Processing the Inner Surfaces of Hollow Ceramic Samples with the Use of Fast Argon Atom Beams

Abstract

1. Introduction

2. Materials and Methods

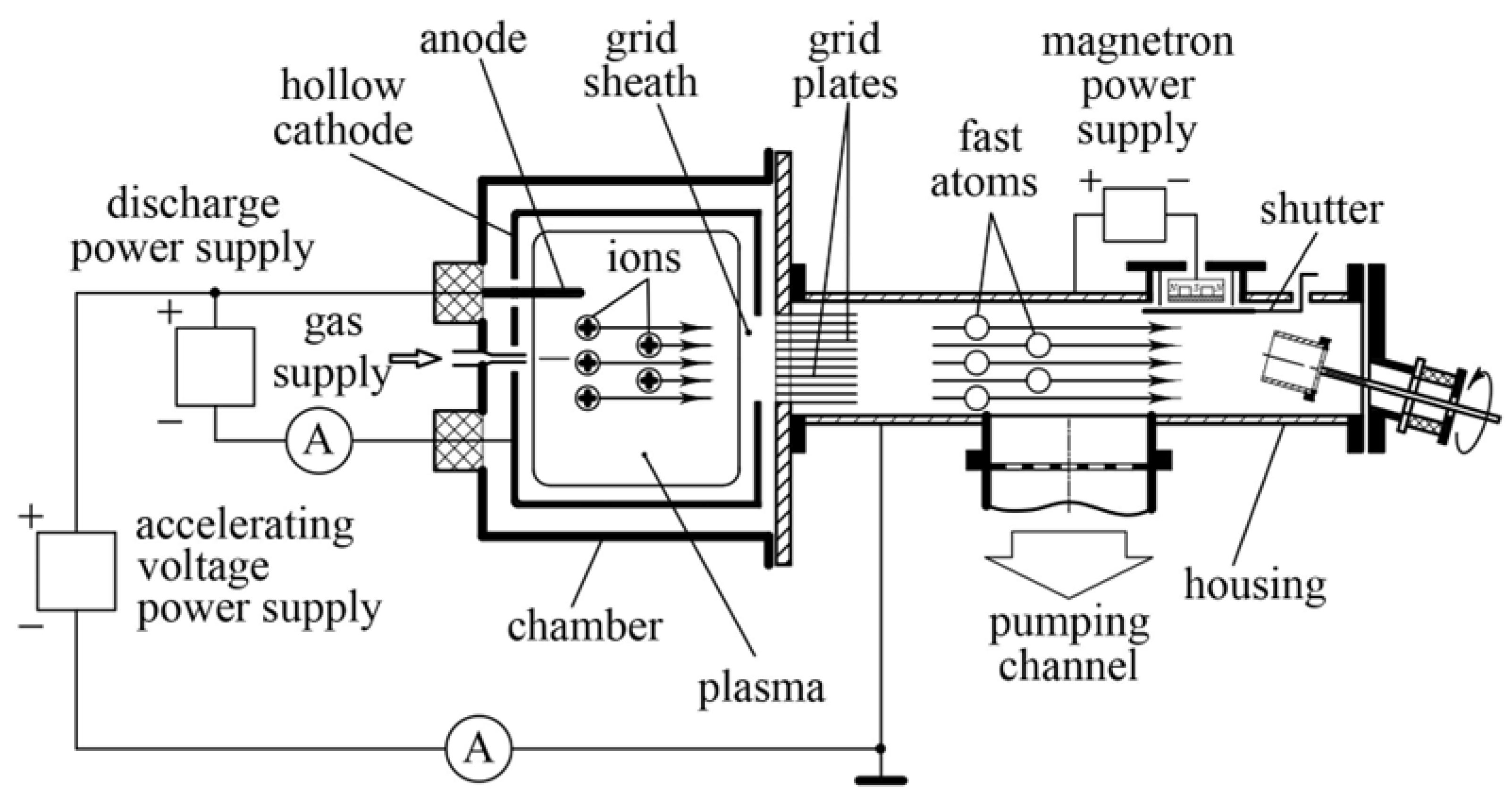

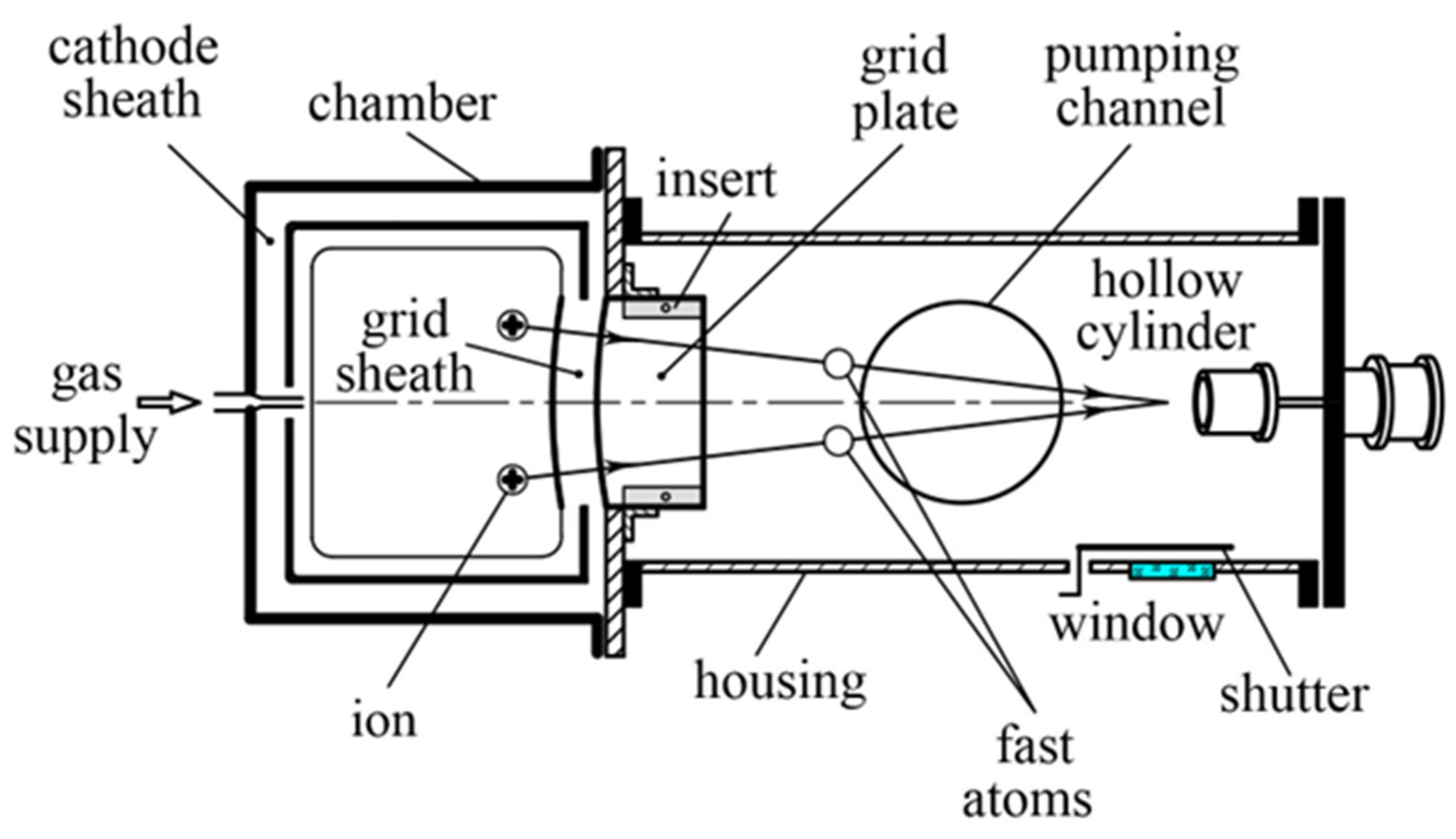

2.1. Plasma and Beam Generation

2.2. Instruments for Characterization of the Samples

3. Results

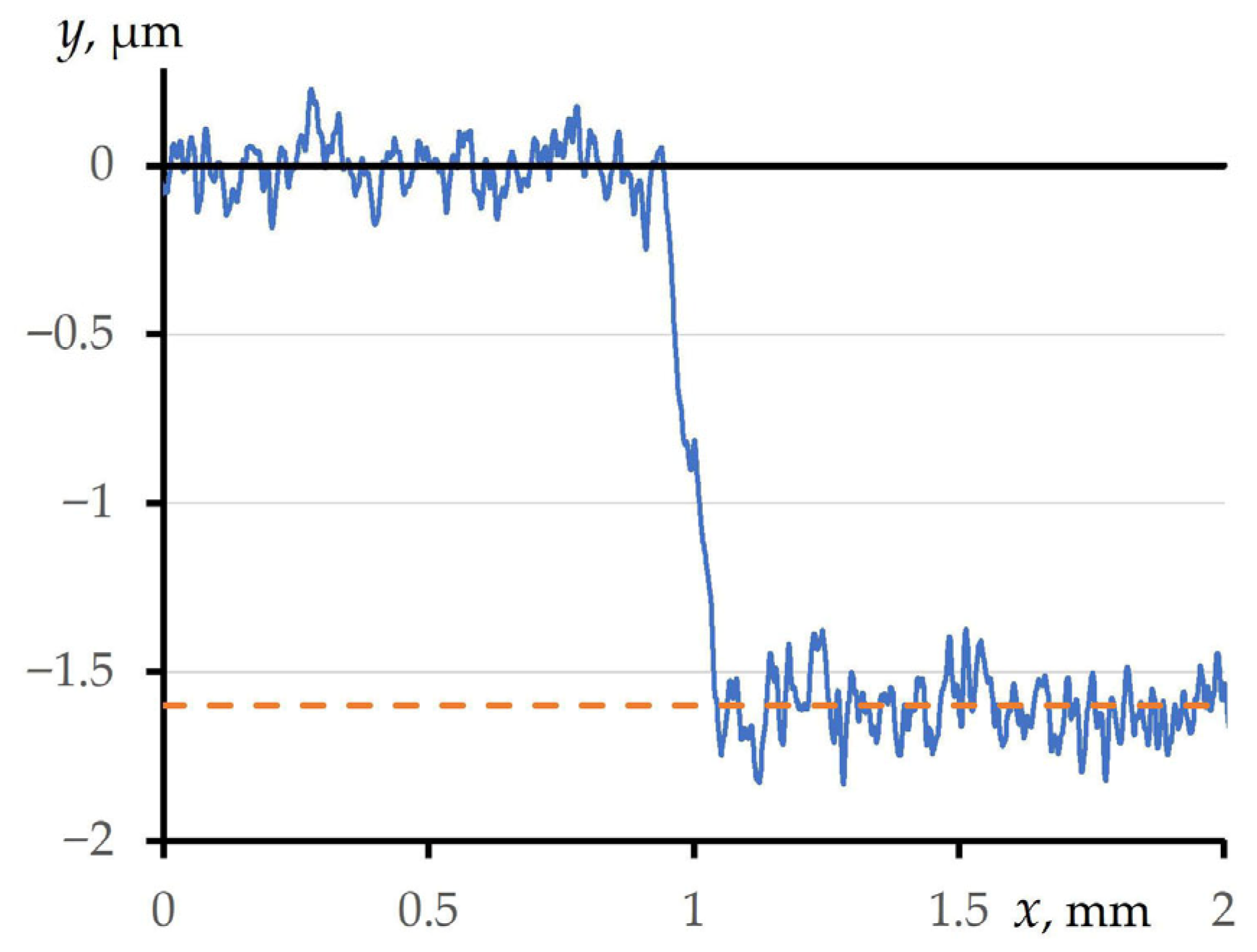

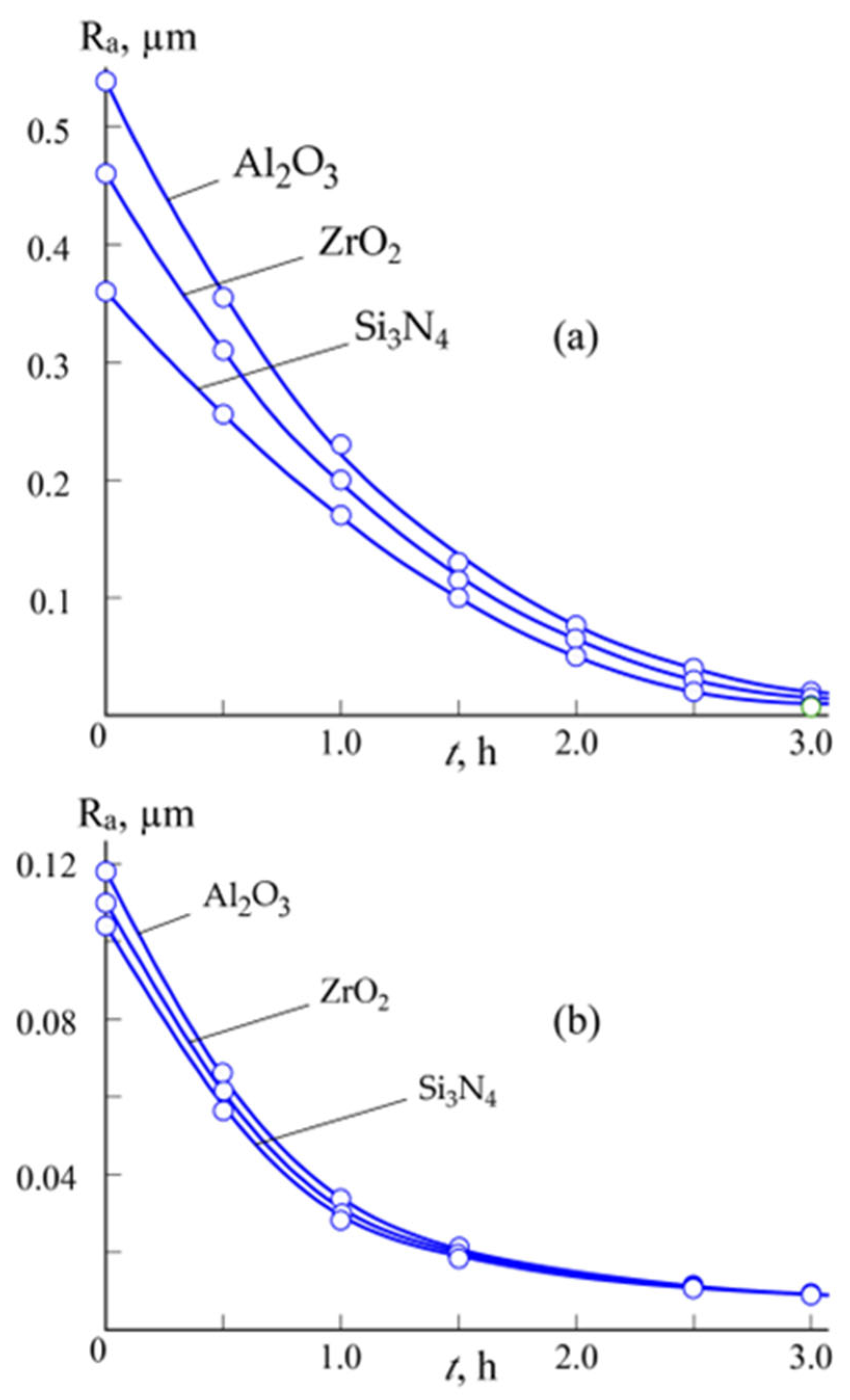

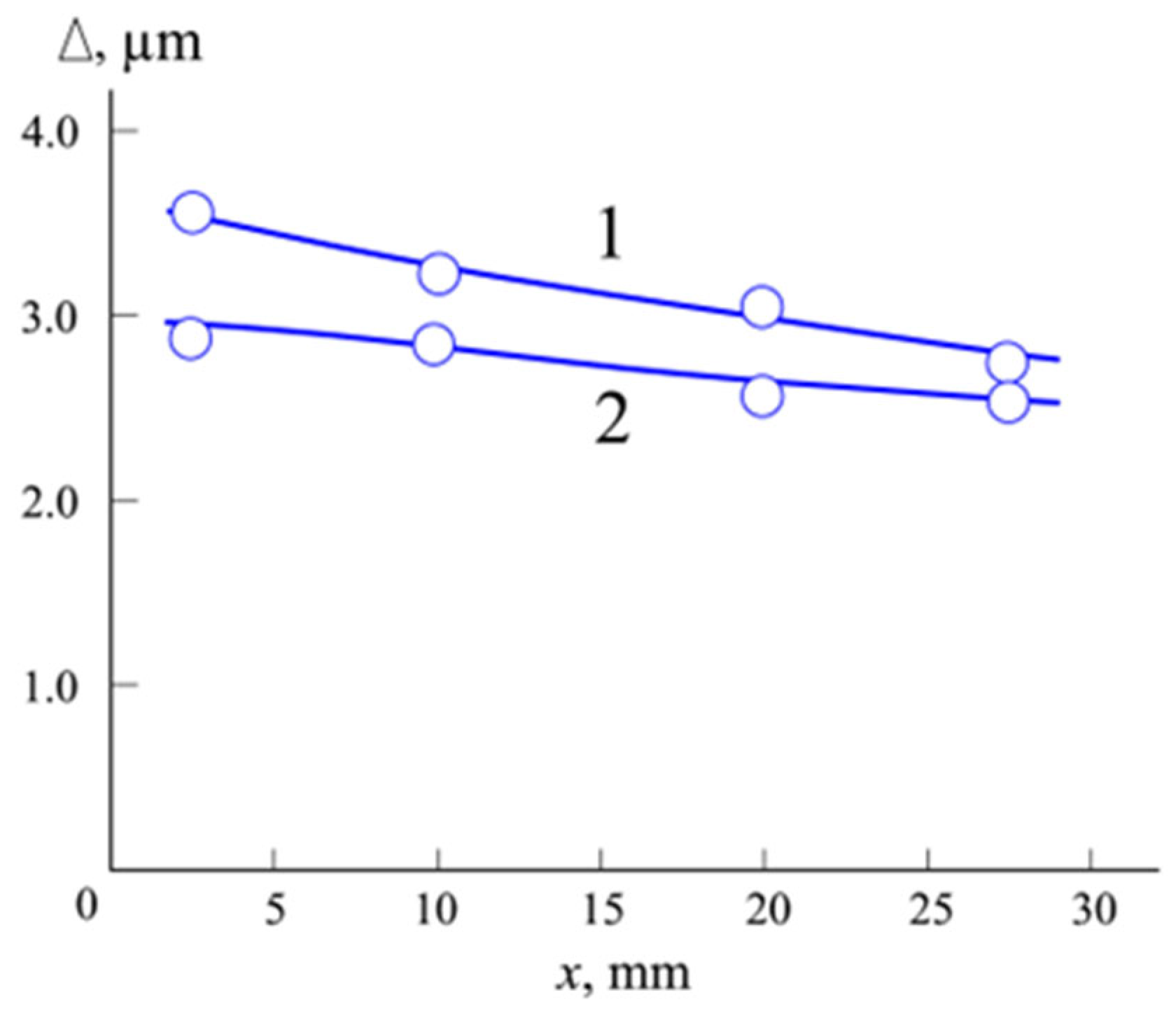

3.1. Sputtering

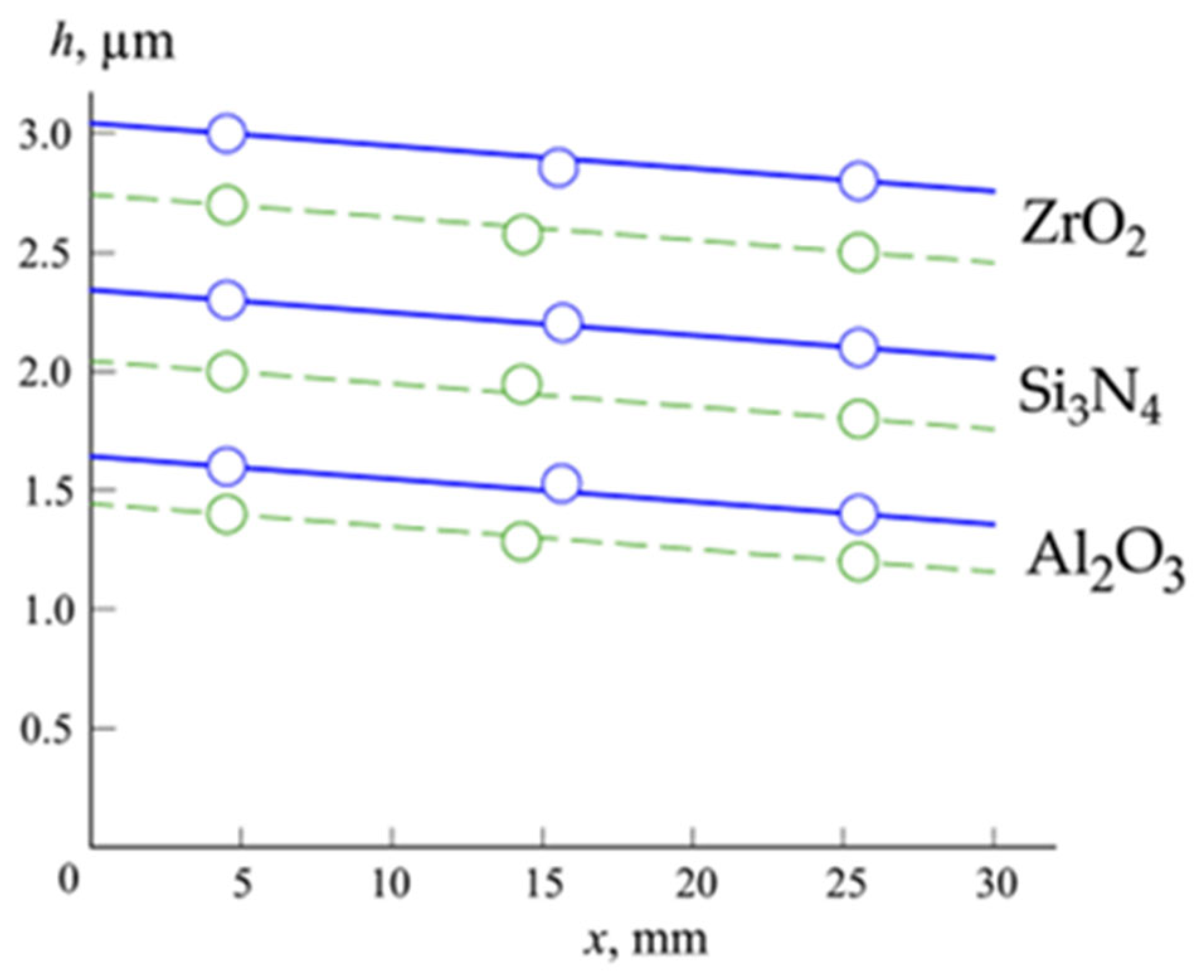

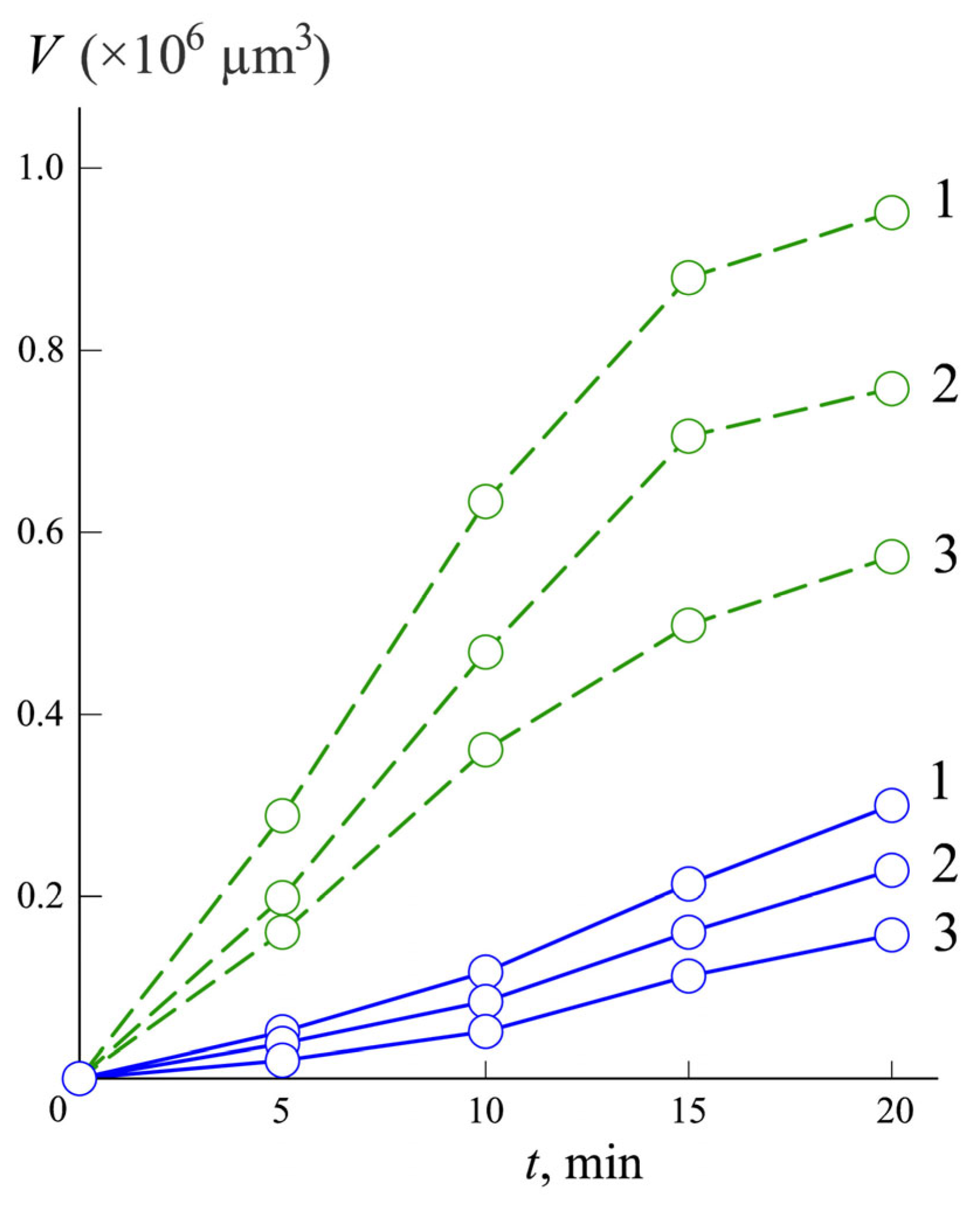

3.2. Coating Deposition

4. Discussion

5. Conclusions

- Using beams of fast argon atoms, it is possible to deposit wear-resistant coatings on inner surfaces of complex-shaped products and noticeably increase their wear-resistance.

- Polishing a product with a beam of fast argon atoms with a large angle of incidence on its surface makes it possible to reduce the surface roughness to Ra ~ 0.01.

- Due to pretreatment of the products with a beam of fast neutral atoms, before the deposition of wear-resistant coating, the coating adhesion was substantially improved, and the abrasive wear became three times smaller.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Danilov, I.; Hackert-Oschätzchen, M.; Zinecker, M.; Meichsner, G.; Edelmann, J.; Schubert, A. Process Understanding of Plasma Electrolytic Polishing through Multiphysics Simulation and Inline Metrology. Micromachines 2019, 10, 214. [Google Scholar] [CrossRef]

- Chirkov, A.M.; Rybalko, A.P.; Rogalsky, Y.I.; Sedoy, E.A.; Merkuhin, A.V.; Borisov, N.V. The Method of Laser-Plasma Polishing of a Metallic Surface. RF. Patent RU 2381094, 10 February 2010. [Google Scholar]

- Obeidi, M.A.; McCarthy, E.; O’Connell, B.; Ahad, I.U.; Brabazon, D. Laser Polishing of Additive Manufactured 316L Stainless Steel Synthesized by Selective Laser Melting. Materials 2019, 12, 991. [Google Scholar] [CrossRef]

- Koval, N.N.; Teresov, A.D.; Ivanov, Y.F.; Petrikova, E.A. Pulse Electron-Beam Metal Product Surface Polishing Method. RF. Patent RU 2619543, 16 May 2017. [Google Scholar]

- Abdul-Kader, A. Surface modifications of PADC polymeric material by ion beam bombardment for high technology applications. Radiat. Meas. 2014, 69, 1–6. [Google Scholar] [CrossRef]

- Škereň, T.; Veselý, M.; Čapek, P.; Král, J. Ion-induced nanopattern propagation on metallic surfaces. Phys. Rev. B 2015, 92, 235406. [Google Scholar] [CrossRef]

- Ieshkin, A.E.; Kushkina, K.D.; Kireev, D.S.; Ermakov, Y.A.; Chernysh, V.S. Polishing superhard material surfaces with gas-cluster ion beams. Tech. Phys. Lett. 2017, 43, 95–97. [Google Scholar] [CrossRef]

- Maishev, Y.P.; Shevchuk, S.L.; Kudrya, V.P. Generation of fast neutral beams based on closed drift ion sources. Russ. Microelectron. 2014, 43, 345–351. [Google Scholar] [CrossRef]

- Nam, S.K.; Economou, D.J.; Donnelly, V.M. Generation of fast neutral beams by ion neutralization in high-aspect-ratio holes: A particle-in-cell simulation study. IEEE Trans. Plasma Sci. 2007, 35, 1370–1378. [Google Scholar] [CrossRef]

- Ruset, C.; Grigore, E. The influence of ion implantation on the properties of titanium nitride layer deposited by magnetron sputtering. Surf. Coat. Technol. 2002, 156, 159–161. [Google Scholar] [CrossRef]

- Grigore, E.; Ruset, C.; Short, K.; Hoeft, D.; Dong, H.; Li, X.; Bell, T. In situ investigation of the internal stress within the nc-Ti2N/nc-TiN nanocomposite coatings produced by a combined magnetron sputtering and ion implantation method. Surf. Coat. Technol. 2005, 200, 744–747. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.; Panin, V.V. Filling the vacuum chamber of a technological system with homogeneous plasma using a stationary glow discharge. Plasma Phys. Rep. 2009, 35, 1058–1067. [Google Scholar] [CrossRef]

- Anders, A. Tutorial: Reactive high power impulse magnetron sputtering. J. Appl. Phys. 2017, 121, 171101. [Google Scholar] [CrossRef]

- Kelly, P.J.; Arnell, R.D. Magnetron sputtering: A review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- McDaniel, E.W. Collision Phenomena in Ionized Gases; Willey: New York, NY, USA, 1964. [Google Scholar]

- Kaminsky, M. Atomic and Ionic Impact Phenomena on Metal Surfaces; Springer: Berlin/Heidelberg, Germany, 1965. [Google Scholar]

- Rutherford, K.L.; Hutchings, I.M. Micro-scale abrasive wear testing of PVD coatings on curved substrates. Tribol. Lett. 1996, 2, 1–11. [Google Scholar] [CrossRef]

- Kaufman, H.R. Broad-beam ion sources. Rev. Sci. Instrum. 1990, 61, 230–235. [Google Scholar] [CrossRef]

- Kaufman, H.R.; Hughes, W.E.; Robinson, R.S.; Tompson, G.R. Thirty-eight-centimeter ion source. Nucl. Instrum. Methods Phys. Res. B 1989, 37–38, 98–102. [Google Scholar] [CrossRef]

- Hayes, A.V.; Kanarov, V.; Vidinsky, B. Fifty-centimeter ion beam source. Rev. Sci. Instrum. 1996, 67, 1638–1641. [Google Scholar] [CrossRef]

- Vizir, A.V.; Yushkov, G.Y.; Oks, E.M. Further development of a gaseous ion source based on low-pressure hollow cathode glow. Rev. Sci. Instrum. 2000, 71, 728–730. [Google Scholar] [CrossRef]

- Grigoriev, S.; Melnik, Y.; Metel, A. Broad fast neutral molecule beam sources for industrial-scale beam-assisted deposition. Surf. Coat. Technol. 2002, 156, 44–49. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Bolbukov, V.P. Broad beam sources of fast molecules with segmented cold cathodes and emissive grids. Instrum. Exp. Technol. 2012, 55, 122–130. [Google Scholar] [CrossRef]

- Phelps, A.V. Cross sections and swarm coefficients for nitrogen ions and neutrals in N2 and argon ions and neutrals in Ar for energies from 0.1 eV to 10 keV. J. Phys. Chem. Ref. Data 1991, 20, 557–573. [Google Scholar] [CrossRef]

- Phelps, A.V.; Greene, C.H.; Burke, J.P. Collision cross sections for argon atoms with argon atoms for energies from 0.01 eV to 10 keV. J. Phys. B At. Mol. Opt. Phys. 2000, 33, 2965–2981. [Google Scholar] [CrossRef]

- Moll, E.; Bergmann, E. Hard coatings by plasma-assisted PVD technologies: Industrial practice. Surf. Coat. Technol. 1989, 37, 483–509. [Google Scholar] [CrossRef]

- Cui, X.; Wang, D.; Guo, J. Effects of material microstructure and surface microscopic geometry on the performance of ceramic cutting tools in intermittent turning. Ceram. Int. 2018, 44, 8201–8209. [Google Scholar] [CrossRef]

- Metel, A.S.; Volosova, M.A.; Melnik, Y.A.; Mustafaev, E.S.; Grigoriev, S.N. Removal of Wear-Resistant Coatings from Cutting Tools by Fast Argon Atoms. Coatings 2023, 13, 999. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Metel, A.S.; Volosova, M.A.; Mustafaev, E.S.; Melnik, Y.A. Polishing Ceramic Samples with Fast Argon Atoms at Different Angles of Their Incidence on the Sample Surface. Plasma 2024, 7, 816–825. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metel, A.S.; Volosova, M.A.; Mustafaev, E.S.; Melnik, Y.A.; Grigoriev, S.N. Processing the Inner Surfaces of Hollow Ceramic Samples with the Use of Fast Argon Atom Beams. Plasma 2025, 8, 47. https://doi.org/10.3390/plasma8040047

Metel AS, Volosova MA, Mustafaev ES, Melnik YA, Grigoriev SN. Processing the Inner Surfaces of Hollow Ceramic Samples with the Use of Fast Argon Atom Beams. Plasma. 2025; 8(4):47. https://doi.org/10.3390/plasma8040047

Chicago/Turabian StyleMetel, Alexander S., Marina A. Volosova, Enver S. Mustafaev, Yury A. Melnik, and Sergey N. Grigoriev. 2025. "Processing the Inner Surfaces of Hollow Ceramic Samples with the Use of Fast Argon Atom Beams" Plasma 8, no. 4: 47. https://doi.org/10.3390/plasma8040047

APA StyleMetel, A. S., Volosova, M. A., Mustafaev, E. S., Melnik, Y. A., & Grigoriev, S. N. (2025). Processing the Inner Surfaces of Hollow Ceramic Samples with the Use of Fast Argon Atom Beams. Plasma, 8(4), 47. https://doi.org/10.3390/plasma8040047