Analysis of Flow Field Characteristics of the Propane Jet Combustion Flame

Abstract

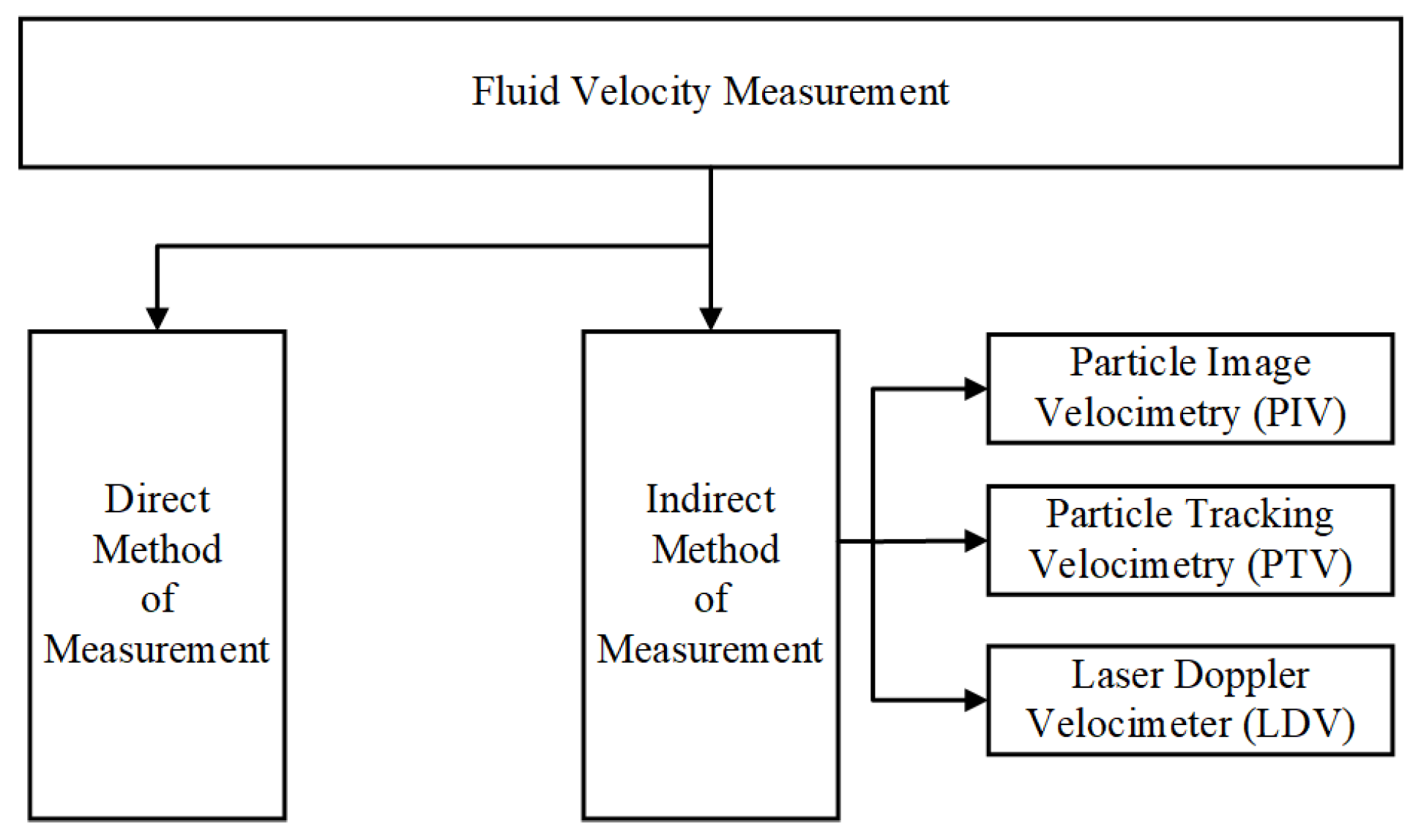

:1. Introduction

2. Experimental Setup and Methods

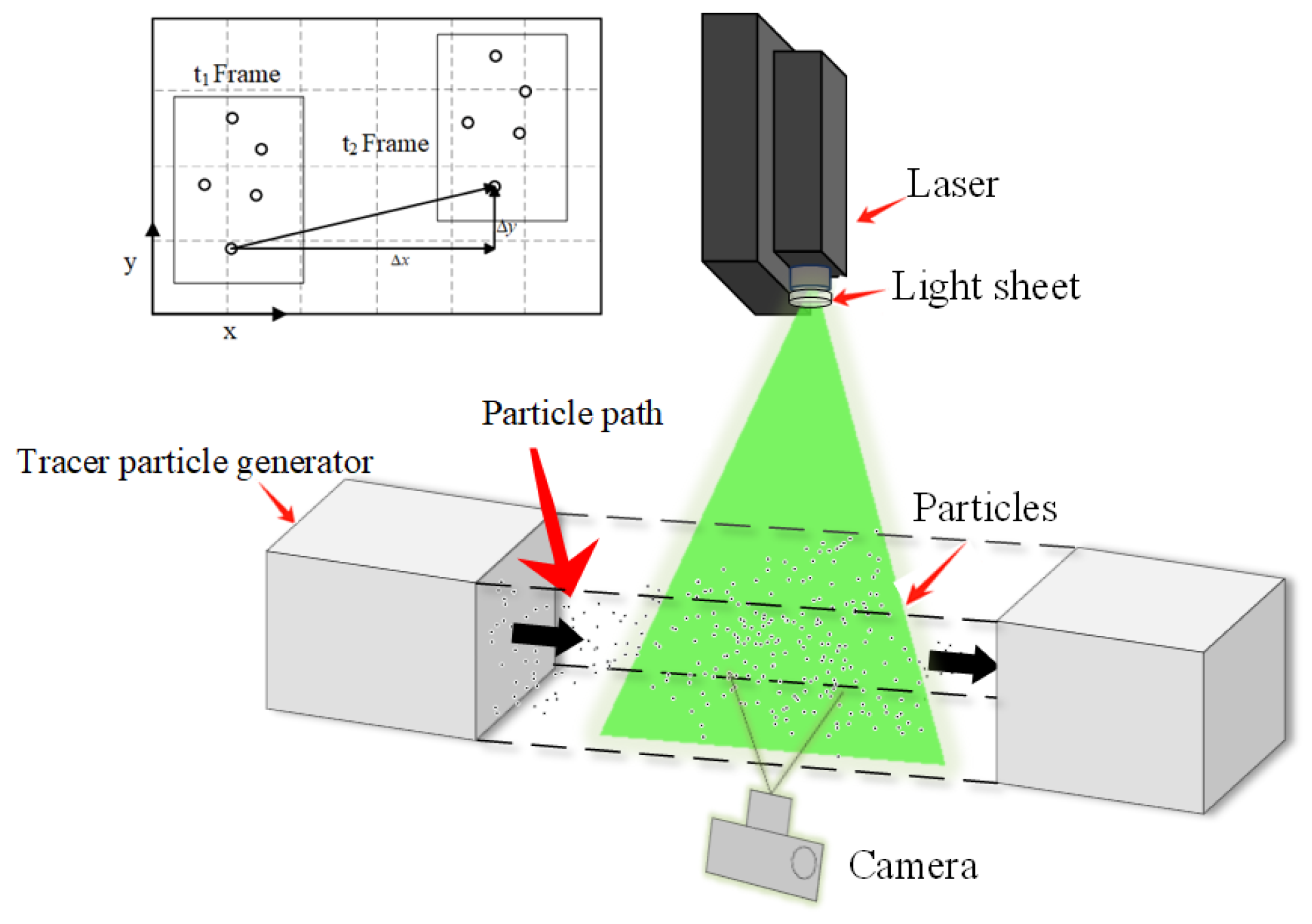

2.1. Basic Principles of PIV Technology

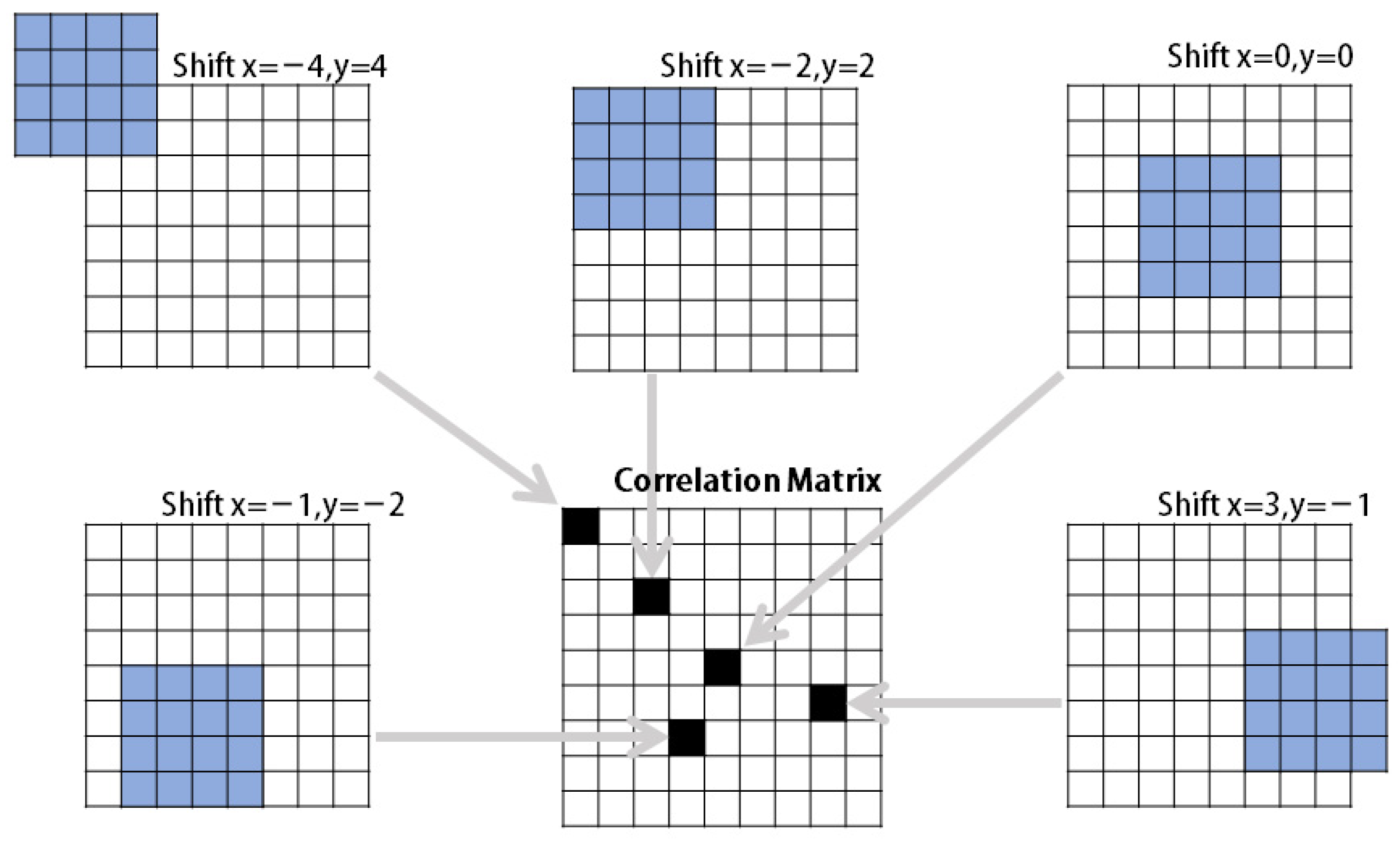

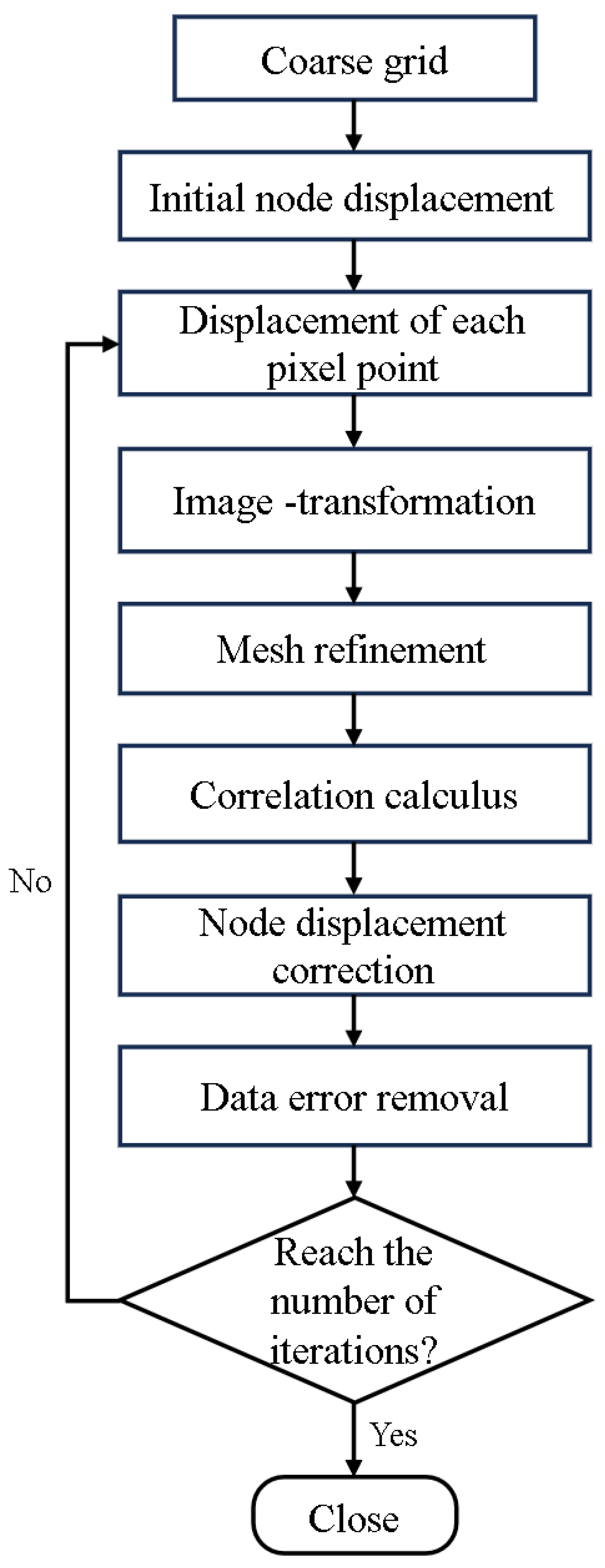

2.2. Cross-Correlation Theory

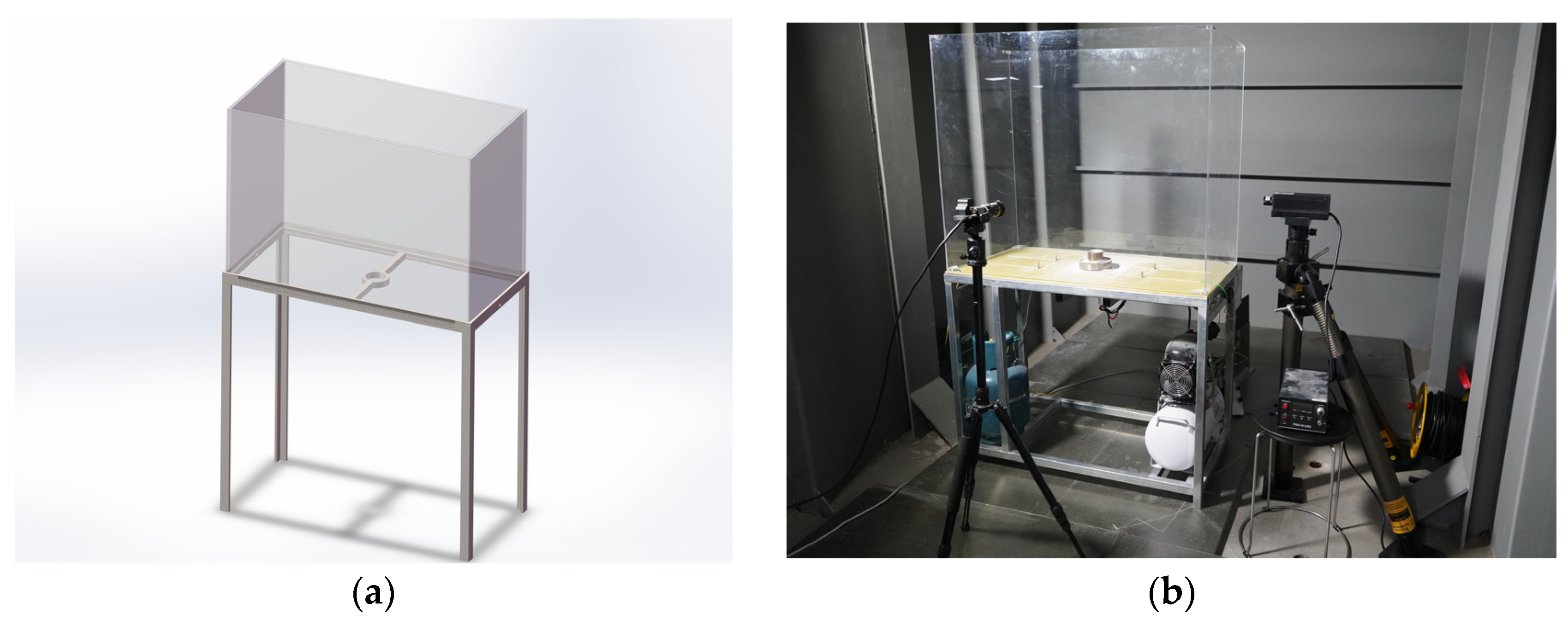

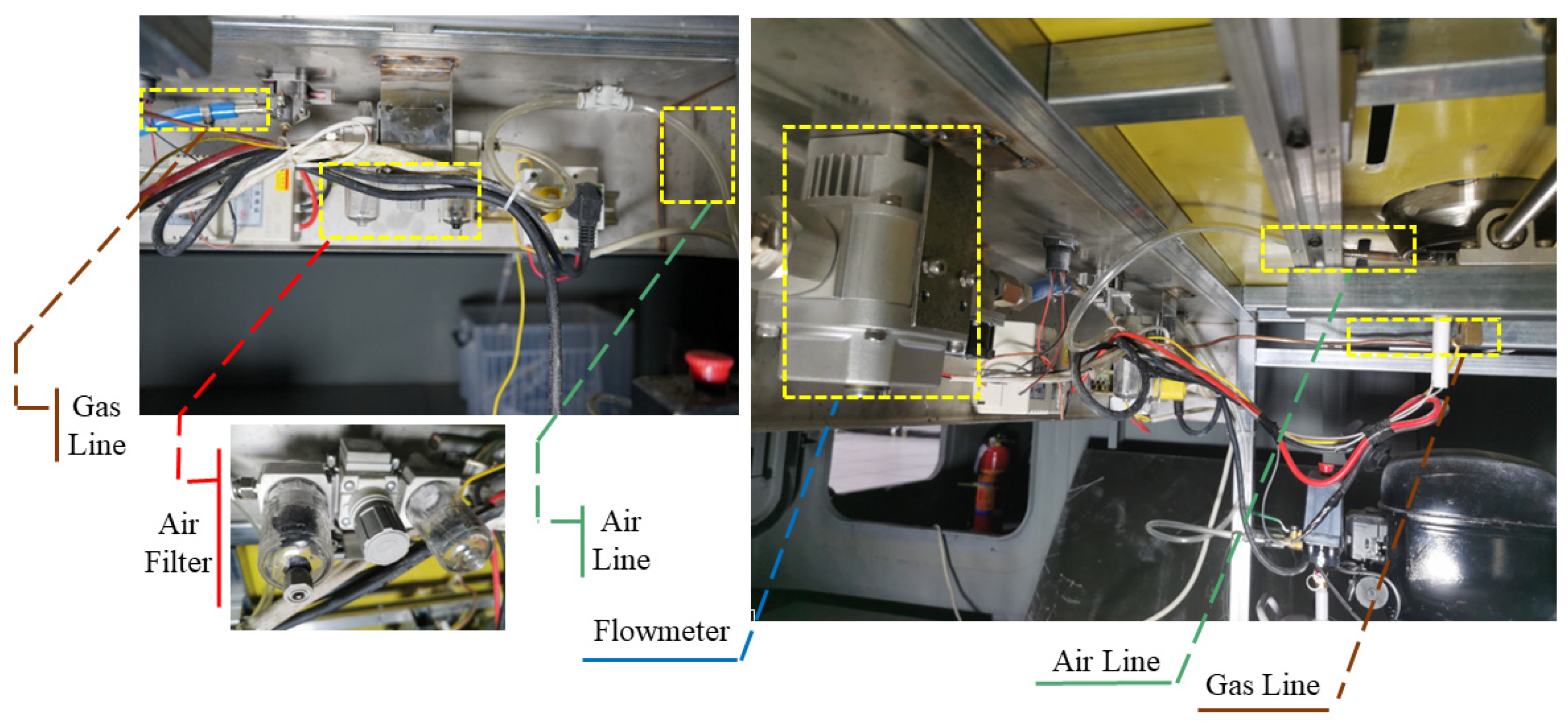

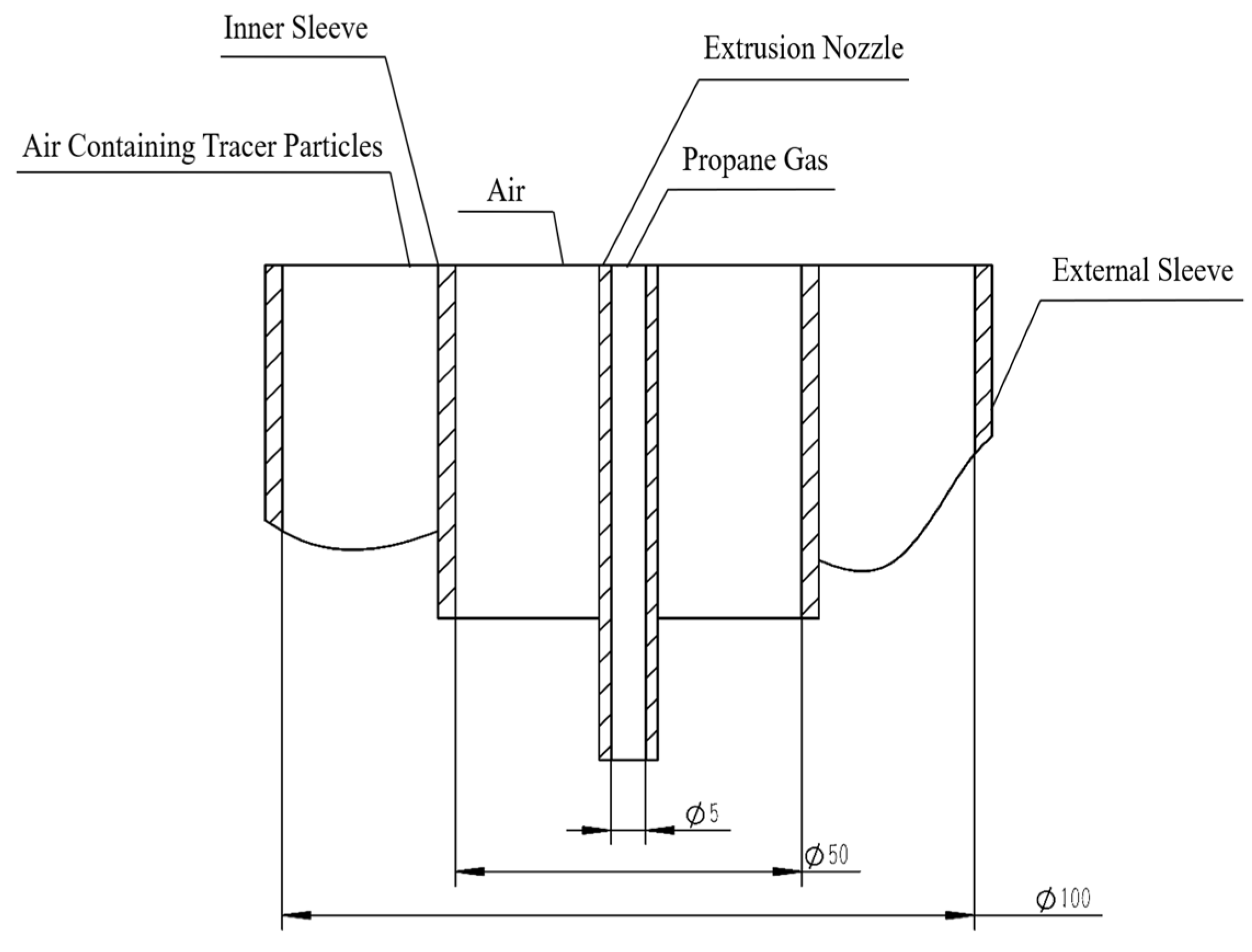

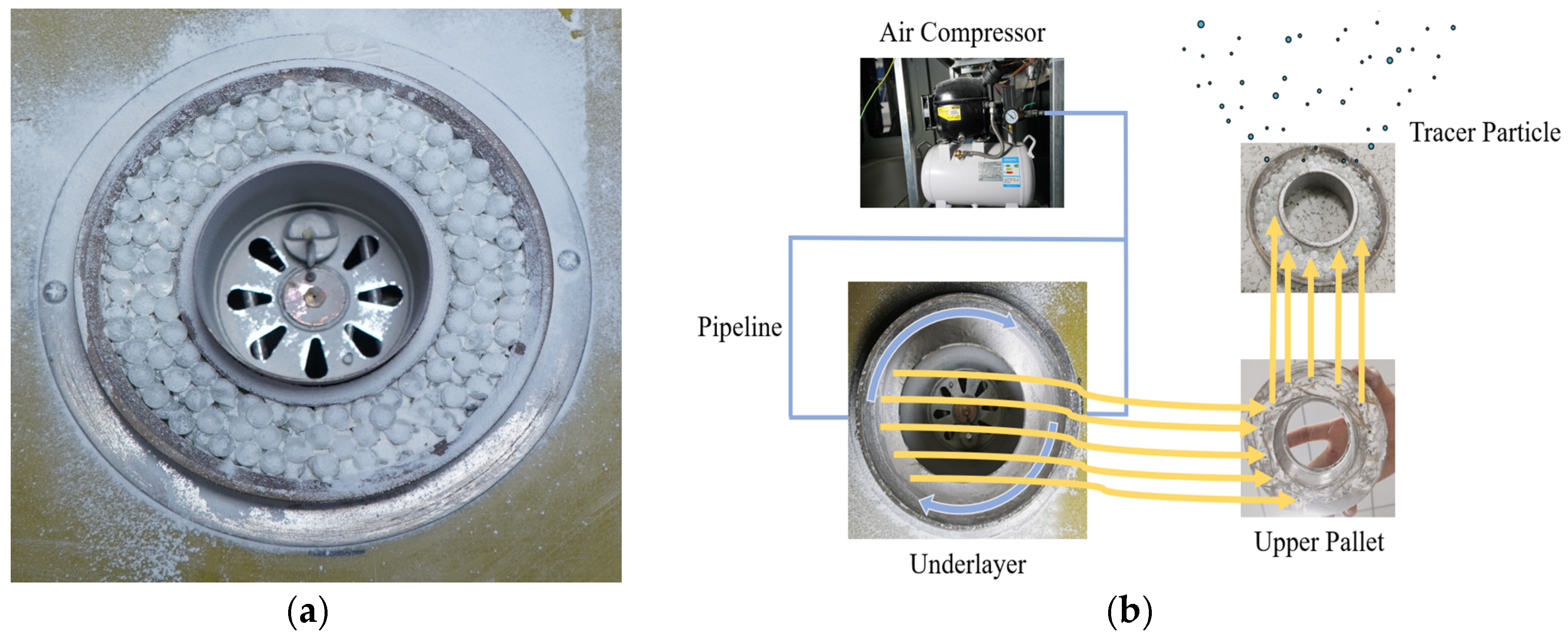

2.3. Design of an Autonomous PIV Experimental Speed Measuring Device

2.4. Experimental Analysis

2.4.1. Experimental Test

- To ensure that the particles were dry and to avoid the surface of the glass beads being exposed to the air for a long time, the water was attached to the surface, which led to the agglomeration of the tracer particles. This was shown in the particle image as an uneven particle size. The ground glass beads in the particle generator were washed, and the tracer particles were placed into the drying box for drying.

- Accessories, such as the transparent plexiglass cover, were cleaned to avoid impurities affecting the laser incidence effect and introducing noise in the particle image.

- To provide oxygen conditions in advance, before the ignition of the propane burner, an appropriate amount of compressed air containing tracer particles was passed into the burner to increase the oxygen content above the burner and reduce the difficulty of ignition. At the same time, tracer particles were introduced to provide conditions for the initial ignition flow field.

- A Deli DL332305 level was used to ensure that the CCD camera body was horizontal and perpendicular to the laser plane in order to ensure the shooting effect.

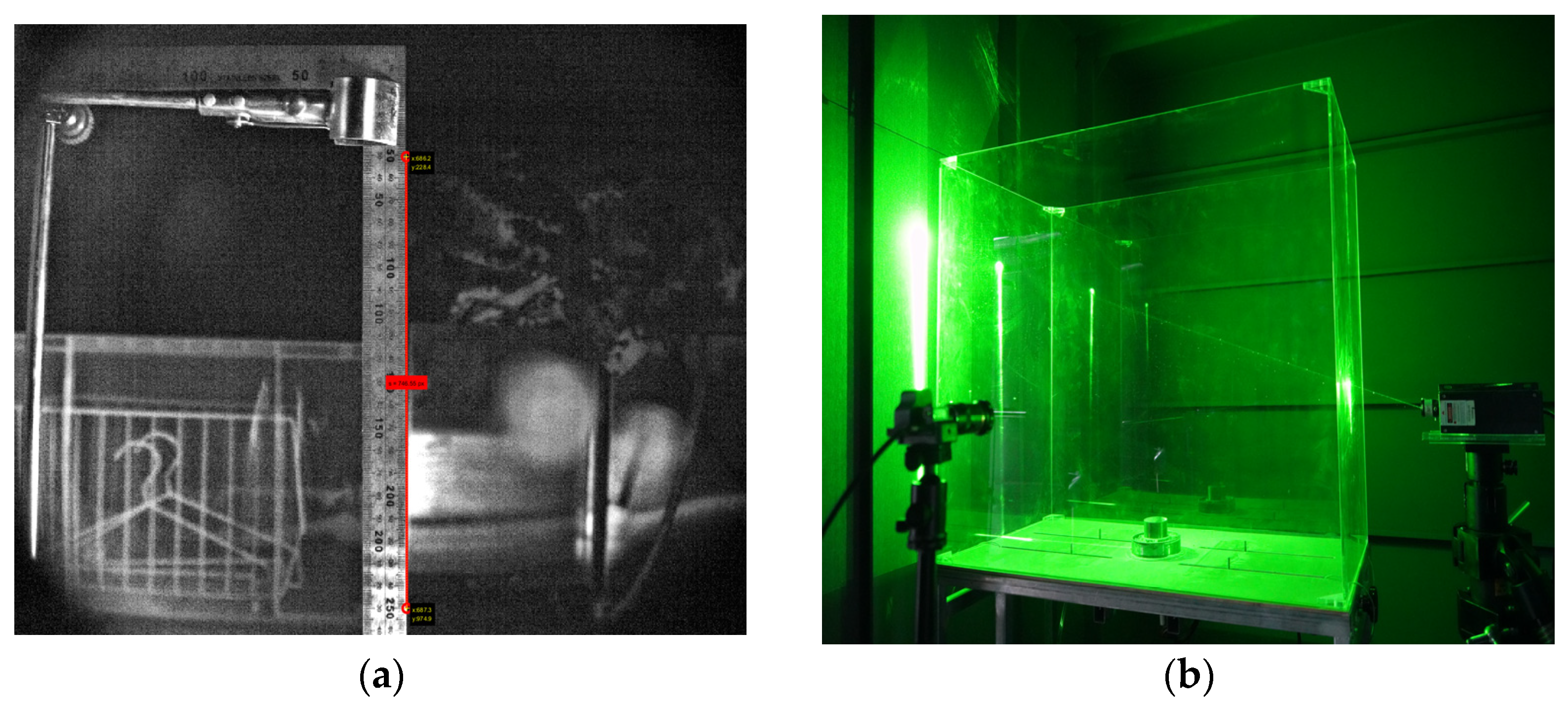

- The focal plane was calibrated to make the laser plane coincide with the focal plane to prevent under-exposure or over-exposure. A calibration ruler was used to focus and change the image distance through repeated focusing until the ruler in the lens picture was clearly imaged, and the length calibration is shown in Figure 10a. At this time, the camera aperture had been adjusted to the maximum, the exposure time parameter was 10,000, and the G-channel gain was 5.0.

2.4.2. Image Pre-Processing

3. Results and Discussion

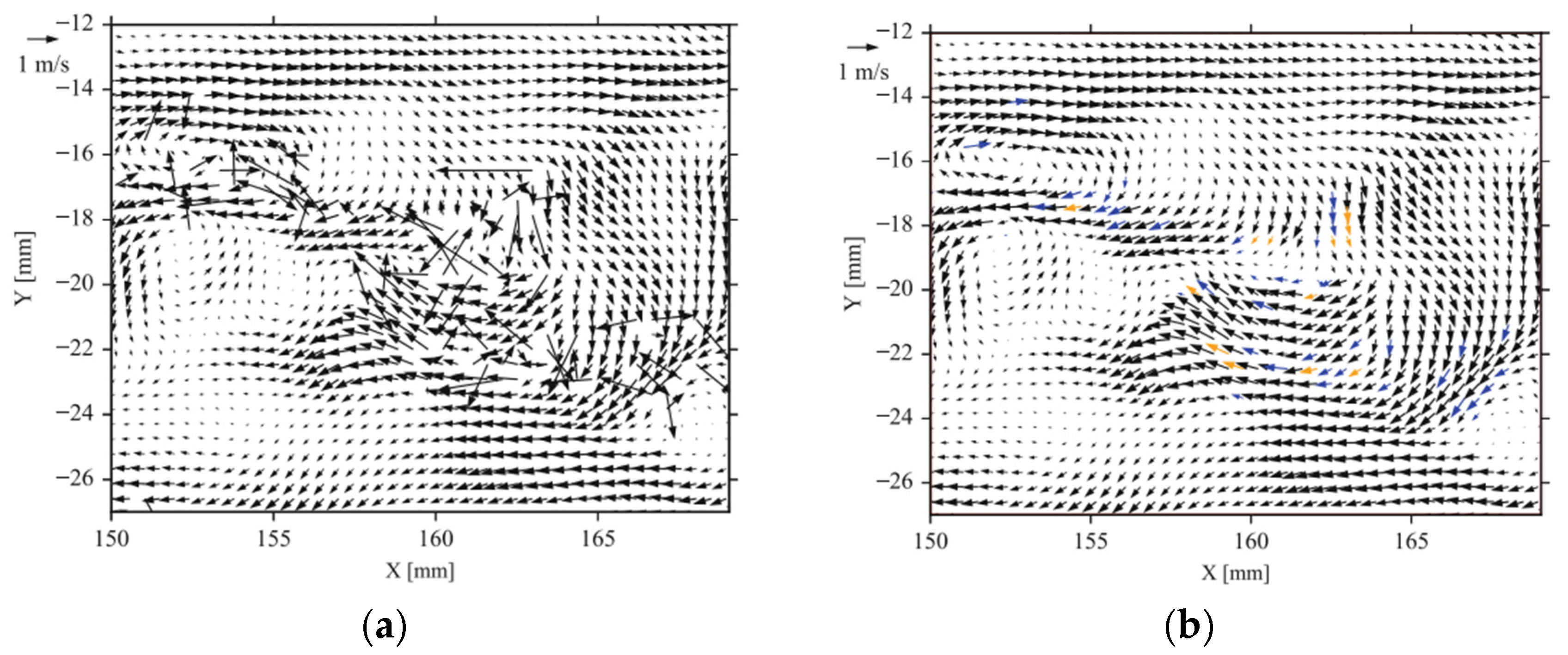

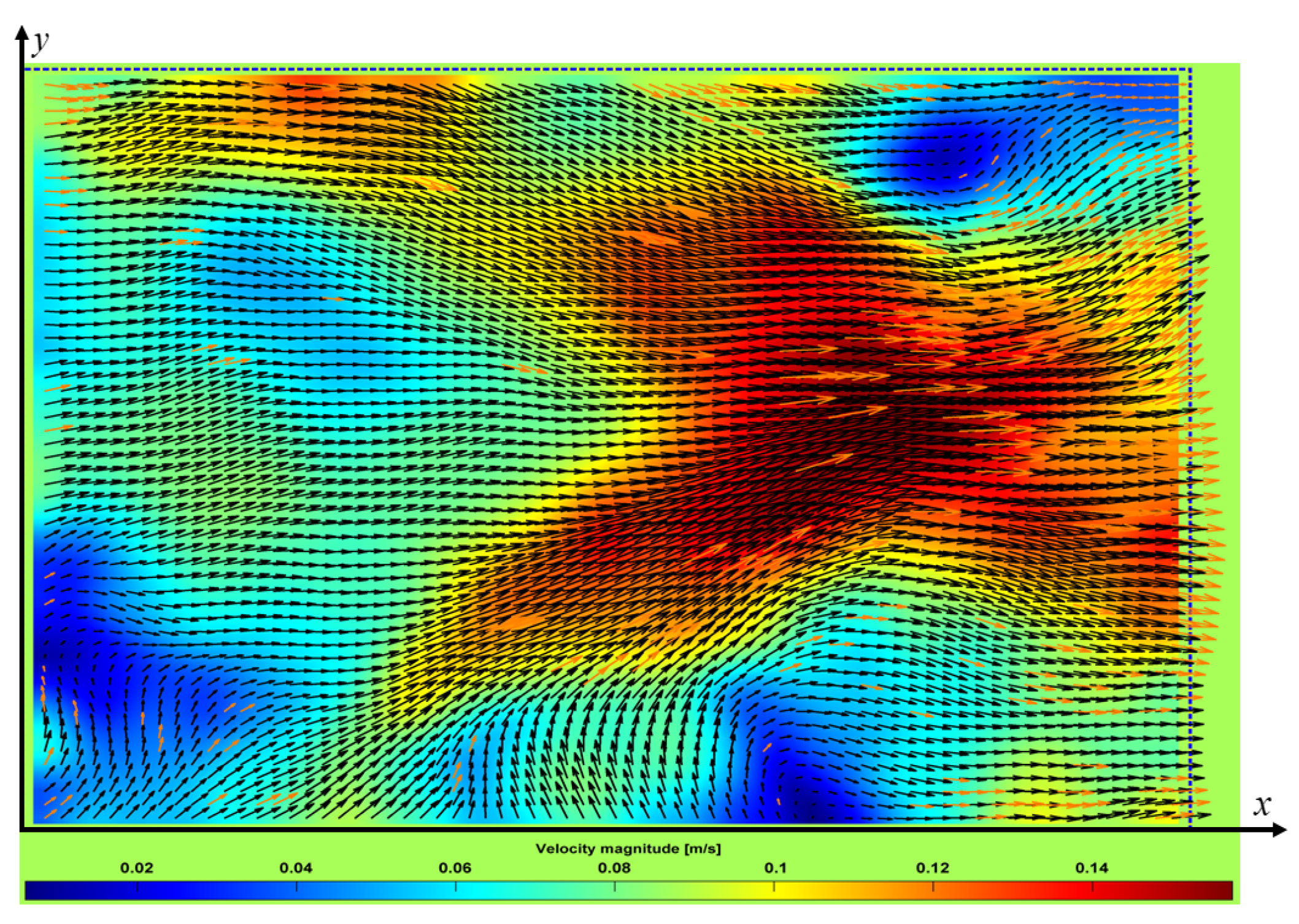

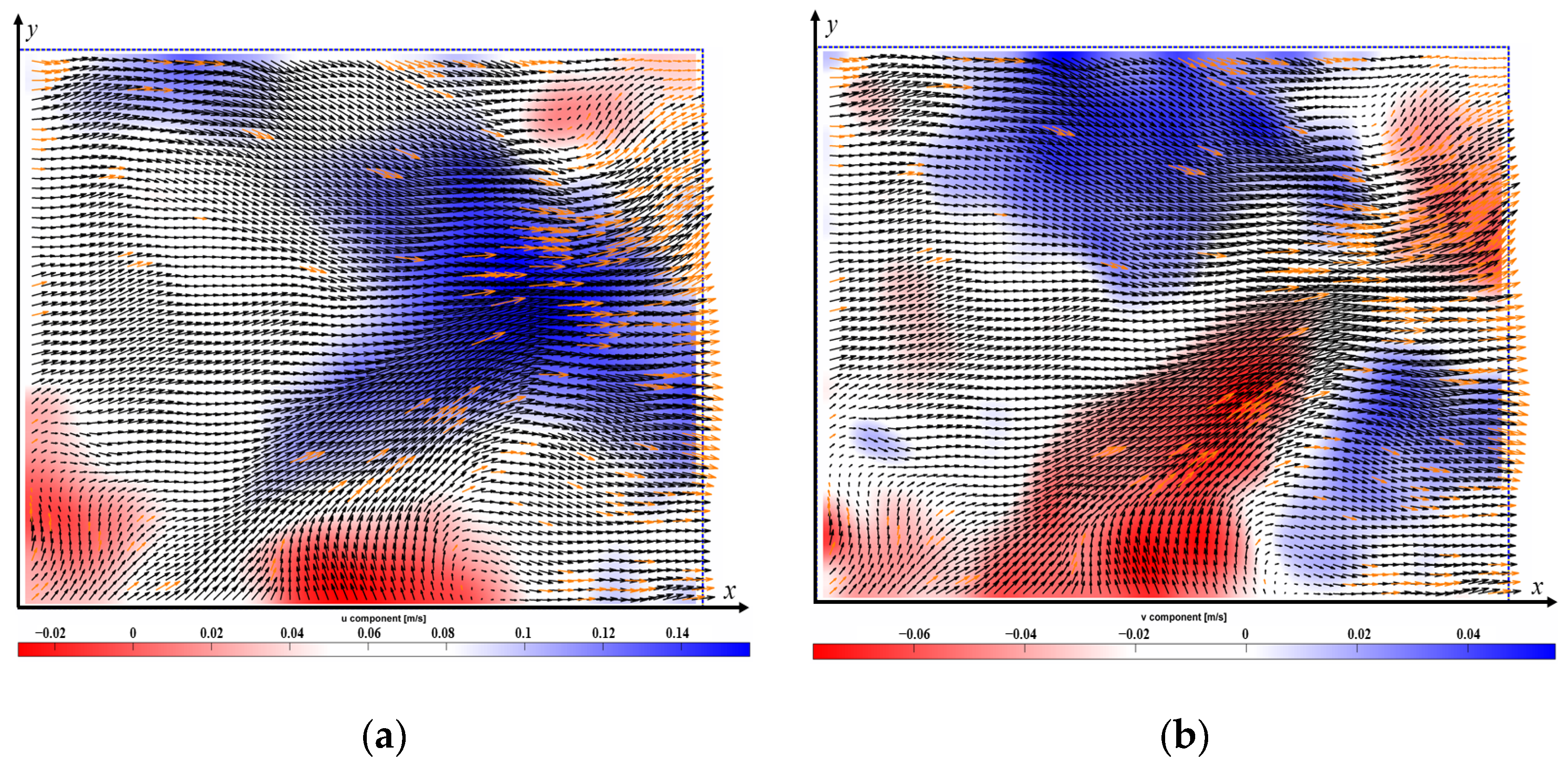

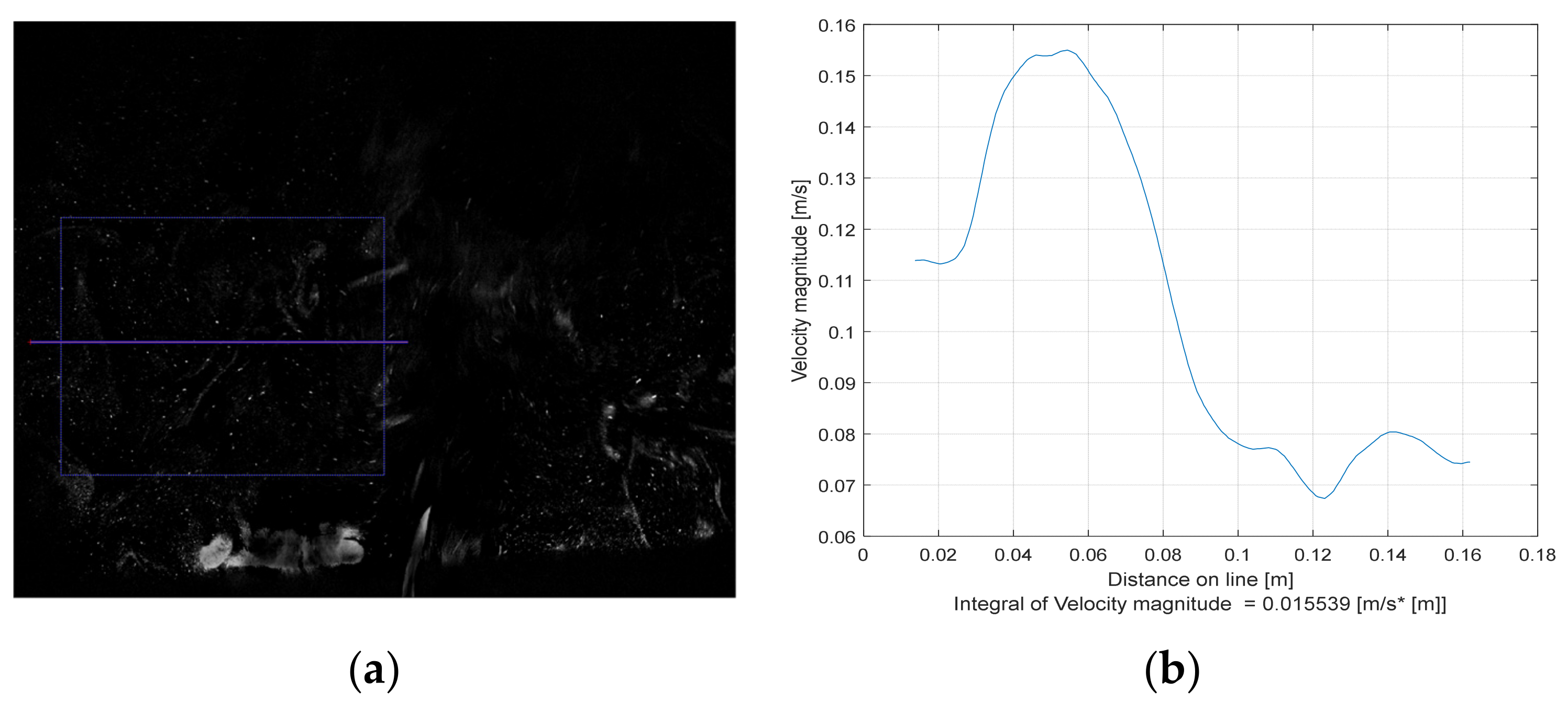

3.1. Flow Rate Analysis

3.2. Vorticity Analysis

4. Conclusions

- (1)

- A particle generator was designed based on the fluidised bed principle and installed in the air pipeline. TiO2 powder with a 10 μm particle size was selected as the tracer particle, and the air and gas carrying the tracer particle were diffused and burned at the centre nozzle of the test bench to achieve stable combustion of the propane flame.

- (2)

- The PIV algorithm program to pre-process the image was prepared. The deformation interrelationship of multi-level grid windows was calculated, the median test was normalised, and the velocity of the air flow field above the flame was analysed with the help of the PIVlab post-processing algorithm.

- (3)

- The visualisation of the flow velocity in the combustion process of a propane flame was realised. The velocity accuracy was 4.8 × 10−4 m/s, and the flow velocity was up to 0.23 m/s at the largest area, with a relative error of ±5%, presenting Gaussian distribution characteristics; the maximum average velocity of the transverse velocity of the flow field in this region was close to 0.15 ± 0.03 m/s; the upper and lower parts of the flow velocity in the longitudinal velocity are opposite to each other; and the phenomenon of convolutional suction is observed in the middle part of the flow field.

- (4)

- The visualisation of the vortex in the propane flame combustion process was realised, and it was found that there was a vortex in the flame jet. In the horizontal plane where the vortex occurred, the air velocity gradually increased as the distance from the centre of the jet was gradually narrowed, and vortices with opposite directions and a size of about 10 s−1 appeared in the upper and lower parts of the airflow at the same time.

- (5)

- The use of PIV technology, the visualisation of the propane flame combustion process, the application of PIV technology in dynamic flow fields and complex combustion chambers, and the analysis of the movement of the air flow field above the flame were used to achieve the visualisation of the flame measurements, providing the experimental basis for the study of fire extinguishing mechanisms and effective management of fires.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Center for World Fire Statistics (CTIF). Center for World Fire Statistics Report No.28 [R/OL]. 2023. Available online: www.ctif.org (accessed on 21 October 2023).

- The State Bureau of Fire Rescue. In the First Half of 2023 Fire Statistics [EB/OL]. 2023. Available online: https://www.119.gov.cn/qmxfgk/sjtj/2023/38420.shtml (accessed on 25 October 2023).

- Dang, X.X. Experimental Research and Numerical Simulation of Double Swirl Annular Combustion Chamber. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2009. [Google Scholar]

- Markus, R.; Jurgen, K.; Wereley, S.T.; Willert, C.E. Particle image velocimetry: A practical guide. Exp. Fluid Mech. 2017, 255, 160–162. [Google Scholar]

- Willert, C.E.; Gharib, M. Digital particle image velocity. Exp. Fluids 1991, 10, 181–193. [Google Scholar] [CrossRef]

- Cowen, E.A.; Monismith, S.G.; Cowen, E.A.; Monismith, S.G. A hybrid digital particle tracking velocimetry technique. Exp. Fluids 1997, 22, 199–211. [Google Scholar] [CrossRef]

- Yeh, Y.; Cummins, H.Z. Localized Fluid Flow Measurements with An He–Ne Laser Spectrometer. Appl. Phys. Lett. 1964, 4, 176–178. [Google Scholar] [CrossRef]

- Westerweel, J.; Elsinga, G.E.; Adrian, R.J. Particle image velocimetry for complex and turbulent flows. Annu. Rev. Fluid Mech. 2013, 45, 409–436. [Google Scholar] [CrossRef]

- Feng, H.; Meng, A.; Zhang, Y.; Gong, Y.; Li, Q. LDV measurements of particle fluctuation velocities in dilute gravity-driven gas-particle flows. Powder Technol. 2019, 360, 1368–1376. [Google Scholar] [CrossRef]

- Raiola, M.; Lopez-Nunez, E.; Cafiero, G.; Discetti, S. Adaptive ensemble PTV. Meas. Sci. Technol. 2020, 31, 085301. [Google Scholar] [CrossRef]

- Adrian, R.J. Scattering particle characteristics and their effect on pulsed laser measurements of fluid flow: Speckle velocimetry vs particle image velocimetry. Appl. Opt. 1984, 23, 1690. [Google Scholar] [CrossRef]

- Scharnowski, S.; Khler, C.J. Particle image velocimetry—Classical operating rules from today’s perspective. Opt. Lasers Eng. 2020, 135, 106185. [Google Scholar] [CrossRef]

- Chen, L.W.; Wang, Q.; Zhang, Y. Flow characterisation of diffusion flame under non-resonant acoustic excitation. Exp. Therm. Fluid Sci. 2013, 45, 227–233. [Google Scholar] [CrossRef]

- Wang, Y.Z. Measurement of Combustion Flow Field by Tracer Particle Imaging. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2018. [Google Scholar]

- Wang, H.P.; Gao, Q.; Wang, S.Z.; Li, Y.H.; Wang, Z.Y.; Wang, J.J. Error reduction for time-resolved PIV data based on Navier–Stokes equations. Exp. Fluids 2018, 59, 149. [Google Scholar] [CrossRef]

- Verdier, A.; Santiago, J.M.; Vandel, A.; Saengkaew, S.; Cabot, G.; Grehan, G.; Renou, B. Experimental study of local flame structures and fuel droplet properties of a spray jet flame. Proc. Combust. Inst. 2017, 36, 2595–2602. [Google Scholar] [CrossRef]

- Meyer, T.R.; Roy, S.; Belovich, V.M.; Corporan, E.; Gord, J.R. Simultaneous planar laser-induced incandescence, OH planar laser-induced fluorescence, and droplet Mie scattering in swirl-stabilized spray flames. Appl. Opt. 2005, 44, 445–454. [Google Scholar] [CrossRef]

- Hiromasa, S.; Hara, S.; Inaoka, K. The velocity and thermal fields of two parallel plane jets using simultaneous PIV and two-color LIF measurements. Int. J. Heat Fluid Flow 2023, 103, 109192. [Google Scholar] [CrossRef]

- Ray, S.C.; Nishida, K.; McDonell, V.; Ogata, Y. Effects of full transient Injection Rate and Initial Spray Trajectory Angle profiles on the CFD simulation of evaporating diesel sprays-comparison between singlehole and multi hole injectors. Energy 2023, 263, 125796. [Google Scholar]

- Li, J.Q. Principle and application of PIV. Water Technol. Econ. 2015, 21, 40–42. [Google Scholar]

- Yang, X.; Yan, J. Principle and Application of PIV velocity measurement. J. Xihua Univ. (Nat. Sci. Ed.) 2005, 1, 19–20+36. [Google Scholar]

- Duan, L.; Kang, Q.; Shen, G.X. Particle image processing by PIV. J. Beijing Univ. Aeronaut. Astronaut. 2000, 26, 79–82. [Google Scholar]

- Duan, L.; Kang, Q.; Ding, H.Q.; Shen, G.X. Research on HPIV and its preliminary application. J. Beijing Univ. Aeronaut. Astronaut. 2000, 26, 83–86. [Google Scholar]

- Stamhuis, E.J. Basics and principles of particle image velocimetry (PIV) for mapping biogenic and biologically relevant flows. Aquat. Ecol. 2006, 40, 463–479. [Google Scholar] [CrossRef]

- Thielicke, W.; Stamhuis, E.J. PIVlab—Towards User-friendly, Affordable and Accurate Digital Particle Image Velocimetry in MATLAB. J. Open Res. Softw. 2014, 2, 30. [Google Scholar] [CrossRef]

- He, J.; Leng, C.; Liu, B.; Chen, Z.; Li, Z. Analysis of flame characteristics of low calorific value gas diffusion combustion under the action of thermal dynamics. Combust. Theory Model. 2020, 24, 965–982. [Google Scholar] [CrossRef]

- Hurley, M.J.; Gottuk, D.T.; Hall, J.R., Jr.; Harada, K.; Kuligowski, E.D.; Puchovsky, M.; Watts, J.M., Jr.; Wieczorek, C.J. SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Gu, X.; Zang, S.S.; Ge, B. Analysis of Velocity field Characteristics of Flame stability in turbulent combustion with humidification. Gas Turbine Technol. 2006, 2, 30–33. [Google Scholar]

- Zhang, J.H. Application Research of PIV Technology in Pulsating Flame Measurement. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 2013. [Google Scholar]

- Wei, X. Study on flame morphology and flow field of lean premixed combustion. Master’s Thesis, Dalian University of Technology, Dalian, China, 2017. [Google Scholar]

- Shavit, U.; Lowe, R.J.; Steinbuck, J.V. Intensity Capping: A simple method to improve cross-correlation PIV results. Exp. Fluids 2007, 42, 225–240. [Google Scholar] [CrossRef]

- Karel, Z. Contrast Limited Adaptive Histogram Equalization. In Graphics Gems IV; Academic Press Professional, Inc.: Cambridge, MA, USA, 1994; pp. 474–485. [Google Scholar]

- Westerweel, J.; Scarano, F. Universal outlier detection for PIV data. Exp. Fluids 2005, 39, 1096–1100. [Google Scholar] [CrossRef]

- Zhang, Y.Z. Research on PIV Measurement of flat Flame combustion Velocity Field. Master’s Thesis, Inner Mongolia University of Science and Technology, Baotou, China, 2008. [Google Scholar]

- Cai, S.; Zhou, S.; Xu, C.; Gao, Q. Dense motion estimation of particle images via a convolutional neural network. Exp. Fluids 2019, 60, 1–16. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.; Li, C.Q.; Fan, D.C. Study on flow field characteristics of fire plume based on different constrained forms of PIV. China Saf. Sci. J. 2020, 30, 135–141. [Google Scholar]

- Wang, Q.A.; Lu, A.Q.; Liang, X.; Li, J.X.; Palacios, A. Thermal radiation distribution of low-momentum jet diffusion flame under the effect of cross airflow. Fire Saf. J. 2023, 135, 103728. [Google Scholar] [CrossRef]

- Liu, Z.G. Research on Simultaneous Measurement of Temperature and Velocity Distribution in Combustion flow Field. Master’s Thesis, Qingdao University of Science and Technology, Qingdao, China, 2018. [Google Scholar]

- Xu, X.H.; Gong, Z.J.; Zhao, Z.W. PIV study of cold axial velocity Field in the main combustion zone of flat Flame combustion. J. Baotou Iron Steel Inst. 2006, 3, 218–221. [Google Scholar]

- Zhang, W. The Interaction between Gas Phase Flame and Solid Surface in Steady State and Accelerated Fire Propagation. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2023. [Google Scholar]

- Lagemann, C.; Lagemann, K.; Mukherjee, S.; Schrder, W. Deep recurrent optical flow learning for particle image velocimetry data. Nat. Mach. Intell. 2021, 3, 641–651. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, H.P. Eigenorthogonal decomposition of bad vector of PIV Velocity Field. J. Exp. Mech. 2013, 28, 199–206. [Google Scholar]

- Wang, H.P.; Gao, Q.; Feng, L.H.; Wei, R.J.; Wang, J.J. Proper orthogonal decomposition based outlier correction for PIV data. Exp. Fluids 2015, 56, 1–15. [Google Scholar] [CrossRef]

| Serial Number | Name | Specification | Operating Parameters |

|---|---|---|---|

| 1 | Propane gas cylinder | 40 L | Working pressure: 0.3–0.9 MPa |

| 2 | TiO2 | 10 μm | - |

| 3 | Copper pipe | Inner diameter: 20 mm | - |

| 4 | Sleeve | Cylinder: h × d = 100 mm × 10 mm | - |

| 5 | Burner | Plum blossom burner | - |

| 6 | Flowmeter | Gas Roots flowmeter HK15-G10 | 0.5 m3/h–16 m3/hTolerance value: ±1.5% |

| 7 | Air compressor | SECOP SC21CL R404 104L2322 | Working pressure: 0.9 MPa |

| 8 | Air filter | AC20A-B | Pressure range: 0.06–0.85 MPaFiltration precision: 5 μm |

| 9 | Ground glass bead | Diameter: 6 mm | - |

| 10 | Plexiglass cover | L × D × H = 1000 mm × 500 mm × 800 mm | - |

| 11 | Iron stand | L × D × H = 1000 mm × 500 mm × 700 mm | - |

| 12 | laser | MGL-FN-532 | Output wavelength: 532 nm |

| 13 | CCD camera | Huagu Power WP-UT130 | Offset angle: 30° |

| 14 | Colour filter | TXLGPZD532 | Resolution: 1280 × 1024 |

| Item | Physical and Chemical Properties |

|---|---|

| Molecular formula | C3H8 |

| Molecular weight | 44.09 |

| Density (kg/m3) | 1.83 |

| Ignition temperature °C | 450 |

| Heat of combustion MJ/kg | 46.36 |

| PH value | 6.0–8.0 |

| Materials | Melting Point (°C) | Density (g/cm3) | Follow Characteristics |

|---|---|---|---|

| TiO2 | 1850 | 4.23 | 0.9992 |

| Al2O3 | 2040 | 3.97 | 0.9993 |

| MgO | 2852 | 3.58 | 0.9994 |

| ZrO2 | 2700 | 5.89 | 0.9988 |

| SiO2 | 1670 | 2.66 | 0.9998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Guo, J.; Chi, Z.; Zhao, B.; Zhao, S. Analysis of Flow Field Characteristics of the Propane Jet Combustion Flame. Fire 2023, 6, 464. https://doi.org/10.3390/fire6120464

Li S, Guo J, Chi Z, Zhao B, Zhao S. Analysis of Flow Field Characteristics of the Propane Jet Combustion Flame. Fire. 2023; 6(12):464. https://doi.org/10.3390/fire6120464

Chicago/Turabian StyleLi, Shengnan, Jingjing Guo, Zheng Chi, Bo Zhao, and Shuai Zhao. 2023. "Analysis of Flow Field Characteristics of the Propane Jet Combustion Flame" Fire 6, no. 12: 464. https://doi.org/10.3390/fire6120464

APA StyleLi, S., Guo, J., Chi, Z., Zhao, B., & Zhao, S. (2023). Analysis of Flow Field Characteristics of the Propane Jet Combustion Flame. Fire, 6(12), 464. https://doi.org/10.3390/fire6120464