Transforming Rice Husk Ash into Road Safety: A Sustainable Approach to Glass Microsphere Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Glass Fabrication

- (1)

- Heating at 10 °C/min to 900 °C, with a 1 h dwell time;

- (2)

- Heating at 7 °C/min to 1200 °C, with a 1 h dwell time;

- (3)

- Heating at 5 °C/min to 1500 °C, held for 3 h.

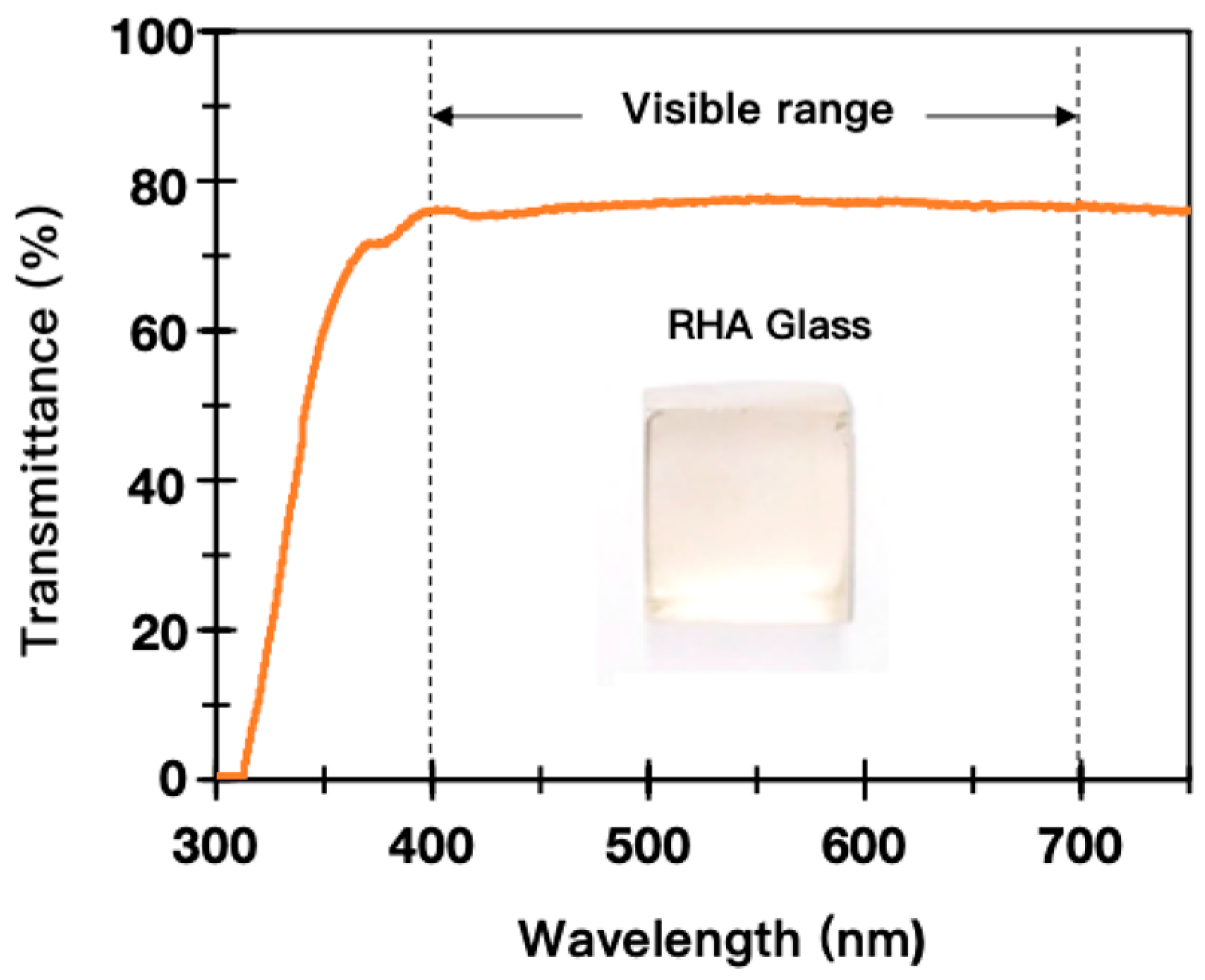

2.2. Glass Characterization

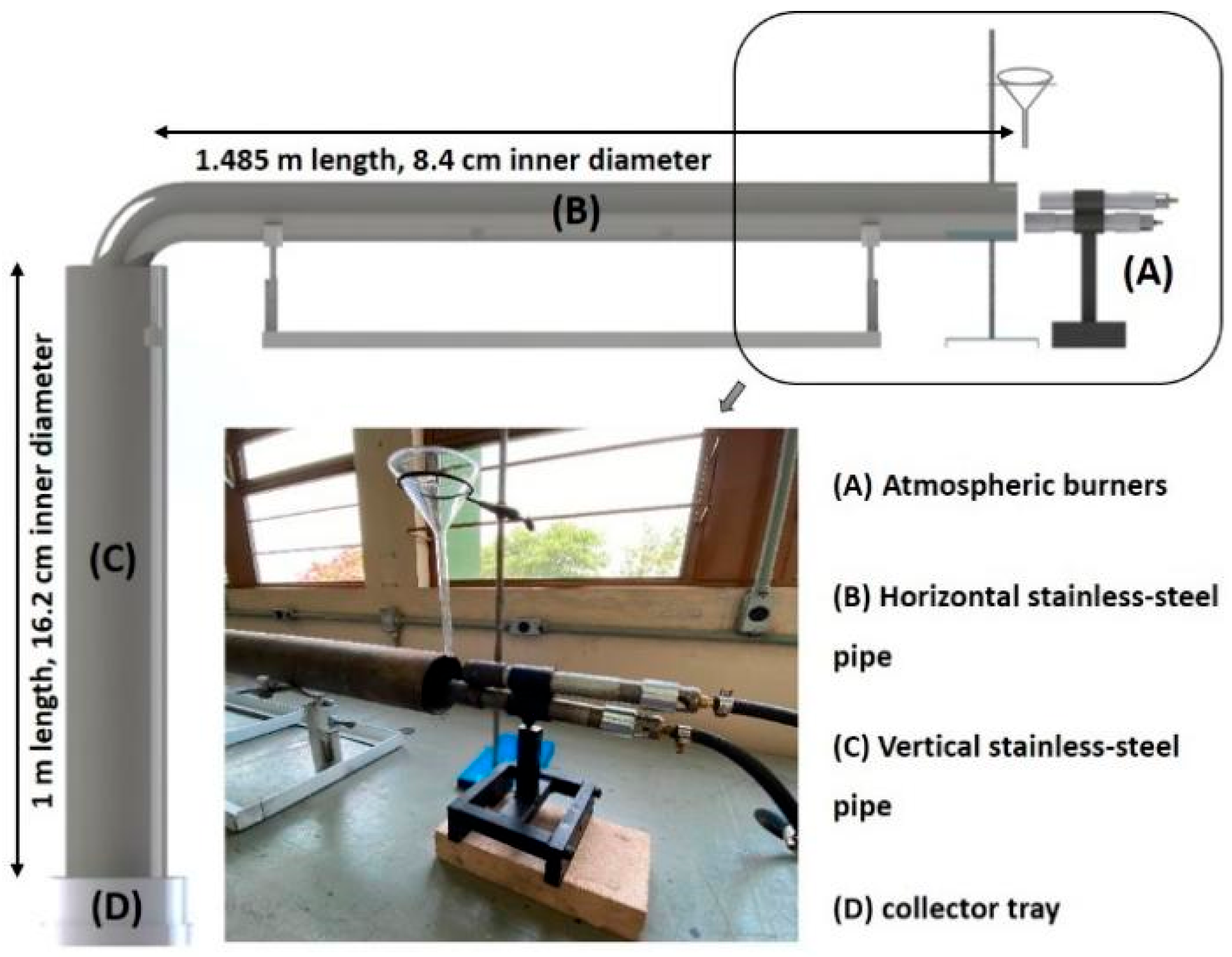

2.3. Microsphere Production

2.4. Microsphere Characterization

2.4.1. Chemical Composition and Density

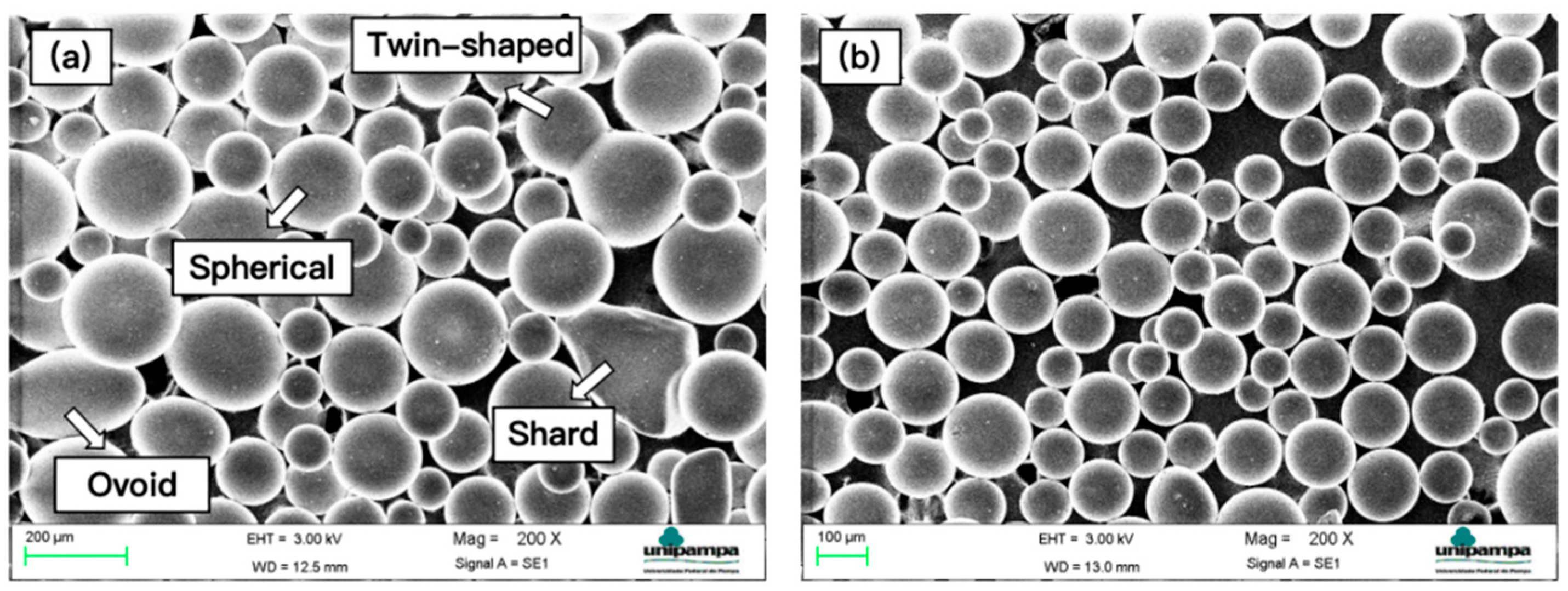

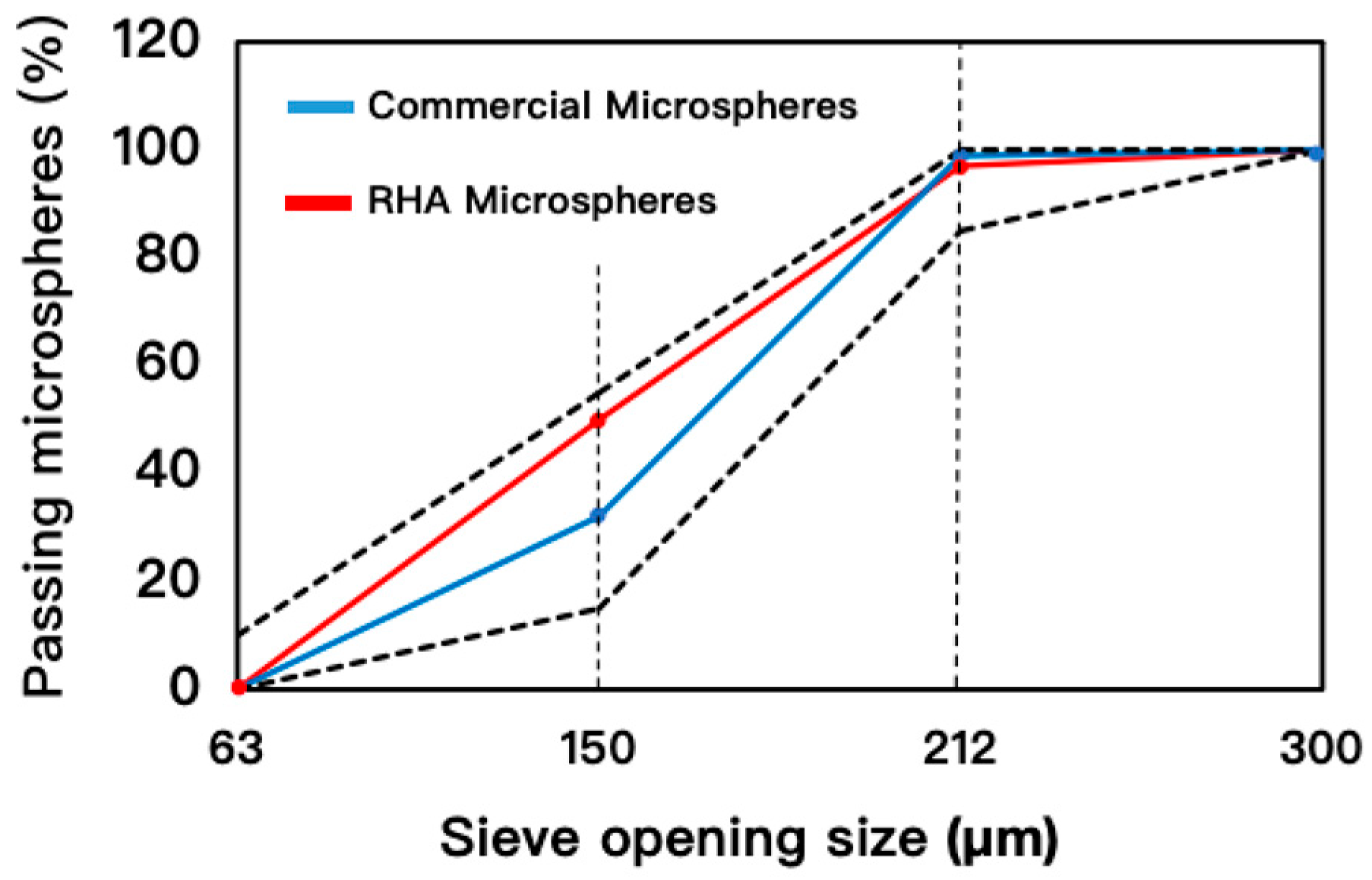

2.4.2. Morphology and Particle Size Distribution

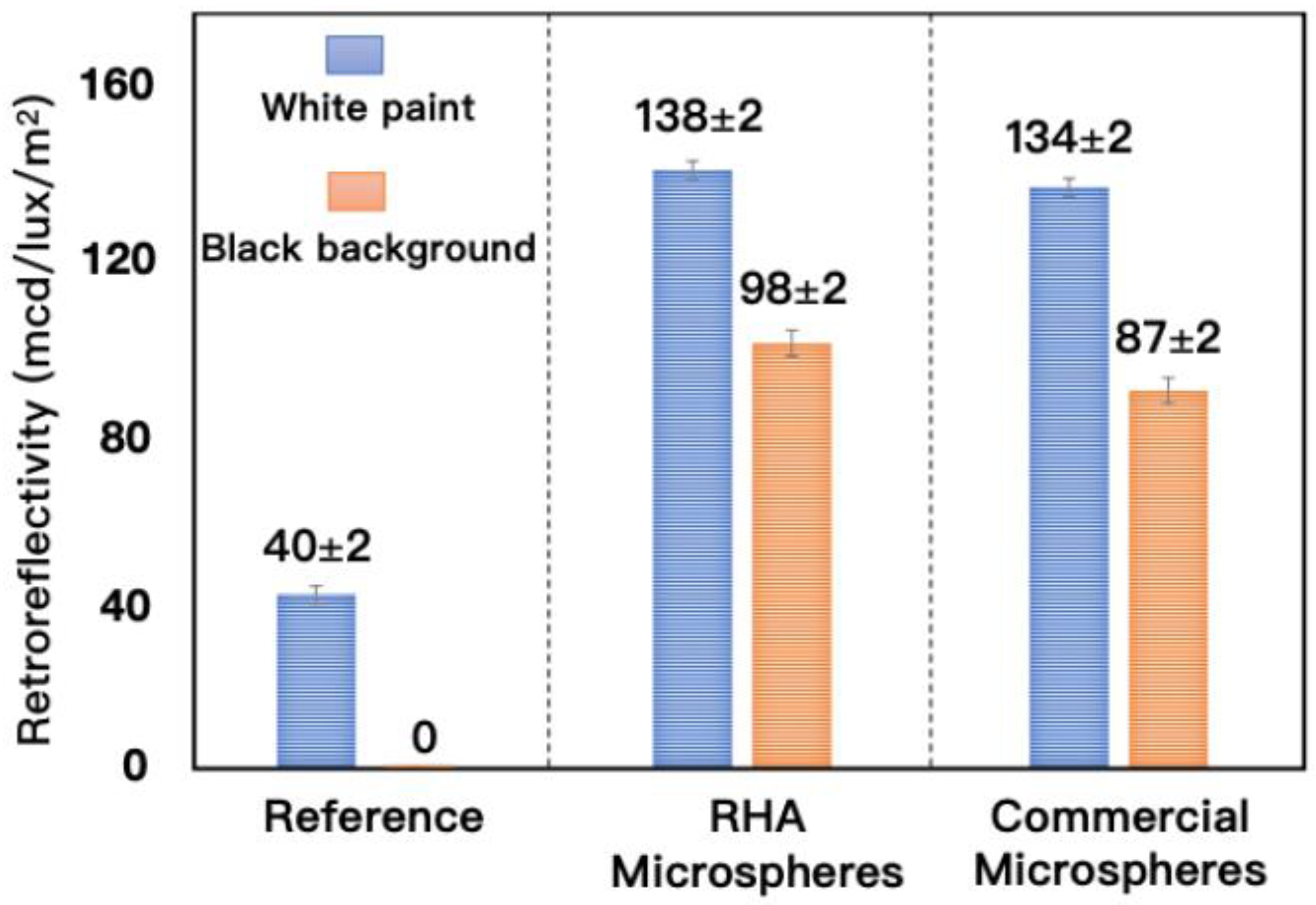

2.4.3. Retroreflectivity Measurements

- (1)

- Black Dry Surface: Medium-density fiberboard (MDF) panels (34 cm × 10 cm) were painted with matte black acrylic paint to represent a low-reflectivity background; in this case, the microspheres were not anchored in the black paint surface, allowing the determination of the intrinsic retroreflectivity.

- (2)

- White Painted Surface: Water-based white acrylic road marking paint was applied to MDF panels using a polyester foam roller. A uniform thickness (~0.6 mm) was ensured using a metal depth gauge. A fixed quantity of 1.7 g of microspheres (equivalent to 50 g/m2) was manually deposited onto both test surfaces: (1) matte black (dry) and (2) white painted. To ensure consistent coverage, the application was performed inside a closed chamber, which allowed any loose microspheres to be collected and uniformly reapplied. For the black dry surface, where the microspheres remained unanchored, ten retroreflectivity measurements were taken per sample (RHA-based and commercial microspheres), moving the panel among measurements to account for different configurations for the bead positions. In contrast, for the white painted surface, where the microspheres adhered to the substrate, three retroreflectivity measurements were conducted for each sample. The average and standard deviation of the retroreflectivity measurements values were reported as the final result.

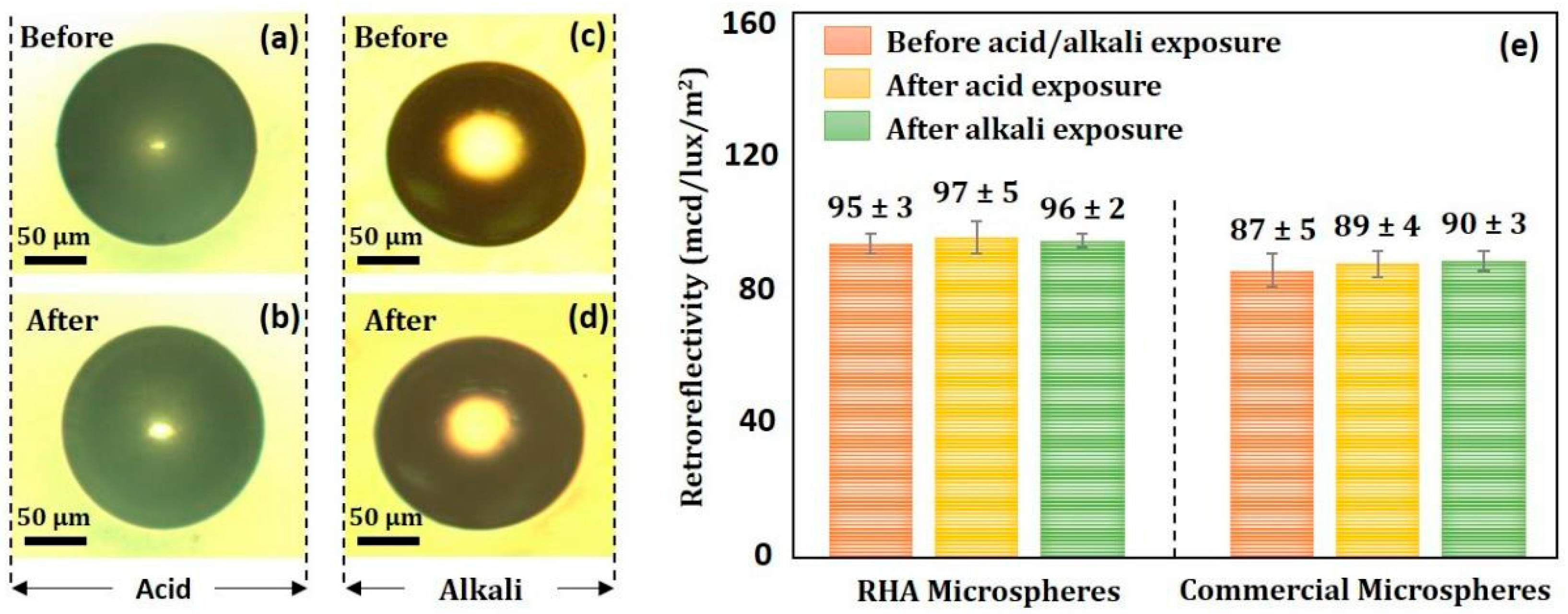

2.4.4. Hydrochloric Acid and Calcium Chloride Corrosion Resistance

3. Results

3.1. Rice Husk Ash Composition and Bulk Glass Measurements

3.2. Microspheres Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| WHO | World Health Organization |

| RHA | Cinza da Casca de Arroz |

| NBR | Brazilian Standard |

| Uv-Vis | Ultraviolet-Visible (spectrophotometry) |

| XRF | X-ray Fluorescence |

| CHN | Carbon, Hydrogen, Nitrogen (elemental analysis) |

| SEM | Scanning Electron Microscopy |

| LPG | Liquefied Petroleum Gas |

| MDF | Medium-Density Fiberboard |

| TM | Transverse Magnetic (polarization mode of laser light) |

| UN | United Nations |

References

- Burghardt, T.E.; Mosböck, H.; Pashkevich, A.; Fiolic, M. Horizontal Road Markings for Human and Machine Vision. Transp. Res. Procedia 2020, 48, 3622–3633. [Google Scholar] [CrossRef]

- Babic, D.; Fiolic, M.; Babic, D.; Gates, T. Road markings and their impact on driver behaviour and road safety: A systematic review of current findings. J. Adv. Transp. 2020, 2020, 7843743. [Google Scholar] [CrossRef]

- World Health Organization. Road Traffic Injuries. Available online: https://www.who.int/health-topics/road-safety (accessed on 15 February 2025).

- Plainis, S.; Murray, I.; Pallikaris, I. Road traffic casualties: Understanding the night-time death toll. Injury Prev. 2006, 12, 125–138. [Google Scholar] [CrossRef] [PubMed]

- Burghardt, T.E.; Popp, R.; Helmreich, B.; Reiter, T.; Bohm, G.; Pitterle, G.; Artmann, M. Visibility of various road markings for machine vision. Case Stud. Constr. Mater. 2021, 15, e00579. [Google Scholar] [CrossRef]

- Qian, H.; Lu, X.; Kou, P.; He, R. Influence of construction technology on the retroreflective performance of two-component traffic marking. Vibroeng. Procedia 2022, 47, 35–41. [Google Scholar] [CrossRef]

- Mazzoni, L.N.; Vasconcelos, K.; Albarracín, O.; Bernucci, L.; Linhares, G. Field Data Analysis of Pavement Marking Retroreflectivity and Its Relationship with Paint and Glass Bead Characteristics. Appl. Sci. 2024, 14, 4205. [Google Scholar] [CrossRef]

- Salles, L.S.; Pereira, D.S.; Teixeira, D.L.K.; Specht, L.P. Road markings retroreflectivity experimental assessment: Observations on rainfall, dirt, retroreflectometer geometry and minimum requirements. In Proceedings of the Transportation Research Board 95th Annual Meeting, Washington, DC, USA, 10–14 January 2016. [Google Scholar]

- Lee, S.; Koh, E.; Jeon, S.; Kim, R.E. Pavement marking construction quality inspection and night visibility estimation using computer vision. Case Stud. Constr. Mater. 2024, 20, e02953. [Google Scholar] [CrossRef]

- Lee, M.Y.; Tan, J.; Heng, J.Y.; Cheeseman, C. A Comparative Study of Production of Glass Microspheres by using Thermal Process. IOP Conf. Ser. Mater. Sci. Eng. 2017, 205, 012022. [Google Scholar] [CrossRef]

- NBR 16184; Road Horizontal Signaling—Glass Beads and Microbeads—Requirements and Test Methods. ABNT—Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2021.

- Mahmoud, M.; Kraxner, J.; Elsayed, H.; Bernardo, E.; Galusek, D. Fabrication and environmental applications of glass microspheres: A review. Ceram. Int. 2023, 49, 39745–39759. [Google Scholar] [CrossRef]

- Zhong, X.; Deetman, S.; Tukker, A.; Behrens, P. Increasing material efficiencies of buildings to address the global sand crisis. Nat. Sustain. 2022, 5, 389–392. [Google Scholar] [CrossRef]

- Cao, Z.; Masanet, E. Material efficiency to tackle the sand crisis. Nat. Sustain. 2022, 5, 370–371. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Sand and Sustainability: 10 Strategic Recommendations to Avert a Crisis; UNEP: Nairobi, Kenya, 2022; Available online: https://www.unep.org/resources/report/sand-and-sustainability-10-strategic-recommendations-avert-crisis (accessed on 18 December 2024).

- Zou, Y.; Yang, T. Rice Husk, Rice Husk Ash and Their Applications. In Rice Bran and Rice Bran Oil; Elsevier: Amsterdam, The Netherlands, 2019; pp. 207–246. [Google Scholar] [CrossRef]

- Sulaiman. Rice Husk, Rice Husk Ash, and Their Applications. In Rice Husk Biomass: Processing, Properties and Applications; Jawaid, M., Parmar, B., Eds.; Springer: Singapore, 2025; pp. 43–54. [Google Scholar] [CrossRef]

- Nzereogu, P.U.; Omah, A.D.; Ezema, F.I.; Iwuoha, E.I.; Nwanya, A.C. Silica Extraction from Rice Husk: Comprehensive Review and Applications. Hybrid Adv. 2023, 4, 100111. [Google Scholar] [CrossRef]

- Xia, M.; Yang, X.; Hou, Z. Preparation of High-Purity Quartz Sand by Vein Quartz Purification and Characteristics: A Case Study of Pakistan Vein Quartz. Minerals 2024, 14, 727. [Google Scholar] [CrossRef]

- Marçal, J.M.M.; Chim, M.R.; Teixeira, I.M.; Armas, L.E.; Buchner, S.; Vasconcellos, M.; Menezes, J.W.; Valsecchi, C. Characterization of rice husk ash glass produced at low temperature as a sustainable alternative for the glass industry. Int. J. Environ. Sci. Technol. 2025. [Google Scholar] [CrossRef]

- Kaewkhao, J.; Limsuwan, P. Utilization of rice husk fly ash in the color glass production. Procedia Eng. 2012, 32, 670–675. [Google Scholar] [CrossRef]

- United States Department of Agriculture (USDA). Brazil Rice Area, Yield and Production. Available online: https://ipad.fas.usda.gov/countrysummary/Default.aspx?crop=Rice&id=BR (accessed on 2 March 2025).

- Silva, L.A.; Santos, I.F.S.; Machado, G.O.; Tiago Filho, G.L.; Barros, R.M. Rice Husk Energy Production in Brazil: An Economic and Energy Extensive Analysis. J. Clean. Prod. 2021, 290, 125188. [Google Scholar] [CrossRef]

- UN General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/2030agenda (accessed on 15 December 2024).

- Synowicki, R.A.; Johs, B.D.; Martin, A.C. Optical properties of soda-lime float glass from spectroscopic ellipsometry. Thin Solid Films 2011, 519, 2907–2913. [Google Scholar] [CrossRef]

- Verma, J.P.; Verma, P. Determining Sample Size and Power in Research Studies; Springer: Singapore, 2020. [Google Scholar]

- EN 1436:2018; Road Marking Materials—Road Marking Performance for Road Users and Test Methods. European Committee for Standardization: Brussels, Belgium, 2018.

- E1710-18; Standard Test Method for Measurement of Retroreflective Pavement Marking Materials with CEN Prescribed Geometry Using a Portable Retroreflectometer. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- NBR 14723; Road Horizontal Signaling—Measurement of Retroreflectivity Using Handheld Equipment with 15 m Geometry—Test Method. ABNT—Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2020.

- Endale, S.A.; Taffese, W.Z.; Vo, D.; Yehualaw, M.D. Rice Husk Ash in Concrete. Sustainability 2023, 15, 137. [Google Scholar] [CrossRef]

- Smadi, O.; Hawkins, N.; Bektas, B.A.; Carlson, P.; Pike, A.; Davies, C. Recommended Laboratory Test for Predicting the Initial Retroreflectivity of Pavement Markings from Glass Bead Quality. Transp. Res. Rec. 2014, 2440, 94–102. [Google Scholar] [CrossRef]

- Shelby, J.E. Compositions and Properties of Commercial Glasses. In Introduction to Glass Science and Technology; Royal Society of Chemistry: Cambridge, UK, 2005; pp. 262–274. [Google Scholar] [CrossRef]

- NBR 13699; Road Horizontal Signaling—Water-Based Acrylic Resin Paint. ABNT—Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2021.

- Zhang, G.; Hummer, J.E.; Rasdorf, W. Impact of bead density on paint pavement marking retroreflectivity. J. Transp. Eng. 2010, 136, 773–781. [Google Scholar] [CrossRef]

- Smith, D.Y.; Shiles, E.; Inokuti, M. Refraction and dispersion in optical glass. Nucl. Instrum. Methods Phys. Res. B 2004, 218, 170–175. [Google Scholar] [CrossRef]

- Pavliukevich, Y.G.; Papko, L.F.; Trusova, E.E. Optical Glass with Increased Refractive Index Based on the BaO–B2O3–SiO2 System. Chem. Chem. Eng. 2024, 2024, 1. [Google Scholar] [CrossRef]

- Wenzel, K.M.; Burghardt, T.E.; Pashkevich, A.; Buckermann, W.A. Glass Beads for Road Markings: Surface Damage and Retroreflection Decay Study. Appl. Sci. 2022, 12, 2258. [Google Scholar] [CrossRef]

| RHA Composition (wt%) | ||||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | MgO | CaO | P2O5 | C * | Others < 0.1 |

| 88.3 | 1.4 | 3.1 | 0.3 | 0.5 | 6.3 | 0.1 |

| Microspheres Composition (wt%) | |||||

|---|---|---|---|---|---|

| SiO2 | Na2O | CaO | Toxic Oxides (As2O3, PbO, Sb2O3) | Others | |

| From RHA | 72.8 | 2.8 | 20.5 | ND | 3.9 |

| Commercial | 72.7 | 4.7 | 21. 0 | ND | 1.6 |

| Sample | Total Counts | Spheres (%) | Ovoids/Twinned (%) | Shards (%) |

|---|---|---|---|---|

| RHA Glass | 1200 | 91 ± 3 | 7 ± 2 | 1.5 ± 0.2 |

| Commercial Glass | 1200 | 86 ± 3 | 11 ± 3 | 2.1 ± 0.4 |

| Type IB Microspheres (Premix) | |||

|---|---|---|---|

| SiO2 content | ≥65% | ||

| Toxic elements (As, Pb, Sb) | Maximum 200 mg/kg | ||

| Color | Colorless | ||

| Refractive index | ≥1.5 | ||

| Granulometry (φ) | 63 µm ≤ φ ≤ 250 µm | ||

| Morphology | Ovoid/twin | Shards | Spherical |

| Maximum 20% | Maximum 3% | ≥77% | |

| Density (g/cm3) | 2.4 ≤ d ≤ 2.6 | ||

| Resistance to hydrochloric acid | Surface without fogging | ||

| Sample Properties | RHA Microspheres | Commercial Microspheres |

|---|---|---|

| SiO2 Content (%) | 72.8 | 72.7 |

| Toxic Elements (As, Pb, Sb) | ND | ND |

| Color | Colorless | Colorless |

| Refractive Index | 1.55 ± 0.03 | – |

| Granulometry (φ) | Categorized as Type IB | Categorized as Type IB |

| Morphology | ||

| — Ovoid/Twin (%) | 7 ± 2 | 11 ± 3 |

| — Shards (%) | 1.5 ± 0.2 | 2.1 ± 0.4 |

| — Spherical (%) | 91 ± 3 | 86 ± 3 |

| Density (g/cm3) | 2.42 ± 0.01 | 2.43 ± 0.01 |

| Resistance to Hydrochloric Acid | Surface without fogging | Surface without fogging |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teixeira, I.M.; Pase Neto, J.; Budny, A.; Armas, L.E.G.; Valsecchi, C.; Menezes, J.W.d. Transforming Rice Husk Ash into Road Safety: A Sustainable Approach to Glass Microsphere Production. Ceramics 2025, 8, 93. https://doi.org/10.3390/ceramics8030093

Teixeira IM, Pase Neto J, Budny A, Armas LEG, Valsecchi C, Menezes JWd. Transforming Rice Husk Ash into Road Safety: A Sustainable Approach to Glass Microsphere Production. Ceramics. 2025; 8(3):93. https://doi.org/10.3390/ceramics8030093

Chicago/Turabian StyleTeixeira, Ingrid Machado, Juliano Pase Neto, Acsiel Budny, Luis Enrique Gomez Armas, Chiara Valsecchi, and Jacson Weber de Menezes. 2025. "Transforming Rice Husk Ash into Road Safety: A Sustainable Approach to Glass Microsphere Production" Ceramics 8, no. 3: 93. https://doi.org/10.3390/ceramics8030093

APA StyleTeixeira, I. M., Pase Neto, J., Budny, A., Armas, L. E. G., Valsecchi, C., & Menezes, J. W. d. (2025). Transforming Rice Husk Ash into Road Safety: A Sustainable Approach to Glass Microsphere Production. Ceramics, 8(3), 93. https://doi.org/10.3390/ceramics8030093