Unraveling the Characteristics of ESS Fires in South Korea: An In-Depth Analysis of ESS Fire Investigation Outcomes

Abstract

:1. Introduction

2. ESS Fires

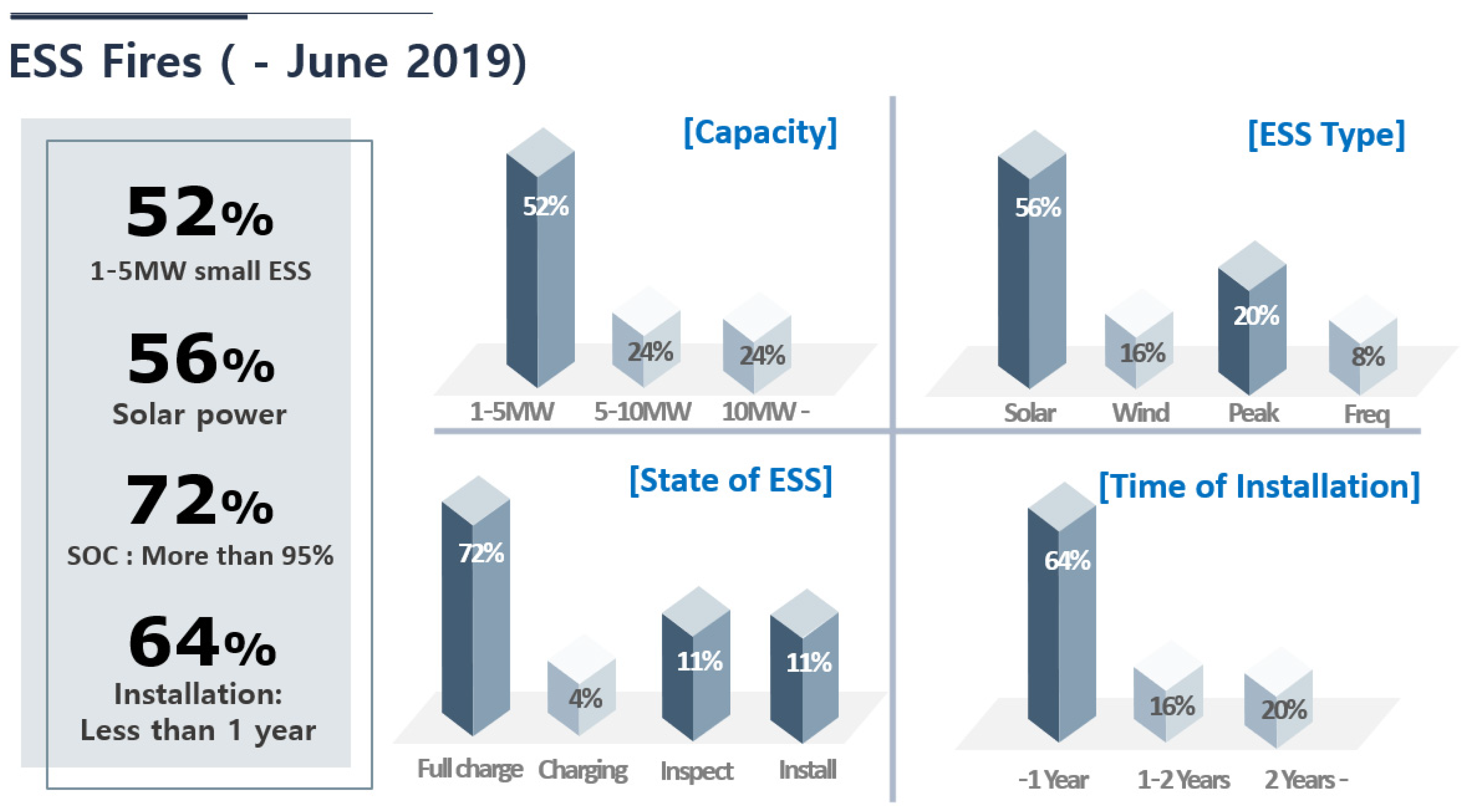

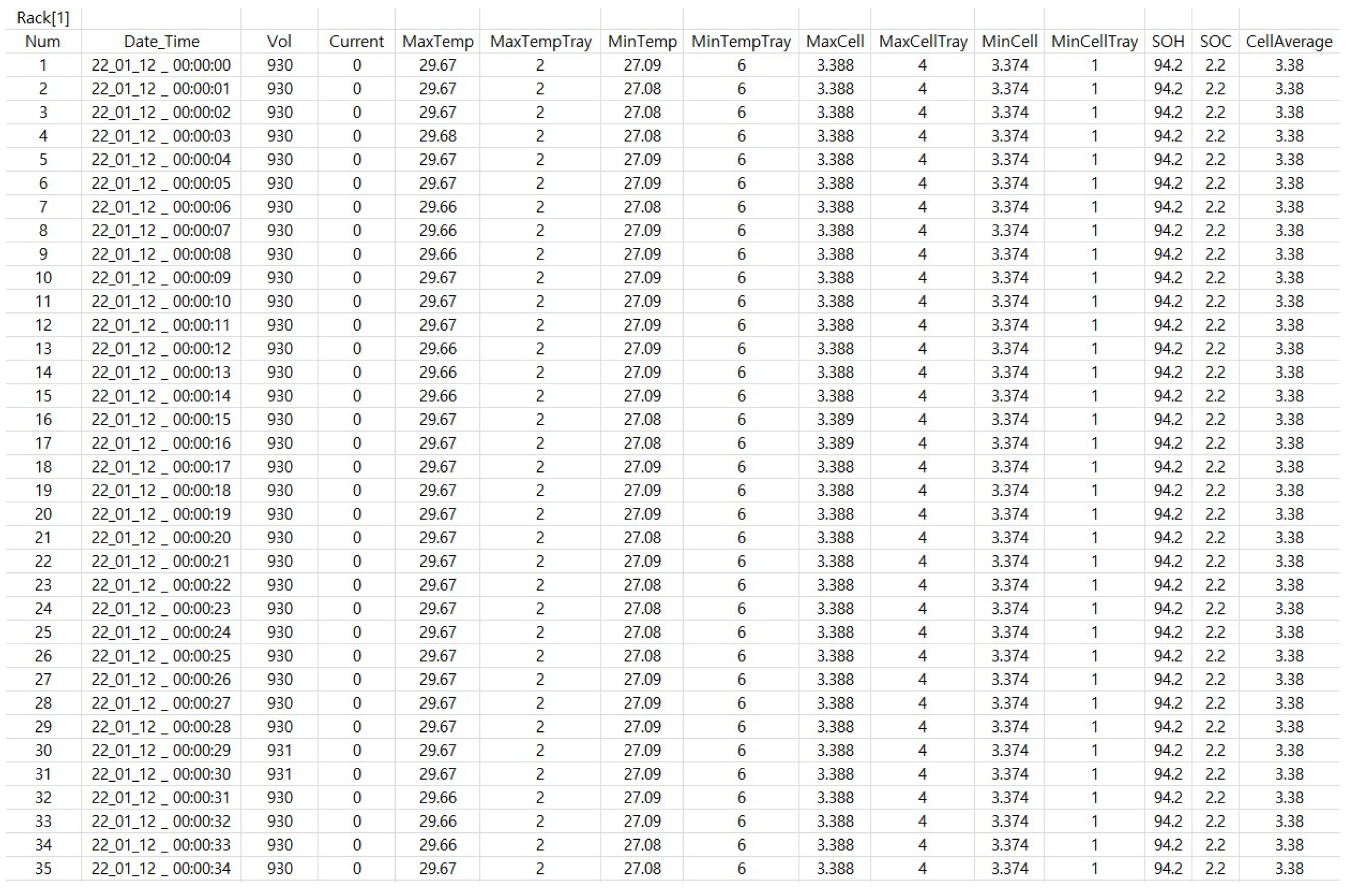

2.1. Phase #1 (–June 2019, 23 Cases)

2.2. Phase #2 (June–October 2019, 5 Cases)

3. Fire Investigation

3.1. Fire Investigation Committee (Phase #1)

- Lithium-ion battery cell fault.

- Insufficient electrical surge protection system.

- Ineffective environmental management and inadequate installation.

- Absence of ESS integrated management system.

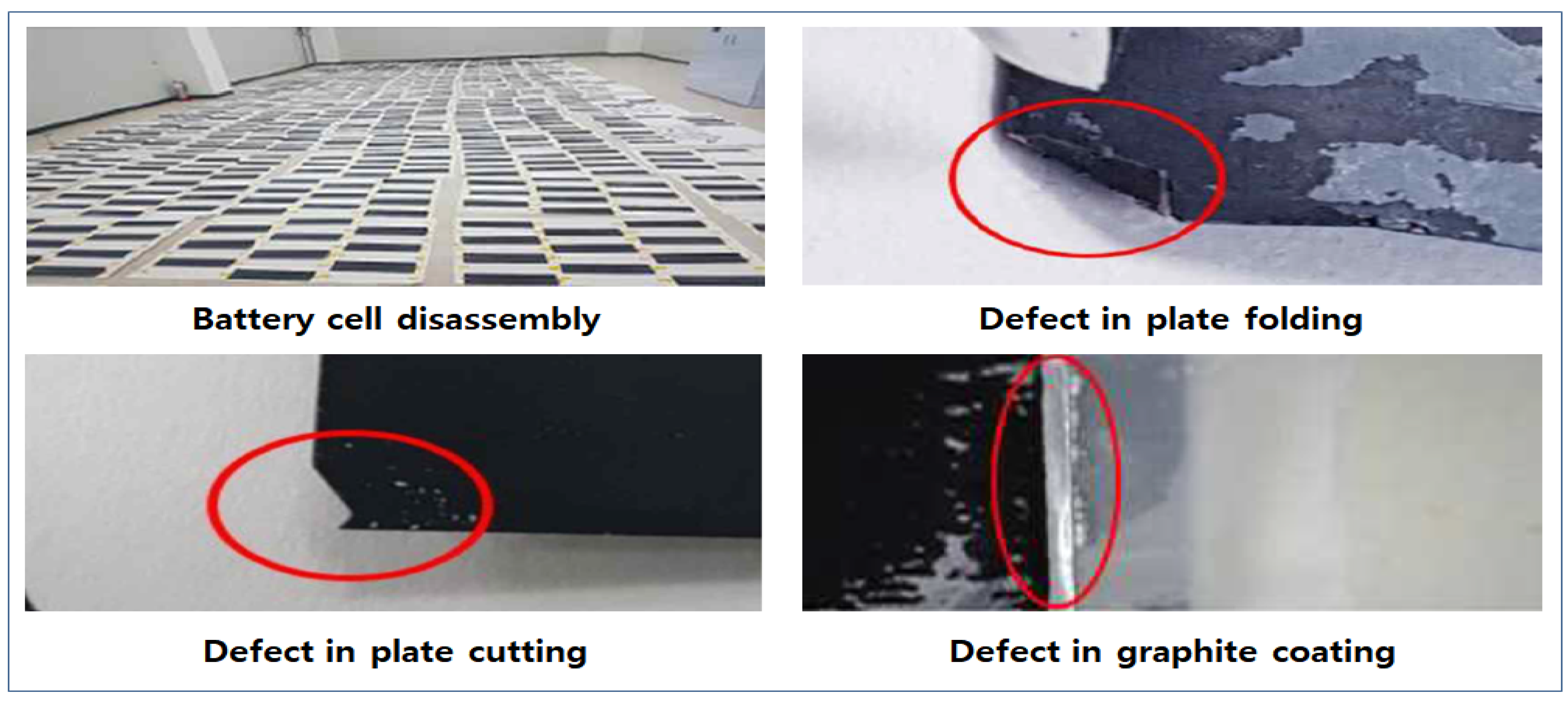

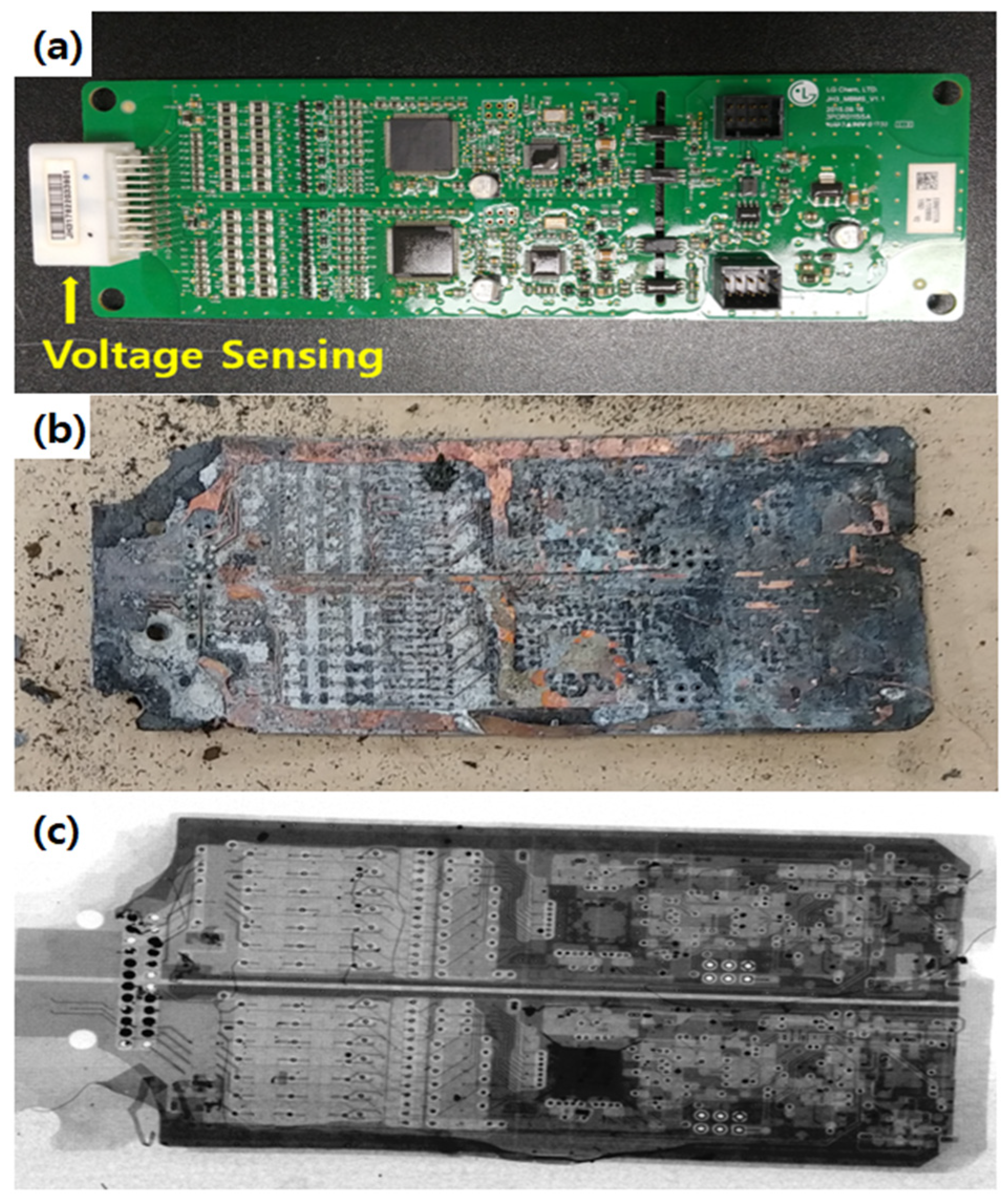

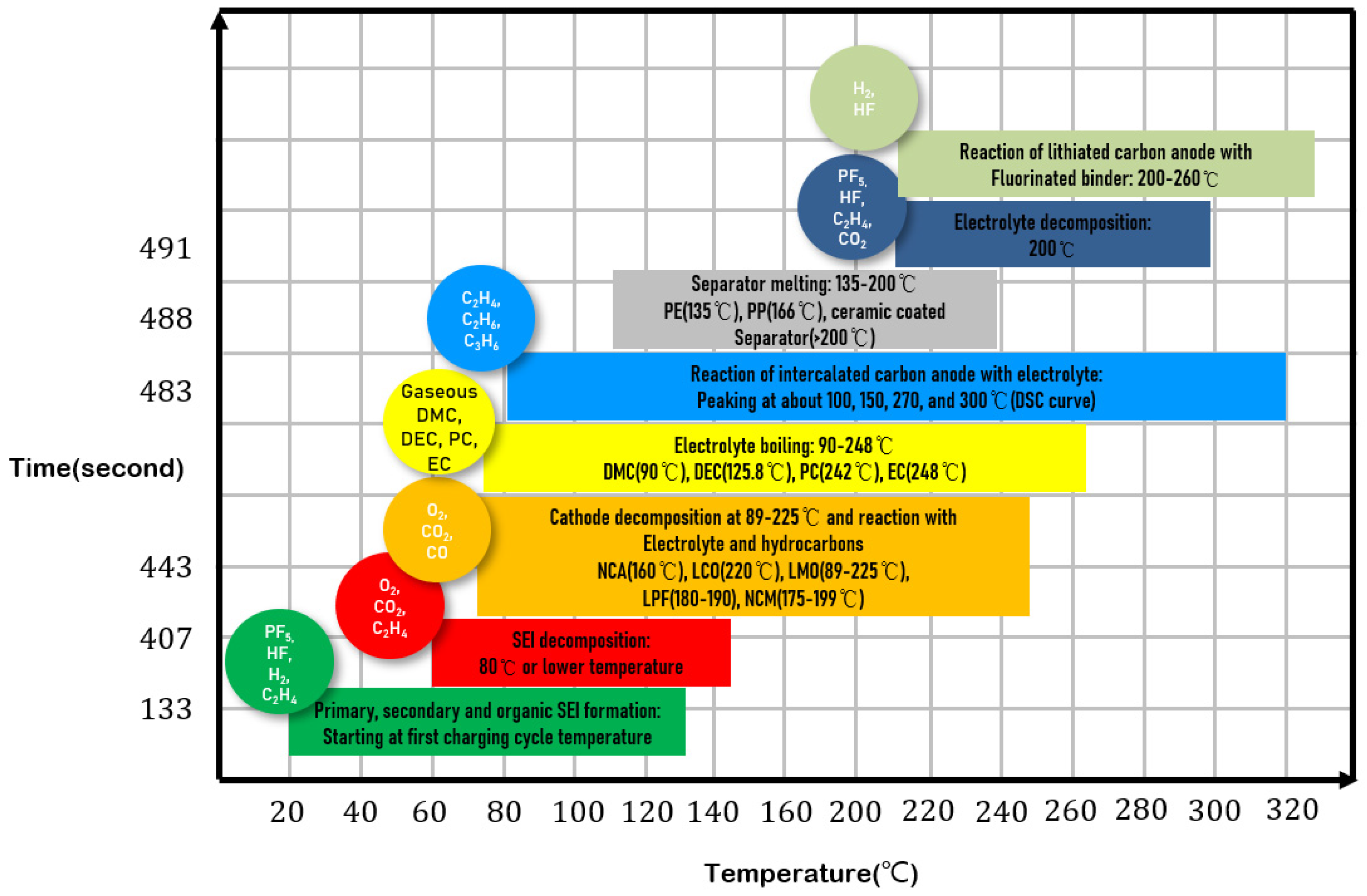

3.1.1. Lithium-Ion Battery Cell Fault

3.1.2. Insufficient Electrical Surge Protection System

3.1.3. Ineffective Environmental Management and Inadequate Installation

3.1.4. Absence of ESS Integrated Management System

3.2. Fire Investigation Committee (Phase #2)

3.2.1. ESS Fire Site Investigation

3.2.2. Investigation of Similar ESS Sites

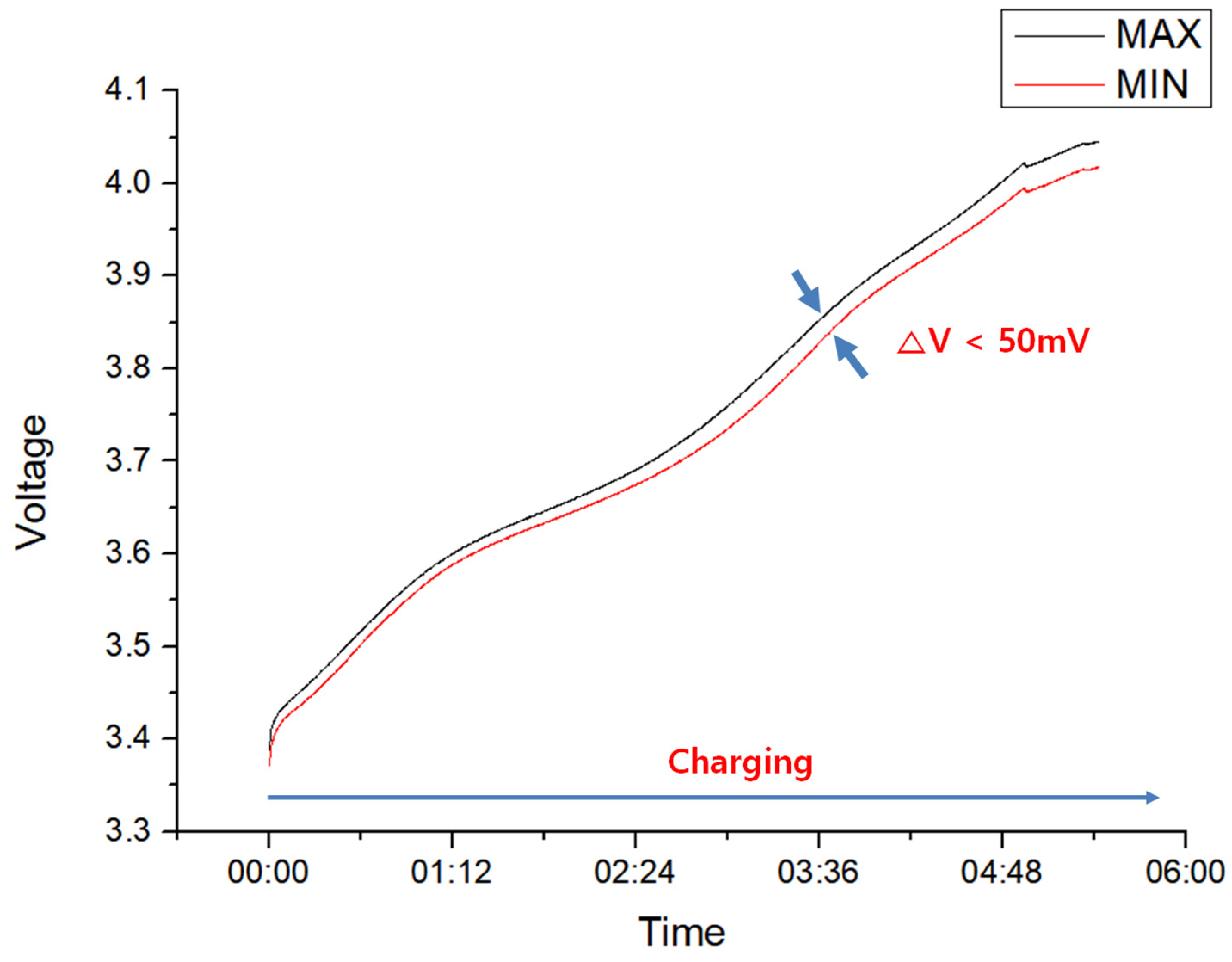

3.2.3. ESS SOC Analysis

3.2.4. Results

4. ESS Fire Characteristics

4.1. SOC (−95%)

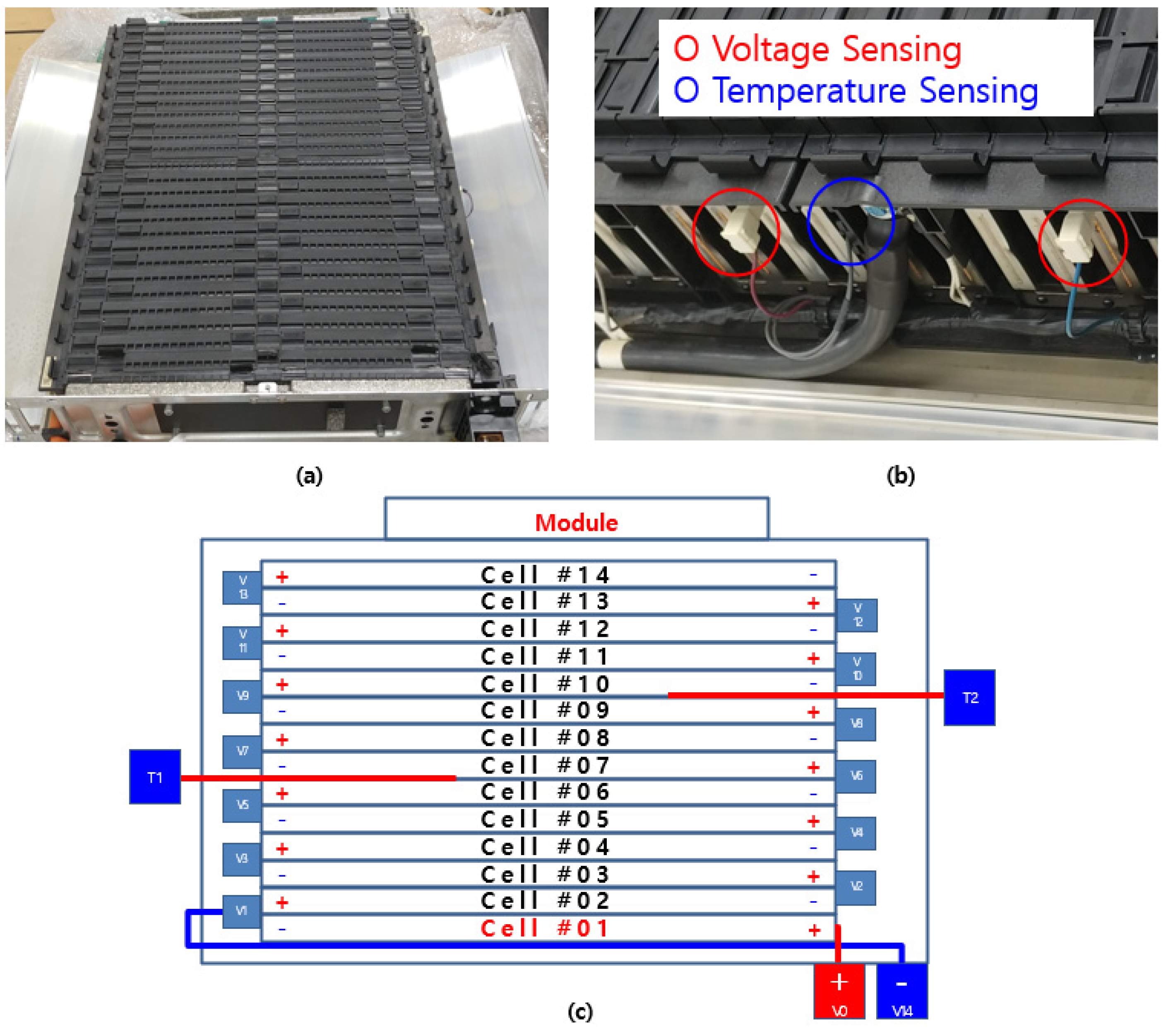

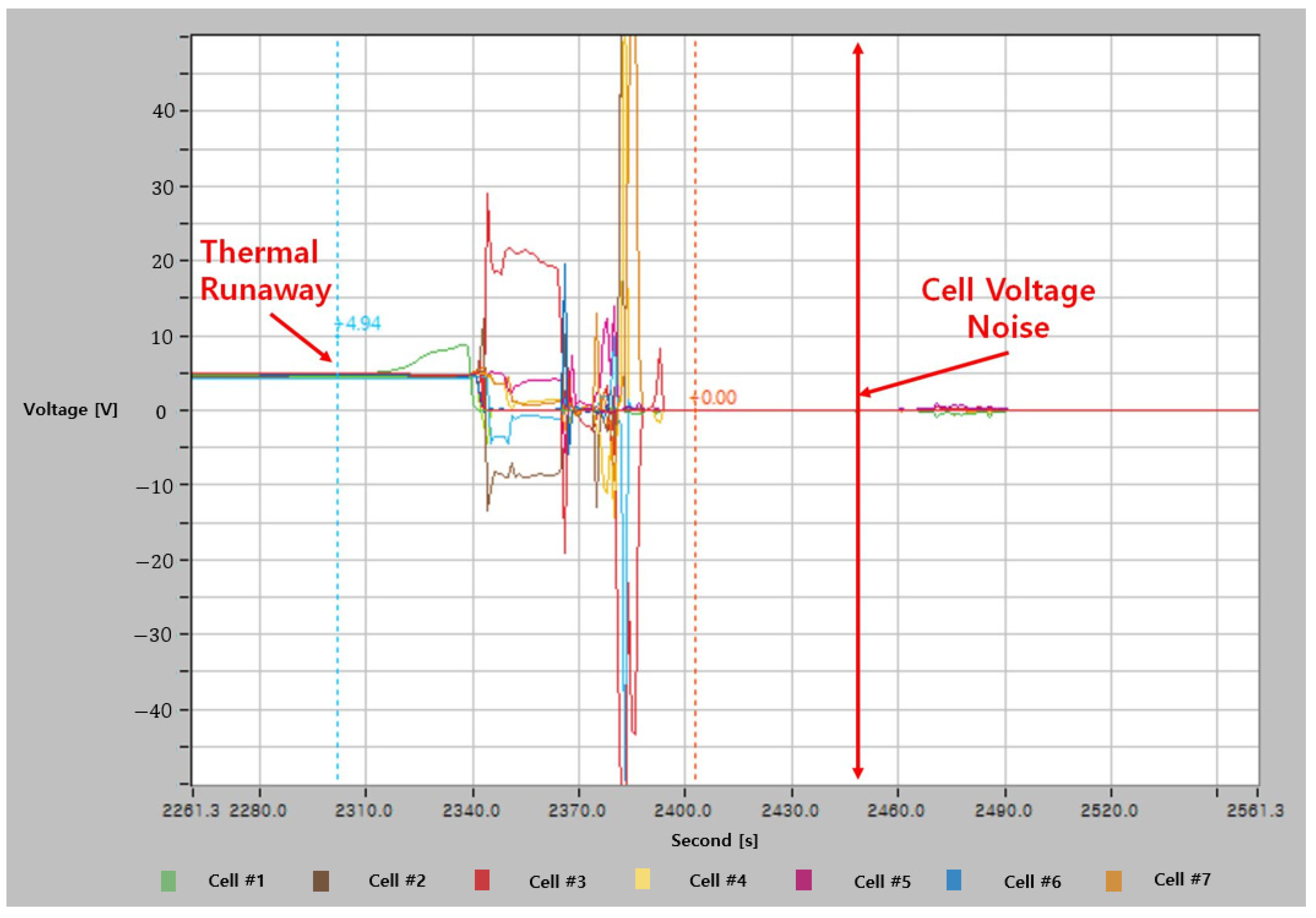

4.2. ESS Fires Originating in a Particular Cell

4.3. Overcurrent

4.4. Noise from BMS Log Data

4.5. Structure Collapse

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, C.; Negro, E.; Vezzù, K.; Pagot, G.; Cavinato, G.; Nale, A.; Herve Bang, Y.H.; Di Noto, V. Hybrid inorganic-organic proton-conducting membranes based on SPEEK doped with WO3 nanoparticles for application in vanadium redox flow batteries. Electrochim. Acta 2019, 309, 311–325. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, H. Review of the development of first-generation redox flow batteries: Iron-chromium system. ChemSusChem 2022, 15, e202101798. [Google Scholar] [CrossRef]

- Victoria, M.; Zhu, K.; Brown, T.; Andresen, G.B.; Greiner, M. The role of storage technologies throughout the decarbonisation of the sector-coupled European energy system. Energy Convers. Manag. 2019, 201, 111977. [Google Scholar] [CrossRef]

- Serrano-Canalejo, C.; Sarrias-Mena, R.; García-Triviño, P.; Fernández-Ramírez, L.M. Energy management system design and economic feasibility evaluation for a hybrid wind power/pumped hydroelectric power plant. IEEE Lat. Am. Trans. 2019, 17, 1686–1693. [Google Scholar] [CrossRef]

- Abrell, J.; Kosch, M. Cross-country spillovers of renewable energy promotion-The case of Germany. Resour. Energy Econ. 2022, 68, 101293. [Google Scholar] [CrossRef]

- Ibrahim, H.; Ilinca, A.; Perron, J. Energy storage systems-characteristics and comparisons. Renew. Sustain. Energy Rev. 2008, 12, 1221–1250. [Google Scholar] [CrossRef]

- Olabi, A.G.; Onumagebu, C.; Tabbi, W.; Mohamad, R.; Mohamad, A.; Abdul, H. Critical review of energy storage system. Energy 2021, 214, 118987. [Google Scholar] [CrossRef]

- Deepika, V.; Ankit, B. Thermal Behavior of Lithium-and Sodium-Ion Batteries: A Review on Heat Generation, Battery Degradation, Thermal Runway-Perspective and Future Directions. Energy Fuels 2022, 36, 14000–14029. [Google Scholar]

- Vijay, S.; Kevin, M.; Quinn, H. Quantification of Combustion Hazards of Thermal Runaway Failures in Lithium-Ion Batteries. SAE Int. J. Altern. Powertrains 2014, 3, 98–104. [Google Scholar]

- Dongxu, O.; Jiahao, L.; Mingyi, C.; Jian, W. Investigation into the Fire Hazards of Lithium-Ion Batteries under Overcharging. Appl. Sci. 2017, 7, 1314. [Google Scholar]

- Kai, Z.; Lu, W.; Chenbo, X.; Hejun, W.; Dongmei, H.; Kan, J.; Xiaomeng, X. Study on Thermal Runaway Risk Prevention of Lithium-Ion Battery with Composite Phase Change Materials. Fire 2023, 6, 208. [Google Scholar]

- Ghassan, Z.; Rodolfo, D.; Monica, C.; Guzay, P. The lithium-ion battery: State of the art and future perspective. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar]

- Chen, S.; Huaiguo, W. Research on the Technological Development of Lithium Ion Battery Industry in China. J. Phys. Conf. Ser. 2019, 1347, 012087. [Google Scholar]

- Electrical Energy Storage; White Paper; International Electrotechnical Commission: Geneva, Switzerland, 2011; pp. 17–30.

- Matthew, T.L.; Bharatkumar, S.; Paul WC, N.; Sumitava, D. Battery Energy Storage System (BESS) and Battery Management System (BMS) for Grid-Scale Applications. Proc. IEEE 2014, 102, 1014–1030. [Google Scholar]

- Seongyun, P.; Jeongho, A.; Taewoo, K.; Sungbeak, P.; Youngmi, K.; Inho, C.; Jonghoon, K. Review of state-of-the-art battery state estimation technologies for battery management systems of stationary energy storage systems. J. Power Electron. 2020, 20, 1526–1540. [Google Scholar]

- Faisal, A.; Lars, J.; Bo, E. Simultaneous Thermal and State-of-Charge Balancing of Batteries: A Review. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Coimbra, Portugal, 27–30 October 2014. [Google Scholar]

- Mina, N.; Phillip, K.; Ali, E. Lithium-Ion Battery Pack Robust State of Charge Estimation, Cell Inconsistencey, and Balancing: Review. IEEE Access 2021, 9, 50570–50582. [Google Scholar]

- Michael, D.; Bin, W.; Alireza, K. Design and optimization of a solar power conversion system for space applications. IEEE Trans. Ind. 2019, 55, 2310–2319. [Google Scholar]

- Na, K.-S.; Lee, J.; Kim, J.-M.; Lee, Y.-S.; Yi, J.; Won, C.-Y. Power Conversion System Operation Algorithm for Efficient Energy Management of Microgirds. Electronics 2021, 10, 2791. [Google Scholar] [CrossRef]

- Mingyi, L.; Xi, C.; Chuanzhao, C.; Pengcheng, W.; Chengrui, W.; Jie, P.; Haodong, L.; Xinyu, J.; Rui, L.; Jianlin, L. A Review of Power Conversion Systems and Design Schemes of High-Capacity Battery Energy Storage Systems. IEEE Access 2022, 10, 52030–52042. [Google Scholar]

- Saima, A.; Yogesh, S.; Viktor, K. Energy management systems: State of the art and emerging trends. IEEE Commun. Mag. 2013, 51, 114–119. [Google Scholar]

- Younes, Z.; Ibrahim, A.; Saad, M.; Reyasudin, B.K.M.; Mehdi, S.; Alex, S.; Ben, H. Energy Management System in Microgrids: A Comprehensive Review. Sustainability 2021, 13, 10492. [Google Scholar]

- Russo, P.; Longobardo, G.; Mazzaro, M.; Di Bari, C.; Cancelliere, P. Fire Behavior of NMC Li-ion Battery Cells. In Proceedings of the Ninth International Seminar on Fire and Explosion Hazards, St. Petersburg, Russia, 21–26 April 2019; pp. 881–890. [Google Scholar]

- Ministry of Trade, Industry and Energy of South Korea. The Result of the First ESS Fire Accident Investigation; Sejong, Republic of Korea, 2019.

- Scott, B. McMicken Battery Energy Storage System Event Technical Analysis and Recommendations; Document No.:10209302-HOU-R-01, Issue: A, Statis: Final; Arizona Public Service: Chalfont, PA, USA, 2020. [Google Scholar]

- Mark, B.; DeCrane, M.S. Stephen Kerber Four Firefighters Injured In Lithium-Ion Battery Energy Storage System Explosion–Arizona; UL Firefighter Safety Research Institute: Columbia, MD, USA, 2020. [Google Scholar]

- Weifeng, L.; Shun, R.; Yang, X.; Zhenhai, G.; Yupeng, C.; Hewu, W.; Minggao, O. Fire boundaries of lithium-ion cell eruption gases caused by thermal runaway. iScience 2021, 24, 102401. [Google Scholar]

| State of ESS Operation: Install -> Inspect -> Operation (Charging and Discharging) Install: Install ESS System (Battery Rack, PCS, EMS) Inspect: Before Operating ESS, Check State of ESS | ||||||

|---|---|---|---|---|---|---|

| ESS Fire Site | Time | State | Type | Capacity (MWh) | SOC | Type (A: Pouch, B: Prismatic) |

| Phase #1 (~June 2019, 23 cases) | ||||||

| Gochang | 2 August 2017 at 05:29. | Install | Wind | 1.46 | 30% | NCM622 (A) |

| Kyungsan | 2 May 2018 at 20:59. | Inspect | Frequency | 8.6 | - | NCM622 (B) |

| Youngam | 2 June 2018 at 16:13. | Inspect | Wind | 14 | - | NCM622 (B) |

| Saemankum | 15 June 2018 at 14:38. | Fully charged | Solar | 18.9 | 100% | NCM622 (A) |

| Haenam | 12 July 2018 at 16:25. | Fully charged | Solar | 2.9 | 98% | NCM622 (A) |

| Geochang | 21 July 2018 at 11:14. | Fully charged | Wind | 9.7 | 99.3% | NCM622 (B) |

| Saejong | 28 July 2018 at 08:31. | Install | Peak load | 18 | 35% | NCM622 (B) |

| Youngdong | 1 September 2018 at 14:19. | Fully charged | Solar | 5.9 | 98.1% | NCM622 (A) |

| Yeonsil | 7 September 2018 at 14:54. | Inspect | Solar | 6 | - | NCM622 (B) |

| Jaeju | 14 September 2018 at 04:53. | Charging | Peak load | 0.2 | - | NCM622 (A) |

| Yongin | 18 October 2018 at 15:23. | Inspect | Frequency | 17.8 | - | NCM622 (B) |

| Yeongju | 12 November 2018 at 15:55. | Fully charged | Solar | 3.7 | 98.4% | NCM622 (A) |

| Jisan | 12 November 2018 at 16:03. | Fully charged | Solar | 1.2 | 96.4% | NCM622 (A) |

| Munkyung | 22 November 2018 at 17:13. | Fully charged | Solar | 4.2 | 95.0% | NCM622 (A) |

| Geochang | 22 November 2018 at 17:19 | Fully charged | Solar | 1.3 | 96% | NCM622 (A) |

| Asea Factory | 17 December 2018 at 07:09. | Fully charged | Peak load | 9.3 | 96% | NCM622 (A) |

| Samchuck | 22 December 2018 at 17:30. | Fully charged | Solar | 2.7 | 97% | NCM622 (A) |

| Yangsan | 14 January 2019 at 07:31. | Fully charged | Peak load | 3.3 | 96% | NCM622 (A) |

| Wando | 14 January 2019 at 14:21. | Fully charged | Solar | 5.2 | 98% | NCM622 (B) |

| Jangsu | 15 January 2019 at 16:16. | Fully charged | Solar | 2.5 | 95% | NCM622 (A) |

| Ulsan | 21 January 2019 at 09:26. | Fully charged | Peak load | 47 | 100% | NCM622 (B) |

| Chilgok | 4 May 2019 at 15:40. | Fully charged | Solar | 3.7 | 96% | NCM622 (A) |

| Phase #2 (June~October 2019, 5 cases) | ||||||

| Jangsu | 26 May 2019 at 17:00. | Fully charged | Solar | 1 | 94% | NCM622 (A) |

| Yesan | 30 August 2019 at 19:18 | Fully charged | Solar | 1.5 | 93.5% | NCM622 (A) |

| Pyeongchang | 24 September 2019 at 11:29 | Fully charged | Wind | 21 | 98% | NCM622 (B) |

| Gunwi | 29 September 2019 at 19:36 | Fully charged and discharging | Solar | 1.5 | 86.5% | NCM622 (A) |

| Hadong | 21 October 2019 at 16:14 | Fully charged | Solar | 1.5 | 94.5% | NCM622 (A) |

| Gimhae | 27 October 2019 at 16:51 | Fully charged | Solar | 1.2 | 92.2% | NCM622 (B) |

| ESS Fire Site | Time | State | Type | Capacity (MWh) |

|---|---|---|---|---|

| Yesan | 30 August 2019 at 19:18 | Fully charged | Solar | 1.5 |

| Pyeongchang | 24 September 2019 at 11:29 | Fully charged | Wind | 21 |

| Gunwi | 29 September 2019 at 19:36 | Fully charged and discharging | Solar | 1.5 |

| Hadong | 21 October 2019 at 16:14 | Fully charged | Solar | 1.5 |

| Gimhae | 27 October 2019 at 16:51 | Fully charged | Solar | 1.2 |

| ESS Fire Site | Upper Limit of SOC | SOC at the Time of the Fire | Additional Changes in SOC |

|---|---|---|---|

| Yesan | 95% | 93.5% | 70% → 95% (8 days before the fire) |

| Pyeongchang | 100% | 98% | 95% → 100% (14 days before the fire) |

| Gunwi | 95% | 86.5% | 70% → 95% (5 days before the fire) |

| Hadong | 95% | 94.5% | - |

| Gimhae | 95% | 92.2% | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Na, Y.-U.; Jeon, J.-W. Unraveling the Characteristics of ESS Fires in South Korea: An In-Depth Analysis of ESS Fire Investigation Outcomes. Fire 2023, 6, 389. https://doi.org/10.3390/fire6100389

Na Y-U, Jeon J-W. Unraveling the Characteristics of ESS Fires in South Korea: An In-Depth Analysis of ESS Fire Investigation Outcomes. Fire. 2023; 6(10):389. https://doi.org/10.3390/fire6100389

Chicago/Turabian StyleNa, Yong-Un, and Jae-Wook Jeon. 2023. "Unraveling the Characteristics of ESS Fires in South Korea: An In-Depth Analysis of ESS Fire Investigation Outcomes" Fire 6, no. 10: 389. https://doi.org/10.3390/fire6100389

APA StyleNa, Y.-U., & Jeon, J.-W. (2023). Unraveling the Characteristics of ESS Fires in South Korea: An In-Depth Analysis of ESS Fire Investigation Outcomes. Fire, 6(10), 389. https://doi.org/10.3390/fire6100389