Latest Developments in 3D-Printed Engineered Cementitious Composites: Technologies, Prospects, and Challenges

Abstract

1. Introduction

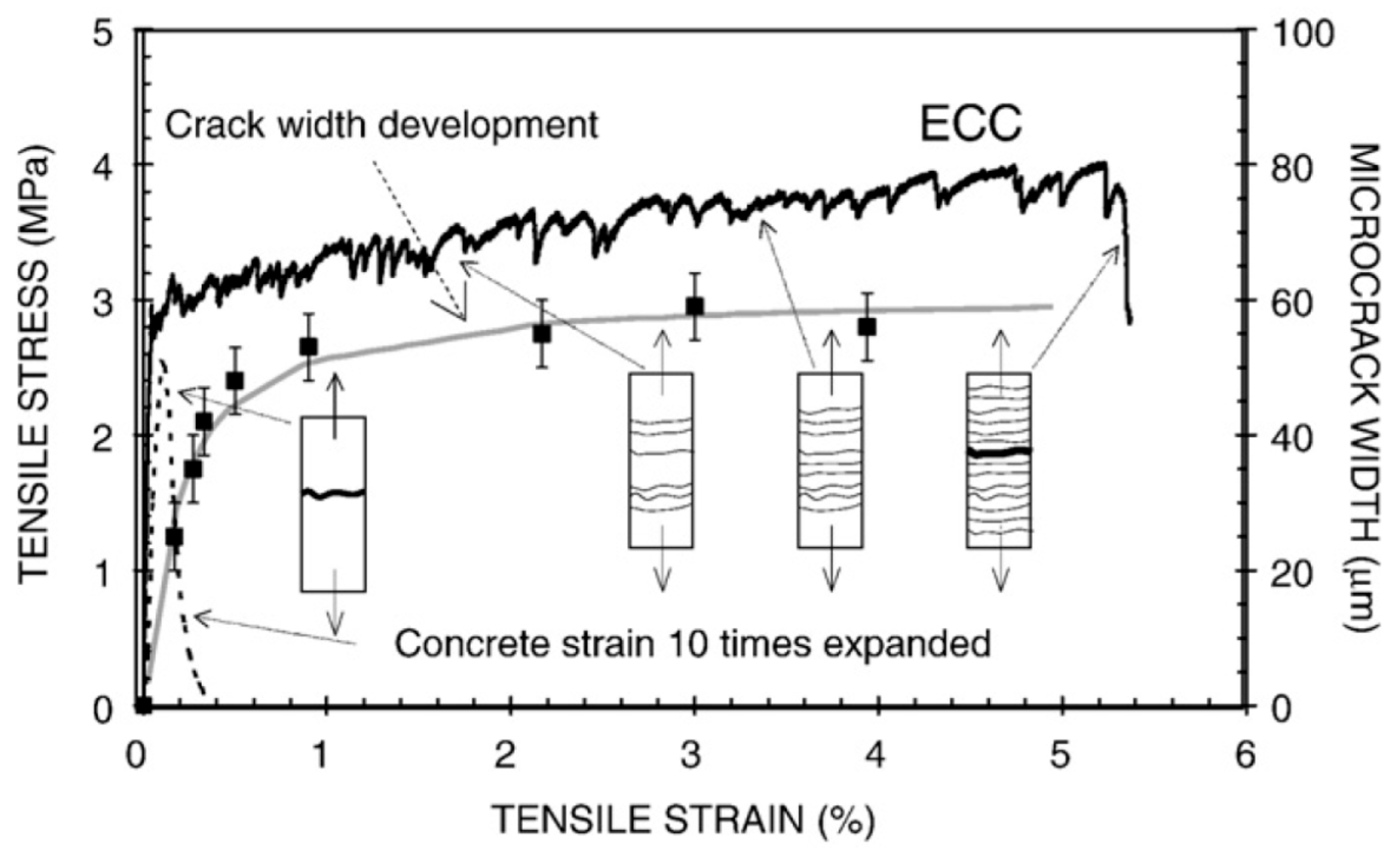

2. Composition of ECC

- Amount ≤ 2 vol%;

- Diameter from 20 to 50 μm;

- Length from 6 to 12 mm; increasing fiber length leads to poorer printability;

- Tensile strength ≥ 800 MPa;

- Elastic tensile modulus ≥ 10 GPa;

- Tensile strain capacity ≥ 3%;

- Limited or no interfacial chemical bond;

- Interfacial frictional bond from 1 to 6 MPa, depending on fiber strength;

- Enough corrosion resistance and chemical stability in cementitious systems;

- Stability of properties over time.

- PE and PVA fibers that are 20–50 µm in Ø are commonly used for ECC manufacturing;

- Recycled aramid nanofibers seem promising as well;

- High aspect ratios are needed;

- A high tensile strength and a rather low bond strength with the cementitious matrix are desirable;

- Common dosages are 1–2 vol%;

- Chemical stability in high-pH environments is mandatory.

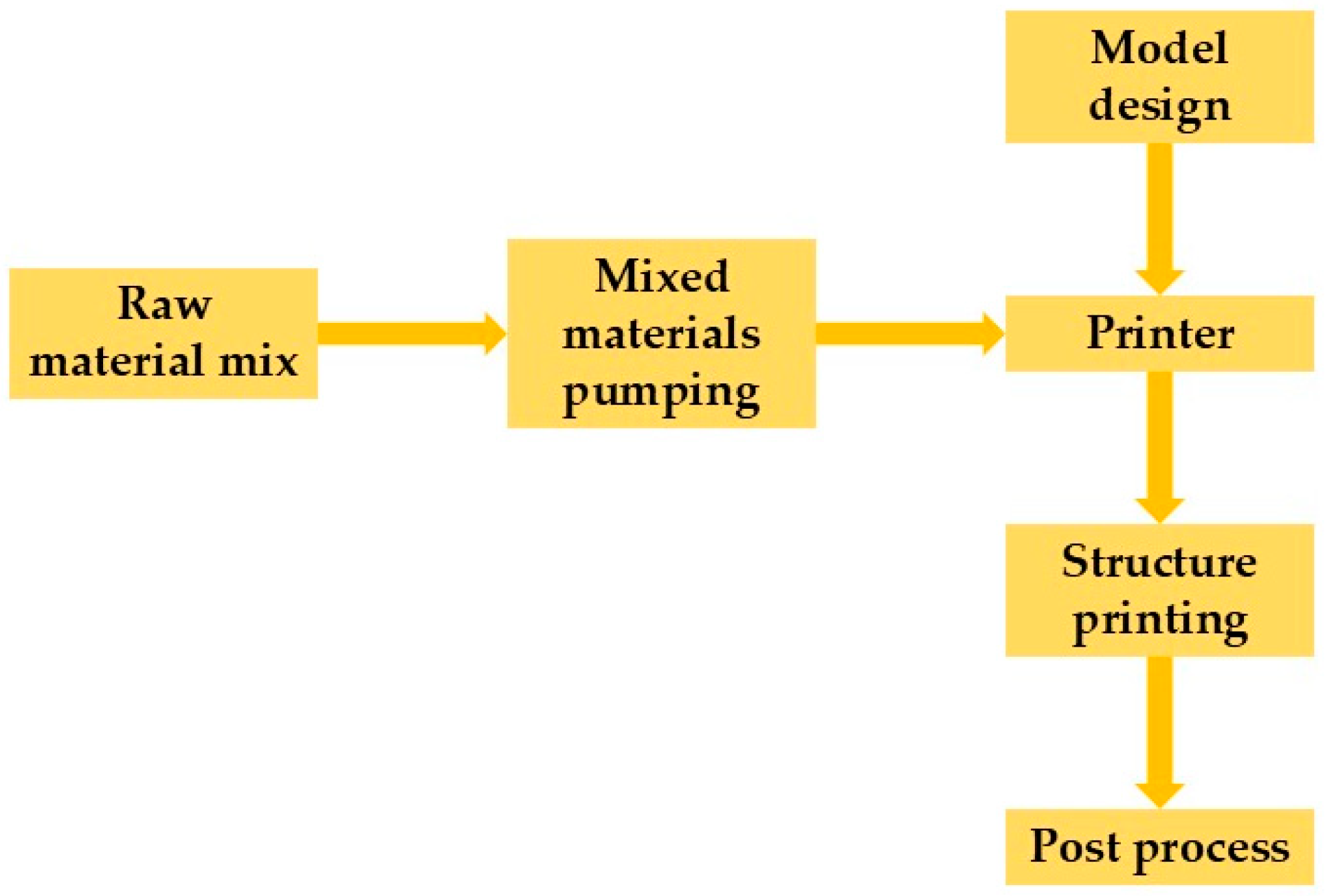

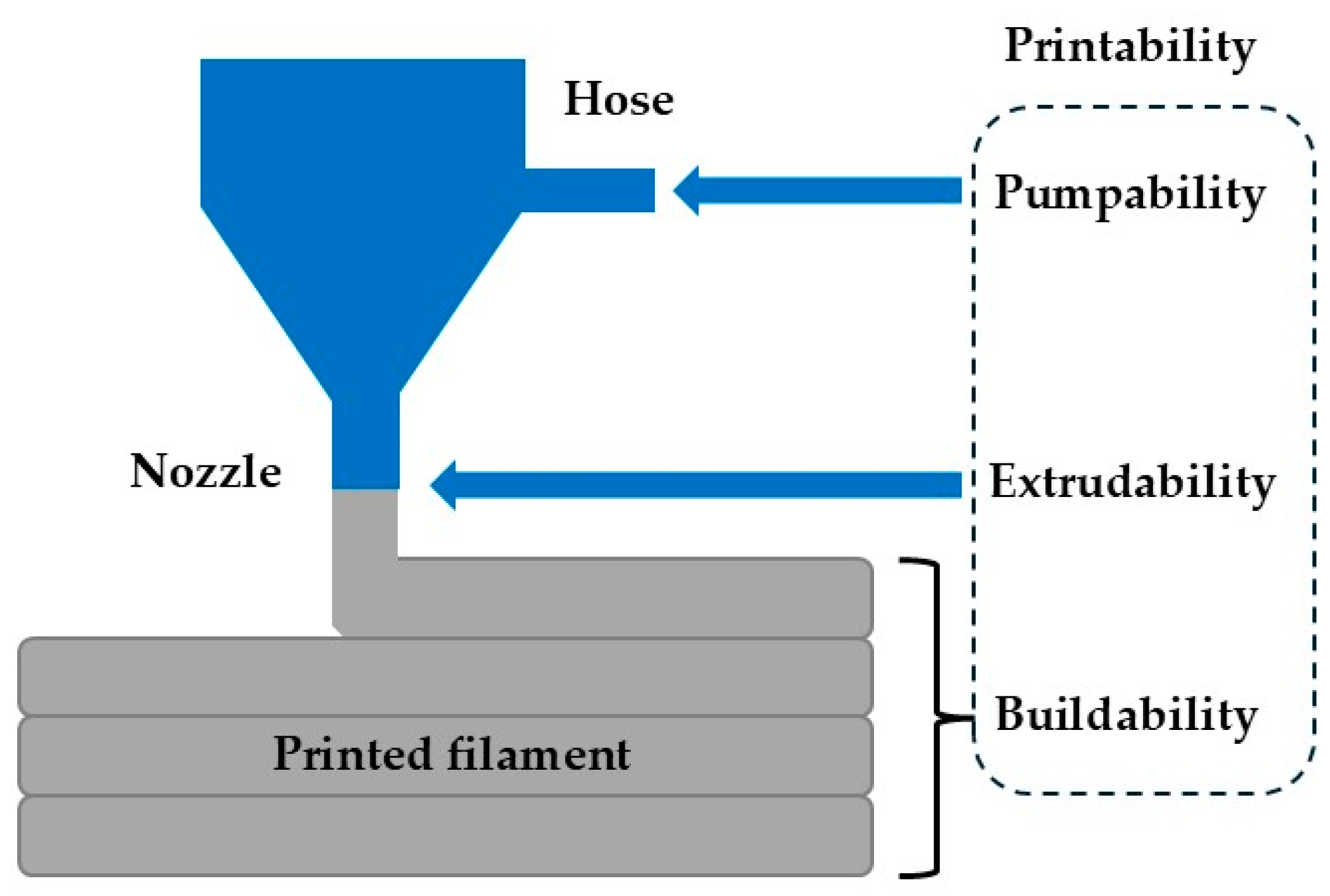

3. Printing Processes with Concrete

- The extrusion speed should match the printing speed to control the shape and quality of printed filaments;

- Long delays between printing one filament above an existing are not advisable;

- The standoff distance should be kept constant throughout the process.

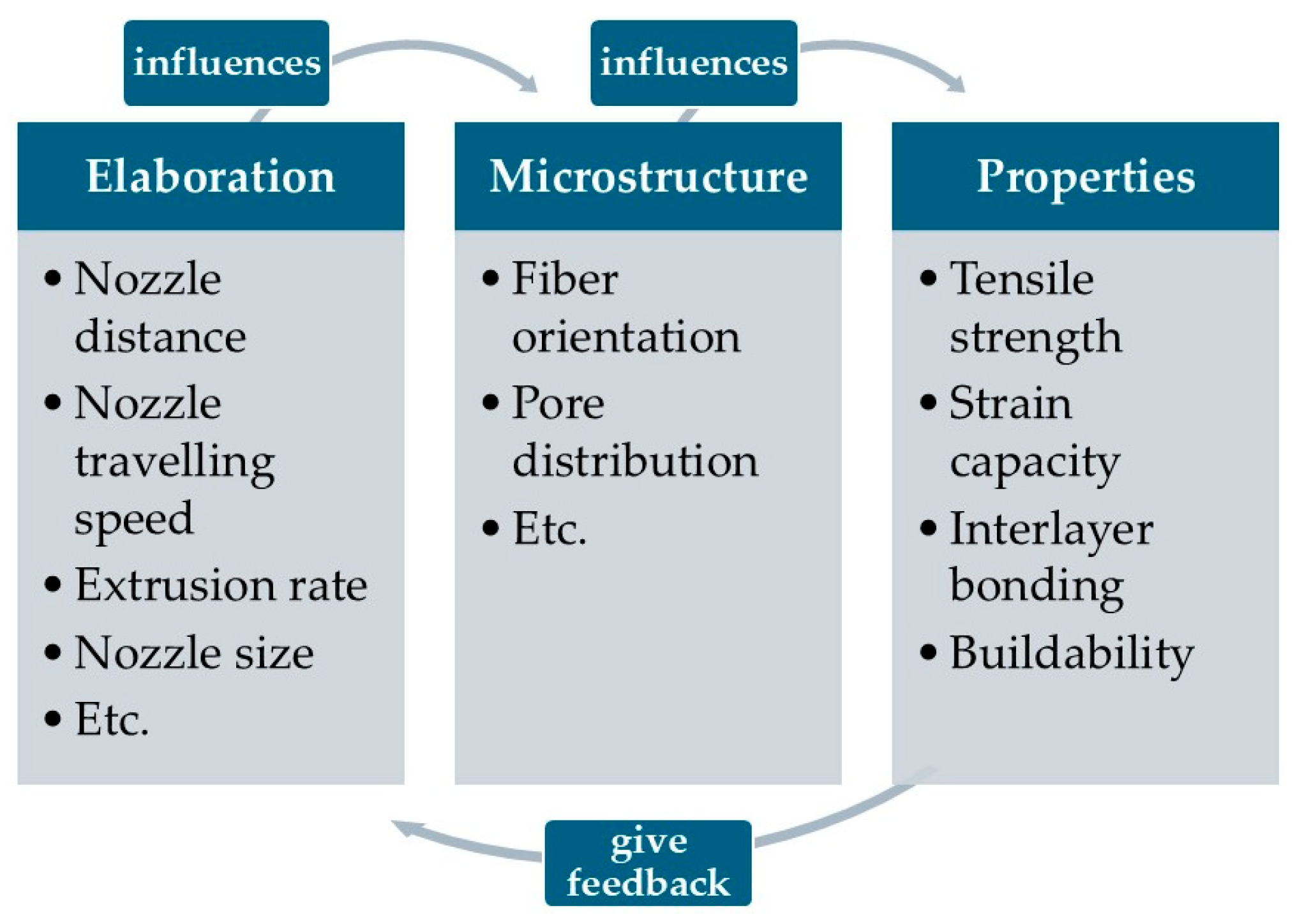

4. Extrusion Process and Fresh State Properties

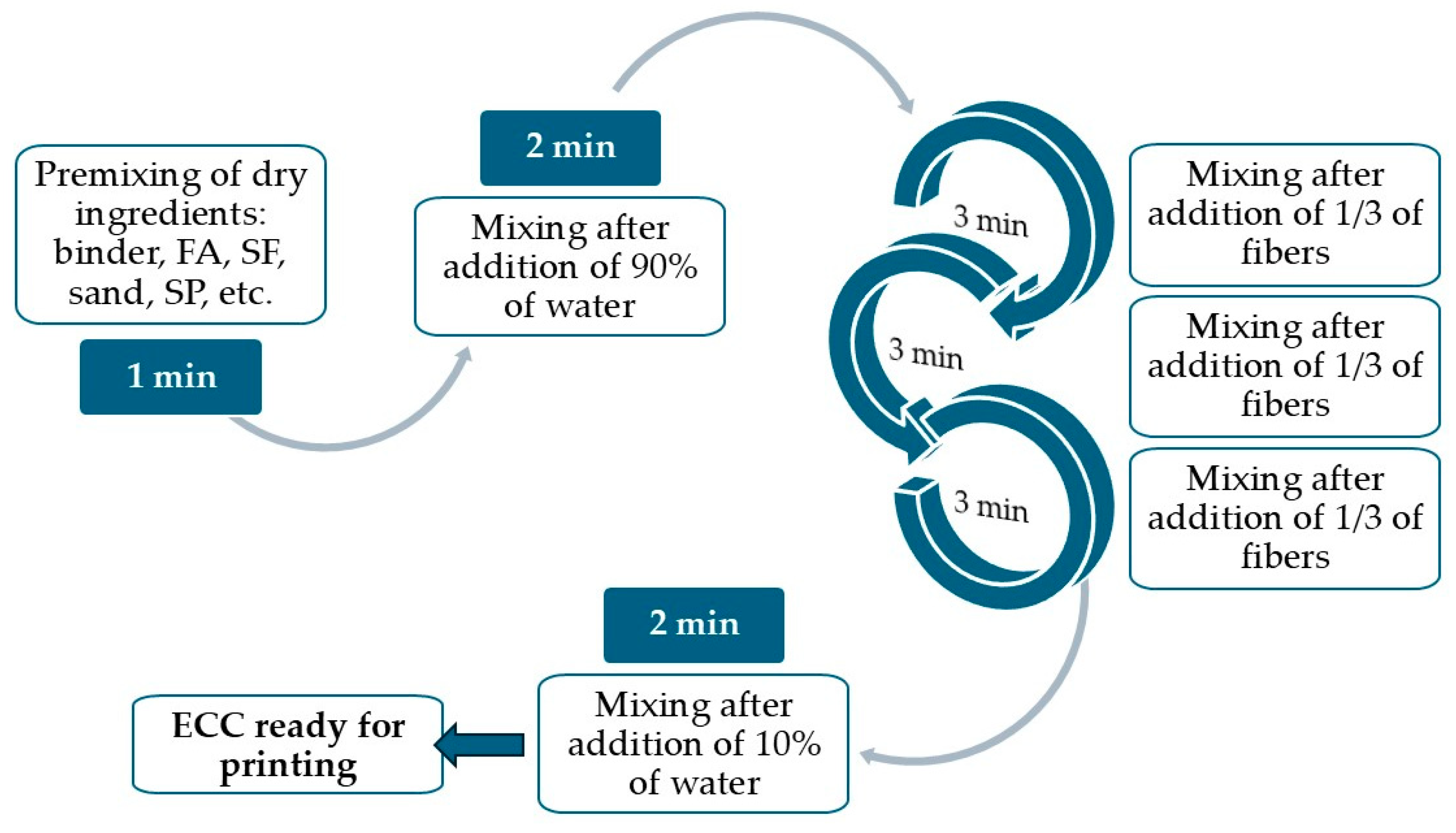

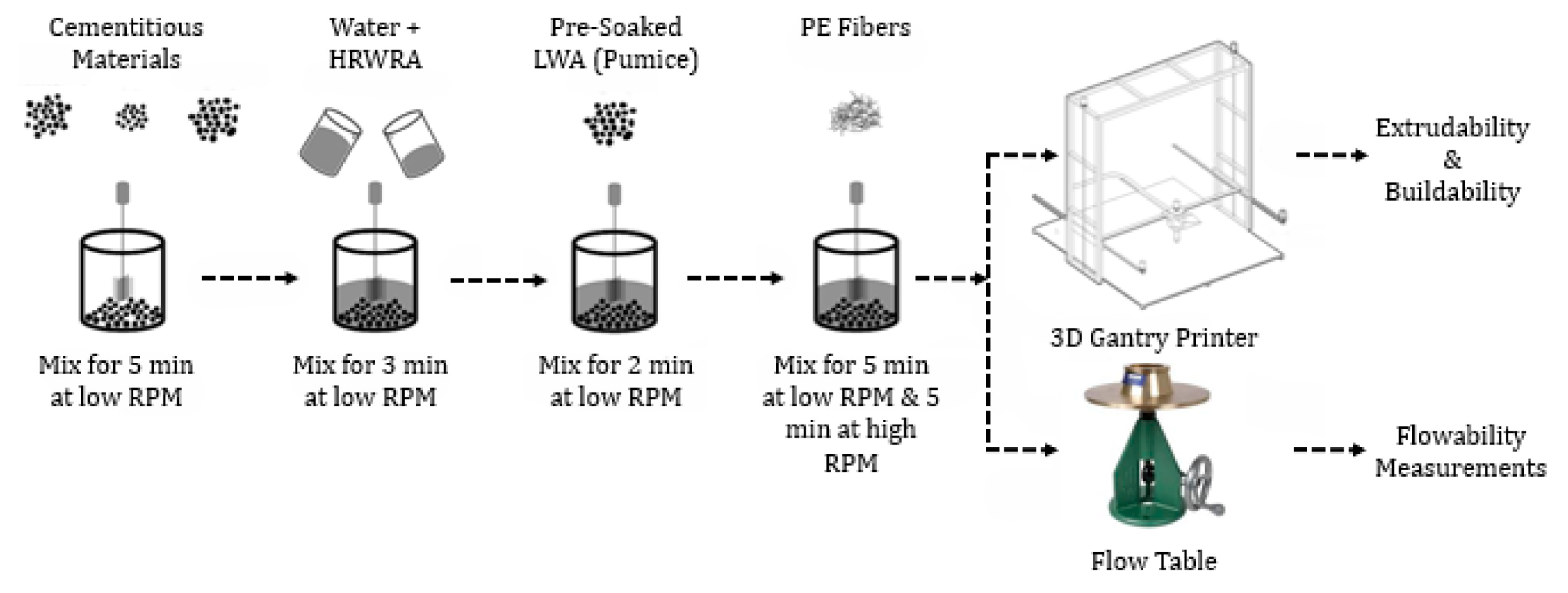

4.1. Mixing Procedure

4.2. Material Features

- -

- Dynamic open time: The material is in the mixer at 140 rpm, simulating its movement in the hopper during the printing process.

- -

- Dynamic–static open time: The material is kept without agitation in the mixer, and agitation is applied at 140 rpm for 30 s before measuring the consistency.

4.3. Influence of Nozzle Size

4.4. Rheological Properties

4.5. Printing Parameters with ECCs

- The order of mixing the products is fundamental in 3DP-ECC: First, solids are dry-mixed, then water and SP are added, and fibers are progressively introduced in the mix. Finally, the VMA is supplemented;

- The open time should be 30–60 min and should be compatible with buildability;

- An optimized particle size distribution guarantees a good packing of particles and contributes to buildability;

- The mix should have a low initial stiffness to be pumped and extruded, while the buildability requirement requires a stiff material able to bear its own weight;

- Fibers increase the yield stress at rest times, as well as the plastic viscosity and the dynamic yield stress;

- HPMC increases the viscosity and the thixotropy and prevents segregation when pumping as well as favors the internal curing effect;

- A high thixotropy is helpful to guarantee that the extruded layers firmly stack up;

- Microsilica, ground silica flour, and attapulgite nanoclay improve early strength and thixotropy and enhance cohesion. The silica fume content and the water-to-solid ratio are important parameters to optimize the fresh properties and strain-hardening behavior. Calcium aluminate and sulphoaluminate cements increase the early flowability and the early strength;

- The liquid-to-solid ratio of the mix is fundamental for the shape stability of printable mixtures, rather than the superplasticizer content;

- A nozzle with a smaller width-to-height ratio has a higher probability of smooth printing;

- The maximum printable height value can be estimated and used to set the nozzle standoff distance when printing to avoid structural instability problems;

- ECC pastes behave as non-Newtonian fluids, whose behavior is usually described by the Bingham model;

- The yield stress of the mix should be lower than the maximum shear force exerted by the extrusion system;

- The yield stress can be related to the slump value.

5. New Compositions

5.1. Use of Limestone-Calcined Clay Cement

5.2. Strain-Sensing Cements

5.3. Rubberized ECCs

5.4. Carbonation Curing

- More sustainable ECC compositions based on limestone-calcined clay cement (LC3) can be successfully developed and printed;

- New mixes containing crumb rubber, recycled aggregates [118], and conducting fillers can be printed to produce more sustainable and self-sensing concretes;

- Carbon curing can be actuated on ECCs, which can lower the pH of the matrix and make it more compatible with natural fibers.

6. Mechanical Properties and Durability of Printed ECCs

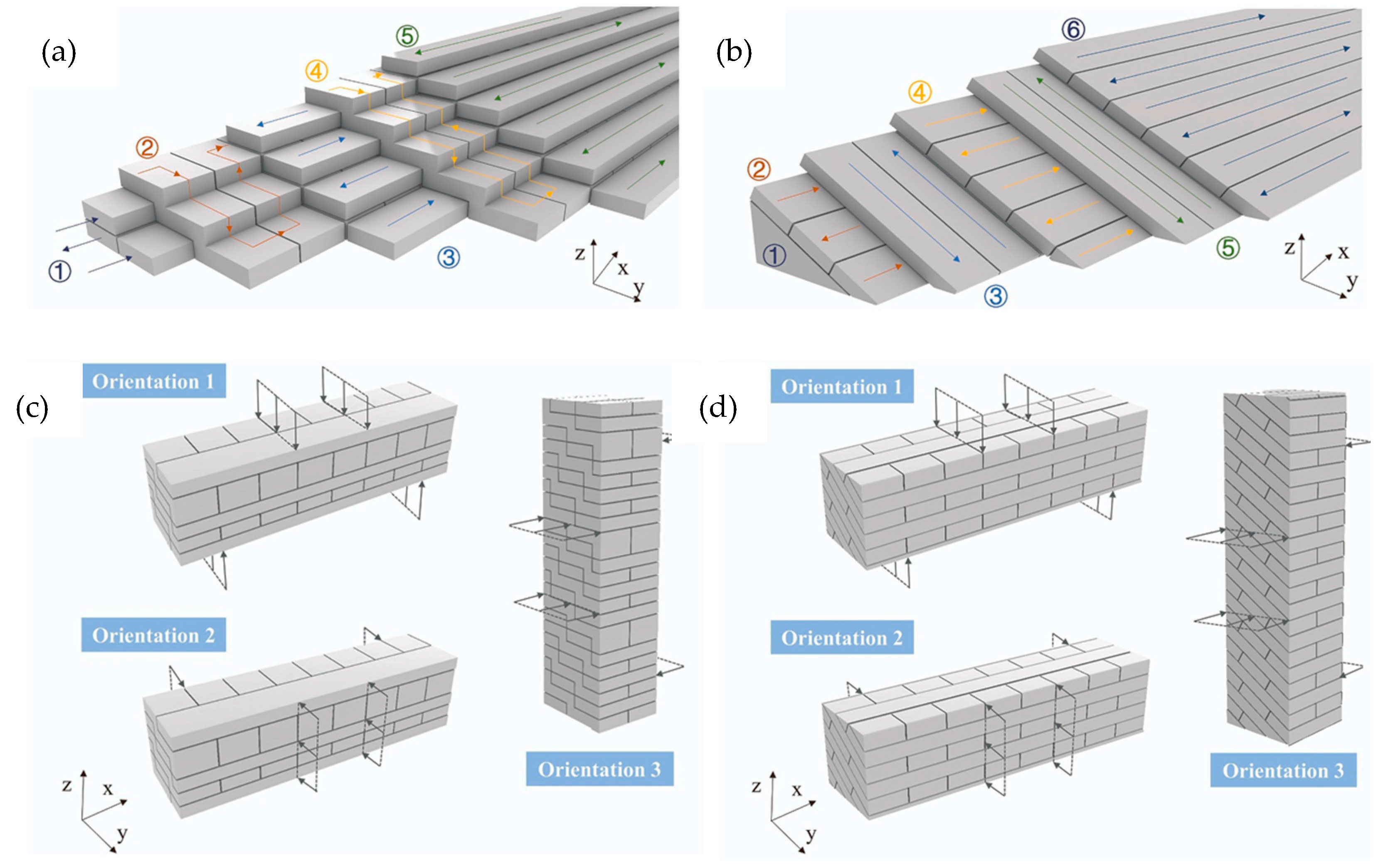

6.1. Anisotropy of Mechanical Properties

6.2. Patterned Structures

- 3DP-ECCs show anisotropic properties according to the printing direction;

- The ductility in the filament in the perpendicular direction is much lower, specifically in the vertical direction across the interfaces;

- Groove printing seems to be a promising solution to produce tougher filament-to-filament interfaces;

- Patterned structures like Bouligand ones, as well as knitted and tilted structures, can improve fracture performance for specific applications. They also fully exploit 3D printing potentialities;

- Durability aspects of 3DP-ECCs are still to be investigated.

7. Critical Steps in the Printing Process

- When the nozzle standoff distance decreases by about 30%, the strain capacity of the same mixture can be increased by about 30%, while the tensile strength can be up to 39% higher;

- Moderate printing speeds yield superior tensile strength;

- Low printing speeds could lead to potential accumulation of an excess of material and should be adapted to the feeding rate of the nozzle (better integration and interface between the hardware of the printing chain).

8. Current Technical Challenges and Limitations

- Fiber dispersion is of paramount importance, and rheological properties should be adapted;

- Internal curing should be considered to improve mechanical strength;

- Further micromechanics and fracture mechanics concepts should be studied to understand the mechanical behavior of 3DP-ECCs;

- Safety precautions should be taken by workers when handling PE fibers.

9. Advancing the Field of ECCs Through Machine Learning

- SCM-to-binder ratio;

- Aggregate-to-binder and water-to-binder ratios;

- Fiber reinforcing index;

- Loading direction.

10. Conclusions and Perspectives

- Chemical stability of fibers in high-pH environments is mandatory;

- PE and PVA fibers that are 20–50 µm in Ø are commonly used for ECC manufacturing;

- Recycled aramid nanofibers seem promising as well;

- High aspect ratios are needed;

- Common dosages are 1–2 vol%;

- A high tensile strength and a rather low bond strength with the cementitious matrix are desirable;

- Fibers increase the yield stress at rest times, as well as the plastic viscosity and the dynamic yield stress;

- Fiber dispersion is of paramount importance, and rheological properties should be adapted;

- An optimized particle size distribution guarantees a good packing of particles and contributes to buildability;

- The open time should be 30-60 min and should be compatible with buildability;

- The order of mixing the products is fundamental in 3DP-ECC: first, solids are dry-mixed, then water and SP are added, and fibers are progressively introduced in the mix. Finally, the VMA is supplemented;

- The mix should have a low initial stiffness to be pumped and extruded, while the buildability requires a stiff material able to bear its own weight. Stiffness can be increased by CSA or sodium silicate additions;

- The extrusion speed should match the printing speed to control the shape and quality of printed filaments;

- Long delays between printing one filament above an existing are not advisable;

- When the nozzle standoff distance decreases by about 30%, the strain capacity of the same mixture can be increased by about 30%, while the tensile strength can be up to 39% higher;

- Internal curing should be considered to improve mechanical strength;

- Carbon curing can be actuated in ECCs, which can lower the pH of the matrix and make it more compatible with natural fibers.

- SCM-to-binder ratio;

- Aggregate-to-binder and water-to-binder ratios;

- Fiber reinforcing index;

- Loading direction.

Funding

Conflicts of Interest

Abbreviations

| ECC | Engineered cementitious composite |

| SHCC | Strain-hardening cementitious composite |

| 3D-SHCC | 3D-printable strain-hardening cementitious composite |

| SCM | Supplementary cementitious material |

| PVA | Polyvinyl alcohol |

| PE | Polyethylene |

| PET | Polyethylene terephthalate |

| 3DPC | 3D printing process of concrete |

| 3DP-ECC | 3D-printed ECC |

| FA | Fly ash |

| SF | Silica fume |

| SP | Superplasticizer |

| HRWRA | High-range water-reducing agent |

| HPMC | Hydroxypropyl methyl cellulose |

| w/b | Water-to-binder |

| IBA | Incinerator bottom ash |

| OPC | Ordinary Portland cement |

| s/b | Sand-to-binder |

| UCCT | Uniaxial unconfined compression test |

| LC3 | Limestone-calcined clay cement |

| CSA | Calcium sulphoaluminate |

| LL-ECC | Lightweight engineered cementitious composites |

| G | Graphite |

| MCMF | Milled carbon microfibers |

| CCMF | Chopped carbon microfibers |

| ML | Machine learning |

| ANN | Artificial neural network |

| NSGA-II | Sorting genetic algorithm II |

| GRA | Grey relational analysis |

| BPANN | Back-propagation artificial neural network |

| SHAP | Shapley additive explanations |

| PDP | Partial dependence plots |

| PEG | Polyethylene glycol |

References

- Mohajerani, A.; Hui, S.-Q.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Abdul Kadir, A.; Rahman, M.T.; Maghool, F. Amazing Types, Properties, and Applications of Fibres in Construction Materials. Materials 2019, 12, 2513. [Google Scholar] [CrossRef]

- Romualdi, J.P.; Batson, G.B. Mechanics of Crack Arrest in Concrete. J. Eng. Mech. Div. 1963, 89, 147–168. [Google Scholar] [CrossRef]

- Romualdi, J.P.; Mandel, J.A. Tensile Strength of Concrete Affected by Uniformly Distributed and Closely Spaced Short Lengths of Wire Reinforcement. ACI J. Proc. 1964, 61, 657–672. [Google Scholar] [CrossRef]

- Gencturk, B. Life-Cycle Cost Assessment of RC and ECC Frames Using Structural Optimization. Earthq. Eng. Struct. Dyn. 2013, 42, 61–79. [Google Scholar] [CrossRef]

- Li, V.C. From Micromechanics to Structural Engineering-the Design of Cementitous Composites for Civil Engineering Applications. Struct. Mech. Earthq. Eng. 1993, 10, 37–48. [Google Scholar] [CrossRef]

- Yu, K.; Li, L.; Yu, J.; Wang, Y.; Ye, J.; Xu, Q. Direct Tensile Properties of Engineered Cementitious Composites: A Review. Constr. Build. Mater. 2018, 165, 346–362. [Google Scholar] [CrossRef]

- Li, V.C. Engineered Cementitious Composites (ECC). In Bendable Concrete for Sustainable and Resilient Infrastructure; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Li, V.C. On engineered cementitious composites (ECC). J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Durability Properties of Micro-Cracked ECC Containing High Volumes Fly Ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Li, V.C. Engineered Cementitious Composites (ECC) Material, Structural, and Durability Performance. In Concrete Construction Engineering Handbook Series; Nawy, E.G., Ed.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 9780849374920. [Google Scholar]

- Sarker, M.; Rahman, M.Z.; Abedin, M.J. Engineered cementitious composites: Design, structural and 3D printing applications. In Comprehensive Materials Processing, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 13, pp. 153–166. [Google Scholar] [CrossRef]

- Lu, C.; Wang, J.; Leung, C.K.; Yao, Y.; Yu, B. Micromechanics-based model of single crack propagation in Engineered cementitious composites (ECC). Constr. Build. Mater. 2023, 369, 130519. [Google Scholar] [CrossRef]

- Li, V.C.; Bos, F.P.; Yu, K.; McGee, W.; Ng, T.Y.; Figueiredo, S.C.; Nefs, K.; Mechtcherine, V.; Nerella, V.N.; Pan, J. On the emergence of 3D printable engineered, strain hardening cementitious composites (ECC/SHCC). Cem. Concr. Res. 2020, 132, 106038. [Google Scholar] [CrossRef]

- Qudah, S.; Maalej, M. Application of engineered cementitious composites (ECC) in interior beam–column connections for enhanced seismic resistance. Eng. Struct. 2014, 69, 235–245. [Google Scholar] [CrossRef]

- Zhang, R.; Matsumoto, K.; Hirata, T.; Ishizeki, Y.; Niwa, J. Application of PP-ECC in beam–column joint connections of rigid-framed railway bridges to reduce transverse reinforcements. Eng. Struct. 2015, 86, 146–156. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Dadkhah, M.; Tulliani, J.M. Damage Management of Concrete Structures with Engineered Cementitious Materials and Natural Fibers: A Review of Potential Uses. Sustainability 2022, 14, 3917. [Google Scholar] [CrossRef]

- Oh, B.H.; Kabele, P. Durability under Chemical Loads in: Durability of Strain-Hardening Fibre-Reinforced Cement-Based Composites (SHCC); Wittmann, F., Van Zijl, G., Eds.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; pp. 41–58. [Google Scholar] [CrossRef]

- Toshiyuki, K.; Kabele, P.; Fukuyama, H.; Uchida, Y.; Suwada, H.; Slowik, V. Strain Hardening Cement Composites: Structural Design and Performance. In State-of-the-Art Report of the RILEM Technical Committee 208-HFC, SC3; Rokugo, K., Kanda, T., Eds.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A Review: Self-Healing in Cementitious Materials and Engineered Cementitious Composite as a Self-Healing Material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- van Overmeir, A.L.; Šavija, B.; Bos, F.P.; Schlangen, E. 3D printable strain hardening cementitious composites (3DP-SHCC), tailoring fresh and hardened state properties. Constr. Build. Mater. 2023, 403, 132924. [Google Scholar] [CrossRef]

- Salet, T.; Ahmed, Z.; Bos, F.; Laagland, H. Design of a 3D printed concrete bridge by testing. Virtual Phys. Prototyp. 2018, 13, 222–236. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.; Le, T.; Austin, S.; Gibb, A.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- He, Z.; Chen, J.; Liu, Z.; Ma, Z. Analytical approach for bursting cracking analysis of post-tensioned anchorage zone. Structures 2023, 52, 401–409. [Google Scholar] [CrossRef]

- Li, V.C.; Mishra, D.K.; Wu, H.-C. Matrix Design for Pseudo-Strain-Hardening Fibre Reinforced Cementitious Composites. Mater. Struct. 1995, 28, 586–595. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile Strain-Hardening Behavior of Polyvinyl Alcohol Engineered Cementitious Composite (PVA-ECC). Mater. J. 2001, 98, 483–492. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface Tailoring for Strain-Hardening Polyvinyl Alcohol Engineered Cementitious Composite (PVA-ECC). ACI Mater. J. 2002, 99, 463–472. [Google Scholar] [CrossRef]

- Myadaraboina, H.; Law, D.; Patnaikuni, I. Durability of Basalt Fibers in Concrete Medium. In Australasia and Southeast Asia Conference in Structural Engineering and Construction (ASEA-SEC-2); ISEC Press: Fargo, ND, USA, 2014; pp. 445–450. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of Macro Plastic Fibres in Concrete: A Review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Pelisser, F.; Montedo, O.R.K.; Gleize, P.J.P.; Roman, H.R. Mechanical Properties of Recycled PET Fibers in Concrete. Mater. Res. 2012, 15, 679–686. [Google Scholar] [CrossRef]

- Lloyd, S. Steel Fibers in Concrete Floor Slabs. Concr. Int. 2014, 36, 47–49. [Google Scholar]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Men, P.; Wang, X.-M.; Liu, D.; Zhang, Z.; Zhang, Q.; Lu, Y. On use of polyvinylpyrrolidone to modify polyethylene fibers for improving tensile properties of high strength ECC. Constr. Build. Mater. 2024, 4177, 135354. [Google Scholar] [CrossRef]

- Huo, Y.; Liu, T.; Lu, D.; Han, X.; Sun, H.; Chen, Z.; Li, Y.; Huang, J.; Yang, Y. Enhancing mechanical properties and crack resistance of high-strength SHCC/ECC for durable transportation through ethylene-vinyl acetate polymer modification. Case Stud. Constr. Mater. 2024, 21, e03878. [Google Scholar] [CrossRef]

- Sun, H.; Wan, Y.; Xu, Z.; Huo, Y.; Jia, M.; Yang, Y. Exploring the potential of aramid nanofibers in advancing green-engineered cementitious composites. Compos. B Eng. 2025, 305, 112724. [Google Scholar] [CrossRef]

- Yu, K.-Q.; Dai, J.-G.; Lu, Z.-D.; Leung, C.K. Mechanical Properties of Engineered Cementitious Composites Subjected to Elevated Temperatures. J. Mater. Civ. Eng. 2015, 27, 04014268. [Google Scholar] [CrossRef]

- Yu, K.; Wang, Y.; Yu, J.; Xu, S. A Strain-Hardening Cementitious Composites with the Tensile Capacity up to 8%. Constr. Build. Mater. 2017, 137, 410–419. [Google Scholar] [CrossRef]

- Yu, K.; Yu, J.; Lu, Z. Mechanical Characteristics of Ultra High Performance Strain Hardening Cementitious Composites. In International Conference on Strain-Hardening Cement-Based Composites; Springer: Dordrecht, The Netherlands, 2017; pp. 230–237. [Google Scholar]

- Maalej, M.; Quek, S.T.; Zhang, J. Behavior of Hybrid-Fiber Engineered Cementitious Composites Subjected to Dynamic Tensile Loading and Projectile Impact. J. Mater. Civ. Eng. 2005, 17, 143–152. [Google Scholar] [CrossRef]

- Maalej, M.; Quek, S.T.; Ahmed, S.F.U.; Zhang, J.; Lin, V.W.J.; Leong, K.S. Review of Potential Structural Applications of Hybrid Fiber Engineered Cementitious Composites. Constr. Build. Mater. 2012, 36, 216–227. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, J.; Wu, H.; Jaworska, B.; Ellis, B.R.; Li, V.C. Discontinuous Micro-Fibers as Intrinsic Reinforcement for Ductile Engineered Cementitious Composites (ECC). Compos. Part. B Eng. 2020, 184, 107741. [Google Scholar] [CrossRef]

- Lei, D.; Jia, H.; Yu, L.; Li, Y.; Wu, Z.; Wang, B.; Zhou, A.; Qin, L.; Sun, J.; Wang, W.; et al. Recent developments in Low-Carbon Engineered Cementitious Composites (ECC). J. Build. Eng. 2025, 100, 111734. [Google Scholar] [CrossRef]

- Shoji, D.; He, Z.; Zhang, D.; Li, V.C. The greening of engineered cementitious composites (ECC): A review. Constr. Build. Mater. 2022, 327, 126701. [Google Scholar] [CrossRef]

- Hu, W.H.; Zhang, D.; Ftwi, E.; Ellis, B.R.; Li, V.C. Development of sustainable low carbon Engineered Cementitious Composites with waste polyethylene fiber, sisal fiber and carbonation curing. Resour. Conserv. Recycl. 2023, 197, 107096. [Google Scholar] [CrossRef]

- Lin, Z.; Li, V.C. Crack Bridging in Fiber Reinforced Cementitious Composites with Slip-Hardening Interfaces. J. Mech. Phys. Solids 1997, 45, 763–787. [Google Scholar] [CrossRef]

- Yang, E.-H.; Wang, S.; Yang, Y.; Li, V.C. Fiber-Bridging Constitutive Law of Engineered Cementitious Composites. J. Adv. Concr. Technol. 2008, 6, 181–193. [Google Scholar] [CrossRef]

- Li, V.C. Large Volume, High-Performance Applications of Fibers in Civil Engineering. J. Appl. Polym. Sci. 2002, 83, 660–686. [Google Scholar] [CrossRef]

- Katz, A.; Li, V.C. Inclination Angle Effect of Carbon Fibers in Cementitious Composites. J. Eng. Mech. 1995, 121, 1340–1348. [Google Scholar] [CrossRef]

- Naaman, A.E.; Shah, S.P. Pull-out Mechanism in Steel Fiber-Reinforced Concrete. J. Struct. Div. 1976, 102, 1537–1548. [Google Scholar] [CrossRef]

- Arnon, B. Role of Interfaces in Controlling Durability of Fiber-Reinforced Cements. J. Mater. Civ. Eng. 2000, 12, 2–7. [Google Scholar] [CrossRef]

- Wang, S.; Li, V.C. Polyvinyl alcohol fiber reinforced engineered cementitious composites: Material design and performances. In Proceedings of the International RILEM Workshop on High Performance Fiber Reinforced Cementitious Composites in Structural Applications, Honolulu, HI, USA, 23–26 May 2005. [Google Scholar]

- Yan, K.-T.; Wang, X.-P.; Ding, Y.; Li, L.-Z.; Bazarov, D.; Deng, B.-Y.; Nikolayevich, K.-S.; Yu, K.-Q. 3D-printed LC3-based lightweight engineered cementitious composites: Fresh state, harden material properties and beam performance. J. Build. Eng. 2024, 93, 109838. [Google Scholar] [CrossRef]

- Xu, N.; Qian, Y. Effects of fiber volume fraction, fiber length, water-binder ratio, and nanoclay addition on the 3D printability of strain-hardening cementitious composites (SHCC). Cem. Concr. Compos. 2023, 39, 105066. [Google Scholar] [CrossRef]

- Marcos-Meson, V.; Michel, A.; Solgaard, A.; Fischer, G.; Edvardsen, C.; Skovhus, T.L. Corrosion Resistance of Steel Fibre Reinforced Concrete—A Literature Review. Cem. Concr. Res. 2018, 103, 1–20. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Hwang, D.; Yao, K.-T.; Yeh, Z. Mega-scale fabrication by contour crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301–320. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Z.; Zhang, X.; Chen, Z. 3D printing concrete structures: State of the art, challenges, and opportunities. Construct. Build. Mater. 2023, 405, 133364. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Mesh reinforcing method for 3D concrete printing. Autom. Construct. 2020, 109, 102992. [Google Scholar] [CrossRef]

- Classen, M.; Ungermann, J.; Sharma, R. Additive manufacturing of reinforced concrete—Development of a 3D printing technology for cementitious composites with metallic reinforcement. Appl. Sci. 2020, 10, 3791. [Google Scholar] [CrossRef]

- Anton, A.; Reiter, L.; Wangler, T.; Frangez, V.; Flatt, R.J.; Dillenburger, B. A 3D concrete printing prefabrication platform for bespoke columns. Autom. Construct. 2021, 122, 103467. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Guo, Y.; Kashani, A.; Wang, K.; Ferrara, L.; Agudelo, I. Concrete 3D printing technology for sustainable construction: A review on raw material, concrete type and performance. Dev. Built Environ. 2024, 17, 100378. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nazari, A.; Nematollahi, B. 3D Concrete Printing Technology: Construction and Building Applications, 1st ed.; Sanjayan, J.G., Nazari, A., Nematollahi, B., Eds.; Butterworth Heinemann: Oxford, UK, 2019. [Google Scholar] [CrossRef]

- Perrot, A. 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction Revolution, 1st ed.; Perrot, A., Ed.; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar] [CrossRef]

- Brar, T.S.; Kamal, M.A.; Singh, S. 3D Concrete Printing Technology: Configuration with Green and Self-Healing Concrete; Brar, T.S., Kamal, M.A., Singh, S., Eds.; Materials Research Forum LLC: Millersville, PA, USA, 2022. [Google Scholar] [CrossRef]

- Grigoriadis, K.; Lee, G. 3D Printing and Material Extrusion in Architecture; Grigoriadis, K., Lee, G., Eds.; DOM Publishers: Berlin, Germany, 2023; ISBN 9783869227504. [Google Scholar]

- Tay, Y.W.D.; Lim, J.H.; Li, M.; Tan, M.J. Creating functionally graded concrete materials with varying 3D printing parameters. Virtual Phys. Prototyp. 2022, 17, 662–681. [Google Scholar] [CrossRef]

- Chen, Y.; Chaves Figueiredo, S.; Li, Z.; Chang, Z.; Jansen, K.; Çopuroğlu, O.; Schlangen, E. Improving printability of limestone-calcined clay-based cementitious materials by using viscosity-modifying admixture. Cement Concr. Res. 2020, 132, 106040. [Google Scholar] [CrossRef]

- Ashrafi, N.; Duarte, J.P.; Nazarian, S.; Meisel, N.A. Evaluating the relationship between deposition and layer quality in large-scale additive manufacturing of concrete. Virtual Phys. Prototyp. 2019, 14, 135–140. [Google Scholar] [CrossRef]

- Soltan, D.G.; Li, V.C. A self-reinforced cementitious composite for building-scale 3d printing. Cem. Concr. Compos. 2018, 90, 1–13. [Google Scholar] [CrossRef]

- Figueiredo, S.C.; Romero Rodriguez, C.; Ahmed, Z.Y.; Bos, D.; Xu, Y.; Salet, T.; Çopuroglu, O.; Schlangen, E.; Bos, F.P. An approach to develop printable strain hardening cementitious composites. Mater. Des. 2019, 169, 107651. [Google Scholar] [CrossRef]

- Ogura, H.; Nerella, V.; Mechtcherine, V. Developing and testing of strain-hardening cement-based composites (shcc) in the context of 3d-printing. Materials 2018, 11, 1375. [Google Scholar] [CrossRef]

- van Overmeir, A.; Figueiredo, S.; Šavija, B.; Bos, F.; Schlangen, E. Design and analysis of printable SHCC with optimized particle size distribution. Constr. Build. Mater. 2022, 324, 126411. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, Y.; Ma, L.; Li, V.C. Influence of printing parameters on 3D printing engineered cementitious composites (3DP-ECC). Cem. Concrete Compos. 2022, 130, 104562. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Li, J.; Wang, P.; Zhang, M. Relationship between microstructure and strain-hardening behavior of 3D printed engineered cementitious composites. Cem. Concr. Compos. 2022, 133, 104677. [Google Scholar] [CrossRef]

- Zafar, T.; Zafar, M.S.; Hojati, M. Exploring the 3D Printability of Engineered Cementitious Composites with Internal Curing for Resilient Construction in Arid Regions. Materials 2025, 18, 3327. [Google Scholar] [CrossRef] [PubMed]

- Asghari, Y.; Mohammadyan-Yasouj, S.E.; Petrůc, M.; Ghandvar, H.; Koloor, S.S.R. 3D Printing and Implementation of Engineered Cementitious Composites—A Review. Case Studies Constr. Mater. 2024, 21, e03462. [Google Scholar] [CrossRef]

- Zhou, W.; McGee, W.; Zhu, H.; Süleyman Gökçe, A.; Li, V.C. Time-dependent fresh properties characterization of 3D printing engineered cementitious composites (3DP-ECC): On the evaluation of buildability. Cem. Concrete Compos. 2022, 133, 104704. [Google Scholar] [CrossRef]

- Fernández, F.; Jarabo, R.; Asensio, E.; Guerrero, A. Non-destructive tests to evaluate the self-healing capacity for a 3D printing ECC material. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Nematollahi, B.; Zhou, Z.; Zhang, Y.; Sanjayan, J. Development of 3D printable engineered cementitious composites with ultra-high tensile ductility for digital construction. Mater. Des. 2019, 181, 108088. [Google Scholar] [CrossRef]

- Figueiredo, S.C.; Rodriguez, C.R.; Ahmed, Z.Y.; Bos, D.; Xu, Y.; Salet, T.; Çopuroglu, O.; Schlangen, E.; Bos, F. Mechanical Behavior of Printed Strain Hardening Cementitious Composites. Materials 2020, 13, 2253. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.; Sierra Beltran, M.G.; Ye, G.; van Breugel, K.; Li, V.C. Development of engineered cementitious composites with limestone powder and blast furnace slag. Mater. Struct. 2010, 43, 803–814. [Google Scholar] [CrossRef]

- Khan, S.W.; Kamal, M.; Khan, F.A.; Gul, A.; Alam, M.; Shah, F.; Shahzada, K. Performance evaluation of the fresh and hardened properties of different PVA-ECC mixes: An experimental approach. Case Stud. Constr. Mater. 2023, 18, e01764. [Google Scholar] [CrossRef]

- Pan, Z.; Wu, C.; Liu, J.; Wang, W.; Liu, J. Study on mechanical properties of cost- effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Constr. Build. Mater. 2015, 78, 397–404. [Google Scholar] [CrossRef]

- Drescher, A.; Waters, A.; Rhoades, C. Arching in hoppers: I. Arching theories and bulk material flow properties. Powder Technol. 1995, 84, 165–174. [Google Scholar] [CrossRef]

- Enstad, G. A Novel Theory on the Arching and Doming in Mass Flow Hoppers. Doctoral Dissertation, Norwegian Technical University, Trondheim, Norway, 1981. [Google Scholar]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital concrete: A review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Roussel, N. A thixotropy model for fresh fluid concretes: Theory, validation and applications. Cem. Concr. Res. 2006, 36, 1797–1806. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal De Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Rahul, A.V.; Mohan, M.K.; De Schutter, G.; Van Tittelboom, K. 3D printable concrete with natural and recycled coarse aggregates: Rheological, mechanical and shrinkage behaviour. Cem. Concr. Compos. 2022, 125, 104311. [Google Scholar] [CrossRef]

- Nerella, V.N.; Krause, M.; Mechtcherine, V. Direct printing test for buildability of 3D-printable concrete considering economic viability. Automat. Constr. 2020, 109, 102986. [Google Scholar] [CrossRef]

- Suiker, A.S.J. Mechanical performance of wall structures in 3D printing processes: Theory, design tools and experiments. Int. J. Mech. Sci. 2018, 137, 145–170. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Rheological behavior of high volume fly ash mixtures containing micro silica for digital construction application. Mater. Lett. 2019, 237, 348–351. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Constr. Build. Mater. 2018, 163, 600–610. [Google Scholar] [CrossRef]

- Joh, C.; Lee, J.; Bui, T.Q.; Park, J.; Yang, I. Buildability and mechanical properties of 3D printed concrete. Materials 2020, 13, 4919. [Google Scholar] [CrossRef]

- Ahmed, S.; Yehia, S. Evaluation of workability and structuration rate of locally developed 3D printing concrete using conventional methods. Materials 2022, 15, 1243. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, Z.; Zhou, D.; Huang, T.; Huang, H.; Jiao, D.; Shi, C. A feasible method for measuring the buildability of fresh 3D printing mortar. Constr. Build. Mater. 2019, 227, 116600. [Google Scholar] [CrossRef]

- Liu, Q.; Jiang, Q.; Huang, M.; Xin, J.; Chen, P.; Wu, S. Modifying effect of anionic polyacrylamide dose for cement-based 3DP materials: Printability and mechanical performance tests. Constr. Build. Mater. 2022, 330, 127156. [Google Scholar] [CrossRef]

- Casagrande, L.; Esposito, L.; Menna, C.; Asprone, D.; Auricchio, F. Effect of testing procedures on buildability properties of 3D-printable concrete. Constr. Build. Mater. 2020, 245, 118286. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Triaxial compression testing on early age concrete for numerical analysis of 3D concrete printing. Cem. Concr. Compos. 2019, 104, 103344. [Google Scholar] [CrossRef]

- Panda, B.; Lim, J.H.; Tan, M.J. Mechanical properties and deformation behaviour of early age concrete in the context of digital construction. Compos. B Eng. 2019, 165, 563–571. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Y.; Pan, T.; Yin, K. The synergistic effect of ester-ether copolymerization thixo-tropic superplasticizer and nano-clay on the buildability of 3D printable cementitious materials. Materials 2021, 14, 4622. [Google Scholar] [CrossRef]

- Tripathi, A.; Nair, S.A.O.; Neithalath, N. A comprehensive analysis of buildability of 3D-printed concrete and the use of bi-linear stress-strain criterion-based failure curves towards their prediction. Cem. Concr. Compos. 2022, 128, 104424. [Google Scholar] [CrossRef]

- Zhu, B.; Nematollahi, B.; Pan, J.; Zhang, Y.; Zhou, Z.; Zhang, Y. 3D concrete printing of permanent formwork for concrete column construction. Cem. Concr. Compos. 2021, 121, 104039. [Google Scholar] [CrossRef]

- Jayathilakage, R.; Rajeev, P.; Sanjayan, J.G. Yield stress criteria to assess the buildability of 3D concrete printing. Constr. Build. Mater. 2020, 240, 117989. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. 3D concrete printing: A lower bound analytical model for buildability performance quantification. Automat. Constr. 2019, 106, 102904. [Google Scholar] [CrossRef]

- Ivanova, I.; Ivaniuk, E.; Bisetti, S.; Nerella, V.N.; Mechtcherine, V. Comparison between methods for indirect assessment of buildability in fresh 3D printed mortar and concrete. Cem. Concr. Res. 2022, 156, 106764. [Google Scholar] [CrossRef]

- Tramontin Souza, M.; Maia Ferreira, I.; Guzi De Moraes, E.; Senff, L.; Arcaro, S.; Castro Pessôa, J.R.; Ribeiro, M.J.; Novaes De Oliveira, A.P. Role of chemical admixtures on 3D printed Portland cement: Assessing rheology and buildability. Constr. Build. Mater. 2022, 314, 125666. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Ye, J.; Cui, C.; Yu, J.; Yu, K.; Dng, F. Effect of polyethylene fiber content on workability and mechanical-anisotropic properties of 3D printed ultra-high ductile concrete. Constr. Build. Mater. 2021, 281, 122586. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; Van Zijl, G. An ab initio approach for thixotropy characterisation of (nanoparticle-infused) 3D printable concrete. Constr. Build. Mater. 2019, 224, 372–386. [Google Scholar] [CrossRef]

- Ge, Y.; Yao, J. Influence of FA and HPMC on the fresh properties and anisotropy of 3D printing engineered cementitious composites (3DP-ECC). Mater. Lett. 2025, 381, 137748. [Google Scholar] [CrossRef]

- Lomboy, G.R.; Wang, X.; Wang, K. Rheological behavior and formwork pressure of SCC, SFSCC, and NC mixtures. Cem. Concr. Compos. 2014, 54, 110–116. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, J.; Ding, T. Flexural performance of 3D-printed composite beams with ECC and recycled fine aggregate concrete: Experimental and numerical analysis. Eng. Struct. 2023, 283, 115865. [Google Scholar] [CrossRef]

- Yu, K.; McGee, W.; Ng, T.Y.; Zhu, H.; Li, V.C. 3D-printable engineered cementitious composites (3DP-ECC): Fresh and hardened properties. Cem. Concr. Res. 2021, 143, 106388. [Google Scholar] [CrossRef]

- Hu, C.; de Larrard, F.; Sedran, T.; Boulay, C.; Bosc, F.; Deflorenne, F. Validation of BTRHEOM, the new rheometer for soft-to-fluid concrete. Mater. Struct. 1996, 29, 620–631. [Google Scholar] [CrossRef]

- Pi, Y.; Lu, C.; Yao, Y.; Li, B. A rheological-based printability assessment method for 3D printing Engineered Cementitious Composites considering fiber dispersion. Case Stud. Constr. Mater. 2024, 20, e02898. [Google Scholar] [CrossRef]

- Jaggi, S.; Sharma, P.K. Fresh, Compressive and Direct-Tensile characterization of Engineered Cementitious Composite. IOP Conf. Ser. Earth Environ. Sci. 2024, 1327, 012004. [Google Scholar] [CrossRef]

- Kan, L.; Shi, R.; Zhu, J. Effect of fineness and calcium content of fly ash on the mechanical properties of engineered cementitious composites (ECC). Constr. Build. Mater. 2019, 209, 476–484. [Google Scholar] [CrossRef]

- Yu, J.; Leung, C.K. Impact of 3D printing direction on mechanical performance of strain-hardening cementitious composite (SHCC). In Proceedings of the First RILEM International Conference on Concrete and Digital Fabrication—Digital Concrete, Zurich, Switzerland, 10–12 September 2018; Springer: Cham, Switzerland, 2018; pp. 255–265. [Google Scholar] [CrossRef]

- Pourchez, J.; Ruot, B.; Debayle, J.; Pourchez, E.; Grosseau, P. Some aspects of cellulose ethers influence on water transport and porous structure of cement-based materials. Cem. Concr. Res. 2010, 40, 242–252. [Google Scholar] [CrossRef]

- Jenni, A.; Holzer, L.; Zurbriggen, R.; Herwegh, M. Influence of polymers on microstructure and adhesive strength of cementitious tile adhesive mortars. Cem. Concr. Res. 2005, 35, 35–50. [Google Scholar] [CrossRef]

- Jenni, A.; Zurbriggen, R.; Holzer, L.; Herwegh, M. Changes in microstructures and physical properties of polymer-modified mortars during wet storage. Cem. Concr. Res. 2006, 36, 79–90. [Google Scholar] [CrossRef]

- Kan, L.; Kong, N.; Wang, F. Effects of thickener on macro- and meso-mechanical properties of ECC. Case Stud. Constr. Mater. 2023, 19, e02292. [Google Scholar] [CrossRef]

- Yu, J.; Xu, F.; Zhang, H.; Ye, J.; Yu, J.; Dai, J.-G. Yiwei Weng Leveraging incinerator bottom ash for mitigating early age shrinkage in 3D printed engineered cementitious composites. Cem. Concr. Compos. 2025, 157, 105933. [Google Scholar] [CrossRef]

- Sun, J.; Aslani, F.; Lu, J.; Wang, L.; Huang, Y.; Ma, G. Fibre-reinforced lightweight engineered cementitious composites for 3D concrete printing. Ceram. Int. 2021, 47, 27107–27121. [Google Scholar] [CrossRef]

- Du, Q.; Qian, Y. Effects of printing patterns and loading directions on fracture behavior of 3D printed Strain-Hardening Cementitious Composites. Eng. Fract. Mech. 2024, 304, 110155. [Google Scholar] [CrossRef]

- Bai, M.; Xiao, J.; Ding, T.; Yu, K. Interfacial bond properties between 3D printed engineered cementitious composite (ECC) and post-cast concrete. Cem. Concr. Compos. 2025, 157, 105897. [Google Scholar] [CrossRef]

- Xiao, J.; Bai, M.; Wu, Y.; Duan, Z.; Qin, J. Interlayer bonding strength and pore characteristics of 3D printed engineered cementitious composites (ECC). J. Build. Eng. 2024, 84, 108559. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Abdelzaher, M.A.; Hamouda, A.S.; Ismail, I.M.; El-Sheikh, M.A. Nano titania reinforced limestone cement: Physico-mechanical investgation. Key Eng. Mater. 2018, 786, 248–257. [Google Scholar] [CrossRef]

- Zhang, D.; Jaworska, B.; Zhu, H.; Dahlquist, K.; Li, V.C. Engineered Cementitious Composites (ECC) with limestone calcined clay cement (LC3). Cem. Concr. Compos. 2020, 114, 103766. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Zhang, T.; Zhang, M. Hardening properties and microstructure of 3D printed engineered cementitious composites based on limestone calcined clay cement. Cem. Concr. Compos. 2024, 152, 105641. [Google Scholar] [CrossRef]

- Zhou, W.; Zhu, H.; Hu, W.-H.; Wollaston, R.; Li, V.C. Low-carbon, expansive engineered cementitious composites (ECC) in the context of 3D printing. Cem. Concr. Compos. 2024, 148, 105473. [Google Scholar] [CrossRef]

- Liu, H.; Laflamme, S.; D’Alessandro, A.; Ubertini, F. 3D printed self-sensing cementitious composites using graphite and carbon microfibers. Meas. Sci. Technol. 2024, 35, 085105. [Google Scholar] [CrossRef]

- Aslani, F.; Dale, R.; Hamidi, F.; Valizadeh, A. Mechanical and shrinkage performance of 3D-printed rubberised engineered cementitious composites. Constr. Build. Mater. 2022, 339, 127665. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Wang, F.; Sanjayan, J. Mechanical anisotropy of aligned fiber reinforced composite for extrusion-based 3D printing. Constr. Build. Mater. 2019, 202, 770–783. [Google Scholar] [CrossRef]

- Du, G.; Sun, Y.; Qian, Y. Nature-inspired approach for enhancing the fracture performance of 3D printed strain-hardening cementitious composites (3DP-SHCC). Eng. Struct. 2025, 322, 119074. [Google Scholar] [CrossRef]

- Zhou, W.; McGee, W.; Gökçe, H.S.; Li, V.C. A bio-inspired solution to alleviate anisotropy of 3D printed engineered cementitious composites (3DP-ECC): Knitting/tilting filaments. Autom. Constr. 2023, 155, 105051. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Zhou, Z.; Cai, J. Mechanical properties of engineered cementitious composites beams fabricated by extrusion-based 3D printing. Eng. Struc. 2021, 238, 112201. [Google Scholar] [CrossRef]

- Bai, M.; Wu, Y.; Xiao, J.; Ding, T.; Yu, K. Workability and hardened properties of 3D printed engineered cementitious composites incorporating recycled sand and PE fibers. J. Build. Eng. 2023, 71, 106477. [Google Scholar] [CrossRef]

- Zhu, L.L.; Yao, J.; Zhao, Y.; Ruan, W.; Yang, G.; Guan, X.M. Effects of composite cementation system on rheological and working performances of fresh 3D-printable engineered cementitious composites. J. Build. Eng. 2023, 65, 105801. [Google Scholar] [CrossRef]

- Zhang, Y.; Aslani, F. Development of fibre reinforced engineered cementitious composite using polyvinyl alcohol fibre and activated carbon powder for 3D concrete printing. Constr. Build. Mater. 2021, 201, 124453. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3Dprinting. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y.; Youssf, O. Experimental investigation of basalt textile reinforced engineered cementitious composite under apparent hoop tensile loading. J. Build. Eng. 2019, 23, 270–279. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y.; Youssf, O. Use of hollow glass microspheres and hybrid fibres to improve the mechanical properties of engineered cementitious composite. Constr. Build. Mater. 2018, 171, 858–870. [Google Scholar] [CrossRef]

- Lu, C.; Pan, J.; Luo, B.; Li, Z.; Leung, C.K.Y. Correlation of flaw structure and cracking behavior in SHCC with X-ray CT scanning technique. Constr. Build. Mater. 2022, 331, 127296. [Google Scholar] [CrossRef]

- Hao, Z.; Lu, C.; Li, Z. Highly accurate and automatic semantic segmentation of multiple cracks in engineered cementitious composites (ECC) under dual premodification deep-learning strategy. Cem. Concr. Res. 2023, 165, 107066. [Google Scholar] [CrossRef]

- Dong, B.; Lu, C.; Pan, J.; Shan, Q.; Yin, W. Mechanical behavior of a novel precast beam-to-column connection with U-shaped bars and engineered cementitious composites. Adv. Struct. Eng. 2018, 21, 1963–1976. [Google Scholar] [CrossRef]

- Pang, Z.; Lu, C.; Li, B.; Wang, J. A multiscale model for quantifying fiber orientation effects on the tensile properties of 3D printed Engineered Cementitious Composites (3DP-ECC). J. Build. Eng. 2023, 68, 106090. [Google Scholar] [CrossRef]

- He, B.; Zhang, H.; Zhu, X.; Zheng, Q.; Onuaguluchi, O.; Banthia, N.; Jiang, Z. Thermal-dependent brittleness effect of ultra-high performance concrete exposed to cryogenic flexural loads by acoustic emission evaluation. Cem. Concr. Compos. 2023, 139, 105056. [Google Scholar] [CrossRef]

- Hou, M.; Zhang, D.; Li, V.C. Crack width control and mechanical properties of low carbon engineered cementitious composites (ECC). Constr. Build. Mater. 2022, 348, 128692. [Google Scholar] [CrossRef]

- Li, M.; Li, V.C. Rheology, fiber dispersion, and robust properties of Engineered Cementitious Composites. Mater. Struct. 2013, 46, 405–420. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; El-Maaddawy, T.A.; Mahmoud, A.A.M. Water-soluble polymers as self-curing agent in cement mixes. Adv. Cem. Res. 2012, 24, 291–299. [Google Scholar] [CrossRef]

- Dixit, A.; Gupta, S.; Dai Pang, S.; Kua, H.W. Waste valorisation using biochar for cement replacement and internal curing in ultra-high performance concrete. J. Clean. Prod. 2019, 238, 117876. [Google Scholar] [CrossRef]

- Wang, T.; Tang, Y.; Qin, S.; Li, G.; Wu, H.; Leung, C.K.Y. Sustainable and mechanical properties of Engineered Cementitious Composites with biochar: Integrating micro- and macro-mechanical insight. Cem. Concr. Compos. 2025, 155, 105813. [Google Scholar] [CrossRef]

- Shi, L.; Lin, S.; Lu, Y.; Ye, L.; Zhang, Y. Artificial neural network based mechanical and electrical property prediction of engineered cementitious composites. Constr. Build. Mater. 2018, 174, 667–674. [Google Scholar] [CrossRef]

- Le, V.-G.; Nguyen, M.-K.; Nguyen, H.-L.; Lin, C.; Hadi, M.; Quang Hung, N.T.; Hoang, H.-G.; Nguyen, K.N.; Tran, H.-T.; Hou, D.; et al. A comprehensive review of micro- and nano-plastics in the atmosphere: Occurrence, fate, toxicity, and strategies for risk reduction. Sci. Total Environ. 2023, 904, 166649. [Google Scholar] [CrossRef]

- Tükoğlu, G.C.; Khomarloo, N.; Mohsenzadeh, E.; Gospodinova, D.N.; Neznakomova, M.; Salaün, F. PVA-Based Electrospun Materials—A Promising Route to Designing Nanofiber Mats with Desired Morphological Shape—A Review. Int. J. Mol. Sci. 2024, 25, 1668. [Google Scholar] [CrossRef]

- Shanmugasundaram, N.; Praveenkumar, S.; Gayathiri, K.; Divya, S. Prediction on compressive strength of engineered cementitious composites using machine learning approach. Constr. Build. Mater. 2022, 342, 127933. [Google Scholar] [CrossRef]

- Chen, W.; Liang, L.; Ye, J.; Liu, L.; Ukrainczyk, N.; Yin, L.; Yu, J.; Yu, K. Machine learning-enabled performance-based design of three-dimensional printed engineered cementitious composites. Eng. Appl. Artif. Intell. 2025, 161, 112117. [Google Scholar] [CrossRef]

| Compressive Strength (MPa) | First Crack Strength (MPa) | Ultimate Tensile Strength (MPa) | Ultimate Tensile Strain (%) | Young’s Modulus (GPa) | Flexural Strength (MPa) | Density (g/cm3) |

|---|---|---|---|---|---|---|

| 20–150 | 3–10 | 4–20 | 3–12 | 18–40 | 10–50 | 0.95–2.3 |

| Composition (In kg/m3 If No Other Information) | Additives SP | w/b | Fiber Type and Content | Open Time Window | Slump/Thixotropy Index | Mechanical Strength | Ref. |

|---|---|---|---|---|---|---|---|

| 259.2 CEM I 42.5, 604.9 BFS, 864.1 limestone powder, 26 PVA | 5.1 kg/m3 methylcellulose (201,000 mPa.s), 17.3 g/m3 SP (BASF Glenium 51) | 0.41 | PVA 2 vol% | n.d. | Mixture could pass through a 5 m hose | 6-10 MPa peak flexural strength // to printing direction ≈2–3 MPa tensile strength | [69] |

| 480.2 CEM I 42.5, 567.6 FA, 109.1 limestone powder, 186.3 sand (125–250 μm), 294 sand (250–500 μm), 26 PVA | 6.5 kg/m3 methylcellulose (201,000 mPa.s,) 13 g/m3 SP (BASF Glenium 51) | 0.31 | PVA 2 vol% | n.d. | Mixture could pass through a 5 m hose | ≈1.6–3.1 MPa peak tensile strength | [69] |

| 309 CEM I 52.5R, 1026 FA, 345 sand (50-550 μm), 26 PVA | 2 kg/m3 HPMC 7500–14,000 mPa.s (2% aqueous solution at 20 ◦C), 3 kg/m3 SP polycarboxylate-based | 0.24 | PVA with 1.2% oil (by mass) 39 μm in ∅ | 70 min | Spread diameter from ≈132 to 123 mm after 20 and 60 min, respectively, in the flow table test. The mixture did not flow before the flow table drop was applied | 31.2 MPa 28 d compressive strength //, 30.6 MPa ⊥ to printing direction on cubes (3.38 ± 0.03) MPa peak stress 28 d tensile stress with (3.09 ± 0.25)% strain capacity | [119] |

| 656 CEM I 52.5, 118 FA, 246 SF, 604 sand, 57 120 mesh crumb rubber | 3 kg/m3 SP | 0.27 | 1–2% PE 25 μm in ∅ | n.d. | Spread diameter of 162 mm with 1.5% of fibers | 19.4 MPa flexural strength with 1.5% fiber // to printing direction and 22 MPa ⊥ to printing direction | [114] |

| 0.38 CEM II 52.5, 0.05 SAC, 0.09 SF, 0.48 FA, 0.26 sand* (<300 μm), | 0.0004 HPMC* (viscosity of 38,000–42,000 mPa.s), 0.01 SP* polycarboxylate-based | 0.26 water* | 0.018 PE* 24 μm in ∅ | n.d. | n.d. | 62.8 kN peak load four-point bending test // to printing direction and 32.3 kN ⊥ to printing direction on 500 mm long and 100 mm high beams | [145] |

| 0.4 CEM II 52.5, 0.03 SAC, 0.57 FA, 0.4 sand | 0.001 HPMC°, 0.005 ANC°, 0.012 SP° | 0.28 water° | 1.5 PE° 24 μm in ∅ | n.d. | Slump flow = 55 mm and spread flow = 155 mm; shear thinning behavior and dynamic yield stress of ≈550 Pa; and plastic viscosity of ≈11.7 Pa.s with 2% of PE fibers | (5.68 ± 0.4) MPa ultimate tensile strength with (9.57 ± 1.01)% tensile strain capacity | [78] |

| 0.38 CEM II 52.5, 0.05 SAC, 0.09 SF, 0.48 FA, 0.26 sand | 0.0004 HPMC (viscosity of 38,000–42,000 mPa s), 0.001 SP polycarboxylate-based | 0.26 water | 0.018 PE 24 μm in ∅ | n.d. | n.d. | (6.15 ± 0.15) MPa ultimate tensile strength with (7.31 ± 1.83)% tensile strain capacity | [73] |

| 72 CEM I, 23 FA, 5 CAC, 45 sand, 10 MS, 5 GS, 5 ANC, | 0.4 HPMC¨, 0.8 SP¨ | 43 water¨ (w/b = 0.36) | 2 vol% PVA | n.d. | n.d. | ≈6 MPa tensile strength with ≈4% tensile strain capacity | [68] |

| 483 CEM 42.5, 314 BFS, 70 SF, 447 LS powder (<250 μm), 284 sand (125–250 μm), | 5.2 HPMC (Tylose MHS 15002 P6), 3.47 SP | 26 PVA 40 μm in ∅ | 3 h 30 min, determined by Vicat penetration test | n.d. | (8.68 ± 2.00) MPa maximum flexural strength | [71] | |

| 1 OPC, 0.11 SF, 0.89 sand, 0.8 hollow glass microspheres (20 μm in ∅) | 0.015 SP¨ | 0.65 water¨ (w/b = 0.59) | 0.0175 PVA¨ 39 μm in ∅ | n.d. | 153 mm slump flow 65 min setting time | (8.46 ± 0.39) MPa flexural strength // to printing direction and 9.12 ± 0.30 MPa ⊥ to printing direction at 28 days | [130] |

| 656 CEM I 52.5, 118 SF, 410 sand | 2 SP | 363 water (w/b = 0.47) | 15 PE 24 μm in ∅ (1.5 vol%) | n.d. | ≈167 mm initial spreading diameter, ≈154 mm spreading time after 100 min | 7.51 MPa maximum flexural strength with a strain capacity of 5.4% | [146] |

| 730.41 OPC 52.5, 87.65 SAC, 233.73 FA, 116.87 SF, 701.19 sand (330 μm average diameter) | 0.18 HPMC, 23.4 SP | 257.1 water (w/b = 0.22) | 17.53 PVA 40 μm in ∅ | Open time of ≈40 min | Initial setting = 37 min, final setting time = 64 min, determined by isothermal calorimetry, dynamic yield stress of 2505 Pa and plastic viscosity of 140.2 Pa.s with 2% of PE fibers | 1.43 kPa initial compressive strength, with a stress increase rate of 0.095 kPa/min. | [147] |

| 1 CEM I 52.5, 1.26 FA, 0.11 densified SF, 5 vol% to FA waste aggregates (1–2 mm), 0.89 sand (<600 μm) | 6 mL SP polyether-based superplasticizer | 0.65 water (w/b = 0.41) | 1.75 vol% PVA 39 μm in ∅ | n.d. | 240 mm slump diameter | ≈9.3 MPa flexural strength // to printing direction, ≈6.2 MPa flexural strength ⊥ to printing direction at 28 days | [141] |

| 0.47 OPC 42.5R, 0.44 FA, 0.09 FA, 0.29 sand | 0.0018 SP | 0.24 water | 0.01 PE 24 μm in ∅ | n.d. | ≈136 mm spread diameter and ≈25 mm slump 20 min after water addition, ≈127 mm spread diameter and ≈21 mm slump 80 min after water addition | ≈7 MPa peak tensile strength with ≈4% tensile strain capacity | [72] |

| 1 OPC 52.5, 1.33 FA, 0.11 SF, 0.89 sand | 0.024 activated carbon powder, 0.025 VMA, 0.068 SP | 0.65 water | 0.021 PVA 39 μm in ∅ | n.d. | n.d. | 10.81 MPa // to printing direction, 10.08 MPa flexural strength ⊥ to printing direction at 28 days | [148] |

| 0.6 OPC, 0.3 FA, 0.1 MS, 0.2 sand | 0–0.5% nanoclay | 0.325–0.375 w/b, function of fiber content | 1–2 vol% PE 24 μm in ∅ | n.d. | Slump = 10.5 mm and slump flow = 198 mm for mix with 1 vol% of 12 mm in length fiber and w/b = 0.35, Static yield stress = 530.8, 809.1, 1477.3, 2552.7, and 3870.1 Pa for 0, 0.5, 1.0, 1.5, and 2.0 vol% of fibers, respectively | n.d. | [53] |

| 75 wt% CEM II/A-M (S-LL) 52.5R, 15 wt% SF and 10 wt% FA | none | 0.22–0.24 w/b | 0.3–1.5 vol% HDPE 12 μm in ∅ | n.d. | 119 mm spread diameter and 133 mm after shocks (w/b = 0.22, s/b = 0.2 and 1.5 vol% fibers) | 5.66 MPa tensile strength with 3.21% ultimate tensile strain (w/b = 0.22, s/b = 0.2, and 1.5 vol% fibers) | [70] |

| 360 OPC 52.5 R, 196.5 MK, 98.3 LS, 360.3 GGBFS, | 1.0 HPMC, 4.0 SP | 264 water | 10–17.5 kg/m3 PE fibers 24 μm in ∅ | 5–45 min recommended | Initial slump diameter of 115 mm and of ≈103 mm after 60 min, initial flow diameter of 130 mm and of ≈115 mm, flow table test (1.25 vol% of fibers) | Anisotropic parameter = 0.799 on nominal flexural strength and 0.067 on compressive strength (1.25 vol% of fibers) | [119] |

| 223 PLC, 71 MK, 51 LS, 841 FA, 30 SF, 30 CR (40–80 mesh), 466 sand | 4.0 SP | 253 water | 26 PVA 39 μm in ∅ | 60 min | Spread diameter = 165 mm 20 min after water addition, ≈145 mm 60 min after water addition | ≈4.8 MPa tensile strength with ≈2.7% tensile strain capacity | [52] |

| 0.6 OPC, 0.3 FA, 0.1 SF, 0.2 sand (100–300 µm) | 0.005 nanoclay | 0.3 water | 1 vol% UHMWPE fibers 24 μm in ∅ | n.d. | n.d. | 17.41 MPa flexural strength Bouligand structure at 30° in the z direction | [143] |

| 497 OPC, 781 FA, 332 sand | 2.5 SP | 320 water (w/b = 0.25) | 26 PVA 39 μm in ∅ (2 vol%) | n.d. | n.d. | 21.6 MPa flexural strength // to printing direction, ≈16.5 MPa ⊥ to printing direction | [144] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tulliani, J.-M. Latest Developments in 3D-Printed Engineered Cementitious Composites: Technologies, Prospects, and Challenges. Ceramics 2025, 8, 141. https://doi.org/10.3390/ceramics8040141

Tulliani J-M. Latest Developments in 3D-Printed Engineered Cementitious Composites: Technologies, Prospects, and Challenges. Ceramics. 2025; 8(4):141. https://doi.org/10.3390/ceramics8040141

Chicago/Turabian StyleTulliani, Jean-Marc. 2025. "Latest Developments in 3D-Printed Engineered Cementitious Composites: Technologies, Prospects, and Challenges" Ceramics 8, no. 4: 141. https://doi.org/10.3390/ceramics8040141

APA StyleTulliani, J.-M. (2025). Latest Developments in 3D-Printed Engineered Cementitious Composites: Technologies, Prospects, and Challenges. Ceramics, 8(4), 141. https://doi.org/10.3390/ceramics8040141