1. Introduction

Piezoelectric ceramics are materials that exhibit the piezoelectric effect, enabling the interconversion between mechanical stress and electrical charge. Such materials are widely used in sensors and actuators, as well as energy harvesting and conversion technologies [

1,

2,

3]. However, the widespread application of lead zirconate titanate (PZT) ceramics, despite their excellent electrical properties, has raised environmental concerns due to the toxicity of lead, which poses serious risks to both the ecological systems and human health [

4]. The introduction of Li, Ta, and Sb into (Na,K)NbO

3(KNN) ceramics by Saito et al. [

5] has significantly advanced the development of lead-free piezoelectric materials. In recent years, intensive research efforts have been devoted to the development of lead-free piezoelectric ceramics. Among these, Bi

1/2Na

1/2TiO

3 (BNT, bismuth sodium titanate) ceramics have attracted considerable attention as a promising lead-free material candidate, owing to their high Curie temperature (~320 °C), favorable piezoelectric performance, and environmental compatibility, making them a strong alternative to lead-based piezoelectric materials [

6].

BNT ceramics possess a perovskite-type structure, where Na

+ and Bi

3+ ions occupy the A-site, and Ti

4+ ions are located at the B-site. The crystal structure is characterized by high spontaneous polarization, which contributes to the material’s strong ferroelectric behavior. The ferroelectric behavior originates from the tilting of TiO

6 octahedra [

7]. Pure BNT ceramics exhibit relatively low sintering temperatures and favorable ferroelectric and piezoelectric properties, but they also display pronounced anisotropy. However, their relatively high conductivity in the ferroelectric phase results in large remnant polarization and high coercive fields, which hinder efficient polarization switching [

8]. To overcome these limitations and enhance their electrical properties, extensive studies have focused on doping modifications of BNT-based ceramics [

9,

10]. The incorporation of suitable dopants can induce the formation of a morphotropic phase boundary (MPB), which facilitates the reorientation of electric domains, thereby improving both piezoelectric and ferroelectric properties [

11,

12].

Typical binary solid solutions based on the BNT system include BNT-(K,Na)NbO

3 [

13], BNT-BaTiO

3(BNT-BT) [

14], BNT-SrTiO

3, and BNT-(Bi

1/2K

1/2)TiO

3(BNT-BKT), among others [

15,

16]. Doping strategies are generally classified into A-site and B-site modifications, depending on the substitution position within the perovskite lattice [

17,

18]. In B-site doping, Ti

4+ ions are substituted with other ions of similar valence and ionic radius, such as Mn

2+, Nb

5+, and Fe

2+, to tailor the electrical properties [

19,

20,

21]. In this study, lead-free (Bi

1/2Na

1/2)(Ti

1−x(Mg

1/3Nb

2/3)

x)O

3 ceramics were synthesized, and the effects of varying (Mg

1/3Nb

2/3)

4+ doping levels on their piezoelectric and ferroelectric properties were systematically investigated.

2. Materials and Methods

In this study, lead-free piezoelectric ceramics with the composition (Bi1/2Na1/2)(Ti1−x(Mg1/3Nb2/3)x)O3 (BNT-xBNMN, x = 0.02, 0.03, 0.04, 0.05) were synthesized via the solid-state reaction method. High-purity raw materials were used: Bi2O3 (99.9%), TiO2 (99.99%), MgCO3 (99.5%), Na2CO3 (99.99%), and Nb2O5 (99.99%). Prior to weighing, all raw materials were dried at 100 °C for 8 h to remove absorbed moisture. The materials were then accurately weighed according to the stoichiometric ratios, placed in a planetary ball mill (YXQM-1L, zirconia (ZrO2) balls) with absolute ethanol, and milled for 8 h. After milling, the powder was dried thoroughly in a drying oven, and then it was calcined at 800 C in an air atmosphere for 2 h. The calcined powders were subsequently remilled with ethanol for 12 h to ensure uniformity. The resulting powders were pressed into pellets using cold isostatic pressing at 230 MPa for 10 min. Finally, the green pellets were sintered at three different temperatures (1150 °C, 1160 °C, and 1170 °C) for 4 h in air using a muffle furnace to obtain dense ceramic samples.

The bulk density of the sintered ceramic samples was measured using the Archimedes drainage method. The phase composition was analyzed by X-ray diffractometer (XRD, D8 ADVANCE, Bruker, Kassel, Germany). Microstructural features were observed via field-emission scanning electron microscope (FE-SEM, Apero Hivoc, FEI, Portland, OR, USA). To assess the electrical properties of the ceramics, silver paste was applied to both sides of the samples and sintered at 550 °C for 30 min to form electrodes. The ferroelectric hysteresis loops (P-E) and current–electric field (J-E) characteristics were measured using a ferroelectric analyzer (TF Analyzer 3000, aixACCT, Aachen, Germany). The samples were polarized in silicone oil for 30 min prior to piezoelectric coefficient (d33) measurements using a quasi-static piezoelectric constant meter (J-6BN, Institute of Acoustics, Chinese Academy of Sciences, Beijing, China). Temperature-dependent dielectric properties were evaluated using an LCR meter (TH2838A, Shanghai, China) in conjunction with a cold-stage system (CH400-100-P8, Suzhou, China).

3. Results and Discussion

3.1. XRD Analysis Results

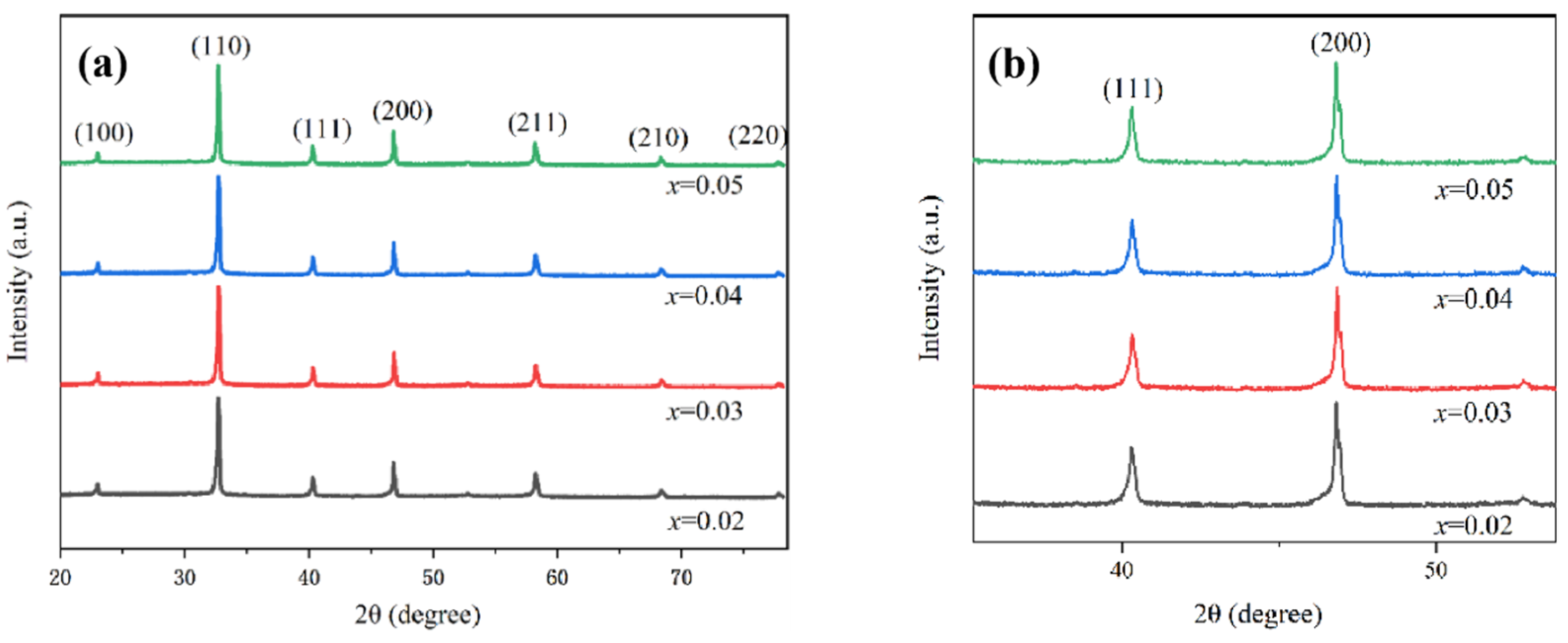

The X-ray diffraction (XRD) patterns of the (Bi

1/2Na

1/2)(Ti

1−x(Mg

1/3Nb

2/3)

x)O

3 ceramics (x = 0.02, 0.03, 0.04, 0.05) are shown in

Figure 1. The XRD patterns reveal BNT ceramics possess a tetragonal perovskite-type structure, with no evidence of secondary phases, indicating that all compositions formed stable perovskite structures [

22]. Meanwhile, ceramics have a typical tetragonal structure (T), which is characterized by a split (200)/(002) peak and a single (111) peak [

23]. This suggests that the doped (Mg

1/3Nb

2/3)

4+ ions were successfully incorporated into the BNT lattice without causing significant alterations to the BNT phase structure.

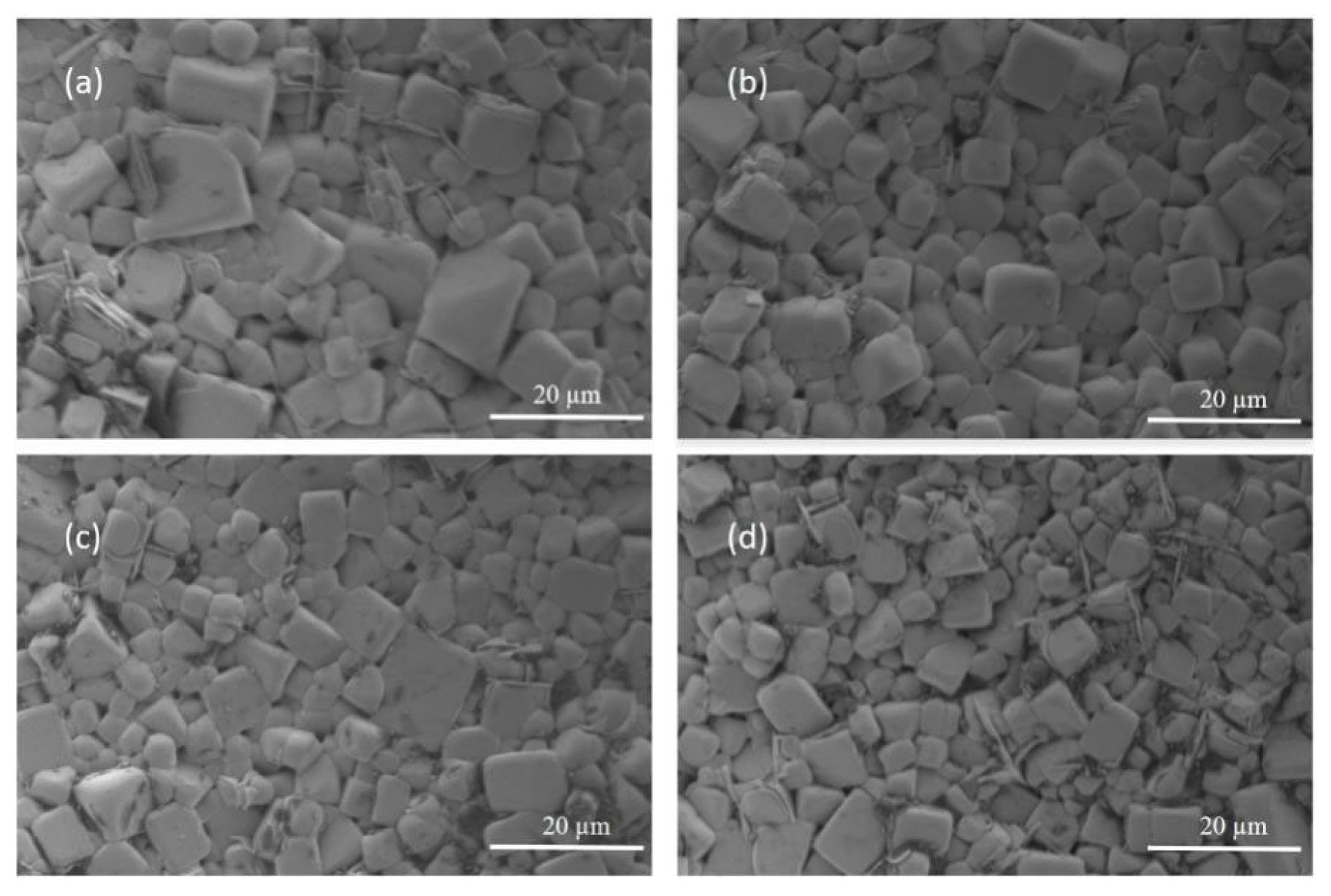

3.2. Microscopic Topography Characterization

Figure 2 presents the scanning electron microscopy (SEM) images of the BNT-

xBNMN ceramic samples. From these images, the microstructure of the samples can be observed. The grain boundaries are clearly defined, and the grains exhibit a block-like morphology. The size distribution of the grains is relatively uniform, and the arrangement is compact. These observations further confirm that the doped (Mg

1/3Nb

2/3)

4+ ions have been effectively incorporated into the perovskite structure of the BNT ceramics, without inducing any significant changes in the microstructure. The density of the samples measured by the drainage method is shown in

Figure 3. As can be seen from the figure, with the increase of BNMN content, the density showed a trend of first decreasing and then rising, from 5.718 g/cm

3 to 5.586 g/cm

3, and then recovered to 5.651 g/cm

3. The sample density was relatively uniform.

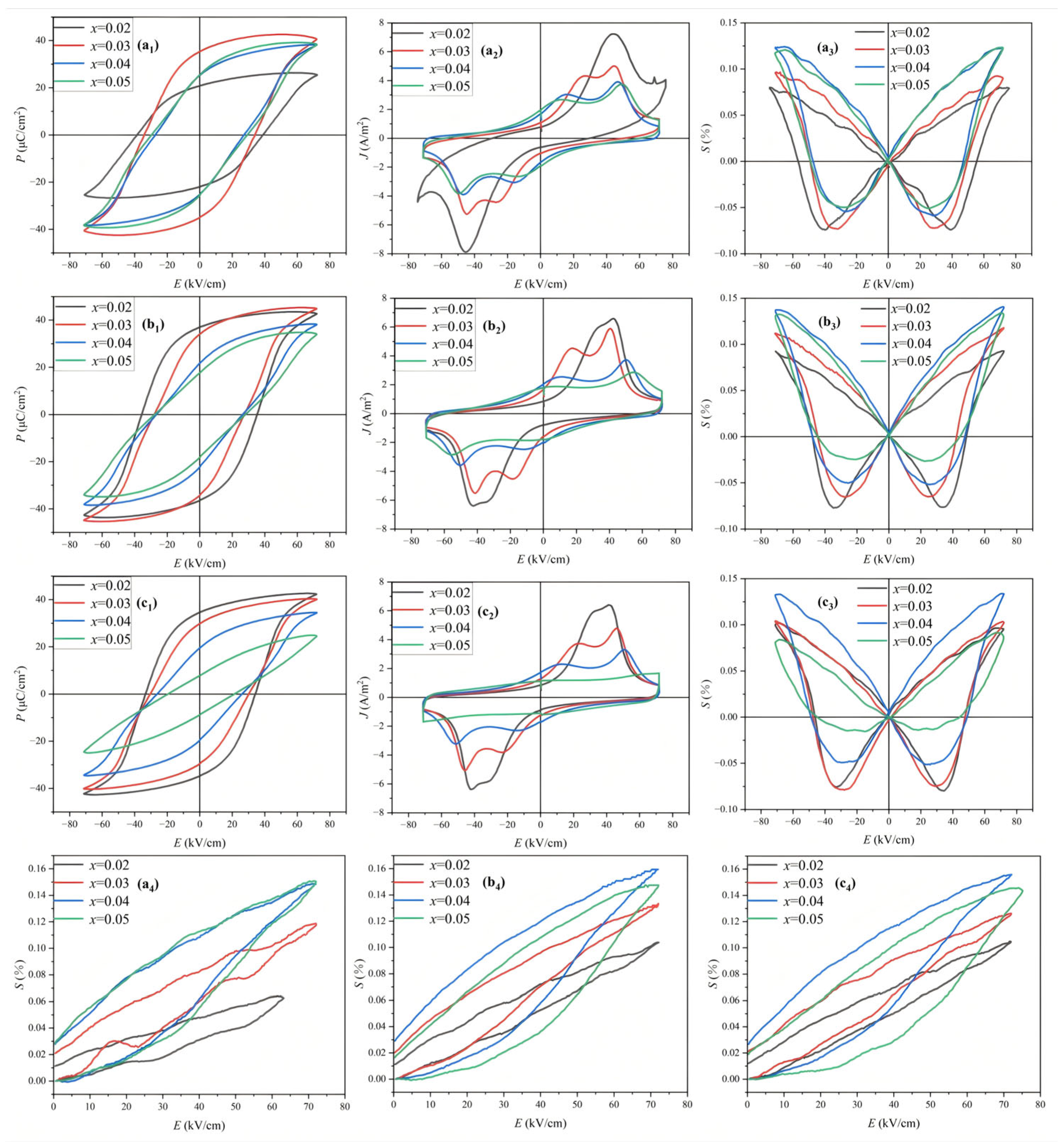

3.3. Analysis of Ferroelectric Properties

The ferroelectric (

P-

E), current (

J-

E), and strain (

S-

E) responses of the BNT-

xBNMN ceramics sintered at 1150 °C, 1160 °C, and 1170 °C are shown in

Figure 4. Both ferroelectric properties and strain behavior are evidently influenced by the doping concentration.

At sintering temperatures of 1150 °C and 1160 °C, the maximum polarization (

Pmax) and remnant polarization (

Pr) initially increase and then decrease with doping, reaching a maximum value at

x = 0.02, indicating improved ferroelectric performance. At low doping (Mg

1/3Nb

2/3)

4+ levels, the dopants promote crystal polarization and domain alignment, producing a well-saturated

P-

E loop, which means that the polarization intensity increases rapidly with the applied electric field and stabilizes with a relatively high remnant polarization. However, as doping increases, the internal ferroelectric domain state may gradually transition toward a relaxor ferroelectric state. This transition makes the domain-switching behavior more complex, which is characterized by a slimmer, waist-shaped

P-

E loop [

24,

25]. In this state, the polarization strength no longer increases rapidly with the applied electric field. Instead, it tends to stabilize, exhibiting a more gradual growth trend as the electric field continues to rise. This behavior is indicative of a transition from a classical ferroelectric state to a relaxor ferroelectric state. Simultaneously, the remnant polarization shows a noticeable decline, signifying a weakened ability of the material to retain polarization after the removal of the external field. As reflected in the J-E current curves, the current peak shifts gradually from higher electric fields toward lower fields with increasing dopant content. This shift suggests that the polarization switching process becomes slower and more dispersed, which is a hallmark of enhanced relaxor characteristics [

26].

At a sintering temperature of 1170 °C, both the maximum polarization Pmax and remnant polarization Pr display a consistent downward trend as the doping concentration increases. This observation implies a degradation in the ferroelectric properties of the ceramic samples at elevated temperatures. One possible explanation is that excessive sintering temperature can adversely affect the structural integrity of the perovskite lattice. The high thermal energy may induce phase instability or promote the formation of microstructural defects during densification. In particular, the volatilization of low-melting-point components such as Bi2O3 is more pronounced at elevated temperatures. The loss of Bi disrupts the charge balance and stoichiometry of the lattice, which can hinder domain formation and reduce spontaneous polarization. These factors collectively contribute to the deterioration of ferroelectric performance observed at 1170 °C.

An analysis of the S-E curves and corresponding unipolar strain data under different sintering temperatures reveals that the strain values generally increase with the doping concentration. At 1160 °C, the sample with a doping concentration of x = 0.04 exhibits the highest strain value of 0.16%. This enhancement in strain behavior can be attributed to the increasing presence of a relaxor ferroelectric phase, induced by the substitution of (Mg1/3Nb2/3)4+ ions. These dopants introduce local structural heterogeneity and disrupt long-range ferroelectric ordering, facilitating the formation of nanoscale polar regions with high electromechanical responsiveness.

Moreover, the relaxor state is characterized by the presence of easily reorientable polar nanoregions, which can respond more readily to external electric fields compared to long-range ferroelectric domains. This leads to larger strain responses, particularly in unipolar measurements. The current–electric field (

J-

E) curves provide supporting evidence for this interpretation, showing broader peaks and delayed current responses in samples with higher doping levels, further confirming the transition toward a relaxor-dominated behavior. Therefore, by carefully tuning the doping concentration and sintering temperature, it is possible to optimize the microstructure and domain dynamics of BNT-

xBNMN ceramics, thereby achieving enhanced electromechanical performance and strain output [

27].

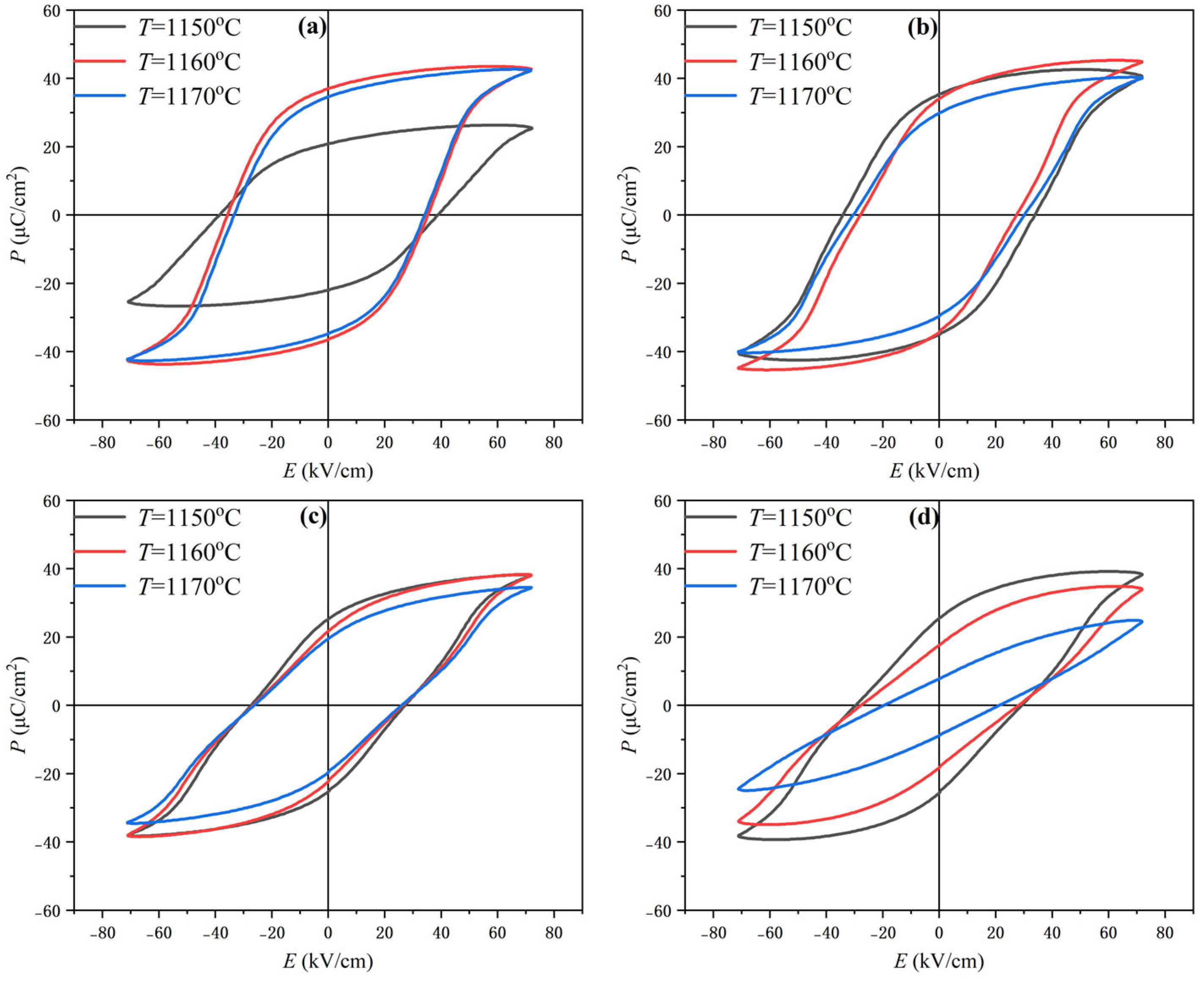

3.4. P-E Curve Analysis of Variable Temperature

The sintering temperature plays a crucial role in determining the ferroelectric performance of piezoelectric ceramics [

28]. This is primarily because the ferroelectric properties are intrinsically linked to the ceramic’s microstructure, phase composition, grain size, and density—all of which are significantly influenced by the sintering process [

29]. A suitable sintering temperature promotes densification and phase stability, while inappropriate temperatures may lead to secondary phases, excessive grain growth, or volatilization of key elements [

30]. To identify the optimal sintering temperature for the BNT-

xBNMN ceramics, the

P-

E hysteresis loops were measured at different sintering temperatures (1150 °C, 1160 °C, and 1170 °C), as shown in

Figure 5. The data indicate that the samples sintered at 1160 °C exhibit enhanced ferroelectric properties, characterized by higher

Pmax and

Pr values, as well as a lower

Ec. These improvements suggest more efficient domain switching and a stronger ferroelectric response [

31]. Furthermore, analysis of the corresponding strain behavior reveals a larger strain output at this temperature, confirming the overall enhancement in electromechanical performance. Based on these observations, samples sintered at 1160 °C were selected for subsequent in-depth investigation.

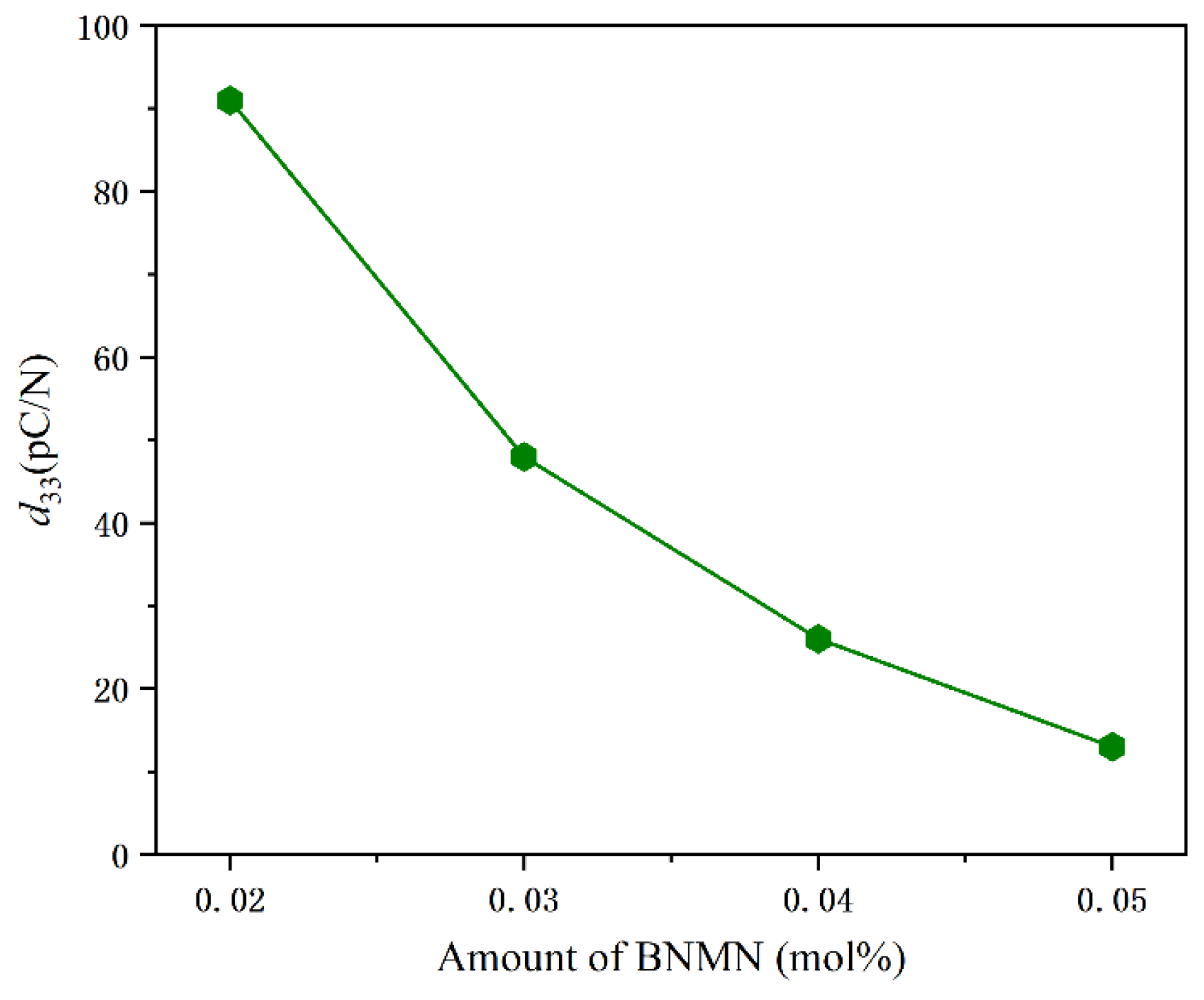

3.5. Piezoelectric Performance Test

To evaluate the piezoelectric response, the piezoelectric constant (

d33) was measured for samples sintered at 1160 °C. As illustrated in

Figure 6, the piezoelectric constant (

d33) value shows a downward trend with increasing doping concentration. The highest value of 91 pC/N was observed at

x = 0.02, indicating that a low doping concentration contributes positively to piezoelectric activity. This finding is consistent with the corresponding

P-

E loop data, further confirming that moderate incorporation of (Mg

1/3Nb

2/3)

4+ ions can enhance the alignment and stability of ferroelectric domains, thereby improving piezoelectric performance.

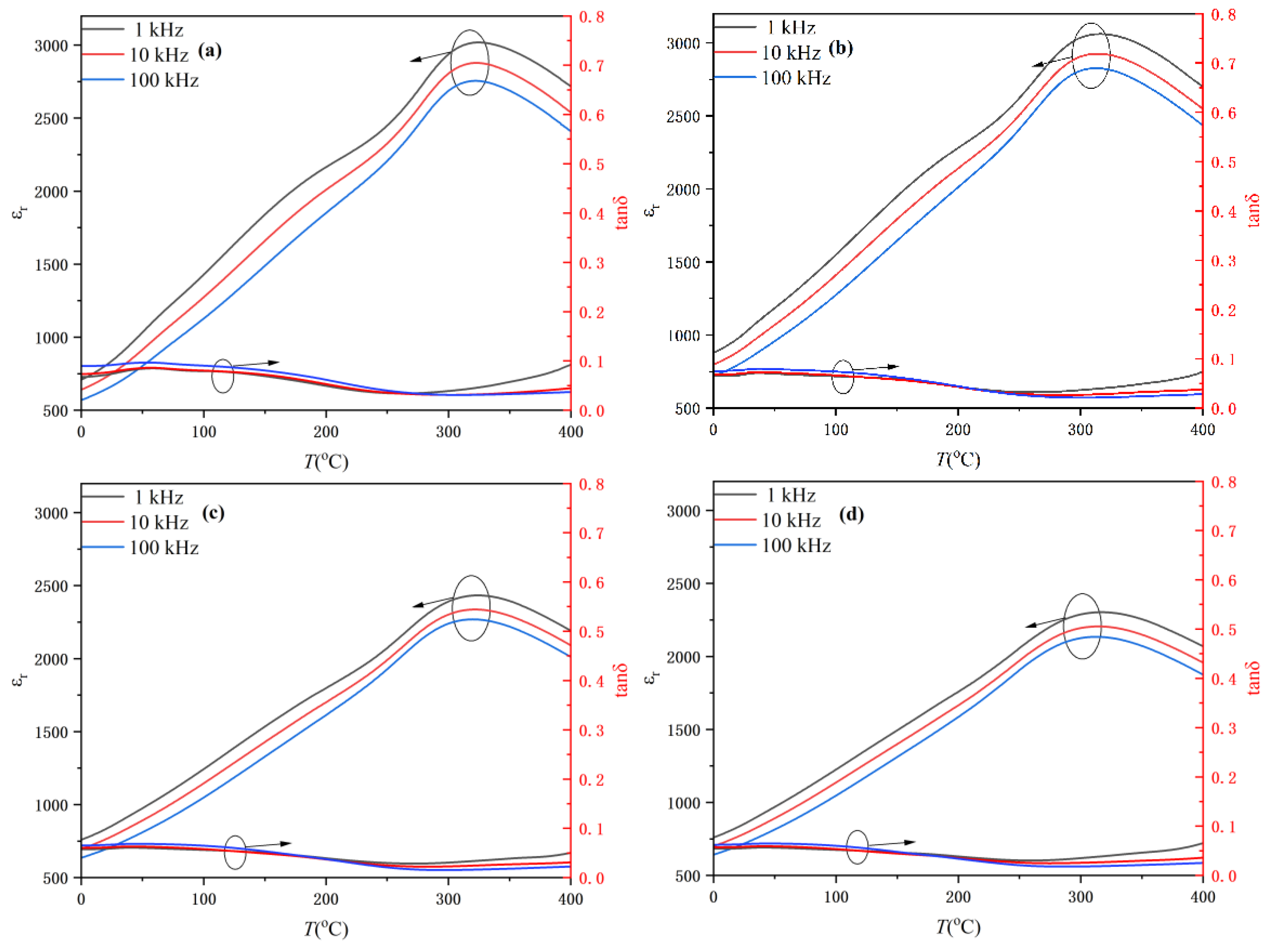

3.6. Dielectric Properties Test

In addition to ferroelectric and piezoelectric properties, the dielectric behavior of BNT-

xBNMN ceramics was examined to assess the influence of doping on phase transition characteristics. The dielectric temperature spectra of the (Bi

1/2Na

1/2)(Ti

1−x(Mg

1/3Nb

2/3)

x)O

3 ceramics sintered at 1160 °C were measured under different doping concentrations and frequencies, as shown in

Figure 7. These spectra provide insights into the materials’ phase transition behavior and dielectric relaxation characteristics. It was observed that, at a fixed frequency, the maximum dielectric constant (

εm) initially increases with increasing dopant content and reaches a peak at

x = 0.02. This indicates that a small amount of (Mg

1/3Nb

2/3)

4+ doping can enhance the polarizability of the material, likely due to improved dipole alignment and domain activity [

32]. However, further increases in the doping concentration beyond this point lead to a decline in

εm, which may be attributed to disruption of long-range ferroelectric ordering, increased defect density, or phase instability induced by excessive dopant incorporation [

33,

34].

Moreover, the dielectric constant shows a decreasing trend with increasing frequency. This frequency dispersion is attributed to the inability of ferroelectric domains and dipoles to respond rapidly enough to the high-frequency alternating external field. As a result, the polarization response diminishes, leading to a reduced dielectric constant at higher frequencies [

35]. Notably, for doping concentrations of

x = 0.02 and

x = 0.03, distinct dielectric Ts peaks associated with dielectric relaxation are clearly observed, indicating pronounced dielectric relaxation behavior and phase transition activity within these compositions.

4. Conclusions

In this study, (Bi1/2Na1/2)(Ti1−x(Mg1/3Nb2/3)x)O3 lead-free piezoelectric ceramics were synthesized using the solid-phase method. The effects of varying (Mg1/3Nb2/3)4+ doping concentrations and sintering temperatures on the structural, ferroelectric, piezoelectric, and dielectric properties of the ceramics were systematically investigated. The results demonstrated that a small amount of (Mg1/3Nb2/3)4+ dopant, particularly at x = 0.02, significantly enhances the maximum polarization (Pmax), remnant polarization (Pr), dielectric constant (εm), and piezoelectric constant (d33), thereby improving the overall electromechanical performance of the BNT-based ceramics. Furthermore, it was found that the sintering temperature has a decisive impact on material performance. Among the three sintering temperatures, 1160 °C, the ceramics exhibit optimal ferroelectric and piezoelectric performance, highlighting the critical role of sintering temperature in optimizing ceramic functionality. These findings provide valuable guidance for the design and processing of high-performance, lead-free piezoelectric ceramics for practical applications in actuators, sensors, and transducers.

Author Contributions

Conceptualization, Y.Z., N.Y., and L.W.; methodology, N.Y. and L.W.; validation, Y.Z., Y.C., X.L., and P.W.; formal analysis, Y.Z., N.Y., Y.C., and X.L.; investigation, Y.Z. and N.Y.; resources, P.W. and G.D.; data curation, N.Y. and L.W.; writing—original draft preparation, Y.Z., N.Y., and L.W.; writing—review and editing, P.W. and G.D.; visualization, Y.Z. and N.Y.; supervision, P.W. and G.D.; project administration, P.W. and G.D.; funding acquisition, G.D. All authors have read and agreed to the published version of the manuscript.

Funding

Supported by the Key Research and Development Program of Shaanxi (2025GH-YBXM-047), the Technology Innovation Leading Program of Shaanxi (2025QCY-KXJ-002), the Fundamental Research Funds for the Central Universities (ZYTS24120, ZYTS23087), the State Key Laboratory of Solidification Processing at NWPU (SKLSP202213), and the Basic Research and Strategic Reserve Technology Research Fund project of CNPC (No. 2023DQ03-10).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Conflicts of Interest

Authors Yonggang Zhao, Yi Chen and Peng Wang were employed by the company Tubular Goods Research institute of China National Petroleum Corporation. Author Xingting Li was employed by the company Tarim Oilfield Company, PetroChina Company Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Xie, M.; Zhang, Y.; Krany, M.J.; Bowen, C.; Khanbareh, H.; Gathercolea, N. Flexible and active self-powered pressure, shear sensors based on freeze casting ceramic–polymer composites. Energy Environ. Sci. 2018, 11, 2919–2927. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Cui, H.; Lu, G. 3D Printing and processing of miniaturized transducers with near-pristine piezoelectric ceramics for localized cavitation. Nat. Commun. 2023, 14, 2418. [Google Scholar] [CrossRef] [PubMed]

- Nikita, A.; Egor, S.; Lidia, A.; Svetlana, I.; Alexander, V.; Larisa, A. Effect of Superstoichiometric Bismuth Addition on the Structure and Dielectric Characteristics of the Solid Solutions (1−x)BiFeO3-xBaTiO3. Ceramics 2025, 8, 7. [Google Scholar] [CrossRef]

- Hiruma, Y.; Yoshii, K.; Aoyagi, R. Electrical Properties and Depolarization Temperature of (Bi1/2Na1/2)TiO3-(Bi1/2K1/2)TiO3 Lead-free Piezoelectric Ceramics. Key Eng. Mater. 2006, 320, 23–26. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef]

- Li, T.; Liu, C.; Shi, P.; Liu, X. High-Performance Strain of Lead-Free Relaxor-Ferroelectric Piezoceramics by the Morphotropic Phase Boundary Modification. Adv. Funct. Mater. 2022, 32, 2202307. [Google Scholar] [CrossRef]

- Karthik, T.; Dhanya, R.; Chandrabhas, N.; Saket, A. Nature of electric field driven ferroelectric phase transition in lead-free Na1/2Bi1/2TiO3: In-situ temperature dependent ferroelectric hysteresis and Raman scattering studies. J. Alloys Compd. 2018, 25, 945–951. [Google Scholar] [CrossRef]

- Yang, K.H.; Luo, G.G.; Li, M. Excellent energy storage performance in Bi0.5Na0.5TiO3-based lead-free high-entropy relaxor ferroelectrics via B-site modification. J. Adv. Ceram. 2024, 13, 345–353. [Google Scholar] [CrossRef]

- Wang, X.; Huan, Y.; Ji, S. Ultra-high piezoelectric performance by rational tuning of heterovalent-ion doping in lead-free piezoelectric ceramics. Nano Energy 2022, 101, 107580. [Google Scholar] [CrossRef]

- Tan, W. Improved Non-Piezoelectric Electric Properties Based on La Modulated Ferroelectric-Ergodic Relaxor Transition in (Bi0.5Na0.5)TiO3-Ba(Ti, Zr)O3 Ceramics. Materials 2021, 14, 6666. [Google Scholar] [CrossRef]

- Nikita, A.; Eugene, I.; Lidia, A. Structure and Relaxor Behavior of (0.5-x)BiFeO3-0.5PbFe0.5Nb0.5O3-xPbTiO3 Ternary Ceramics. Ceramics 2023, 6, 1735–1748. [Google Scholar] [CrossRef]

- Lv, X.; Liu, X.; Wu, J. Decoding the correlation between initial polarity and strain property of BNT-based ceramics. J. Appl. Phys. 2022, 132, 164101. [Google Scholar] [CrossRef]

- Dittmer, R.; Jo, W.; Roedel, J. Nanoscale Insight into Lead-Free BNT-BT-xKNN. Adv. Funct. Mater. 2012, 22, 4208–4215. [Google Scholar] [CrossRef]

- Cernea, M.; Galca, A.C.; Cioangher, M.C. Piezoelectric BNT-BT0.11 thin films processed by sol–gel technique. J. Mater. Sci. 2011, 46, 5621–5627. [Google Scholar] [CrossRef]

- Pradhan, L.K.; Kumari, S.; Manglam, M.K. Microstructure-dependent electrical properties of Bi0.5Na0.5TiO3–BaTiO3–SrTiO3 ternary solid solution. J. Mater. Sci. Mater. Electron. 2021, 32, 6607–6622. [Google Scholar] [CrossRef]

- Feng, J.; Huang, R.; Liang, Z. The effect of B site doping of Nb5+ and aging process on the properties of BNKT-BT lead-free piezoelectric ceramics. Ceram. Int. 2022, 48, 2355–2361. [Google Scholar] [CrossRef]

- Sapna, K.; Amit, K.; Aman, K. Enhanced Curie temperature and superior temperature stability by site selected doping in BCZT based lead-free ceramics. Ceram. Int. 2022, 10, 13780–13793. [Google Scholar] [CrossRef]

- Dong, G.; Fan, H.; Jia, Y.; Liu, H. Dielectric temperature stability and energy storage performance of B-site Sn4+-doped BNKBST ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 13620–13627. [Google Scholar] [CrossRef]

- Glaum, J.; Simons, H.; Acosta, M. Tailoring the Piezoelectric and Relaxor Properties of (Bi1/2Na1/2)TiO3-BaTiO3 via Zirconium Doping. J. Am. Ceram. Soc. 2013, 96, 2881–2886. [Google Scholar] [CrossRef]

- Peng, P.; Liu, K.; Li, K.; Luo, X.; Xiao, X.; Li, W.; Zheng, C. Effect of doping Mn/Fe/Co on the ferroelectric properties and depolarization behavior of BNT ceramics. J. Mater. Sci. Mater. Electron. 2023, 4, 2238. [Google Scholar] [CrossRef]

- Rui, Y.J.; Wan, C.M.; Li, J. Reversible phase transitions and enhanced electrostrain in BNST-xFN ceramics under electric and thermal stimuli. Microstructures 2025, 5, 2025047. [Google Scholar] [CrossRef]

- Chen, Z.; Hao, Y.; Huang, J. Poling above the Curie temperature driven large enhancement in piezoelectric performance of Mn doped PZT-based piezoceramics. Nano Energy 2023, 113, 108546. [Google Scholar] [CrossRef]

- Ren, P.; Fan, H.; Wang, X.; Dong, G. Phase transition, high figure of merit and polar nano-regions in dielectric tunable lanthanum substituted barium titanate. J. Alloys Compd. 2014, 617, 337–344. [Google Scholar] [CrossRef]

- Li, M.; Li, Q.; Yan, B. Large strain with enhanced energy-storage and temperature stable dielectric properties in Bi0.38Na0.38Sr0.24Ti (1−x)(Mn1/3Nb2/3)xO3 ceramics. Ceram. Int. 2021, 47, 1325–1332. [Google Scholar] [CrossRef]

- Gao, S.; Yao, Z.; Ning, L. Enhanced Bipolar Strain Response in Lithium/Niobium Co-Doped Sodium–Barium Bismuth Titanate Lead-Free Ceramics. Adv. Eng. Mater. 2017, 19, 1700125. [Google Scholar] [CrossRef]

- Luo, Y.; Pu, T.; Fan, S. Enhanced piezoelectric properties in low-temperature sintering PZN-PZT ceramics by adjusting Zr/Ti ratio. J. Adv. Dielectr. 2022, 12, 2250001. [Google Scholar] [CrossRef]

- Dong, G.; Fan, H.; Jia, Y. Strain properties of (1−x) Bi0.5Na0.4K0.1TiO3-xBi(Mg2/3Ta1/3)O3 electroceramics. Ceram. Int. 2020, 46, 21211–21215. [Google Scholar] [CrossRef]

- Peng, W.; Chang, J.; Wang, B. Ultrahigh piezoelectricity of PNN–PZT ceramics via constructing defect dipoles. Ceram. Int. 2024, 50, 6598–6605. [Google Scholar] [CrossRef]

- Yu, H.L.; Kang, W.S.; Lee, J.H. Transparent high-performance piezoceramics through pressureless sintering. J. Adv. Ceram. 2024, 13, 561–567. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, X.; Wang, Y. Giant strain and electric-field-induced phase transition in lead-free (Na0.5Bi0.5)TiO3-BaTiO3- (K0.5Na0.5)NbO3 single crystal. Appl. Phys. Lett. 2016, 108, 022903. [Google Scholar] [CrossRef]

- Qin, H.; Zhao, J.; Chen, X. Improved piezoelectric properties in Bi(Mg2/3Nb1/3)O3-modified BiFeO3–BaTiO3 lead-free piezoelectric ceramics. J. Am. Ceram. Soc. 2024, 107, 6833–6843. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, J.; Li, Y. Multifunctional BNT-based ferroelectric ceramics with large electrostrain and strong photoluminescence properties. J. Adv. Dielectr. 2024, 14, 2440009. [Google Scholar] [CrossRef]

- Dinh, T.; Han, H.; Tran, V.D. Thermally-Stable High EFIS Properties of Ternary Lead-Free BNT-BKT-BZ Piezoelectric Ceramics. J. Electron. Mater. 2023, 52, 2977–2985. [Google Scholar] [CrossRef]

- Ma, B.; Wu, X.; Zhao, C. An interpretable machine learning strategy for pursuing high piezoelectric coefficients in (K0.5Na0.5)NbO3-based ceramics. Comput. Mater. 2023, 9, 229. [Google Scholar] [CrossRef]

- Turik, A.V.; Pugachev, O.V.; Volgin, V.V.; Novikovet, M.S. Infralow-frequency dispersion of piezoelectric and dielectric constants in PbTiO3-based ferroelectric ceramics. J. Eur. Ceram. Soc. 1999, 19, 6–7. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).