Fire Hazard Analysis on Different Fire Source Locations in Multi-Segment Converging Tunnel with Structural Beams

Abstract

:1. Introduction

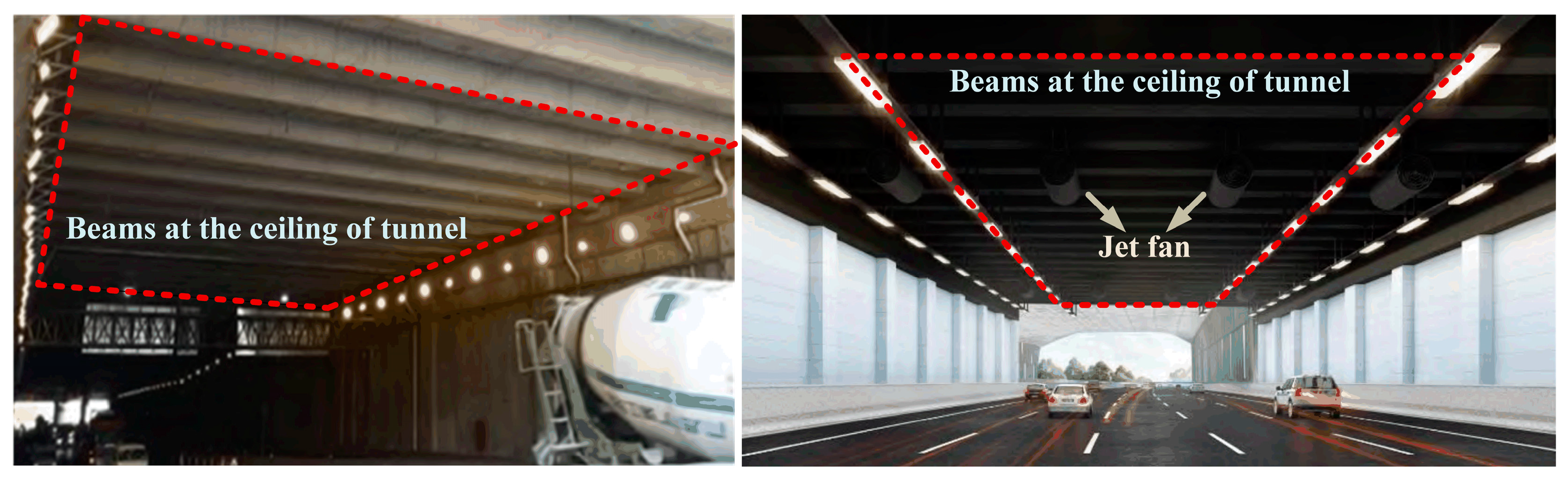

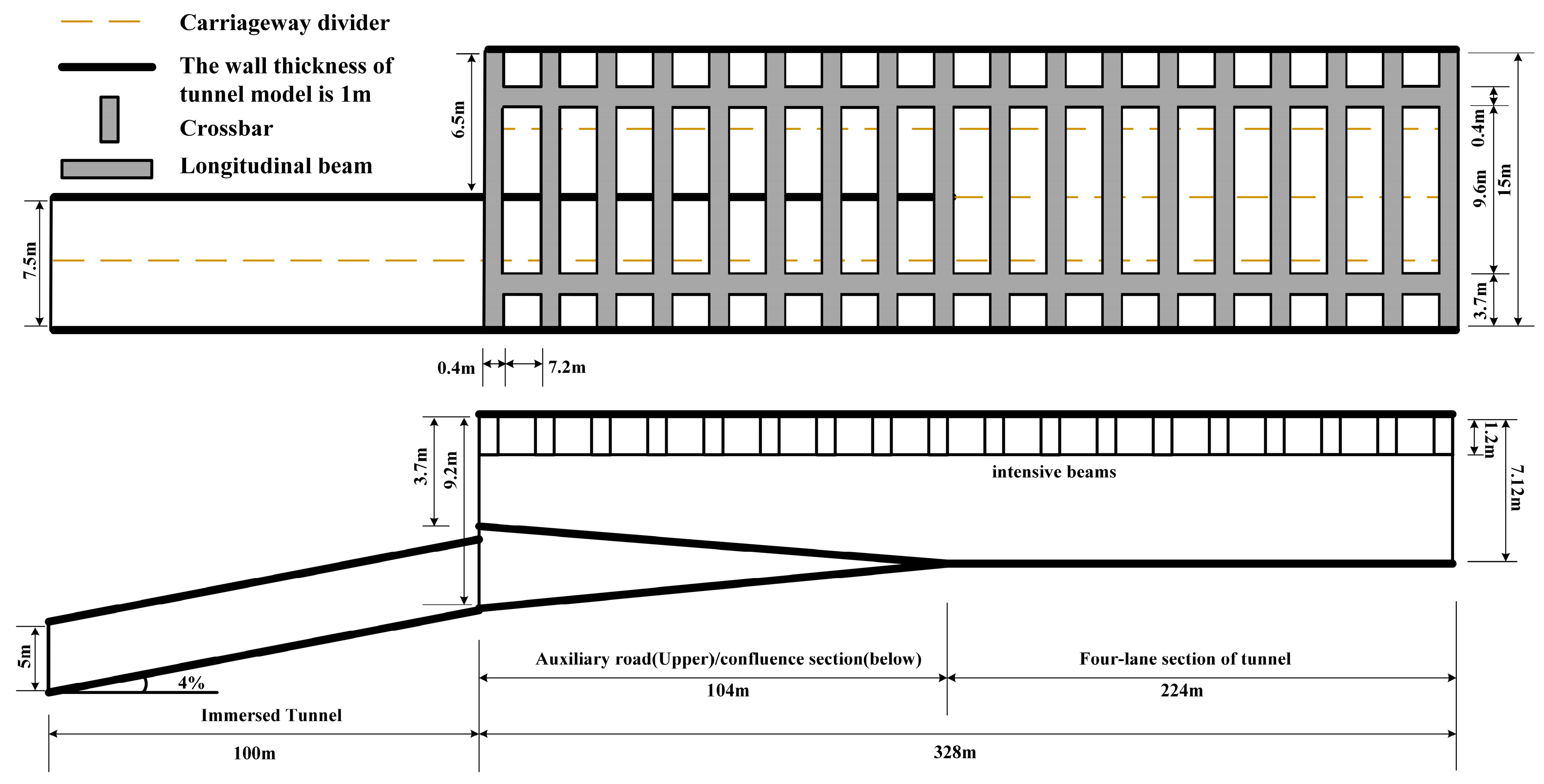

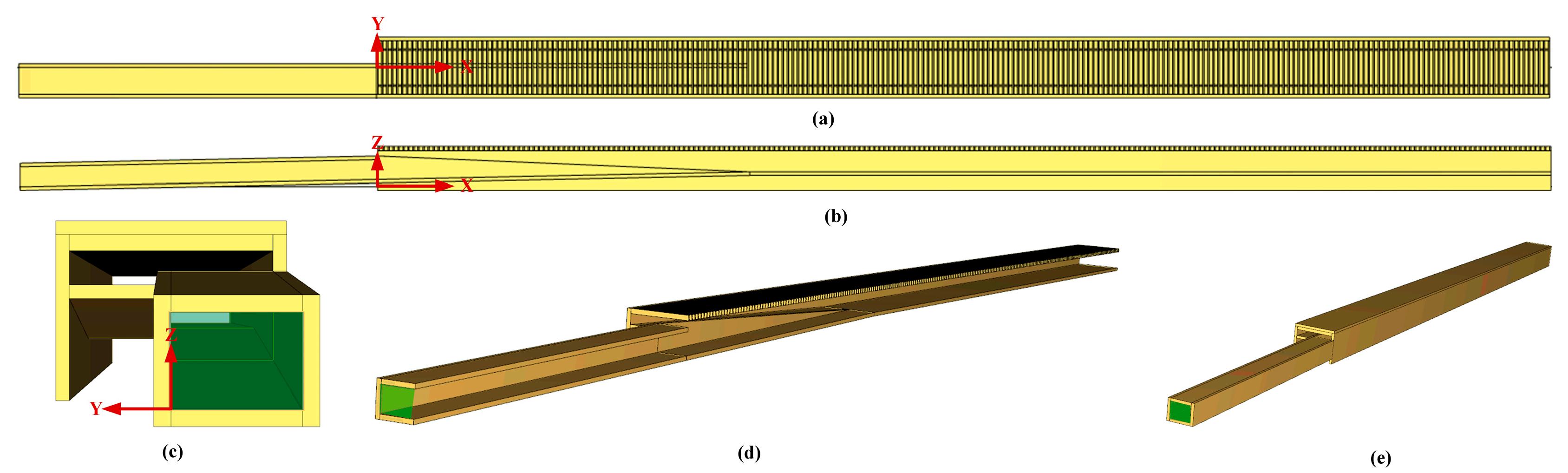

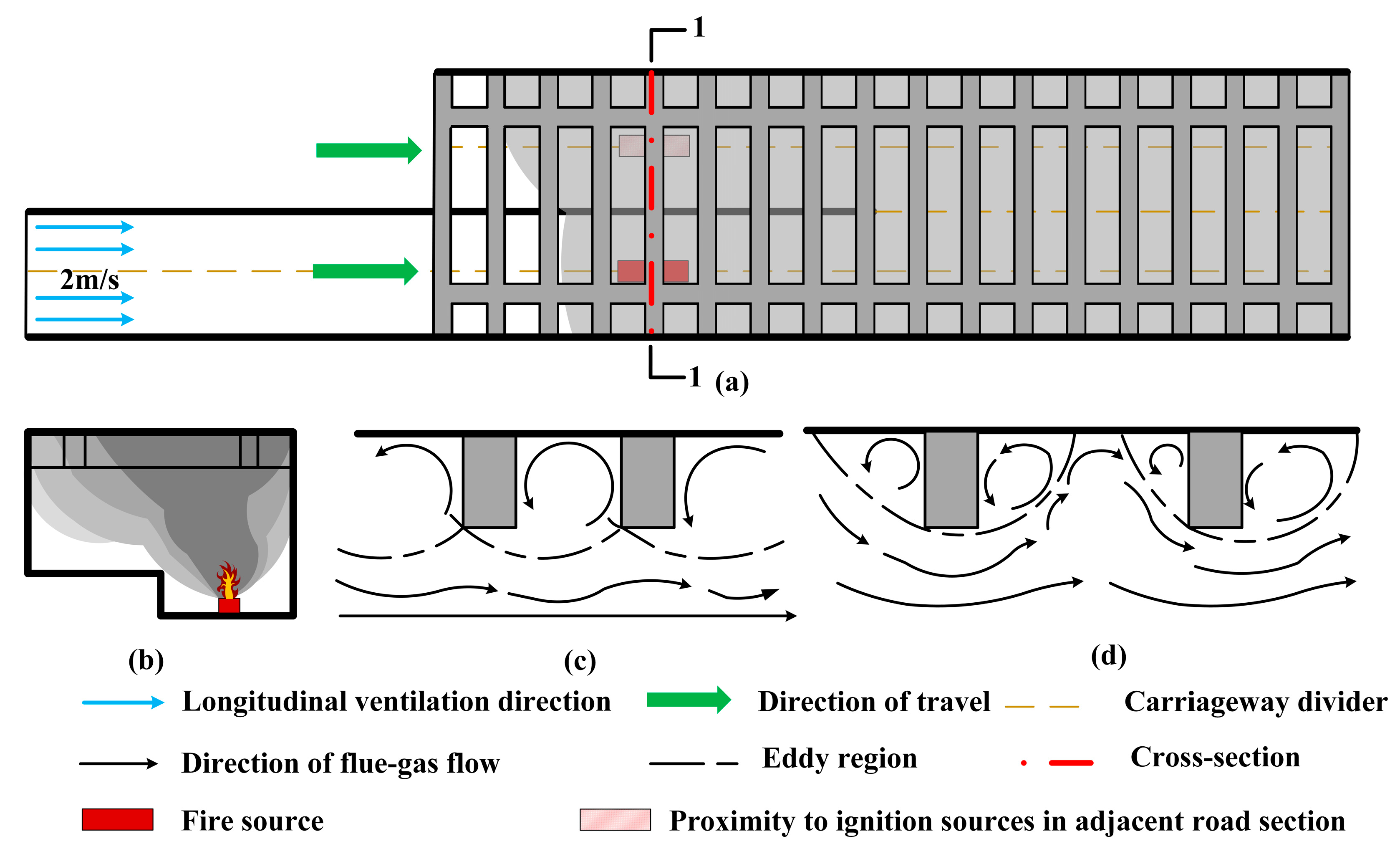

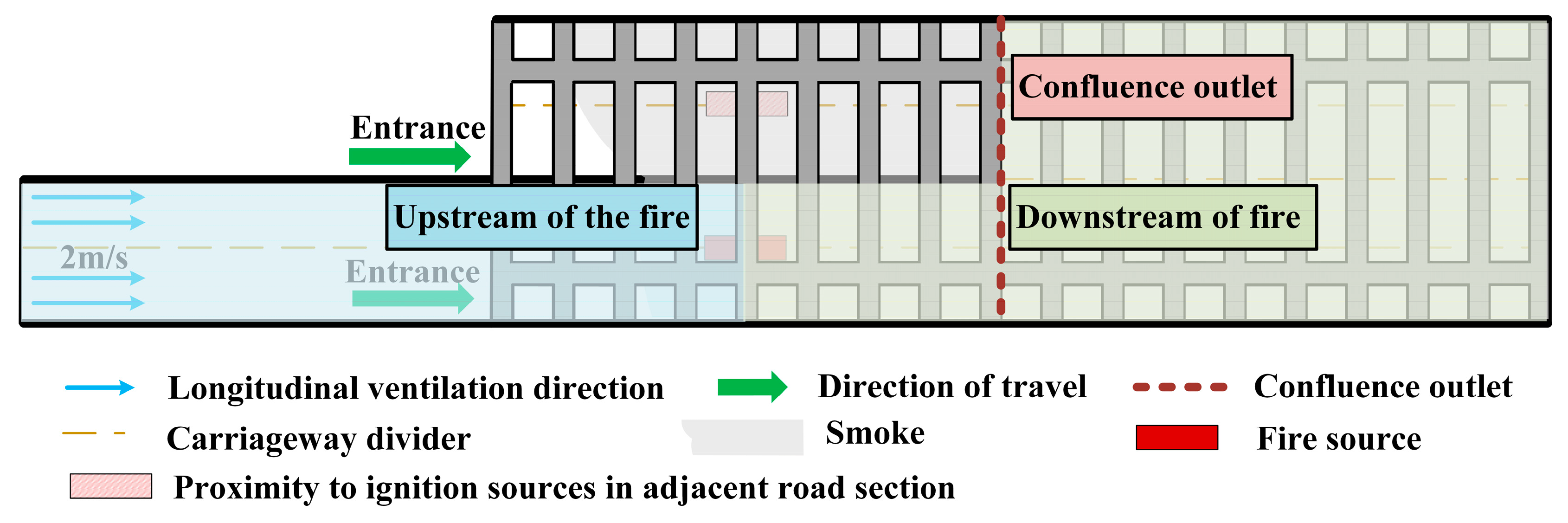

2. Materials and Methods

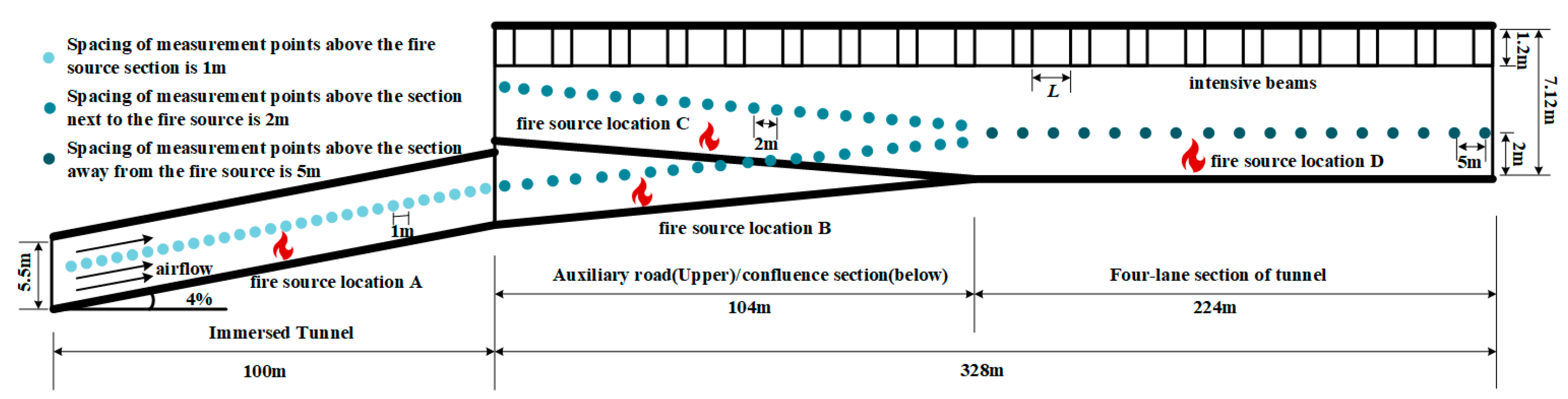

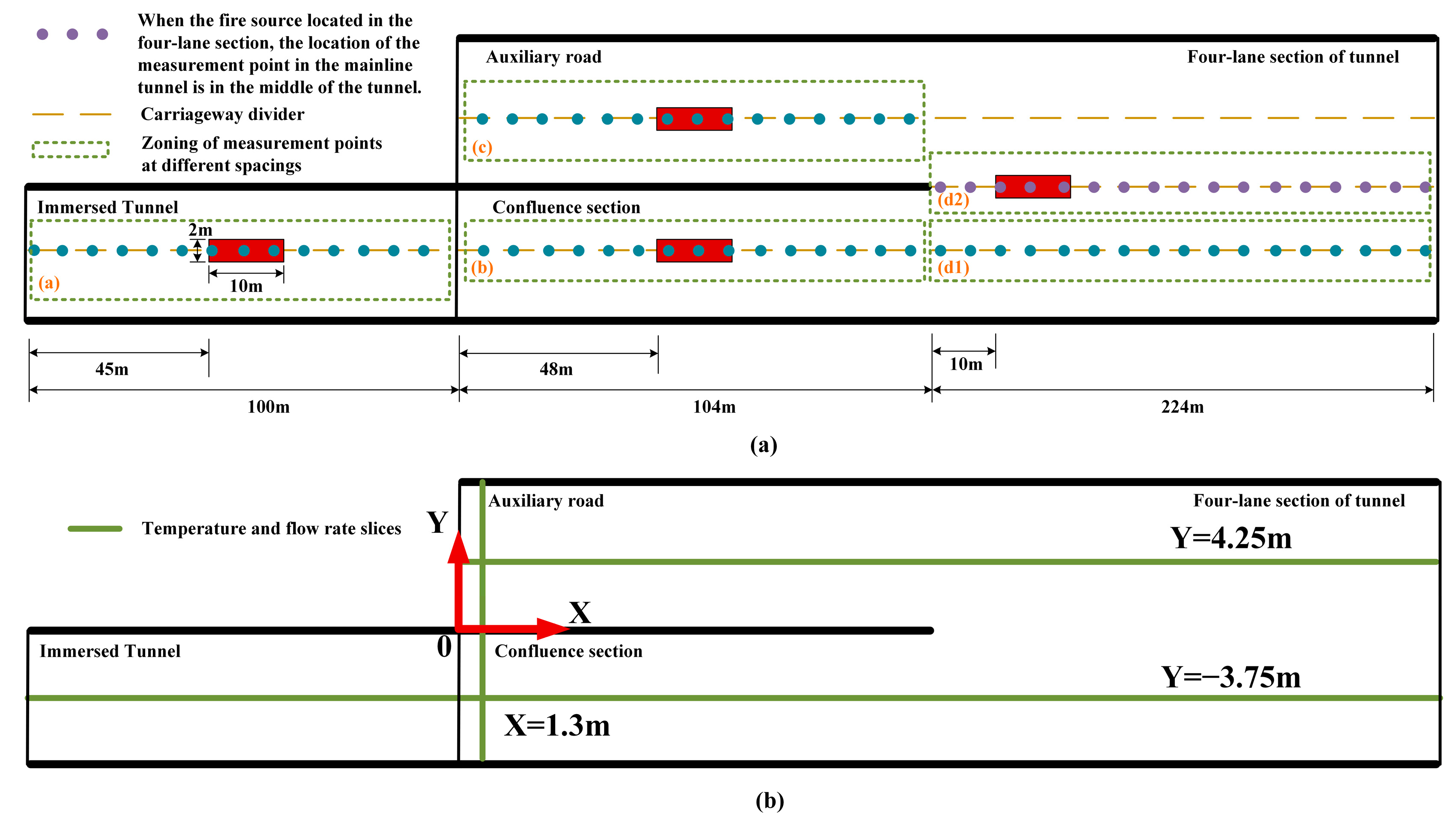

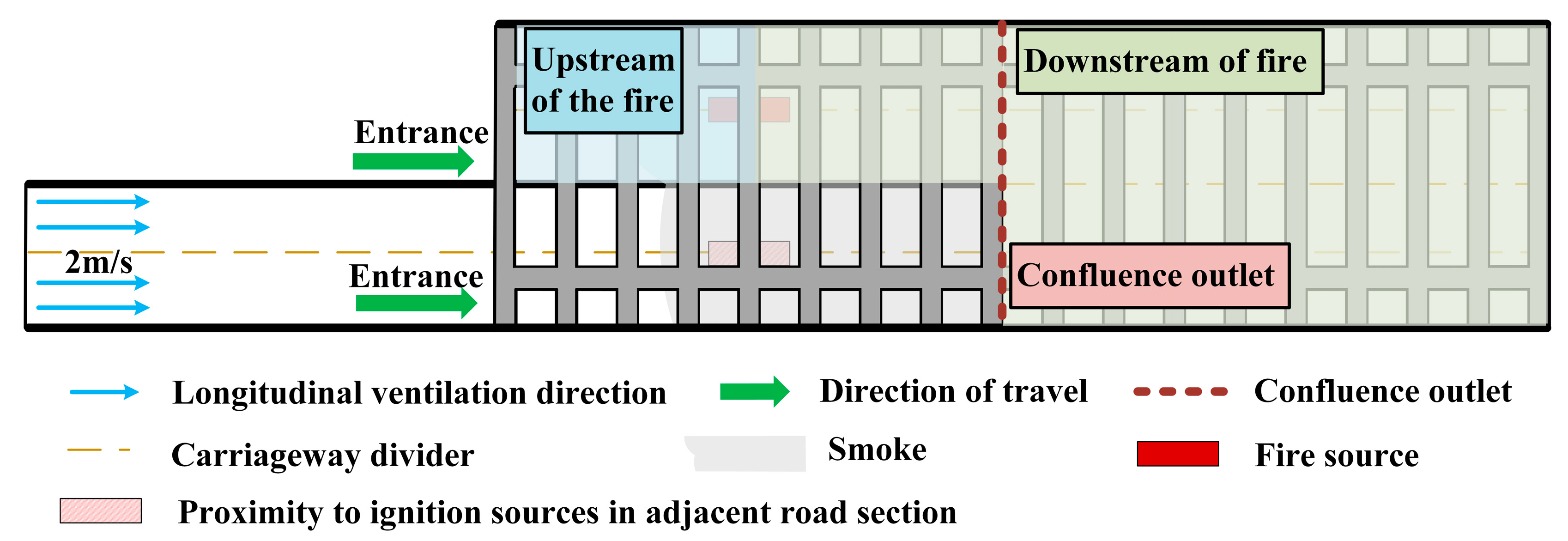

2.1. Model Settings

2.2. Boundary Conditions

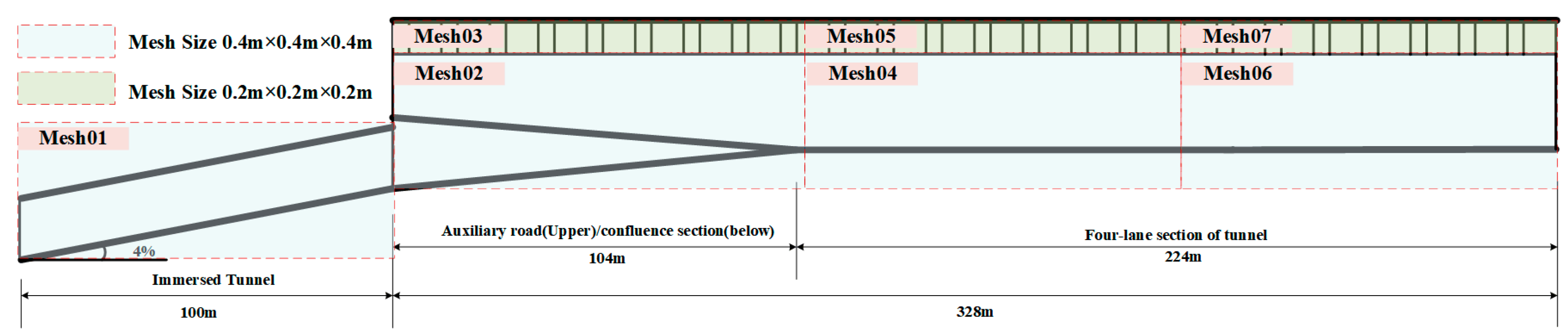

2.3. Grid Division

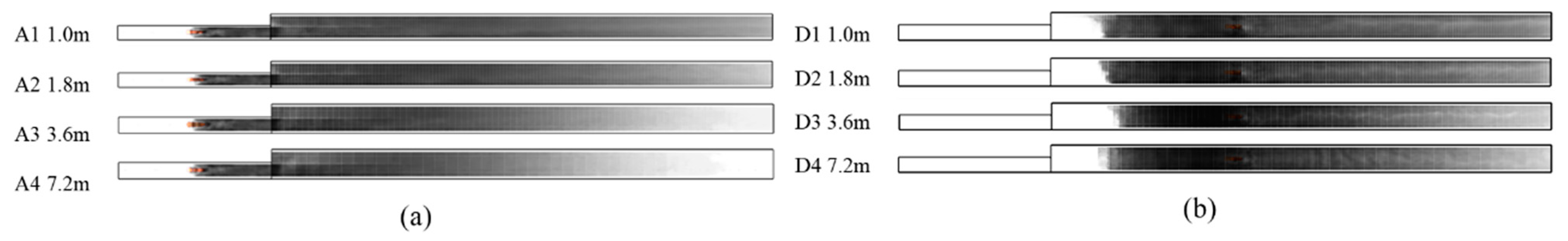

2.4. Working Condition Settings

3. Results and Discussion

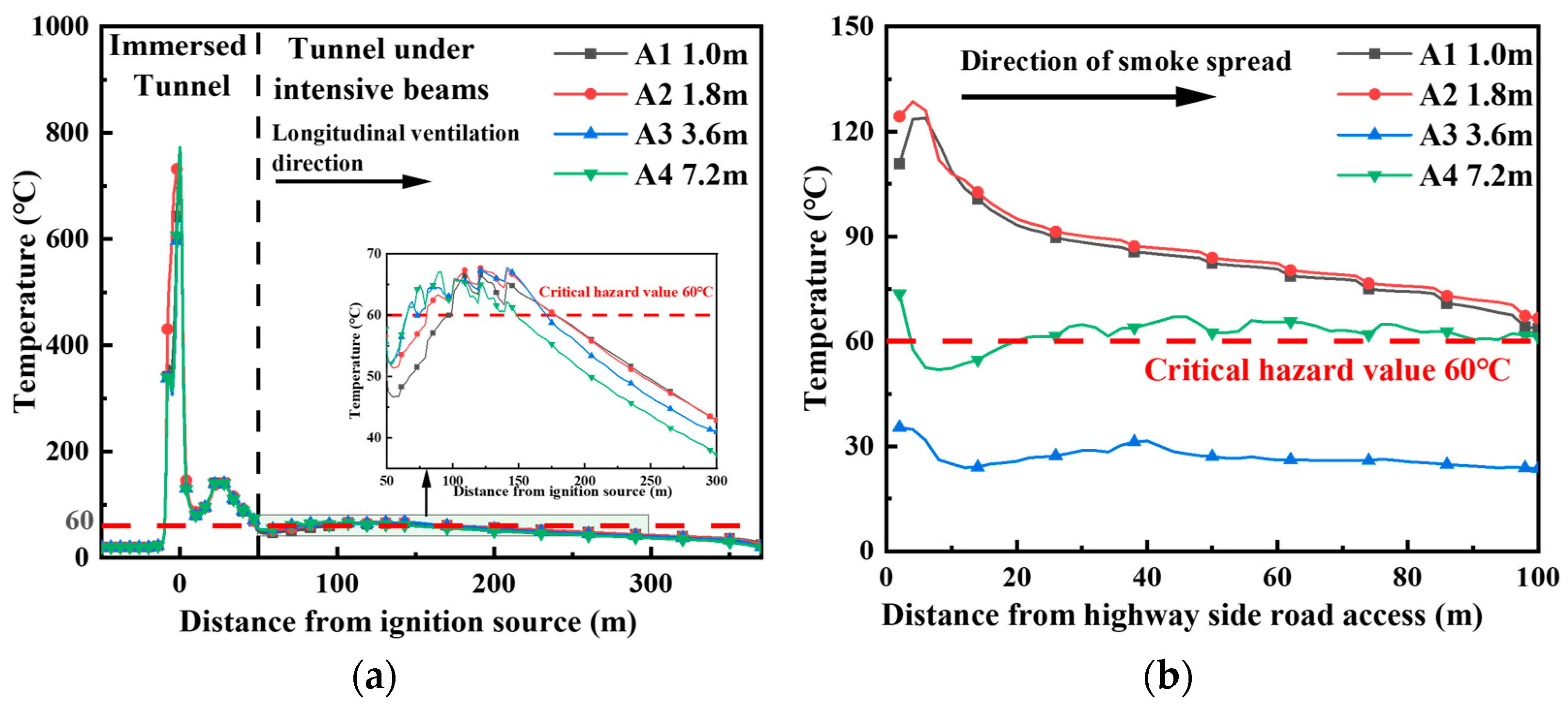

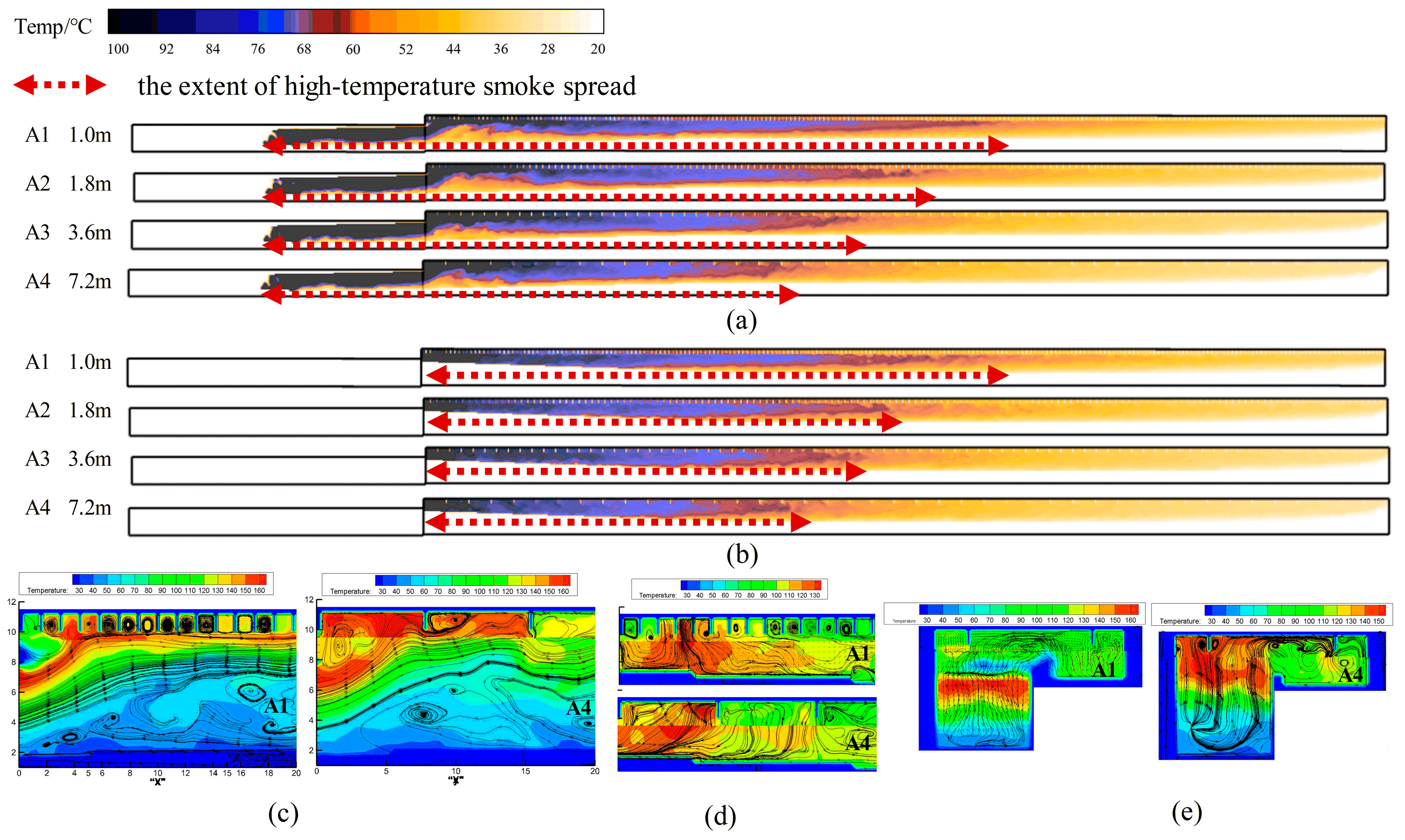

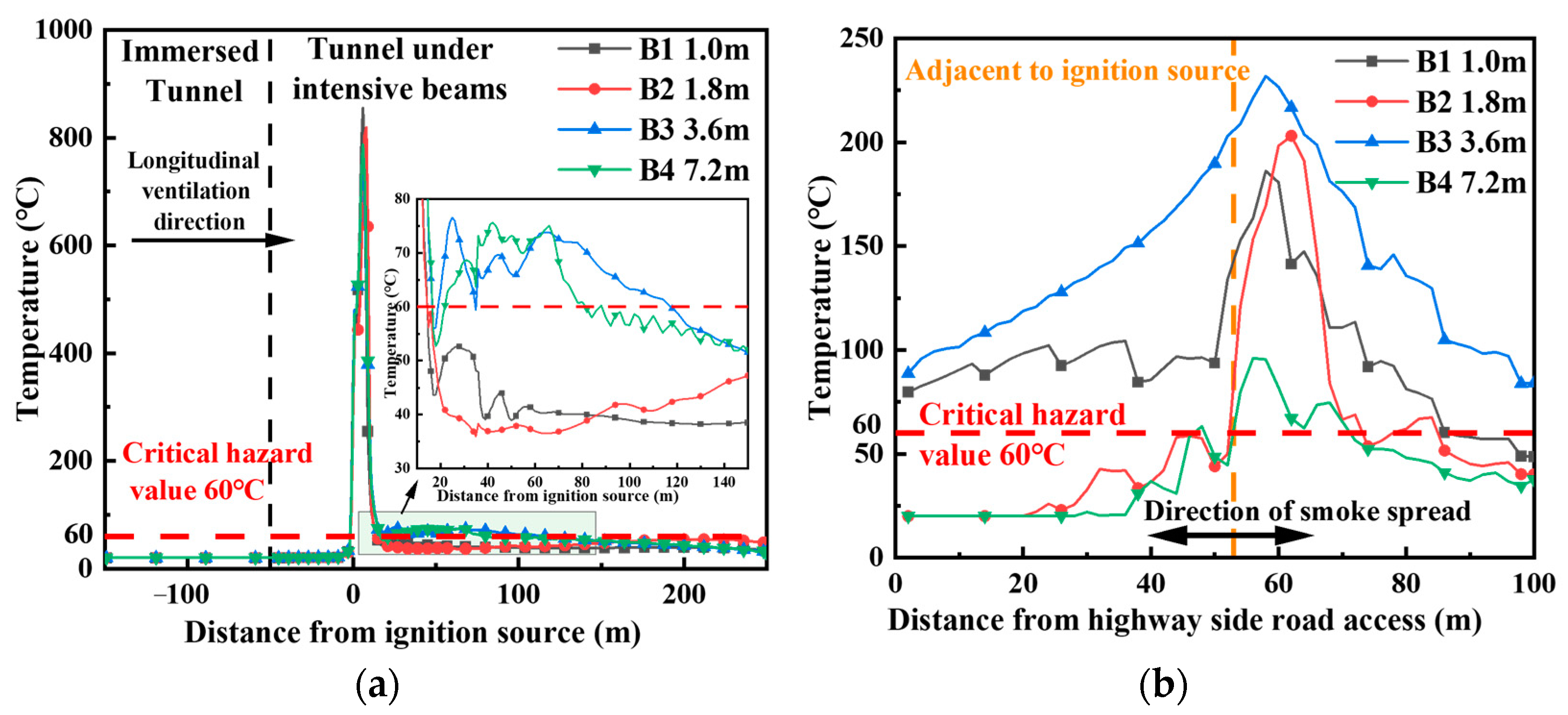

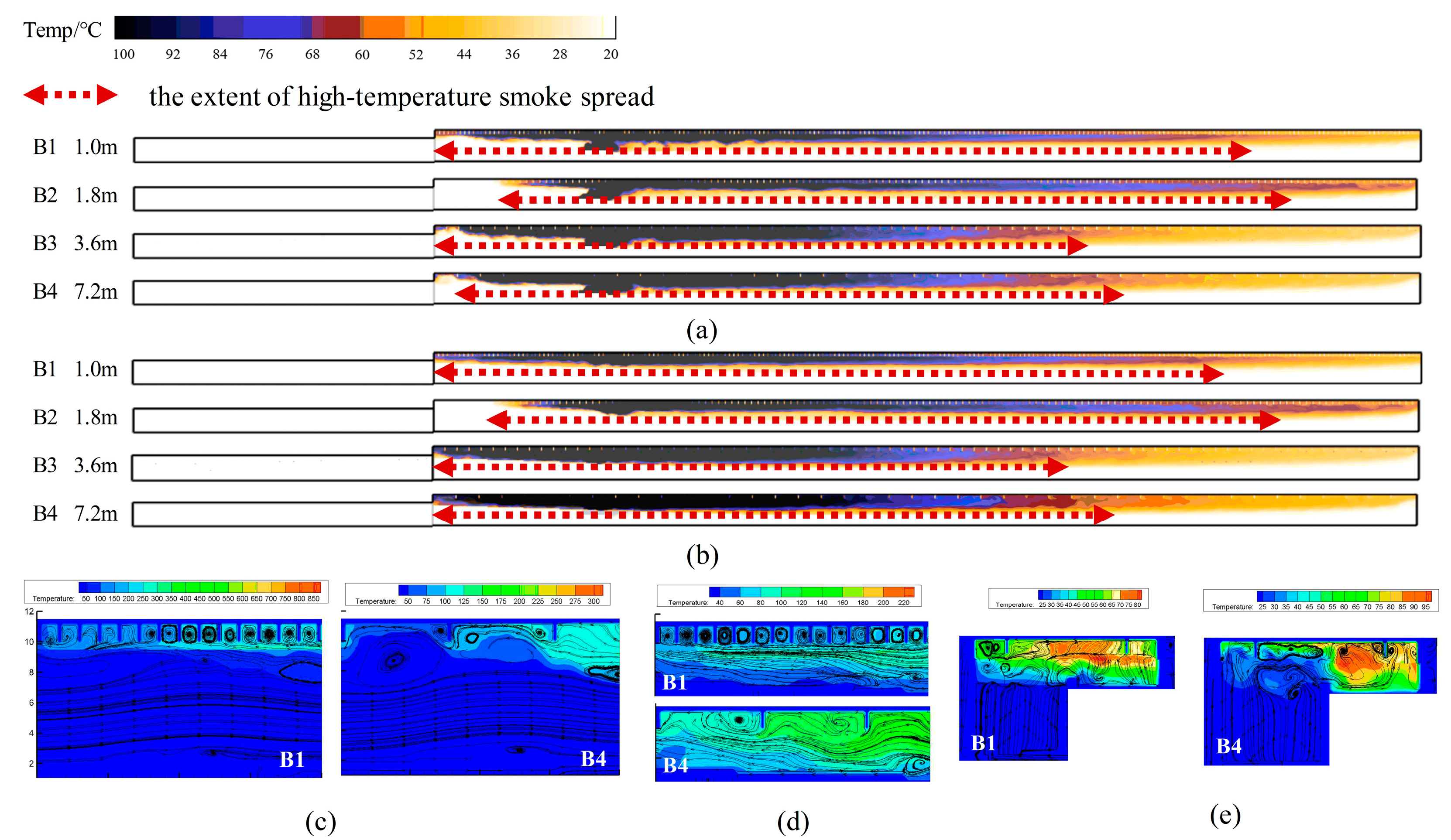

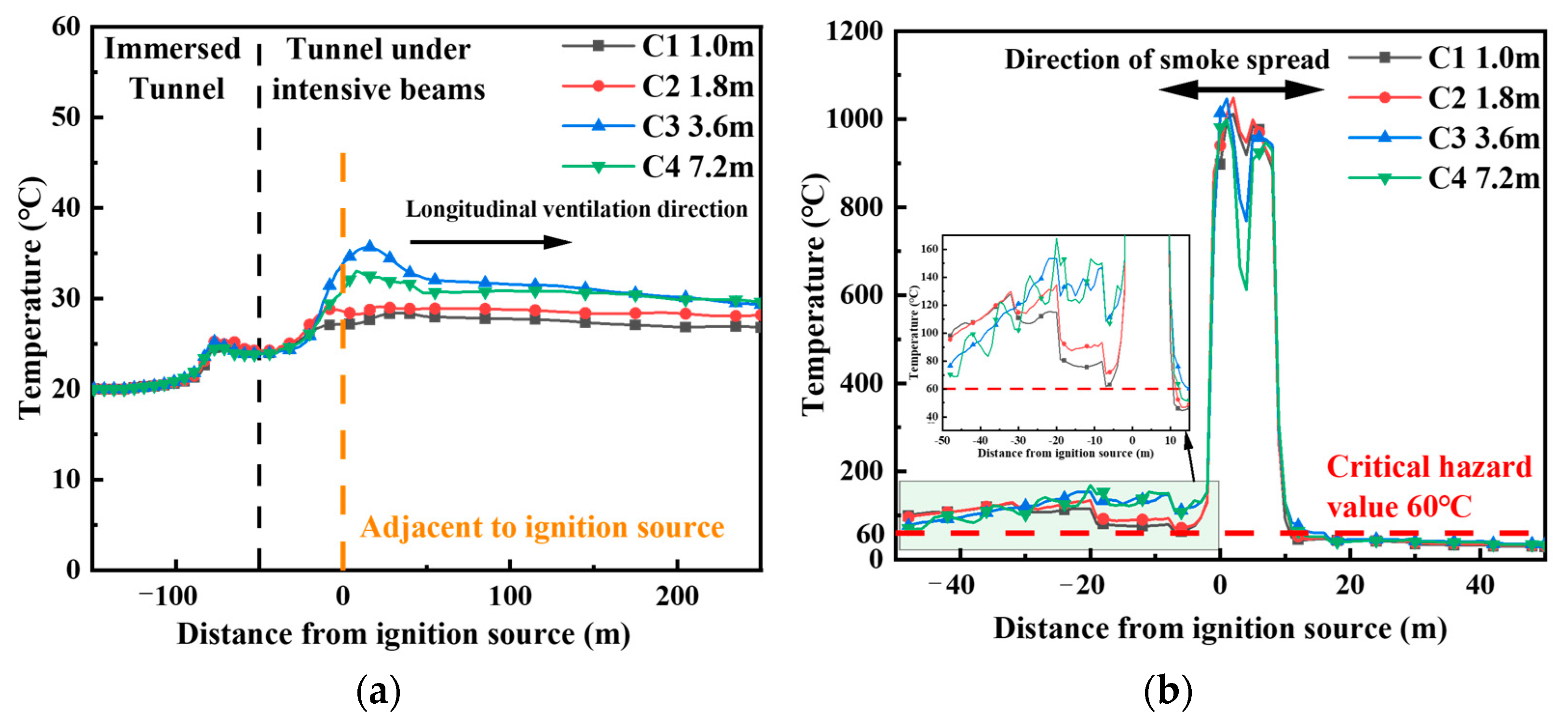

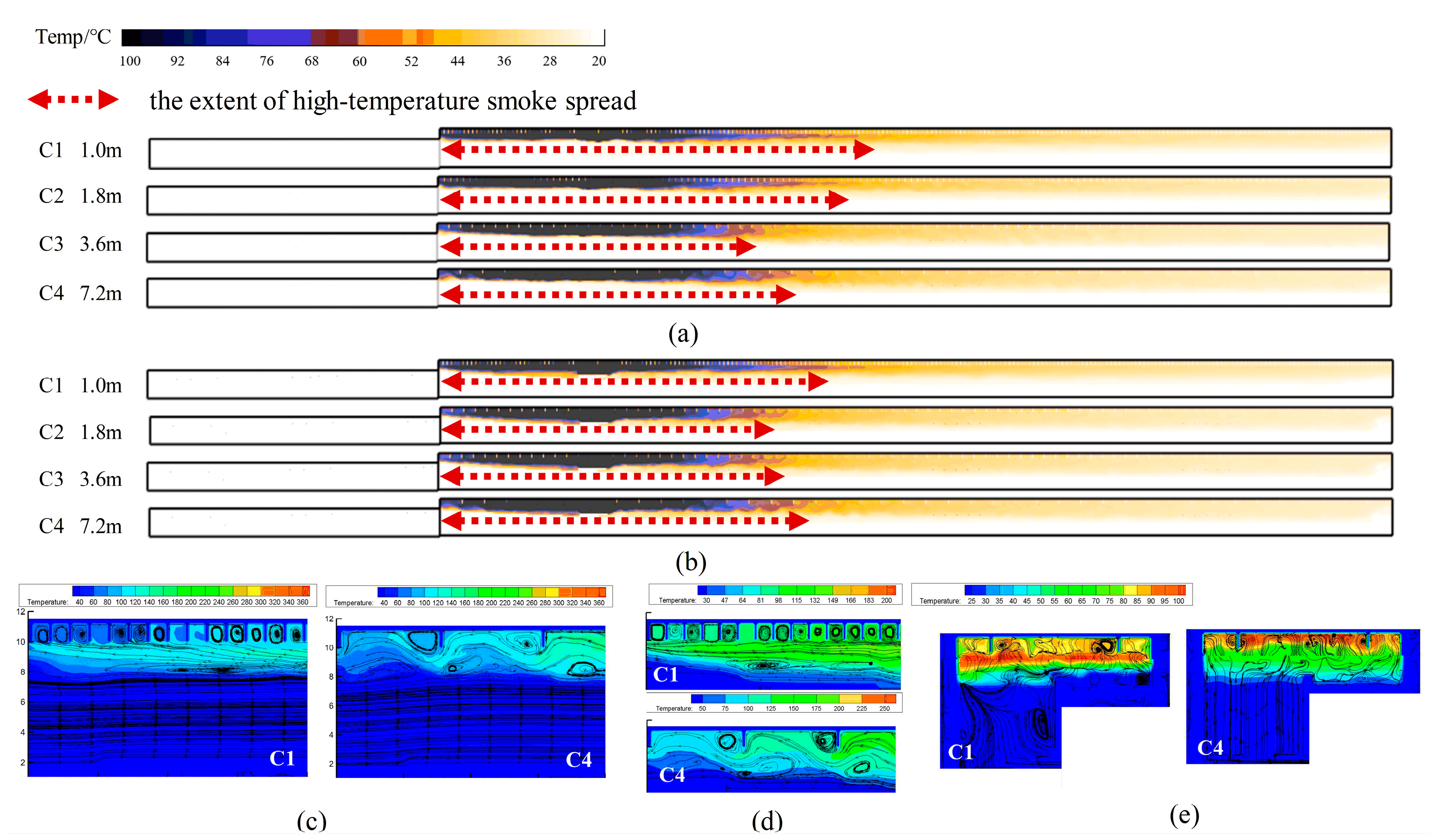

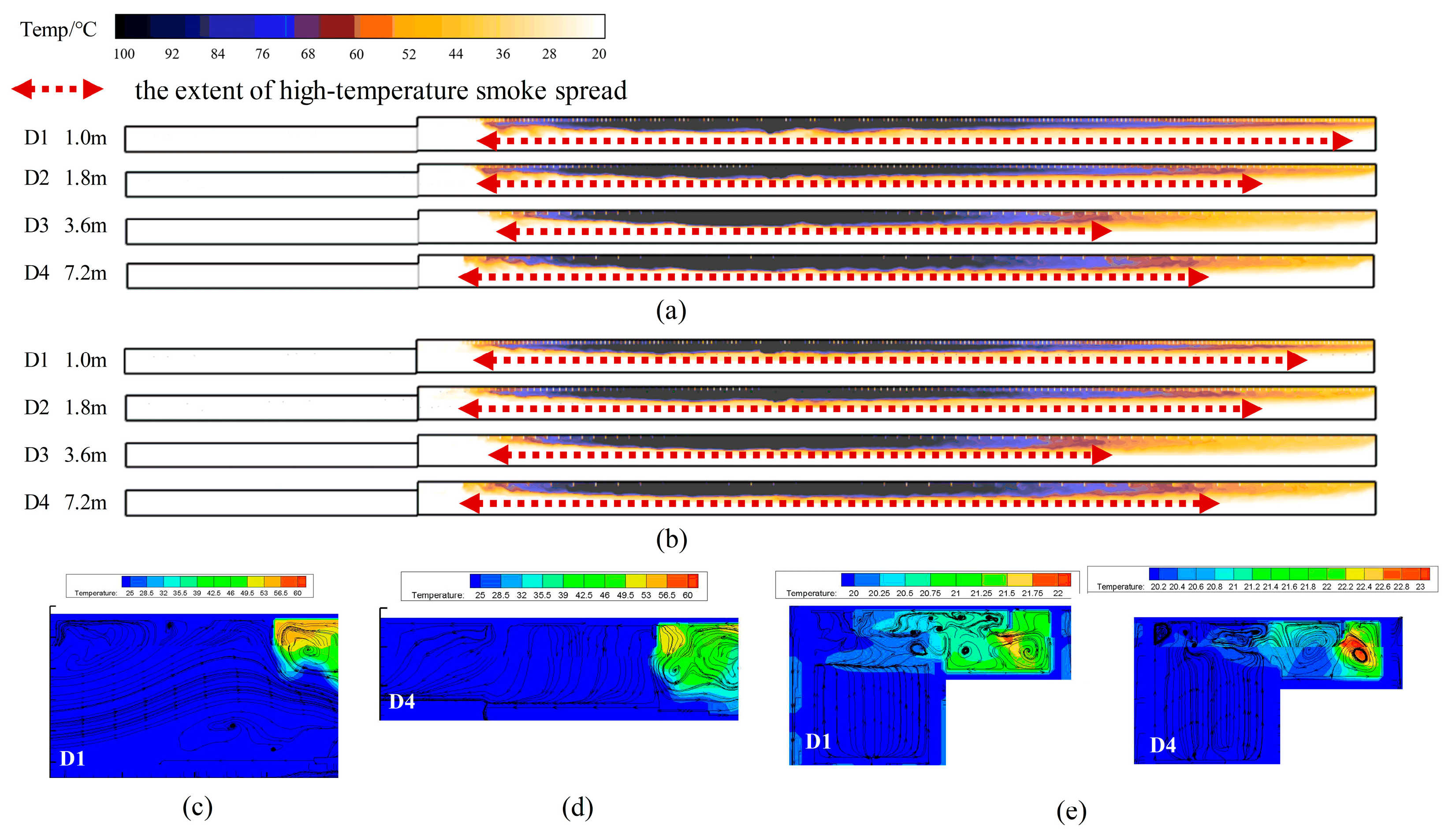

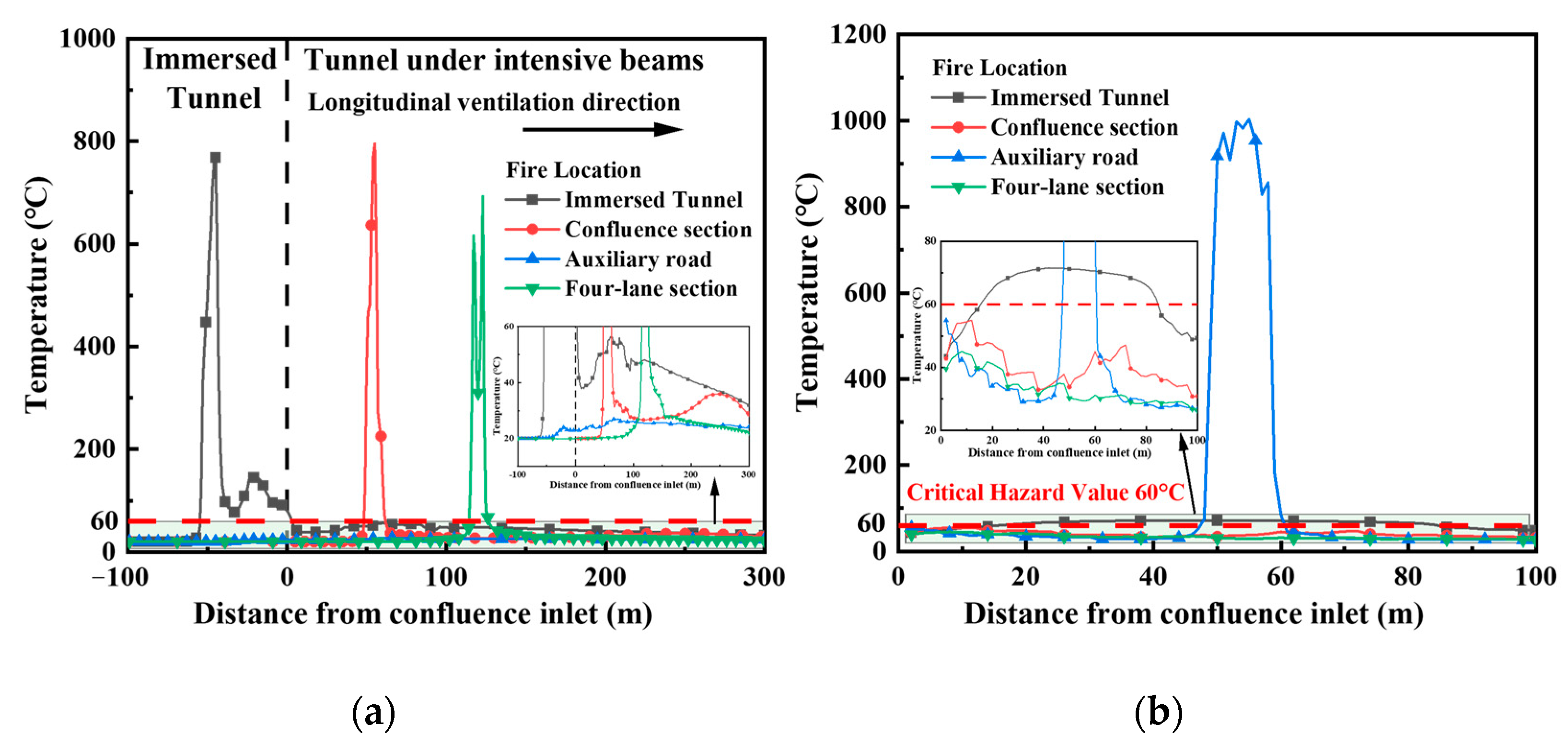

3.1. Temperature Distribution in the Tunnel at Different Fire Locations

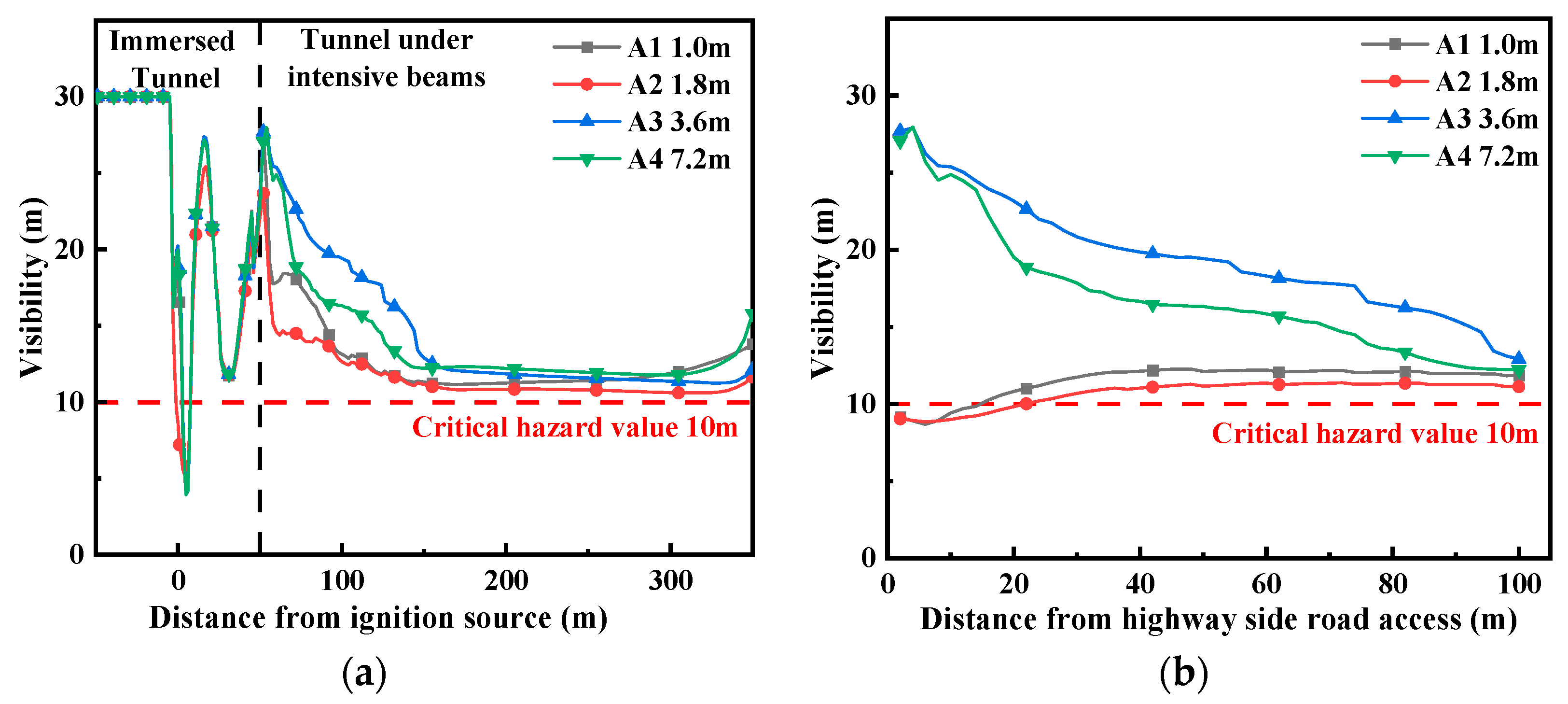

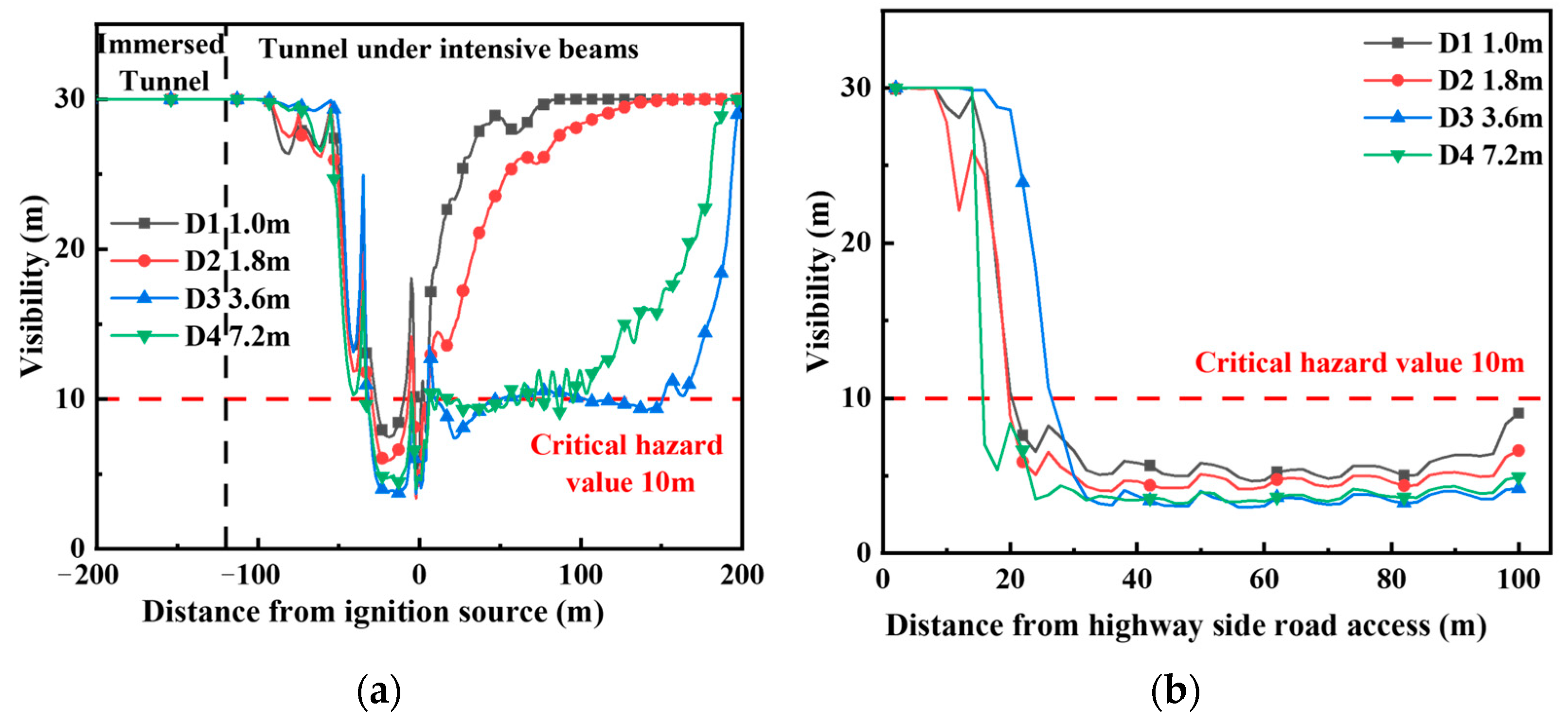

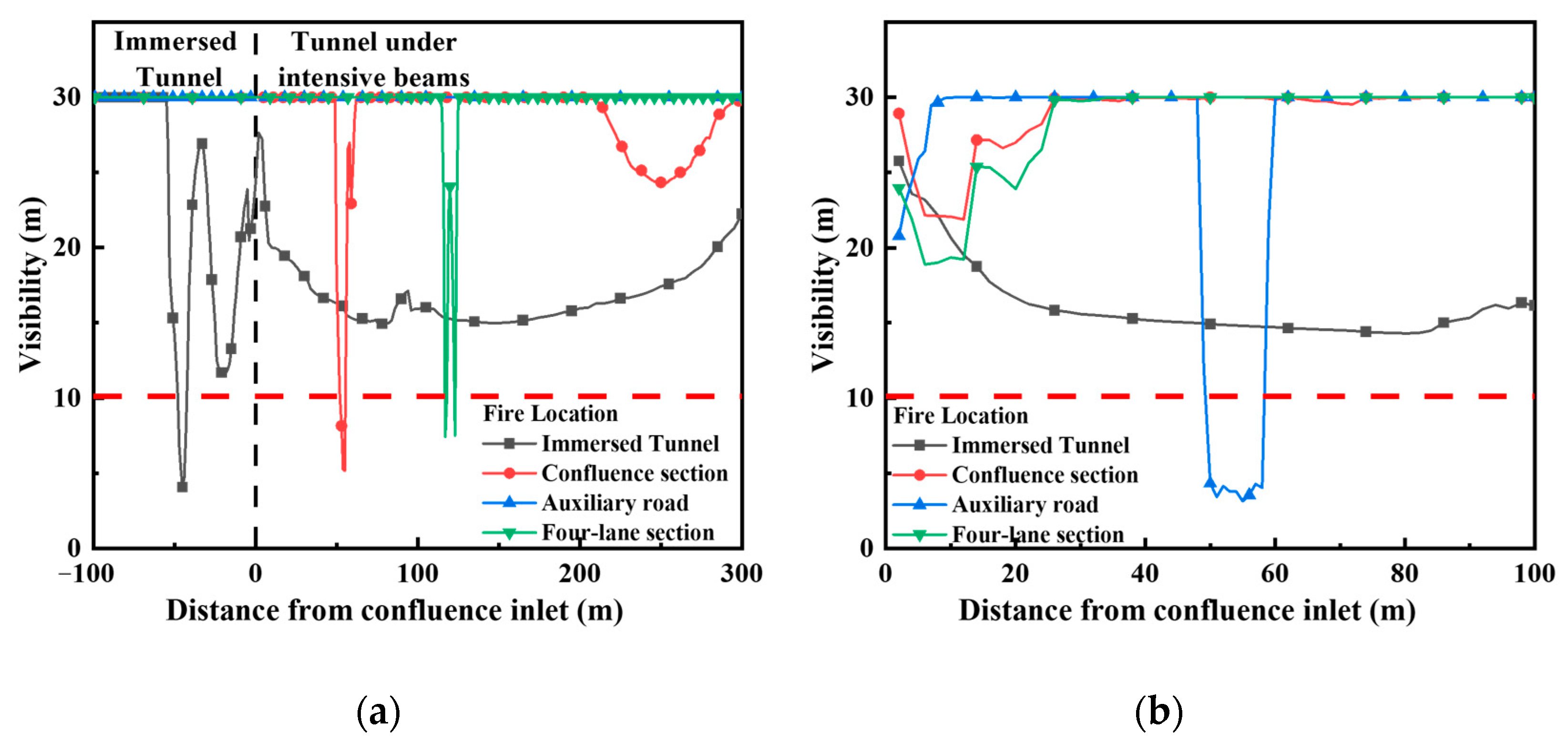

3.2. Distribution of Tunnel Visibility at Different Fire Locations

3.3. Tunnel Fire Safety Analysis

4. Conclusions

- Increased beam grid spacing enhances the smoke storage capacity and reduces the distance smoke can spread but disrupts the stability of the smoke layer, resulting in a thicker smoke layer, higher temperatures, and reduced visibility at a 2 m height. Increased spacing between the beams undermines the stability of the smoke layer, causing the deposition of high-temperature smoke, a rise in the temperature of the fire scene, and diminished visibility. This heightened risk poses challenges for the evacuation environment during tunnel fires.

- Regardless of the location of the fire, larger beam grid spacing results in a slower rate of smoke spread. A spacing of 3.6 m minimizes the range of the smoke spread. However, when the fire source is in the four-lane section, due to uneven ventilation wind speed distribution, the smoke return rate above the highway auxiliary road is faster than in the converging section.

- The beam lattice structure on the tunnel’s ceiling heightens the fire hazard, especially with larger beam lattice spacing, which signifies a more perilous fire evacuation environment. In such scenarios, ensuring the safe evacuation of vehicles and individuals becomes crucial, necessitating additional firefighting assistance. This is particularly critical when the fire originates in the four-lane section. With a girder spacing of 7.2 m, the evacuation hazardous area has expanded by 197 m, approximately 46% of the tunnel length, compared to the condition without beam grids. Furthermore, the evacuation environment in the auxiliary roadway becomes perilous, demanding heightened attention.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, L.; Mao, P.; Zhang, Y.; Xing, S.; Li, T. Experimental study on smoke characteristics of bifurcated tunnel fire. Tunn. Undergr. Space Technol. 2020, 98, 103295. [Google Scholar] [CrossRef]

- Zhong, W.; Li, Z.; Wang, T.; Liang, T.; Liu, Z. Experimental Study on the Influence of Different Transverse Fire Locations on the Critical Longitudinal Ventilation Velocity in Tunnel Fires. Fire Technol. 2015, 51, 1217–1230. [Google Scholar] [CrossRef]

- Huang, P.; Ye, S.; Xie, J.; Chen, M.; Liu, C.; Yu, L. Study on the maximum and longitudinal distribution of ceiling gas temperature in a naturally ventilated tunnel: The effect of longitudinal fire location. Int. J. Therm. Sci. 2023, 185, 108037. [Google Scholar] [CrossRef]

- Zhao, P.; Chen, T.; Yuan, Z.; Xie, Y.; Yu, N. Critical shaft height for complete smoke exhaustion during fire at the worst longitudinal fire location in tunnels with natural ventilation. Fire Saf. J. 2020, 116, 103207. [Google Scholar] [CrossRef]

- Haddad, R.K.; Zulkifli, R.; Maluk, C.; Harun, Z. Experimental Investigation on the Influences of Different Horizontal Fire Locations on Smoke Temperature Stratification under Tunnel Ceiling. J. Appl. Fluid Mech. 2020, 13, 1289–1298. [Google Scholar] [CrossRef]

- Gannouni, S. Critical velocity for preventing thermal backlayering flow in tunnel fire using longitudinal ventilation system: Effect of floor-fire separation distance. Int. J. Therm. Sci. 2022, 171, 107192. [Google Scholar] [CrossRef]

- Barbato, L.; Cascetta, F.; Musto, M.; Rotondo, G. Fire safety investigation for road tunnel ventilation systems–An overview. Tunn. Undergr. Space Technol. 2014, 43, 253–265. [Google Scholar] [CrossRef]

- Xu, G.; Zhu, G.; Pan, R.; Liu, X. Investigation on temperature distribution under the coupling action of transverse position and fire sealing of linear fire in tunnel. Case Stud. Therm. Eng. 2021, 26, 101032. [Google Scholar] [CrossRef]

- Guo, F.; Ding, L.; Ji, J.; Gao, Z.; Yu, L. Effects of longitudinal wind and sidewall restriction on downstream radiative heat flux and temperature rise distribution in tunnel fires. Fire Saf. J. 2022, 134, 103689. [Google Scholar] [CrossRef]

- Li, Z.; Luo, Y.; Gao, Y.; Yang, X.; Guo, H.; Zhang, Y. Experimental and Theoretical Studies of the Effects of Fire Location on the Smoke Temperature Distribution in a Branched Tunnel. Fire Technol. 2022, 58, 1265–1284. [Google Scholar] [CrossRef]

- Qiu, D.Z.; Yang, J.; Liu, C.X.; Zheng, Y.H.; Zheng, J.H. Experimental study on temperature distribution beneath tunnel ceiling under the condition of transverse double fire sources. Tunn. Undergr. Space Technol. 2023, 132, 104889. [Google Scholar] [CrossRef]

- Liu, C.; Zhong, M.; Tian, X.; Zhang, P.; Xiao, Y.; Mei, Q. Experimental and numerical study on fire-induced smoke temperature in connected area of metro tunnel under natural ventilation. Int. J. Therm. Sci. 2019, 138, 84–97. [Google Scholar] [CrossRef]

- Ura, F.; Kawabata, N.; Tanaka, F. Characteristics of smoke extraction by natural ventilation during a fire in a shallow urban road tunnel with ceiling openings. Fire Saf. J. 2014, 67, 96–106. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, J.; Zhu, D. Full-scale experiment research and theoretical study for fires in tunnels with ceiling openings. Fire Saf. J. 2009, 44, 339–348. [Google Scholar] [CrossRef]

- Tanaka, F.; Kawabata, N.; Ura, F. Effects of a transverse external wind on natural ventilation during fires in shallow urban road tunnels with ceiling openings. Fire Saf. J. 2016, 79, 20–36. [Google Scholar] [CrossRef]

- Chen, R.; Guo, Z.; Liu, Y.; Yang, Y.; Tan, Q. Numerical Study of the Effect of Different Transverse Fire Locations on Smoke Mass Flow Rate in Tunnel Fires. Fire Technol. 2023, 59, 2567–2586. [Google Scholar] [CrossRef]

- Lu, K.; Xia, K.; Shi, C.; Yang, M.; Wang, J.; Ding, Y. Investigation on the Tunnel Curvature Effect upon the Ceiling Temperature of Tunnel Fires: A Numerical Simulation. Fire Technol. 2021, 57, 2839–2858. [Google Scholar] [CrossRef]

- Chow, W.K.; Gao, Y.; Zhao, J.H.; Dang, J.F.; Chow, C.L.; Miao, L. Smoke movement in tilted tunnel fires with longitudinal ventilation. Fire Saf. J. 2015, 75, 14–22. [Google Scholar] [CrossRef]

- Zhao, Z.; Tang, F.; Wang, Q.; Qin, Z. Experimental study on the characteristics of fire smoke longitudinal crossflow in adjacent tunnels. Tunn. Undergr. Space Technol. 2021, 114, 103992. [Google Scholar] [CrossRef]

- Zhu, Z.; Guo, Q.; Quiel, S.E.; Naito, C.J. Rapid prediction of fire-induced heat flux on the liners of horseshoe and circular tunnels with longitudinal ventilation at critical velocity. Fire Saf. J. 2022, 130, 103590. [Google Scholar] [CrossRef]

- Tian, X.; Liu, C.; Zhong, M. Numerical and experimental study on the effects of a ceiling beam on the critical velocity of a tunnel fire based on virtual fire source. Int. J. Therm. Sci. 2021, 159, 106635. [Google Scholar] [CrossRef]

- Chaabat, F.; Creyssels, M.; Mos, A.; Wingrave, J.; Correia, H.; Marro, M.; Salizzoni, P. The effects of solid barriers and blocks on the propagation of smoke within longitudinally ventilated tunnels. Build. Environ. 2019, 160, 106207. [Google Scholar] [CrossRef]

- Halawa, T.; Safwat, H. Fire-smoke control strategies in road tunnels: The effectiveness of solid barriers. Case Stud. Therm. Eng. 2021, 27, 101260. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, Y.; Shi, L.; Wu, Y.; Wang, J.; Liu, J.; Yao, Y. Numerical study on lateral centralized smoke extraction in immersed tunnel with a new-style inclined smoke barrier. Case Stud. Therm. Eng. 2023, 42, 102770. [Google Scholar] [CrossRef]

- Klein, R.A. SFPE handbook of fire protection engineering. Fire Saf. J. 1995, 29, 61–63. [Google Scholar] [CrossRef]

| Parametric | Settings |

|---|---|

| Longitudinal ventilation velocity | 2 m/s |

| Heat release rate | 20 MW (t2, 326 s) |

| Environmental temperature | 293 K |

| Gravitational acceleration | 9.8 m/s2 |

| Surface materials | INERT |

| Simulation time | 1800 s |

| No | Fire Location | HRR/MW | Velocity/m/s | Beam Spacing/m |

|---|---|---|---|---|

| A0–A4 | Immersed tunnel | 20 | 2.5 | No beam, 1, 1.8, 3.6, 7.2 |

| B0–B4 | Confluence section | No beam, 1, 1.8, 3.6, 7.2 | ||

| C0–C4 | Auxiliary road | No beam, 1, 1.8, 3.6, 7.2 | ||

| D0–D4 | Four-lane section tunnel | No beam, 1, 1.8, 3.6, 7.2 |

| No. | Fire Location | Beam Spacing/m | Hazard Range/m | ||||

|---|---|---|---|---|---|---|---|

| Immersed Tunnel | Confluence Section | Auxiliary Road | Four-Lane Section | Sum | |||

| A0 | Immersed tunnel | None | 55 | SAFE | 70 | SAFE | 125 |

| A1 | 1 | 58 | 53 | SAFE | 25 | 136 | |

| A2 | 1.8 | 58 | 69 | SAFE | 25 | 152 | |

| A3 | 3.6 | 58 | 83 | 104 | 20 | 265 | |

| A4 | 7.2 | 58 | 85 | 16 | SAFE | 159 | |

| B0 | Confluence section | None | SAFE | 14 | SAFE | SAFE | 14 |

| B1 | 1 | SAFE | 16 | 24 | SAFE | 40 | |

| B2 | 1.8 | SAFE | 16 | 104 | SAFE | 120 | |

| B3 | 3.6 | SAFE | 49 | 34 | 68 | 151 | |

| B4 | 7.2 | SAFE | 46 | 88 | 38 | 172 | |

| C0 | Auxiliary road | None | SAFE | SAFE | 12 | SAFE | 12 |

| C1 | 1 | SAFE | SAFE | 61 | SAFE | 61 | |

| C2 | 1.8 | SAFE | SAFE | 62 | SAFE | 62 | |

| C3 | 3.6 | SAFE | SAFE | 66 | SAFE | 66 | |

| C4 | 7.2 | SAFE | SAFE | 63 | SAFE | 63 | |

| D0 | Four-lane section of tunnel | None | SAFE | SAFE | SAFE | 13 | 13 |

| D1 | 1 | SAFE | SAFE | 66 | 15 | 81 | |

| D2 | 1.8 | SAFE | 10 | 70 | 26 | 106 | |

| D3 | 3.6 | SAFE | 13 | 62 | 91 | 166 | |

| D4 | 7.2 | SAFE | 13 | 74 | 113 | 200 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Tang, H.; Zhao, J.; Chen, S.; Xie, Y.; Feng, S.; Xu, Z.; Yu, Z. Fire Hazard Analysis on Different Fire Source Locations in Multi-Segment Converging Tunnel with Structural Beams. Fire 2023, 6, 444. https://doi.org/10.3390/fire6110444

Wei L, Tang H, Zhao J, Chen S, Xie Y, Feng S, Xu Z, Yu Z. Fire Hazard Analysis on Different Fire Source Locations in Multi-Segment Converging Tunnel with Structural Beams. Fire. 2023; 6(11):444. https://doi.org/10.3390/fire6110444

Chicago/Turabian StyleWei, Lixin, Honghui Tang, Jiaming Zhao, Shiyi Chen, Yiqiang Xie, Shilin Feng, Zhisheng Xu, and Zihan Yu. 2023. "Fire Hazard Analysis on Different Fire Source Locations in Multi-Segment Converging Tunnel with Structural Beams" Fire 6, no. 11: 444. https://doi.org/10.3390/fire6110444

APA StyleWei, L., Tang, H., Zhao, J., Chen, S., Xie, Y., Feng, S., Xu, Z., & Yu, Z. (2023). Fire Hazard Analysis on Different Fire Source Locations in Multi-Segment Converging Tunnel with Structural Beams. Fire, 6(11), 444. https://doi.org/10.3390/fire6110444