ZrB2 Gear Fabrication by Spark Plasma Sintering Coupled to Interface 3D Printing

Abstract

1. Introduction

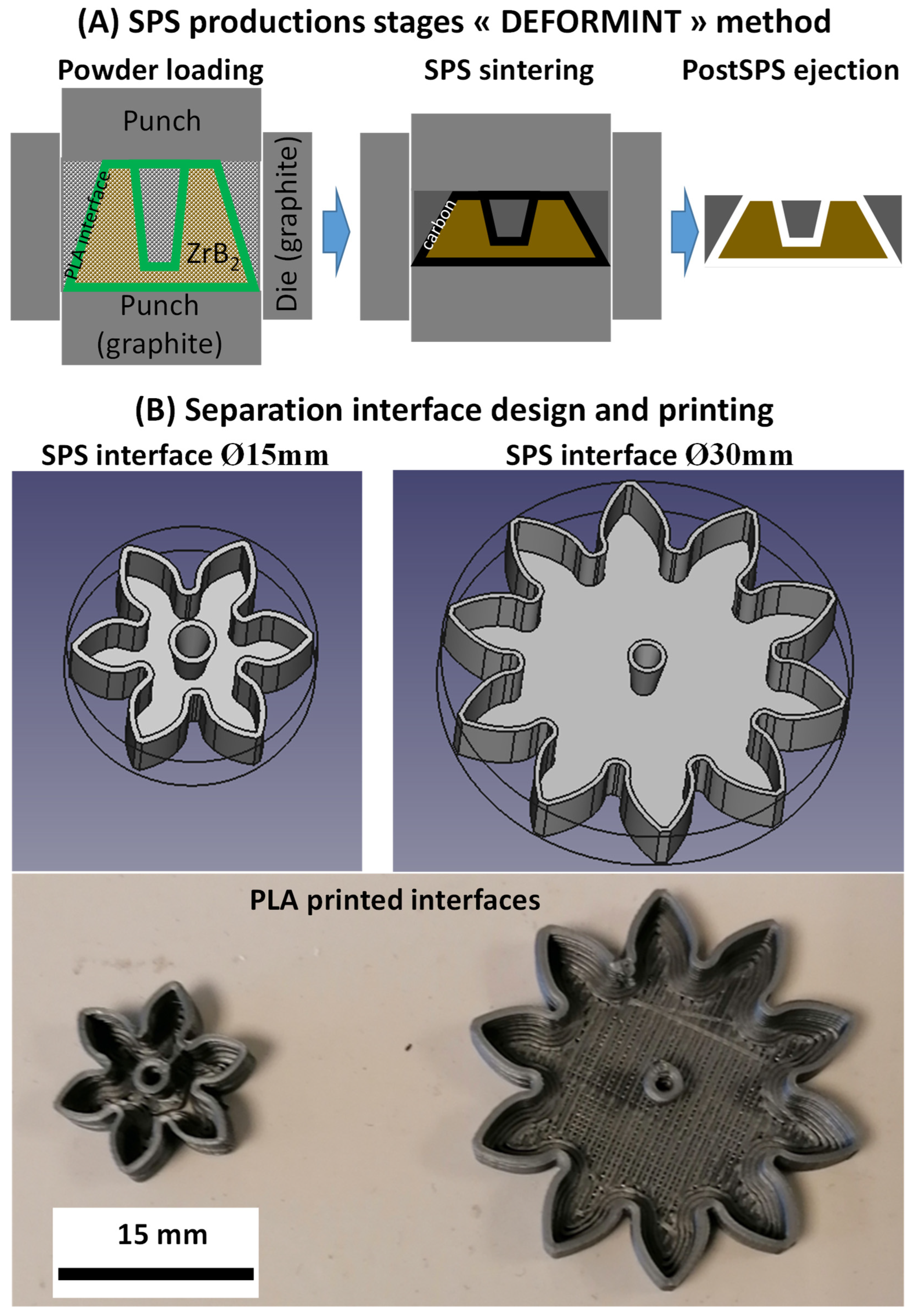

2. Materials and Methods

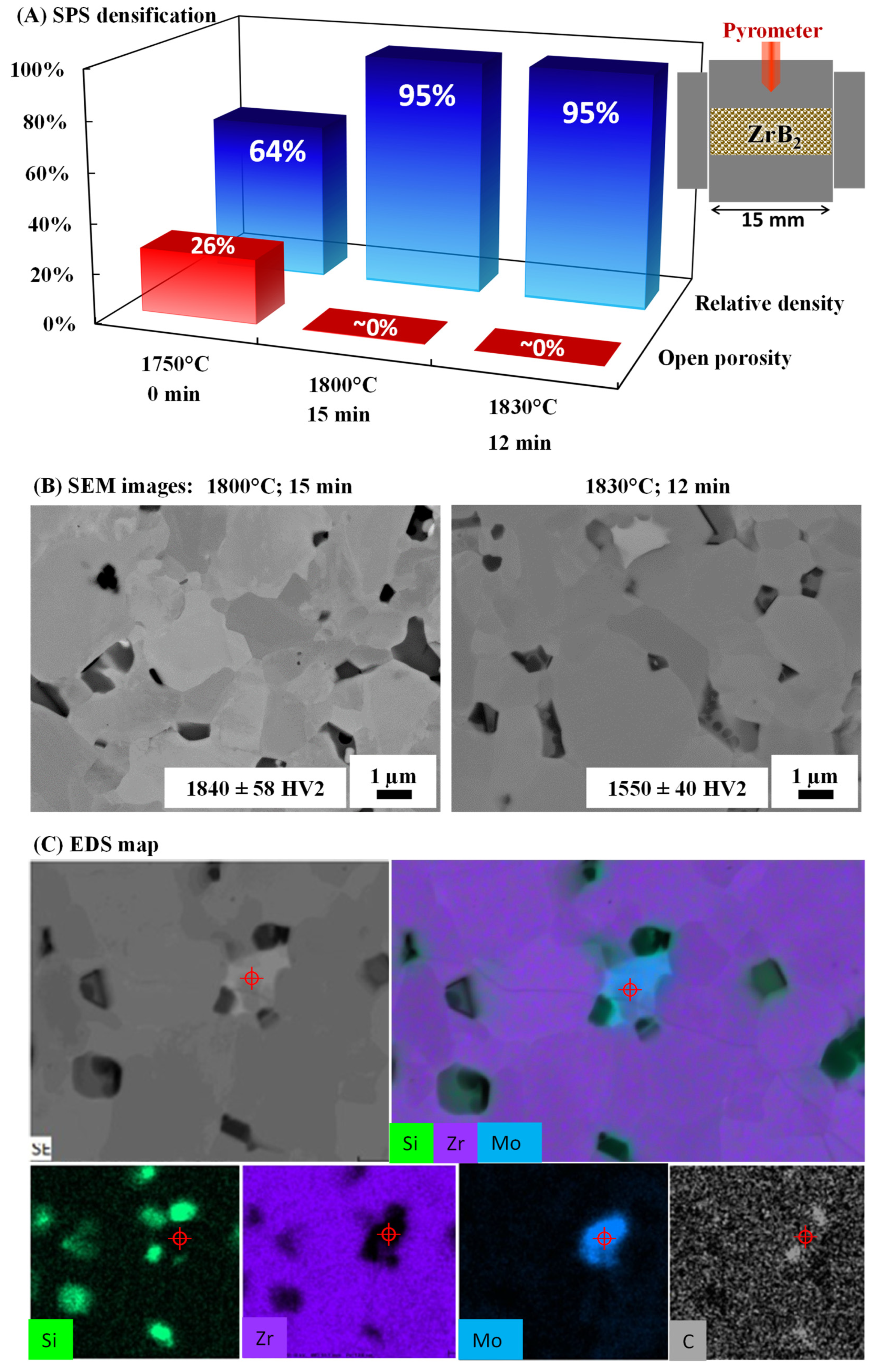

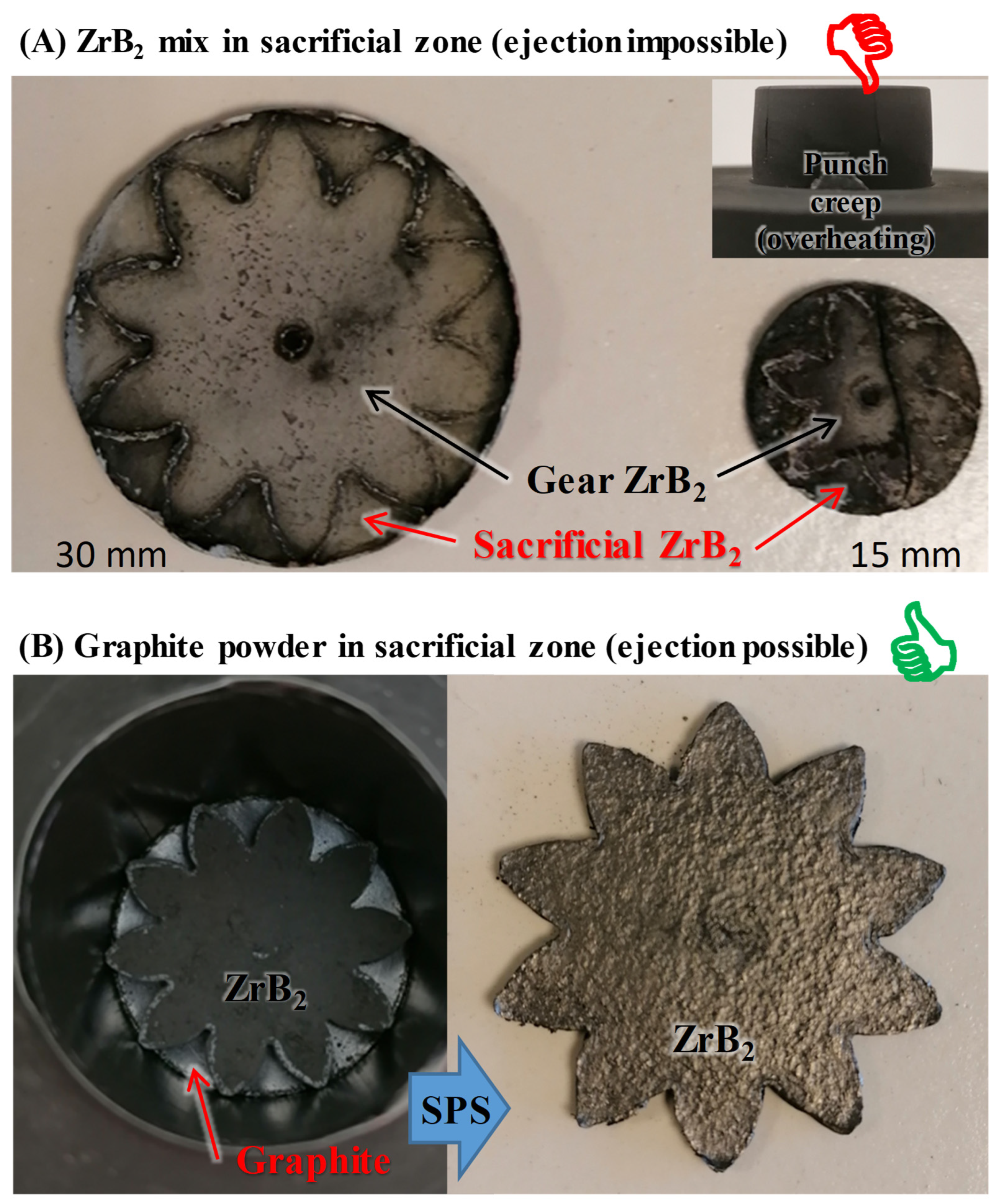

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| UHTCs | Ultra-High-Temperature Ceramics |

| PLA | Polylactic Acid |

| SPS | Spark Plasma Sintering |

| HP | Hot Pressing |

| HIP | Hot Isostatic Pressing |

| GPS | Gas Pressure Sintering |

| AM | Additive Manufacturing |

| FDM | Fuse Deposition Modeling |

References

- Wyatt, B.C.; Nemani, S.K.; Hilmas, G.E.; Opila, E.J.; Anasori, B. Ultra-High Temperature Ceramics for Extreme Environments. Nat. Rev. Mater. 2023, 9, 773–789. [Google Scholar] [CrossRef]

- Wuchina, E.; Opila, E.; Fahrenholtz, W.; Talmy, I. UHTCs: Ultra-High Temperature Ceramic Materials for Extreme Environment Applications. Electrochem. Soc. Interface 2007, 16, 30–36. [Google Scholar] [CrossRef]

- Orrù, R.; Cao, G. Ultra-High Temperature Ceramics by Spark Plasma Sintering. In Spark Plasma Sintering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 49–76. [Google Scholar]

- Justin, J.F.; Jankowiak, A. Ultra High Temperature Ceramics: Densification, Properties and Thermal Stability. Aerospace Lab 2011, 3, 1–11. [Google Scholar]

- Nisar, A.; Hassan, R.; Agarwal, A.; Balani, K. Ultra-High Temperature Ceramics: Aspiration to Overcome Challenges in Thermal Protection Systems. Ceram. Int. 2022, 48, 8852–8881. [Google Scholar] [CrossRef]

- Golla, B.R.; Mukhopadhyay, A.; Basu, B.; Thimmappa, S.K. Review on Ultra-High Temperature Boride Ceramics. Prog. Mater. Sci. 2020, 111, 100651. [Google Scholar] [CrossRef]

- Fahrenholtz, W.G.; Hilmas, G.E. Ultra-High Temperature Ceramics: Materials for Extreme Environments. Scr. Mater. 2017, 129, 94–99. [Google Scholar] [CrossRef]

- Silvestroni, L.; Kleebe, H.-J.; Fahrenholtz, W.G.; Watts, J. Super-Strong Materials for Temperatures Exceeding 2000 °C. Sci. Rep. 2017, 7, 40730. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Chen, W.; Wu, M.; Wang, J.; Jiang, K.; Liu, J. Microstructure and Densification of the Ti6Al4V–70%TiB2 Metal-Ceramic by Coupled Multi-Physical Fields-Activated Sintering. J. Alloys Compd. 2020, 820, 153091. [Google Scholar] [CrossRef]

- Fahrenholtz, W.G.; Hilmas, G.E.; Li, R. Densification of Ultra-Refractory Transition Metal Diboride Ceramics. Sci. Sinter. 2020, 52, 1–14. [Google Scholar] [CrossRef]

- Grasso, S.; Saunders, T.; Porwal, H.; Cedillos-Barraza, O.; Jayaseelan, D.D.; Lee, W.E.; Reece, M.J. Flash Spark Plasma Sintering (FSPS) of Pure ZrB2. J. Am. Ceram. Soc. 2014, 97, 2405–2408. [Google Scholar] [CrossRef]

- Fahrenholtz, W.G.; Hilmas, G.E.; Talmy, I.G.; Zaykoski, J.A. Refractory Diborides of Zirconium and Hafnium. J. Am. Ceram. Soc. 2007, 90, 1347–1364. [Google Scholar] [CrossRef]

- De Bona, E.; Manière, C.; Sglavo, V.M.; Biesuz, M. Ultrafast High-Temperature Sintering (UHS) of ZrB2-Based Materials. J. Eur. Ceram. Soc. 2024, 44, 567–573. [Google Scholar] [CrossRef]

- Sciti, D.; Nygren, M. Spark Plasma Sintering of Ultra Refractory Compounds. J. Mater. Sci. 2008, 43, 6414–6421. [Google Scholar] [CrossRef]

- Petzow, G.; Herrmann, M. Silicon Nitride Ceramics. In High Performance Non-Oxide Ceramics II; Springer: Berlin/Heidelberg, Germany, 2002; pp. 47–167. ISBN 978-3-540-45623-0. [Google Scholar]

- Riley, F.L. Silicon Nitride and Related Materials. J. Am. Ceram. Soc. 2004, 83, 245–265. [Google Scholar] [CrossRef]

- Schneider, J.A.; Risbud, S.H.; Mukherjee, A.K. Rapid Consolidation Processing of Silicon Nitride Powders. J. Mater. Res. 1996, 11, 358–362. [Google Scholar] [CrossRef]

- Grippi, T.; Béhar-Lafenêtre, S.; Friedrich, H.; Haas, D.; Schenderlein, U.; Marinel, S.; Manière, C. Densification Modeling for Gas Pressure Sintered Silicon Nitride-Based Ceramics with Thermo-Optical Dilatometry. J. Eur. Ceram. Soc. 2024, 44, 822–830. [Google Scholar] [CrossRef]

- Grippi, T.; Béhar-Lafenetre, S.; Friedrich, H.; Haas, D.; Schenderlein, U.; Marinel, S.; Manière, C. Finite Element Simulation for Si3N4 Heating and Sintering. J. Eur. Ceram. Soc. 2024, 44, 116703. [Google Scholar] [CrossRef]

- Rahaman, M.N. Sintering of Ceramics; CRC Press: Boca Raton, FL, USA, 2007; ISBN 9780849372865. [Google Scholar]

- Lee, S.-H.; Tanaka, H.; Kagawa, Y. Spark Plasma Sintering and Pressureless Sintering of SiC Using Aluminum Borocarbide Additives. J. Eur. Ceram. Soc. 2009, 29, 2087–2095. [Google Scholar] [CrossRef]

- Hotta, M.; Hojo, J. Inhibition of Grain Growth in Liquid-Phase Sintered SiC Ceramics by AlN Additive and Spark Plasma Sintering. J. Eur. Ceram. Soc. 2010, 30, 2117–2122. [Google Scholar] [CrossRef]

- Raju, K.; Yoon, D.-H. Sintering Additives for SiC Based on the Reactivity: A Review. Ceram. Int. 2016, 42, 17947–17962. [Google Scholar] [CrossRef]

- Grasso, S.; Saunders, T.; Porwal, H.; Milsom, B.; Tudball, A.; Reece, M. Flash Spark Plasma Sintering (FSPS) of α and β SiC. J. Am. Ceram. Soc. 2016, 99, 1534–1543. [Google Scholar] [CrossRef]

- Manière, C.; Nigito, E.; Durand, L.; Weibel, A.; Beynet, Y.; Estournès, C. Spark Plasma Sintering and Complex Shapes: The Deformed Interfaces Approach. Powder Technol. 2017, 320, 340–345. [Google Scholar] [CrossRef]

- Laptev, A.M.; Bram, M.; Garbiec, D.; Räthel, J.; van der Laan, A.; Beynet, Y.; Huber, J.; Küster, M.; Cologna, M.; Guillon, O. Tooling in Spark Plasma Sintering Technology: Design, Optimization, and Application. Adv. Eng. Mater. 2024, 26, 2301391. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-Assisted Sintering Technology/Spark Plasma Sintering: Mechanisms, Materials, and Technology Developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Durand, L.; Karnatak, N.; Thomas, M.; Couret, A. An Innovative Way to Produce γ-TiAl Blades: Spark Plasma Sintering. Adv. Eng. Mater. 2015, 17, 1408–1413. [Google Scholar] [CrossRef]

- Manière, C.; Durand, L.; Weibel, A.; Estournès, C. Spark-Plasma-Sintering and Finite Element Method: From the Identification of the Sintering Parameters of a Submicronic α -Alumina Powder to the Development of Complex Shapes. Acta Mater. 2016, 102, 169–175. [Google Scholar] [CrossRef]

- Manière, C.; Durand, L.; Weibel, A.; Chevallier, G.; Estournès, C. A Sacrificial Material Approach for Spark Plasma Sintering of Complex Shapes. Scr. Mater. 2016, 124, 126–128. [Google Scholar] [CrossRef]

- Matsugi, K.; Kuramoto, H.; Yanagisawa, O.; Kiritani, M. A Case Study for Production of Perfectly Sintered Complex Compacts in Rapid Consolidation by Spark Sintering. Mater. Sci. Eng. A 2003, 354, 234–242. [Google Scholar] [CrossRef]

- German, R.M. Powder Metallurgy of Iron and Steel. Choice Rev. Online 1998, 36, 36–0981. [Google Scholar] [CrossRef]

- German, R.M. Sintering Theory and Practice; Wiley: Hoboken, NJ, USA, 1996; ISBN 978-0-471-05786-4. [Google Scholar]

- Maniere, C.; Durand, L.; Estournès, C. Use of a Deformable Interface for the Production of Complex Parts. Patent WO2017077028 A1, 4 November 2016. [Google Scholar]

- Manière, C.; Torresani, E.; Olevsky, E.A. Simultaneous Spark Plasma Sintering of Multiple Complex Shapes. Materials 2019, 12, 557. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; Olevsky, E.A. Flash Sintering of Complex Shapes. Appl. Mater. Today 2022, 26, 101293. [Google Scholar] [CrossRef]

- Manière, C.; Olevsky, E.A. In Situ Partially Degradable Separation Interface for Fabrication of Complex near Net Shape Objects by Pressure Assited Sintering. U.S. Patent 2021/0016499 A1, 27 March 2019. [Google Scholar]

- Le Cloarec, J.; Marinel, S.; Estournès, C.; Dehmas, M.; Folton, C.; Manière, C. Stereolithography Coupled with Spark Plasma Sintering to Produce Ti-6Al-4V Complex Shapes. J. Manuf. Process. 2024, 114, 122–135. [Google Scholar] [CrossRef]

- Le Cloarec, J.; Marinel, S.; Estournès, C.; Dehmas, M.; Manière, C. Ti–6Al–4V Complex Shape Production by Spark Plasma Sintering with Ceramic–Metal Sacrificial Powder and Interface 3D Printing. Prog. Addit. Manuf. 2024, 10, 3321–3334. [Google Scholar] [CrossRef]

- Van der Laan, A.; Epherre, R.; Chevallier, G.; Beynet, Y.; Weibel, A.; Estournès, C. Fully Coupled Electrothermal and Mechanical Simulation of the Production of Complex Shapes by Spark Plasma Sintering. J. Eur. Ceram. Soc. 2021, 41, 4252–4263. [Google Scholar] [CrossRef]

- Manière, C.; Durand, L.; Brisson, E.; Desplats, H.; Carré, P.; Rogeon, P.; Estournès, C. Contact Resistances in Spark Plasma Sintering: From in-Situ and Ex-Situ Determinations to an Extended Model for the Scale up of the Process. J. Eur. Ceram. Soc. 2017, 37, 1593–1605. [Google Scholar] [CrossRef]

- Le Cloarec, J.; Marinel, S.; Chevallier, G.; Estournès, C.; Manière, C. Impact of Graphite Foil Rolling on the Thermal Field Homogeneity of Spark Plasma Sintering. Ceram. Int. 2023, 49, 19545–19551. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; McKittrick, J.; Maximenko, A.; Olevsky, E.A. Graphite Creep Negation during Flash Spark Plasma Sintering under Temperatures Close to 2000 °C. Carbon 2020, 162, 106–113. [Google Scholar] [CrossRef]

- Achenani, Y.; Saâdaoui, M.; Cheddadi, A.; Fantozzi, G. Finite Element Analysis of the Temperature Uncertainty during Spark Plasma Sintering: Influence of the Experimental Procedure. Ceram. Int. 2017, 43, 15281–15287. [Google Scholar] [CrossRef]

- Achenani, Y.; Saâdaoui, M.; Cheddadi, A.; Bonnefont, G.; Fantozzi, G. Finite Element Modeling of Spark Plasma Sintering: Application to the Reduction of Temperature Inhomogeneities, Case of Alumina. Mater. Des. 2017, 116, 504–514. [Google Scholar] [CrossRef]

- Torresani, E.; Carrillo, M.; Haines, C.; Martin, D.; Olevsky, E. Fabrication of Powder Components with Internal Channels by Spark Plasma Sintering and Additive Manufacturing. J. Eur. Ceram. Soc. 2023, 43, 1117–1126. [Google Scholar] [CrossRef]

- Grippi, T.; Torresani, E.; Maximenko, A.L.; Olevsky, E.A. Additive Manufacturing-Assisted Sintering: Low Pressure, Low Temperature Spark Plasma Sintering of Tungsten Carbide Complex Shapes. Ceram. Int. 2024, 50, 37228–37240. [Google Scholar] [CrossRef]

- Ranjit, K.V.; Mahesh, N.S.; Anwar, M.I. Numerical Analysis of Powder Compaction to Obtain High Relative Density in ‘601AB’ Aluminum Powder. SASTECH 2012, 11, 79–84. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manière, C.; Estournès, C. ZrB2 Gear Fabrication by Spark Plasma Sintering Coupled to Interface 3D Printing. Ceramics 2025, 8, 81. https://doi.org/10.3390/ceramics8030081

Manière C, Estournès C. ZrB2 Gear Fabrication by Spark Plasma Sintering Coupled to Interface 3D Printing. Ceramics. 2025; 8(3):81. https://doi.org/10.3390/ceramics8030081

Chicago/Turabian StyleManière, Charles, and Claude Estournès. 2025. "ZrB2 Gear Fabrication by Spark Plasma Sintering Coupled to Interface 3D Printing" Ceramics 8, no. 3: 81. https://doi.org/10.3390/ceramics8030081

APA StyleManière, C., & Estournès, C. (2025). ZrB2 Gear Fabrication by Spark Plasma Sintering Coupled to Interface 3D Printing. Ceramics, 8(3), 81. https://doi.org/10.3390/ceramics8030081