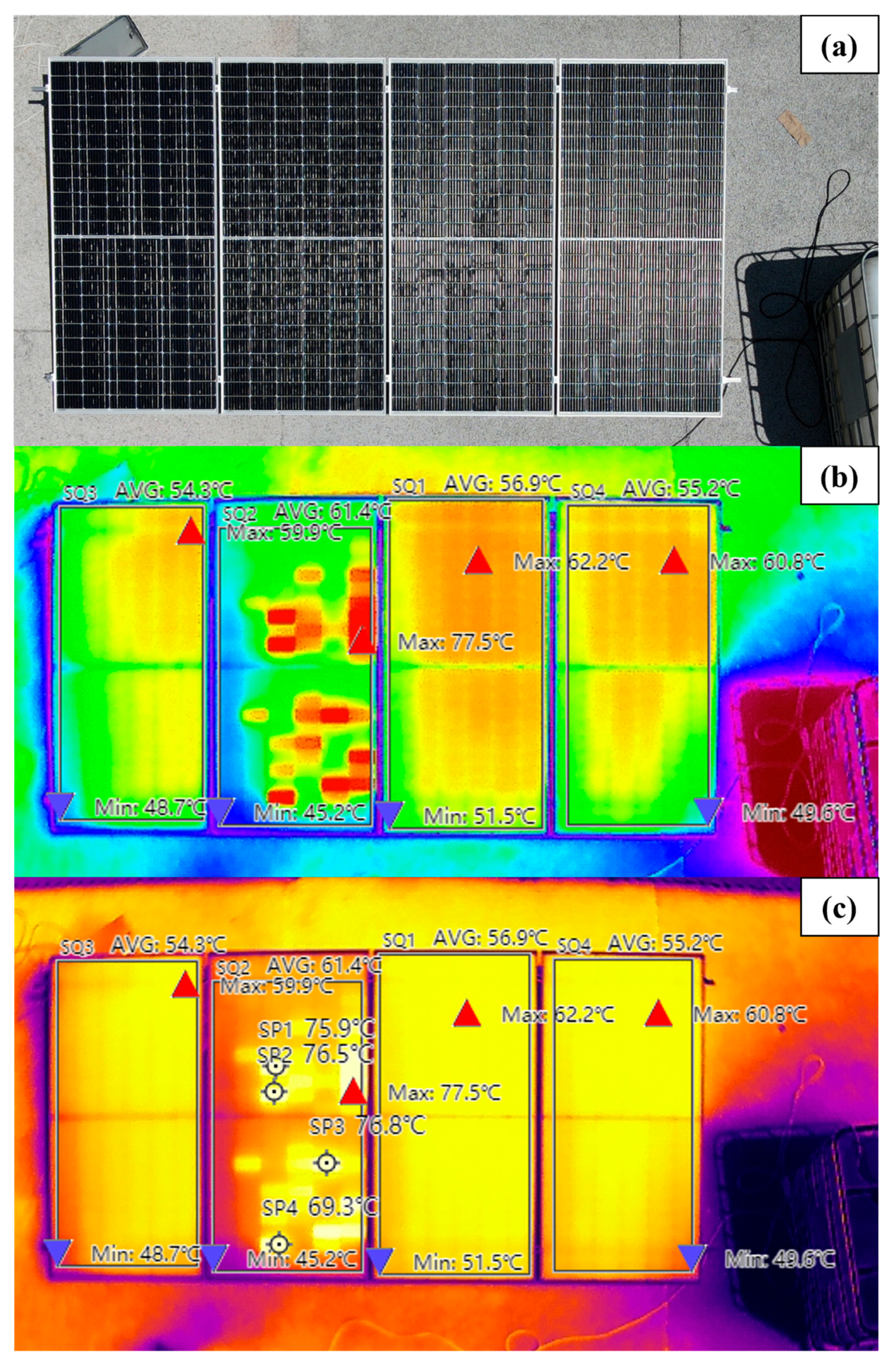

Thermal Analysis

3. Results and Discussions

3.1. Thermal Analysis

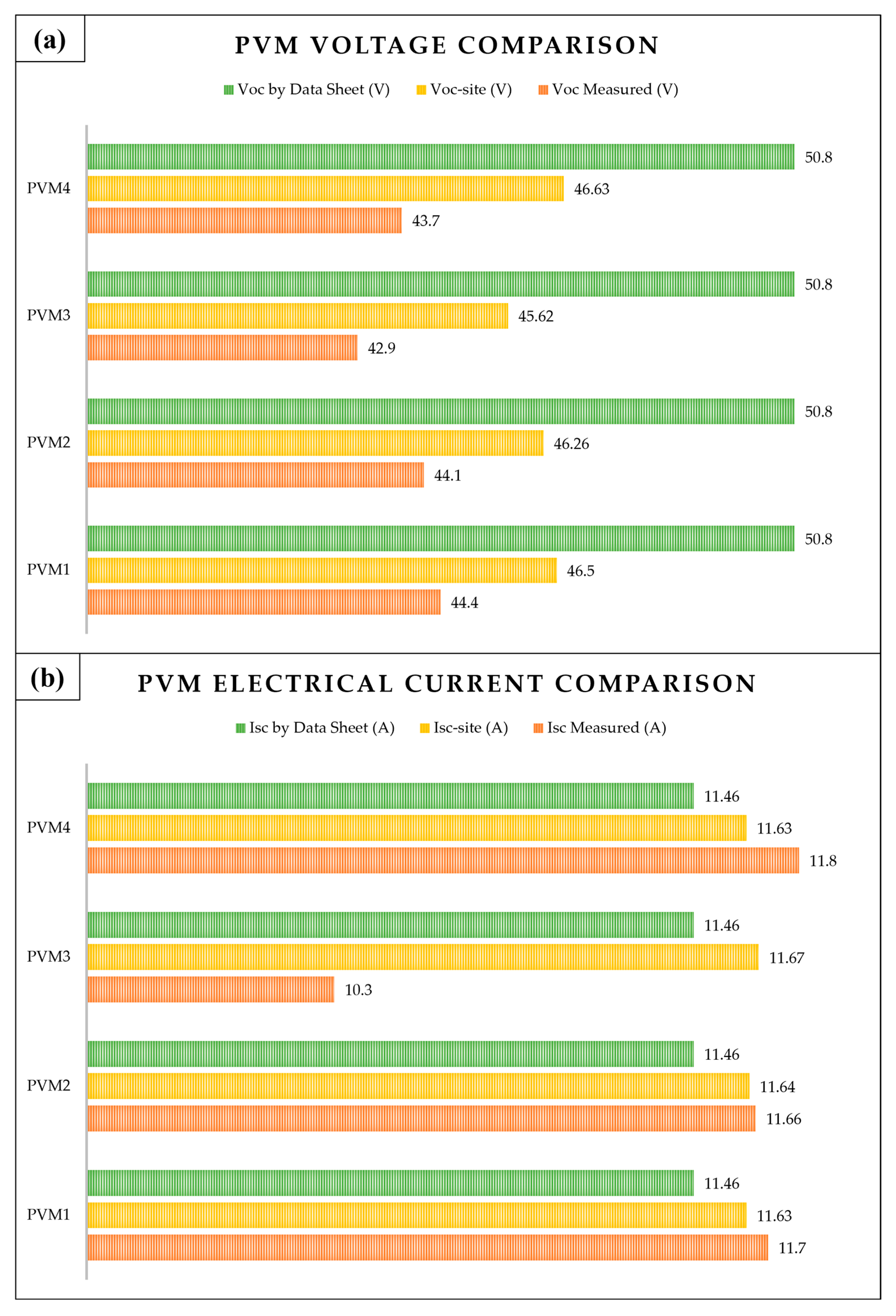

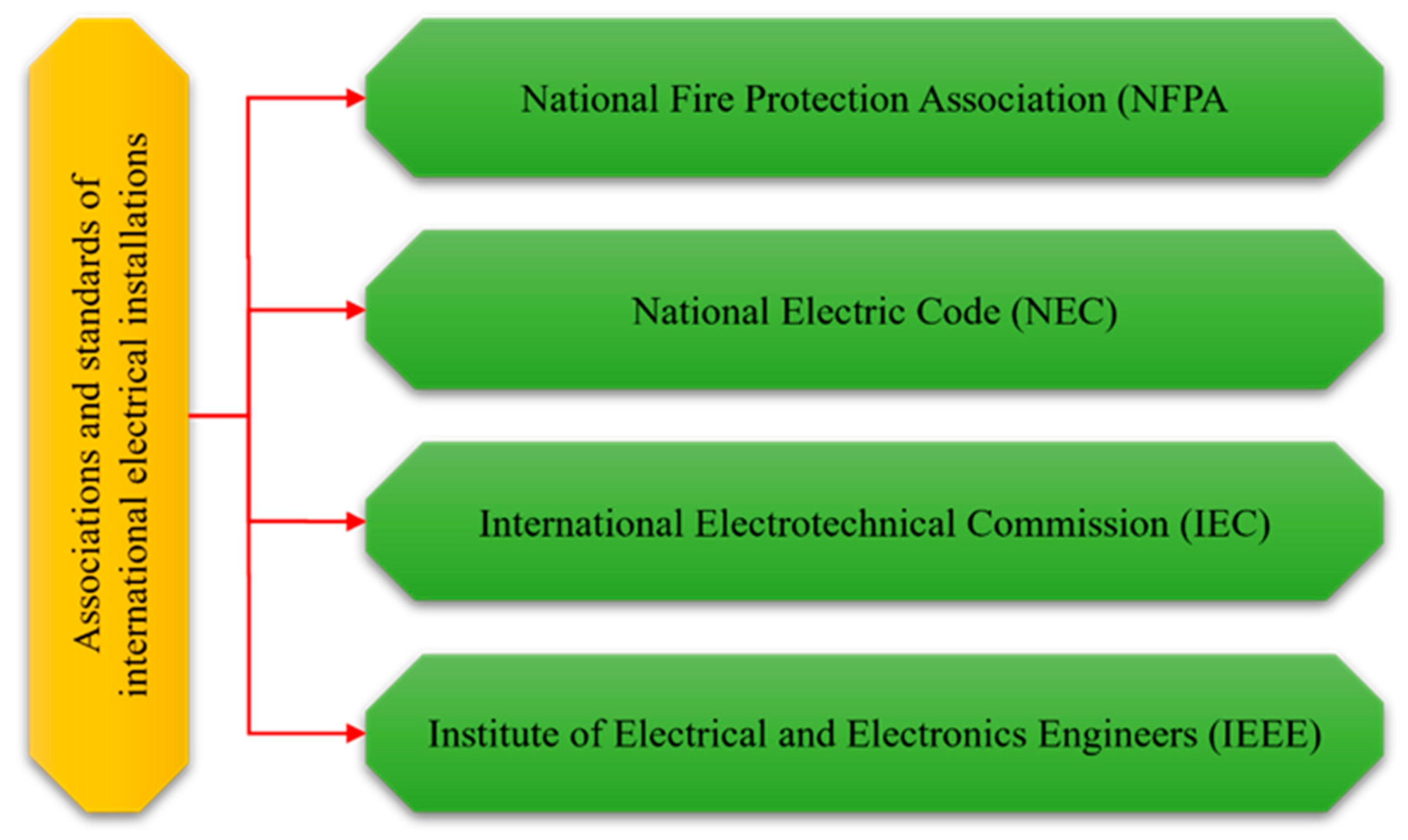

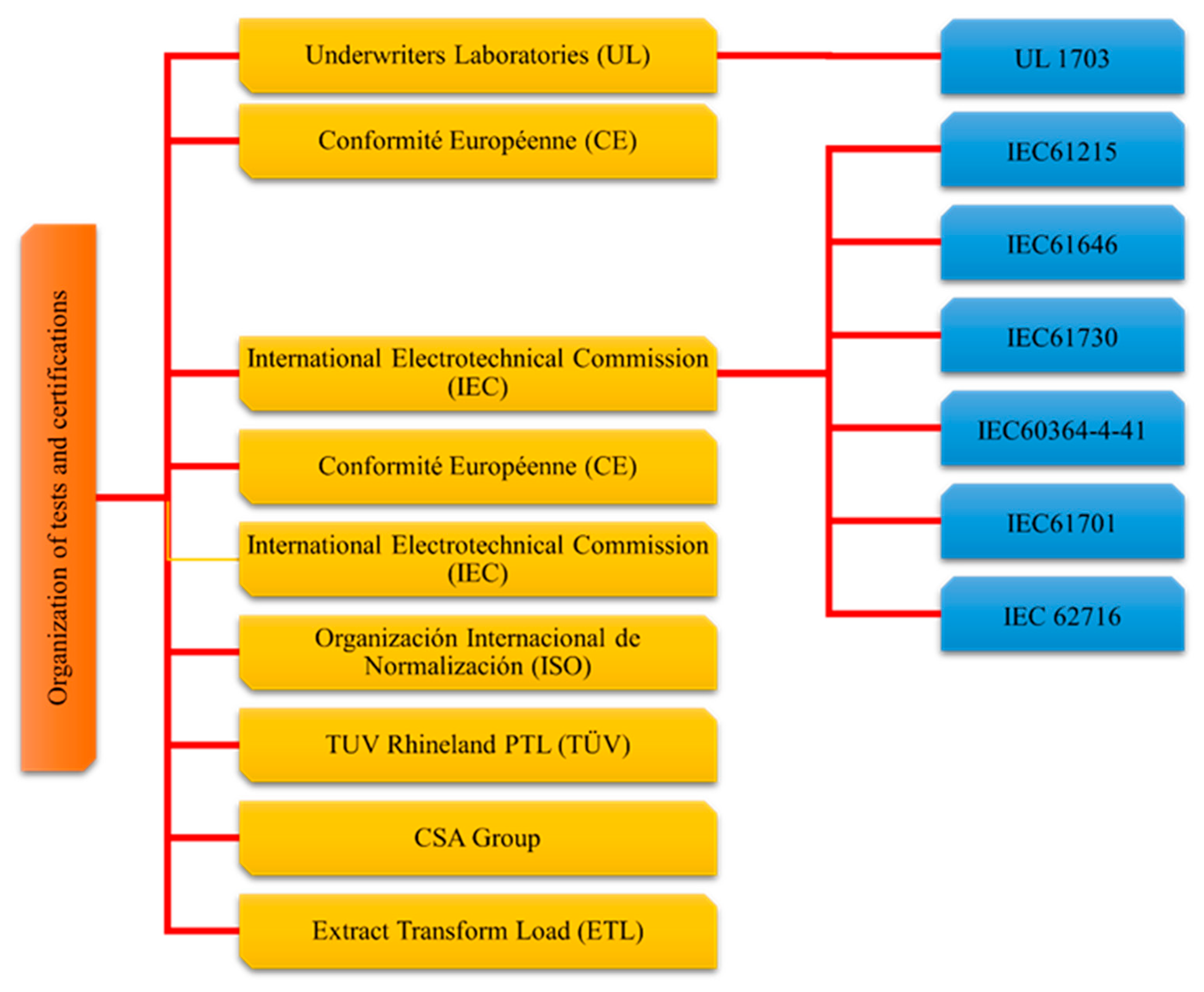

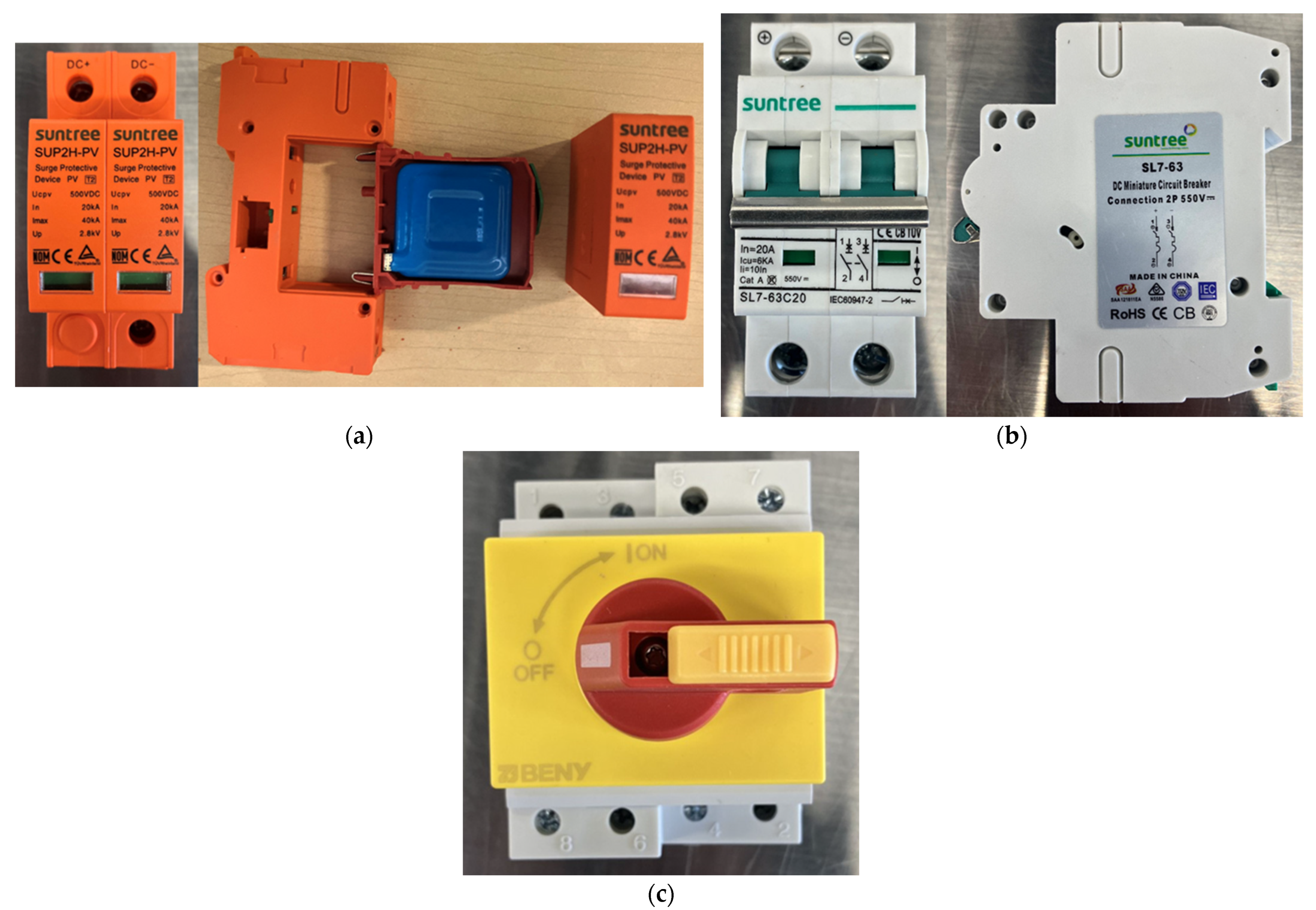

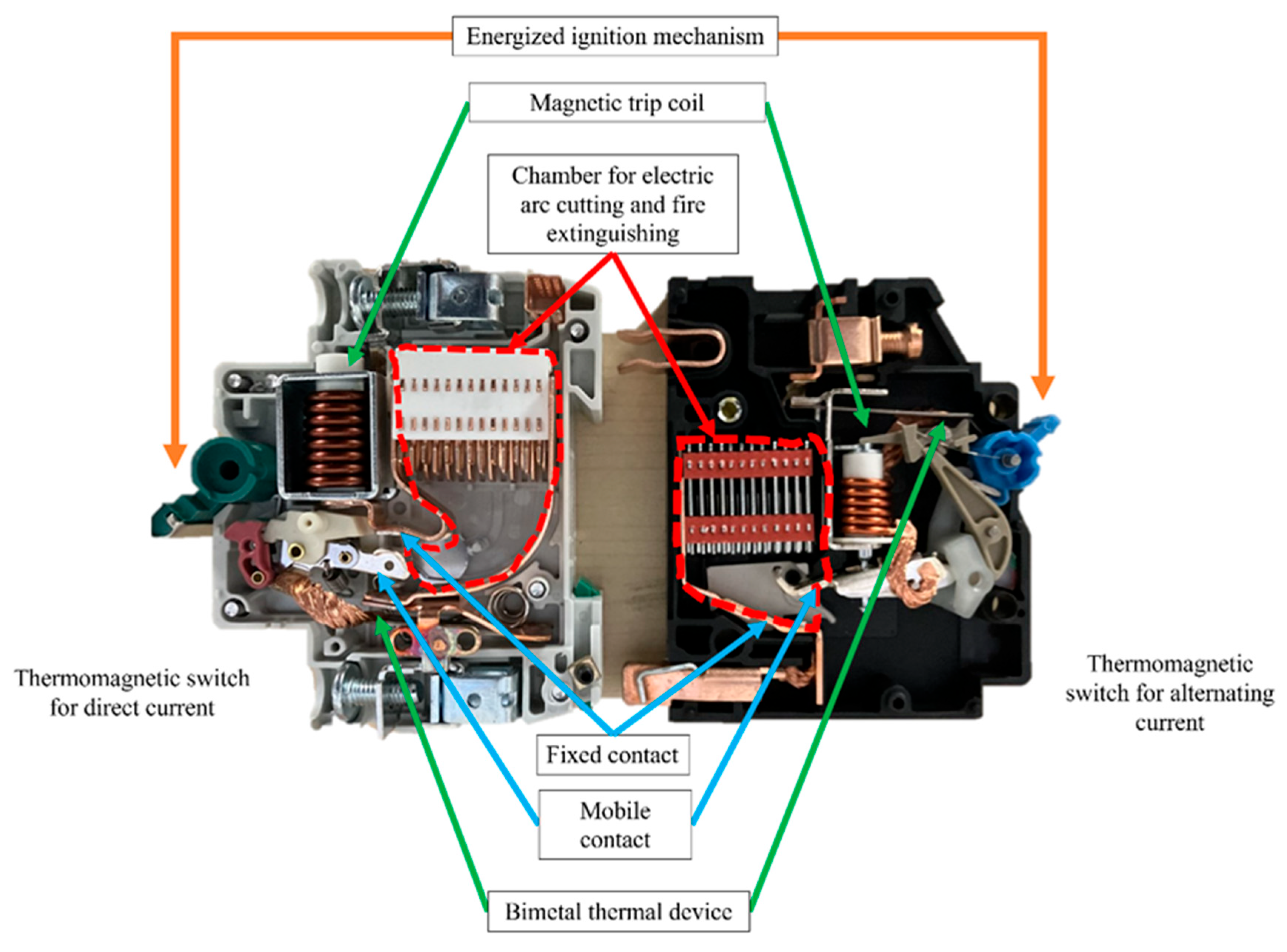

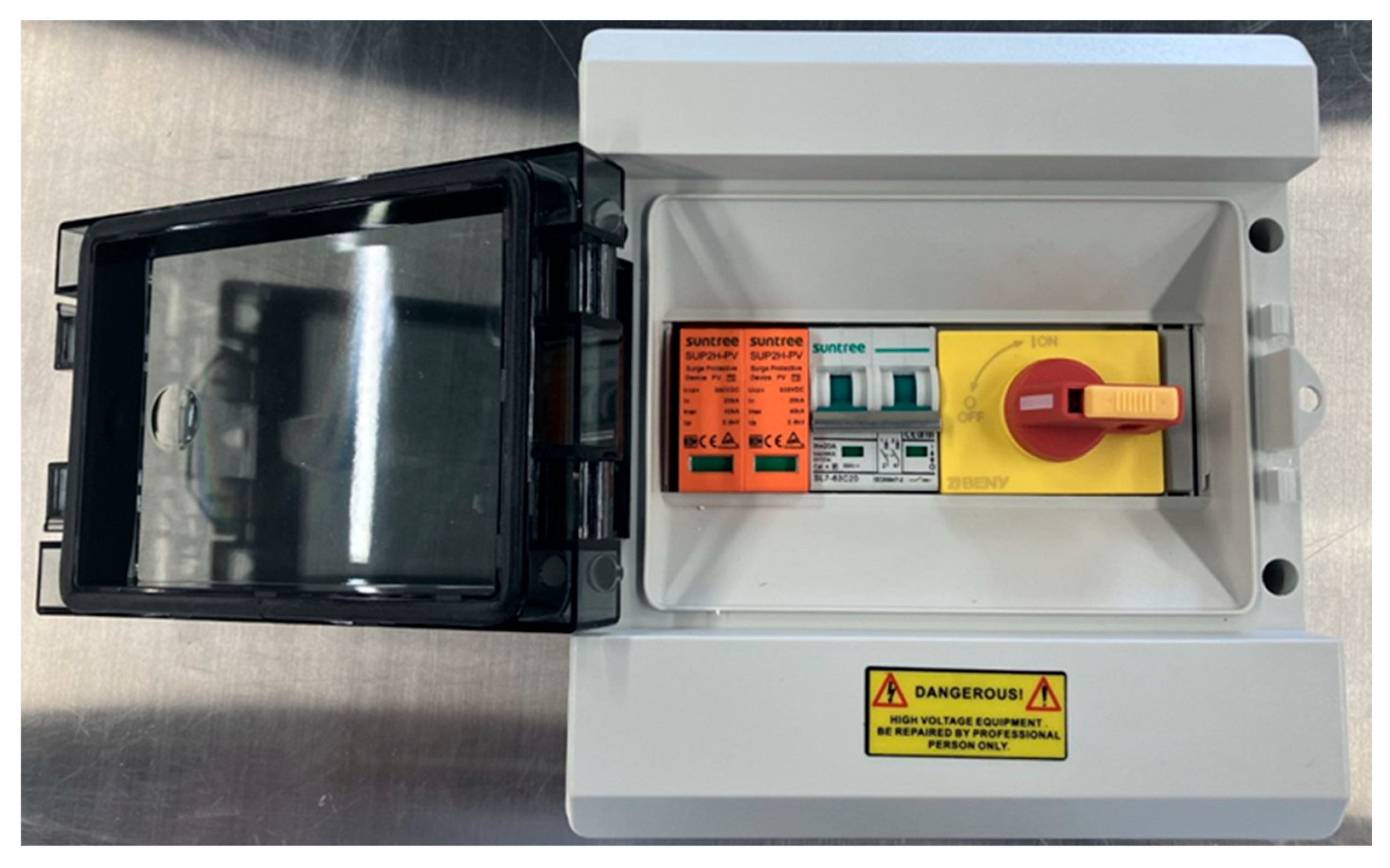

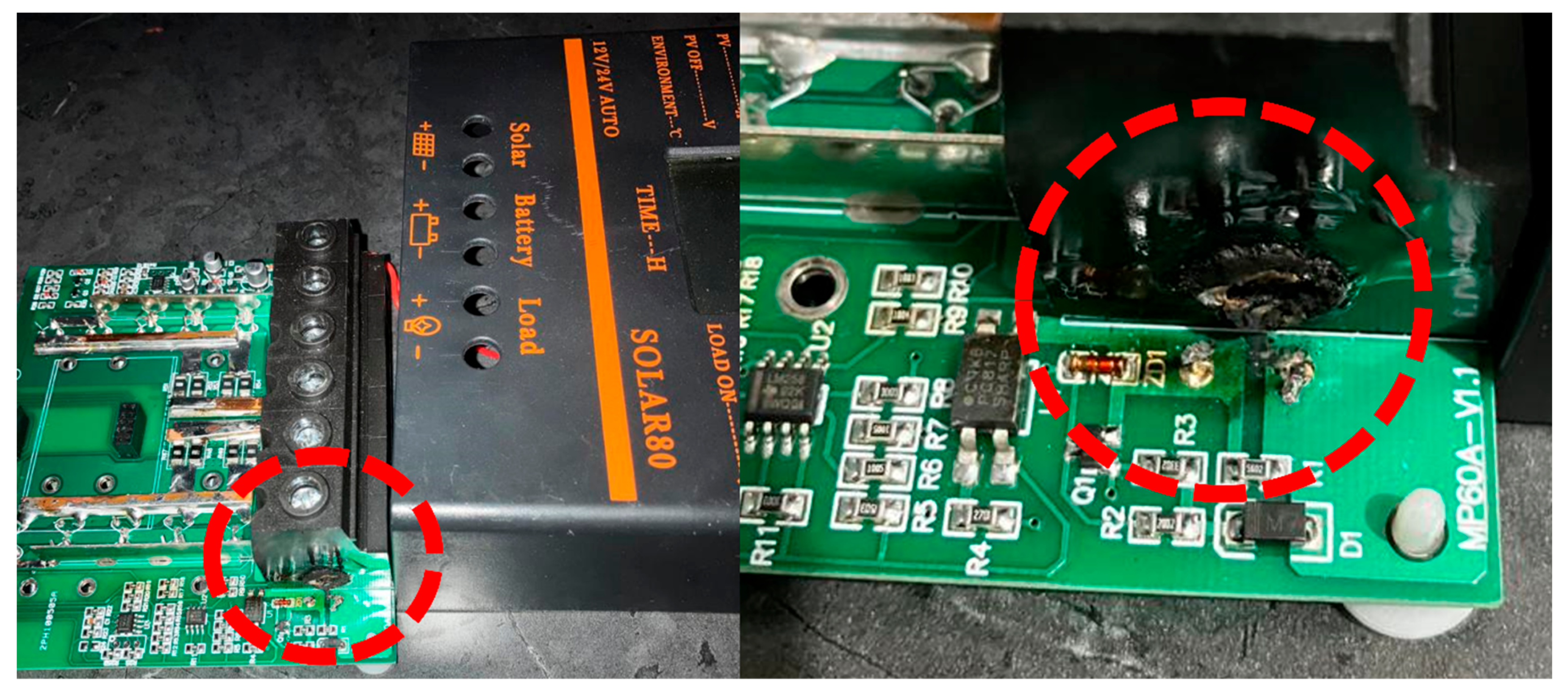

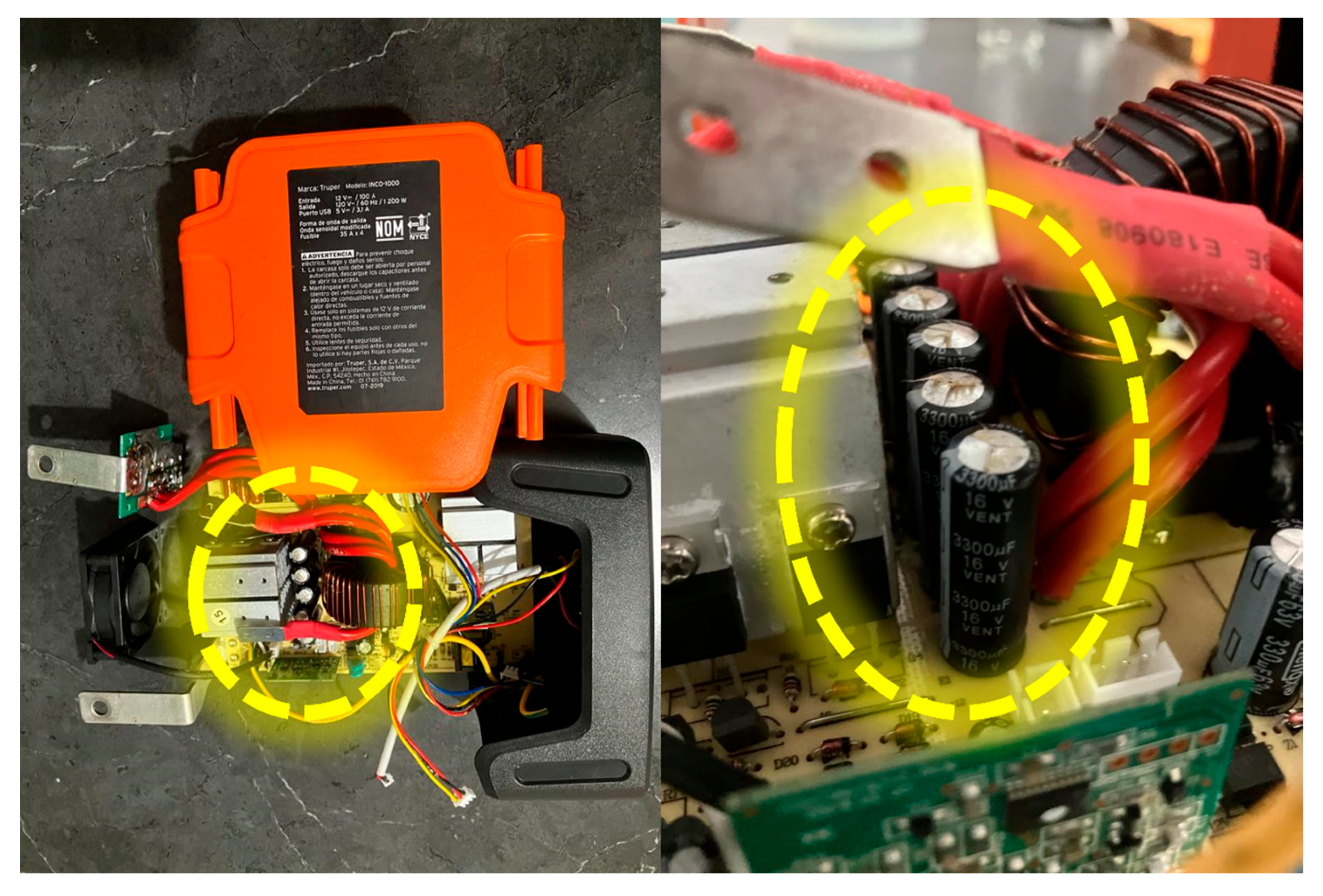

3.2. Electrical Safety Methodology Proposal for the Design of a Photovoltaic System to Prevent Hotspot Fires

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Renewable Capacity Statistics. 2022. Available online: https://www.irena.org/publications/2022/Apr/Renewable-Capacity-Statistics-2022 (accessed on 5 March 2023).

- Laukamp, H.; Bopp, G.; Grab, R.; Wittwer, C.; Häberlin, H.; Heeckeren, B.V.; Phillip, S.; Reil, F.; Schmidt, H.; Sepanski, A.; et al. PV Fire Hazard—Analysis and Assessment of Fire Incidents. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Paris, France, 30 September–4 October 2013; pp. 4304–4311. [Google Scholar] [CrossRef]

- Akram, M.W.; Li, G.; Jin, Y.; Chen, X. Failures of Photovoltaic modules and their Detection: A Review. Appl. Energy 2022, 313, 118822. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Zhou, X.-D.; Yang, L.-Z.; Zhang, T.-L. Experimental Studies on the Flammability and Fire Hazards of Photovoltaic Modules. Materials 2015, 8, 4210–4225. [Google Scholar] [CrossRef]

- Köntges, M.; Kurtz, S.; Packard, C.; Jahn, U.; Berger, K.A.; Kato, K. Performance and Reliability of Photovoltaic Systems: Subtask 3.2: Review of Failures of Photovoltaic Modules: IEA PVPS Task 13: External Final Report IEA-PVPS; International Energy Agency, Photovoltaic Power Systems Programme: Sankt Ursen, Switzerland, 2014; ISBN 978-3-906042-16-9. [Google Scholar]

- Manzini, G.; Gramazio, P.; Guastella, S.; Liciotti, C.; Baffoni, G.L. The Fire Risk in Photovoltaic Installations—Checking the PV Modules Safety in Case of Fire. Energy Procedia 2015, 81, 665–672. [Google Scholar] [CrossRef]

- Ju, X.; Zhou, X.; Zhao, K.; Peng, F.; Yang, L. Experimental study on fire behaviors of flexible photovoltaic panels using a cone calorimeter. J. Fire Sci. 2017, 36, 63–77. [Google Scholar] [CrossRef]

- Vaverková, M.D.; Winkler, J.; Uldrijan, D.; Ogrodnik, P.; Vespalcová, T.; Aleksiejuk-Gawron, J.; Adamcová, D.; Koda, E. Fire hazard associated with different types of photovoltaic power plants: Effect of vegetation management. Renew. Sustain. Energy Rev. 2022, 162, 112491. [Google Scholar] [CrossRef]

- Szultka, S.; Czapp, S.; Tomaszewski, A.; Ullah, H. Evaluation of Fire Hazard in Electrical Installations Due to Unfavorable Ambient Thermal Conditions. Fire 2023, 6, 41. [Google Scholar] [CrossRef]

- Aram, M.; Zhang, X.; Reda, I.; Dghim, M.; Qi, D.; Ko, Y. Similarity assessment of using helium to predict smoke movement through buildings with double skin façades during building integrated photovoltaics fires. J. Clean. Prod. 2023, 405, 136996. [Google Scholar] [CrossRef]

- Miao, L.; Chow, C.-L. Investigation of burning photovoltaic panels on a double-skin facade with ejecting flame from an adjacent room fire. Indoor Built Environ. 2018, 28, 938–949. [Google Scholar] [CrossRef]

- Despinasse, M.-C.; Krueger, S. First developments of a new test to evaluate the fire behavior of photovoltaic modules on roofs. Fire Saf. J. 2015, 71, 49–57. [Google Scholar] [CrossRef]

- Mazziotti, L.; Cancelliere, P.; Paduano, G.; Setti, P.; Sassi, S. Fire risk related to the use of PV systems in building facades. MATEC Web Conf. 2016, 46, 5001. [Google Scholar] [CrossRef]

- NFPA. Development of Fire Mitigations Solutions for PV Systems. Available online: https://www.nfpa.org/News-and-Research/Data-research-and-tools/Electrical/Development-of-Fire-Mitigations-Solutions-for-PV-Systems-Installed-on-Building-Roofs-Phase-1 (accessed on 25 April 2023).

- SFPE Europe Digital Issue 21—Investigation of the Effects of Photovoltaic (PV) System Component Aging on Fire Properties for Residential Rooftop Applications. Available online: https://www.sfpe.org/publications/periodicals/sfpeeuropedigital/sfpeeurope21/europeissue21feature5#_ENREF_11 (accessed on 25 April 2023).

- Yang, R.; Zang, Y.; Yang, J.; Wakefield, R.; Nguyen, K.; Shi, L.; Trigunarsyah, B.; Parolini, F.; Bonomo, P.; Frontini, F.; et al. Fire safety requirements for building integrated photovoltaics (BIPV): A cross-country comparison. Renew. Sustain. Energy Rev. 2023, 173, 113112. [Google Scholar] [CrossRef]

- Mohd Nizam Ong, N.A.F.; Sadiq, M.A.; Md Said, M.S.; Jomaas, G.; Mohd Tohir, M.Z.; Kristensen, J.S. Fault tree analysis of fires on rooftops with photovoltaic systems. J. Build. Eng. 2022, 46, 103752. [Google Scholar] [CrossRef]

- Cancelliere, P.; Manzini, G.; Traina, G.; Cavriani, M.G. PV modules on buildings—Outlines of PV roof samples fire rating assessment. Fire Saf. J. 2020, 120, 103139. [Google Scholar] [CrossRef]

- Zhao, G.; Li, M.; Jian, L.; He, Z.; Shuang, J.; Yuping, S.; Zhang, Q.; Zhongxian, L. Analysis of Fire Risk Associated with Photovoltaic Power Generation System. Adv. Civ. Eng. 2018, 2018, 2623741. [Google Scholar] [CrossRef]

- Kristensen, J.S.; Jomaas, G. Experimental Study of the Fire Behaviour on Flat Roof Constructions with Multiple Photovoltaic (PV) Panels. Fire Technol. 2018, 54, 1807–1828. [Google Scholar] [CrossRef]

- Kristensen, J.S.; Faudzi, F.B.M.; Jomaas, G. Experimental study of flame spread underneath photovoltaic (PV) modules. Fire Saf. J. 2020, 120, 103027. [Google Scholar] [CrossRef]

- Aram, M.; Zhang, X.; Qi, D.; Ko, Y. A state-of-the-art review of fire safety of photovoltaic systems in buildings. J. Clean. Prod. 2021, 308, 127239. [Google Scholar] [CrossRef]

- Mohd Nizam Ong, N.A.F.; Mohd Tohir, M.Z.; Said, M.S.; Md Said, M.S.; Alias, A.H.; Ramali, M.R. Development of fire safety best practices for rooftops grid-connected photovoltaic (PV) systems installation using systematic review methodology. Sustain. Cities Soc. 2021, 78, 103637. [Google Scholar] [CrossRef]

- Ko, Y.; Aram, M.; Zhang, X.; Qi, D. Fire safety of building integrated photovoltaic systems: Critical review for codes and standards. Indoor Built Environ. 2022, 32, 25–43. [Google Scholar] [CrossRef]

- Ramali, M.R.; Mohd Nizam Ong, N.A.F.; Md Said, M.S.; Mohamed Yusoff, H.; Baharudin, M.R.; Tharima, A.F.; Akashah, F.W.; Mohd Tohir, M.Z. A Review on Safety Practices for Firefighters During Photovoltaic (PV) Fire. Fire Technol. 2022, 59, 247–270. [Google Scholar] [CrossRef] [PubMed]

- Fiorentini, L.; Marmo, L.; Danzi, E.; Puccia, V. Fire risk assessment of photovoltaic plants. a case study moving from two large fires: From accident investigation and forensic engineering to fire risk assessment for reconstruction and permitting purposes. Chem. Eng. Trans. 2016, 48, 427–432. [Google Scholar] [CrossRef]

- Wu, Z.; Hu, Y.; Wen, J.X.; Zhou, F.; Ye, X. A Review for Solar Panel Fire Accident Prevention in Large-Scale PV Applications. IEEE Access 2020, 8, 132466–132480. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mather, P.; Sibley, M. Novel hot spot mitigation technique to enhance photovoltaic solar panels output power performance. Sol. Energy Mater. Sol. Cells 2018, 179, 72–79. [Google Scholar] [CrossRef]

- Dhimish, M.; Badran, G. Current limiter circuit to avoid photovoltaic mismatch conditions including hot-spots and shading. Renew. Energy 2019, 145, 2201–2216. [Google Scholar] [CrossRef]

- Guerriero, P.; Tricoli, P.; Daliento, S. A bypass circuit for avoiding the hot spot in PV modules. Sol. Energy 2019, 181, 430–438. [Google Scholar] [CrossRef]

- Pillai, D.S.; Rajasekar, N. A comprehensive review on protection challenges and fault diagnosis in PV systems. Renew. Sustain. Energy Rev. 2018, 91, 18–40. [Google Scholar] [CrossRef]

- Singh, S.K.; Chander, N. Mid-life degradation evaluation of polycrystalline Si solar photovoltaic modules in a 100 kWp grid-tied system in east-central India. Renew. Energy 2022, 199, 351–367. [Google Scholar] [CrossRef]

- Bansal, N.; Pany, P.; Singh, G. Visual degradation and performance evaluation of utility scale solar photovoltaic power plant in hot and dry climate in western India. Case Stud. Therm. Eng. 2021, 26, 101010. [Google Scholar] [CrossRef]

- Carta González, J.A.; Calero Pérez, R.; Colmenar Santos, A.; Castro Gil, M.A.; Collado Fernández, E. Centrales de Energías Renovables: Generación Eléctrica con Energías Renovables; Pearson Educación: Madrid, Spain, 2013; ISBN 978-84-8322-997-2. [Google Scholar]

- Čabo, F.G.; Marinić-Kragić, I.; Garma, T.; Nižetić, S. Development of thermo-electrical model of photovoltaic panel under hot-spot conditions with experimental validation. Energy 2021, 230, 120785. [Google Scholar] [CrossRef]

- Aghaei, M.; Fairbrother, A.; Gok, A.; Ahmad, S.; Kazim, S.; Lobato, K.; Oreski, G.; Reinders, A.; Schmitz, J.; Theelen, M.; et al. Review of degradation and failure phenomena in photovoltaic modules. Renew. Sustain. Energy Rev. 2022, 159, 112160. [Google Scholar] [CrossRef]

- Ammari, C.; Belatrache, D.; Touhami, B.; Makhloufi, S. Sizing, optimization, control and energy management of hybrid renewable energy system—A review. Energy Built Environ. 2021, 3, 399–411. [Google Scholar] [CrossRef]

- Lu, S.; Dai, R.; Zhang, G.; Wang, Q. Investigation of Street Lamp with Automatic Solar Tracking System. J. Sol. Energy Eng. 2018, 140, 061002. [Google Scholar] [CrossRef]

- Sutopo, W.; Mardikaningsih, I.S.; Zakaria, R.; Ali, A. A Model to Improve the Implementation Standards of Street Lighting Based on Solar Energy: A Case Study. Energies 2020, 13, 630. [Google Scholar] [CrossRef]

- Zajac, P.; Przybylek, G. Lighting lamps in recreational areas—Damage and prevention, testing and modelling. Eng. Fail. Anal. 2020, 115, 104693. [Google Scholar] [CrossRef]

- Tobajas Vásquez, C. Instalaciones Solares Fotovoltaicas, 2nd ed.; Ediciones de la U: Bogota, Colombia, 2015; ISBN 978-958-762-267-6. [Google Scholar]

- Casa Vilaseca, M.; Barrio López, M. Instalaciones Solares Fotovoltaicas, 1st ed.; Alfaomega Marcombo: Barcelona, Spain, 2017; ISBN 978-607-622-055-9. [Google Scholar]

- Pérez-Higueras, P.; Ferrer-Rodríguez, J.P.; Almonacid, F.; Fernández, E.F. Efficiency and acceptance angle of High Concentrator Photovoltaic modules: Current status and indoor measurements. Renew. Sustain. Energy Rev. 2018, 94, 143–153. [Google Scholar] [CrossRef]

- Farret, F.A.; Simões, M.G. Integration of Alternative Sources of Energy; Power, Energy and Industry Applications; Wiley-IEEE Press: Hoboken, NJ, USA, 2006; ISBN 978-0-471-71232-9. [Google Scholar]

- Tejeda Martínez, A.; Gómez Azpeitia, G. Prontuario Solar de México; Universidad de Colima: Colima, Mexico, 2015; ISBN 978-607-8356-45-4. [Google Scholar]

- Twidell, J.; Weir, T. Renewable Energy Resources, 3rd ed.; Routledge: London, UK, 2015; ISBN 978-0-415-58438-8. [Google Scholar]

(W/m2) | (W/m2) | (°C) | (°C) | (°C) | (°C) |

|---|---|---|---|---|---|

| 820 | 800 | 43 (±2) | 20 | 31 | 54.57 |

| PVM1 | PVM2 | PVM3 | PVM4 | |

|---|---|---|---|---|

| 55.2 °C | 56.9 °C | 61.4 °C | 54.3 °C | |

| 30.2 °C | 31.9 °C | 36.4 °C | 29.3 °C | |

| −8.456% | −8.932% | −10.192% | −8.204% | |

| 1.51% | 1.595% | 1.82% | 1.465% | |

| −10.87% | −11.48% | −13.10% | −10.55% |

| PVM1 | PVM2 | PVM3 | PVM4 | |

|---|---|---|---|---|

| 55.2 °C | 56.9 °C | 61.4 °C | 54.3 °C | |

| 30.2 °C | 31.9 °C | 36.4 °C | 29.3 °C | |

| −8.456% | −8.932% | −10.192% | −8.204% | |

| 18.96% | 18.83% | 18.48% | 19.03% |

| Electrical Conductor Material | Type of Electrical Conductor | Conductor Coating | Standards | Maximum Operating Temperatures |

|---|---|---|---|---|

| Aluminum Aluminum–Tin Copper | XLPE UV | UL 854 | 60 °C 75 °C 90 °C | |

| THW | UL 4703 | |||

| THW-LS | UL 1685 | |||

| THHW | UL 44 | |||

| THHW-LS | UL 83 | |||

| RHW-2 | ASTM B3 | |||

| USE-2 | ASTM B8 | |||

| THHN | ASTM B787 | |||

| THWN-2 | ASTM B800 | |||

| XHHW | ANSI/NEMA WC-70 ICEA S-95-658 | |||

| XHHW-2 | NTE INEN 2 345 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juarez-Lopez, J.M.; Franco, J.A.; Hernandez-Escobedo, Q.; Muñoz-Rodríguez, D.; Perea-Moreno, A.-J. Analysis of a Novel Proposal Using Temperature and Efficiency to Prevent Fires in Photovoltaic Energy Systems. Fire 2023, 6, 196. https://doi.org/10.3390/fire6050196

Juarez-Lopez JM, Franco JA, Hernandez-Escobedo Q, Muñoz-Rodríguez D, Perea-Moreno A-J. Analysis of a Novel Proposal Using Temperature and Efficiency to Prevent Fires in Photovoltaic Energy Systems. Fire. 2023; 6(5):196. https://doi.org/10.3390/fire6050196

Chicago/Turabian StyleJuarez-Lopez, Jose Manuel, Jesus Alejandro Franco, Quetzalcoatl Hernandez-Escobedo, David Muñoz-Rodríguez, and Alberto-Jesus Perea-Moreno. 2023. "Analysis of a Novel Proposal Using Temperature and Efficiency to Prevent Fires in Photovoltaic Energy Systems" Fire 6, no. 5: 196. https://doi.org/10.3390/fire6050196

APA StyleJuarez-Lopez, J. M., Franco, J. A., Hernandez-Escobedo, Q., Muñoz-Rodríguez, D., & Perea-Moreno, A.-J. (2023). Analysis of a Novel Proposal Using Temperature and Efficiency to Prevent Fires in Photovoltaic Energy Systems. Fire, 6(5), 196. https://doi.org/10.3390/fire6050196