MXenes: Properties, Applications, and Potential in 3D Printing

Abstract

:1. Introduction

2. Synthesis of MXenes: Methods and Approaches

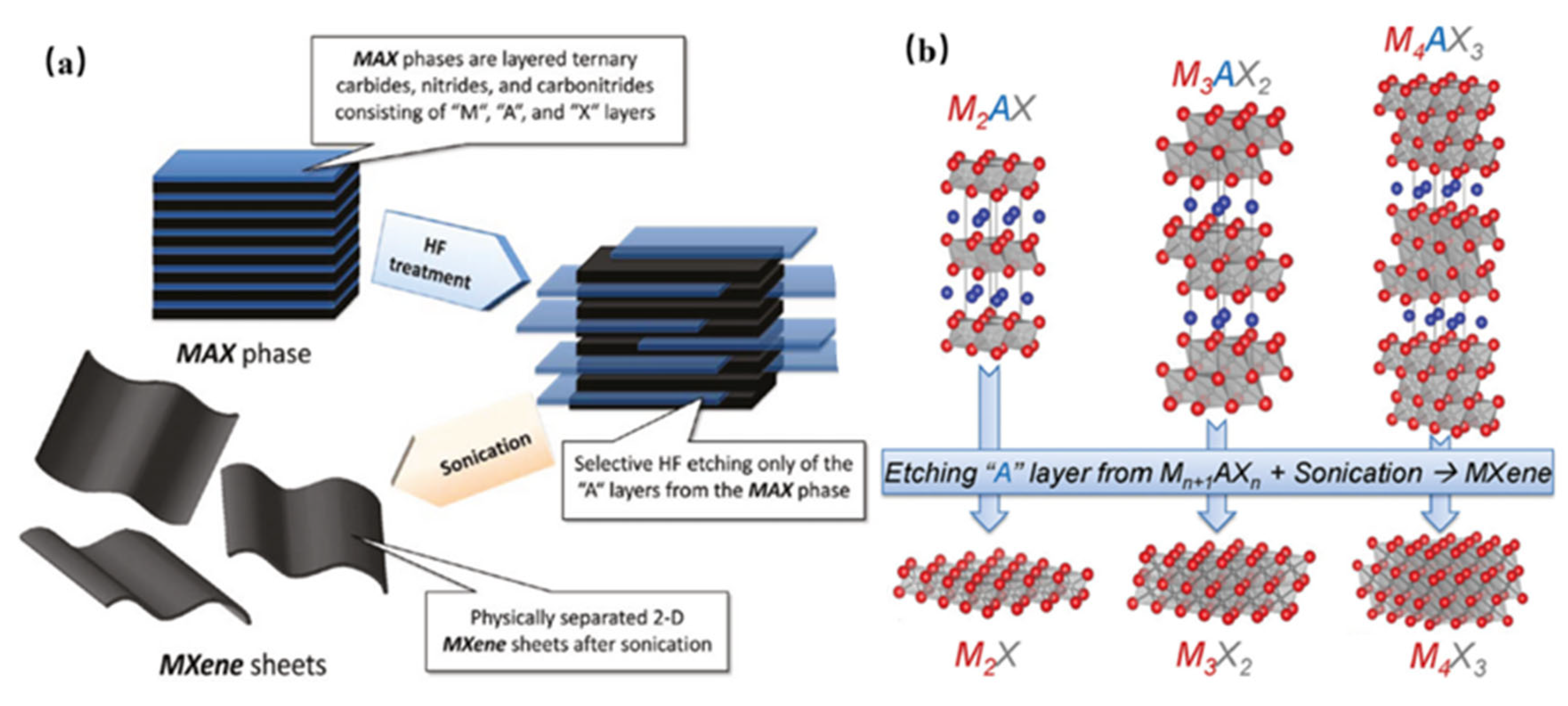

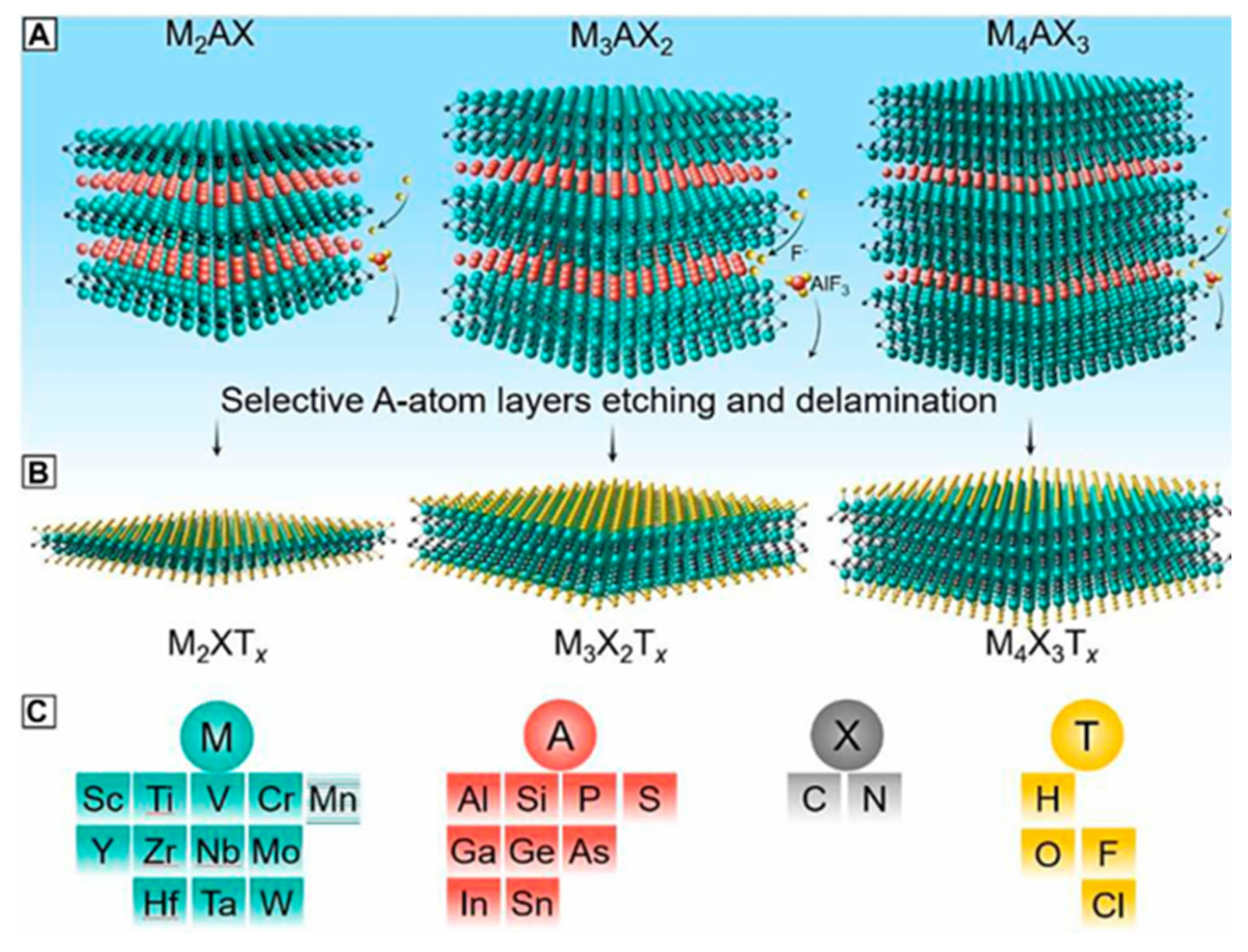

2.1. Structure of MXenes

2.2. Top-Down Approach

2.2.1. HF Etching and Fluoride-Based Acid Etching

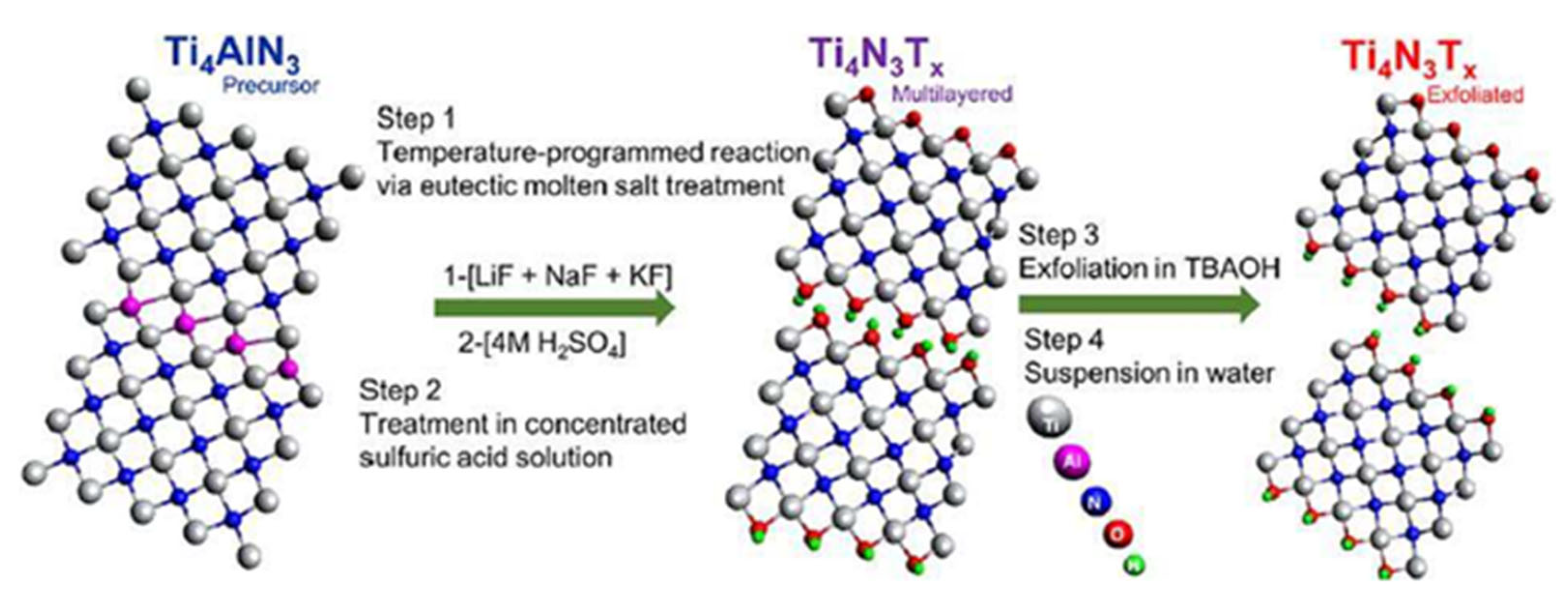

2.2.2. Molten Salt Method

2.2.3. Lewis Acidic Etching Methods

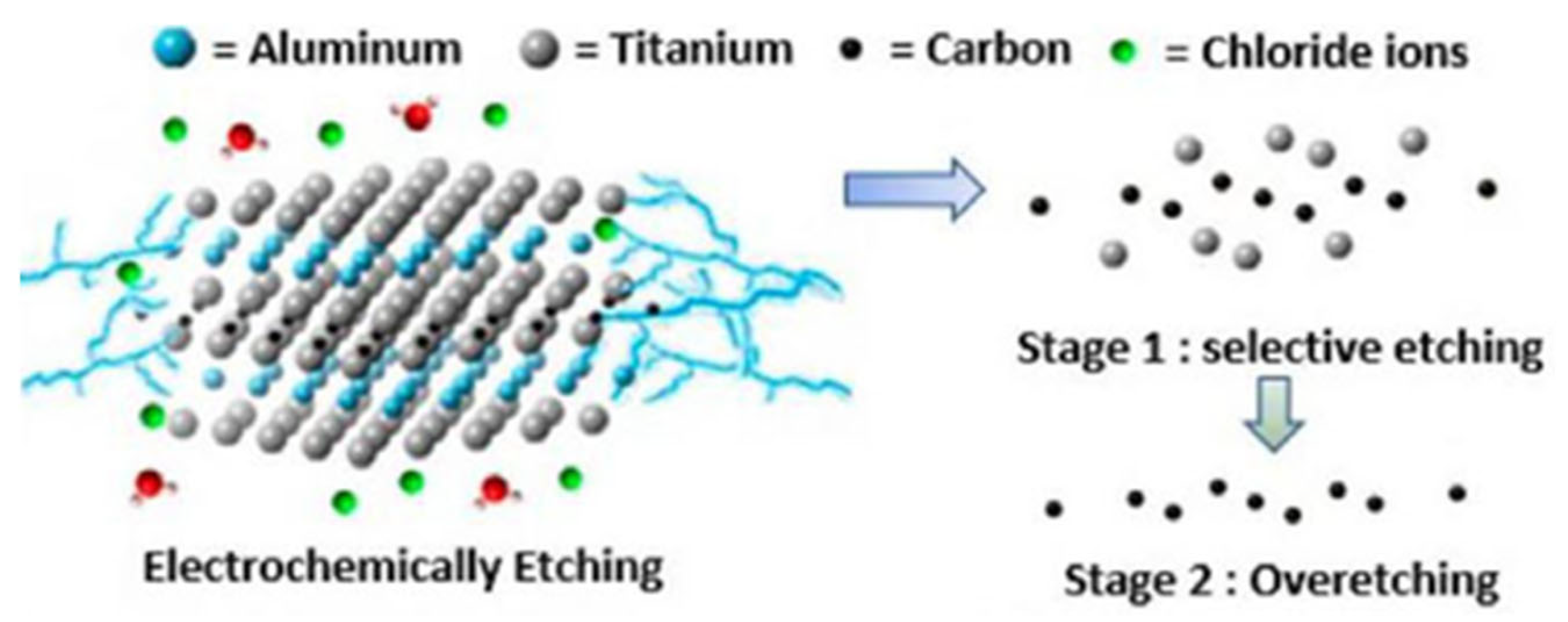

2.2.4. Electrochemical Etching

2.3. Bottom-Up Approach

CVD Process

2.4. Other Synthesis Methods

3. Properties of MXenes

3.1. Mechanical Properties

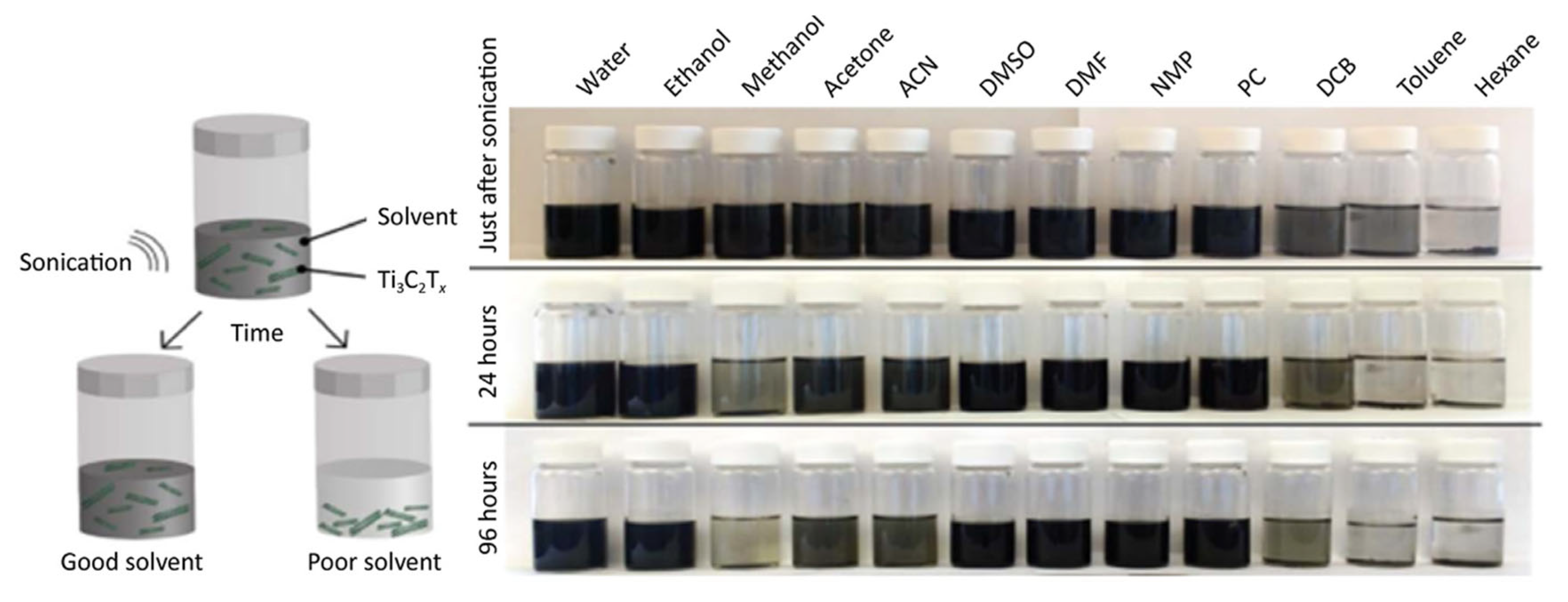

3.2. Chemical Stability

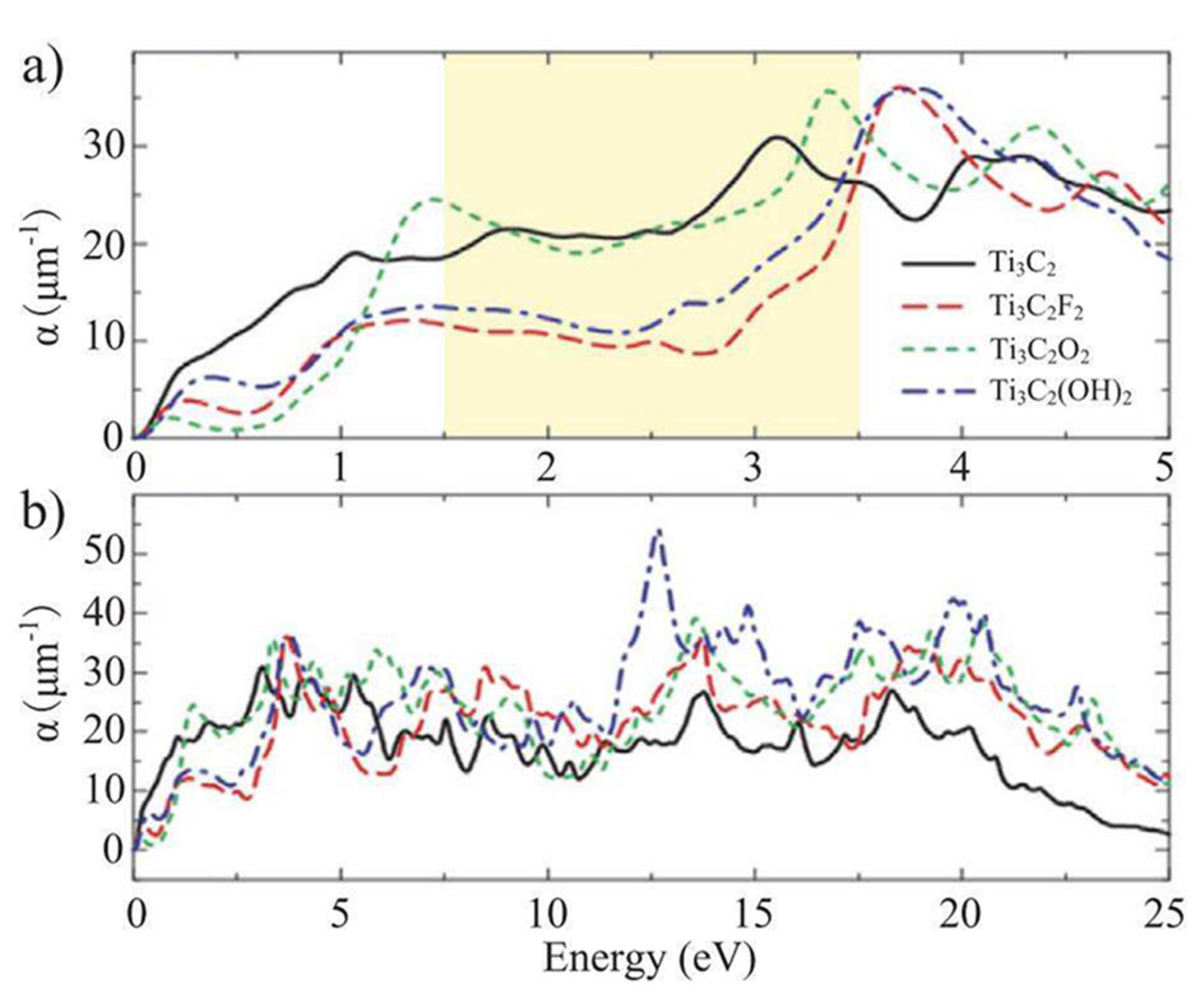

3.3. Optical Properties

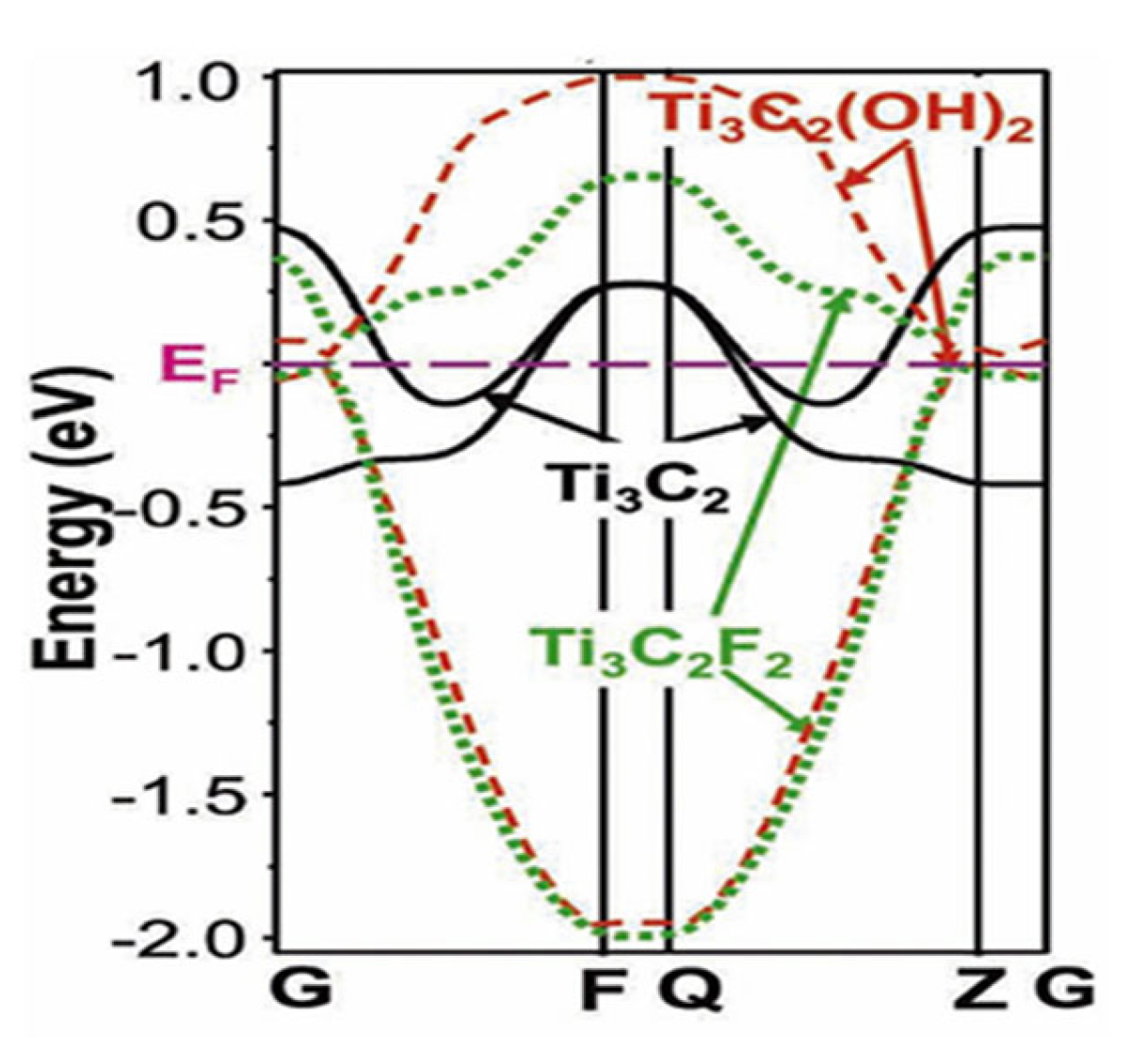

3.4. Electronic and Electrical Properties

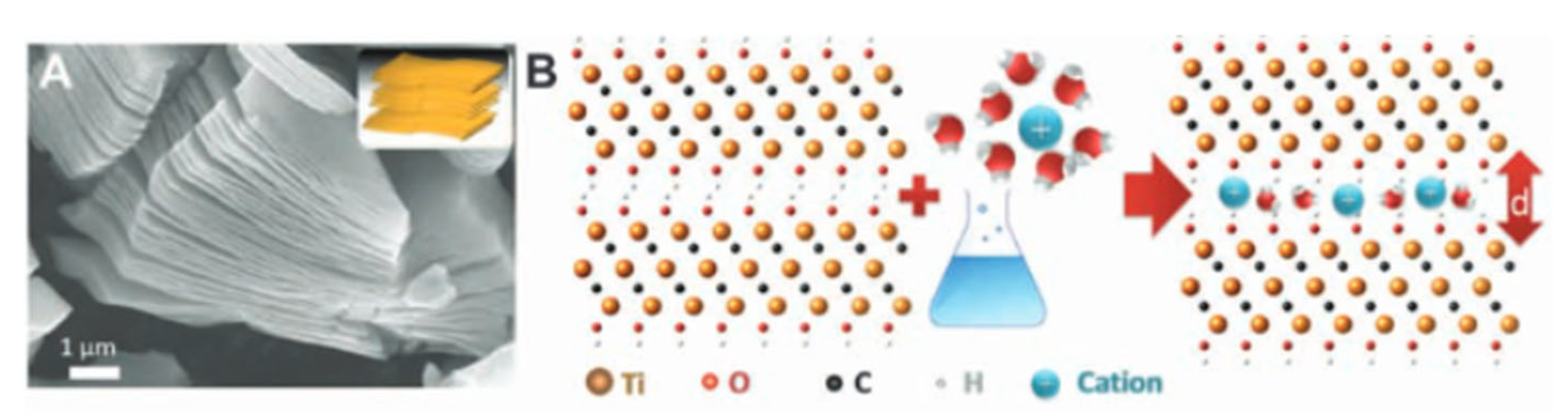

3.5. Surface Modification and Multifunctionalization

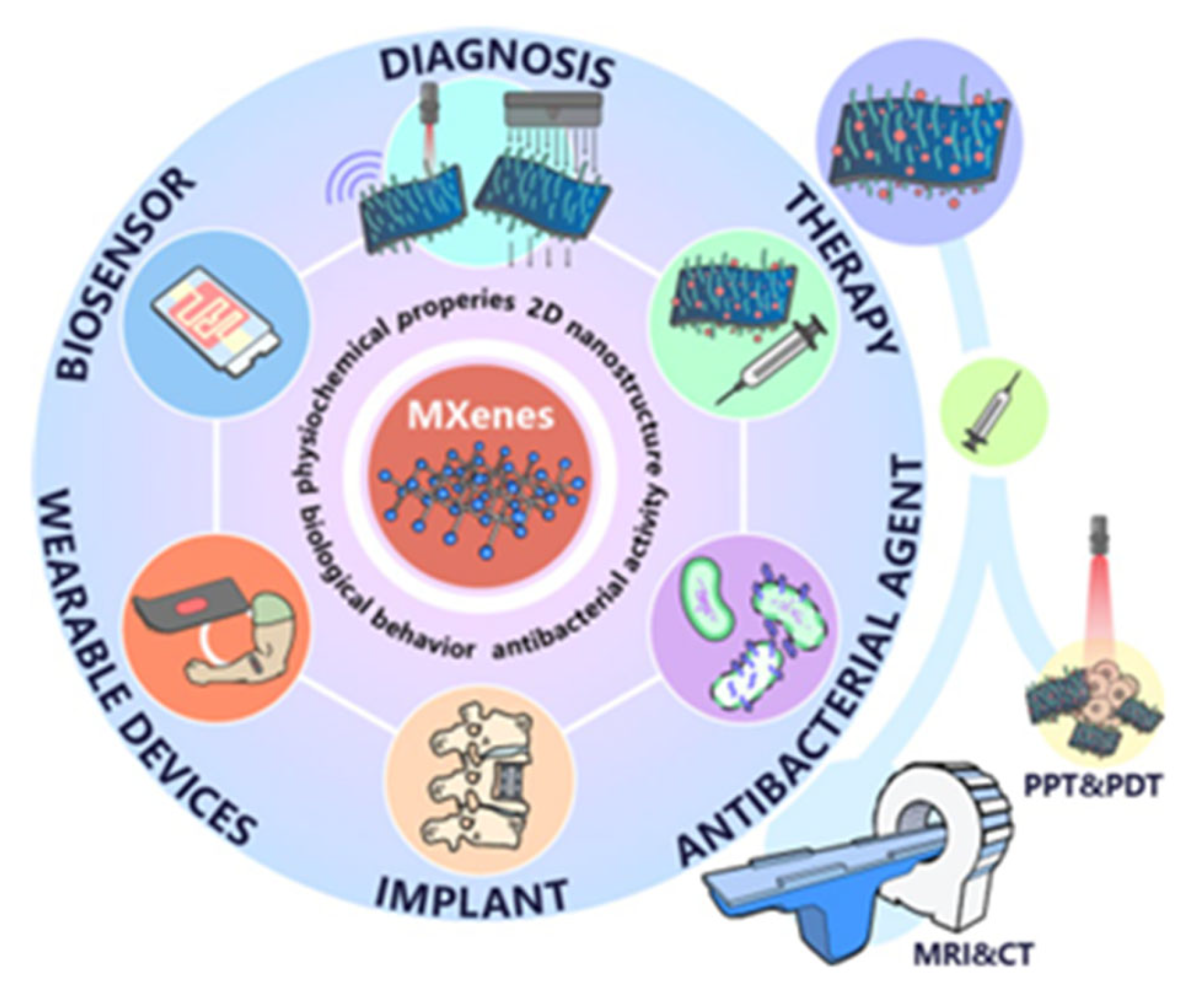

4. Applications

4.1. Biomedical Applications

4.1.1. Biosensing

4.1.2. Imaging

4.1.3. Theranostic Applications

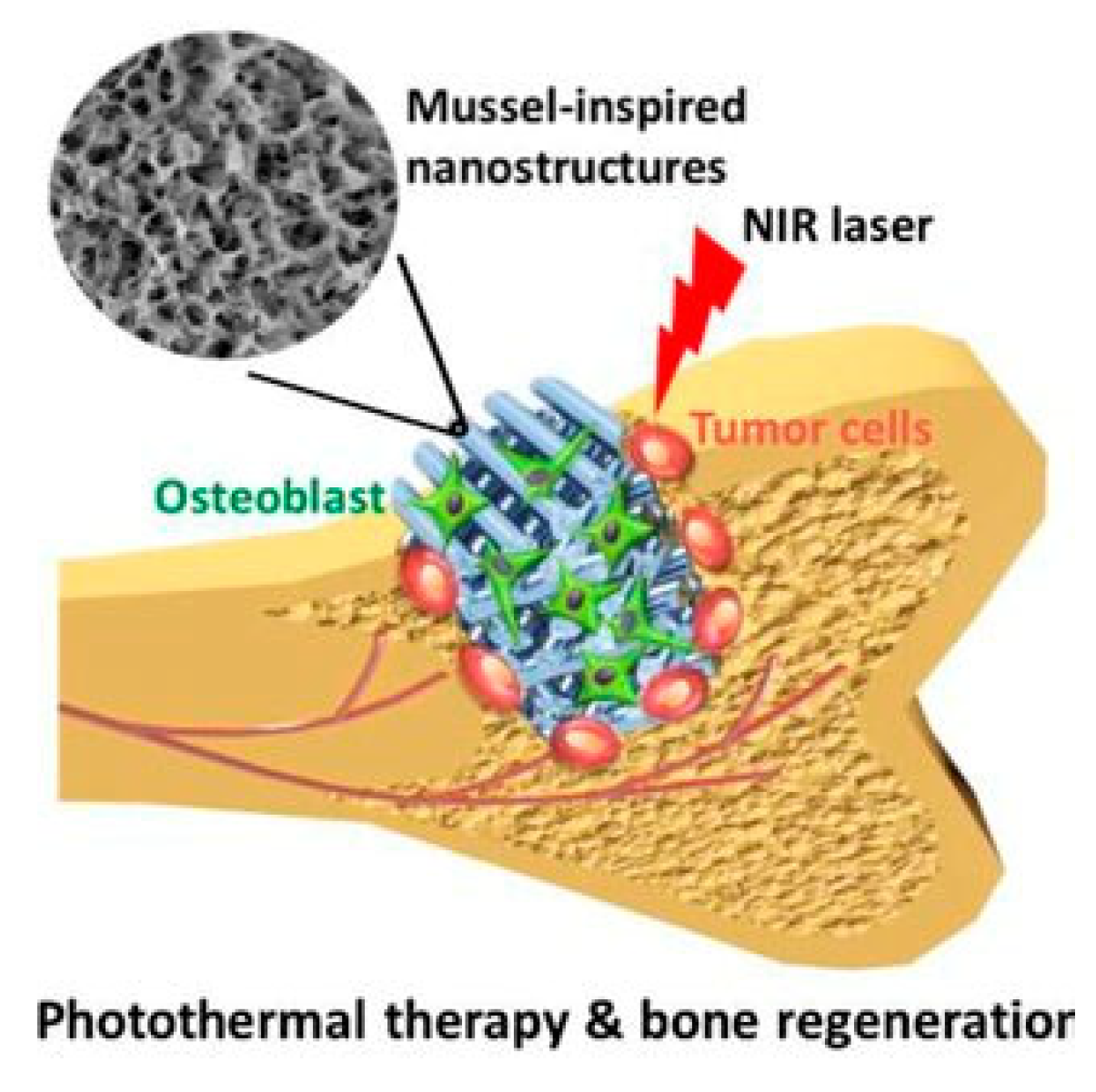

4.1.4. Tissue Engineering

4.1.5. Drug Delivery

4.2. Electronic Applications

4.2.1. Supercapacitors

4.2.2. Perovskite Solar Cells

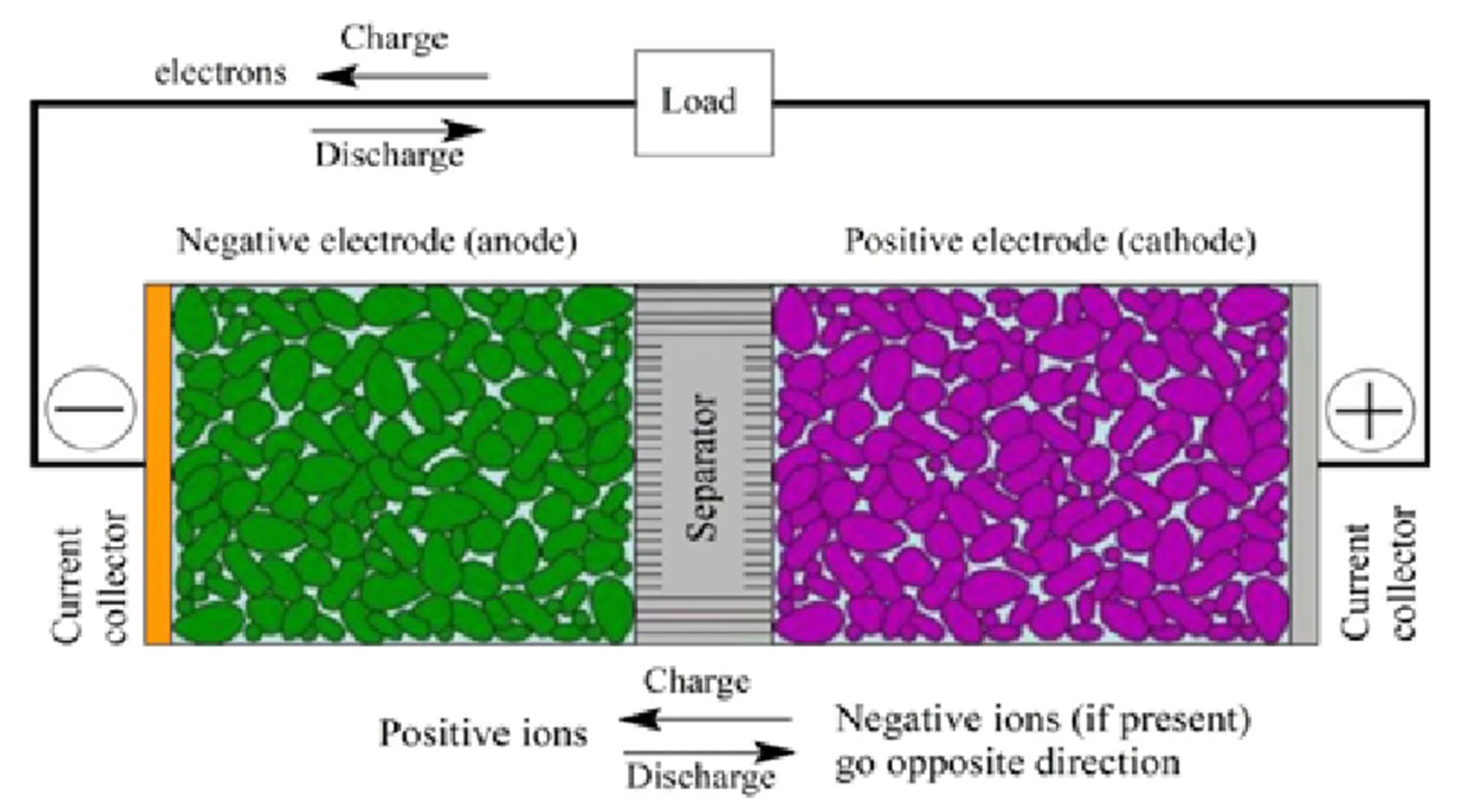

4.2.3. Batteries

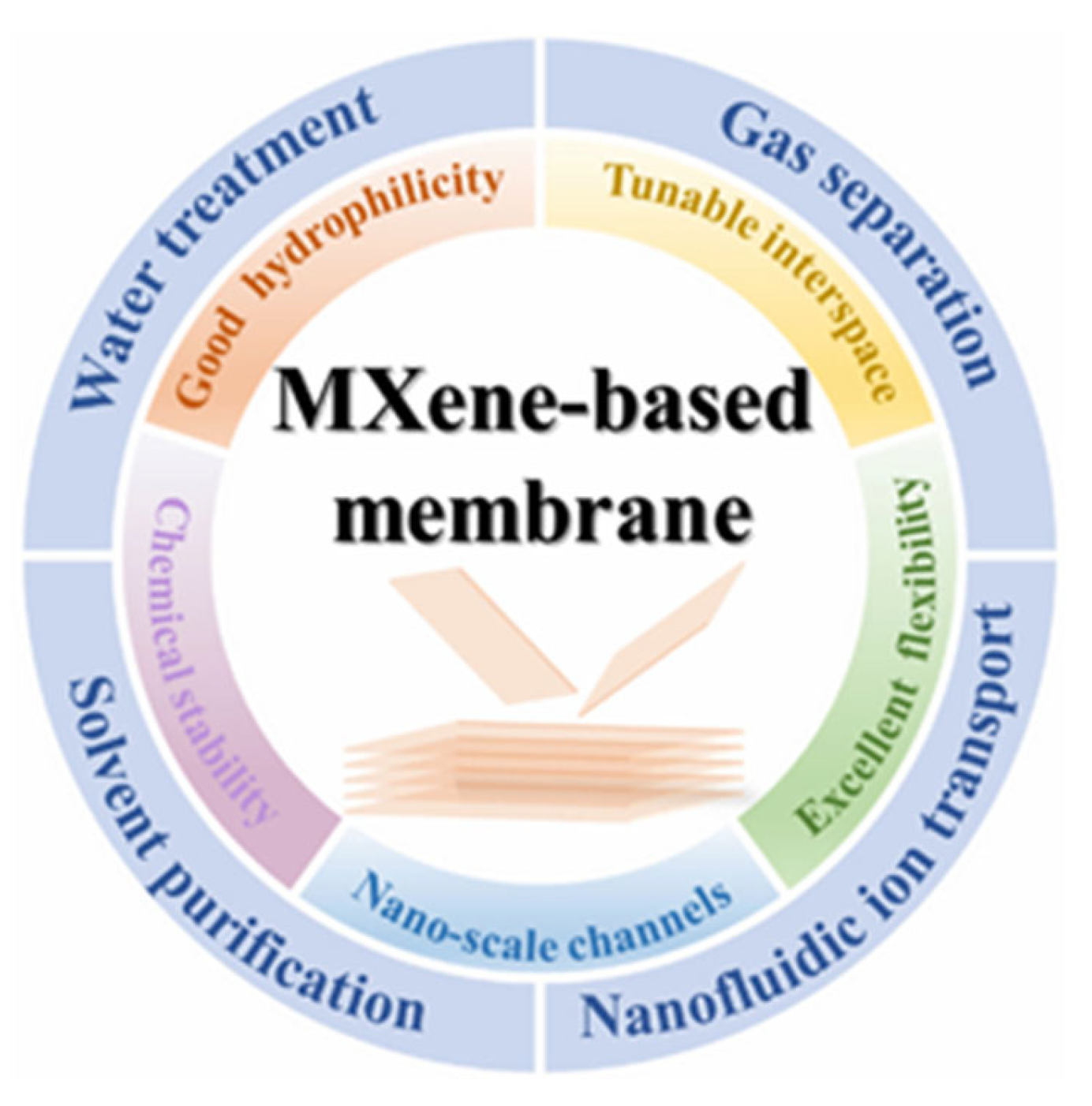

4.3. Separation and Filtration Applications

4.3.1. Water Treatment

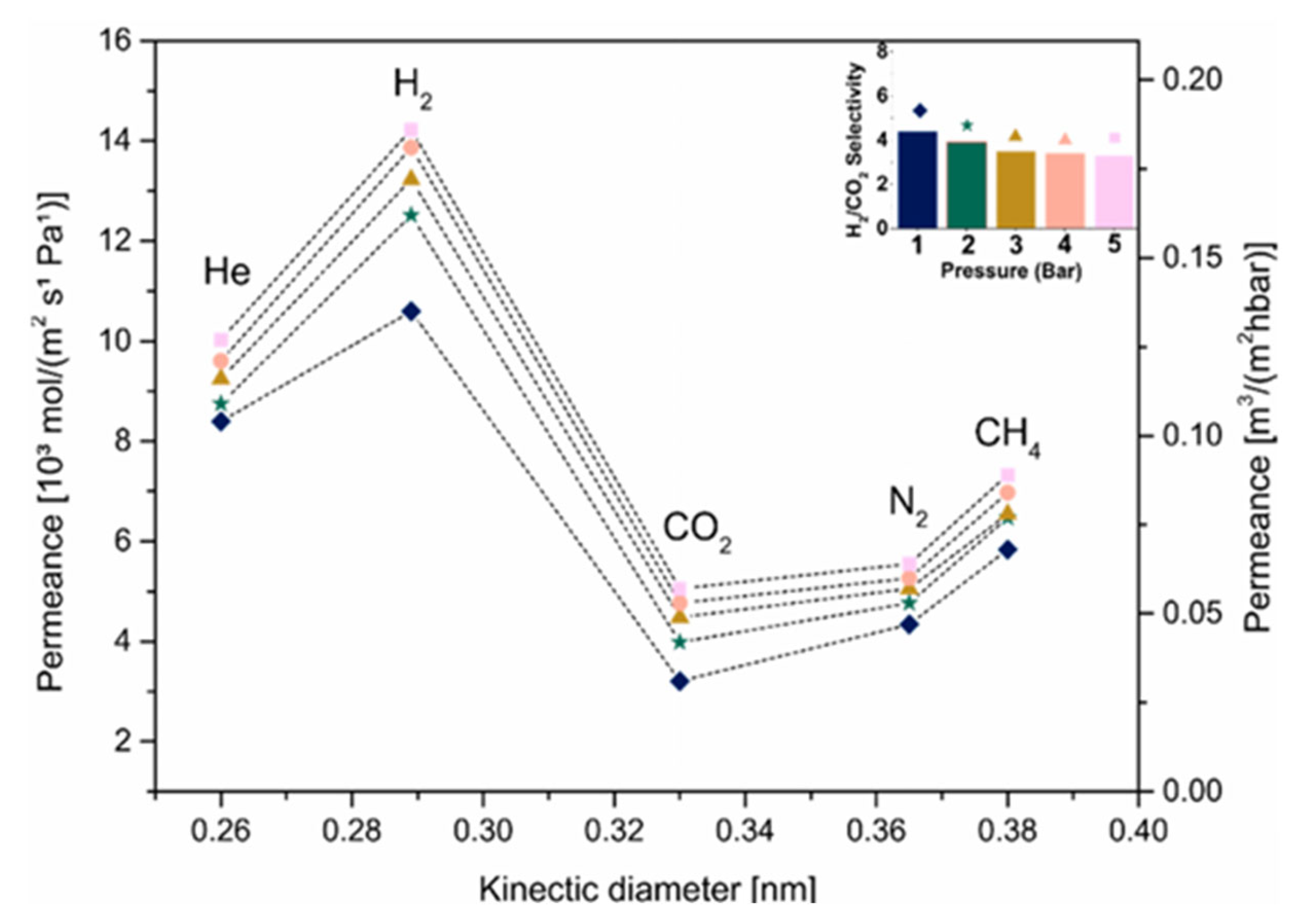

4.3.2. Gas Separation

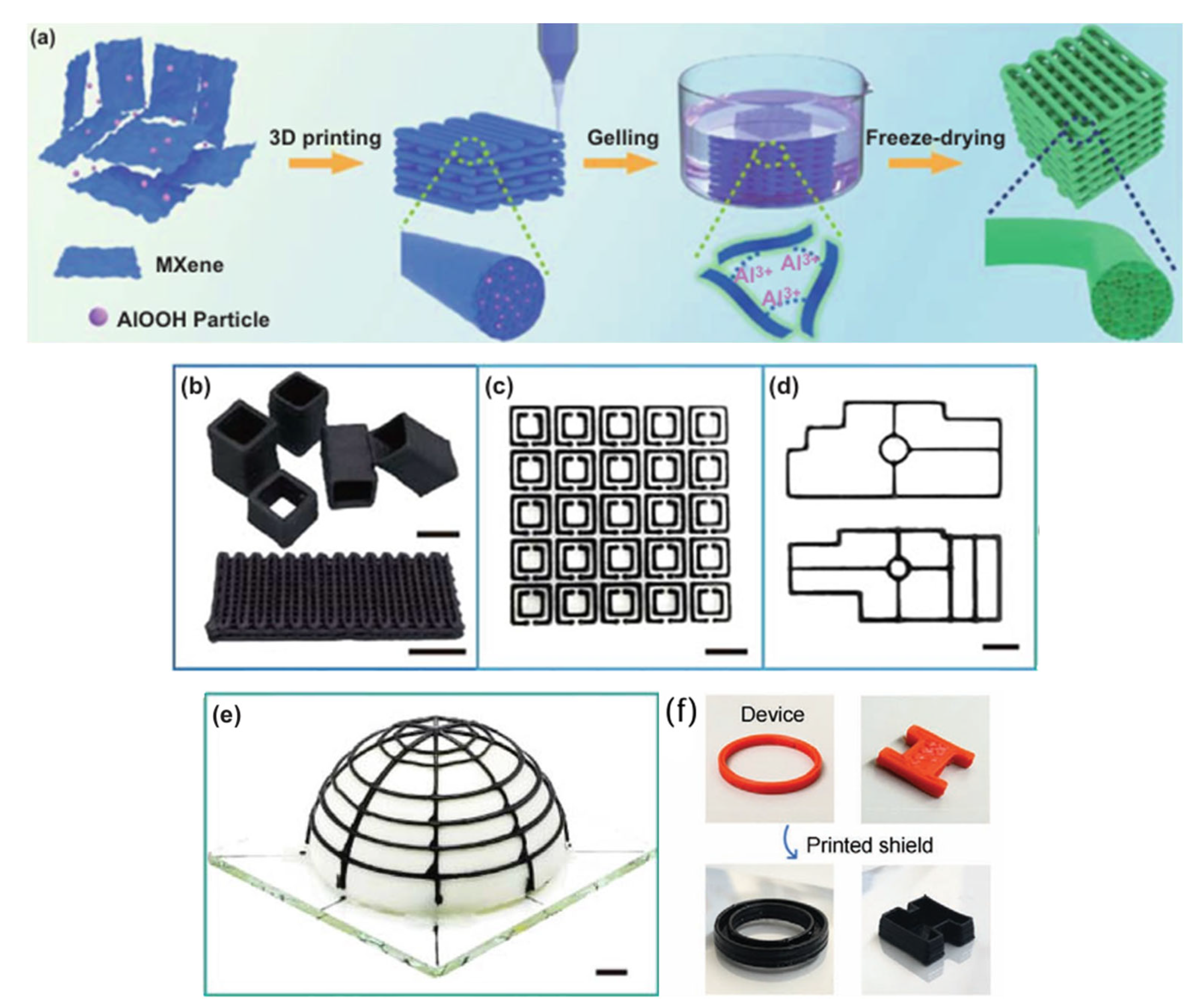

5. Perspectives in 3D Printing

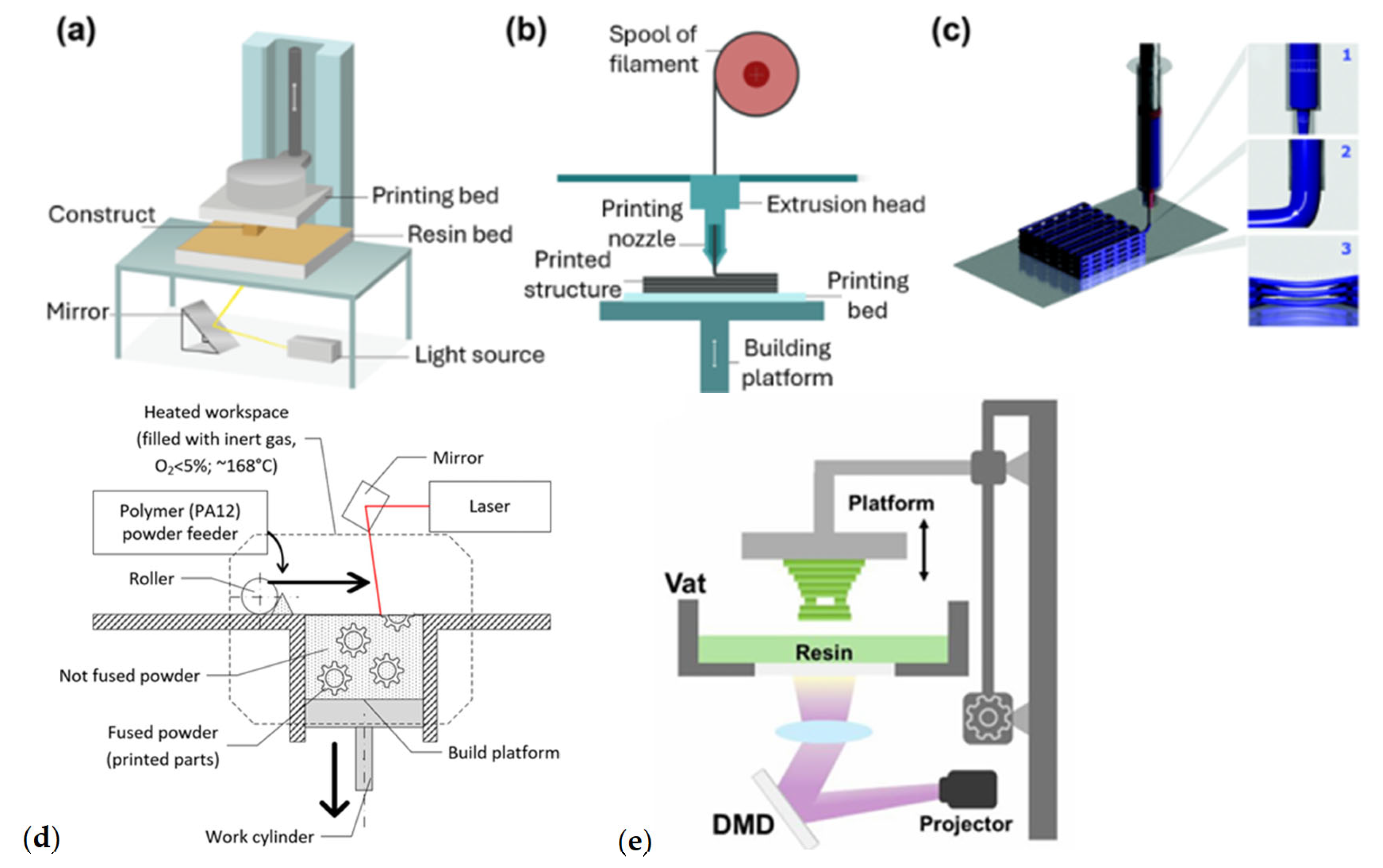

5.1. Key Techniques in 3D Printing

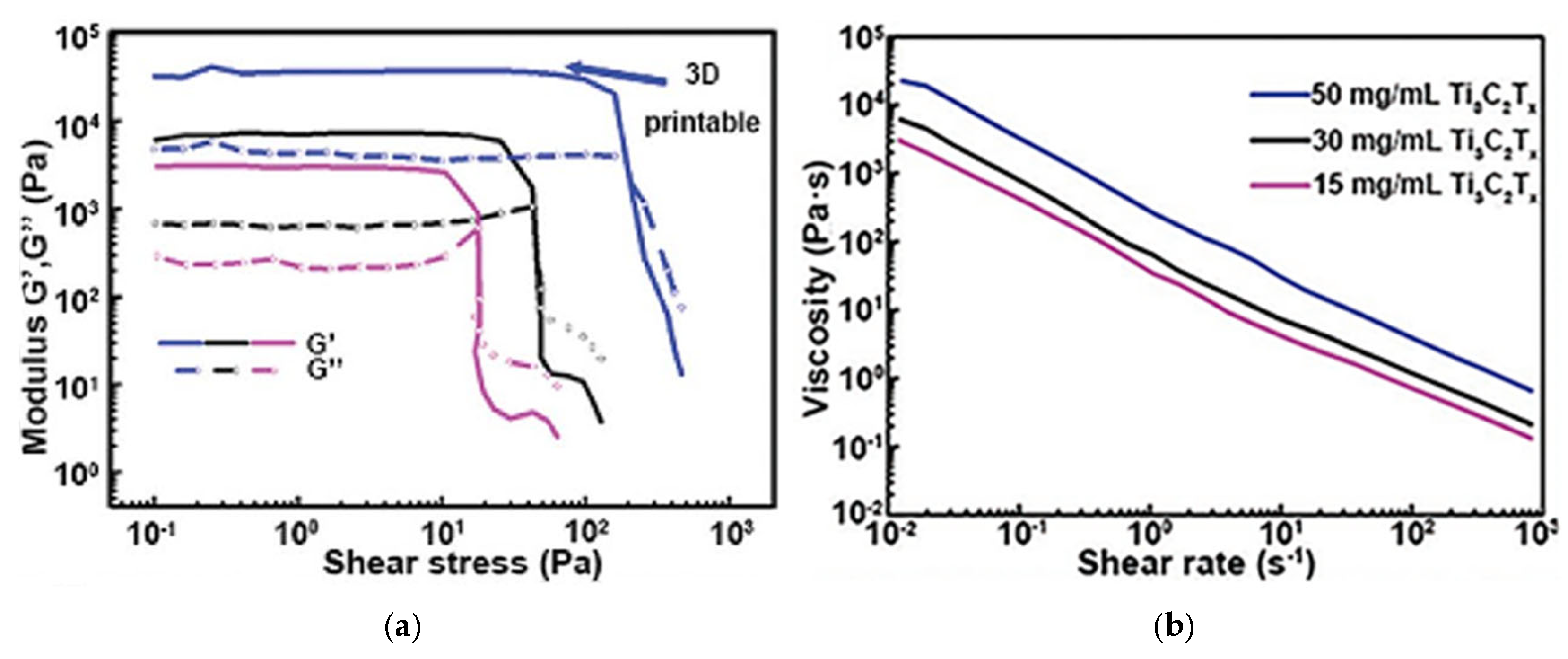

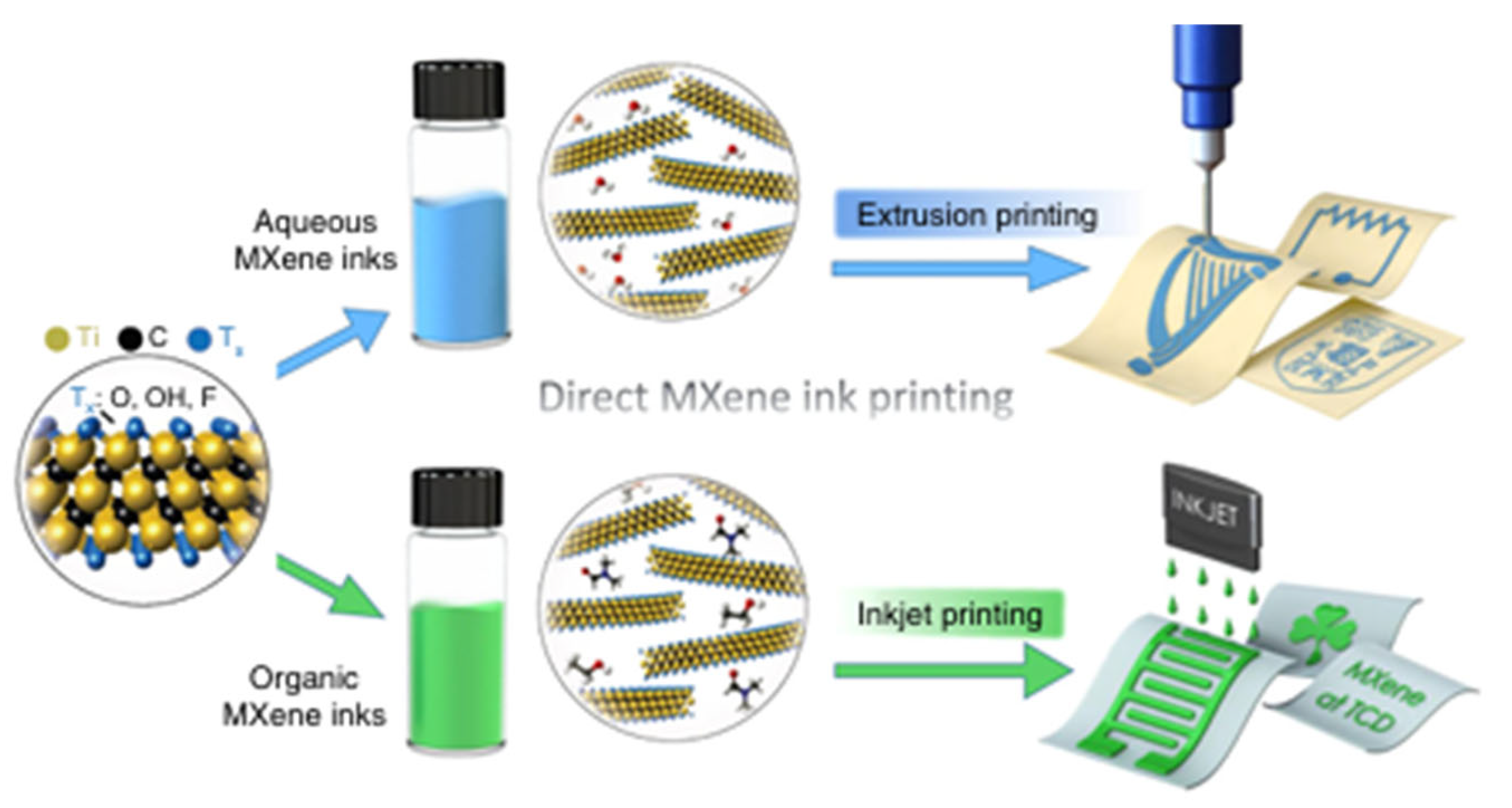

5.2. MXene-Based Inks for Additive Manufacturing

5.3. Emerging Applications of 3D-Printed MXene-Based Materials

5.3.1. Biomedical Applications

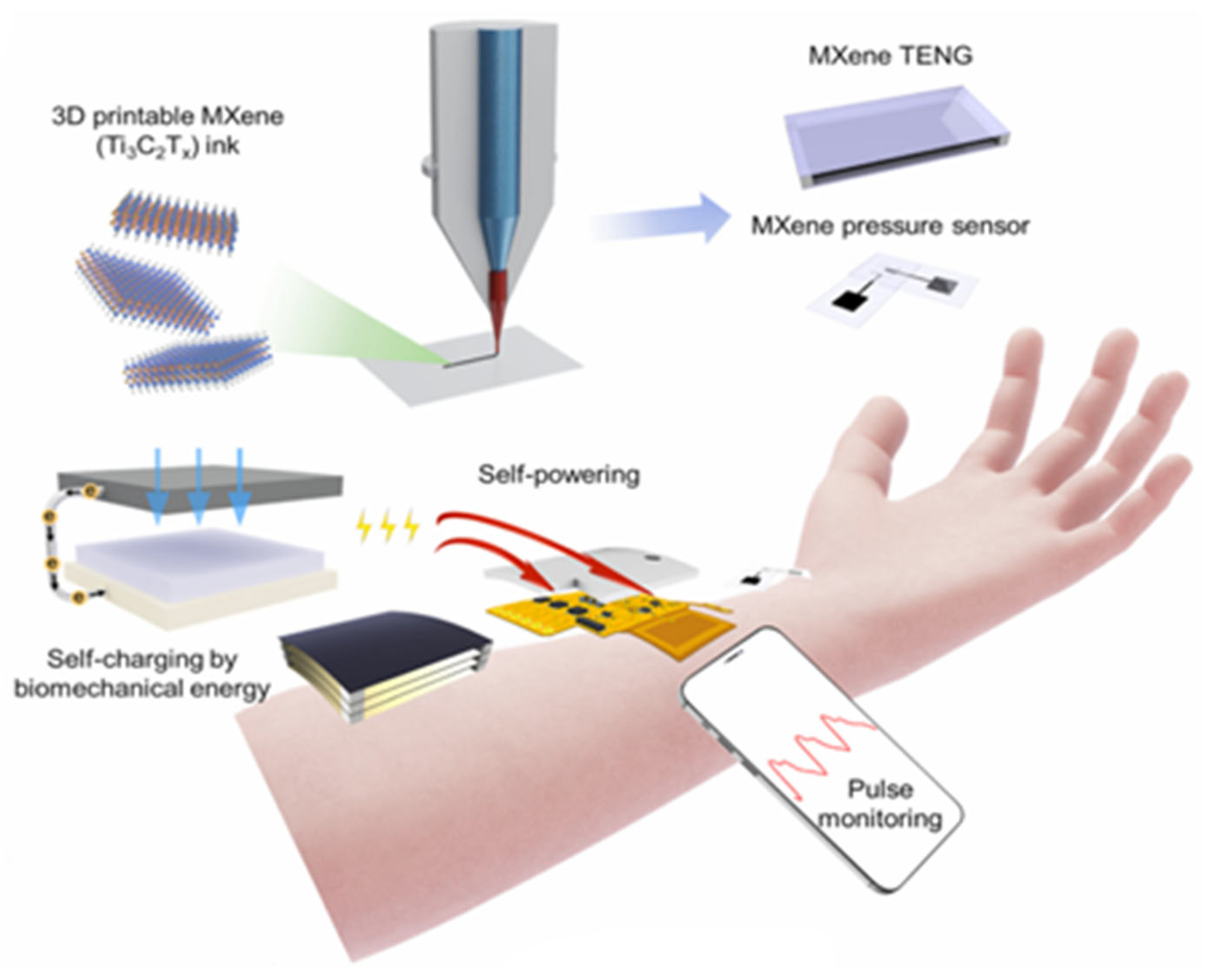

5.3.2. Electronic Applications

5.3.3. Electromagnetic Shielding Applications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Matias, M.L.; Pereira, C.; Almeida, H.V.; Jana, S.; Panigrahi, S.; Menda, U.D.; Nunes, D.; Fortunato, E.; Martins, R.; Nandy, S. 3D printed MXene architectures for a plethora of smart applications. Mater. Today Adv. 2024, 23, 100512. [Google Scholar] [CrossRef]

- Lokhande, P.E.; Pakdel, A.; Pathan, H.M.; Kumar, D.; Vo, D.-V.N.; Al-Gheethi, A.; Sharma, A.; Goel, S.; Singh, P.P.; Lee, B.-K. Prospects of MXenes in energy storage applications. Chemosphere 2022, 297, 134225. [Google Scholar] [CrossRef] [PubMed]

- Rahman, U.; Humayun, M.; Ghani, U.; Usman, M.; Ullah, H.; Khan, A.; El-Metwaly, N.M.; Khan, A. MXenes as Emerging Materials: Synthesis, Properties, and Applications. Molecules 2022, 27, 4909. [Google Scholar] [CrossRef]

- Bigham, A.; Zarepour, A.; Khosravi, A.; Iravani, S.; Zarrabi, A. 3D and 4D printing of MXene-based composites: From fundamen-tals to emerging applications. Mater. Horiz. 2024, 11, 6257–6288. [Google Scholar] [CrossRef]

- Duan, X.; Wang, C.; Pan, A.; Yu, R.; Duan, X. Two-dimensional transition metal dichalcogenides as atomically thin semiconduc-tors: Opportunities and challenges. Chem. Soc. Rev. 2015, 44, 8859–8876. [Google Scholar] [CrossRef]

- Shaheen, I.; Akkinepally, B.; Hussain, I.; Hussain, S.; Rosaiah, P.; Qureshi, A.; Niazi, J.H. Fabrication of MXene/cellulose composite-based flexible supercapacitor: Synthesis, properties, and future perspectives. J. Energy Storage 2024, 87, 111513. [Google Scholar] [CrossRef]

- Naguib, M.; Mashtalir, O.; Carle, J.; Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional transition metal carbides. ACS Nano 2012, 6, 1322–1331. [Google Scholar] [CrossRef]

- Naguib, M.; Mochalin, V.N.; Barsoum, M.W.; Gogotsi, Y. 25th anniversary article: MXenes: A new family of two-dimensional materials. Adv. Mater. 2014, 26, 992–1005. [Google Scholar] [CrossRef]

- Parwaiz, S.; Sohn, Y.; Khan, M.M. Insights into MXenes and MXene-based heterostructures for various photocatalytic applications. Mater. Sci. Semicond. Process. 2025, 186, 109099. [Google Scholar] [CrossRef]

- Wang, R.; Jang, W.Y.; Zhang, W.; Reddy, C.V.; Kakarla, R.R.; Li, C.; Gupta, V.K.; Shim, J.; Aminabhavi, T.M. Emerging two-dimensional (2D) MXene-based nanostructured materials: Synthesis strategies, properties, and applications as efficient pseudo-supercapacitors. Chem. Eng. J. 2023, 472, 144913. [Google Scholar] [CrossRef]

- Parajuli, D. MXenes-polymer nanocomposites for biomedical applications: Fundamentals and future perspectives. Front. Chem. 2024, 12, 1400375. [Google Scholar] [CrossRef]

- Gogotsi, Y.; Anasori, B. The rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef]

- Anasori, B.; Lukatskaya, M.R.; Gogotsi, Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat. Rev. Mater. 2017, 2, 16098. [Google Scholar] [CrossRef]

- Jun, B.M.; Kim, S.; Heo, J.; Park, C.M.; Her, N.; Jang, M.; Yoon, Y. Review of MXenes as new nanomaterials for energy storage/de-livery and selected environmental applications. Nano Res. 2019, 12, 471–487. [Google Scholar] [CrossRef]

- Kurtoglu, M.; Naguib, M.; Gogotsi, Y.; Barsoum, M.W. First principles study of two- dimensional early transition metal carbides. Mrs Commun. 2012, 2, 133–137. [Google Scholar] [CrossRef]

- Chen, J.; Ding, Y.; Yan, D.; Huang, J.; Peng, S. Synthesis of MXene and its application for zinc-ion storage. SusMat 2022, 2, 293–318. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Mathis, T.S.; Sarycheva, A.; Hatter, C.B.; Uzun, S.; Levitt, A.; Gogotsi, Y. Selective etching of silicon from Ti3SiC2 (MAX) to obtain 2D titanium carbide (MXene). Angew. Chem. Int. Ed. 2018, 57, 5444–5448. [Google Scholar] [CrossRef]

- Djire, A.; Zhang, H.; Liu, J.; Miller, E.M.; Neale, N.R. Electrocatalytic and Optoelectronic characteristics of the two-dimensional titanium nitride Ti4N3Tx MXene. ACS Appl. Mater. Interfaces 2019, 11, 11812–11823. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Hu, Z.; Jin, H.; Wu, J.; Liu, K.; Xu, Z.; Wan, J.; Zhou, H.; Duan, J.; Hu, B.; et al. Salt-assisted synthesis of 2D materials. Adv. Funct. Mater. 2020, 30, 1908486. [Google Scholar] [CrossRef]

- Li, M.; Lu, J.; Luo, K.; Li, Y.; Chang, K.; Chen, K.; Zhou, J.; Rosen, J.; Hultman, L.; Eklund, P.; et al. Element replacement approach by reaction with Lewis acidic molten salts to synthesize nano-laminated MAX phases and MXenes. J. Am. Chem. Soc. 2019, 141, 4730–4737. [Google Scholar] [CrossRef]

- Pang, S.-Y.; Wong, Y.-T.; Yuan, S.; Liu, Y.; Tsang, M.-K.; Yang, Z.; Huang, H.; Wong, W.-T.; Hao, J. Universal strategy for HF-free facile and rapid synthesis of two-dimensional MXenes as multifunctional energy materials. J. Am. Chem. Soc. 2019, 141, 9610–9616. [Google Scholar] [CrossRef] [PubMed]

- Lukatskaya, M.R.; Halim, J.; Dyatkin, B.; Naguib, M.; Buranova, Y.S.; Barsoum, M.W.; Gogotsi, Y. Room-temperature carbide- derived carbon synthesis by electrochemical etching of MAX phases. Angew. Chem. 2014, 126, 4977–4980. [Google Scholar] [CrossRef]

- Xu, C.; Wang, L.; Liu, Z.; Chen, L.; Guo, J.; Kang, N.; Ma, X.-L.; Cheng, H.-M.; Ren, W. Large-area high-quality 2D ultrathin Mo2C superconducting crystals. Nat. Mater. 2015, 14, 1135–1141. [Google Scholar] [CrossRef]

- Li, H.; Fan, R.; Zou, B.; Yan, J.; Shi, Q.; Guo, G. Roles of MXenes in biomedical applications: Recent developments and prospects. J. Nanobiotechnol. 2023, 21, 73. [Google Scholar] [CrossRef]

- Lin, H.; Chen, Y.; Shi, J. Insights into 2D MXenes for Versatile Biomedical Applications: Current Advances and Challenges Ahead. Adv. Sci. 2018, 5, 1800518. [Google Scholar] [CrossRef]

- Mumtahina, M.; Khairul, H.; Nayeem, F.S.; Awais, A.S.; Abu, Z.M.; Mohammad, Y.; Saidur, R. MXene: A Roadmap to Sustainable Energy Management, Synthesis Routes, Stabilization, and Economic Assessment. ACS Omega 2024, 9, 32350–32393. [Google Scholar] [CrossRef]

- Rahman, M.; Al Mamun, M.S. Future prospects of MXenes: Synthesis, functionalization, properties, and application in field effect transistors. Nanoscale Adv. 2024, 6, 367–385. [Google Scholar] [CrossRef]

- Bao, W.; Shen, H.; Zeng, G.; Zhang, Y.; Wang, Y.; Cui, D.; Xia, J.; Jing, K.; Liu, H.; Guo, C.; et al. Engineering the next generation of MXenes: Challenges and strategies for scalable production and enhanced performance. Nanoscale 2025, 17, 6204–6265. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, X.; Jin, S.; Xia, Q.; Chang, Y.; Wang, L.; Zhou, A. Synthesis of Mo2C MXene with high electrochemical performance by alkali hydrothermal etching. J. Adv. Ceram. 2023, 10, 1889–1901. [Google Scholar] [CrossRef]

- Huang, Z.; Qin, J.; Zhu, Y.; He, K.; Chen, H.; Hoh, H.Y.; Batmunkh, M.; Benedetti, T.M.; Zhang, Q.; Su, C.; et al. Green and scalable electrochemical routes for cost-effective mass production of MXenes for supercapacitor electrodes. Carbon Energy 2023, 5, e295. [Google Scholar] [CrossRef]

- Gong, S.; Zhao, F.; Zhang, Y.; Xu, H.; Li, M.; Qi, J.; Wang, H.; Wang, Z.; Hu, Y.; Fan, X.; et al. Few-layered Ti3C2Tx MXene synthesized via water-free etching toward high-performance supercapacitors. J. Colloid Interface Sci. 2023, 632 Pt A, 216–222. [Google Scholar] [CrossRef]

- Ahmed, B.; Hossain, M.J.; Al Parvez, A.; Talukder, A.; Al-Amin, M.; Al Mahmud, M.A.; Islam, T. Recent Advancements of MXene/Nanocellulose-Based Hydrogel and Aerogel: A Review. Adv. Energy Sustain. Res. 2024, 5, 2300231. [Google Scholar] [CrossRef]

- Jawaid, A.; Hassan, A.; Neher, G.; Nepal, D.; Pachter, R.; Kennedy, W.J.; Ramakrishnan, S.; Vaia, R.A. Halogen Etch of Ti3AlC2 MAX Phase for MXene Fabrication. ACS Nano 2021, 15, 2771–2777. [Google Scholar] [CrossRef]

- Chan, K.C.; Guan, X.; Zhang, T.; Lin, K.; Huang, Y.; Lei, L.; Georgantas, Y.; Gogotsi, Y.; Bissett, M.A.; Kinloch, I.A. The fabrication of Ti3C2 and Ti3CN MXenes by electrochemical etching. J. Mater. Chem. A 2024, 12, 25165–25175. [Google Scholar] [CrossRef]

- Sun, Z.; Yuan, M.; Lin, L.; Yang, H.; Nan, C.; Li, H.; Sun, G.; Yang, X. Selective lithiation–expansion microexplosion synthesis of two-dimensional fluoride-free Mxene. ACS Mater. Lett. 2019, 1, 628–632. [Google Scholar] [CrossRef]

- Lokhande, P.E.; Rednam, U.; Kadam, V.; Jagtap, C.; Kumar, D.; Aepuru, R. Microwave assisted synthesis of Ti3C2-MXene for supercapacitor application. Chem. Commun. 2025, 61, 2111–2114. [Google Scholar] [CrossRef]

- Ullah, S.; Najam, T.; Rehman, A.U.; Alarfaji, S.S.; Ahmad, M.A.; Riaz, S.; Akkinepally, B.; Shah, S.S.A.; Nazir, M.A. MXene nano-materials: Synthesis, properties and applications in energy and environment sector. J. Alloys Compd. 2024, 1001, 175172. [Google Scholar] [CrossRef]

- Kamarulazam, F.; Bashir, S.; Ramesh, S.; Ramesh, K. Emerging trends towards MXene-based electrolytes for electrochemical applications. Mater. Sci. Eng. B 2023, 290, 116355. [Google Scholar] [CrossRef]

- Khazaei, M.; Ranjbar, A.; Arai, M.; Yunoki, S. Topological insulators in the ordered double transition metals M 2′ M″C2 MXenes (M′ = Mo, W; M″ = Ti, Zr, Hf). Phys. Rev. B 2016, 94, 125152. [Google Scholar] [CrossRef]

- Zhan, X.; Si, C.; Zhou, J.; Sun, Z. MXene and MXene-based composites: Synthesis, properties and environment-related applications. Nanoscale Horiz. 2020, 5, 235–258. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, Y.; Li, L.; Wang, Y.; Wang, J.; Xiong, J.; Yu, J. MXene/polymer nanocomposites: Preparation, properties, and applications. Polym. Rev. 2021, 61, 80–115. [Google Scholar] [CrossRef]

- Huang, S.; Mochalin, V.N. Hydrolysis of 2D transition-metal carbides (MXenes) in colloidal solutions. Inorg. Chem. 2019, 58, 1958–1966. [Google Scholar] [CrossRef] [PubMed]

- Otgonbayar, Z.; Yang, S.; Kim, I.-J.; Oh, W.-C. Recent advances in two-dimensional MXene for supercapacitor applications: Progress, challenges, and perspectives. Nanomaterials 2023, 13, 919. [Google Scholar] [CrossRef]

- Akhter, R.; Maktedar, S.S. MXenes: A comprehensive review of synthesis, properties, and progress in supercapacitor applications. J. Mater. 2023, 9, 1196–1241. [Google Scholar] [CrossRef]

- Zhang, B.; Wong, P.W.; Guo, J.; Zhou, Y.; Wang, Y.; Sun, J.; Jiang, M.; Wang, Z.; Kyoungjin An, A. Transforming Ti3C2Tx MXene’s intrinsic hydrophilicity into superhydrophobicity for efficient photothermal membrane desalination. Nat. Commun. 2022, 13, 3315. [Google Scholar] [CrossRef]

- Rasool, K.; Pandey, R.P.; Rasheed, P.A.; Buczek, S.; Gogotsi, Y.; Mahmoud, K.A. Water treatment and environmental remediation applications of two-dimensional metal carbides (MXenes). Mater. Today 2019, 30, 80–102. [Google Scholar] [CrossRef]

- Berdiyorov, G.R. Optical properties of functionalized Ti3C2T2 (T = F, O, OH) MXene: First-principles calculations. AIP Adv. 2016, 6, 055105. [Google Scholar] [CrossRef]

- Shan, Q.; Mu, X.; Alhabeb, M.; Shuck, C.E.; Pang, D.; Zhao, X.; Chu, X.-F.; Wei, Y.; Du, F.; Chen, G. Two-dimensional vanadium carbide (V2C) MXene as electrode for supercapacitors with aqueous electrolytes. Electrochem. Commun. 2018, 96, 103–107. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Han, X.; Liu, D.; Zhao, H.; Li, Z.; Xu, P.; Du, Y. Ultrasmall Mo2C Nanoparticle-Decorated Carbon Polyhedrons for Enhanced Microwave Absorption. ACS Appl. Nano Mater. 2018, 1, 5366–5376. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, N.; Wang, T.; Wang, Y.; Liang, B.; Zhang, Y.; Luo, S.; Xiong, Y.; Wang, Q.; Fan, J. Theoretical insights and design of MXene for aqueous batteries and supercapacitors: Status, challenges, and perspectives. Nanoscale Horiz. 2025, 10, 78–103. [Google Scholar] [CrossRef]

- Lukatskaya, M.R.; Kota, S.; Lin, Z.; Zhao, M.-Q.; Shpigel, N.; Levi, M.D.; Halim, J.; Taberna, P.-L.; Barsoum, M.W.; Simon, P. Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. Nat. Energy 2017, 2, 17105. [Google Scholar] [CrossRef]

- Zhang, Z.; Yao, Z.; Zhang, X.; Jiang, Z. 2D Carbide MXene under postetch low-temperature annealing for high–performance supercapacitor electrode. Electrochim. Acta 2020, 359, 136960. [Google Scholar] [CrossRef]

- Hou, M.; Xu, M.; Hu, Y.; Li, B. Fabrication of hybrid tin oxide-cellulose nanocomposite as the flexible and thin supercapacitor. Electrochim. Acta 2019, 313, 245–254. [Google Scholar] [CrossRef]

- Geng, X.; Zhang, Y.; Han, Y.; Li, J.; Yang, L.; Benamara, M.; Chen, L.; Zhu, H. Two-Dimensional Water-Coupled Metallic MoS2 with Nanochannels for Ultrafast Supercapacitors. Nano Lett. 2017, 17, 1825–1832. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef]

- Yang, X.; Feng, M.H.; Xia, J.F.; Zhang, F.F.; Wang, Z.H. An electrochemical biosensor based on AuNPs/Ti3C2 MXene three-dimensional nanocomposite for microRNA-155 detection by exonuclease III-aided cascade target recycling. J. Electroanal. Chem. 2020, 878, 114669. [Google Scholar] [CrossRef]

- Lukatskaya, M.R.; Mashtalir, O.; Ren, C.E.; Dall’Agnese, Y.; Rozier, P.; Taberna, P.L.; Naguib, M.; Simon, P.; Barsoum, M.W.; Gogotsi, Y. Cation intercalation and high volumetric capacitance of two-dimensional titanium carbide. Science 2013, 341, 1502–1505. [Google Scholar] [CrossRef]

- Murali, A.; Lokhande, G.; Deo, K.A.; Brokesh, A.; Gaharwar, A.K. Emerging 2D Nanomaterials for Biomedical Applications. Mater. Today 2021, 50, 276–302. [Google Scholar] [CrossRef]

- Kohestani, A.A.; Xu, Z.; Baştan, F.E.; Boccaccini, A.R.; Pishbin, F. Electrically conductive coatings in tissue engineering. Acta Biomater. 2024, 186, 30–62. [Google Scholar] [CrossRef]

- Mayerberger, E.A.; Street, R.M.; McDaniel, R.M.; Barsoum, M.W.; Schauer, C.L. Antibacterial properties of electrospun Ti3C2Tz (MXene)/chitosan nanofibers. RSC Adv. 2018, 8, 35386–35394. [Google Scholar] [CrossRef]

- Chen, K.; Chen, Y.; Deng, Q.; Jeong, S.H.; Jang, T.S.; Du, S.; Kim, H.E.; Huang, Q.; Han, C.M. Strong and biocompatible poly(lactic acid) membrane enhanced by Ti3C2Tz (MXene) nanosheets for Guided bone regeneration. Mater. Lett. 2018, 229, 114–117. [Google Scholar] [CrossRef]

- Bilal, M.; Singh, A.K.; Iqbal, H.M.N.; Boczkaj, G. Enzyme-conjugated MXene nanocomposites for biocatalysis and biosensing. Chem. Eng. J. 2023, 474, 145020. [Google Scholar] [CrossRef]

- Barman, S.C.; Jin, Y.; El-Demellawi, J.K.; Thomas, S.; Wehbe, N.; Lei, Y.; Hota, M.K.; Xu, X.; Hasan, E.A.; Mohammed, O.F.; et al. Antibody-functionalized MXene-based electrochemical biosensor for point-of-care detection of vitamin D deficiency. Commun. Mater. 2025, 6, 31. [Google Scholar] [CrossRef]

- Huang, J.; Li, Z.; Mao, Y.; Li, Z. Progress and biomedical applications of MXenes. Nano Select 2021, 2, 1480–1508. [Google Scholar] [CrossRef]

- Iravani, S.; Varma, R.S. MXenes and MXene-based materials for tissue engineering and regenerative medicine: Recent advances. Mater. Adv. 2021, 2, 2906–2917. [Google Scholar] [CrossRef]

- Dai, C.; Chen, Y.; Jing, X.X.; Xiang, L.H.; Yang, D.Y.; Lin, H.; Liu, Z.; Han, X.X.; Wu, R. Two-Dimensional Tantalum Carbide (MXenes) Composite Nanosheets for Multiple Imaging-Guided Photothermal Tumor Ablation. ACS Nano 2017, 11, 12696–12712. [Google Scholar] [CrossRef]

- Yang, G.H.; Zhao, J.L.; Yi, S.Z.; Wan, X.J.; Tang, J.N. Biodegradable and photostable Nb2C MXene quantum dots as promising nanofluorophores for metal ions sensing and fluorescence imaging. Sens. Actuators B Chem. 2020, 309, 127735. [Google Scholar] [CrossRef]

- Fang, Z.; Chen, J.; Pan, J.; Liu, G.; Zhao, C. The Development Tendency of 3D-Printed Bioceramic Scaffolds for Applications Ranging From Bone Tissue Regeneration to Bone Tumor Therapy. Front. Bioeng. Biotechnol. 2021, 9, 754266. [Google Scholar] [CrossRef]

- Garg, R.; Vitale, F. Latest advances on MXenes in biomedical research and health care. MRS Bull. 2023, 48, 283–290. [Google Scholar] [CrossRef]

- Koyappayil, A.; Chavan, S.G.; Roh, Y.-G.; Lee, M.-H. Advances of MXenes; Perspectives on Biomedical Research. Biosensors 2022, 12, 454. [Google Scholar] [CrossRef]

- Huang, R.; Chen, X.; Dong, Y.; Zhang, X.; Wei, Y.; Yang, Z.; Li, W.; Guo, Y.; Liu, J.; Yang, Z.; et al. MXene Composite Nanofibers for Cell Culture and Tissue Engineering. ACS Appl. Bio Mater. 2020, 3, 2125–2131. [Google Scholar] [CrossRef] [PubMed]

- Liao, M.; Cui, Q.; Hu, Y.; Xing, J.; Wu, D.; Zheng, S.; Zhao, Y.; Yu, Y.; Sun, J.; Chai, R. Recent advances in the application of MXenes for neural tissue engineering and regeneration. Neural Regen. Res. 2024, 19, 258–263. [Google Scholar] [CrossRef] [PubMed]

- Ye, G.; Wen, Z.; Wen, F.; Song, X.; Wang, L.; Li, C.; He, Y.; Prakash, S.; Qiu, X. Mussel-inspired conductive Ti2C-cryogel promotes functional maturation of cardiomyocytes and enhances repair of myocardial infarction. Theranostics 2020, 10, 2047–2066. [Google Scholar] [CrossRef]

- Zoughaib, M.; Avdokushina, S.; Savina, I.N. MXene-Reinforced Composite Cryogel Scaffold for Neural Tissue Repair. Molecules 2025, 3, 479. [Google Scholar] [CrossRef]

- Khodabandehloo, A.H.; Pourmadadi, M.; Shamsabadipour, A.; Langari, H.; Manicum, A.L.; Rahdar, A.; Baino, F. Two-dimensional materials for bone-tissue engineering. J. Am. Ceram. Soc. 2023, 106, 5111–5132. [Google Scholar] [CrossRef]

- Zhang, P.; Yang, X.-J.; Li, P.; Zhao, Y.; Niu, Q.J. Fabrication of novel MXene(Ti3C2)/polyacrylamide nanocomposite hydrogels with enhanced mechanical and drug release properties. Soft Matter 2020, 16, 162–169. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Y.; An, J.; Sedgwick, A.C.; Li, M.; Xie, J.; Hu, W.; Kang, J.; Sen, S.; Steinbrueck, A.; et al. 2D-ultrathin MXene/DOXjade platform for iron chelation chemo-photothermal therapy. Bioact. Mater. 2022, 14, 76–85. [Google Scholar] [CrossRef]

- Liu, Y.; Han, Q.; Yang, W.; Gan, X.; Yang, Y.; Xie, K.; Xie, L.; Deng, Y. Two dimensional MXene/cobalt nanowire heterojunction for controlled drug delivery and chemo-photothermal therapy. Mater. Sci. Eng. C 2020, 116, 111212. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, Y.; Xie, Z.; Wang, D.; Yuan, Y.; Kang, H.; Su, B.; Cheng, Z.; Liu, Y. Modified MXene/Holey Graphene Films for Advanced Supercapacitor Electrodes with Superior Energy Storage. Adv. Sci. 2018, 5, 1800750. [Google Scholar] [CrossRef]

- Guo, L.; Jiang, W.Y.; Shen, M.; Xu, C.; Ding, C.X.; Zhao, S.F.; Yuan, T.T.; Wang, C.Y.; Zhang, X.Q.; Wang, J.Q. High capacitance of MXene (Ti3C2Tx) through Intercalation and Surface Modification in Molten Salt. Electrochim. Acta 2022, 401, 139476. [Google Scholar] [CrossRef]

- Sun, C.; Zuo, P.; Sun, W.; Xia, R.; Dong, Z.; Zhu, L.; Lv, J.; Deng, G.; Tan, L.; Dai, Y. Self-assembly of alternating stacked 2D/2D Ti3C2Tx MXene/ZnMnNi LDH van der Waals heterostructures with ultrahigh supercapacitive performance. ACS Appl. Energy Mater. 2020, 3, 10242–10254. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Xu, Z.; Peng, B.; Tran, N.Q.; Saxena, K.K.; Vadivel, S.; Liu, X. MXene-based materials for efficient applications in perovskite solar cells: A review. J. Mater. Sci. Technol. 2025, 215, 214–232. [Google Scholar] [CrossRef]

- Yang, L.; Li, P.; Ma, J.; Zhang, X.; Wang, X.-F.; Liu, Y. MXenes for perovskite solar cells: Progress and prospects. J. Energy Chem. 2023, 81, 443–461. [Google Scholar] [CrossRef]

- Jin, X.; Yang, L.; Wang, X.-F. Efficient Two-Dimensional Perovskite Solar Cells Realized by Incorporation of Ti3C2Tx MXene as Nano-Dopants. Nano-Micro Lett. 2021, 113, 68. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, C.; Yu, H. Modulate the work function of Nb2CTx MXene as the hole transport layer for perovskite solar cells. Appl. Phys. Lett. 2021, 119, 033506. [Google Scholar] [CrossRef]

- Hussain, S.; Liu, H.; Vikraman, D.; Hussain, M.; Jaffery, S.H.A.; Ali, A.; Kim, H.-S.; Kang, J.; Jung, J. Characteristics of Mo2C-CNTs hybrid blended hole transport layer in the perovskite solar cells and X-ray detectors. J. Alloys Compd. 2021, 885, 161039. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Khan, K.; Yao, S.; Nawaz, M.; Miotello, A.; Assiri, M.A.; Bashir, T.; Tamang, T.L.; Javed, M.S. Recent progress in MXene-based materials, synthesis, design, and application in lithium-sulfur batteries. Mater. Today Chem. 2024, 40, 102200. [Google Scholar] [CrossRef]

- Song, J.; Su, D.; Xie, X.; Guo, X.; Bao, W.; Shao, G.; Wang, G. Immobilizing polysulfides with MXene-functionalized separators for stable lithium-sulfur batteries. ACS Appl. Mater. Interfaces 2016, 8, 29427–29433. [Google Scholar] [CrossRef]

- Enyashin, A.N.; Ivanovskii, A.L. Structural and electronic properties and stability of MXenes Ti2C and Ti3C2 functionalized by methoxy groups. J. Phys. Chem. C 2013, 117, 13637–13643. [Google Scholar] [CrossRef]

- Wang, L.; Liu, D.; Lian, W.; Hu, Q.; Liu, X.; Zhou, A. The preparation of V2CTx by facile hydrothermal-assisted etching processing and its performance in lithium-ion battery. J. Mater. Res. Technol. 2020, 9, 984–993. [Google Scholar] [CrossRef]

- Ampong, D.N.; Agyekum, E.; Agyemang, F.O.; Mensah-Darkwa, K.; Andrews, A.; Kumar, A.; Gupta, R.K. MXene: Fundamentals to applications in electrochemical energy storage. Discov. Nano 2023, 18, 3. [Google Scholar] [CrossRef] [PubMed]

- Zou, H.; Li, S.; Yang, W.; Liu, Q.; Chen, S. Synthesis of a hollow MoSe2@MXene anode material for sodium-ion batteries. Nanoscale 2025, 17, 9480–9489. [Google Scholar] [CrossRef]

- Fan, W.; Gao, Y.; Hui, Q.; Ma, Z.; Gan, H.; Xia, X.; Liu, H. A closed-ended MXene armor on hollow Sn4P3 nanospheres for ultrahigh-rate and stable sodium storage. Chem. Eng. J. 2023, 465, 142963. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, P.; Li, Y.; Feng, L.; Xu, M.; Soomro, R.A.; Xu, B. Ultrastable Organic Anode Enabled by Electrochemically Active MXene Binder toward Advanced Potassium Ion Storage. ACS Nano 2024, 18, 16027–16040. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, K.; Wu, S.; Guo, Y.; He, M.; Xue, M. Carbon Quantum Dots-Derived Carbon Nanosphere Coating on Ti3C2 MXene as a Superior Anode for High-Performance Potassium-Ion Batteries. ACS Appl. Mater. Interfaces 2023, 15, 3077–3088. [Google Scholar] [CrossRef]

- Huang, L.; Ding, L.; Wang, H. MXene-Based Membranes for Separation Applications. Small Sci. 2021, 1, 2100013. [Google Scholar] [CrossRef]

- Tunesi, M.M.; Soomro, R.A.; Han, X.; Zhu, Q.; Wei, Y.; Xu, B. Application of MXenes in environmental remediation technologies. Nano Converg. 2021, 8, 5. [Google Scholar] [CrossRef]

- Pandey, R.P.; Rasool, K.; Madhavan, V.E.; Aissa, B.; Gogotsi, Y.; Mahmoud, K.A. Ultrahigh-flux and fouling-resistant membranes based on layered silver/MXene (Ti3C2Tx) nanosheets. J. Mater. Chem. A 2018, 6, 3522–3533. [Google Scholar] [CrossRef]

- Kang, K.M.; Kim, D.W.; Ren, C.E.; Cho, K.M.; Kim, S.J.; Choi, J.H.; Nam, Y.T.; Gogotsi, Y.; Jung, H.-T. Selective Molecular Separation on Ti3C2Tx-Graphene Oxide Membranes during Pressure-Driven Filtration: Comparison with Graphene Oxide and MXenes. ACS Appl. Mater. Interfaces 2017, 9, 44687–44694. [Google Scholar] [CrossRef]

- Meskher, H.; Thakur, A.K.; Hazra, S.K.; Ahamed, M.S.; Saleque, A.M.; Alsalhy, Q.F.; Shahzad, M.W.; Al Subri Ivan, M.N.; Saha, S.; Lynch, I. Recent advances in applications of MXenes for desalination, water purification and as an antibacterial: A review. Environ. Sci. Nano 2025, 12, 1012–1036. [Google Scholar] [CrossRef]

- Zaed, M.A.; Saidur, R.; Pandey, A.K.; Kadhom, M.; Tan, K.H.; Cherusseri, J.; Abdullah, N. Utilization of recycled materials for low-cost MXene synthesis and fabrication of graphite/MXene composite for enhanced water desalination performance. Sep. Purif. Technol. 2025, 354, 129055. [Google Scholar] [CrossRef]

- Li, R.; Zhang, L.; Shi, L.; Wang, P. MXene Ti3C2: An Effective 2D Light-to-Heat Conversion Material. ACS Nano 2017, 11, 3752–3759. [Google Scholar] [CrossRef] [PubMed]

- Rasool, K.; Helal, M.; Ali, A.; Ren, C.E.; Gogotsi, Y.; Mahmoud, K.A. Antibacterial Activity of Ti3C2Tx MXene. ACS Nano 2016, 10, 3674–3684. [Google Scholar] [CrossRef]

- Emerenciano, A.A.; do Nascimento, R.M.; Barbosa, A.P.C.; Ran, K.; Meulenberg, W.A.; Gonzalez-Julian, J. Ti3C2 MXene Mem-branes for Gas Separation: Influence of Heat Treatment Conditions on D-Spacing and Surface Functionalization. Membranes 2022, 12, 1025. [Google Scholar] [CrossRef]

- Qiu, X.; Zheng, Y.; Li, H.; Qu, K.; Yan, H.; Li, R. Unveiling gas transport mechanisms in tunable MXene nanochannels: Insights from molecular dynamics simulations. J. Membr. Sci. 2025, 715, 123459. [Google Scholar] [CrossRef]

- Wang, Q.; Fan, Y.; Wu, C.; Jin, Y.; Li, C.; Sunarso, J.; Meng, X.; Yang, N. Palladium-intercalated MXene membrane for efficient separation of H2/CO2: Combined experimental and modeling work. J. Membr. Sci. 2022, 653, 120533. [Google Scholar] [CrossRef]

- Luo, W.; Niu, Z.; Mu, P.; Li, J. MXene/poly(ethylene glycol) mixed matrix membranes with excellent permeance for highly efficient separation of CO2/N2 and CO2/CH4. Colloids Surf. A Physicochem. Eng. Asp. 2022, 640, 128481. [Google Scholar] [CrossRef]

- Fan, Y.; Wei, L.; Meng, X.; Zhang, W.; Yang, N.; Jin, Y.; Wang, X.; Zhao, M.; Liu, S. An unprecedented high-temperature-tolerance 2D laminar MXene membrane for ultrafast hydrogen sieving. J. Membr. Sci. 2019, 569, 117–123. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive- Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Maity, C.K.; De, S.; De Adhikari, A.; Kumari, A.; Verma, K.; Moniruzzaman, M.; Sahoo, S. Impact of 3D printed MXene electrodes on energy storage: Different dimensionalities, electrochemistry and performance optimization of printable MXene ink. Energy Storage Mater. 2024, 73, 103873. [Google Scholar] [CrossRef]

- Han, T.; Kundu, S.; Nag, A.; Xu, Y. 3D Printed Sensors for Biomedical Applications: A Review. Sensors 2019, 19, 1706. [Google Scholar] [CrossRef]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef]

- Mohhammad, R.; Mohammed, S.; Sukhbir, S.; Abhijit, D. Three-Dimensional Hydrogel Bioprinting Technology as a Scaffold of Novel Drug Delivery and Biomedical Devices: A Comprehensive Review. BIO Web Conf. 2024, 86, 01013. [Google Scholar] [CrossRef]

- Salas, A.; Pazniak, H.; Gonzalez-Julian, J.; Bianco, S.; Amici, J.; Ouisse, T.; Roppolo, I.; Cocuzza, M. Developing poly- meric/MXenes composite inks towards printable electronics. Composites 2023, 263 Pt B, 110854. [Google Scholar] [CrossRef]

- Hu, Y.; Gu, J.; Zhang, Y.; Liu, G.; Yi, X.; Liu, X. FDM 3D printed MXene/Recycled carbon fibre reinforced polylactic acid composites: Interface optimization, toughening and enhanced electromagnetic shielding performance. Compos. Commun. 2024, 48, 101953. [Google Scholar] [CrossRef]

- Kolan, K.; Leu, M.C.; Hilmas, G.E.; Brown, R.F.; Velez, M. Fabrication of 13–93 bioactive glass scaffolds for bone tissue engineering using indirect selective laser sintering. Biofabrication 2011, 3, 025004. [Google Scholar] [CrossRef]

- Chen, L.; Huang, B.; Wei, F.; Guo, X.; Zhang, D.; Thummavichai, K.; Chen, D.; Wang, N.; Zhu, Y. Selective Laser Sintering of MXene-on-MOF (HKUST-1) Hybrids Enhanced Mechanical and Fire Safety Performances of Polyamide 12 Composites. ACS Appl. Polym. Mater. 2023, 5, 9852–9864. [Google Scholar] [CrossRef]

- Li, L.; Meng, J.; Bao, X.; Huang, Y.; Yan, X.P.; Qian, H.L.; Zhang, C.; Liu, T. Direct-ink-write 3D printing of programmable micro-supercapacitors from MXene-regulating conducting polymer inks. Adv. Energy Mater. 2023, 13, 2203683. [Google Scholar] [CrossRef]

- Marczis, A.; Odrobina, M.; Drégelyi-Kiss, Á. Computed tomography as distortion mitigation method for selective laser sintering mass production. Int. J. Adv. Manuf. Technol. 2024, 133, 4845–4864. [Google Scholar] [CrossRef]

- Nam, J.; Kim, M. Advances in materials and technologies for digital light processing 3D printing. Nano Converg. 2024, 11, 45. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Yang, W. MXene-Based Micro-Supercapacitors: Ink Rheology, Microelectrode Design and Integrated System. ACS Nano 2024, 18, 4651–4682. [Google Scholar] [CrossRef] [PubMed]

- Orangi, J.; Hamade, F.; Davis, V.A.; Beidaghi, M. 3D Printing of Additive-Free 2D Ti3C2Tx (MXene) Ink for Fabrication of Micro-Supercapacitors with Ultra-High Energy Densities. ACS Nano 2020, 14, 640–650. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Wang, Y.; Jiang, Q.; El-Demellawi, J.K.; Kim, H.; Alshareef, H.N. MXene Printing and Patterned Coating for Device Applications. Adv. Mater. 2020, 32, 1908486. [Google Scholar] [CrossRef]

- Seok, S.-H.; Choo, S.; Kwak, J.; Ju, H.; Han, J.-H.; Kang, W.-S.; Lee, J.; Kim, S.-Y.; Lee, D.H.; Lee, J.; et al. Synthesis of high quality 2D carbide MXene flakes using a highly purified MAX precursor for ink applications. Nanoscale Adv. 2021, 3, 517–527. [Google Scholar] [CrossRef]

- Greaves, M.; Mende, M.; Wang, J.; Yang, W.; Barg, S. Investigating the rheology of 2D titanium carbide (MXene) dispersions for colloidal processing: Progress and challenges. J. Mater. Res. 2021, 36, 4578–4600. [Google Scholar] [CrossRef]

- Dai, Y.; Wu, X.; Li, L.; Zhang, Y.; Deng, Z.; Yu, Z.-Z.; Zhang, H.-B. 3D printing of resilient, lightweight and conductive MXene/reduced graphene oxide architectures for broadband electromagnetic interference shielding. J. Mater. Chem. A Mater. 2022, 10, 11375–11385. [Google Scholar] [CrossRef]

- Fagade, M.; Patil, D.; Thummalapalli, S.V.; Jambhulkar, S.; Ravichandran, D.; Kannan, A.M.; Song, K. 3D printing aqueous Ti3C2Tx inks for MXene-based energy devices. Mater. Adv. 2023, 4, 4103–4109. [Google Scholar] [CrossRef]

- Mamanazirov, J.I.; Ruzimuradov, O.N.; Mamatkulov, S.I. The impact of 2D MXene on alumina based inks for direct ink writing. Ceram. Int. 2025, 51, 15725–15732. [Google Scholar] [CrossRef]

- Nouseen, S.; Pumera, M. MXene 3D/4D Printing: Ink Formulation and Electrochemical Energy Storage Applications. Adv. Funct. Mater. 2025, 35, 2421987. [Google Scholar] [CrossRef]

- Zhang, C.; Kremer, M.P.; Seral-Ascaso, A.; Park, S.-H.; McEvoy, N.; Anasori, B.; Gogotsi, Y.; Nicolosi, V. Stamping of Flexible, Coplanar Micro-Supercapacitors Using MXene Inks. Adv. Funct. Mater. 2018, 28, 1705506. [Google Scholar] [CrossRef]

- Sharma, C.S. Rout, Two-Dimensional MXene Based Materials for Micro-Supercapacitors. Supercapacitors Next Gener. 2021, 6. [Google Scholar] [CrossRef]

- Yu, L.; Fan, Z.; Shao, Y.; Tian, Z.; Sun, J.; Liu, Z. Versatile N-Doped MXene Ink for Printed Electrochemical Energy Storage Application. Adv. Energy Mater. 2019, 9, 1901839. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Liang, J.; Chen, Y. Hydrous RuO2-Decorated MXene Coordinating with Silver Nanowire Inks Enabling Fully Printed Micro-Supercapacitors with Extraordinary Volumetric Performance. Adv. Energy Mater. 2019, 9, 1803987. [Google Scholar] [CrossRef]

- Yang, W.; Yang, J.; Byun, J.J.; Moissinac, F.P.; Xu, J.; Haigh, S.J.; Domingos, M.; Bissett, M.A.; Dryfe, R.A.W.; Barg, S. 3D Printing of Freestanding MXene Architectures for Current-Collector-Free Supercapacitors. Adv. Mater. 2019, 31, 1902725. [Google Scholar] [CrossRef]

- Cho, S.; Kim, M.; Jang, J. Screen-Printable and Flexible RuO2 Nanoparticle-Decorated PEDOT:PSS/Graphene Nanocomposite with Enhanced Electrical and Electrochemical Performances for High-Capacity Supercapacitor. ACS Appl. Mater. Interfaces 2015, 7, 10213. [Google Scholar] [CrossRef]

- Shen, K.; Ding, J.; Yang, S. 3D Printing Quasi-Solid-State Asymmetric Micro-Supercapacitors with Ultrahigh Areal Energy Density. Adv. Energy Mater. 2018, 8, 1800408. [Google Scholar] [CrossRef]

- Fu, K.; Wang, Y.; Yan, C.; Yao, Y.; Chen, Y.; Dai, J.; Lacey, S.; Wang, Y.; Wan, J.; Li, T.; et al. Graphene Oxide-Based Electrode Inks for 3D-Printed Lithium-Ion Batteries. Adv. Mater. 2016, 28, 2587–2594. [Google Scholar] [CrossRef]

- Hu, G.; Albrow-Owen, T.; Jin, X.; Ali, A.; Hu, Y.; Howe, R.C.T.; Shehzad, K.; Yang, Z.; Zhu, X.; Woodward, R.I.; et al. Black Phosphorus Ink Formulation for Inkjet Printing of Optoelectronics and Photonics. Nat. Commun. 2017, 8, 278. [Google Scholar] [CrossRef]

- McManus, D.; Vranic, S.; Withers, F.; Sanchez-Romaguera, V.; Macucci, M.; Yang, H.; Sorrentino, R.; Parvez, K.; Son, S.-K.; Iannaccone, G.; et al. Water-based and Biocompatible 2D Crystal Inks for All-Inkjet Printed Hetero-structures. Nat. Nanotechnol. 2017, 12, 343–350. [Google Scholar] [CrossRef]

- Li, J.; Naiini, M.M.; Vaziri, S.; Lemme, M.C.; Östling, M. Inkjet Printing of MoS2. Adv. Funct. Mater. 2014, 24, 6524–6531. [Google Scholar] [CrossRef]

- Baino, F.; Fiume, E. 3D printing of hierarchical scaffolds based on mesoporous bioactive glasses (MBGs)-fundamentals and applications. Materials 2020, 13, 1688. [Google Scholar] [CrossRef]

- Pan, S.; Yin, J.; Yu, L.; Zhang, C.; Zhu, Y.; Gao, Y.; Chen, Y. 2D MXene-Integrated 3D-Printing Scaffolds for Augmented Osteosar-coma Phototherapy and Accelerated Tissue Reconstruction. Adv. Sci. 2020, 7, 1901511. [Google Scholar] [CrossRef] [PubMed]

- Mi, X.; Su, Z.; Fu, Y.; Li, S.; Mo, A. 3D printing of Ti3C2-MXene-incorporated composite scaffolds for accelerated bone regeneration. Biomed. Mater. 2022, 17, 035002. [Google Scholar] [CrossRef]

- Lee, S.H.; Kang, M.S.; Jeon, S.; Jo, H.J.; Hong, S.W.; Kim, B.; Han, D. 3D bioprinting of human mesenchymal stem cells-laden hydrogels incorporating MXene for spontaneous osteodifferentiation. Heliyon 2023, 9, e14490. [Google Scholar] [CrossRef]

- Yi, Q.; Pei, X.; Das, P.; Qin, H.; Lee, S.W.; Esfandyarpour, R. A self-powered triboelectric MXene-based 3D-printed wearable physiological biosignal sensing system for on-demand, wireless, and real-time health monitoring. Nano Energy 2022, 101, 107511. [Google Scholar] [CrossRef]

- Zhang, C.; McKeon, L.; Kremer, M.P.; Park, S.-H.; Ronan, O.; Seral-Ascaso, A.; Barwich, S.; Coileáin, C.Ó.; McEvoy, N.; Nerl, H.C.; et al. Additive-free MXene inks and direct printing of micro-supercapacitors. Nat. Commun. 2019, 10, 1795. [Google Scholar] [CrossRef]

- Bu, F.; Zhou, W.; Xu, Y.; Du, Y.; Guan, C.; Huang, W. Recent developments of advanced micro-supercapacitors: Design, fabrication and applications. npj Flex. Electron. 2020, 4, 31. [Google Scholar] [CrossRef]

- Zhou, G.; Li, M.-C.; Liu, C.; Wu, Q.; Mei, C. 3D Printed Ti3C2Tx MXene/Cellulose Nanofiber Architectures for Solid-State Supercapacitors: Ink Rheology, 3D Printability, and Electrochemical Performance. Adv. Funct. Mater. 2022, 32, 2109593. [Google Scholar] [CrossRef]

- Zhang, C.J.; Park, S.-H.; Seral-Ascaso, A.; Barwich, S.; McEvoy, N.; Boland, C.S.; Coleman, J.N.; Gogotsi, Y.; Nicolosi, V. High capacity silicon anodes enabled by MXene viscous aqueous ink. Nat. Commun. 2019, 10, 849. [Google Scholar] [CrossRef]

- Wu, X.; Tu, T.; Dai, Y.; Tang, P.; Zhang, Y.; Deng, Z.; Li, L.; Zhang, H.-B.; Yu, Z.-Z. Direct Ink Writing of Highly Conductive MXene Frames for Tunable Electromagnetic Interference Shielding and Electromagnetic Wave-Induced Thermochromism. Nano-Micro Lett. 2021, 13, 148. [Google Scholar] [CrossRef]

- Liu, J.; Mckeon, L.; Garcia, J.; Pinilla, S.; Barwich, S.; Möbius, M.; Stamenov, P.; Coleman, J.N.; Nicolosi, V. Additive Manufacturing of Ti3C2-MXene-Functionalized Conductive Polymer Hydrogels for Electromagnetic-Interference Shielding. Adv. Mater. 2022, 34, 2106253. [Google Scholar] [CrossRef] [PubMed]

| Synthesis Strategies | Reagents | Morphology | Merits | Demerits |

|---|---|---|---|---|

| HF etching [16,17] | HF | Accordion-like structure with abundant -F terminations and defects | 1. Effective for most MAX 2. High yield | 1. Dangerous operation 2. Cannot be peeled in situ |

| Fluoride-based acid etching [16,17] | LiF/NaF/KF + HCl NH4HF2 | Clay-like MXene with large interlayer spacing and few -F terminations | 1. Relatively safe 2. Direct ultrasonic peeling | 1. Long etching time 2. Introducing fluoride salt impurities |

| Alkaline solution etching [13,29] | NaOH TMAOH | Accordion-like structure only with -O, -OH terminations (For TMAOH terminated with Al(OH)4−) | 1. No risk of acid corrosion 2. fluorine-free functional group | 1. For NaOH: severe etching conditions 2. For TMAOH: need HF pretreatment |

| Molten fluoride salt and Lewis acidic molten melts etching [17,18] | LiF + NaF + KF Lewis Acid | Accordion-like structure (For Lewis Acid terminated with various halogens) | 1. For molten fluoride salt: can obtain nitride MXene 2. For Lewis acid: achieve precise control of surface functional groups | 1. Introduce salt impurities 2. Severe etching conditions |

| Electrochemical etching [17,18,30] | NH4Cl + TMAOH | Single or few-lawyer structure without -F functional group | 1. Safe etching environment 2. Fluorine-free functional group 3. Get stripped MXene directly | 1. Strict etching conditions 2. Introduce salt impurities |

| Water-free etching [16,31] | NH4HF2 in organic solvents | Accordion-like structure with extremely high -F terminations | 1. Conducive to the use of organic systems due to the absence of water 2. Can be delaminated directly by ultrasonication | 1. Long etching time 2. Tedious washing steps |

| HCl-based hydrothermal etching [16,32] | HCl-hydrothermal | Layered structure with-Cl and -O terminations | 1. Simple experiment operation 2. Fluorine-free functional group | 1. Severe etching conditions 2. Rely on the prediction of precise reaction conditions by DFT |

| Halogenetching [33] | Br2, I2, ICl, IBr | Accordion-like structure terminated with various halogens | 1. Mild etching environment 2. Precise control of surface functional groups | 1. Tedious etching and purification steps 2. Strict etching condition |

| Chemical vapor deposition (CVD) process [26,27] | Methane and bimetal foil (Cu/Mo) | Ultra-thin and large-size flake | 1. High purity 2. Accurate control of thickness | 1. Low productivity 2. High synthesis temperature |

| In Situ electrochemical synthesis [15,34] | LiTFSI + Zn(OTF)2 | In situ etching and stripping in the battery | 1. Green synthetic environment friendly 2. Extremely convenient operation | 1. Rely on expensive metal ion salts 2. Restricted to be used inside the battery |

| Lithiation-expansion micro explosion mechanism [15,35] | Lithium-ion | Single-layer or few-layer structure without -F functional group | 1. Simple and safe synthesis environment 2. Fluorine-free functional group | 1. Low productivity 2. Consume resources |

| Microwave-assisted etching [36] | Ti3AlC2 + HF | Layered MXene sheets | 1. Very rapid (30 s) 2. High-quality sheets 3. Good capacitance 4. Scalable | 1. Slight oxidation to TiO2 |

| Materials | Electrolyte | Capacitance (Scan Rate) | Stability (Retention/Cycles/Scan Rate) | Energy Density (W h kg−1) | Power Density (W h kg−1) | Ref. |

|---|---|---|---|---|---|---|

| Ti3C2Tx | 3M H2SO4 | 210 F g−1 at 10 V s−1 | - | - | - | [51] |

| Ti3C2Tx | 1M H2SO4 | 429 F g−1 at 1 A g−1 | 89% after 5000 cycles at 10 A g−1 | 29.2 at 1 A g−1 | 320 at 1 A g−1 | [52] |

| PPy/Graphene | 1 M H2SO4 | 626 F g−1 at 0.22 A g−1 | 75.4% after 5000 cycles at 4 A g−1 | 21.7 | 110 | [53] |

| MoS2 | 0.5 M Li2SO4 | 350 F g−1 at 5 mV s−1 | 88.0% after 10,000 cycles at 5 A g−1 | 1 50 at 1 A g−1 | 1000 at 1 A g−1 | [54] |

| Samples | Methods | Structures |

|---|---|---|

| Porous Ti3C2Tx Aerogel shaped | Freeze drying | Mesoporus/macroporous |

| MXene lamellar-liquid-crystal | Mechanically shearing assisted freeze drying | Aligned vertically mesoporous/macroporous |

| Lamellar structured Ti3C2Tx/SiCnws foam | Bidirectional freeze-drying | Aligned vertically mesoporous/macroporous |

| Super-elastic MXene/PI aerogels | Freeze drying | Meso/macropore with wide size distribution |

| Fluffy-type MXene microspheres | Spray drying | Mesoporous/macroporous |

| 3DMXenefilms | Hard-template method | Mesoporous/macroporous |

| Cellular-type MXene foam | Hydrazine reduction technique | Mesoporous/macroporous |

| hybrid 3D porous network of MXene-Sponge | Dip-coating and drying | Macroporous |

| MXene-rGO aerogel | Chemical-reduction | Mesoporous/macroporous |

| MXene-rGO aerogel | Freeze drying-calcination | Mesoporous/macroporous |

| Cellulose-MXene aerogel | Chemical crosslinking | Mesoporous/macroporous |

| TiO2/MXene, SnO2/MXene | Self-assembly | Mesoporous |

| FeNi-LDH-MXene | In situ growth | Mesoporous |

| Core–shell Ti3C2-mSiO2 | Sol–gel | Mesoporous |

| MXene flakes | Oxidative-etching | Mesoporous |

| MXene with divacancy-ordering | Selective-etching | Microporous and mesoporous |

| Printing Technology | Resolution [µm] | Viscosity [cP] | Thickness [µm] | Speed |

|---|---|---|---|---|

| 3D printing | ≈10–100 | ≈105–108 | >50 | ≈4 (m min⁻1) |

| Screen printing | ≈30–100 | ≈100–107 | ≈10–100 | ≈70 (m min⁻1) |

| Inkjet printing | ≈10–50 | ≈1–100 | ≈0.5–5 | ≈1 (m min⁻1) |

| Material | Fabrication Technique | Concentration | Solvent | Viscosity | Application | Ref. |

|---|---|---|---|---|---|---|

| Ti3C2Tx | Stamping | 22 mg mL⁻1 | Water | 1.37 Pa.s | MSc | [131] |

| MXene (Ti3C2Tx) | Extrusion 3D printing | 36 mg mL⁻1 | Water | 0.71 Pa.s | MSc | [132] |

| MXene (Ti3C2Tx) | Inkjet printing | 12.5 mg mL⁻1 | NMP | 13.8 m Pa.s | MSc | [132] |

| MXene (Ti3C2Tx) | Inkjet printing | 2.1 mg mL⁻1 | DMSO | 12.8 m Pa.s | MSc | [132] |

| MXene (Ti3C2Tx) | Inkjet printing | 0.8 mg mL⁻1 | ethanol | 7.3 m Pa.s | MSc | [132] |

| N-doped MXene | Screen printing | - | Water | >104 Pa.s | Sc | [133] |

| AC/CNT/MXene-N/GO | Extrusion 3D printing | - | Water | >104 Pa.s | Sc | [133] |

| Pure MXene | Screen printing | - | Water | 288.2 Pa.s | MSc | [134] |

| M-A | Screen printing | - | Water | 371.7 Pa.s | MSc | [134] |

| R-M-A | Screen printing | - | Water | 234.4 Pa.s | MSc | [134] |

| R-M-A0.75:1 | Screen printing | - | Water | 179 Pa.s | MSc | [134] |

| 2D Ti3C2Tx | Extrusion-based 3D printing | 15 mg mL⁻1 | Water | >103 Pa.s | Sc | [135] |

| 2D Ti3C2Tx | Extrusion-based 3D printing | 30 mg mL⁻1 | Water | >103 Pa.s | Sc | [135] |

| 2D Ti3C2Tx | Extrusion-based 3D printing | 50 mg mL⁻1 | Water | >10⁴ Pa.s | Sc | [135] |

| RuO2/PEDOT: PSS/Graphene | Screen printing | - | Water | >103 cP | Sc | [136] |

| V2O5/GO and G- VNQDs/GO | Extrusion 3D printing | 50 mg mL⁻1 | - | >10⁴ Pa.s | MSc | [137] |

| GO LFP/GO and LTO/GO | Extrusion 3D printing | - | Water | 102 to 103 Pa.s | Batteries | [138] |

| B-phosphorous | Inkjet printing | ≈5 gL⁻1 | IPA/2-butanol | ≈2 mPa.s | Optoelectronics and photonics | [139] |

| Graphene MoS2 WS2 and hexagonal boron nitride (h-BN) | Inkjet printing | - | Water | Between 1.38 and 1.27 mPa.s | Biocompatibility (cytotoxicity studies) | [140] |

| MoS2 | Inkjet printing | 0.1 mg mL⁻1 | Terpineol | ≈40 cP | - | [141] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palladino, D.L.; Baino, F. MXenes: Properties, Applications, and Potential in 3D Printing. Ceramics 2025, 8, 64. https://doi.org/10.3390/ceramics8020064

Palladino DL, Baino F. MXenes: Properties, Applications, and Potential in 3D Printing. Ceramics. 2025; 8(2):64. https://doi.org/10.3390/ceramics8020064

Chicago/Turabian StylePalladino, Donato Luca, and Francesco Baino. 2025. "MXenes: Properties, Applications, and Potential in 3D Printing" Ceramics 8, no. 2: 64. https://doi.org/10.3390/ceramics8020064

APA StylePalladino, D. L., & Baino, F. (2025). MXenes: Properties, Applications, and Potential in 3D Printing. Ceramics, 8(2), 64. https://doi.org/10.3390/ceramics8020064