Parametric Analysis of a Steel Frame under Fire Loading Using Monte Carlo Simulation

Abstract

:1. Introduction

2. Monte Carlo Simulation

2.1. Time-Temperature Curves for a Compartment

2.2. Thermal Response of Structural Members

2.3. Monte Carlo Simulation

3. Finite Element Analysis

3.1. Finite Element Model

3.2. Heat Transfer Analysis

3.3. Mechanical Analysis

4. Parametric Analysis

4.1. Effect of Opening Factor

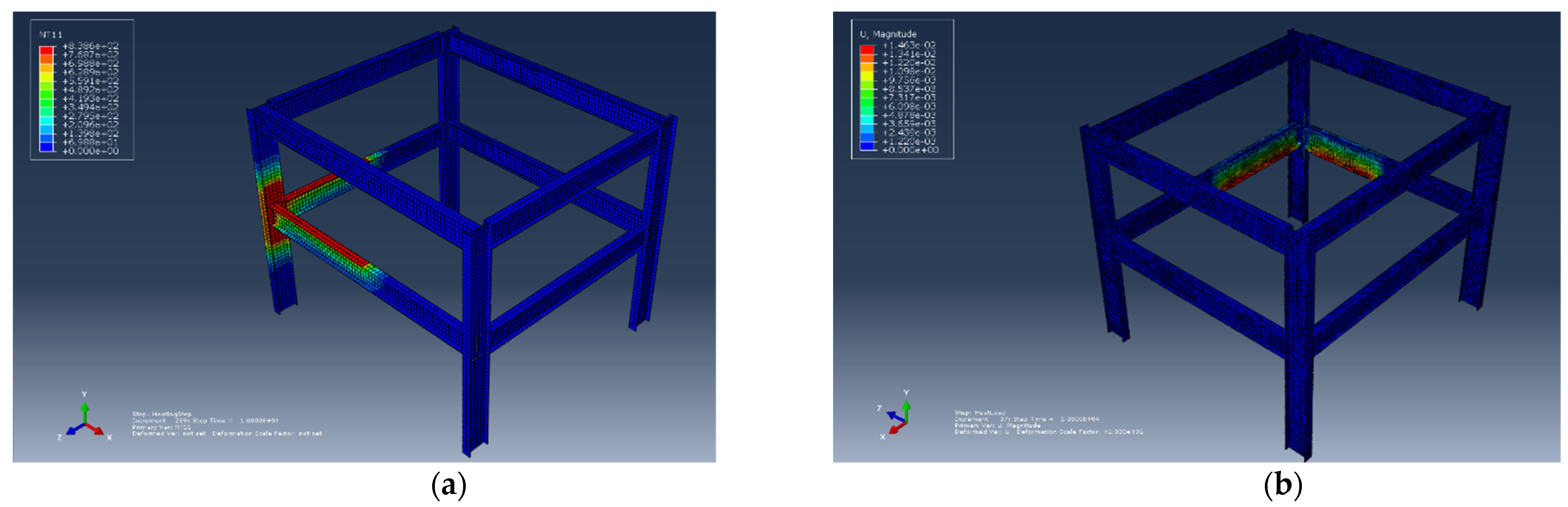

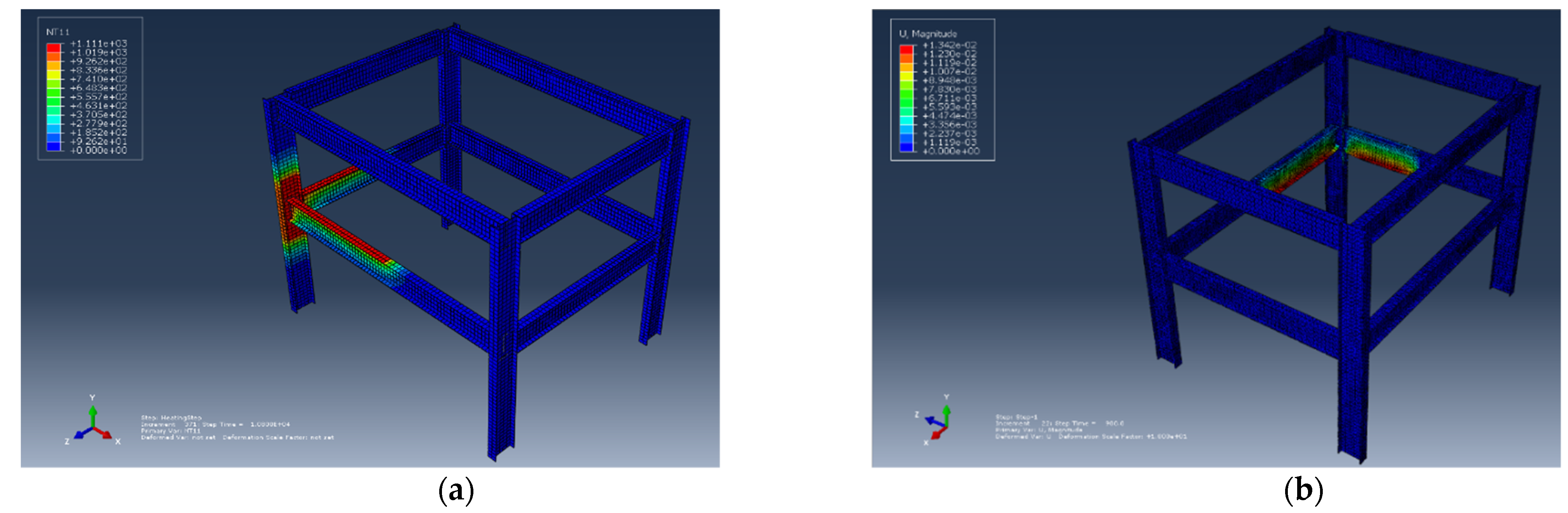

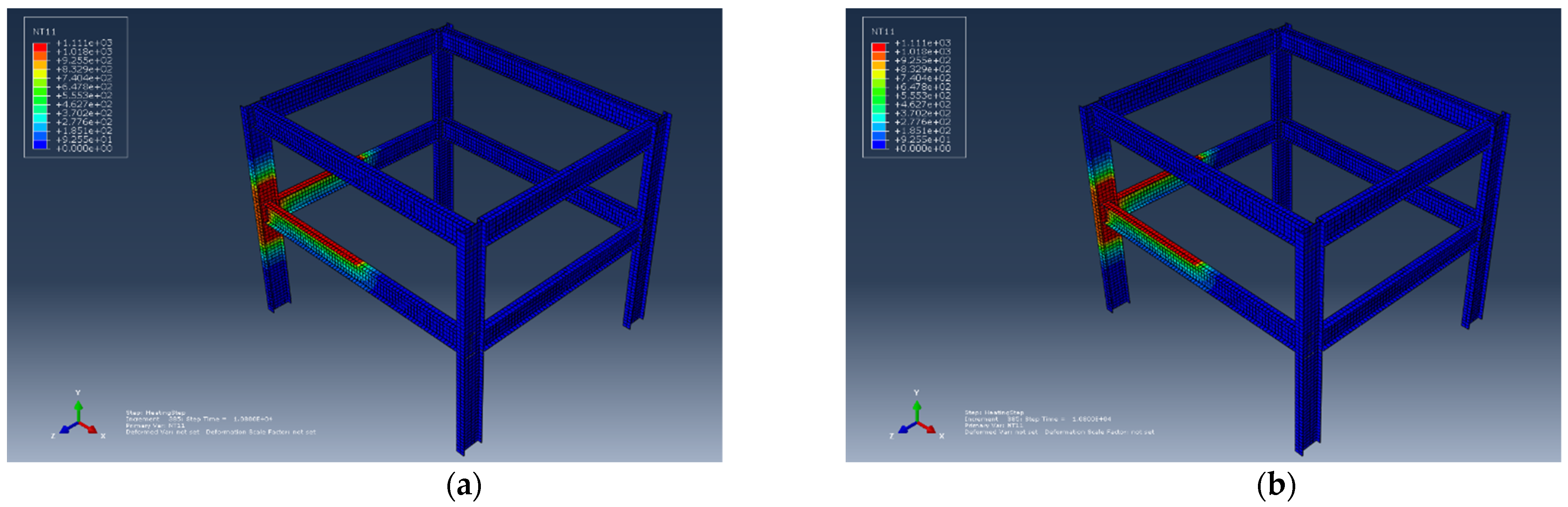

- Scenario 1: An opening factor with a value of 0.0251 was used, and the corresponding results are shown in Figure 1a,b.

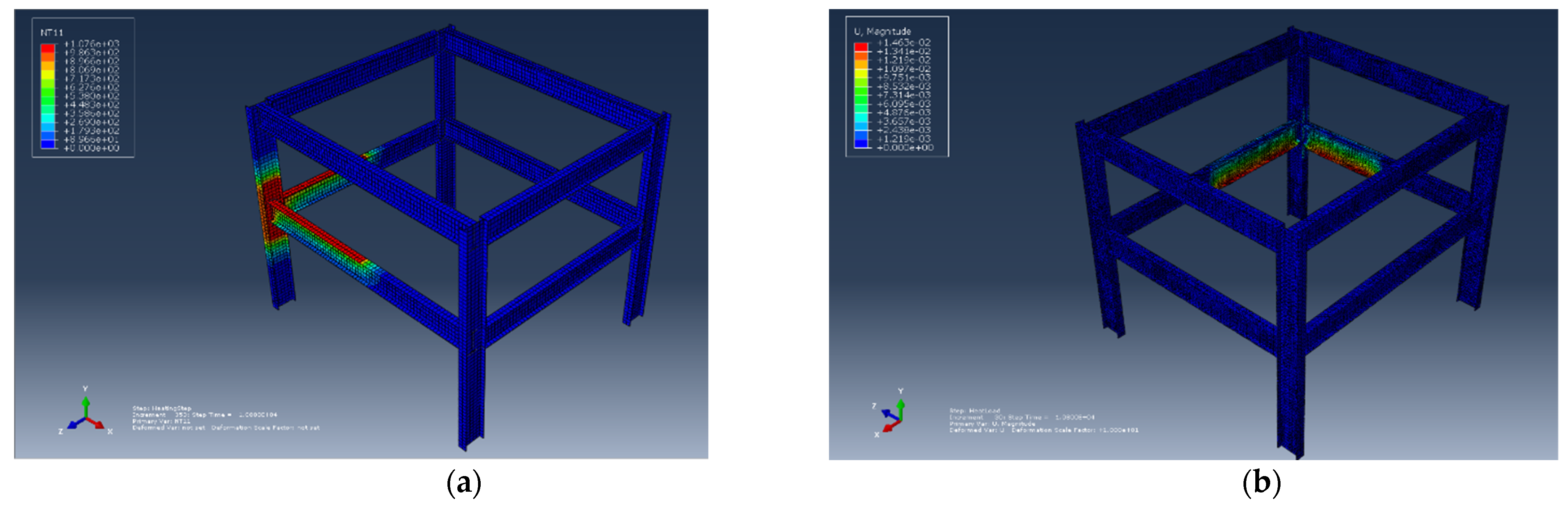

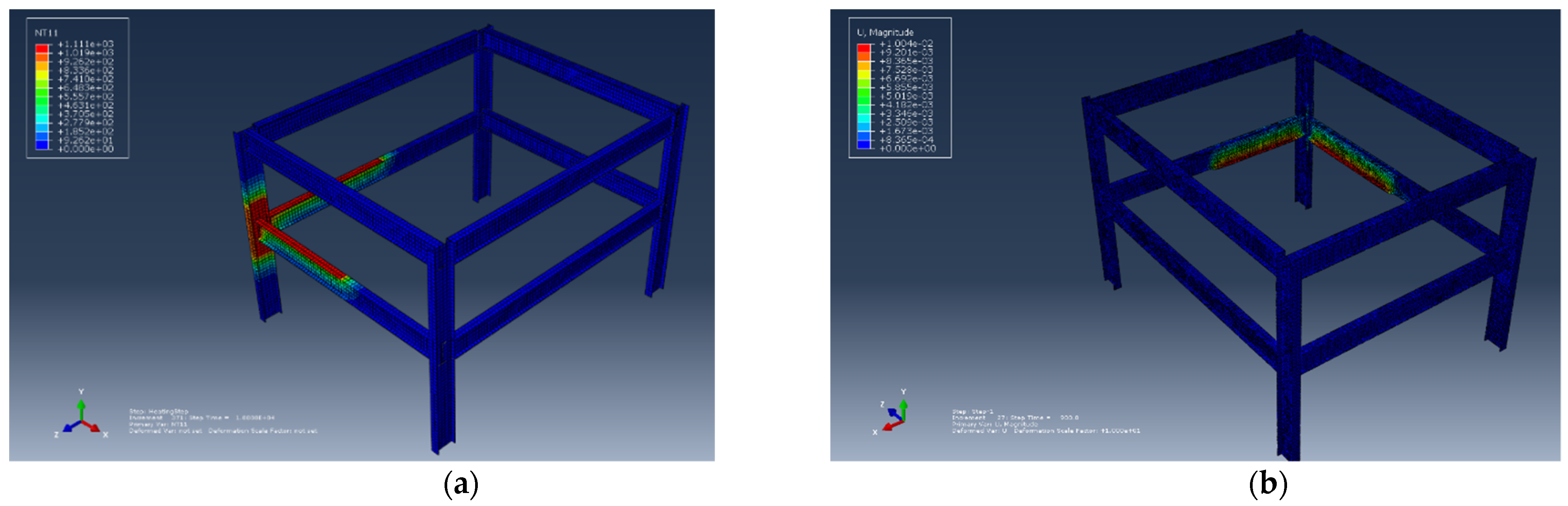

- Scenario 2: An opening factor with a value of 0.0554 was used, and the corresponding results are shown in Figure 2a,b.

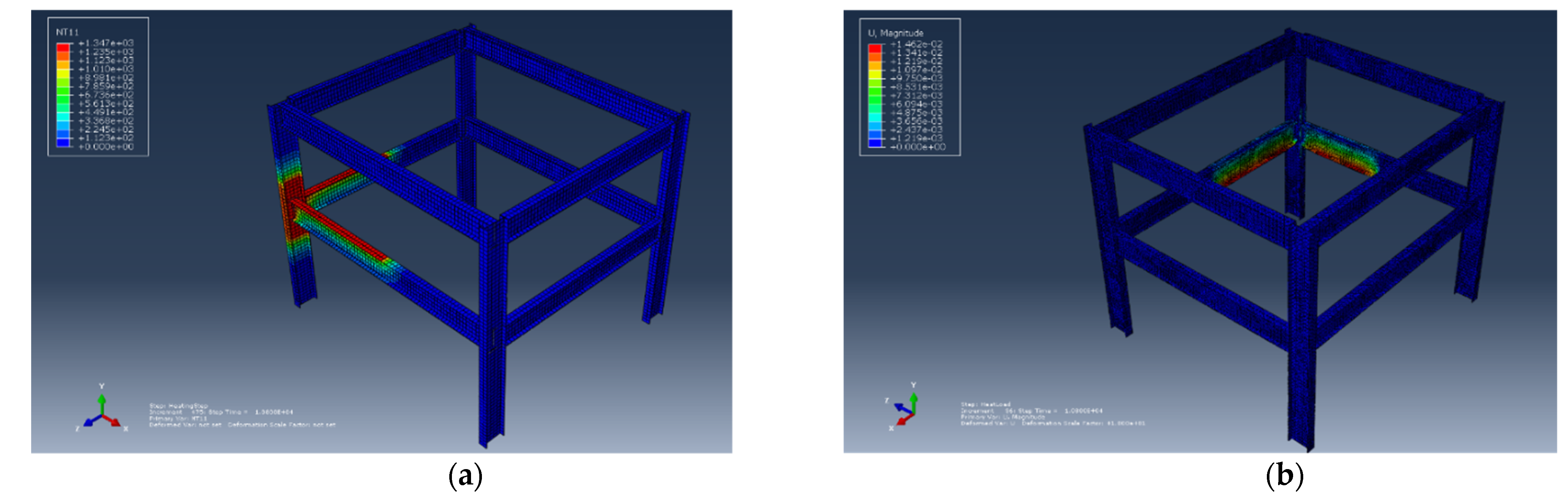

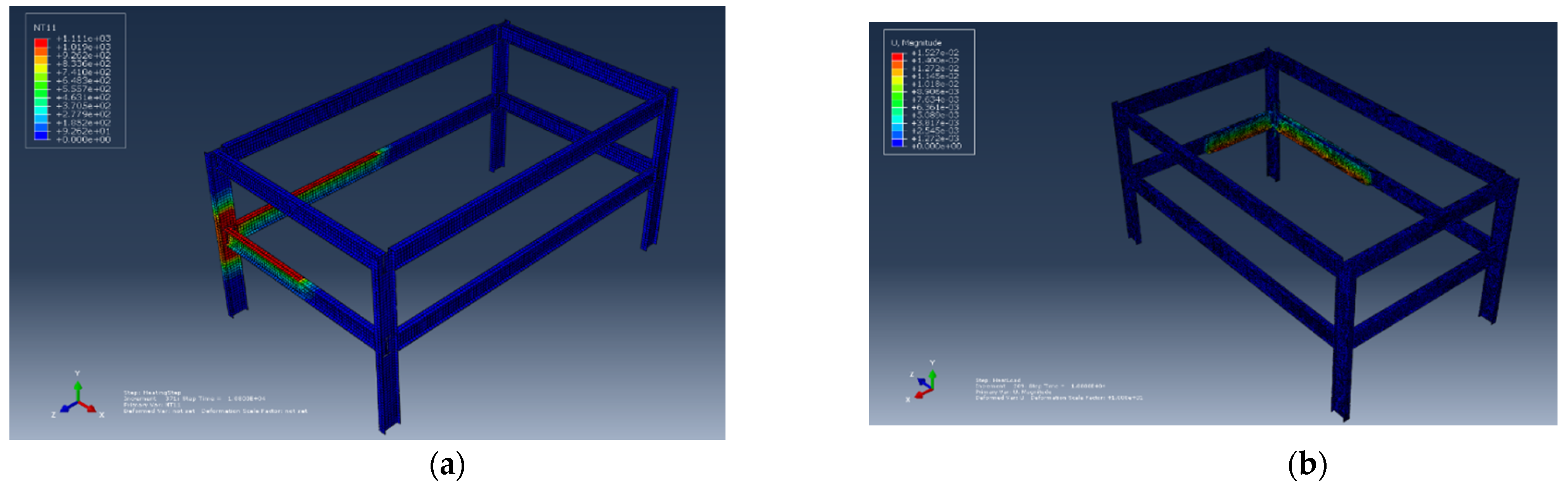

- Scenario 3: An opening factor with a value of 0.1129 was used, and the corresponding results are shown in Figure 3a,b.

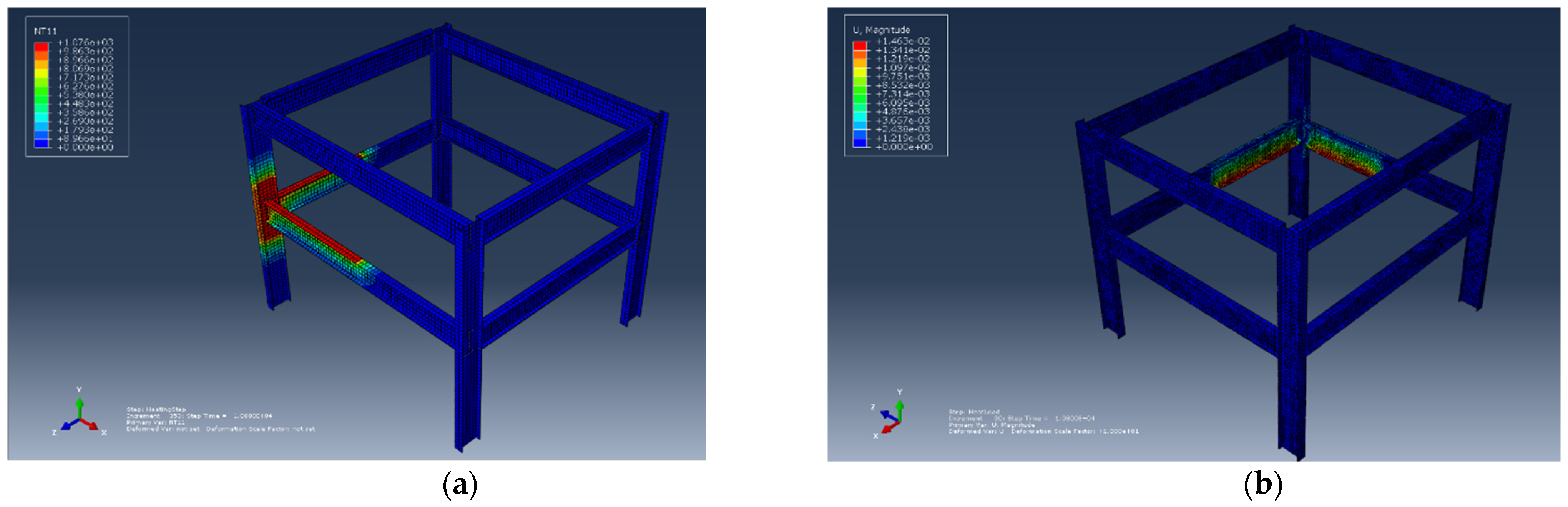

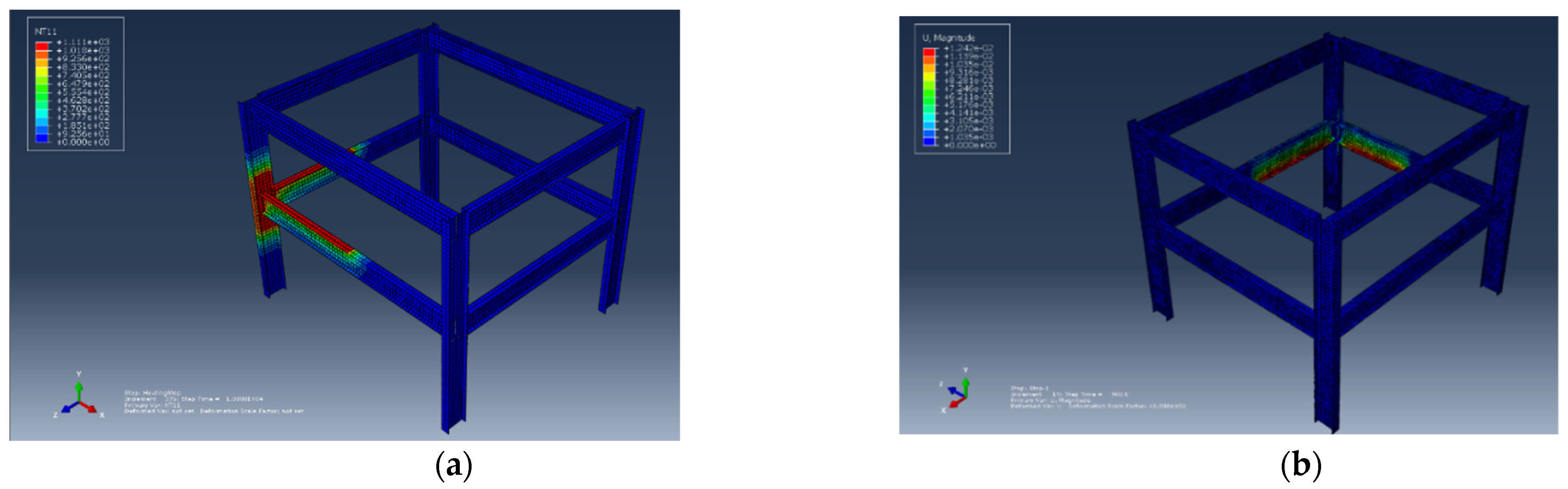

- Scenario 4: An opening factor with a value of 0.1689 was used, and the corresponding results are shown in Figure 4a,b.

- Scenario 5: An opening factor with a value of 0.1961 was used, and the corresponding results are shown in Figure 5a,b.

4.2. Effect of Compartment Area

- Scenario 1: A compartment area with a size of 32.9 m2 was modelled, and the beam lengths were 7 and 4.7 m in length. The corresponding results are shown in Figure 6a,b.

- Scenario 2: A compartment area with a size of 42 m2 was modelled, and the beams were 7 and 6 m long. The corresponding results are shown in Figure 7a,b.

- Scenario 3: A compartment area with a size of 56 m2 was modelled, and the beams were 7 and 8 m long. The corresponding results are shown in Figure 8a,b.

- Scenario 4: A compartment area with a size of 70 m2 was modelled, and the beams were 7 and 10 m long. The corresponding results are shown in Figure 9a,b.

- Scenario 5: A compartment area with a size of 79.8 m2 was modelled, and the beams were 7 and 11.4 m long. The corresponding results are shown in Figure 10a,b.

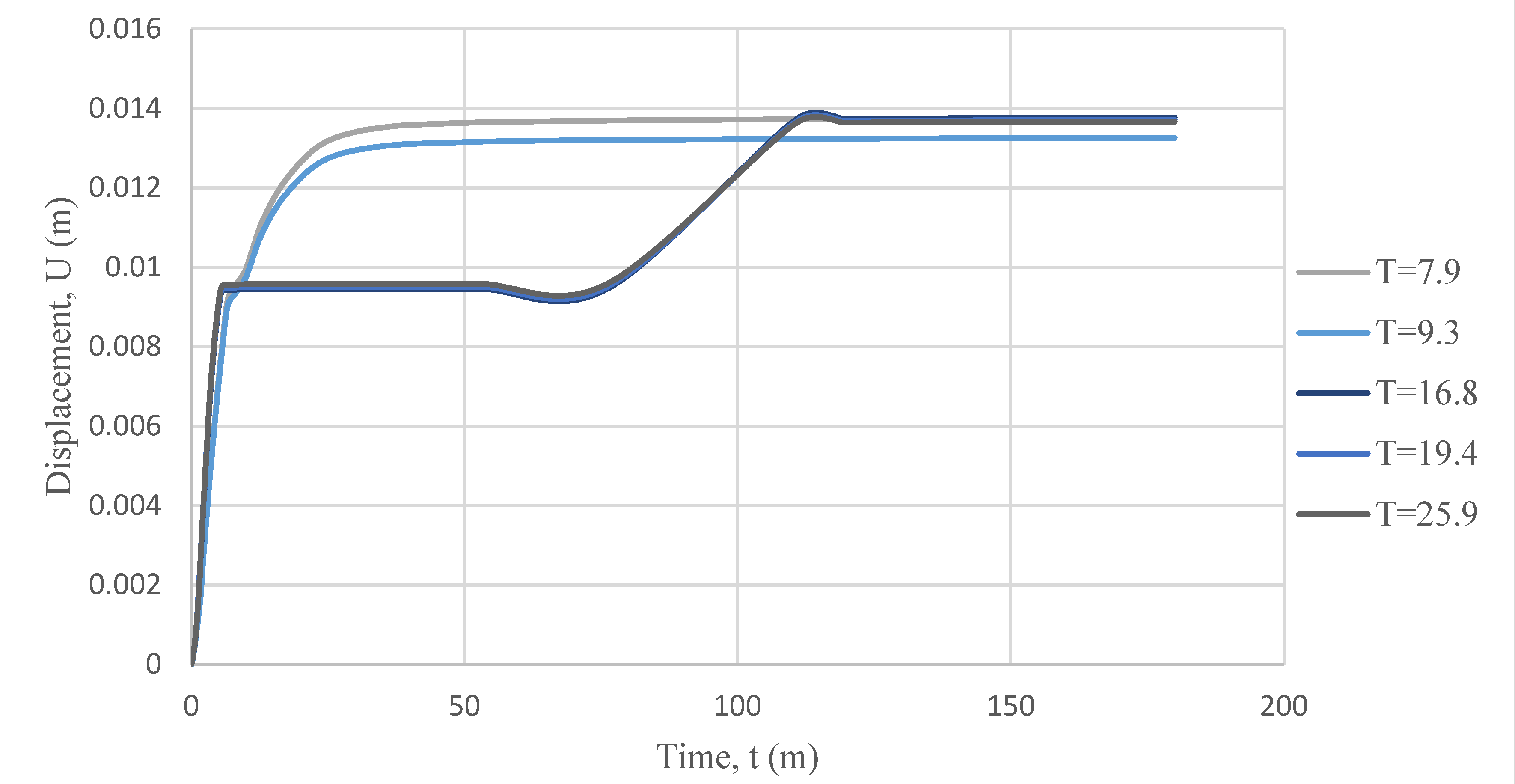

4.3. Effect of Flange Thickness

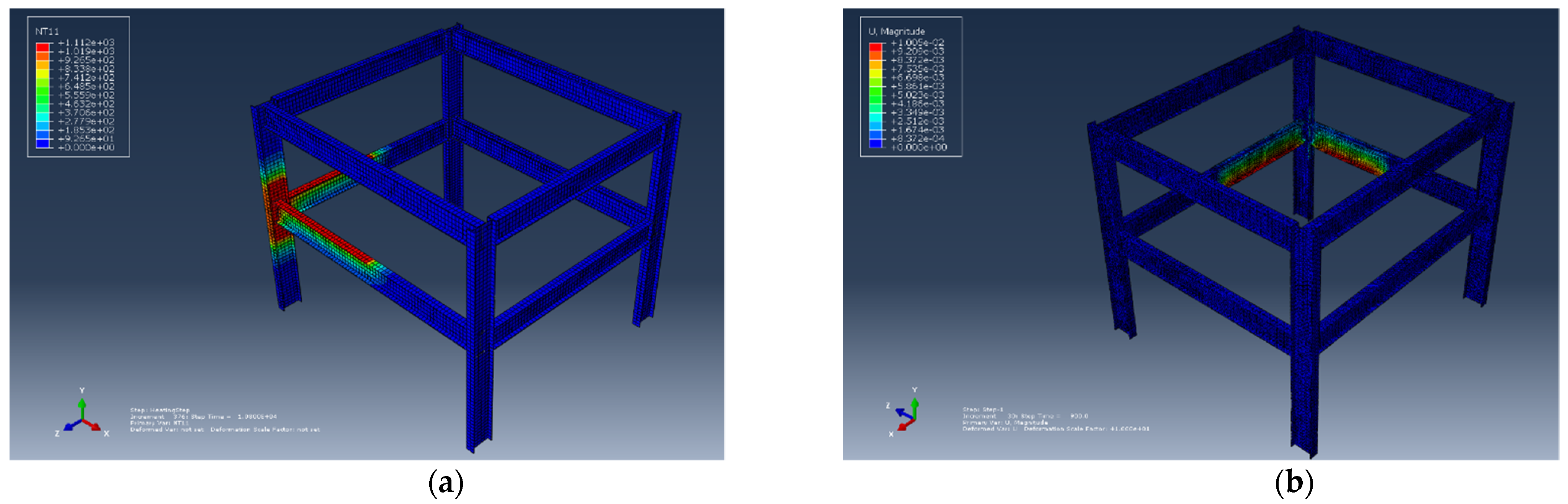

- Scenario 1: The thickness of the flange was set to 7.9 mm, and the corresponding results are shown in Figure 11a,b.

- Scenario 2: The thickness of the flange was set to 9.3 mm, and the corresponding results are shown in Figure 12a,b.

- Scenario 3: The thickness of the flange was set to 16.7 mm, and the corresponding results are shown in Figure 13a,b.

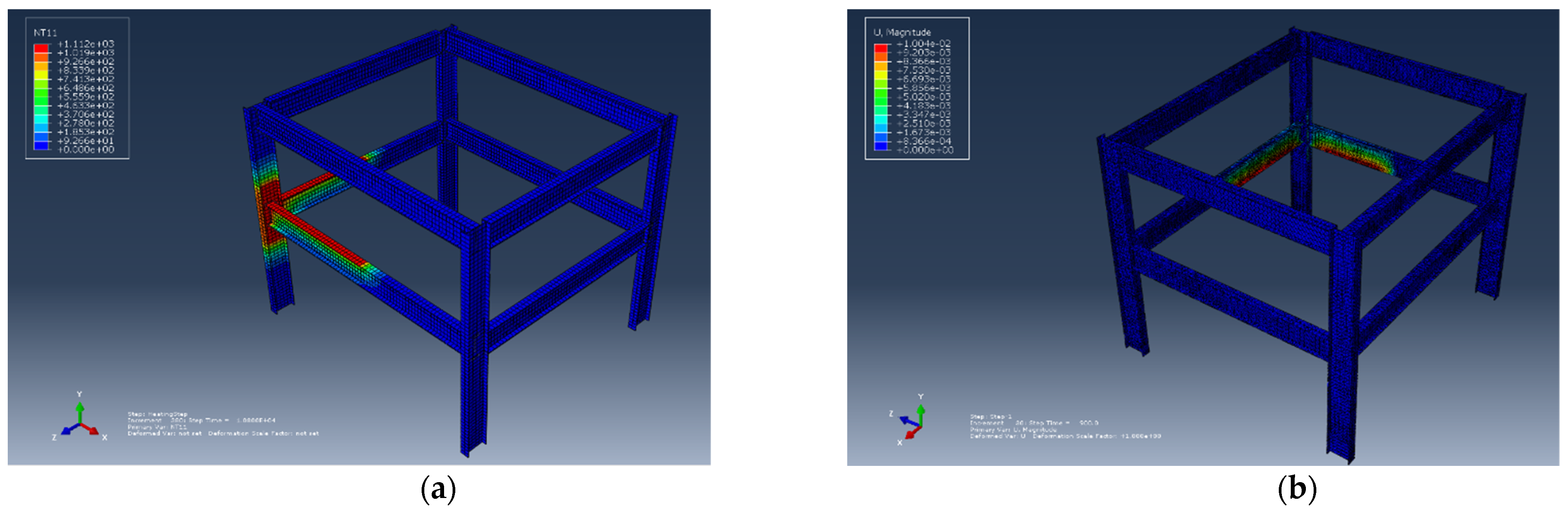

- Scenario 4: The beam flange thickness was set to 19.3 mm, and the corresponding results are shown in Figure 14a,b.

- Scenario 5: The beam flange thickness was set to 25.8 mm, and the corresponding results are shown in Figure 15a,b.

4.4. Summary

5. Conclusions

- The opening factor was found to be the parameter with the most influence on the rate of spread and temperature increase in the fire compartment.

- The flange thickness also has significant influence on the response of structural members, due to its influence on the section factors.

- The compartment area has less of an effect on the response of the structural member

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acom | Area of Compartment |

| At | Area of total internal surface of fire compartment |

| Av | Area of ventilation |

| B | Width of Section |

| b | Thermal Diffusivity |

| C | Specific Heat |

| Ca | Specific Heat of Steel |

| D | Depth of Section |

| heq | Height of Openings |

| O | Opening Factor |

| T | Thickness of Flange |

| t | Time |

| U | Displacement |

| α | Expansion Co-efficient |

| εp | Plastic Strain |

| θa | Steel’s Temperature |

| θg | Gas Temperature in the Fire Compartment |

| λ | Thermal Conductivity |

| λa | Thermal Conductivity of Steel |

| ρ | Density |

| ρa | Density of Steel |

| σ | Stephan-Boltzmann Constant |

| σy | Yield Stress |

| ν | Poisson’s Ratio |

References

- Fitzgerald, R.W. Structural Integrity During Fire; National Fire Protection Association: Quincy, MA, USA, 1997. [Google Scholar]

- Bailey, C. Prescriptive Design Methods in Fire. 2004. Available online: http://www.mace.manchester.ac.uk/project/research/structures/strucfire/Design/prescriptive/default.htm (accessed on 5 January 2018).

- Bailey, C. Zone Models. 2004. Available online: http://www.mace.manchester.ac.uk/project/research/structures/strucfire/Design/performance/fireModelling/zoneModels/default.htm?p=28|#28 (accessed on 5 January 2018).

- Fu, F. Advanced Modelling Techniques in Structural Design; John Wiley & Sons, Ltd.: Chichester, UK, 2015. [Google Scholar]

- Fu, F. Structural Analysis and Design to Prevent Disproportionate Collapse; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Fu, F. Fire Safety Design for Tall Buildings; Taylor Francis: Boca Raton, FL, USA, 2021; ISBN 978-0-367-44452-5. [Google Scholar]

- Fu, F. Design and Analysis of Tall and Complex Structures; Butterworth-Heinemann: Oxford, UK, 2018; ISBN 978-0-08-101121-8. [Google Scholar]

- Tavelli, S.; Rota, R.; Derudi, M. A critical comparison between CFD and zone models for the consequence analysis of fires in congested environments. AIDIC 2014, 36. [Google Scholar] [CrossRef]

- Tagawa, H.; Miyamura, T.; Yamashita, T.; Kohiyama, M.; Ohsaki, M. Detailed finite element analysis of full-scale four-storey steel frame structure subjected to consecutive ground motions. Jpn. Int. J. High-Rise Build. 2015, 4, 65–73. [Google Scholar]

- Wong, J. Reliability of Structural Fire Design; University of Canterbury: Christchurch, New Zealand, 1999. [Google Scholar]

- MathWorks Perform Sensitivity Analysis through Random Parameter. 2018. Variation. Available online: https://www.mathworks.com/discovery/monte-carlo-simulation.html (accessed on 28 March 2018).

- EN 1991-1-2 (2005b)Eurocode 1. Actions on Structures, Part 1-2: General Actions—Actions on Structures Exposed to Fire, Commission of the European Communities: Brussels, Belgium, 2005.

- EN 1993-1-2 (2005a)Eurocode 3. Design of Steel Structures, Part 1-2; General Rules. Structural Fire Design, Commission of the European Communities: Brussels, Belgium, 2005.

- Tartaglia, R.; D’Aniello, M.; Wald, F. Behaviour of seismically damaged extended stiffened end-plate joints at elevated temperature. Eng. Struct. 2021, 247, 113193. [Google Scholar] [CrossRef]

- Qiang, X.; Bijlaard, F.S.K.; Kolstein, H.; Jiang, X. Behaviour of beam-to-column high strength steel endplate connections under fire conditions—Part 2: Numerical study. Eng. Struct. 2014, 64, 39–51. [Google Scholar] [CrossRef]

- Shakil, S.; Lu, W.; Puttonen, J. Response of high-strength steel beam and single-storey frame in fire: Numerical simulation. J. Constr. Steel Res. 2018, 148, 551–561. [Google Scholar] [CrossRef]

| Opening Factor, O (m1/2) | 0.02 ≤ O ≤ 0.2 [12] |

| Compartment Area, Acom (m2) | Acom ≤ 500 [12] |

| Beam Flange Thickness, T (mm) | 7.5 < T < 55 [13] |

| Opening Factor, O (m1/2) | O = 0.0251 |

| O = 0.0554 | |

| O = 0.1129 | |

| O = 0.1689 | |

| O = 0.1961 | |

| Compartment Area, Acom (m2) | Acom = 32.9 |

| Acom = 42 | |

| Acom = 56 | |

| Acom = 70 | |

| Acom = 79.8 | |

| Beam Flange Thickness, T (mm) | T = 7.9066 |

| T = 9.3202 | |

| T = 16.7989 | |

| T = 19.3693 | |

| T = 25.8854 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almadani, R.; Fu, F. Parametric Analysis of a Steel Frame under Fire Loading Using Monte Carlo Simulation. Fire 2022, 5, 25. https://doi.org/10.3390/fire5010025

Almadani R, Fu F. Parametric Analysis of a Steel Frame under Fire Loading Using Monte Carlo Simulation. Fire. 2022; 5(1):25. https://doi.org/10.3390/fire5010025

Chicago/Turabian StyleAlmadani, Ragad, and Feng Fu. 2022. "Parametric Analysis of a Steel Frame under Fire Loading Using Monte Carlo Simulation" Fire 5, no. 1: 25. https://doi.org/10.3390/fire5010025

APA StyleAlmadani, R., & Fu, F. (2022). Parametric Analysis of a Steel Frame under Fire Loading Using Monte Carlo Simulation. Fire, 5(1), 25. https://doi.org/10.3390/fire5010025